Disposal method of using As-containing wastewater in LED industry for preparing electronic-grade ultrapure water

A treatment method, electronic-level technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, non-polluted water treatment, etc., can solve the problem of increasing the cost of subsequent hazardous waste/solid waste treatment and large sludge output , waste of water resources and other issues, to achieve the effect of reducing sludge production, realizing zero discharge of wastewater, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

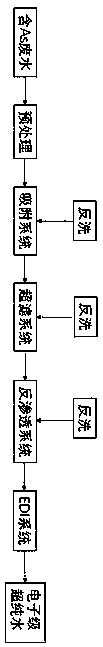

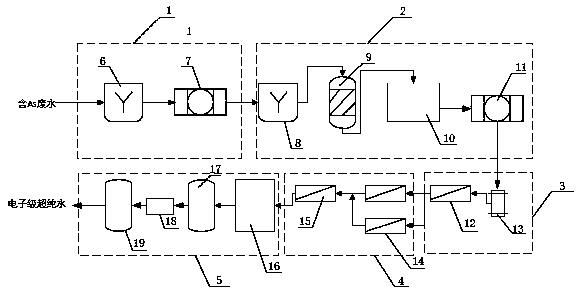

Method used

Image

Examples

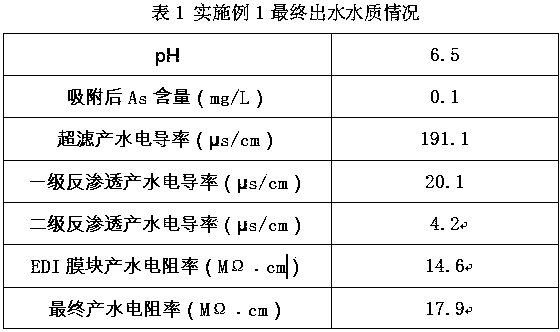

Embodiment 1

[0041] An LED industry contains As-containing wastewater, in which the As content is 35mg / L, the conductivity=200μs / cm, and the pH=6.7.

[0042] Step (1): Take 20 L of the above wastewater, add 0.5g / L pretreatment agent, stir and react for 20 minutes, add sodium hydroxide to adjust pH=8, let stand and filter, the filtrate pH=7.2;

[0043]Step (2): After step (1), the effluent water enters the adsorption system, the adsorption water flow rate is 5BV / h, the amount of activator added is 0.05%, and the aeration rate is 1mL / min;

[0044] Step (3): The effluent from step (2) enters the ultrafiltration system, in which the security filter selects a PP cotton filter element with a pore size of 5 μm, and the ultrafiltration membrane selects a hollow fiber membrane made of polyvinylidene fluoride with a pore size of 0.005 μm. Choose 0.1MPa, the operating temperature is 25 degrees Celsius;

[0045] Step (4): The effluent from step (3) enters the reverse osmosis system. The reverse osmos...

Embodiment 2

[0050] An LED industry contains As-containing wastewater, in which the As content is 10 mg / L, the conductivity is 100 μs / cm, and the pH is 7.2.

[0051] Step (1): After the As-containing wastewater is directly filtered, it enters the adsorption system, the adsorption water flow rate is 5 BV / h, the amount of activator is 0.1%, and the aeration rate is 1mL / min;

[0052] Step (2): The effluent from step (1) enters the ultrafiltration system, in which the security filter selects a PP cotton filter element with a pore size of 5 μm, and the ultrafiltration membrane selects a hollow fiber membrane made of polyvinylidene fluoride with a pore size of 0.005 μm. Choose 0.15MPa, the operating temperature is 25 degrees Celsius;

[0053] Step (3): The effluent from step (2) enters the reverse osmosis system, using only one-stage reverse osmosis with a membrane pressure of 2MPa and an operating temperature of 25 degrees Celsius.

[0054] Step (5): The effluent from step (4) enters the EDI s...

Embodiment 3

[0058] An LED industry contains As-containing wastewater, in which the As content is 100 mg / L, the conductivity=500μs / cm, and the pH=5.9.

[0059] Step (1): Take 20 L of the above wastewater, add 1g / L pretreatment agent, stir and react for 20 minutes, add sodium hydroxide to adjust pH = 8, let stand and filter, the filtrate pH = 7.2;

[0060] Step (2): After step (1), the filtered effluent enters the adsorption system, the adsorption water flow rate is 4BV / h, the amount of activator added is 0.1%, and the aeration rate is 2mL / min;

[0061] Step (3): The effluent from step (2) enters the ultrafiltration system, in which the security filter selects a PP cotton filter element with a pore size of 5 μm, and the ultrafiltration membrane selects a hollow fiber membrane made of polyvinylidene fluoride with a pore size of 0.005 μm. Choose 0.1MPa, the operating temperature is 25 degrees Celsius;

[0062] Step (4): The effluent from step (3) enters the reverse osmosis system. The revers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com