Industrial wastewater zero discharging treatment process and system

A technology for treating process and industrial wastewater, which is applied in the field of water treatment, can solve the problems of secondary environmental pollution and incomplete treatment, and achieve the effect of thorough wastewater treatment and not easy secondary environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

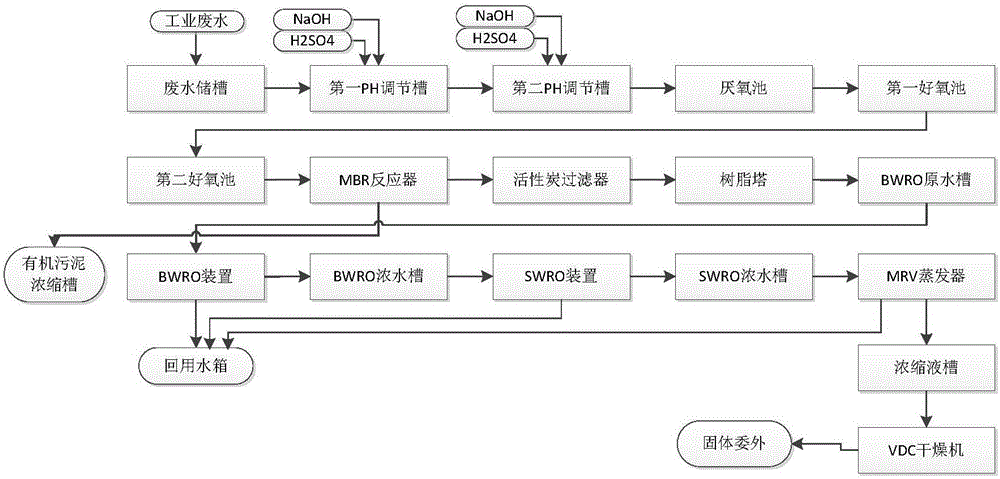

[0085] Industrial Wastewater Zero Discharge Treatment System

[0086] The treatment system provided in this embodiment includes: wastewater storage tank, first pH adjustment tank, second pH adjustment tank, anaerobic tank, first aerobic tank, second aerobic tank, membrane bioreactor, organic sludge concentration tank, activated carbon filter, resin tower, BWRO raw water tank, BWRO unit, BWRO concentrated water tank, SWRO unit, SWRO concentrated water tank, MRV evaporator, concentrate tank, VDC dryer, condenser and reuse water tank.

[0087] The waste water storage tank is provided with a water inlet and a water outlet.

[0088] The first pH adjusting tank is provided with a pH adjusting agent feeding port, a water inlet and a water outlet. The water inlet of the first pH adjustment tank is connected with the water outlet of the waste water storage tank.

[0089] The second pH adjusting tank is provided with a pH adjusting agent feeding port, a water inlet and a water outlet....

Embodiment 2

[0110] Industrial Wastewater Zero Discharge Treatment Process

[0111] Adopt the treatment system that embodiment 1 provides to carry out zero-discharge treatment to industrial waste water

[0112] Daily processing capacity: 360t / d; imported salt content: 4500mg / L, imported COD: 350mg / L, imported ammonia nitrogen: 35mg / L, imported total phosphorus: 15mg / L.

[0113] During the operation of the treatment system, the pH value of the effluent from the second pH adjustment tank is 7-8;

[0114] Anaerobic tank, the first aerobic tank and the second aerobic tank, the total hydraulic retention time during the treatment process is 10 hours, the BOD5 sludge load is 0.2, the dissolved oxygen in the anaerobic tank is 0.15 mg / L, and the dissolved oxygen in the aerobic tank is 2 mg / L , TN load 0.05 (aerobic section), TP load 0.06 (anaerobic section), sludge concentration 4500mg / L, sludge age 20 days, reflux ratio 150%. The water quality indicators of aerobic treatment effluent, COD≤70mg / L...

Embodiment 3

[0125] Industrial Wastewater Zero Discharge Treatment Process

[0126] Adopt the treatment system that embodiment 1 provides to carry out zero-discharge treatment to industrial waste water

[0127] Daily processing capacity: 500t / d; imported salt content: 5000mg / L, imported COD: 450mg / L, imported ammonia nitrogen: 25mg / L, imported total phosphorus: 10mg / L.

[0128] During the operation of the treatment system, the pH value of the effluent from the second pH adjustment tank is 7-8;

[0129] The total hydraulic retention time in the treatment process of the anaerobic tank, the first aerobic tank and the second aerobic tank is 8 hours, the BOD5 sludge load is 0.2, the dissolved oxygen in the anaerobic tank is 0.15 mg / L, the dissolved oxygen in the aerobic tank is 5 mg / L, TN load 0.05 (aerobic section), TP load 0.06 (anaerobic section), sludge concentration 3500mg / L, sludge age 15 days, reflux ratio 120%. The water quality index of aerobic treatment effluent, COD≤60mg / L, ammonia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com