Purification method of printing and dyeing waste alkaline liquor

A technology for waste lye and clear liquid, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage multi-stage treatment, etc. To achieve the effect of reducing the degree of membrane fouling and improving the efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

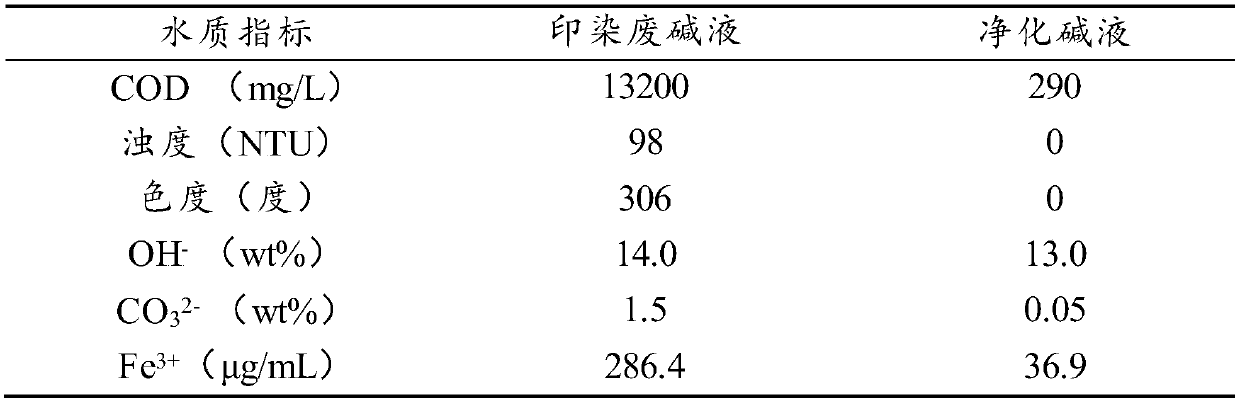

Embodiment 1

[0036] (1) Calcium Oxide Precipitation

[0037] Take 1L of waste printing and dyeing lye from the factory, add 20g / L calcium oxide, stir at room temperature, stirring speed 300rpm, stirring time 30min, then let it stand overnight, filter out the precipitate, and obtain the first clear liquid.

[0038] (2) polyaluminum chloride flocculation

[0039] At 25°C, take the first clear liquid, add 5g / L polyaluminum chloride, first stir at 200rpm for 1.5min, then stir at 80rpm for 20min, and finally let it settle for 30min to obtain the second clear liquid.

[0040] (3) Ultrafiltration membrane separation

[0041] Using the second clear liquid as the material liquid, it is separated by ultrafiltration membrane, and the PES ultrafiltration membrane with a molecular weight cut off of 1000 is used as the filtration membrane. The effective diameter of the diaphragm is 4.5cm, and the effective membrane area is 1.59×10 -3 m 2 . During the ultrafiltration membrane separation process, the ...

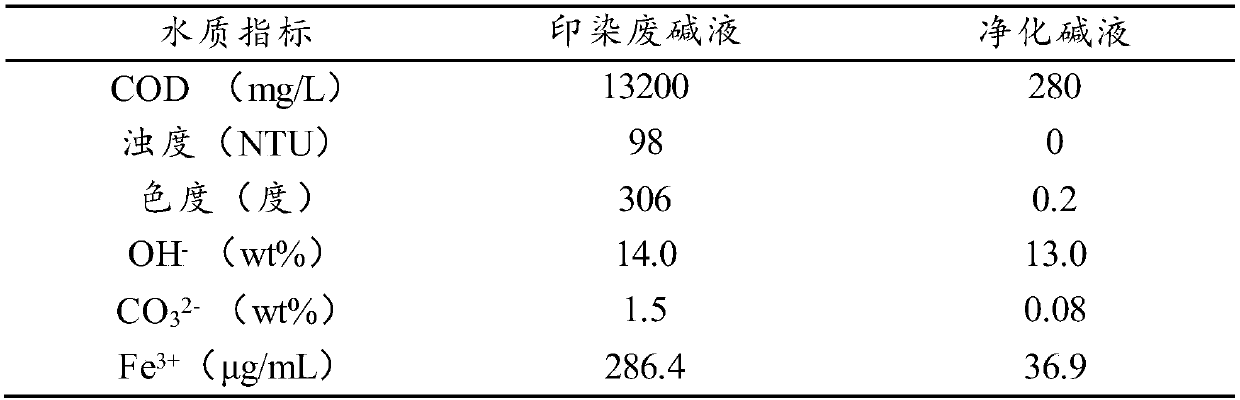

Embodiment 2

[0048] (1) Magnesium oxide precipitation

[0049] Take 1L of waste printing and dyeing lye from the factory, add 14g / L magnesium oxide, stir at room temperature, stirring speed 300rpm, stirring time 30min, then let it stand overnight, filter out the precipitate, and obtain the first clear liquid.

[0050] (2) polyaluminum chloride flocculation

[0051] At 25°C, take the first clear liquid, add 5g / L polyaluminum chloride, first stir at 200rpm for 1.5min, then stir at 80rpm for 20min, and finally let it settle for 30min to obtain the second clear liquid.

[0052] (3) Ultrafiltration membrane separation

[0053] Using the second clear liquid as the material liquid, it is separated by ultrafiltration membrane, and the PES ultrafiltration membrane with a molecular weight cut off of 1000 is used as the filtration membrane. The effective diameter of the diaphragm is 4.5cm, and the effective membrane area is 1.59×10 -3 m 2 . During the ultrafiltration membrane separation process, ...

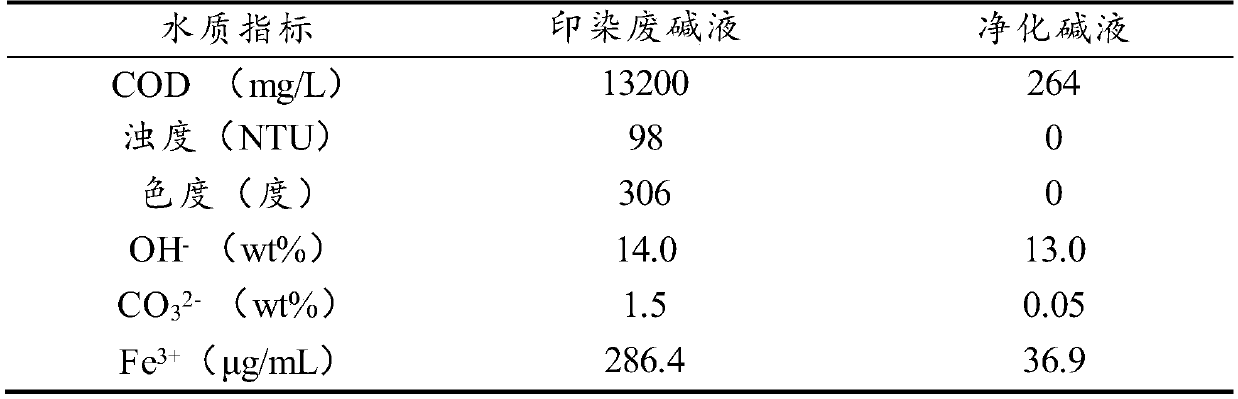

Embodiment 3

[0060] (1) Calcium Oxide Precipitation

[0061] Take 1L of waste printing and dyeing lye from the factory, add 20g / L calcium oxide, stir at room temperature, stirring speed 300rpm, stirring time 30min, then let it stand overnight, filter out the precipitate, and obtain the first clear liquid.

[0062] (2) Sodium styrene sulfonate flocculation

[0063] At 40°C, take the first clear liquid, add 20 mg / L sodium p-styrene sulfonate, stir at 300 rpm for 5 min, and then let it settle for 30 min to obtain the second clear liquid.

[0064] (3) Ultrafiltration membrane separation

[0065] Using the second clear liquid as the material liquid, it is separated by ultrafiltration membrane, and the PES ultrafiltration membrane with a molecular weight cut off of 1000 is used as the filtration membrane. The effective diameter of the diaphragm is 4.5cm, and the effective membrane area is 1.59×10 -3 m 2 . During the ultrafiltration membrane separation process, the temperature of the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective diameter | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com