Method for simultaneously removing sulfate and ammonia nitrogen in smelting wastewater

A sulfate and wastewater technology, which is applied in metallurgical wastewater treatment, chemical instruments and methods, water aeration, etc., can solve the problems of difficult smelting wastewater treatment and high operating costs, and achieves small footprint, reduced investment, and ancillary equipment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

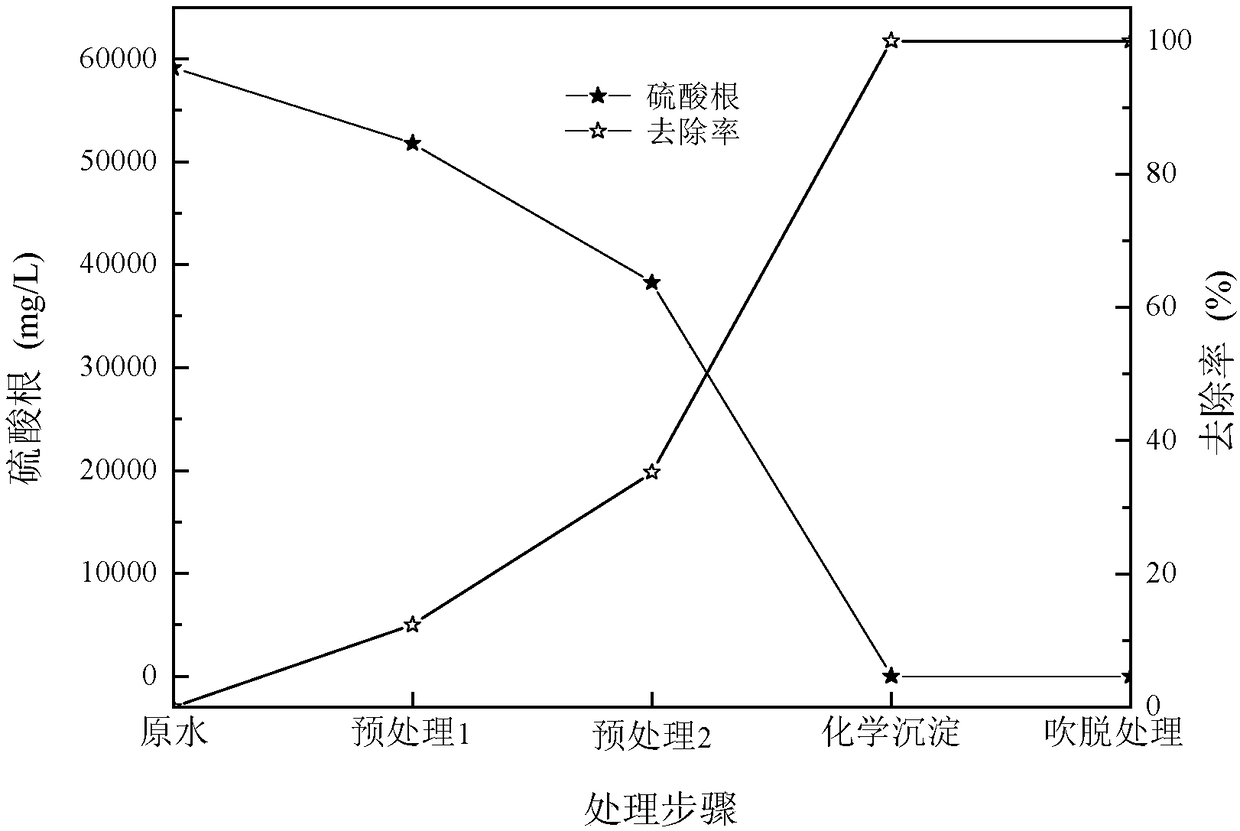

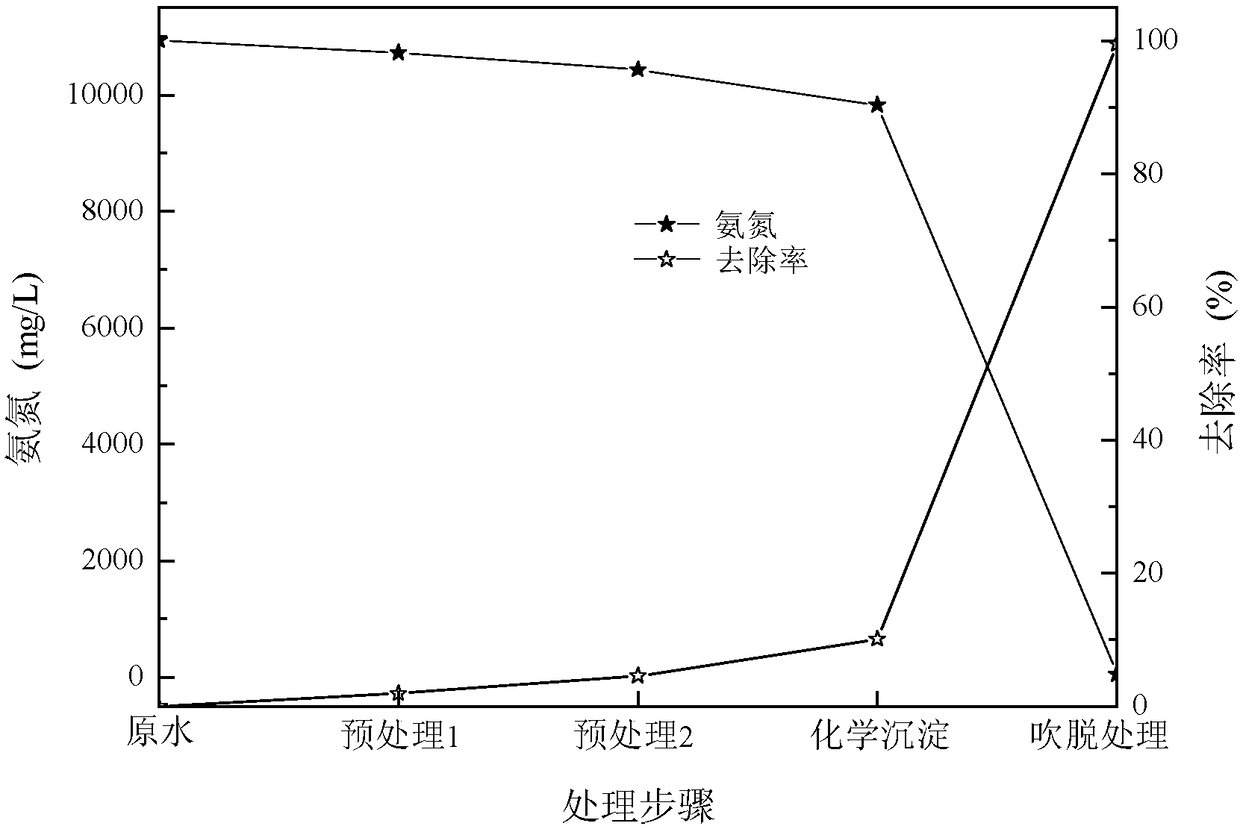

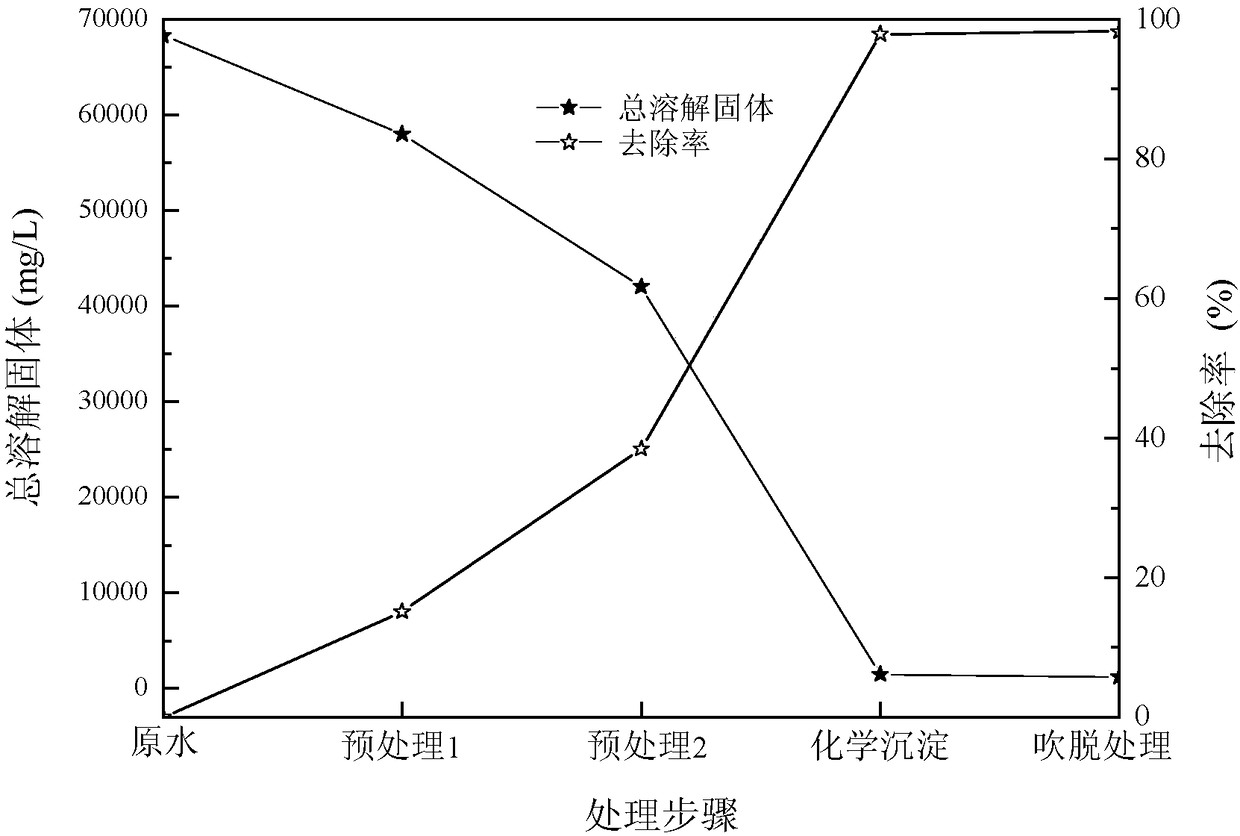

[0019] Specific implementation mode one: the method for synchronously removing sulfate and ammonia nitrogen in the smelting waste water of the present embodiment is carried out according to the following steps:

[0020] 1. Pretreatment 1: Add sodium hydroxide solution to the smelting wastewater, so that the pH of the wastewater reaches 9-10, and there is hydroxide precipitation, filter, remove the hydroxide precipitation, and obtain the filtrate;

[0021] 2. Pretreatment 2: Continue to add sodium hydroxide solution to the filtrate obtained in step 1, so that the pH of the filtrate is 12 to 13, and a hydroxide precipitate is produced. After standing, the hydroxide precipitate in the lower layer is removed to obtain the upper layer. Serum;

[0022] 3. Chemical precipitation: Add solid calcium hydroxide to the supernatant obtained in step 2, so that the concentration of calcium hydroxide in the supernatant is 29.5 to 30.5g / L, and calcium sulfate precipitation is produced. Filter ...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass percent concentration of the sodium hydroxide solution in step 1 is 10-12%; the others are the same as Embodiment 1.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the pH of the wastewater in step 1 reaches 9.5; the others are the same as Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com