System and method for recycling application of desulfurization waste water

A desulfurization wastewater and recycling technology, applied in the field of water treatment, can solve problems such as energy waste, affecting biological growth environment, and soil salinization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

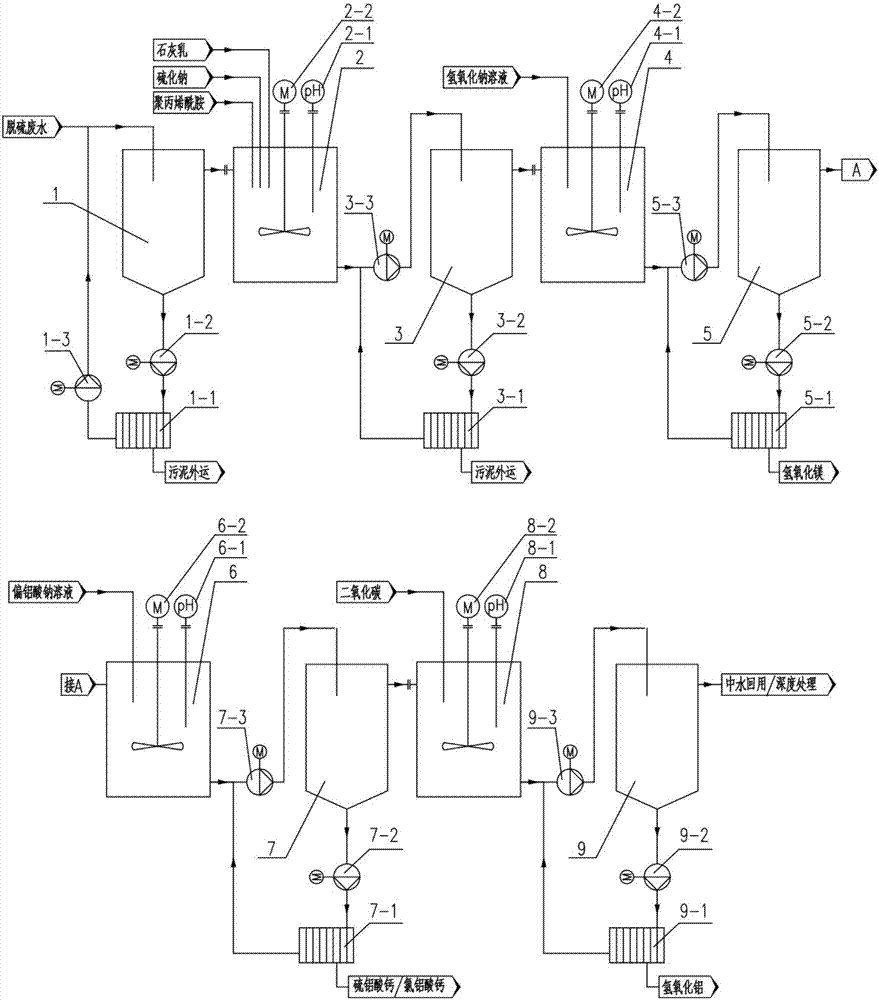

[0073] A) Desulfurization wastewater resource utilization system

[0074] The system provided in this example mainly includes a primary clarifier, a primary reaction tank, a primary clarifier, a secondary pool composition. Among them, the primary clarifier, the primary clarifier, the secondary clarifier, the tertiary clarifier and the quaternary clarifier all have water outlets and sediment outlets. The outlet of the reaction box is connected to the inlet of the primary clarification tank, the outlet of the primary clarification tank is connected to the secondary reaction tank, the outlet of the secondary reaction tank is connected to the secondary clarification tank, and the outlet of the secondary clarification tank is connected to the tertiary reaction tank The outlet of the third-stage reaction box is connected with the inlet of the third-stage clarifier, the outlet of the third-stage clarifier is connected with the fourth-stage reaction box, and the outlet of the fourth-...

Embodiment 2

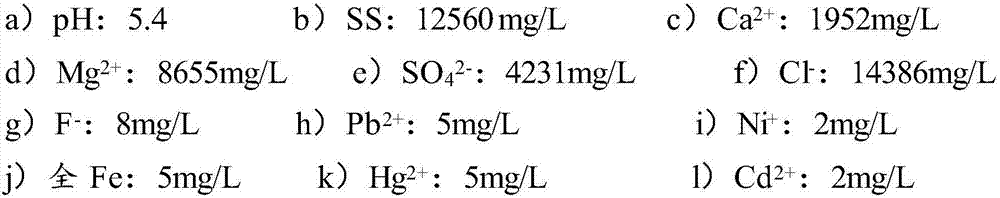

[0094] Take the flue gas wet desulfurization wastewater from another coal-fired power plant, and use the system in Example 1 to recycle the desulfurization wastewater. The specific process includes:

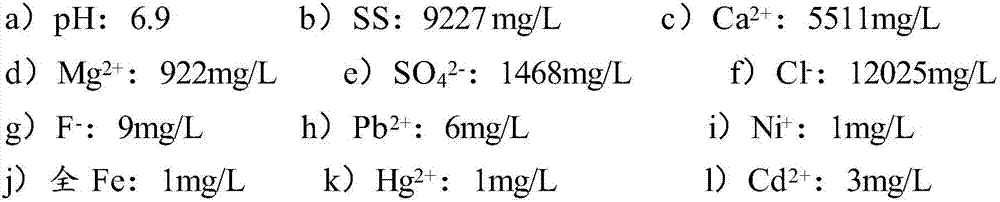

[0095] 1) The desulfurization wastewater first passes through the primary clarifier for clarification and separation for 2 hours. The sediment enters the filter press of the clarifier through the sludge pump of the clarifier for dehydration. For outbound processing. The waste water from the clarification tank was sampled, and the water quality was tested and analyzed. The main components are as follows:

[0096]

[0097] 2) The supernatant of the primary clarification tank is input to the primary reaction tank after water quality testing, and the pH meter and agitator in the tank are started, and 5wt% milk of lime is added at the same time to adjust the pH value to 9.5, then stop adding milk of lime, and then add sodium sulfide , the dosage of sodium sulfide is 25mg / L, after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com