Microbial fuel cell system

A fuel cell system and microorganism technology, applied in the field of pollutant degradation and energy regeneration, can solve the problems of long adjustment time, low power generation efficiency of the system, slow reaction rate, etc. The effect of synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

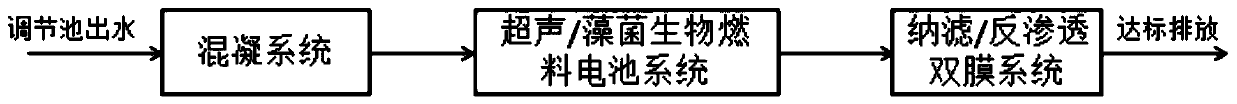

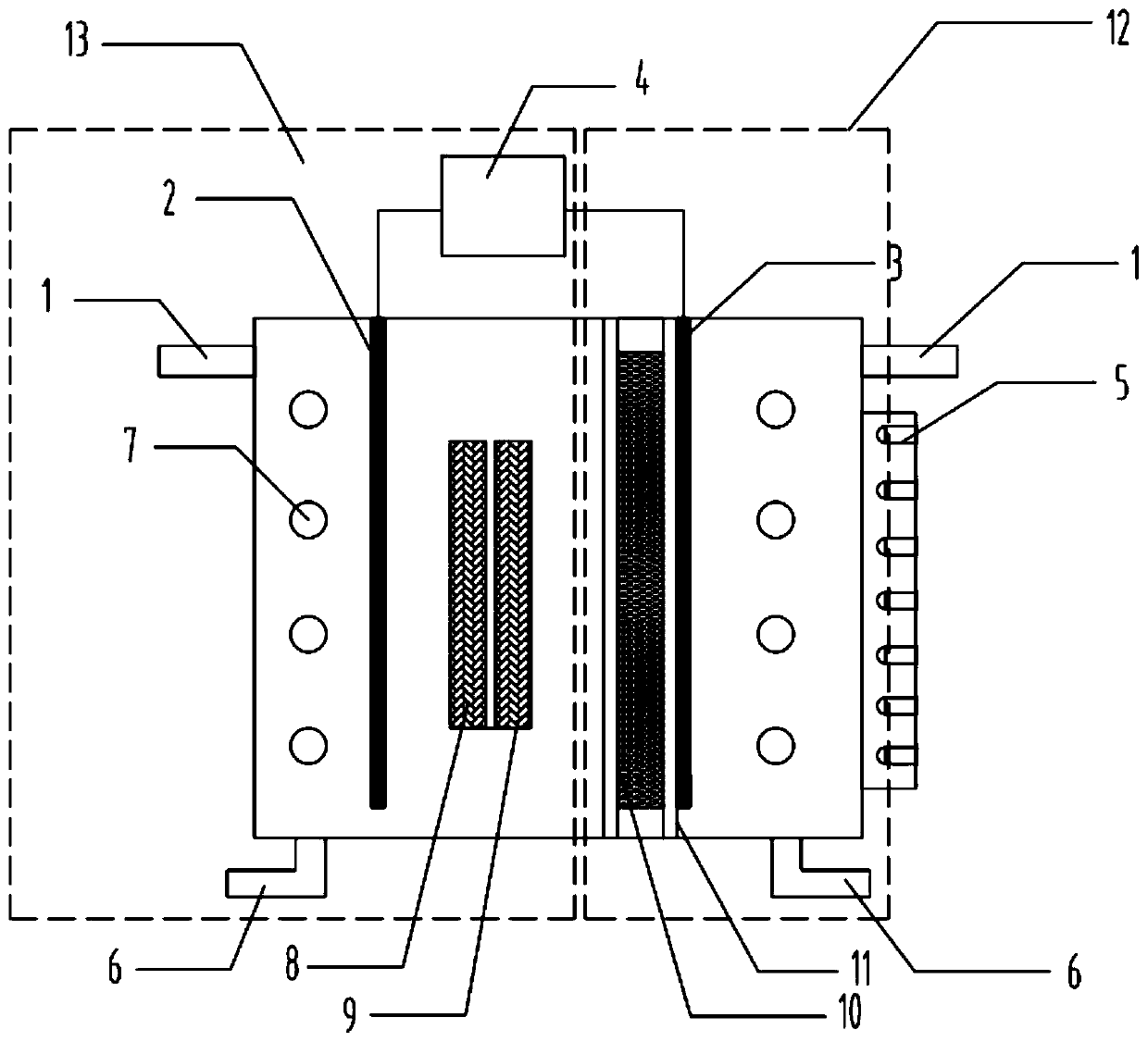

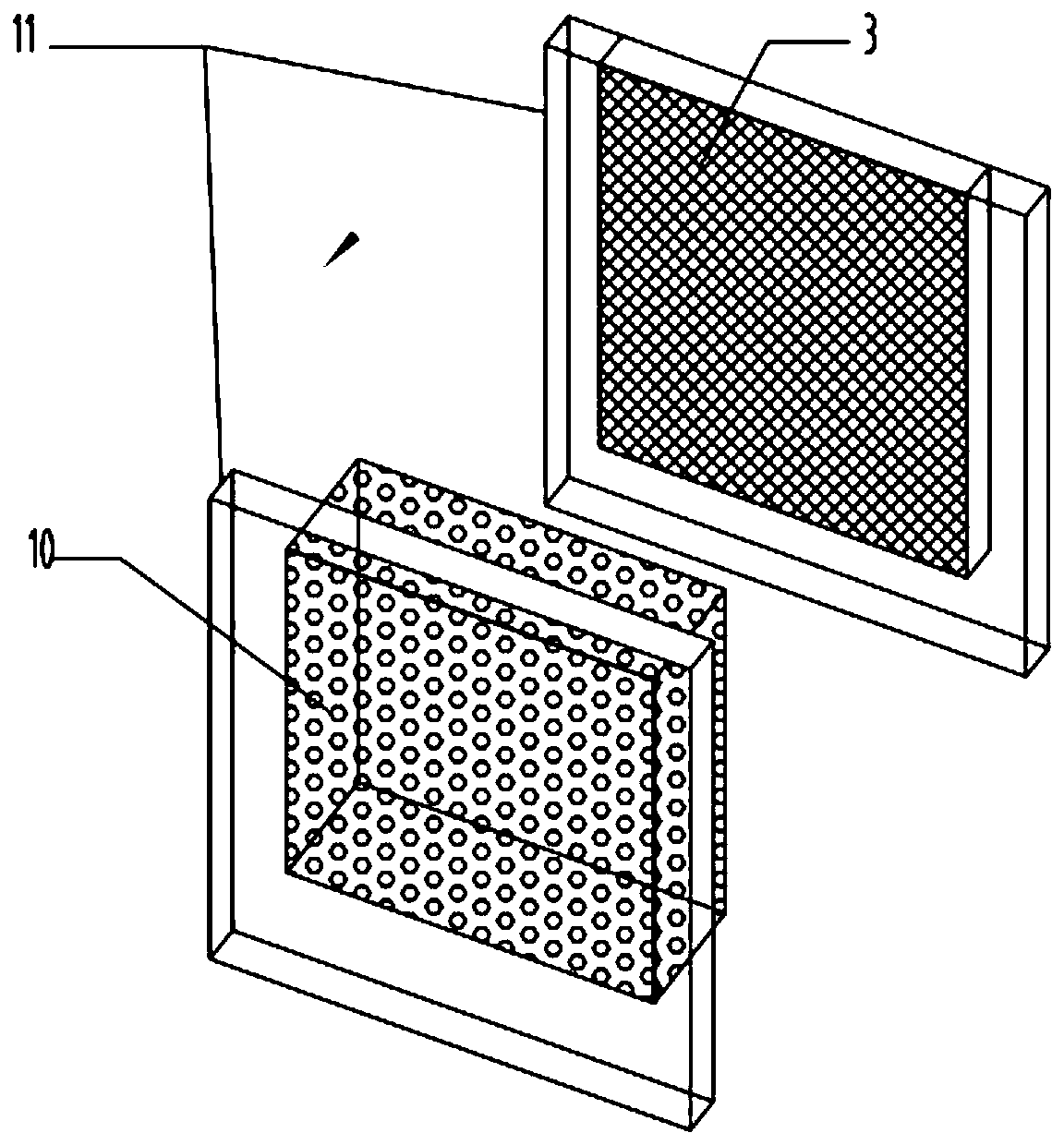

[0027] As a microbial fuel cell system according to an embodiment of the present invention, the microbial fuel cell system includes a sequentially connected coagulation system, an ultrasonic / algae biofuel cell system, a nanofiltration / reverse osmosis double-membrane system, and the ultrasonic / algae In the bacterial biofuel cell system, there are waste water inlet 1, anode electrode 2, cathode electrode 3, power storage system 4, LED fluorescent lamp group 5, water outlet 6, ultrasonic probe 7, anion exchange resin layer 8, stainless steel mesh 9, and catalytic layer 10, hollow separator 11, cathode chamber 12, anode chamber 13, described anode chamber 13 comprises positive electrode 2 and anion exchange resin layer 8, anion exchange resin layer 8 is fixed in the anode chamber 13 by stainless steel net 9, described The cathode chamber 12 includes a cathode 3, the cathode 3 is fixed by a hollow partition 11, the cathode 3 is bonded with a catalytic layer 10 on the side close to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com