Patents

Literature

67results about How to "Meet reuse requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

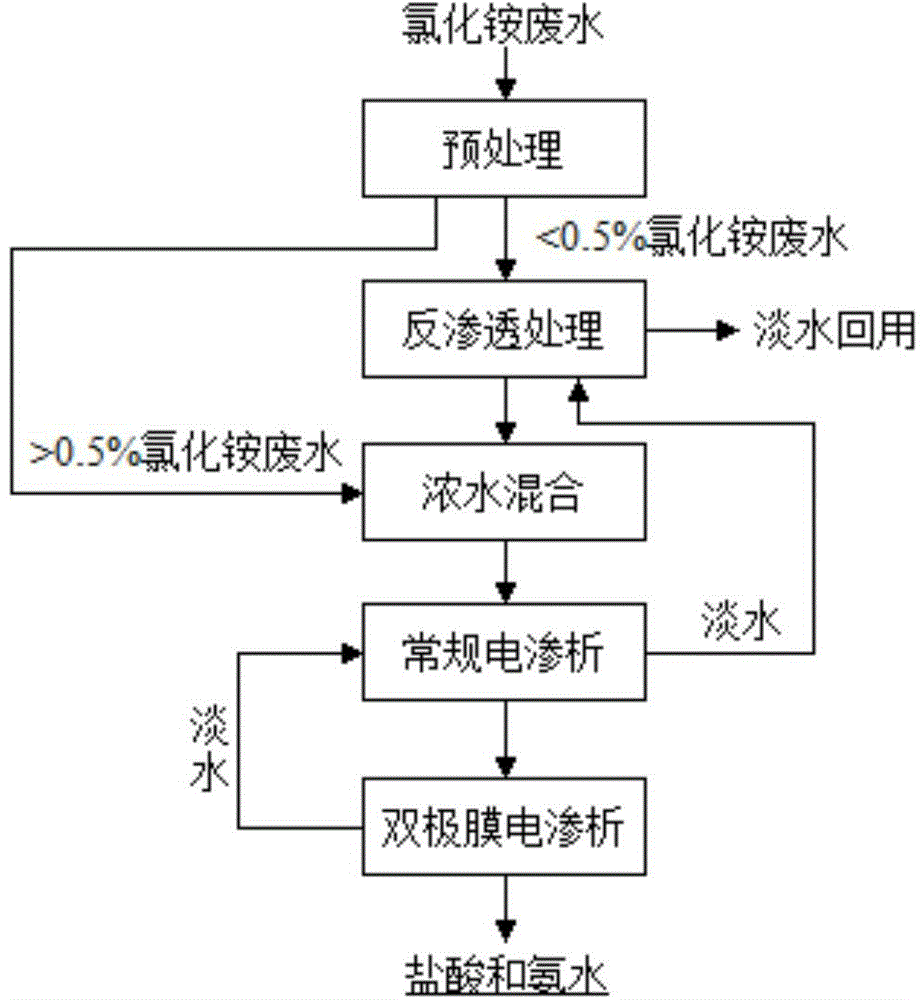

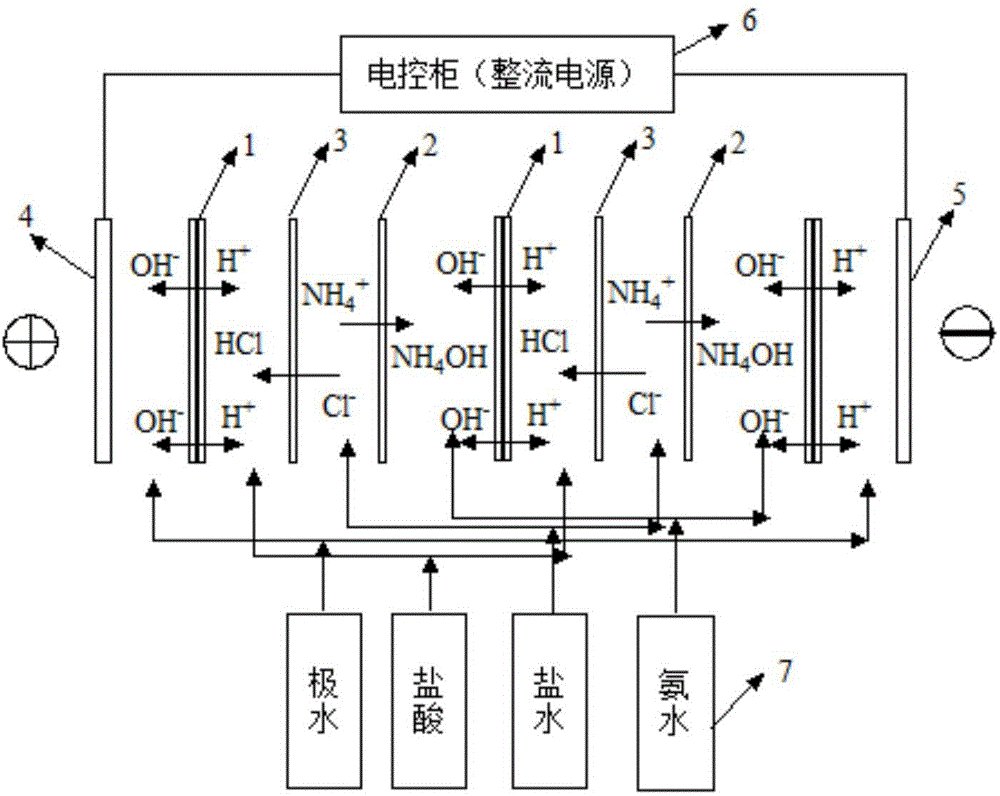

Method for resourceful treatment of ammonia chloride wastewaters

ActiveCN104445755ARealize resource processingAchieving processing powerGeneral water supply conservationWater contaminantsReverse osmosisImpurity

The invention relates to a method for resourceful treatment of ammonia chloride wastewaters. The method comprises the following steps: (1) respectively carrying out pretreatment on ammonia chloride wastewater with different concentrations for removing impurities; (2) carrying out reverse osmosis treatment on a clear liquor of the ammonia chloride wastewater, which is obtained in the step (1), with the concentration being lower than 0.5%; (3) mixing obtained reverse osmosis concentrated water with a clear liquid of the ammonia chloride wastewater, which is obtained in the step (2), with the concentration being higher than 0.5% so as to obtain ammonia chloride mixed wastewater; (4) carrying out conventional electrodialysis treatment on the obtained ammonia chloride mixed wastewater so as to obtain electrodialysis fresh water; (5) returning the obtained electrodialysis fresh water, carrying out reverse osmosis treatment the obtained electrodialysis fresh water to obtain electrodialysis concentrated water, and carrying out acid-alkali regeneration on the electrodialysis concentrated water by adopting bipolar membrane electrodialysis; and (6) converting ammonia chloride in the wastewater into hydrochloric acid and ammonium hydroxide by adopting the bipolar membrane electrodialysis to obtain low-concentration ammonia chloride wastewater, simultaneously returning the obtained low-concentration ammonia chloride wastewater and carrying out the conventional electrodialysis treatment on the obtained low-concentration ammonia chloride wastewater. According to the method, the resourceful treatment and the zero emission of the ammonia chloride wastewater can be really achieved.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

Full-active cooling hypersonic flight vehicle

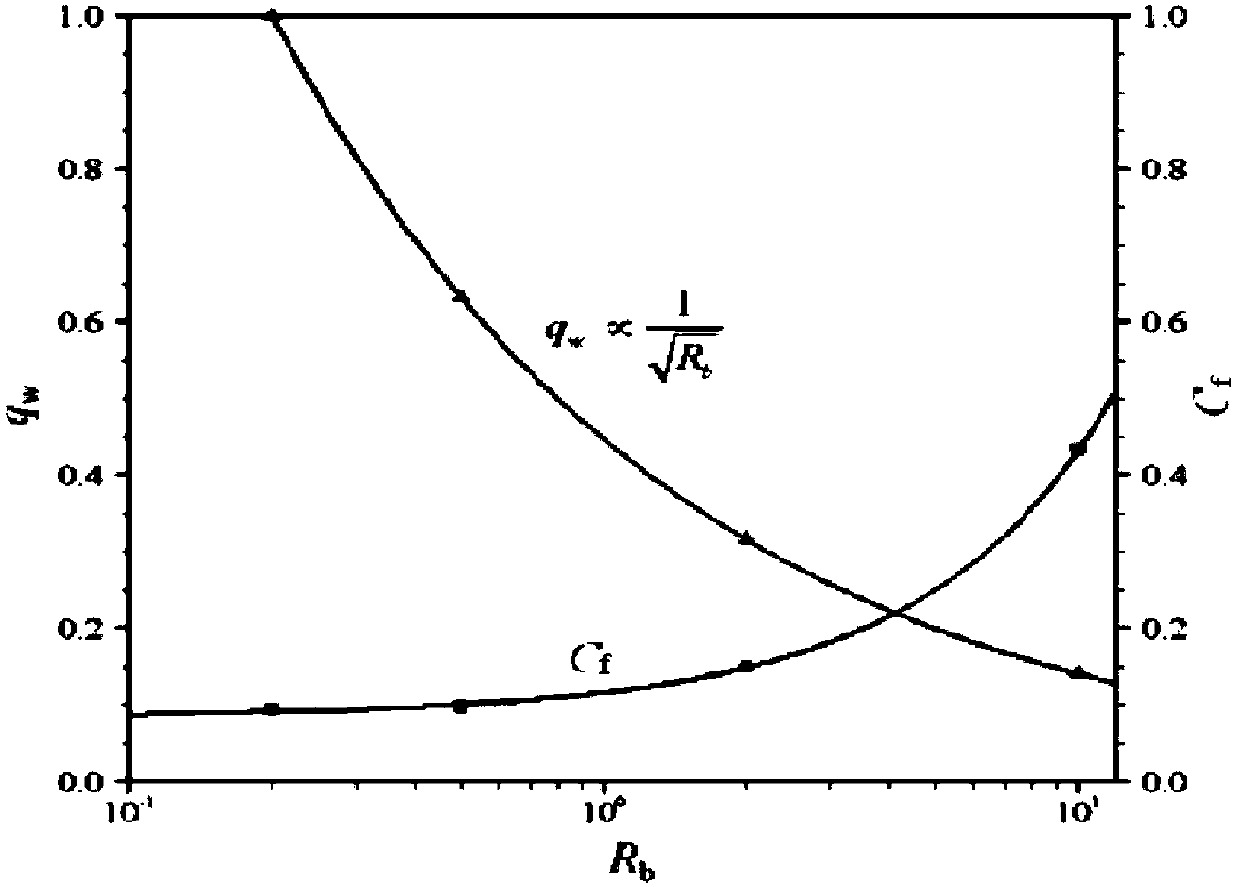

ActiveCN107914862AAvoid thermal structural thermal matching problemsGuaranteed aerodynamic shapeBoundary layer controlsFuselage insulationFlight vehicleTranspiration

The invention discloses a full-active cooling hypersonic flight vehicle which comprises a transpiration cooling end, a transpiration cooling wing front edge, a transpiration cooling rudder front edge,a regenerative cooling rudder surface, a regenerative cooling windward side and a flight vehicle leeside, wherein porous structures are formed in the transpiration cooling end, the transpiration cooling wing front edge and the transpiration cooling rudder front edge, and the interiors of the porous structures are filled with liquid cooling media; the liquid cooling media can be supplied outwardsfrom the porous structures, flow through the porous structures to perform heat exchange, are heated and then flow out of the outer surface of the end in a gaseous form; and the regenerative cooling rudder surface and the regenerative cooling windward side are respectively used for cooling the rudder surface and the windward side of the flight vehicle in a regenerative cooling manner, and the liquid cooling media carried inside the flight vehicle are used for blocking, cooling and taking away pneumatic heating volume of the flight vehicle transferred into the flight vehicle in the hypersonic flight process, so that thermal protection requirements of the flight vehicle on high-speed, long-term and long-distance flight in the atmosphere are met.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

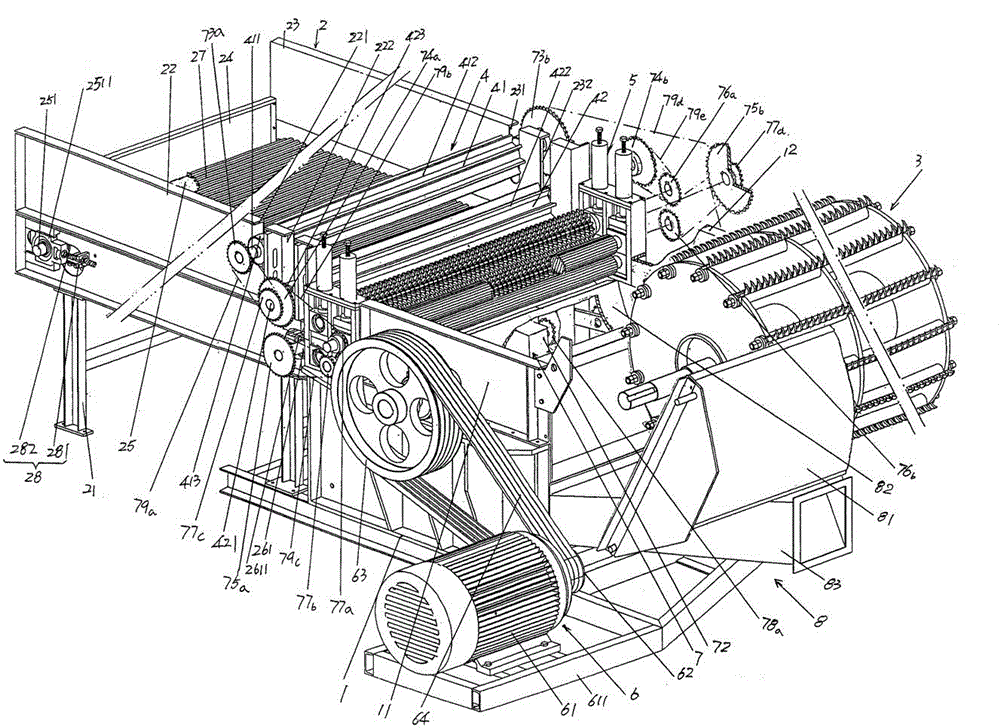

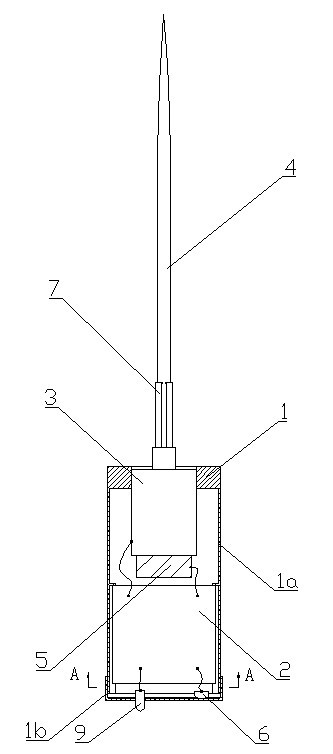

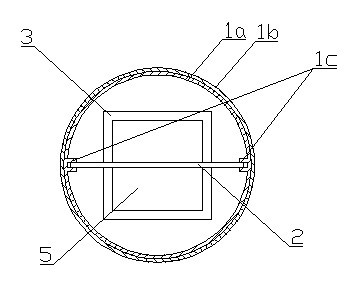

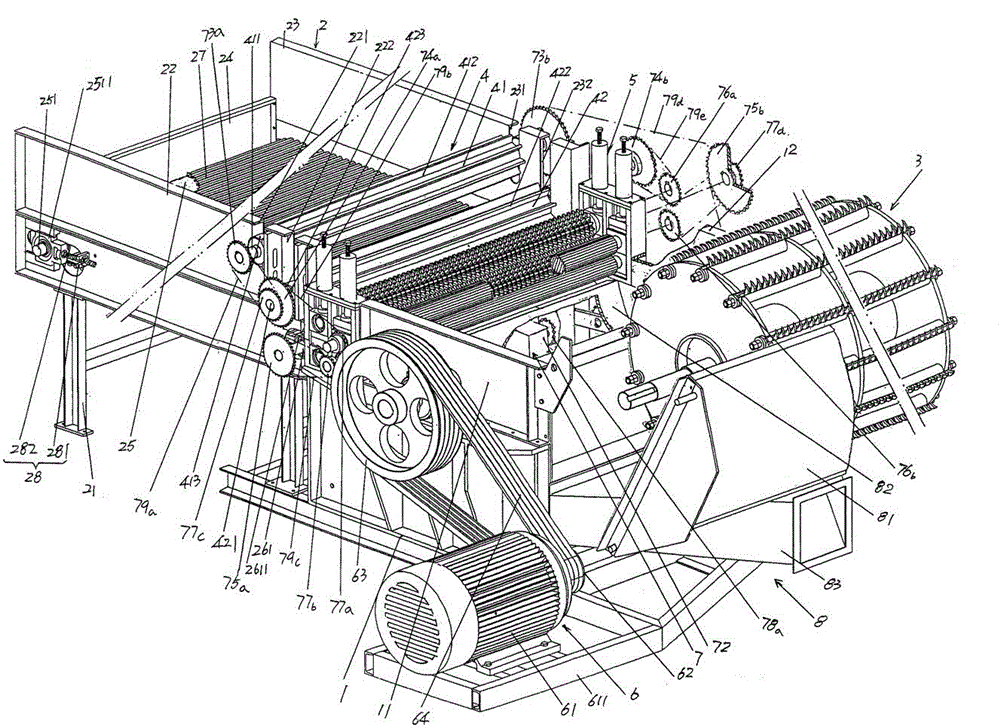

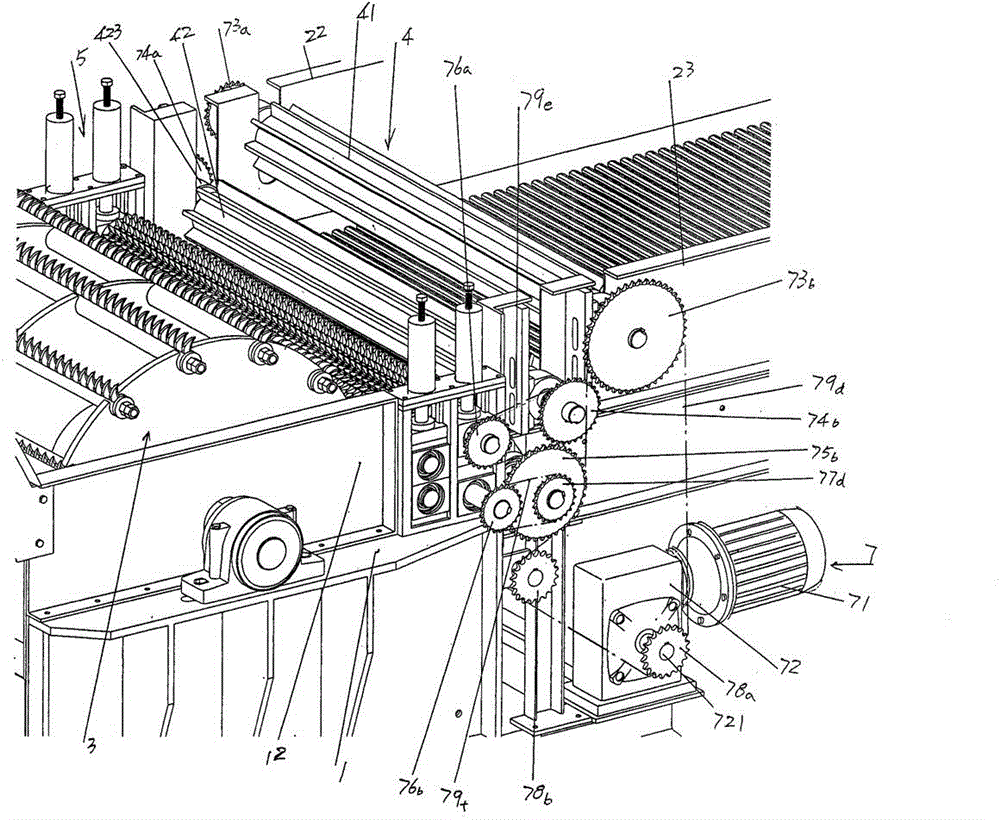

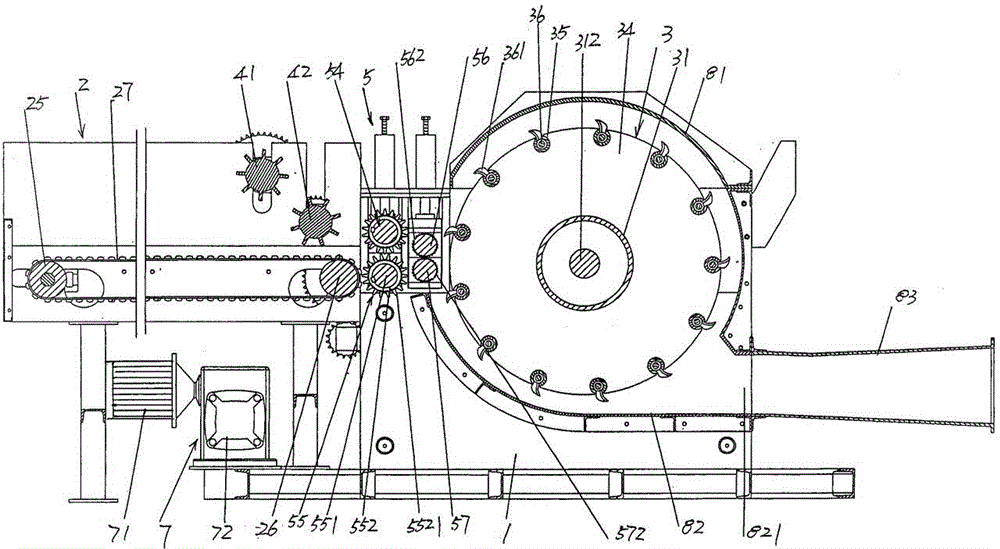

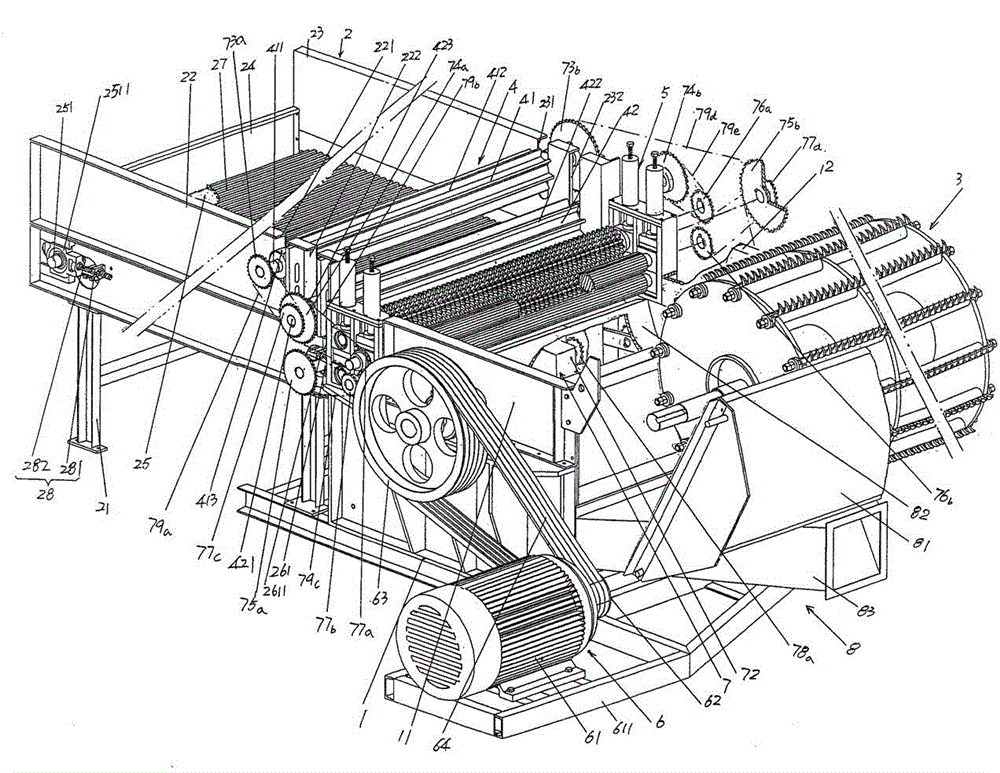

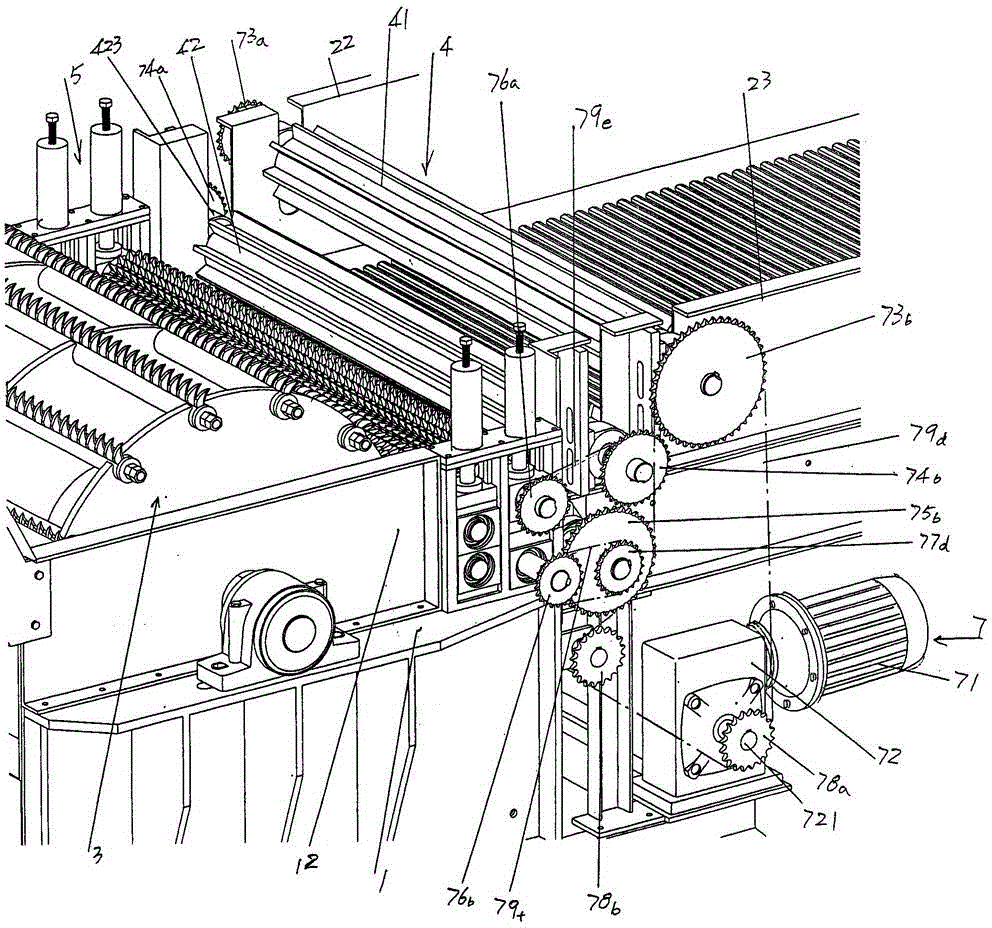

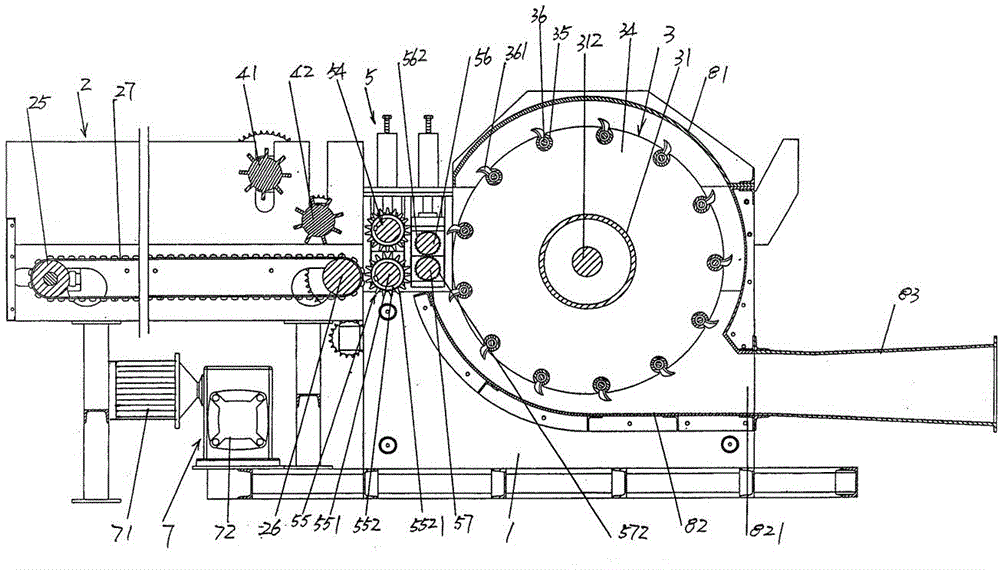

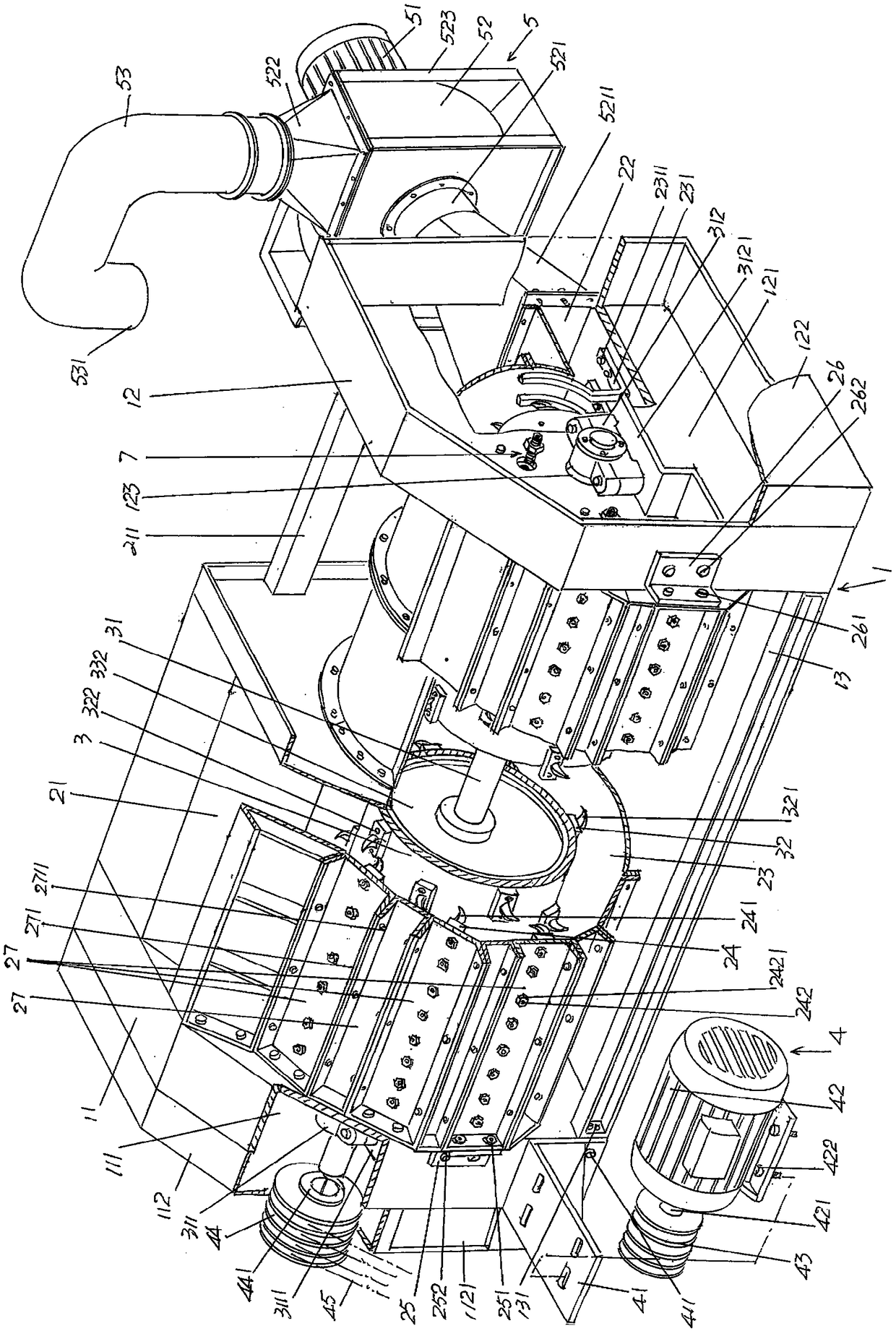

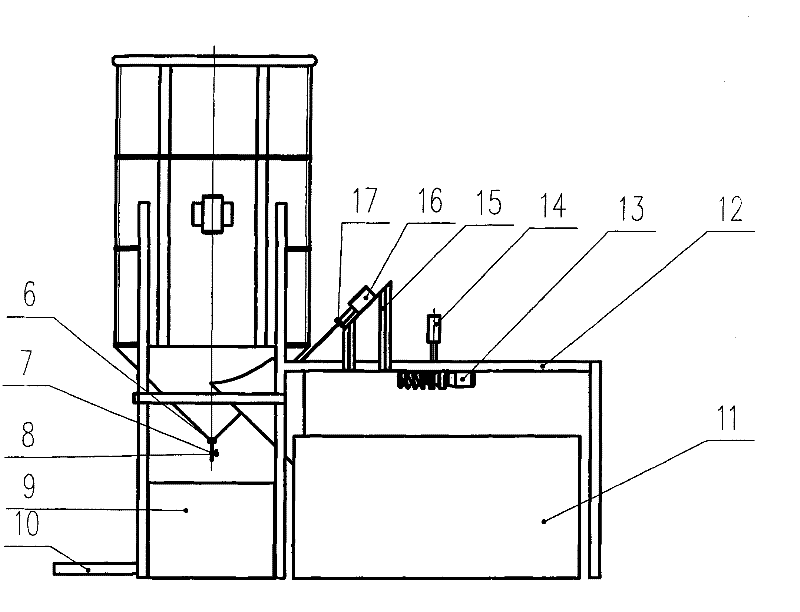

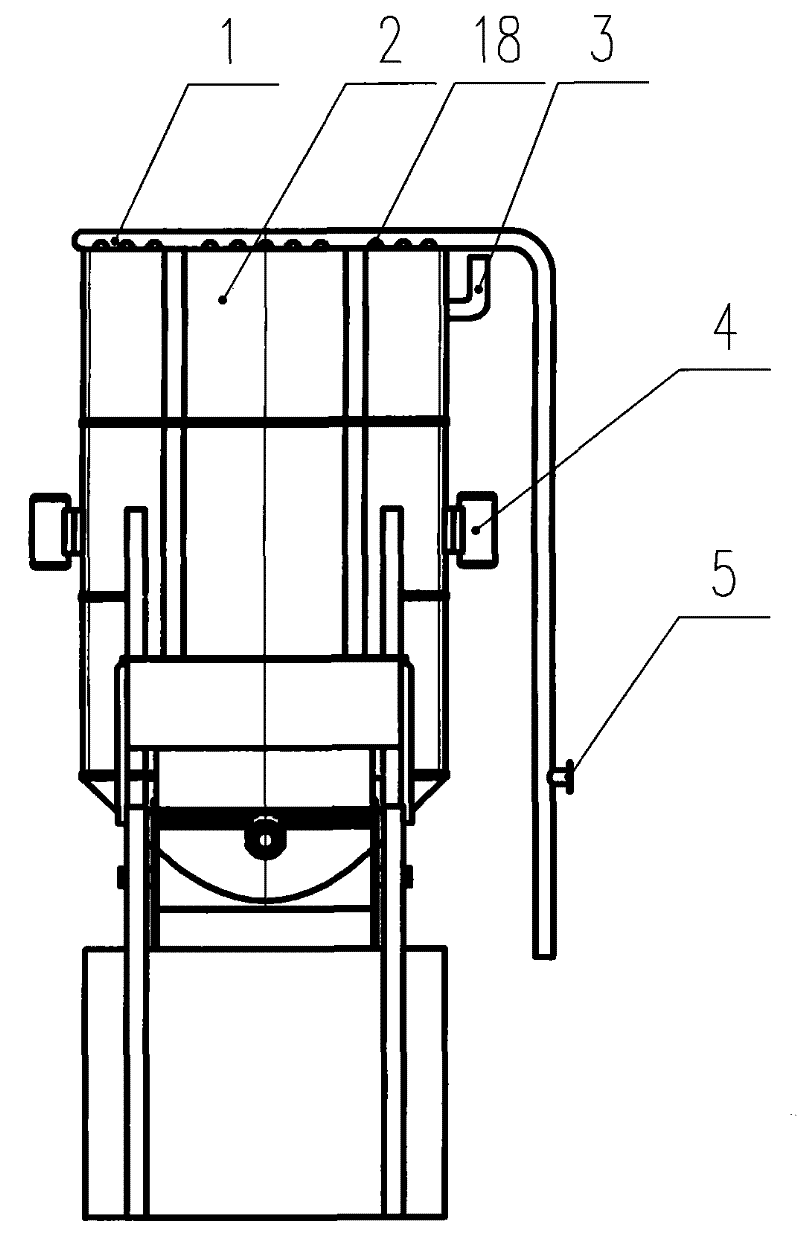

Waste fiber leftover pre-opener

ActiveCN103147172AMeet reuse requirementsReduce manufacturing costFibre cleaning/opening machinesTextile disintegration and recoveryFiberCircular economy

The invention relates to a waste fiber leftover pre-opener, belonging to the field of non-woven fabric machines. The waste fiber leftover pre-opener comprises a pre-opening roller rack, a waste fiber leftover conveying mechanism, a pre-opening roller, a pressing mechanism, a feeding mechanism, a pre-opening roller driving mechanism, a power transmission mechanism and a fiber leading-out mechanism, wherein a first wallboard is fixedly arranged above one side of the pre-opening roller rack and a second wallboard is fixedly arranged above the other side of the pre-opening roller rack; the waste fiber leftover conveying mechanism is connected with one end of the pre-opening roller rack; the pre-opening roller is supported between the first wallboard and the second wallboard; the pressing mechanism is arranged on the waste fiber leftover conveying mechanism; the feeding mechanism is arranged on the pre-opening roller rack and is arranged between the pre-opening roller and the pressing mechanism; the pre-opening roller driving mechanism is arranged on the pre-opening roller rack and is connected with the pre-opening roller; the power transmission mechanism is arranged on the pre-opening roller rack and is connected with the waste fiber leftover conveying mechanism, the pressing mechanism and the feeding mechanism; and the fiber leading-out mechanism is fixedly arranged on the pre-opening roller rack. The waste fiber leftover pre-opener has the advantages that the opening effect is good, the opening efficiency is ideal, the requirement on reuse of waste fibers can be satisfied, the resources are saved, the environment is protected, the circular economy is reflected and the manufacturing cost of automobile interior ornaments is reduced.

Owner:江苏常盛无纺设备有限公司

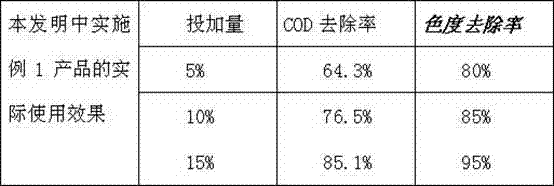

Composite water treatment agent special for coal washing wastewater and preparation method thereof

InactiveCN102198963AReduce water consumptionReduce water colorWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionChemical oxygen demandFiller Excipient

The invention relates to a composite water treatment agent special for coal washing wastewater and a preparation method thereof. The composite water treatment agent is composed of the following components in parts by weight: 20-40 parts of chitosan, gelatine or Arabic gum used as a flocculant, 20-30 parts of activated carbon, diatomite or neutral aluminum oxide used as an adsorbent, 40-60 parts of diatomite or activated clay used as a filler, and 0.5-1 part of Tween-80 or alkanolamide used as a suspending aid. The composite water treatment agent provided by the invention can be used for greatly lowering the color degree and COD (chemical oxygen demand) of treated water, ensuring the treated water to meet the reuse requirement, enormously reducing the water consumption of enterprises and improving the utilization rate of water resources.

Owner:夏建锋

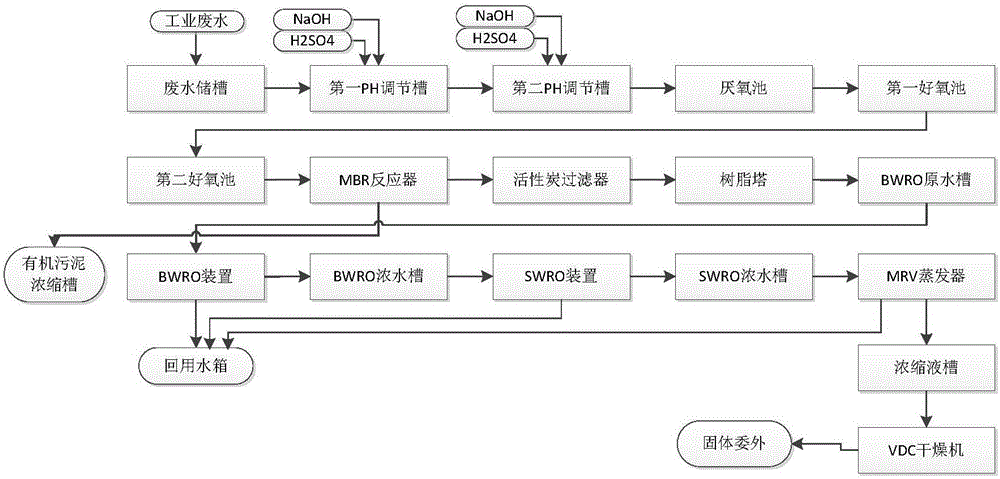

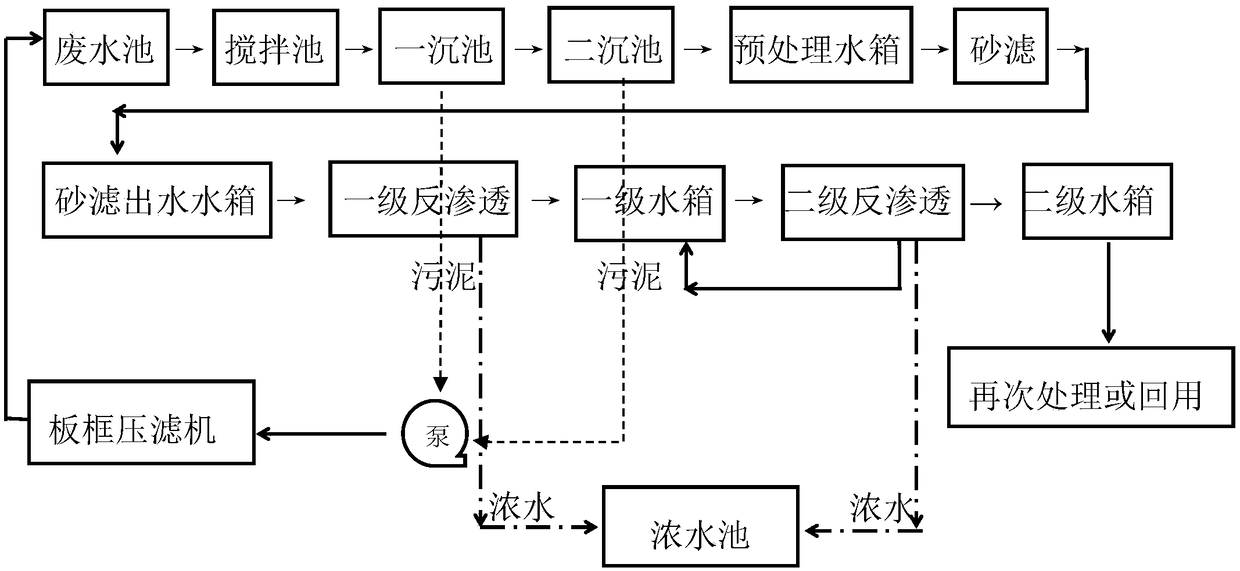

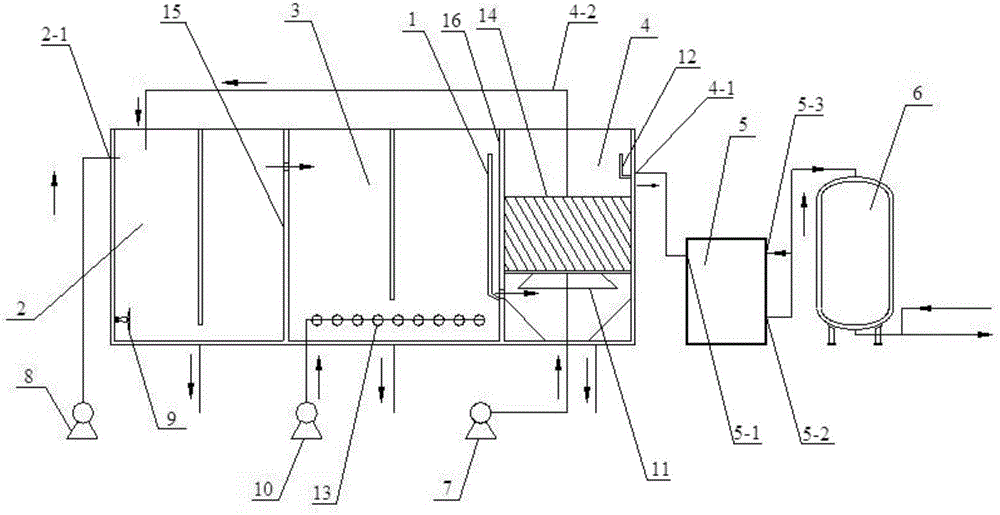

Industrial wastewater zero discharging treatment process and system

InactiveCN106746116AAchieve emissionsThorough dischargeTreatment using aerobic processesGeneral water supply conservationIndustrial effluentFiltration

The invention belongs to the field of water treatment and particularly relates to an industrial wastewater zero discharging treatment process and system. The industrial wastewater zero discharging treatment process comprises the following steps: (a) sequentially performing pH adjustment, anaerobic treatment, aerobic treatment and membrane bioreactor treatment on industrial wastewater to obtain pre-treated wastewater; (b) sequentially performing carbon filtration and resin adsorption on the pre-treated wastewater to obtain softened wastewater; (b) processing the softened wastewater by a brackish water desalination reverse osmosis membrane element to obtain first fresh water and first concentrated water, and recovering the first fresh water; (d) processing the first concentrated water by a seawater desalination reverse osmosis membrane element to obtain second fresh water and second concentrated water, and recovering the second fresh water; (e) performing evaporation and concentration on the second concentrated water to obtain steam and a concentrated solution, condensing the steam, recovering condensate water, and dehydrating the concentrated solution to obtain solid residues. According to the industrial wastewater zero discharging treatment process, industrial wastewater is subjected to a series of treatments, so that zero discharging of the industrial wastewater is realized.

Owner:TG HILYTE ENVIRONMENTAL TECHNOLOGY (BEIJING) CO LTD

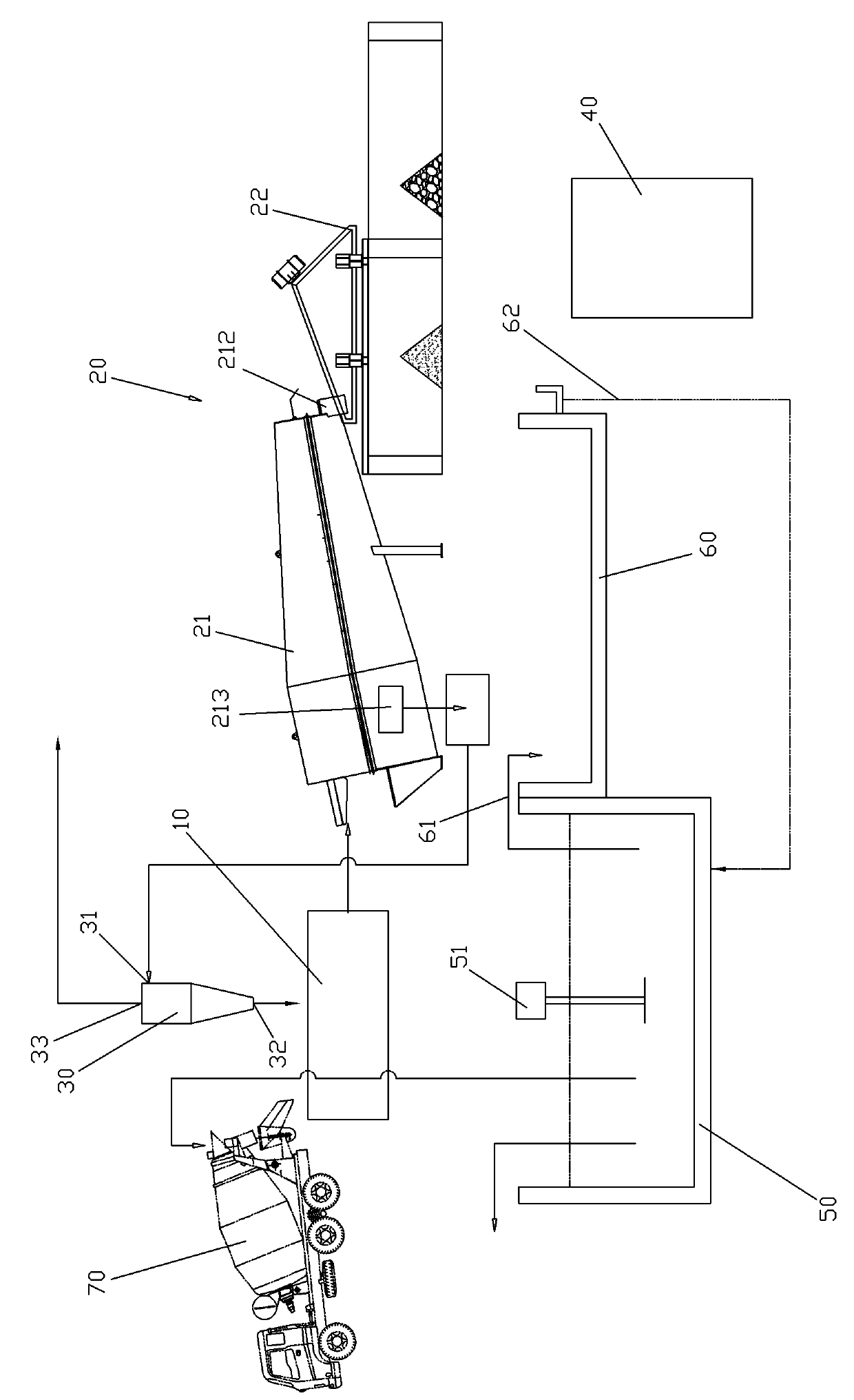

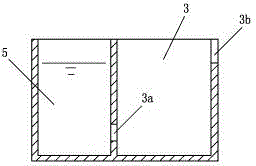

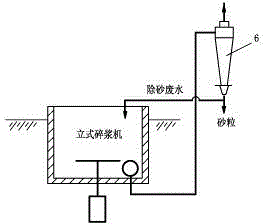

Residual wet concrete recovering system

InactiveCN102555066ASolve the sealing problemAvoid enteringMixing operation plantSolid particlePre treatment

A residual wet concrete recovering system comprises a car washing tank, a sand and rock separating unit and a stirring pool; the sand and rock separating unit comprises a wet concrete recovering machine; the feed opening of the wet concrete recovering machine is connected with the car washing tank; an overflow port is formed on the wet concrete recovering machine; and the recovering system further comprises a pretreatment device used for pretreating muddy water separated by the sand and rock separating unit. Compared with the prior art, the residual wet concrete recovering system has the advantage that after muddy water overflowing from the wet concrete recovering machine is further separated by the pretreatment device, low-concentration muddy water conforming to concrete production requirements is discharged into the stirring pool, the muddy water entering the stirring pool does not contain solid particles any longer, and the concentration of the muddy water is reduced greatly, so that the production quality of concrete is ensured.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

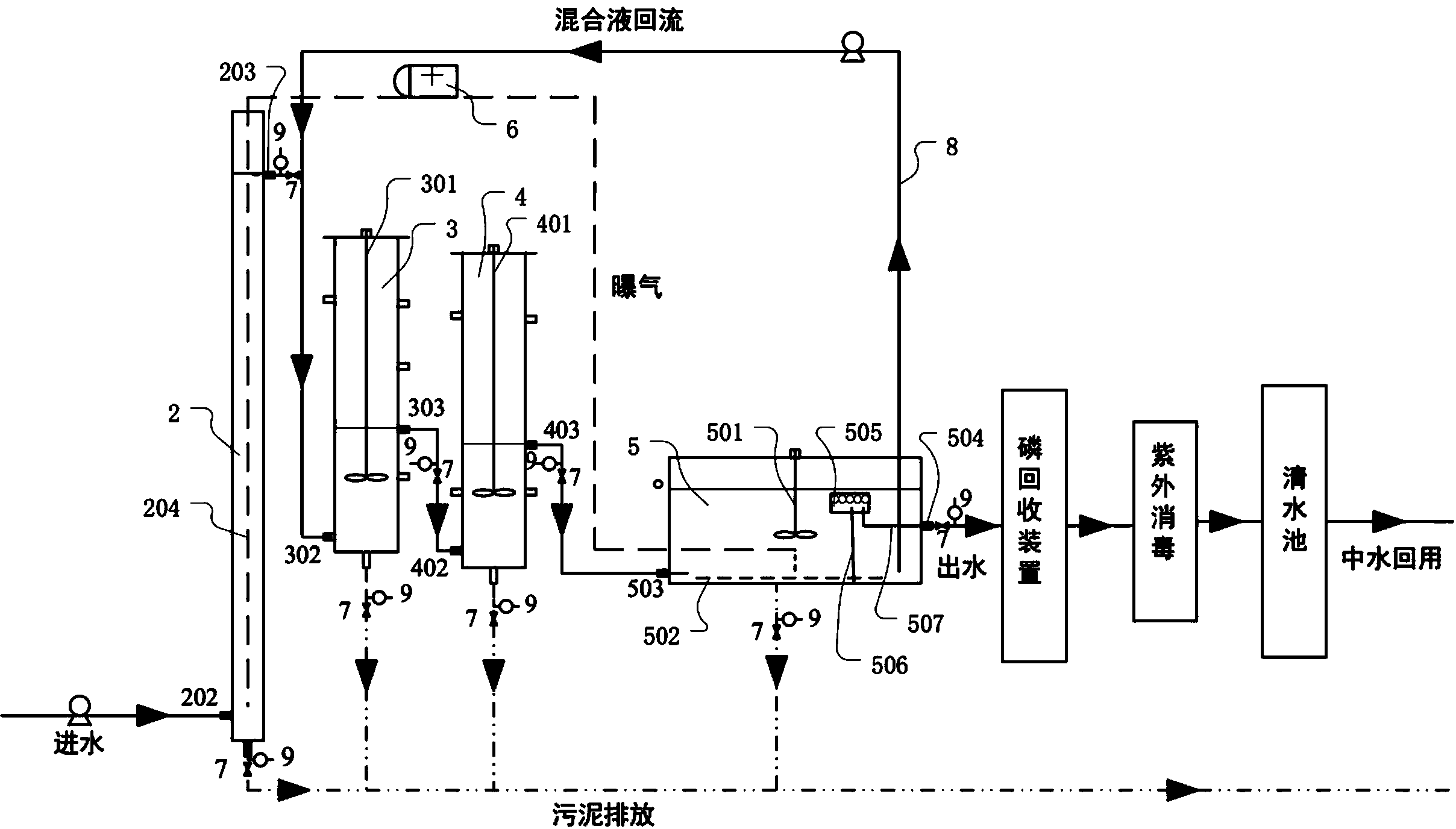

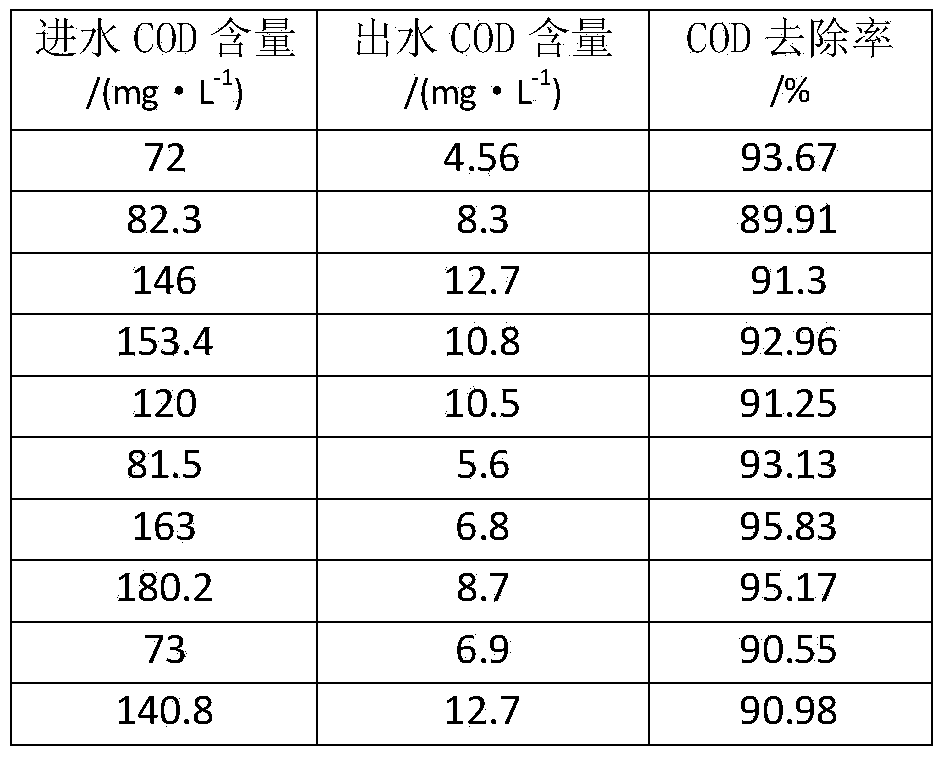

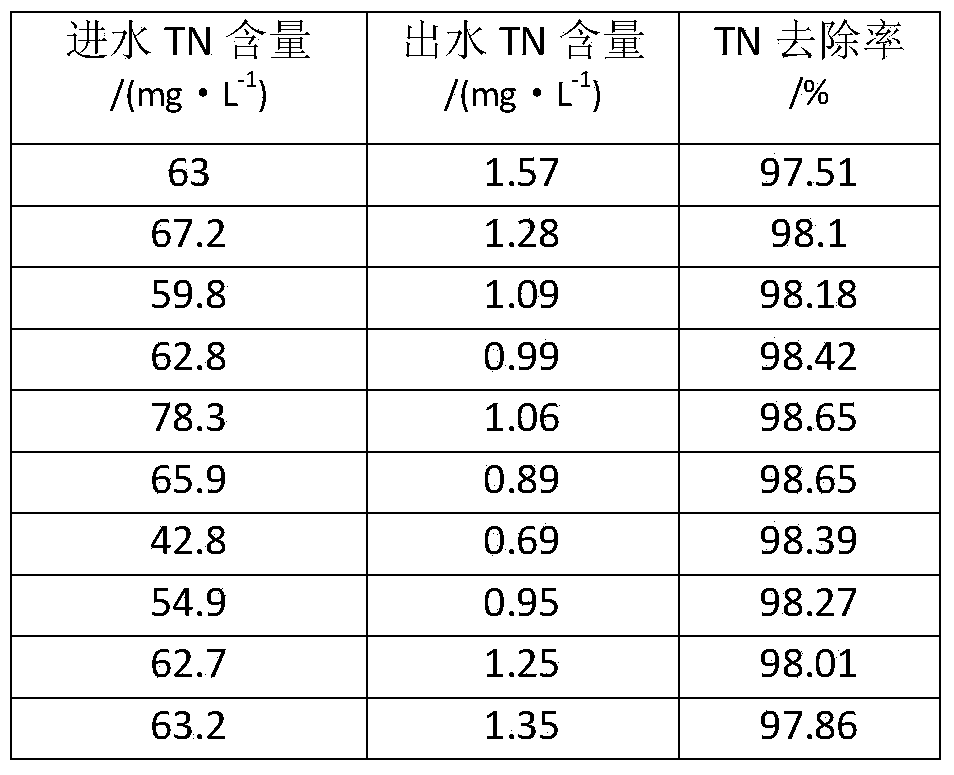

Sewage treatment equipment and sewage treatment method

InactiveCN103880241AInhibit swellingEasy to handleMultistage water/sewage treatmentActivated sludgeEngineering

The invention relates to sewage treatment equipment, which comprises a pre-aeration device, an anoxic device, an anaerobic device and an intermittent aeration device; a stirring device is arranged in the anoxic device, the anaerobic device and the intermittent aeration device; an aeration head is arranged in the pre-aeration device and the intermittent aeration device; a mixed solution back-flow device is arranged between the intermittent aeration device and the anoxic device; and sewage treated through the intermittent aeration device flows back to the anoxic device through the mixed solution back-flow device. The advantages of the activated sludge method and the intermittent aeration method are combined in the sewage treatment equipment disclosed by the invention; sewage high-efficiency denitrification having low C / N ratio is realized; furthermore, the impact load resistant performance of the system is good; the amount of residual sludge is low; the process is flexible; and the operation cost is low.

Owner:HEBEI AGRICULTURAL UNIV.

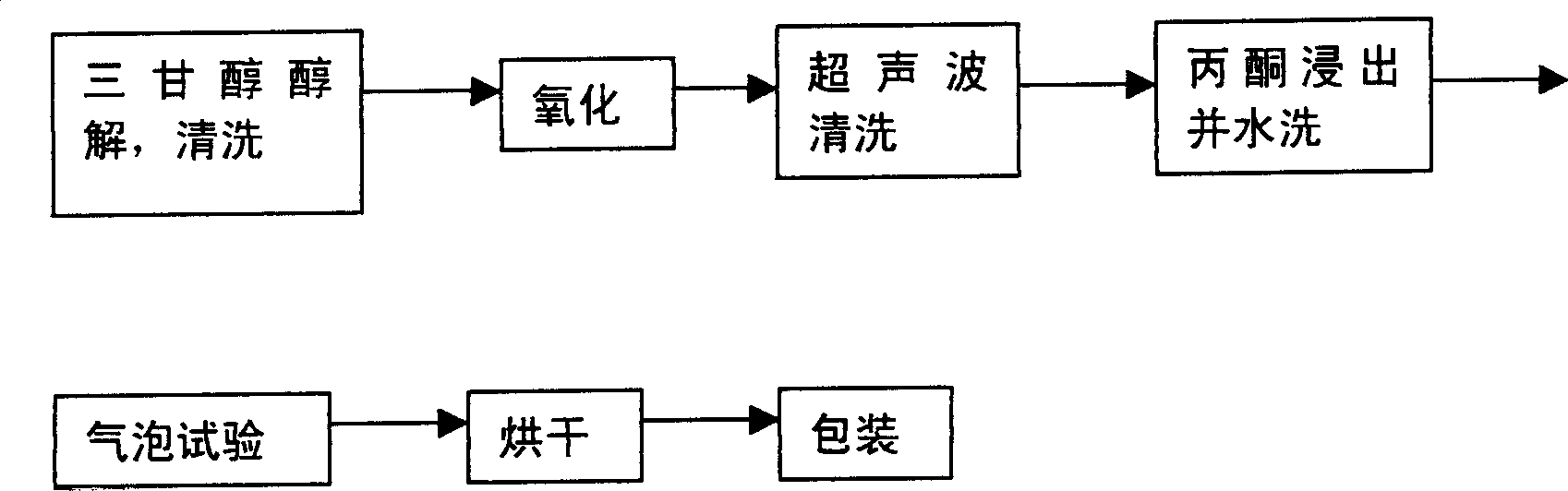

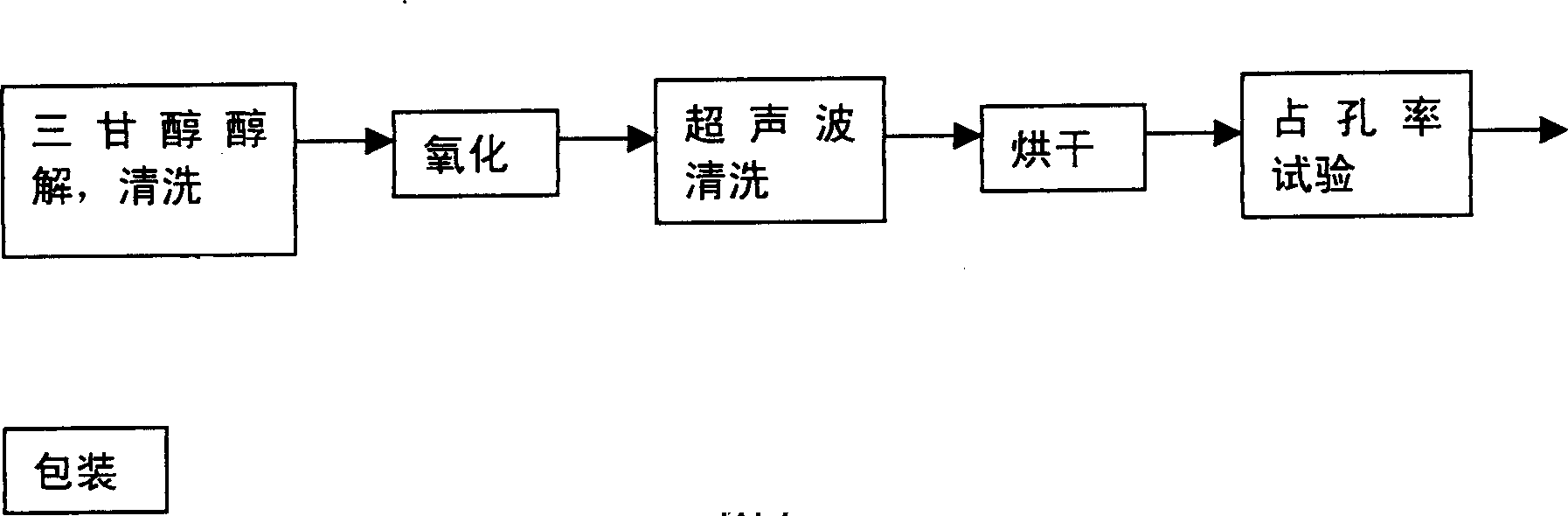

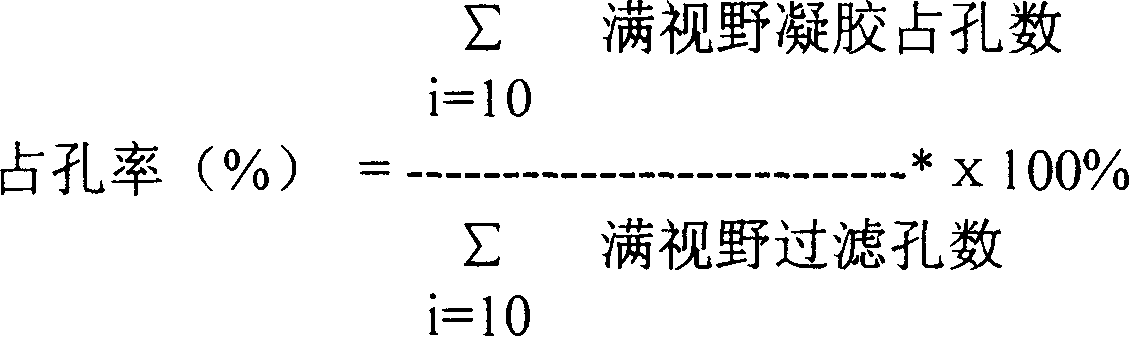

Cleaing method of polyurethane filter leaf or filter core

InactiveCN1712580ADecompose thoroughlyHigh removal rateFilament-forming treatmentSolventSupersonic waves

A wash method of filtering chip and filtering core polluted by polyurethane. It contains steps as follow. A. Use TEG to wash it at high temperature. B. Wash it in oxidant. C. Wash it in soaping solvent, the solvent of compound surface active agent and builder. D. Wash by supersonic wave. E. Gross detect by acetone. F. Evaluate effect of wash, including pop experience and cleanliness. G. Dry and pack it.

Owner:上海康维科技发展有限公司

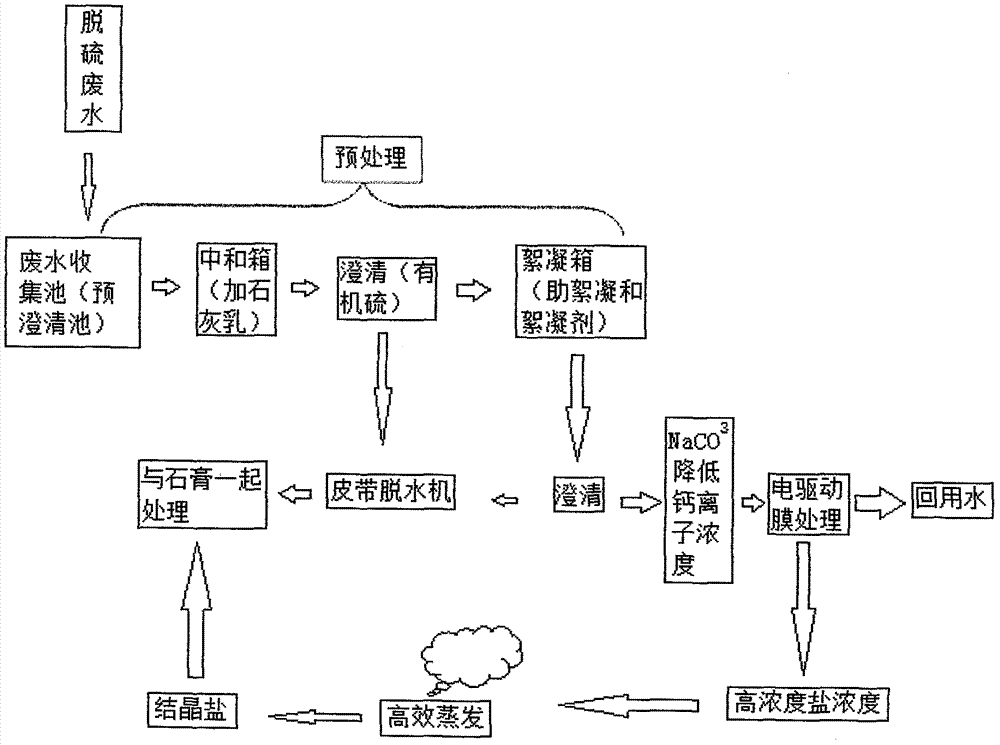

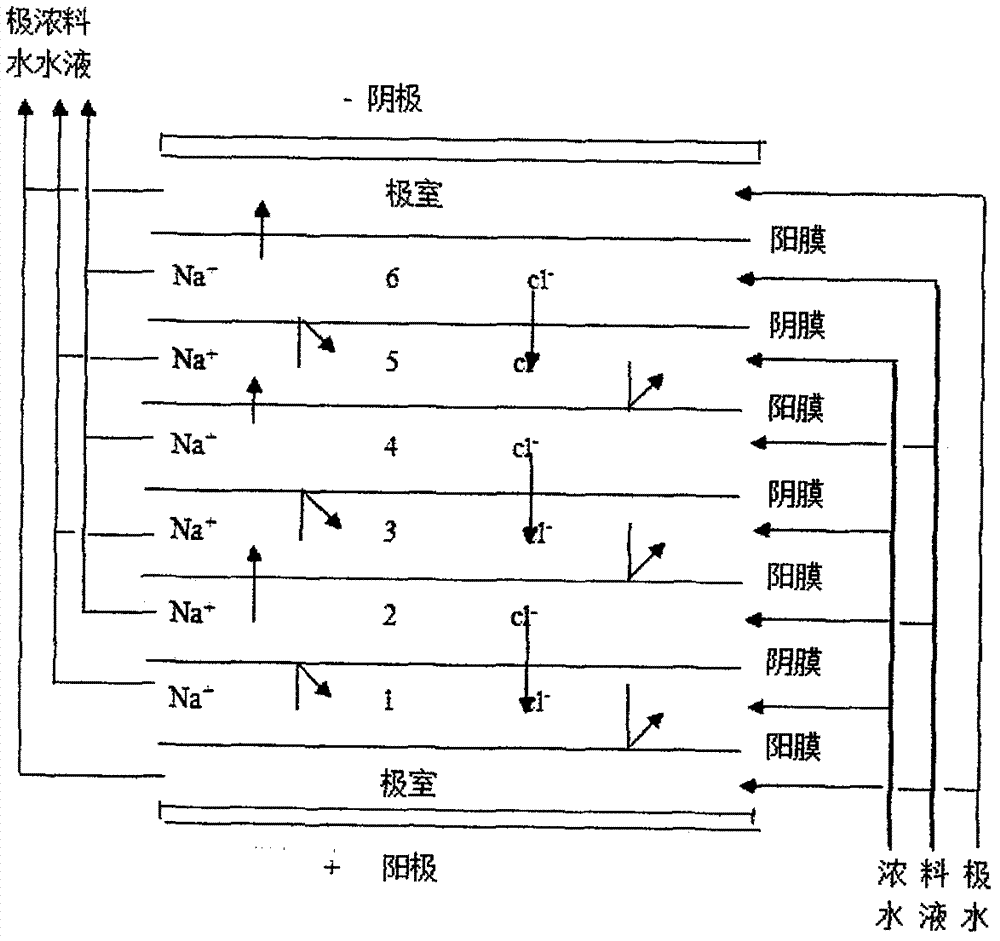

Method for separating desulfurization waste water by using electric drive membrane

InactiveCN107417023AAvoid excessive foulingGood self-cleaning effectWaste water treatment from gaseous effluentsMultistage water/sewage treatmentWater qualityEvaporation

The invention relates to the technical field of desulfurization and particularly discloses a method for separating desulfurization waste water by using an electric drive membrane. The method comprises the following steps of (A) front-end pretreatment; (B) separation and concentration by the electric drive membrane; and (C) multiple-effect evaporation crystallization. The water production rate of the method can reach over 95%, if water quality of a system fluctuates, when the SO4<2-> content is relatively high, excessive scaling of an assembler can be avoided by only adopting a rearrangeable electrode, that is to say, the system has a good self-cleaning effect on inorganic salt scaling. Compared with a double-membrane method, the residual chlorine resistance of the electric drive membrane is greatly enhanced, so that a small amount of fungicide can be added and the system is prevented from being polluted by bacteria; and meanwhile, the electric drive membrane runs through the propelling force from DC, so that the method also has a sterilization effect on microorganisms.

Owner:辽宁清新环境科技有限公司

Underwater dry-type oil production device suitable for development of shallow water oil-gas field

The invention discloses an underwater dry-type oil production device suitable for development of a shallow water oil-gas field. The underwater dry-type oil production device comprises a large-diametersteel cylinder and an underwater dry-type sealed cabin. The underwater dry-type sealed cabin is arranged inside the large-diameter steel cylinder, and a Christmas tree cabin, a lifesaving cabin and pieces of ground conventional oil-gas treatment equipment are arranged inside the underwater dry-type sealed cabin; the underwater dry-type sealed cabin is of a closed structure, and a reserved connector is formed in the top of the underwater dry-type sealed cabin and connected with maintenance channels; and power supplies of the pieces of ground conventional oil-gas treatment equipment are provided by submarine cables, and when the submarine cables pass through the large-diameter steel cylinder and the cabin wall of the underwater dry-type sealed cabin, sealing treatment is conducted. According to the underwater dry-type oil production device suitable for development of the shallow water oil-gas field, the ground conventional oil-gas treatment equipment is adopted, investment is greatly reduced, construction is conducted in a dry-type environment, compared with a conventional underwater production system, the cost of the underwater dry-type oil production device is lowered greatly, andunderwater dry-type oil production operation of the shallow water oil-gas field is achieved.

Owner:CNOOC ENERGY TECH & SERVICES

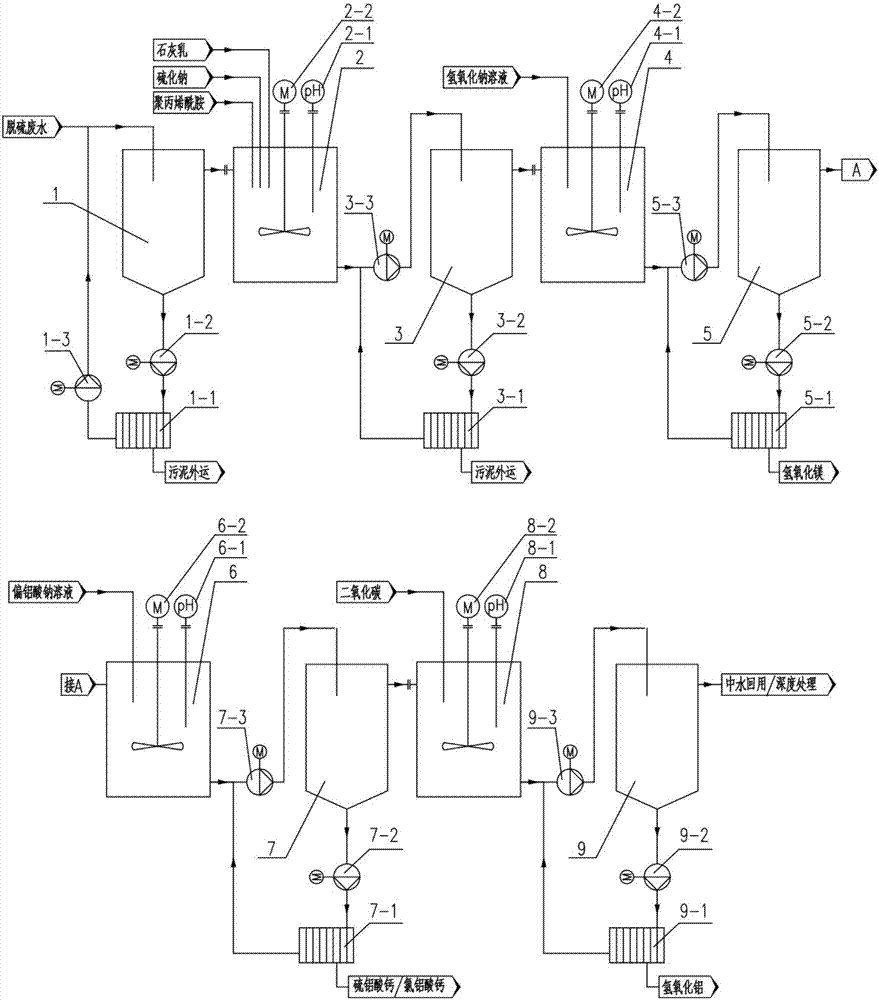

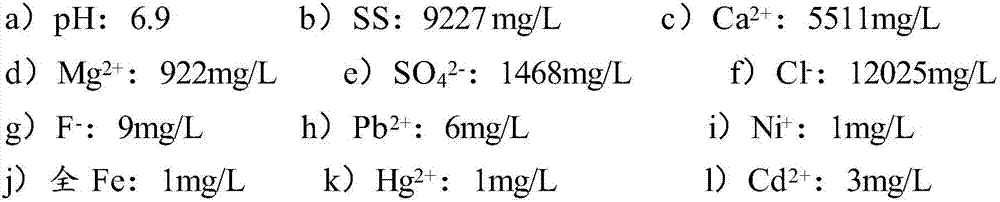

System and method for recycling application of desulfurization waste water

PendingCN106938866AWide range of usesReduce hardnessWater treatment compoundsWaste water treatment from gaseous effluentsCalcium aluminatesEnvironmental chemistry

The invention relates to the field of water treatment and particularly relates to a system and method for recycling application of desulfurization waste water. The system comprises a primary clarification tank, a primary reaction tank which is connected to the primary clarification tank and is provided with lime milk, alkali metal sulfide and flocculant feeding inlets, a primary clarification tank which is connected to the primary reaction tank, a secondary reaction tank which is connected to the primary clarification tank and is provided with an alkali metal hydroxide feeding inlet, a secondary clarification tank which is connected to the secondary reaction tank, a tertiary reaction tank which is connected to the secondary clarification tank and is provided with an alkali metal meta-aluminate feeding inlet, a tertiary clarification tank which is connected to the tertiary reaction tank, a quaternary reaction tank which is connected to the tertiary clarification tank and is provided with a CO2 gas inlet, and a quaternary clarification tank which is connected to an outlet of the quaternary reaction tank. Waste water treated by the system can satisfy supplementary water quality requirements of a desulfurization tower. Resources in the waste water can be recovered and are used for preparation of chemical products such as magnesium hydroxide, calcium sulphoaluminate / calcium chloroaluminate and aluminum hydroxide.

Owner:FUJIAN LONGKING

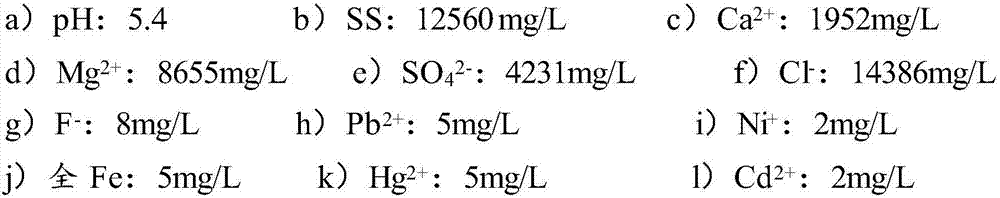

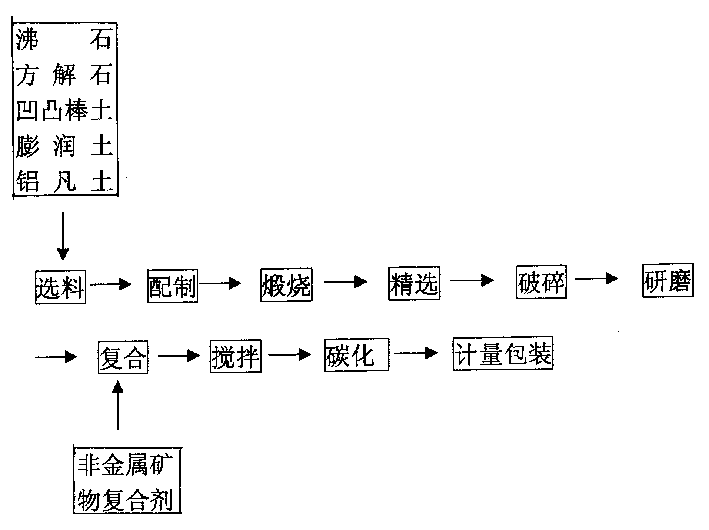

Superfine water quality improving powder and its prepn process

InactiveCN1436732AGood effectPH value is stableOther chemical processesWater/sewage treatment by flocculation/precipitationSodium BentoniteCalcite

The superfine water quality improving powder is prepared through mixing and calcining non-metal ore calcite, zeolite, attapulgite, bentonite and bauxite in certain proportion; selecting concentrate, crushing, grinding to reach fineness over 600 mesh, mixing the superfine powder and non-metal mineral composite agent through stirring; carbonizing the mixture powder and packing. The superfine water quality improving powder has no toxic matter and harmful matter and may be used in treating industrial effluent, domestic sewage, river water, etc., the treated water may reach the first and second water quality standard, and the used treating agent may be reused. The precipitate produced during the treatment may be reused or used as fertilizer or feed.

Owner:徐清明

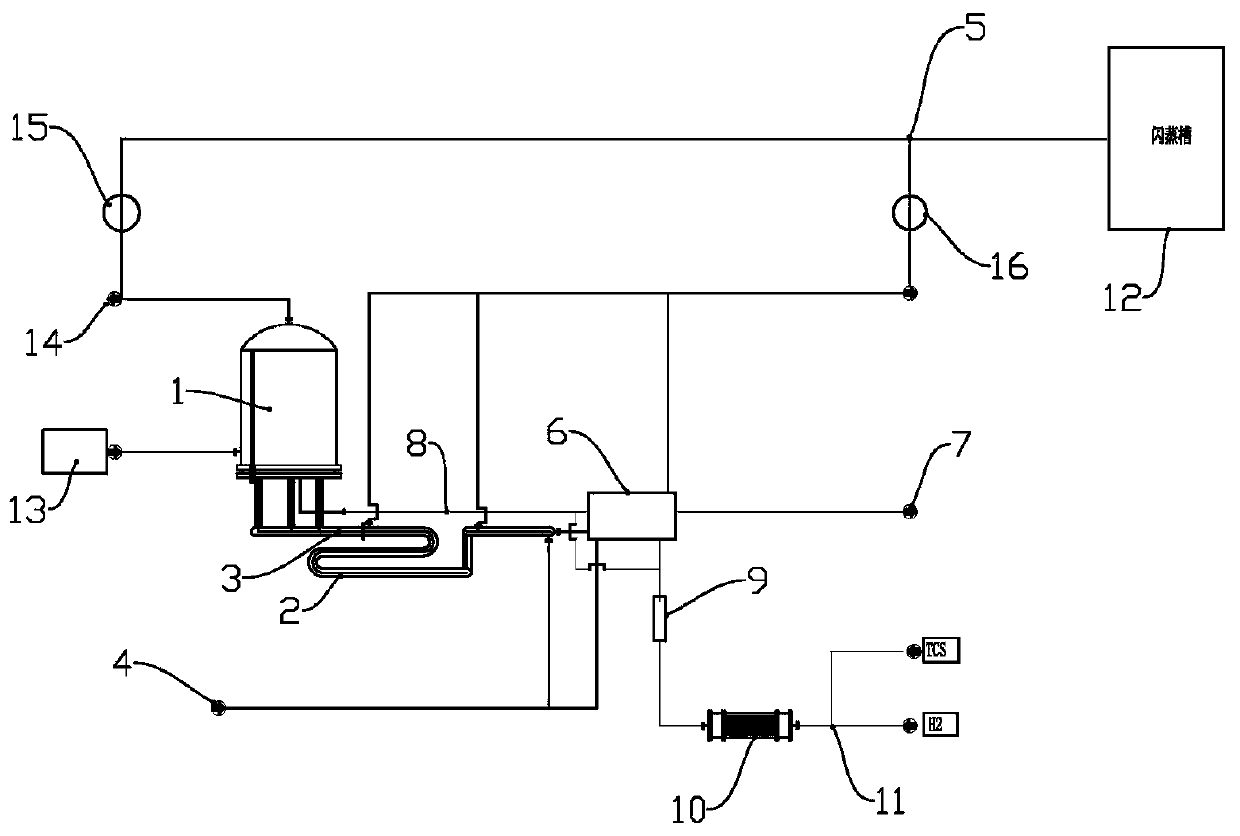

Tail gas heat recovery system of polycrystalline silicon production equipment and operation method thereof

PendingCN109665527ASolve the situation that the heat is low and the intake air temperature cannot be metGuaranteed cooling effectSiliconChemical industryRecuperatorProcess engineering

The invention relates to a tail gas heat recovery system of polycrystalline silicon production equipment and an operation method thereof. The tail gas heat recovery system of the polycrystalline silicon production equipment comprises a reducing furnace, the tail gas outlet of the reducing furnace is connected with a tail gas conveying pipe with a jacketed pipe, and the jacketed pipe is connected with a cooling water inlet and a high-temperature water outlet; the tail gas conveying pipe is connected with a tail gas exhaust outlet through a heat exchanger; the heat exchange medium inlet and theheat exchange medium outlet of the heat exchanger are connected with the cooling water inlet and the high-temperature water outlet respectively; the raw material inlet pipe of the reducing furnace isconnected with a total feeding port via a buffer and a vaporizer; two branches are arranged between the buffer and the raw material inlet pipe of the reducing furnace, one branch is directly connectedwith the raw material inlet pipe, and the other branch passes through the heat exchanger and exchanges heat with tail gas and high-temperature water in the heat exchanger and is then connected with the raw material inlet pipe; the high-temperature water outlet is communicated with a flash tank for producing saturated vapor. The tail gas heat recovery system of the polycrystalline silicon production equipment can efficiently recycle heat of tail gas produced during polycrystalline silicon production, achieve stable heat output and produce vapor applicable to polycrystalline silicon productionprocesses.

Owner:JIANGSU DONGFANG RUIJI ENERGY EQUIP CO LTD

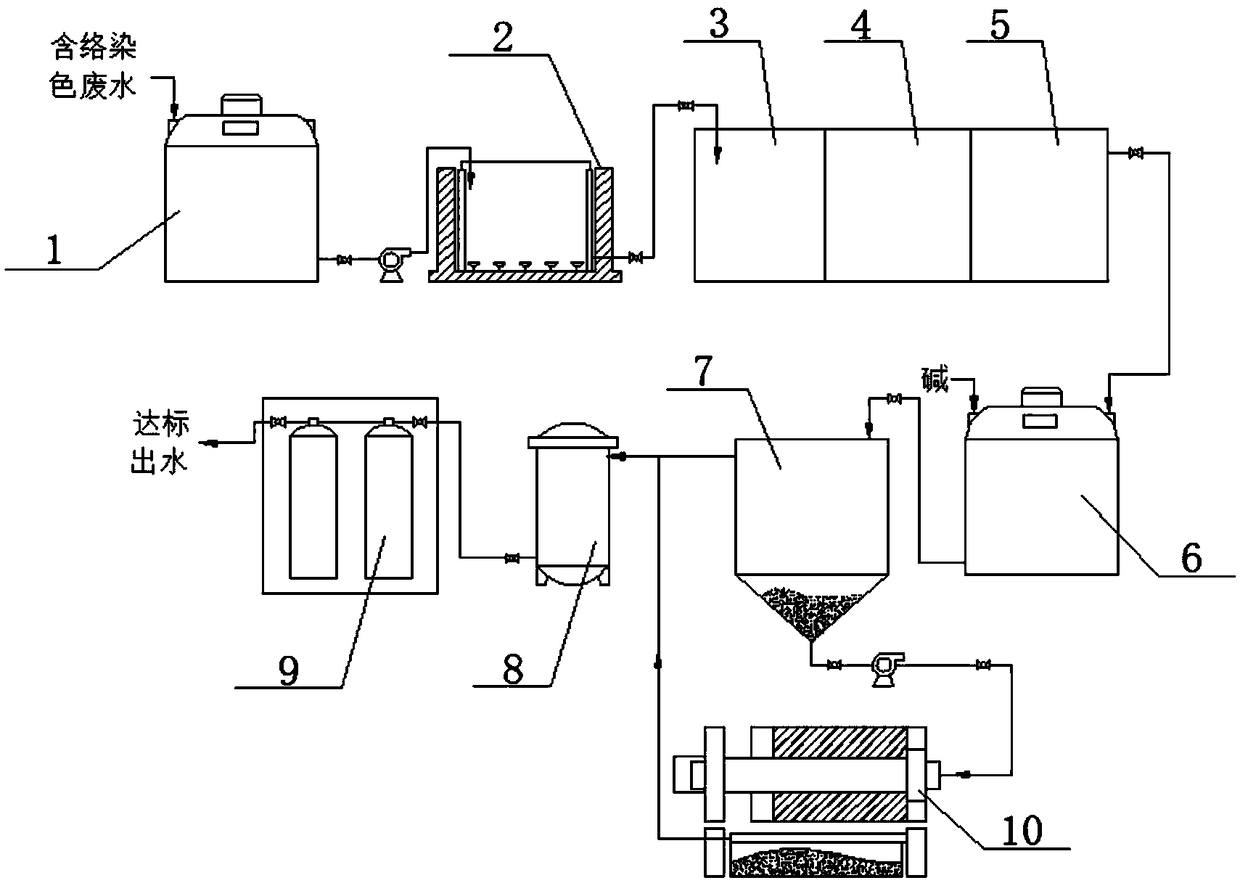

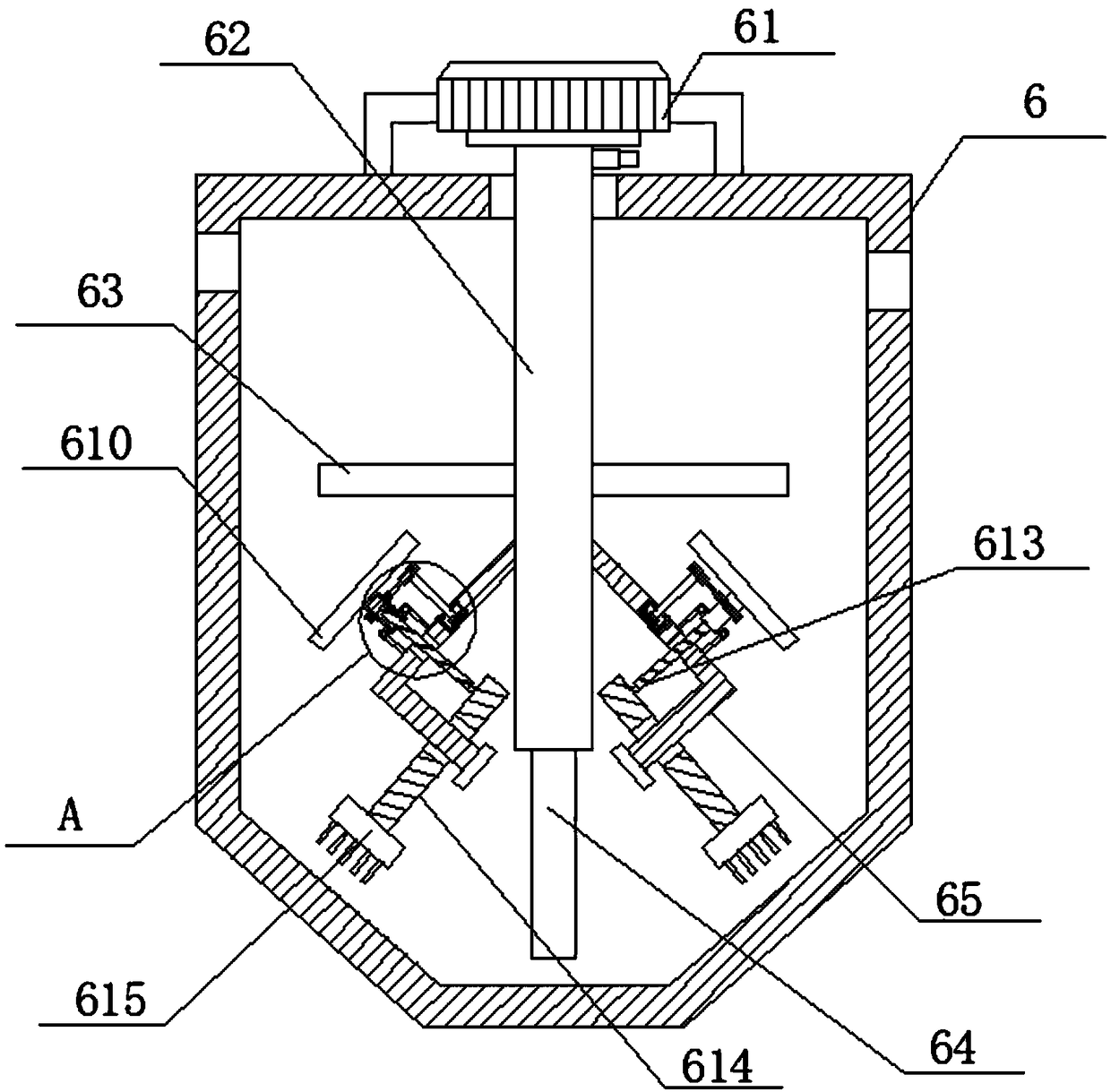

Treatment system for chromium-containing dyeing wastewater and implementation method thereof

PendingCN108928971AImprove processing efficiencyStrong resistance to shock loadsWater contaminantsTreatment involving filtrationFlocculationElectrolysis

The invention discloses a treatment system for chromium-containing dyeing wastewater and an implementation method thereof. The treatment system consists of a wastewater collection bucket, a three-dimensional electrolytic reaction tank, a 1# Ph regulating tank, an advanced oxidation decolorization tank, a reduction tank, a 2# Ph regulating tank, a flocculation sedimentation tank, a filter, an ion adsorption device and a sludge press. The treatment system for chromium-containing dyeing wastewater has a simple structure, and adopts the three-dimensional electrolysis, advanced oxidation decolorization, coagulation and ion exchange combined technology, after chromium-containing dyeing wastewater is treated by the wastewater collection bucket, the three-dimensional electrolytic reaction tank, the 1# Ph regulating tank, the advanced oxidation decolorization tank, the reduction tank, the 2# Ph regulating tank, the flocculation sedimentation tank, the filter and the ion adsorption device in order, the treated wastewater has a total chromium content of less than 0.5mg / L and a Cr<6+> content of less than 0.1mg / L that both reach the electroplating sewage discharge requirements specified in Table 3-3 of "GB 21900-2008", thus ensuring that the effluent water can achieve up-to-stand discharge and meet the reuse requirements. Also, the treatment process has strong impact load resistance.

Owner:深圳市世清环保科技有限公司

Infusion alarm

The invention discloses an infusion alarm. The alarm comprises a shell, a circuit board in the shell, a vibration exciter and a paracentetic needle which is arranged on the vibration exciter and protrudes the shell, wherein the vibration exciter is provided with a vibration sensor; a signal of the vibration sensor is inputted into the circuit board; the circuit board is connected with a buzzer; the circuit board controls work of the vibration exciter and the buzzer; when the alarm is used, the paracentetic needle penetrates into a infusion channel, and the vibration exciter vibrates to drive the paracentetic needle to vibrate; when the periphery of the paracentetic needle is changed into air, the vibration frequence, the amplitude and other parameters of the paracentetic needle are changed, and the vibration parameter of the vibration exciter changes due to the influence; the vibration sensor detects the change, generates a signal and sends the signal to the circuit board; the circuit board controls the buzzer to produce sound; and matched use of the infusion alarm with the conventional infusion device can be quickly realized by penetrating the paracentetic needle into an infusion pipeline. The infusion alarm is convenient and quick in operation, and the paracentetic needle can be quickly changed after the infusion alarm is used every time, so infusion alarm can fulfill the requirement of repeated use, has low cost, and contributes to popularization and application.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

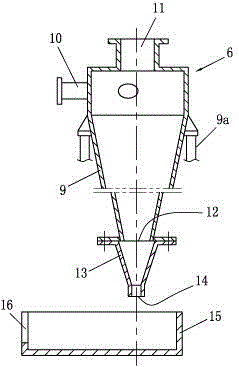

Zero-emission reusing device for paper-making wastewater for fireworks paper

ActiveCN104480765AEfficient removalSatisfy productivityWater/sewage treatment by centrifugal separationPulp liquor regenerationFireworksWastewater

The invention discloses a zero-emission reusing device for paper-making wastewater for fireworks paper. An outlet of a wastewater conveying member (1) is communicated with a pulper; a discharge opening of a screening wastewater pool (2) is communicated with the wastewater conveying member; the discharge opening of a sheet forming wastewater pool (3) is communicated with the wastewater conveying member; the discharge opening of a squeezing wastewater pool (4) is communicated with the wastewater conveying member; a first wastewater outlet for providing dilution water (5) to a paper pulp dilution pool is formed in the sheet forming wastewater pool; the first wastewater outlet is formed in the lower part of a side wall of the sheet forming wastewater pool, and is communicated with the lower part of the paper pulp dilution pool; the discharge opening capable of playing a control role in a paper pulp liquid level in the paper pulp dilution pool is formed in the upper part of the other side wall of the sheet forming wastewater pool; a paper pulp sand remover (6) is arranged; and pulping wastewater is communicated with the pulper via the wastewater outlet of the paper pulp sand remover. According to the zero-emission reusing device disclosed by the invention, sand grains in the pulped paper pulp can be effectively removed; the reuse quality of the sand-removing wastewater is improved; and the zero-emission reusing device has the characteristics of being relatively reasonable in structure, practical and the like.

Owner:钟立福

Method for treating COW-DM sewage with high chemical stability and biodegradation difficulty

ActiveCN104803547ACompletely degradedHigh water standardMultistage water/sewage treatmentPtru catalystSludge

The invention provides a method for treating COW-DM sewage with high chemical stability and biodegradation difficulty. The method comprises the following steps in sequence: catalytic ozonation, A / O (anaerobic / oxic) tank biochemical reaction and sludge-water separation, and the emission standard is met finally, wherein 30-50 ppm of a solid catalyst is added in a catalytic ozonation reaction process, the height of the solid catalyst is 3-4 m, pH is 7-9, the temperature is 25-30 DEG C, the solid catalyst adopts metal or metal oxide supported on a carrier, the retention time for catalytic ozonation is 1-1.5 h, the ozone contact time is 20-30 min, the A / O tank biochemical reaction adopts an A tank and an O tank, the DO (dissolved oxygen) of the A tank is smaller than 0.5 mg / L, pH is 6.5-7.5, the DO of the O tank is 1.5-4.0 mg / L, pH is 7-8, MLSS (mixed liquor suspended solids) is controlled to be 3-6 g / L, the temperature is 20-35 DEG C, the retention time is 6-10 h, denitrification is performed in the A tank, and the required carbon source proportion BOD (biochemical oxygen demand) / TN (total nitrogen) is larger than 4.

Owner:JIANGSU BODA ENVIRONMENTAL PROTECTION

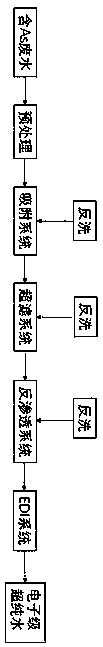

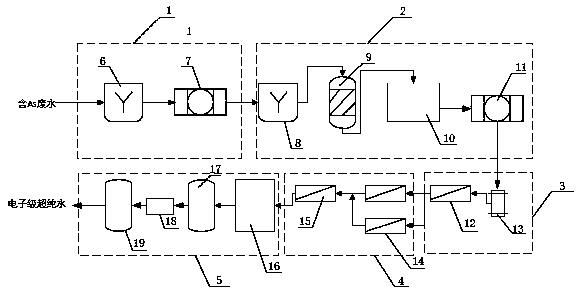

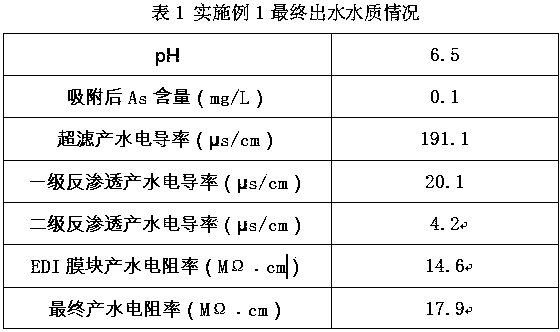

Disposal method of using As-containing wastewater in LED industry for preparing electronic-grade ultrapure water

InactiveCN109775904AAchieving zero emissionsMeet reuse requirementsWater contaminantsMultistage water/sewage treatmentWater sourceSludge

The invention discloses a disposal method of using As-containing wastewater in the LED industry for preparing electronic-grade ultrapure water. According to the method, the wastewater is subjected topretreatment first to reduce the As content, enters an adsorption system and then sequentially enters an ultrafiltration system, a reverse osmosis system and an EDI system for disposal after As is completely removed through the adsorption system, and final effluent after disposal satisfies the reuse standard of the electronic-grade ultrapure water. By means of the method, not only can As in the wastewater be completely removed, but also the wastewater can be prepared into the electronic-grade ultrapure water, reuse requirements of enterprises are met, waste of water sources is reduced, the generation amount of sludge is reduced, zero discharge of the wastewater is achieved, and a broad application prospect is achieved.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

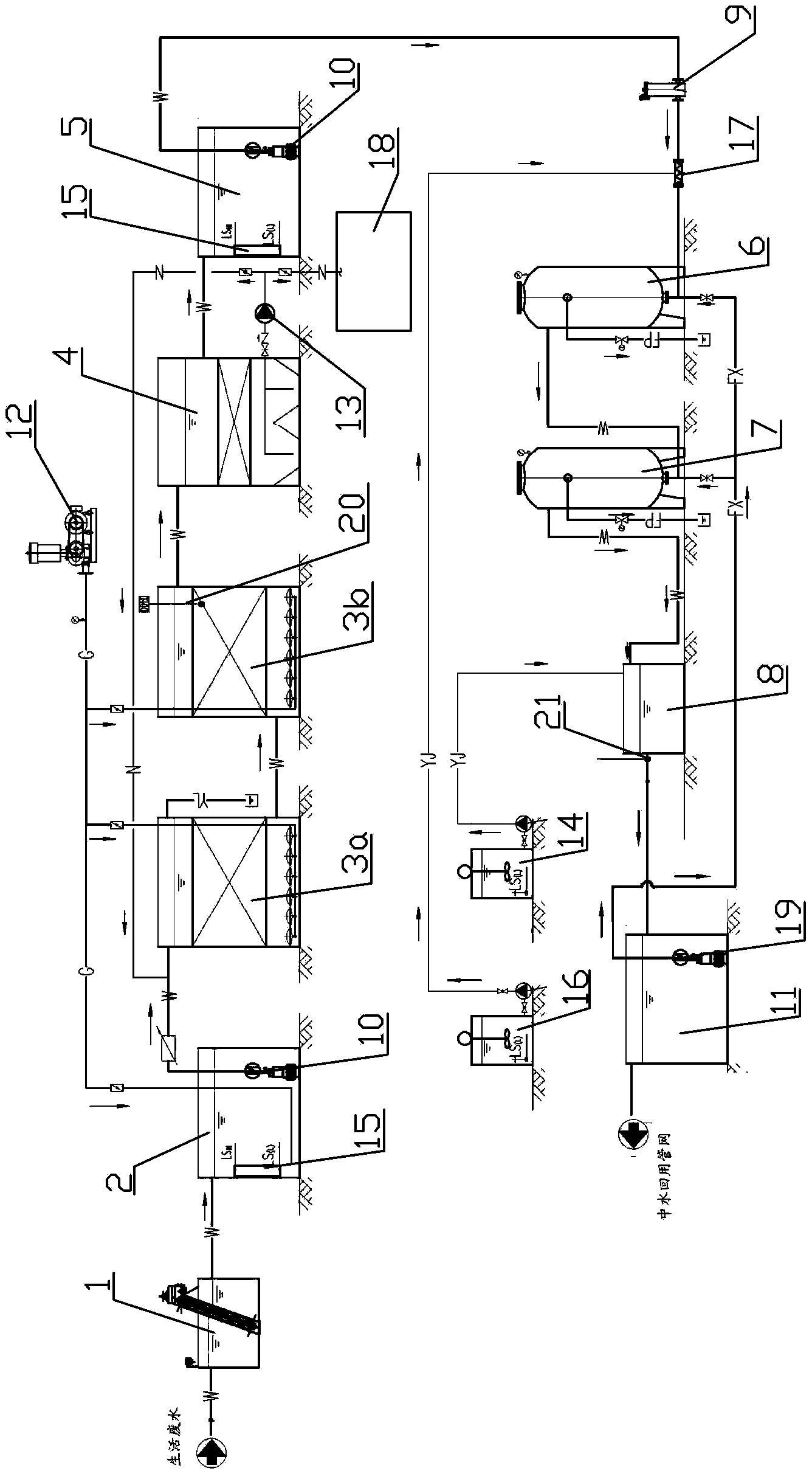

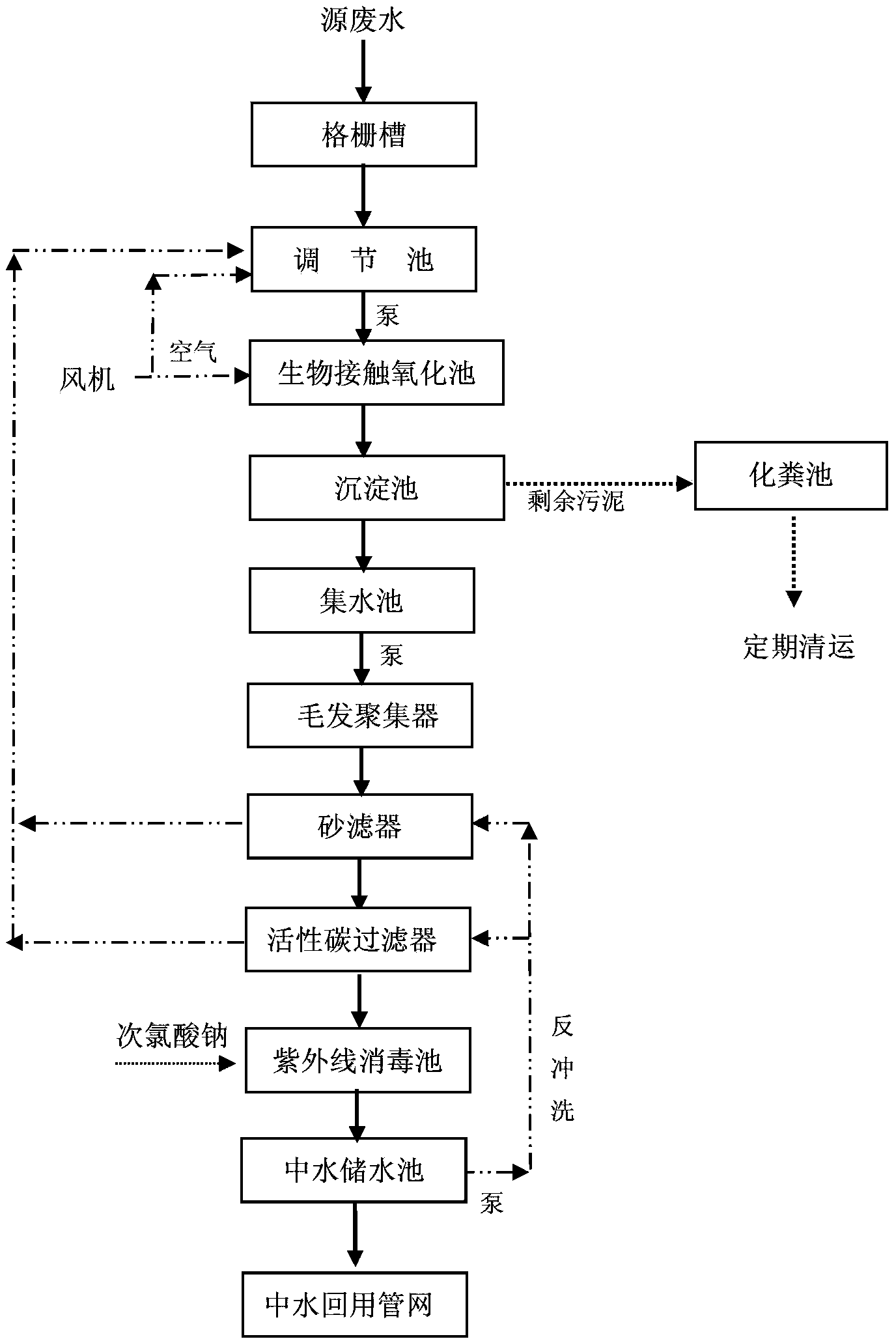

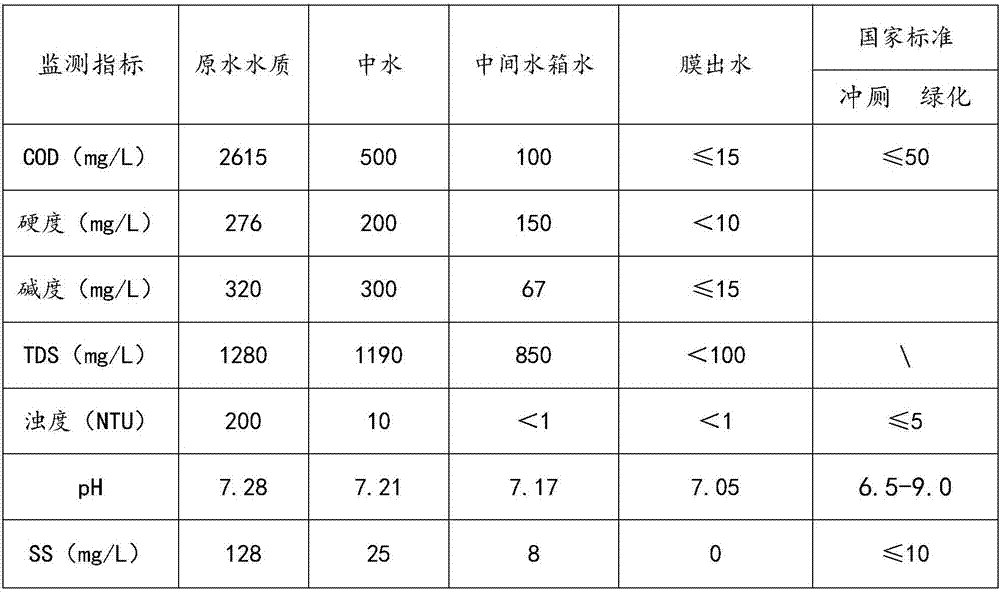

Recycled water reusing processing system

ActiveCN103319051BThorough treatmentReduce labor intensityMultistage water/sewage treatmentGratingActivated carbon filtration

The invention discloses a recycled water reusing processing system. The system comprises a grating tank, an adjusting pond, a biological contact oxidation pond, a settlement pond, a water collecting pond, a sand filter, an active carbon filter and an ultraviolet light disinfecting pond which are sequentially communicated with one another along the flow direction of wastewater through a pipeline, wherein the grating tank is communicated with a wastewater drain pipe; the water outlet of the ultraviolet light disinfecting pond is communicated with a recycled water reusing pipe network; and a hair collector is arranged on the pipeline by which the water collecting pond and the sand filter are communicated. The system can completely process relatively clean wastewater, the reused water meets the reusing requirement, and the system is high in automation degree and can be controlled and managed automatically by a central controller, so that the shift of workers, the labor intensity and the like are reduced.

Owner:CHONGQING TAIKE ENVIRONMENTAL PROTECTION TECH CO LTD

Method for preparing biomass fuel from fresh cow dung

InactiveCN103509626AHigh calorific valueSolving resource constraintsBiofuelsSolid fuelsPotassium permanganateZeolite

The invention relates to a biomass material prepared by taking fresh cow dung as a raw material, which comprises the following components in parts by weight: 35-50 parts of fresh cow dung, 20-35 parts of dry coal powder, 8-15 parts of deodorizing adsorbent and 0-22 parts of loess, wherein the deodorizing adsorbent comprises the following components in parts by weight: 17-25 parts of bentonite, 6-13 parts of zeolite powder and 3-5 parts of potassium permanganate. The method for preparing biomass fuel from fresh cow dung comprises the following steps: (1) under the condition of continuous fine weather, collecting the fresh cow dung, and uniformly mixing for later use; (2) preparing raw coal, and pulverizing to uniform powder for later use; (3) preparing the deodorizing adsorbent: weighing a proper amount of bentonite, zeolite powder and potassium permanganate, and uniformly mixing for later use; and (4) proportionally weighing the treated fresh cow dung, the coal powder and the deodorizing adsorbent, uniformly mixing, and pressing to obtain the biomass fuel. According to the invention, the problem of coal resource constraint is solved to some extent, and the problem of environmental pollution caused by combustion of petrochemical energy is relieved. Thus, the method provided by the invention is of great practical meaning for popularization in vast rural areas and the like.

Owner:QINGDAO JIENENG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Treatment technology and equipment for recycling wastewater of surfactant industry

InactiveCN108101264AImprove water qualityLow costWater treatment parameter controlWater contaminantsPotential differenceReverse osmosis

The invention provides a treatment technology for recycling wastewater of a surfactant industry. The treatment technology is characterized by comprising the following steps of sequentially carrying out a stirring procedure, a precipitation procedure, a filtering procedure and a reverse osmosis procedure along a wastewater flowing process, wherein in the stirring procedure, a chemical agent is added into the wastewater to carry out pre-treatment; the precipitation procedure comprises at least two grades of precipitation treatment; the reverse osmosis procedure comprises at least two grades of reverse osmosis treatment; output water in the stirring procedure and the precipitation procedure enters a subsequent procedure through a potential difference overflowing manner. According to wastewater treatment equipment and technology, provided by the invention, surfactant wastewater with different concentrations and types can be effectively treated; the treatment cost is low, water resources also can be saved and the wastewater treatment equipment and technology are green and environmentally friendly.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Splicing type soft environment-friendly platform for remedial work and using method

PendingCN110952954AReduce weightStrong tear resistanceDrilling rodsDrilling casingsConstruction engineeringAbsorbent Pads

The invention provides a splicing type soft environment-friendly platform for remedial work and a using method. The splicing type soft environment-friendly platform for remedial work comprises a liquid collecting pool arranged below an oil pipe bridge, the liquid collecting pool is arranged to be a cuboid without a top and comprises seepage-proof cloth and a quick plugging type support, and the seepage-proof cloth is laid on the quick plugging type support on the periphery and the bottom; and the height of the liquid collecting pool is 15-30 cm. Polyurethane seepage-proof cloth serves as the seepage-proof cloth. Anti-sliding channels are arranged in the liquid collecting pool, and a water absorbing pad is arranged at the bottom of the liquid collecting pool. The splicing type soft environment-friendly platform for remedial work meets the technical requirement for collecting oil dirt in remedial work, can be used repeatedly and is light and convenient to assemble and disassemble.

Owner:PETROCHINA CO LTD

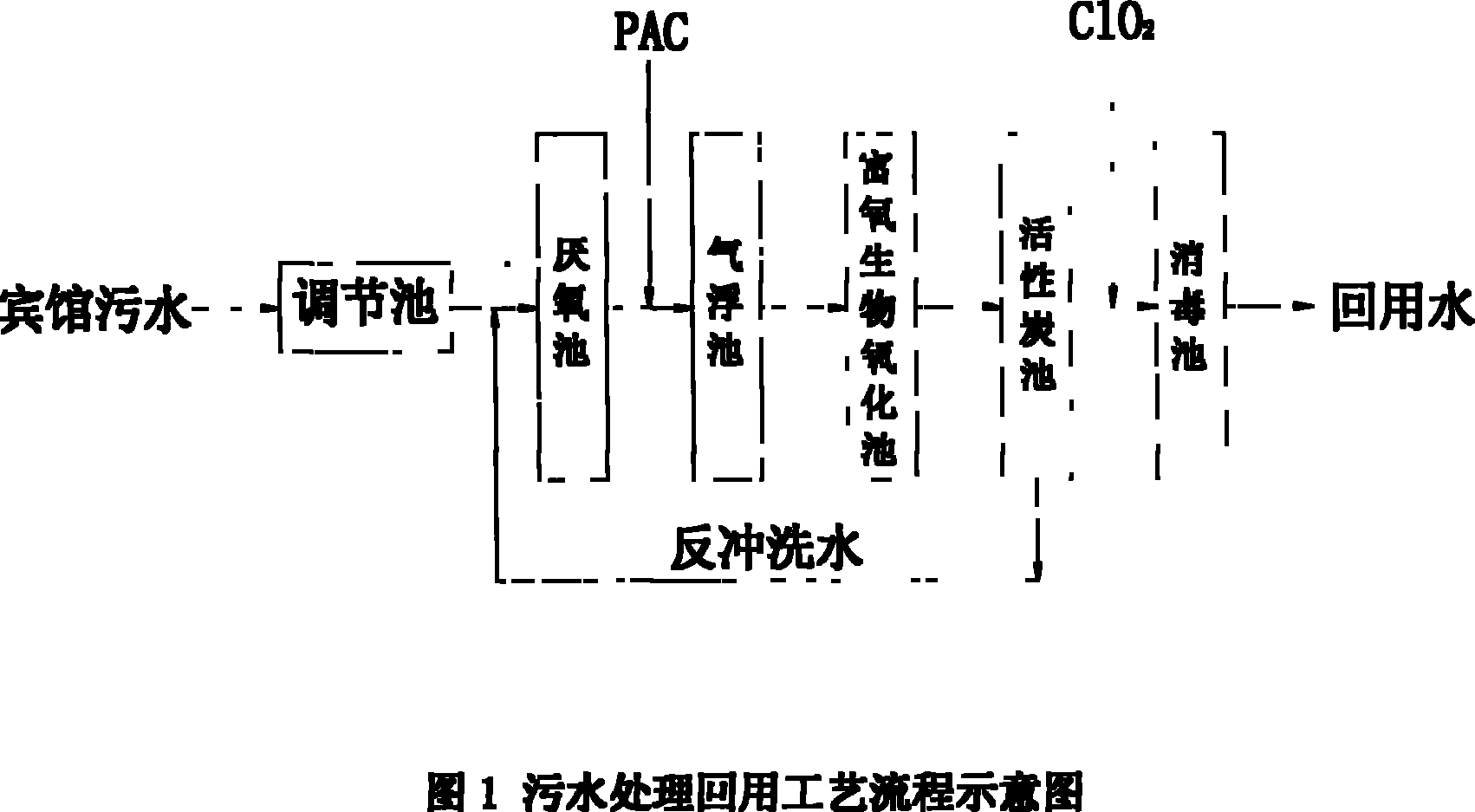

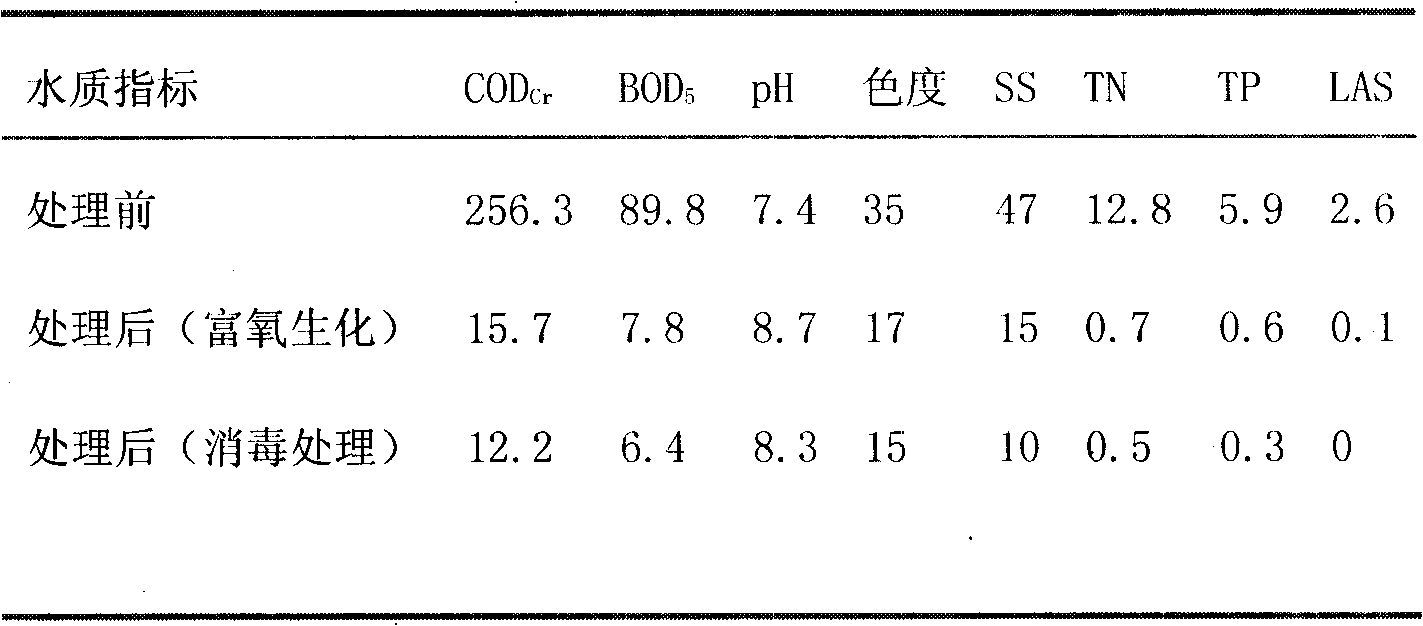

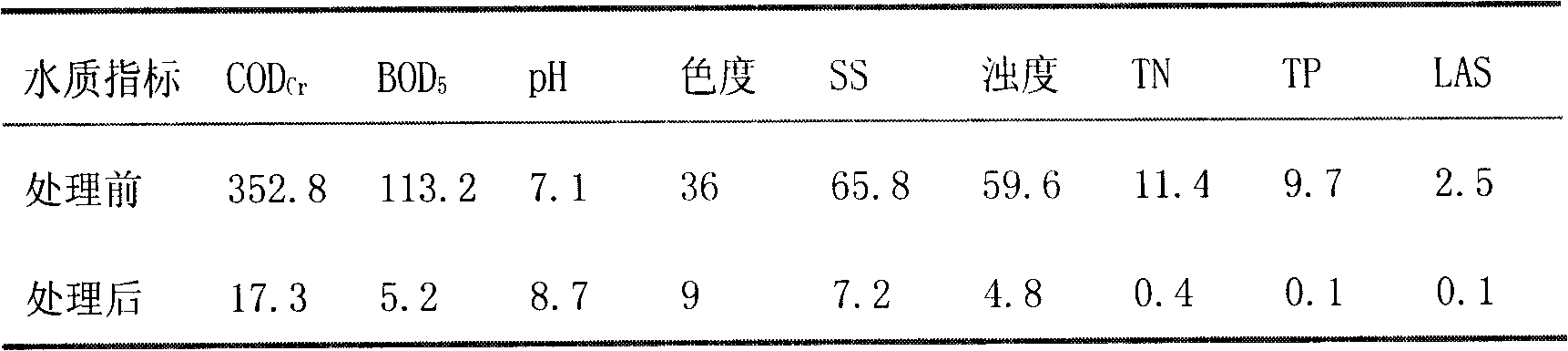

Air float-oxygen-enriched organism processing and reusing method for hotel sewage

InactiveCN1994937BEfficient degradationEliminate pollutionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentWater qualityEngineering

The invention discloses a hotel effluent processing and recycling technique in the effluent processing domain, which comprises the following flow paths: effluent; adjusting pond; anaerobic hydrolytic pond; floatation pond; oxygen-enriched biological contact oxidizing pond; activated charcoal filter; ClO2 sterilizing pond; recycling water. The invention stabilizes system operation, which makes recycling water superior to living service water.

Owner:NANKAI UNIV

Waste fiber leftover pre-opener

ActiveCN103147172BMeet reuse requirementsReduce manufacturing costFibre cleaning/opening machinesTextile disintegration and recoveryFiberCircular economy

The invention relates to a waste fiber leftover pre-opener, belonging to the field of non-woven fabric machines. The waste fiber leftover pre-opener comprises a pre-opening roller rack, a waste fiber leftover conveying mechanism, a pre-opening roller, a pressing mechanism, a feeding mechanism, a pre-opening roller driving mechanism, a power transmission mechanism and a fiber leading-out mechanism, wherein a first wallboard is fixedly arranged above one side of the pre-opening roller rack and a second wallboard is fixedly arranged above the other side of the pre-opening roller rack; the waste fiber leftover conveying mechanism is connected with one end of the pre-opening roller rack; the pre-opening roller is supported between the first wallboard and the second wallboard; the pressing mechanism is arranged on the waste fiber leftover conveying mechanism; the feeding mechanism is arranged on the pre-opening roller rack and is arranged between the pre-opening roller and the pressing mechanism; the pre-opening roller driving mechanism is arranged on the pre-opening roller rack and is connected with the pre-opening roller; the power transmission mechanism is arranged on the pre-opening roller rack and is connected with the waste fiber leftover conveying mechanism, the pressing mechanism and the feeding mechanism; and the fiber leading-out mechanism is fixedly arranged on the pre-opening roller rack. The waste fiber leftover pre-opener has the advantages that the opening effect is good, the opening efficiency is ideal, the requirement on reuse of waste fibers can be satisfied, the resources are saved, the environment is protected, the circular economy is reflected and the manufacturing cost of automobile interior ornaments is reduced.

Owner:江苏常盛无纺设备有限公司

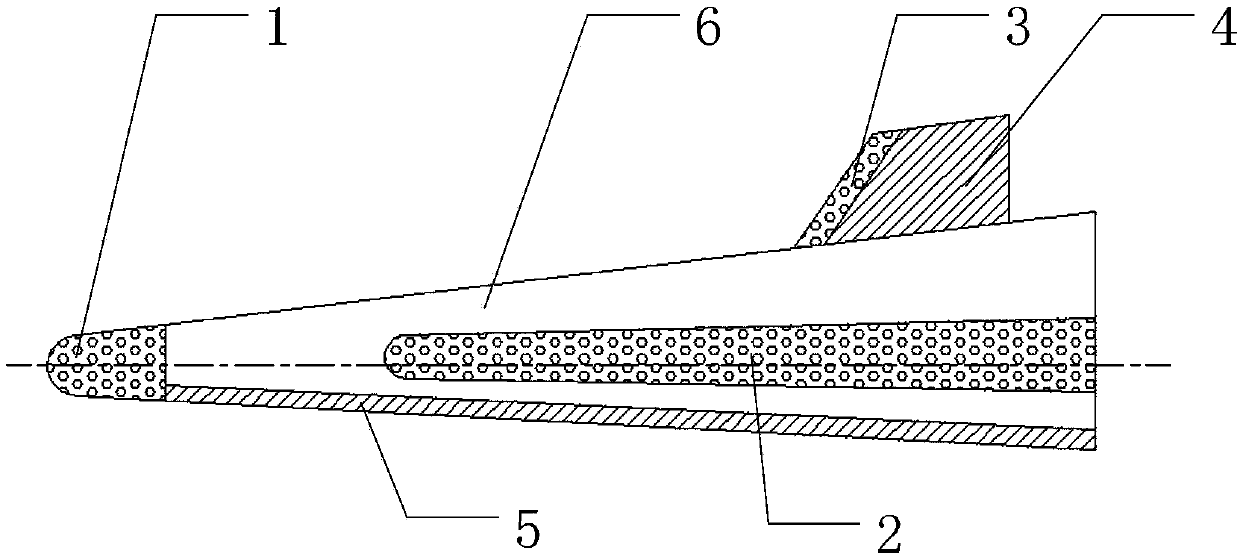

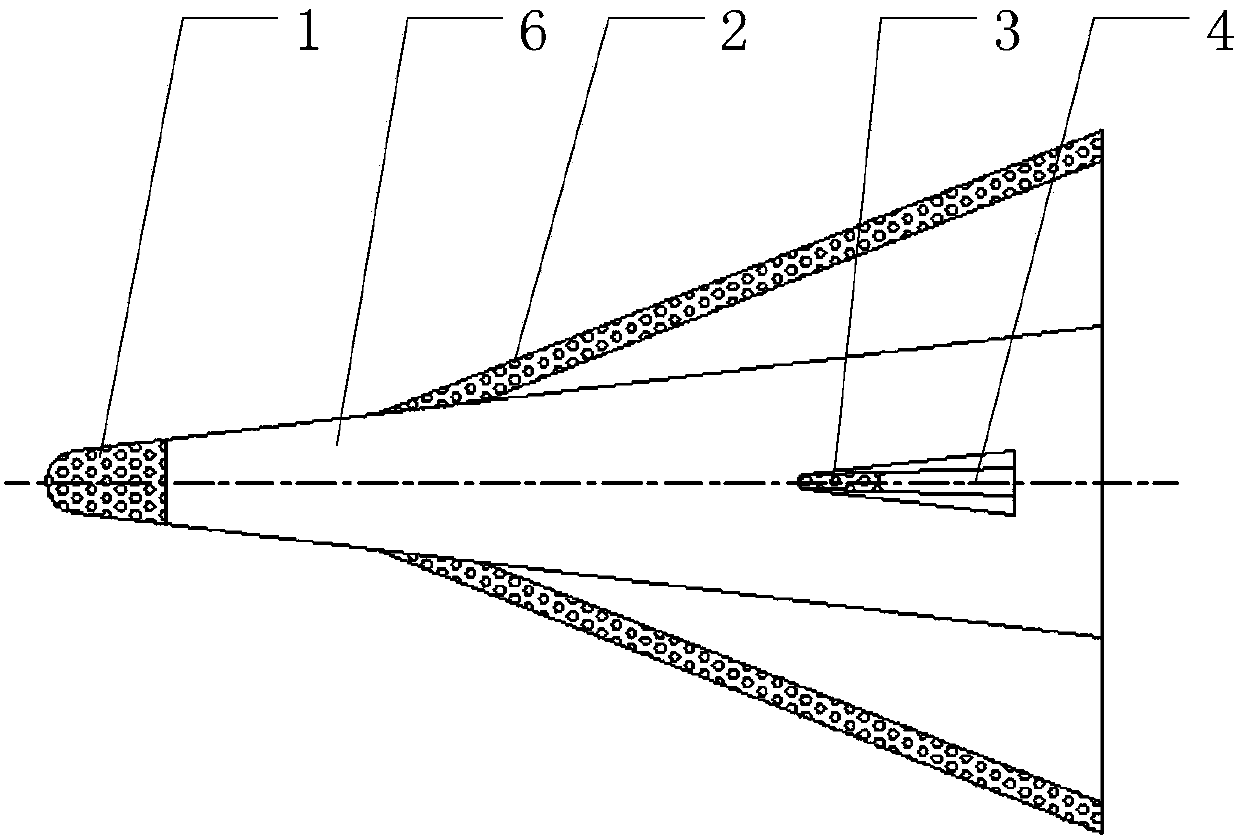

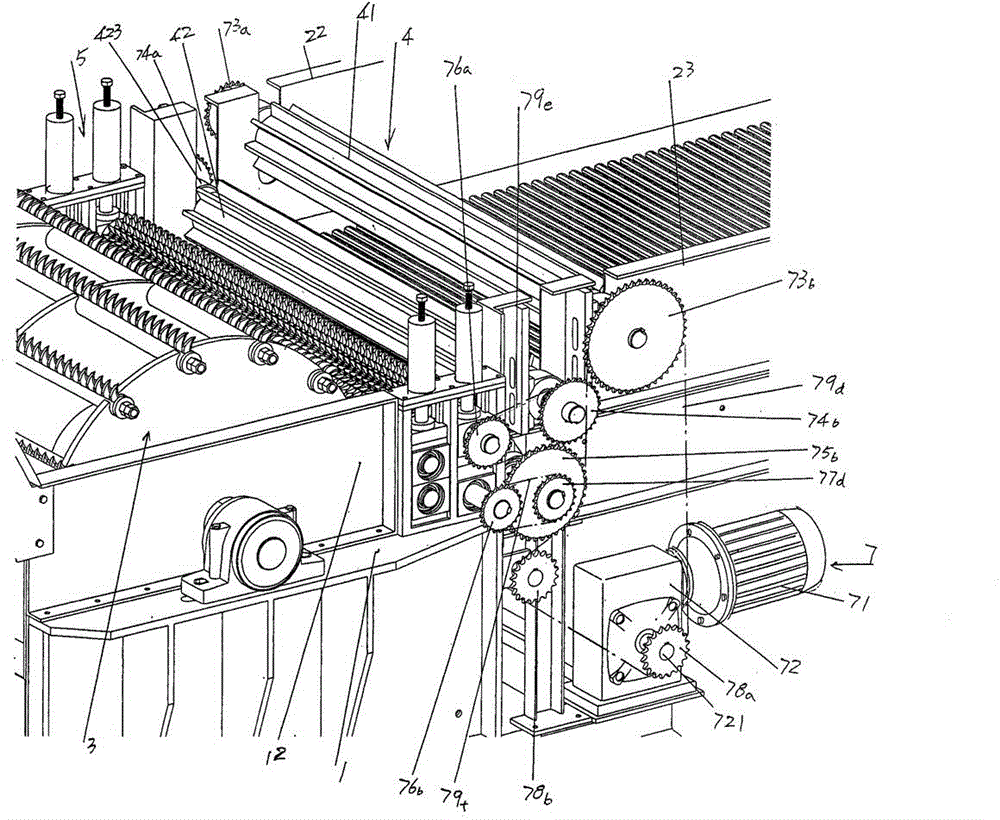

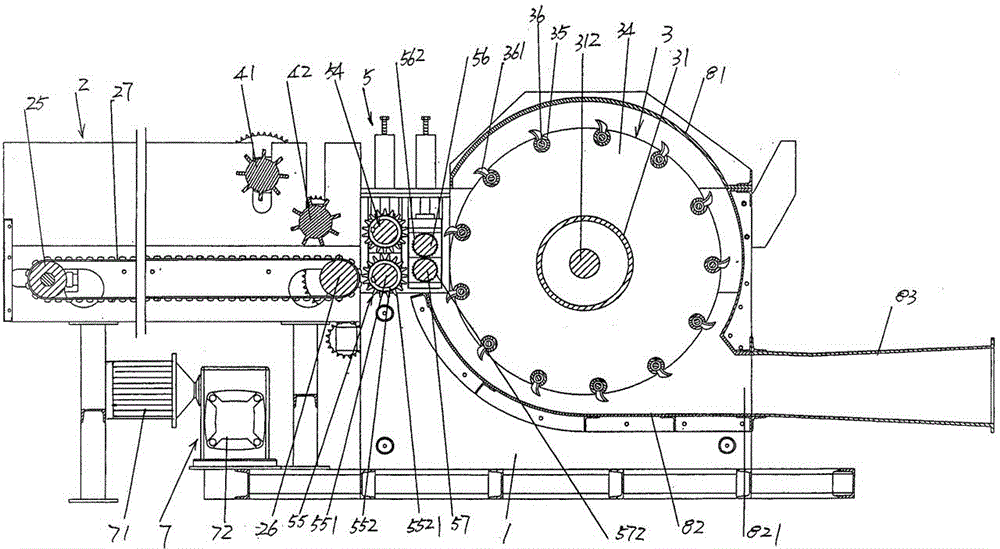

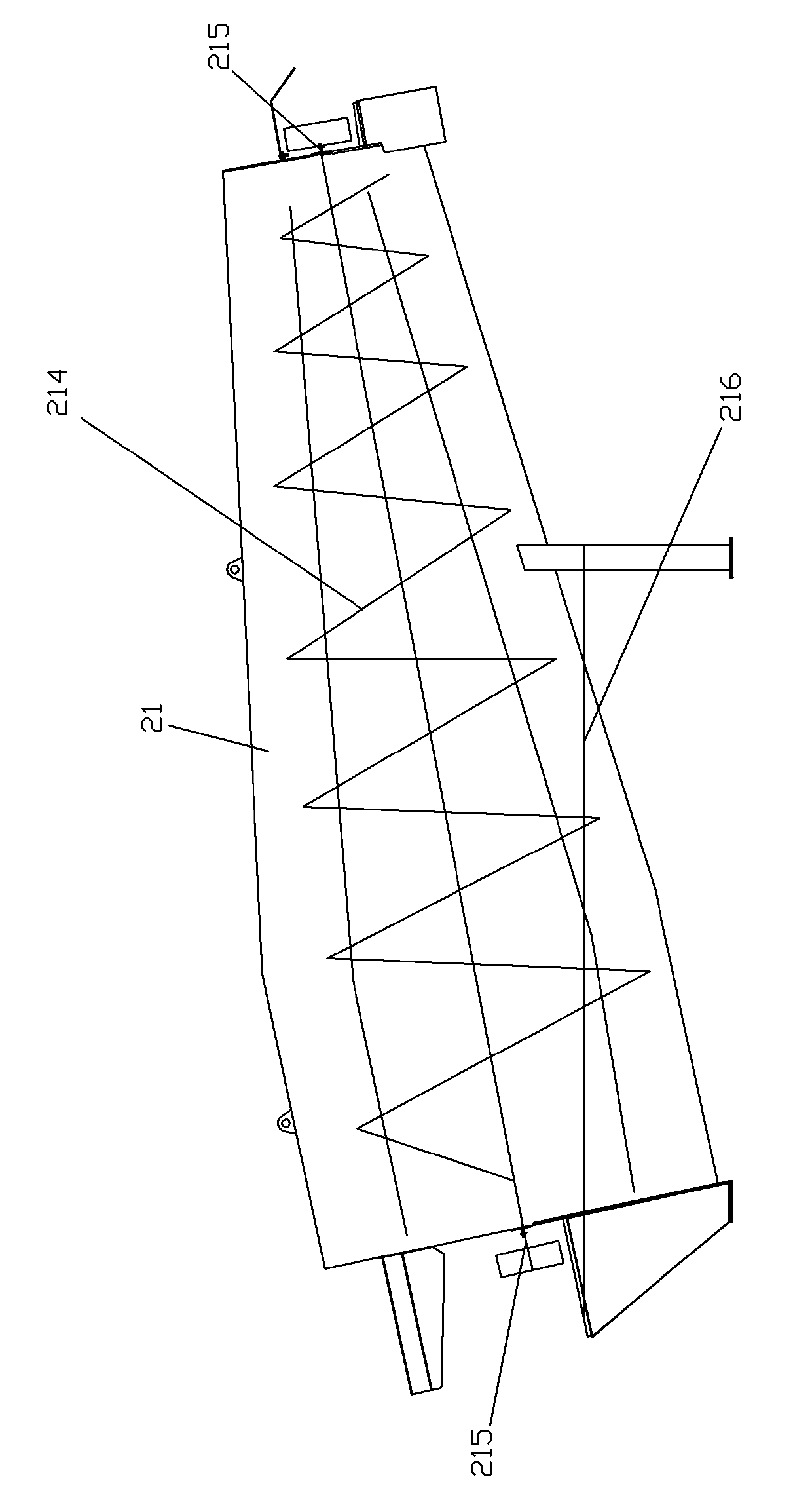

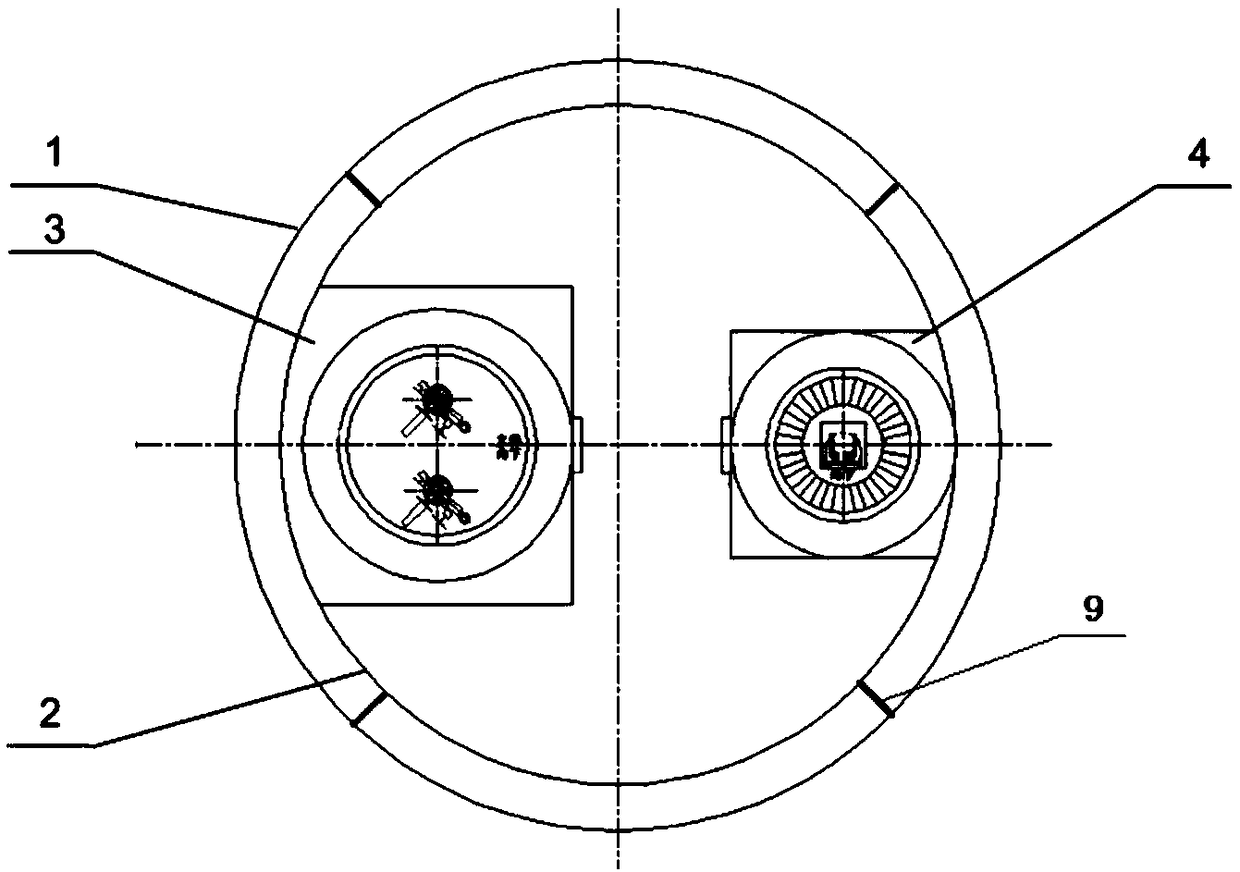

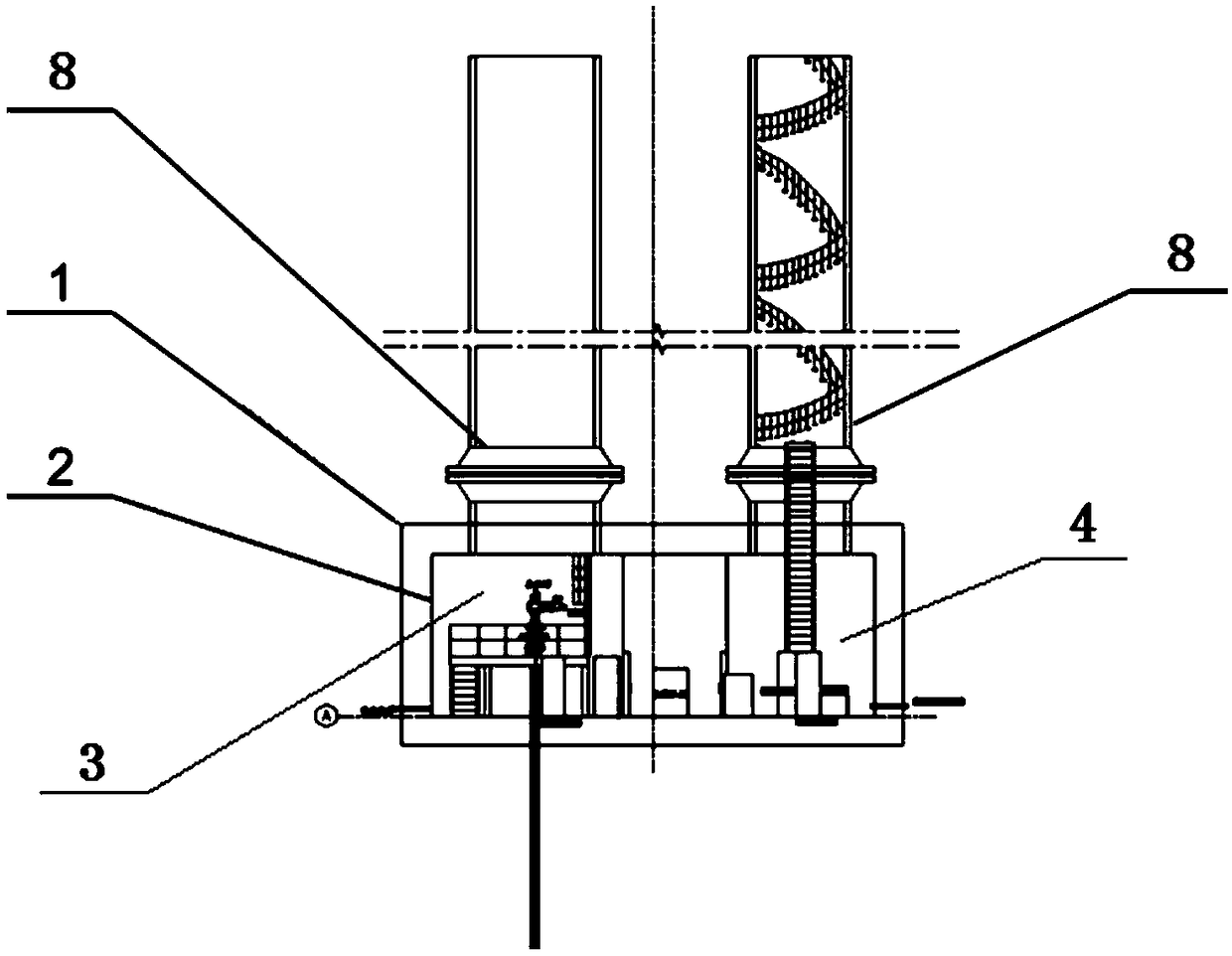

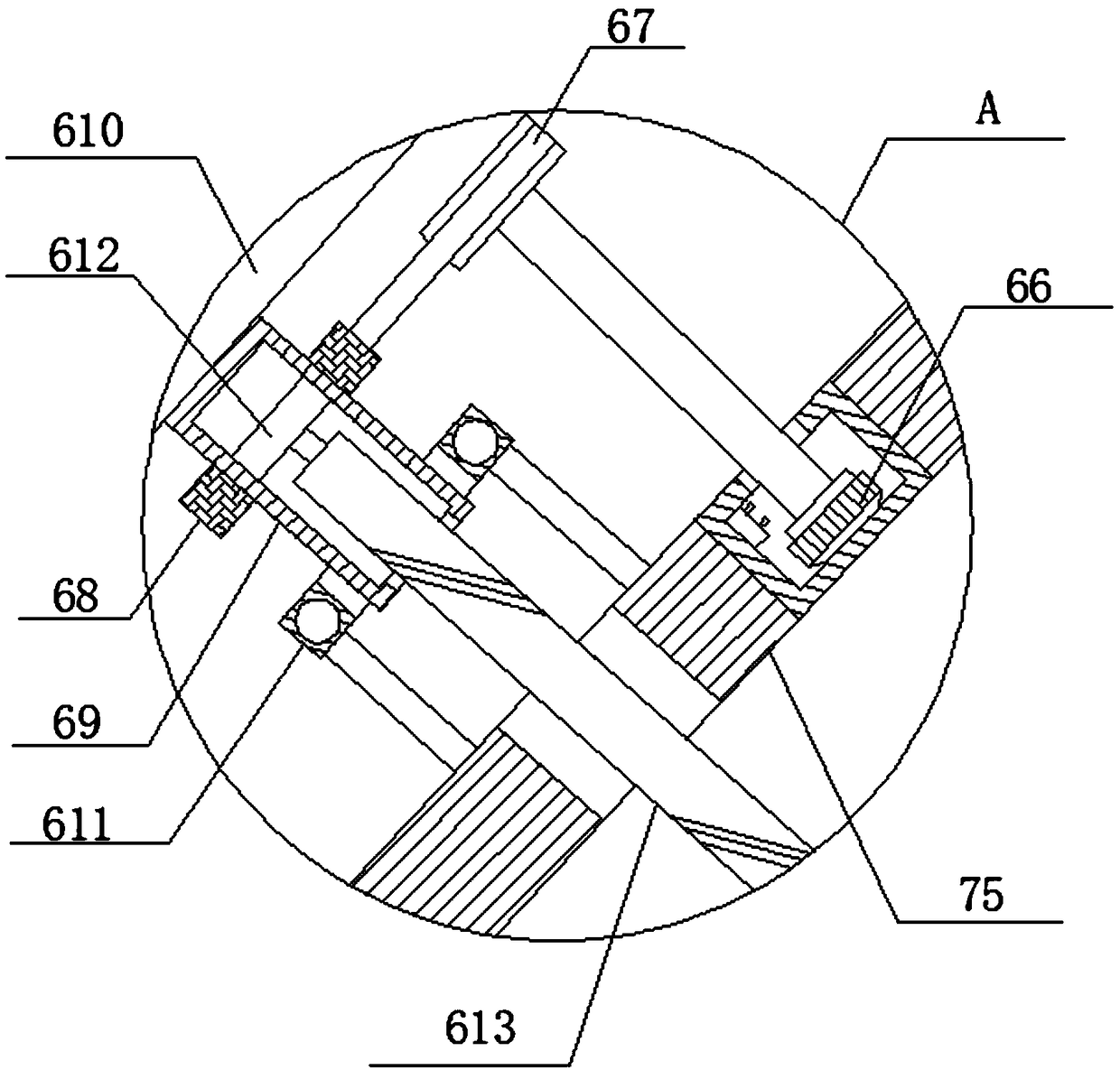

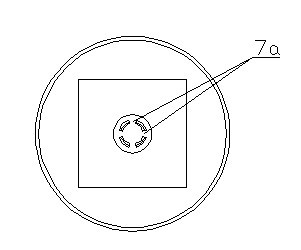

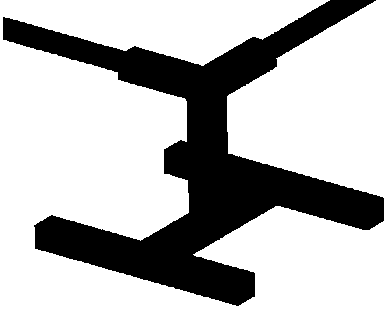

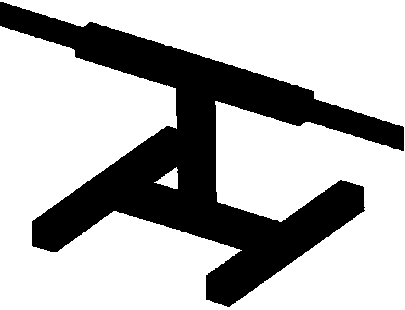

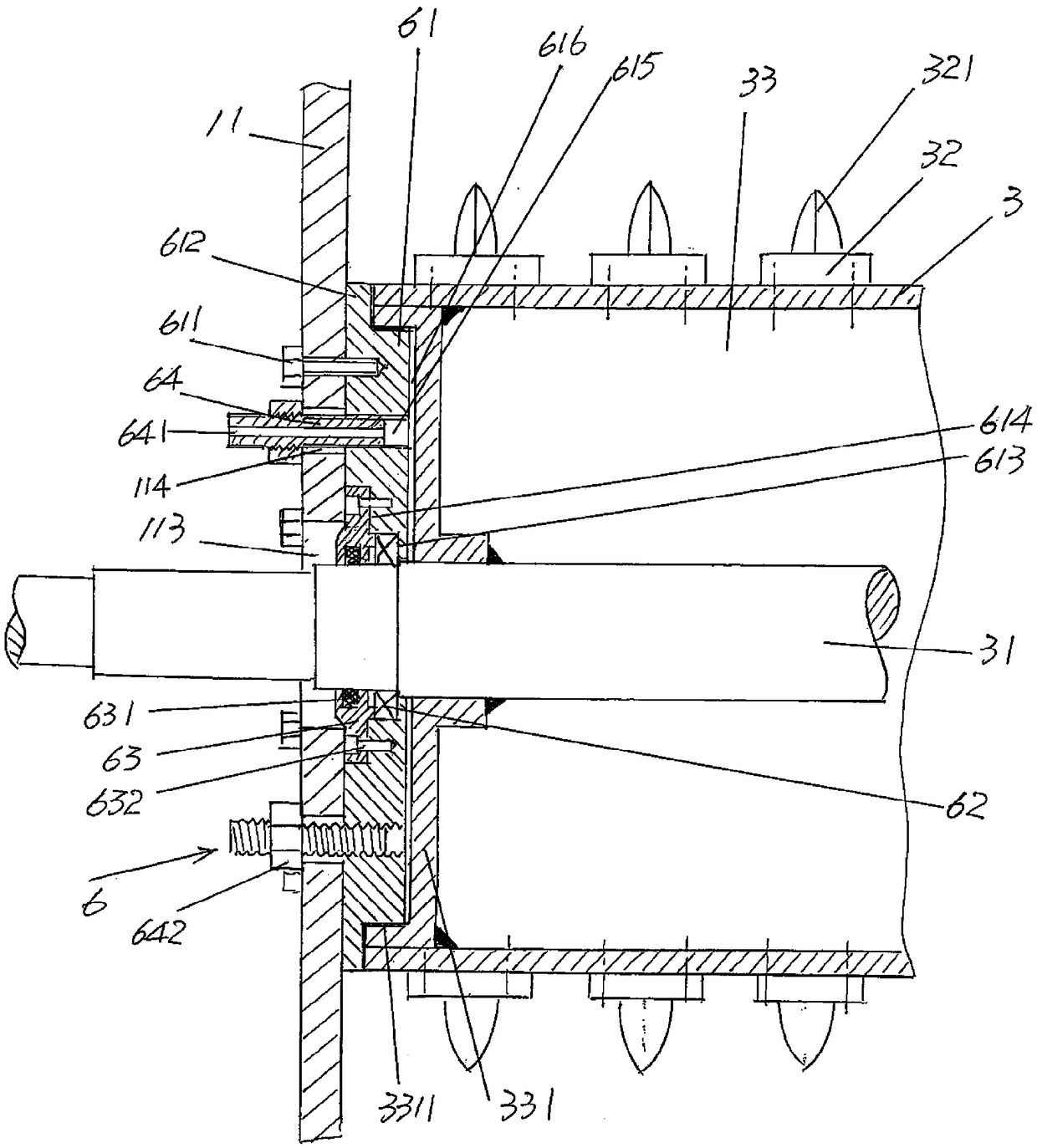

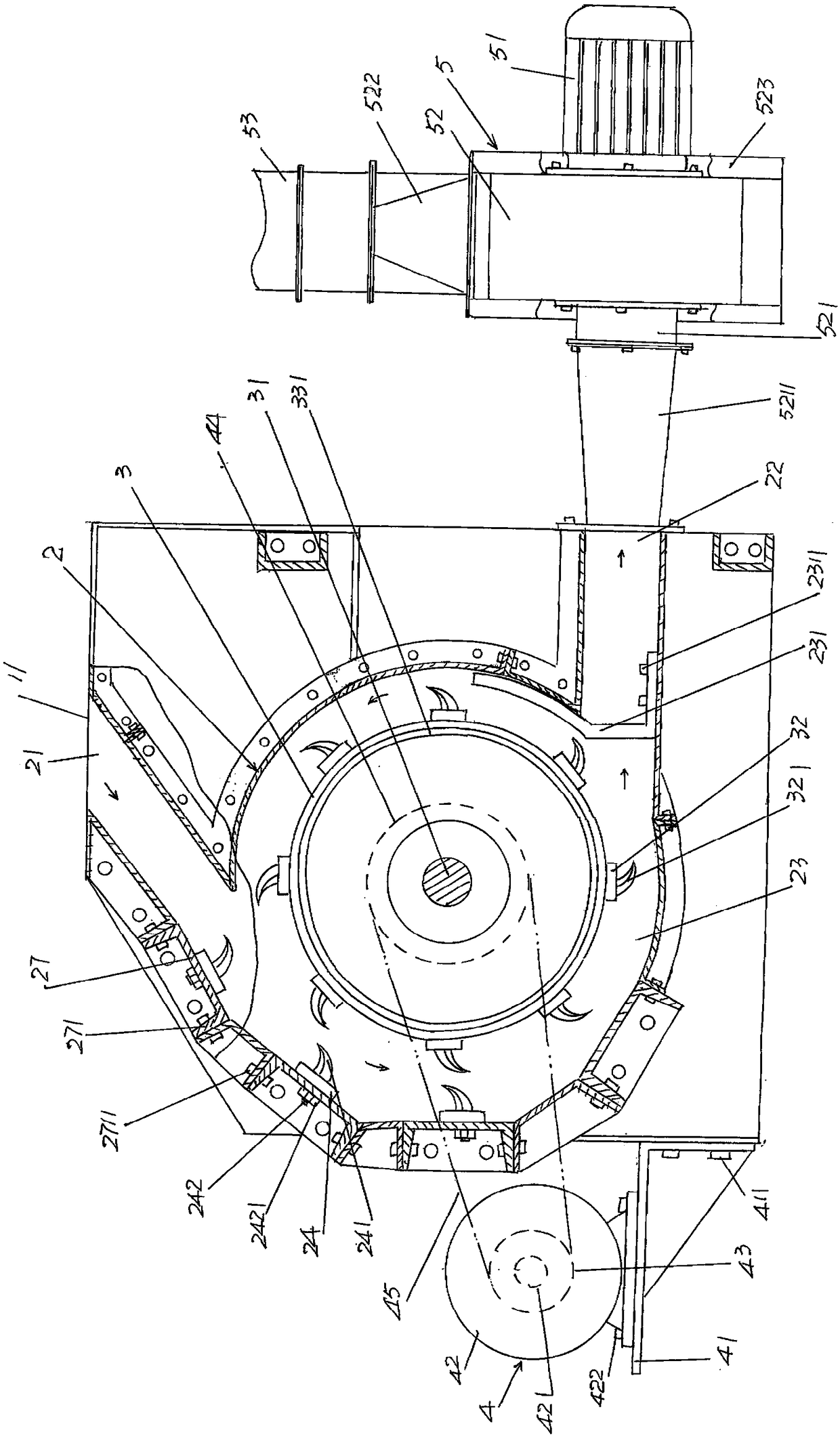

Pre-opening roller structure of waste fiber leftover pre-opener

ActiveCN103147173BReasonable structureSo as not to damageFibre cleaning/opening machinesFiberResource saving

The invention relates to a pre-opening roller structure of a waste fiber leftover pre-opener, belonging to the field of non-woven fabric machines. The pre-opening roller structure comprises a pre-opening roller. The pre-opening roller consists of a pre-opening roller body, a first end disc, a second end disc, middle discs, hook cutter shaft seats and hook cutter shafts. A first opening roller body shaft head and a second opening roller body shaft head extend from the end surfaces of the two ends of the pre-opening roller body. The first end disc and the second end disc are fixedly arranged at the two ends of the pre-opening roller body. A group of middle discs are fixedly arranged at the middle part of the pre-opening roller body. A group of hook cutter shaft seats are equidistantly distributed around the circumferential direction of the pre-opening roller body. One ends of the hook cutter shaft seats are inserted into the first end disc, the other ends of the hook cutter shaft seats are inserted into the second end disc and the middle parts of the hook cutter shaft seats are inserted into the group of middle discs. Hook cutter shaft grooves are formed on the hook cutter shaft seats. A group of hook cutter shafts are distributed on the hook cutter shaft seats and are inserted into the hook cutter shaft grooves. One ends of the hook cutter shafts are fixedly connected with the first end disc and the other ends of the hook cutter shafts are fixedly connected with the second end disc. A group of hook cutters are sheathed at the middle parts of the hook cutter shafts. The pre-opening roller structure has the advantages of good opening effect, high efficiency, resource saving and reasonable and firm structure.

Owner:江苏常盛无纺设备有限公司

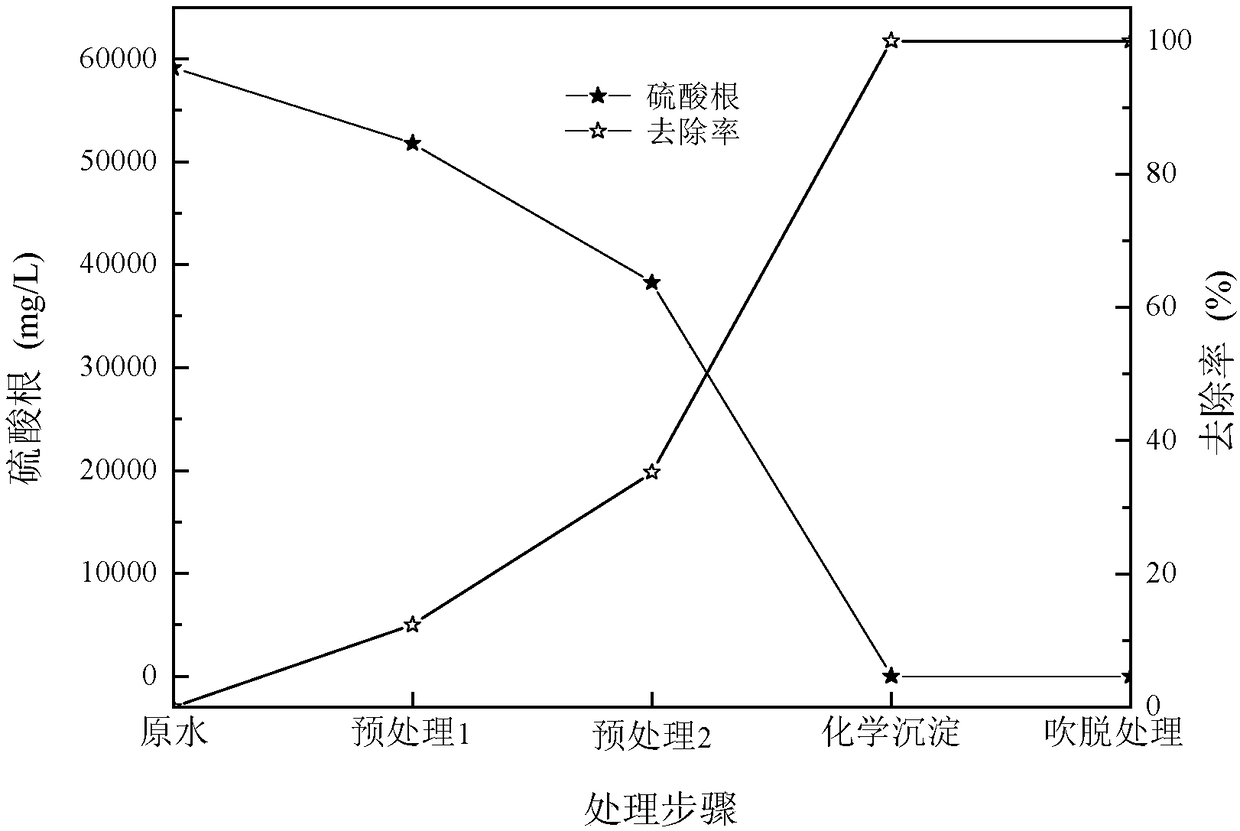

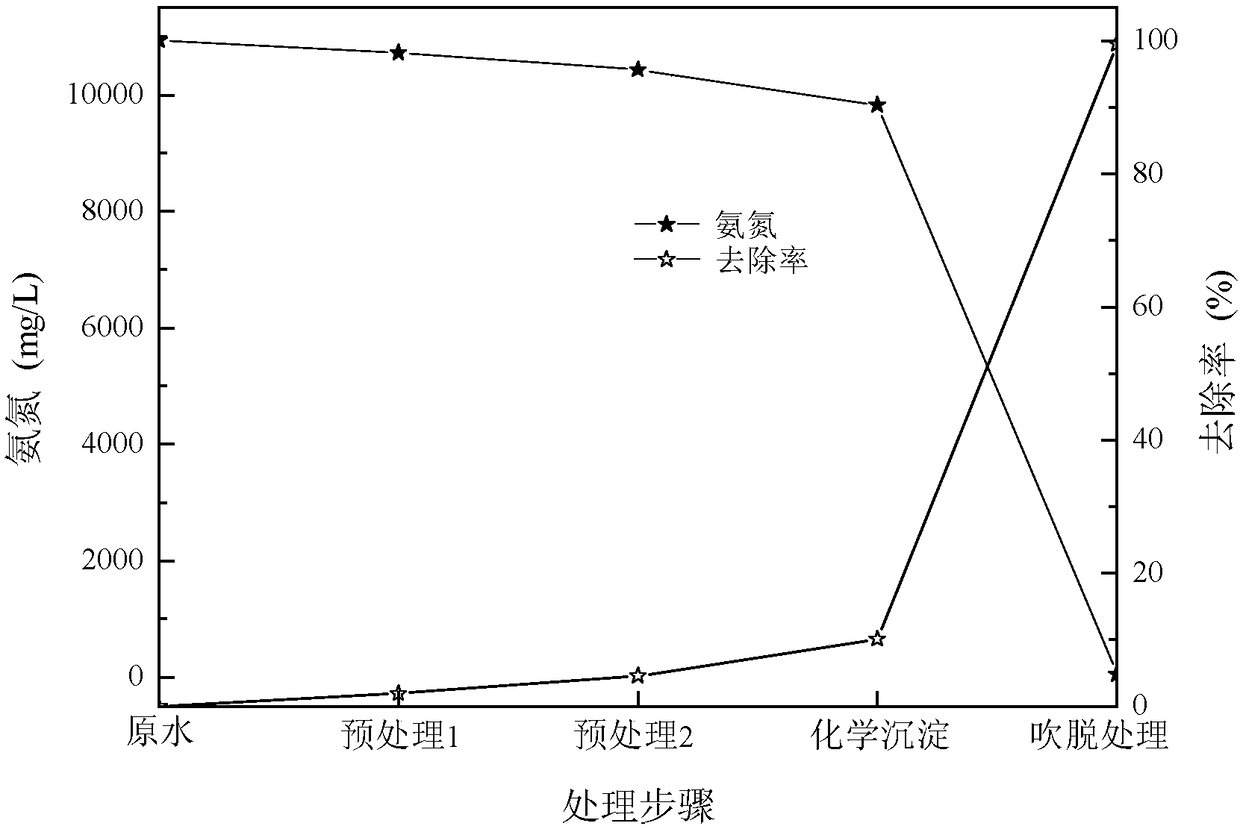

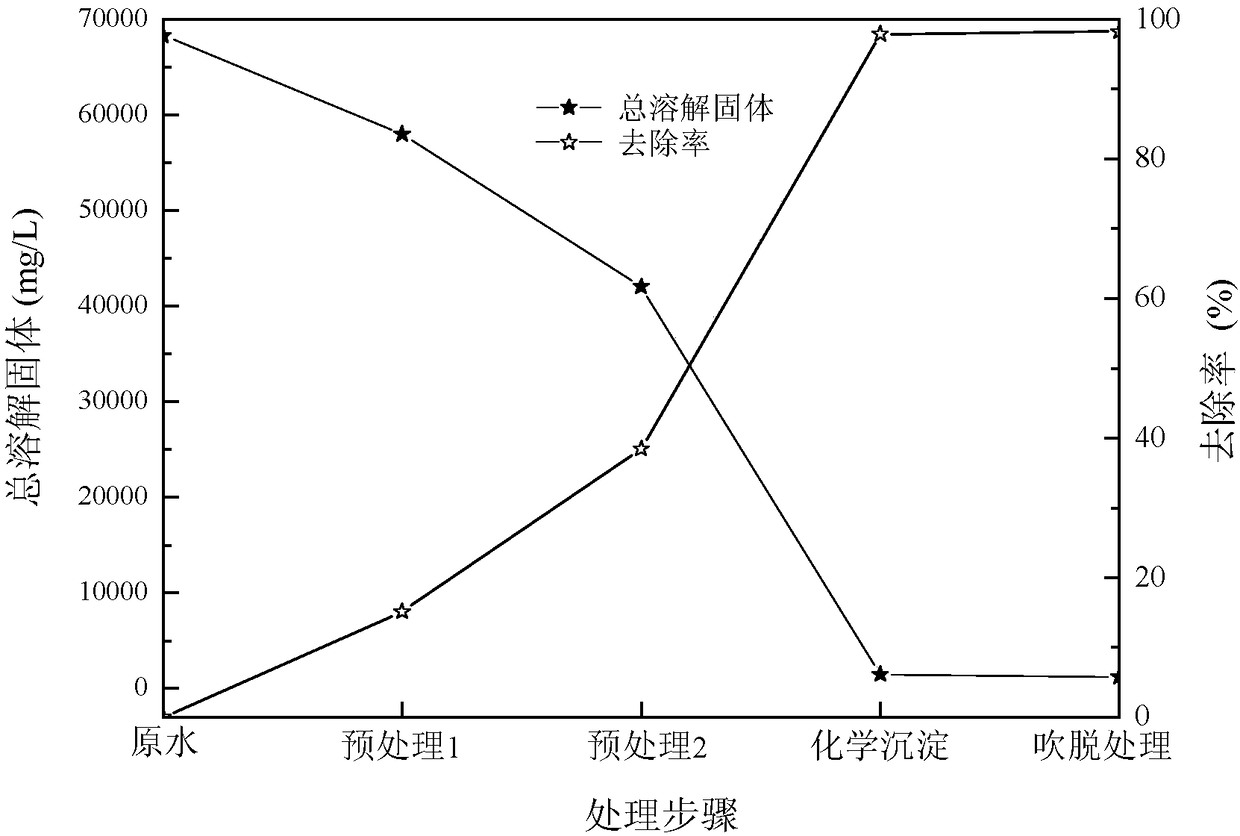

Method for simultaneously removing sulfate and ammonia nitrogen in smelting wastewater

InactiveCN108328789ARealize synchronous removalLow costWater aerationTreatment involving filtrationCalcium hydroxideTotal dissolved solids

The invention relates to a method for simultaneously removing sulfate and ammonia nitrogen in smelting wastewater. The method for simultaneously removing the sulfate and ammonia nitrogen in the smelting wastewater aims at solving the technical problems of high difficulty in treatment of smelting wastewater containing sulfate, ammonia nitrogen and metal ions and high running cost in the prior art.The method comprises the following steps of pretreating the smelting wastewater by a sodium hydroxide solution twice; adding calcium hydroxide to chemically precipitate; finally, stripping to remove the ammonia nitrogen in the wastewater, so as to simultaneously remove the sulfate, ammonia nitrogen and metal ions. After the smelting wastewater is treated by the method, the removal rate of sulfatereaches 99.99%; the removal rate of ammonia nitrogen reaches 99.52%; the removal rate of total dissolved solids reaches 98.23%. The method has the advantages that the investment is small, the runningcost is low, and the method can be used for the wastewater treatment and circulation utilization.

Owner:CHENGDU UNIV OF INFORMATION TECH

Integral device for treating domestic sewage by sludge bed and domestic sewage treatment method

InactiveCN105776773AReduce usageGuaranteed uptimeTreatment involving filtrationTreatment with aerobic and anaerobic processesSewageMixing tank

The invention provides an integral device for treating domestic sewage by a sludge bed and a domestic sewage treatment method, and relates to a domestic sewage treatment device and a sewage treatment method, which mainly aims at solving the problem of treatment of urban, regional and rural domestic sewage under the conditions of scarce land occupation area and lack of technicians. The domestic sewage treatment device comprises an anaerobic contact tank, an aerobic contact tank, a sedimentation tank, a mixing tank, a filtering tank, a submersible lifting pump, a submersible stirring machine, a flow distributer, a contact tank blower, a tubular aerator, an air collecting cover, a filler, and a sedimentation tank blower. The sewage treatment method comprises the following steps of 1, firstly, sending the sewage into a conditioning tank, lifting to the anaerobic contact tank, starting the stirring machine, and enabling the water from the anaerobic contact tank to flow into the aerobic contact tank; 2, starting the contact tank blower, aerating, and enabling the water from the aerobic contact tank to flow into the sedimentation tank; 3, starting the sedimentation tank blower, enabling the water from the sedimentation tank to flow into the mixing tank, and feeding a coagulant; 4, enabling one part of the water from the mixing tank to flow into the filtering tank, and enabling the other part of the water to flow back into the mixing tank. The domestic sewage treatment device and the sewage treatment method are applied to the field of sewage treatment.

Owner:青岛善水生态科学研究院股份有限公司 +1

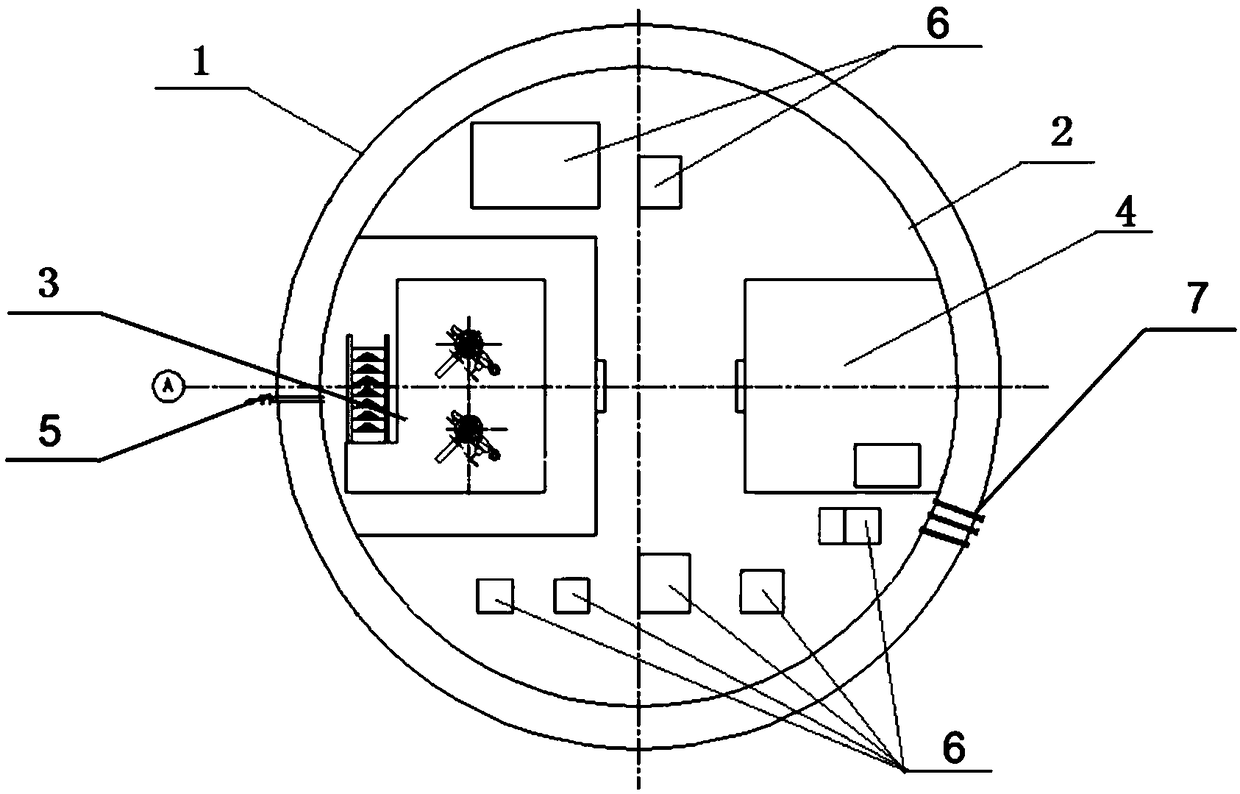

Waste fiber leftover material opening machine

PendingCN108642608AMeet reuse requirementsGuarantee the quality of openingTextile disintegration and recoveryFibre disintegrationFiberEngineering

The invention relates to a waste fiber leftover material opening machine. The waste fiber leftover material opening machine comprises a frame, wherein the frame comprises a left wall plate, a right wall plate and a connecting bottom beam; an opening cylinder, the opening cylinder is fixed between the left and the right wall plates, the rear upper side of left end of the opening cylinder is provided with an opening cylinder waste fiber feeding inlet, the rear lower side of right end of the opening cylinder is provided with an opening fiber leading-out outlet, a waste fiber fixing opening hook base is arranged on the cavity wall of the opening cylinder body cavity, the waste fiber fixing opening hook base is provided with a waste fiber fixing opening hook; an opening roller is positioned inthe body cavity of the opening cylinder, the left end of the opening roller shaft is supported on the left wall plate, the right end is supported on the right wall plate, a waste fiber movement opening hook base is arranged on the outer wall of the opening roller, and a waste fiber movement opening hook is arranged on the waste fiber movement opening hook base; an power transmission mechanism is arranged on the front side of the left wall plate and is connected with the left end of the opening roller shaft; and an opening fiber leading-out mechanism is connected with the opening fiber lead-outoutlet. The waste fiber leftover material opening machine has the advantages that the opening effect is good, the efficiency is high, and the recycling requirement of the waste fiber can be met; small volume and less space occupation; and the opening quality of the waste fiber is ensured.

Owner:常熟市伟成非织造成套设备有限公司

A kind of recycling method of water glass old sand

InactiveCN101462731BEfficient reuseHigh removal rateAlkali metal silicatesMould handling/dressing devicesWater volumeWastewater

The invention provides a method for recycling used water glass sand, the steps are as follows: first, put the used water glass old sand into a funnel-shaped container, and a filter and a valve are arranged at the funnel mouth at the bottom of the container ; After vibrating the water glass sand in the container, add water to the container so that the water submerges the upper surface of the sand. After soaking for 2-4 hours, open the valve at the bottom of the container to slowly discharge the water; finally, drain the water in the container. The glass sand can be reused after releasing and drying. The recycling method of the old water glass sand of the present invention adopts the soaking and percolation method, the removal rate of the residue is as high as more than 95%, the treatment effect is good, and the regenerated sand meets the requirements of recycling; the regeneration treatment of the old water glass sand The method uses less water, so the treatment of waste water is much simpler and easier, and the water glass sand can be effectively reused, saving resources and reducing costs.

Owner:SHIYAN FEIYUAN AUTOMOBILE PARTS

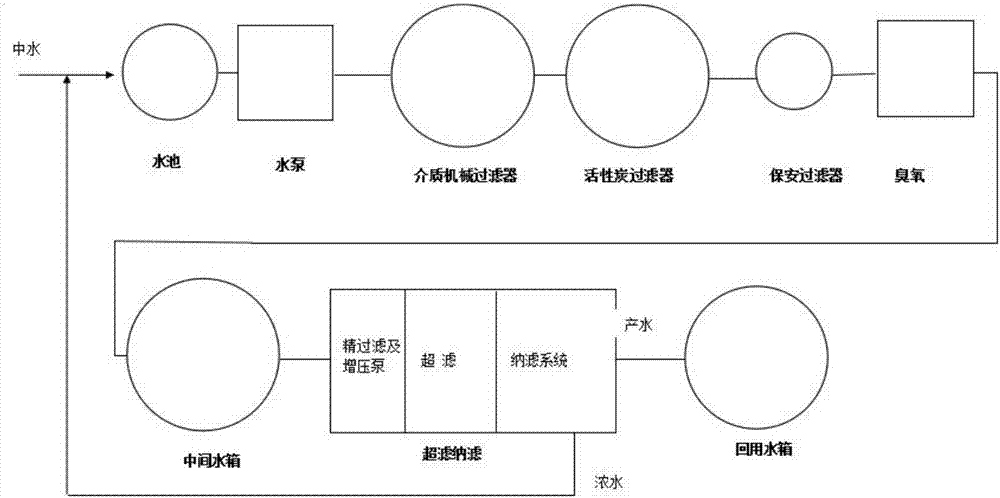

Treatment process for reuse of recycled water in artificial fiber albumen glue and other pollutants in pharmaceutical industry

InactiveCN106927598AImprove processing efficiencyImprove reuse rateTreatment involving filtrationMultistage water/sewage treatmentUltrafiltrationChemistry

The invention provides a reclaimed water treatment process for man-made fibrin glue and other pollutants in the biopharmaceutical industry. After ultrafiltration and nanofiltration process, all or part of the reuse can be realized; the reclaimed water treatment process of the present invention can realize the thorough treatment of the reclaimed water of pollutants such as artificial fibrin glue in the biopharmaceutical industry, the treatment efficiency is high, and the reuse rate is high. High, reused water meets reuse requirements, protects water resources, and reduces operating costs.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com