Method for extracting humic acid from landfill leachate

A landfill leachate and humic acid technology, applied in chemical instruments and methods, neutralized water/sewage treatment, water/sludge/sewage treatment, etc. Large humic acid colloid size and other issues, to achieve the effect of reducing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

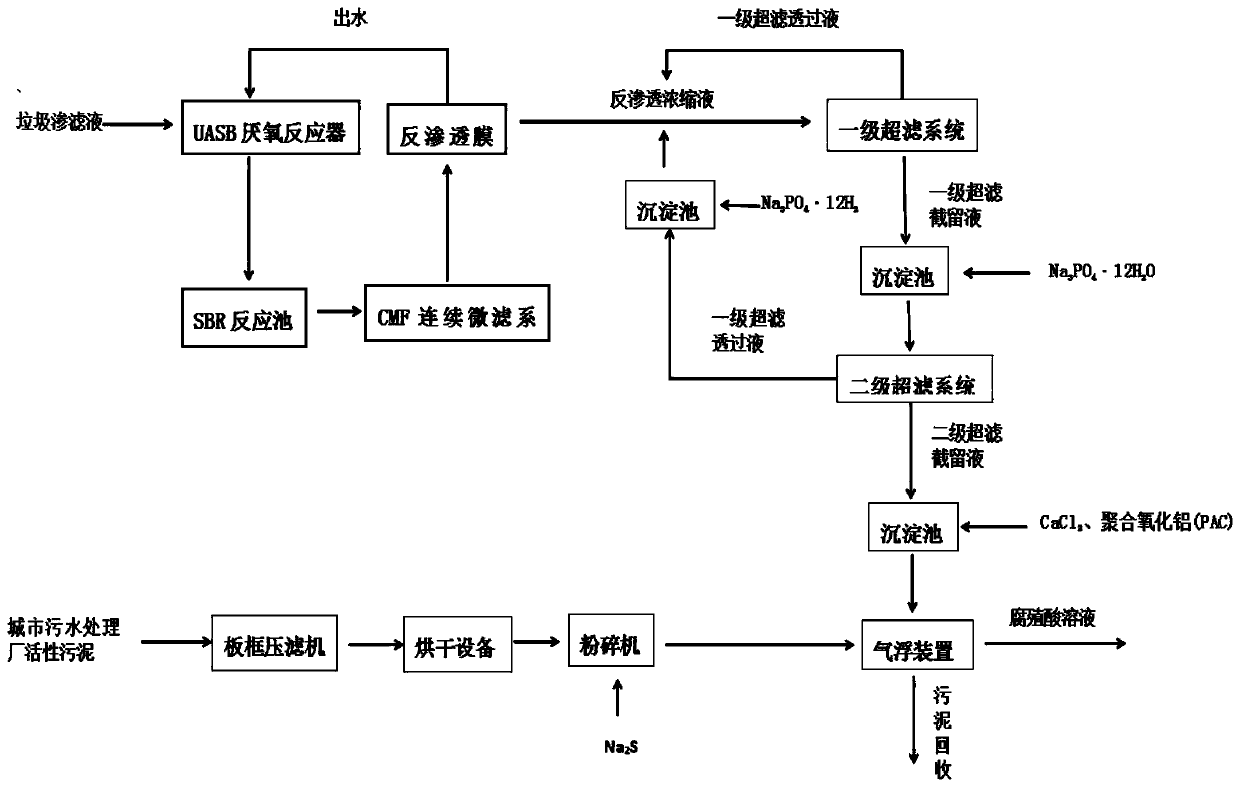

[0022] In order to fully understand the technical content of the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but is not limited thereto.

[0023] The invention provides a kind of method extracting humic acid from landfill leachate, and the method is carried out according to the following steps:

[0024] 1. The landfill leachate is sequentially passed through the anaerobic reactor (UASB), reaction tank (SBR), continuous microfiltration system (CMF) and reverse osmosis membrane (RO), and after joint treatment, the reverse osmosis concentrate is obtained;

[0025] 2. Adjust the pH value of the concentrated solution to 6-6.5, pump it into the first-level ultrafiltration system, and the operating pressure is 0.9Mpa. The obtained first-level ultrafiltration permeate is circulated to the reverse osmosis concentrate. Liquid precipitant Na 3 PO 4 12H 2 O removes calcium and magnesium ions, and then pumps int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com