Underwater dry-type oil production device suitable for development of shallow water oil-gas field

A technology for oil production equipment and oil and gas fields, which is applied in the development of fluids, earthwork drilling, wellbore/well components, etc., can solve the problem of high construction costs, reduce investment, reduce investment and offshore construction costs, and meet the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

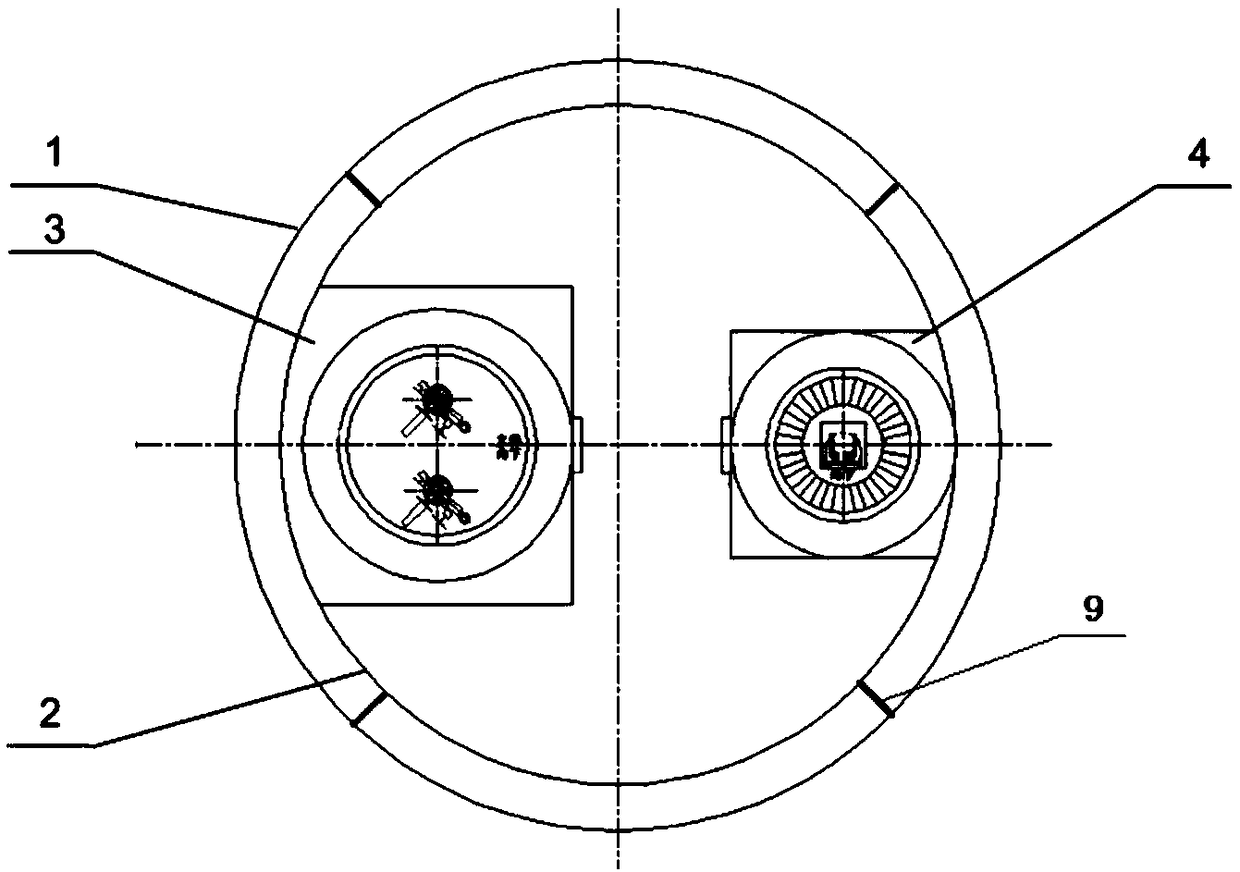

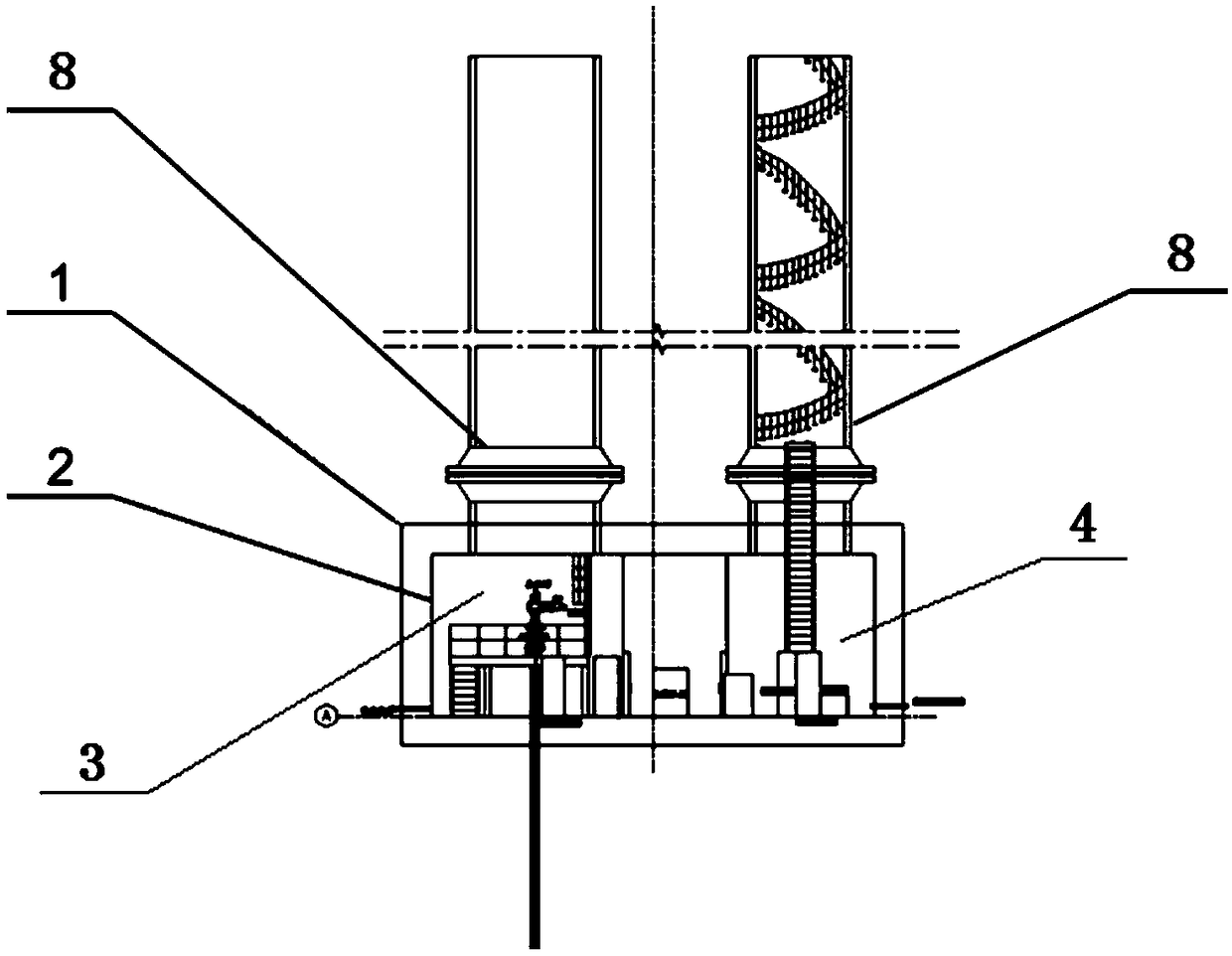

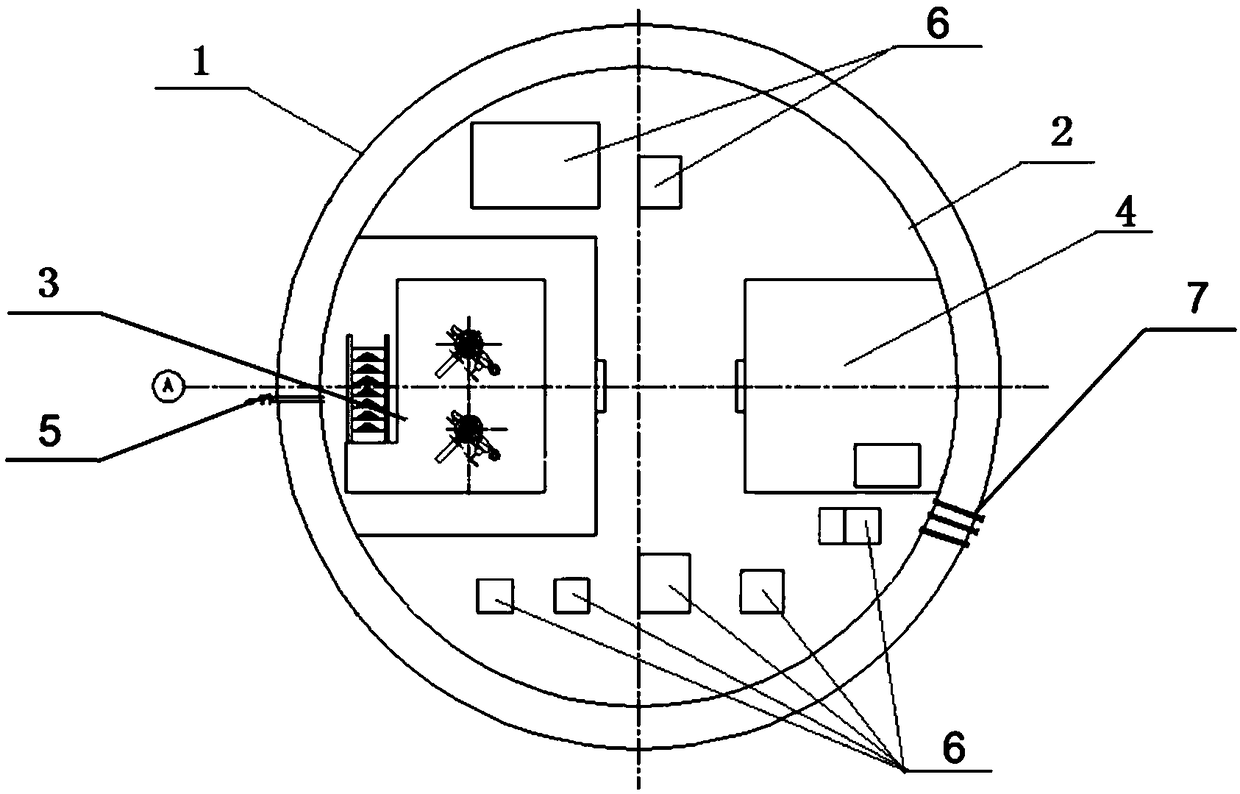

[0022] Such as Figure 1 to Figure 3 As shown, the underwater dry oil recovery device suitable for the development of shallow water oil and gas fields of the present invention includes a large-diameter steel cylinder 1 and an underwater dry-type sealed cabin 2, and the underwater dry-type sealed cabin 2 is arranged on a large-diameter steel circle Inside the cylinder 1, a support structure 9 is provided between the large-diameter steel cylinder 1 and the underwater dry sealed cabin 2. In the early stage of construction, the large-diameter steel cylinder 1 isolates seawater to form a dry environment inside the cylinder. The inner diameter of the large-diameter steel cylinder 1 is set to 12m. When the large-diameter steel cylinder 1 sinks to the target depth, its top is higher than the water surface. Generally, the design depth is 40m.

[0023] The underwater dry-type s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com