Superfine water quality improving powder and its prepn process

A water quality improvement, calcite technology, applied in chemical instruments and methods, other chemical processes, adsorption water/sewage treatment, etc., can solve the problems of poor stability of polymer hydroxyl groups, high production equipment requirements, complex production processes, etc., to reduce ammonia nitrogen Effects of concentration, cost reduction, and pH stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

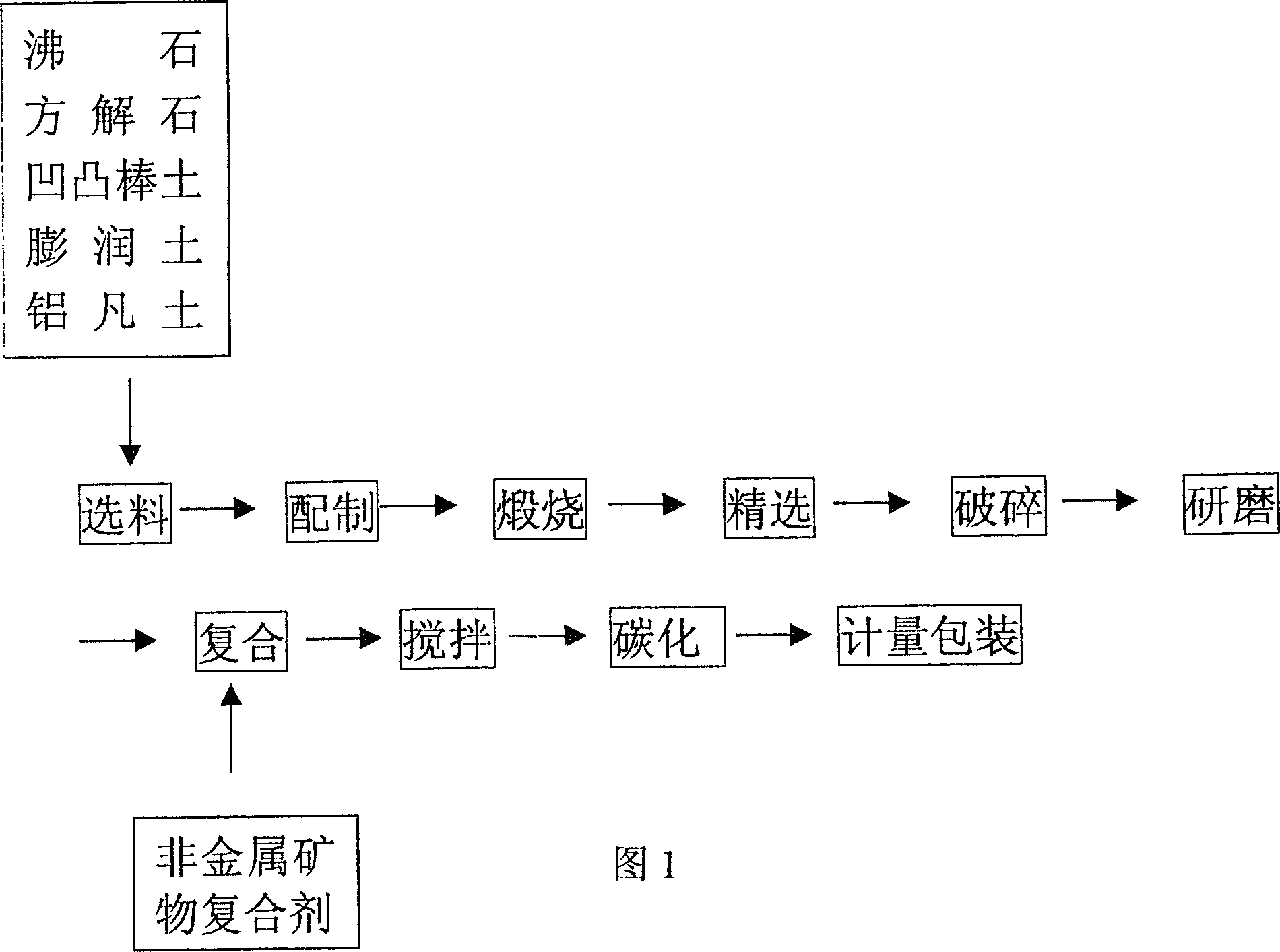

[0026] Embodiment 1: Get 280kg of zeolite, 470kg of calcite, 80kg of attapulgite, 80kg of bentonite, and 80kg of bauxite. Put the above-mentioned ore into the calciner, calcined at 1400 degrees for 20 hours, select the calcined ore, send it to the jaw crusher for crushing, and then send it to the Raymond machine for grinding until it reaches a fineness of 600 mesh, and then add A small amount of phosphate rock powder compounding agent is used for compounding. Send the above-mentioned compounded minerals into the mixer for thorough mixing and then send them into the carbonization furnace for carbonization treatment. The powder after the above carbonization treatment is packed into a plastic bag with 50 kg as the unit of measurement, and then becomes the finished product of the ultrafine water quality improving powder produced by the preparation method of the present invention.

Embodiment 2

[0027] Embodiment 2: Get zeolite 360kg, calcite 550kg, attapulgite 150kg, bentonite 150kg, bauxite 150kg. Put the above-mentioned ore into the calciner, calcined at 1500 degrees for 24 hours, select the calcined ore, send it to the jaw crusher for crushing, and then send it to the Raymond machine for grinding until the fineness of 1000 mesh, and then add A small amount of phosphate rock powder compounding agent is used for compounding. Send the above-mentioned compounded minerals into the mixer for thorough mixing and then send them into the carbonization furnace for carbonization treatment. The powder after the above carbonization treatment is packed into a plastic bag with 50 kg as the unit of measurement, and then becomes the finished product of the ultrafine water quality improving powder produced by the preparation method of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com