Residual wet concrete recovering system

A recovery system and concrete technology, which is applied in the direction of clay preparation equipment, mixing operation control, mixing plant, etc., can solve the problems of easy damage, and achieve the effect of preventing sewage from entering, not easy to damage, and solving sealing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below through specific embodiments.

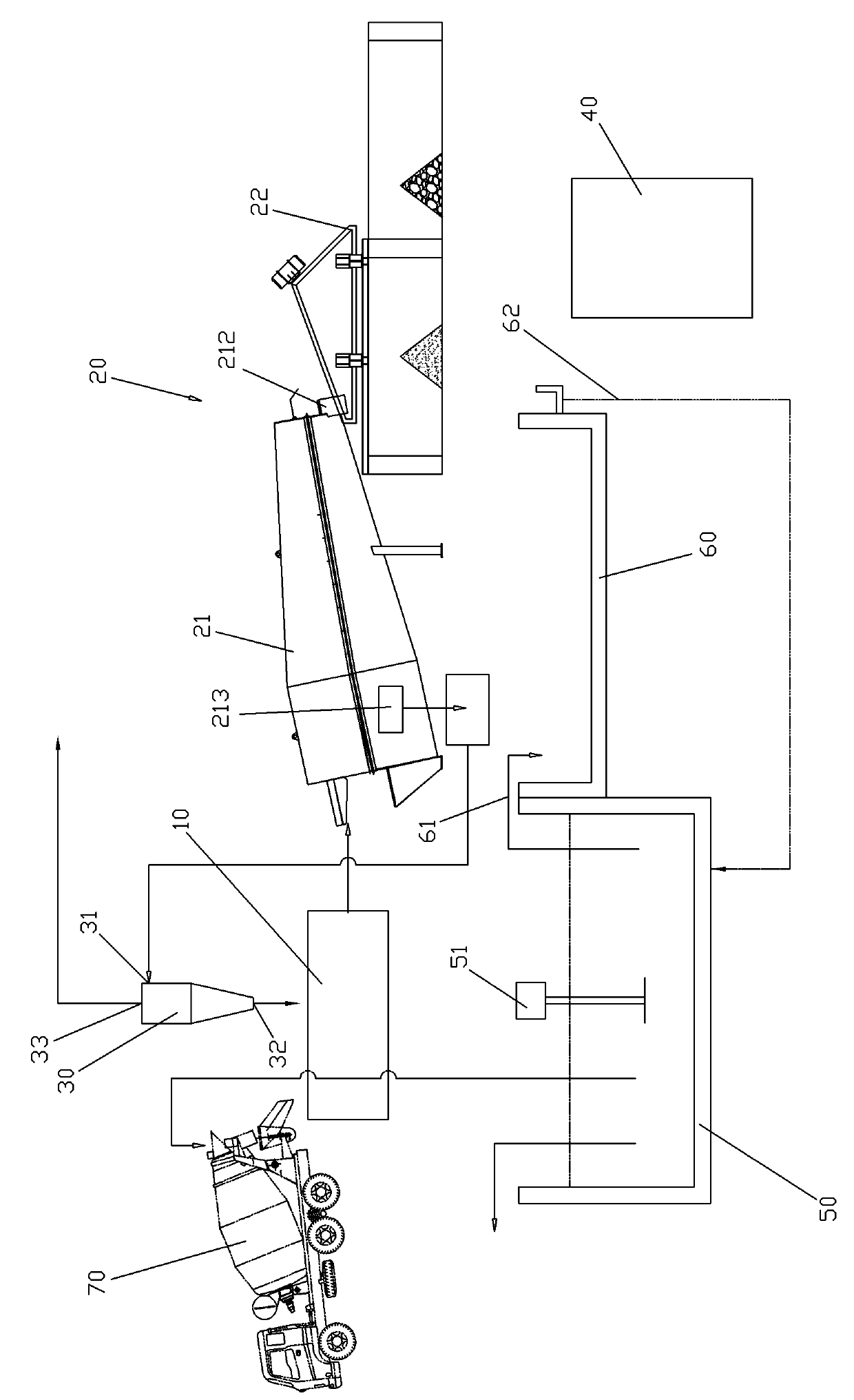

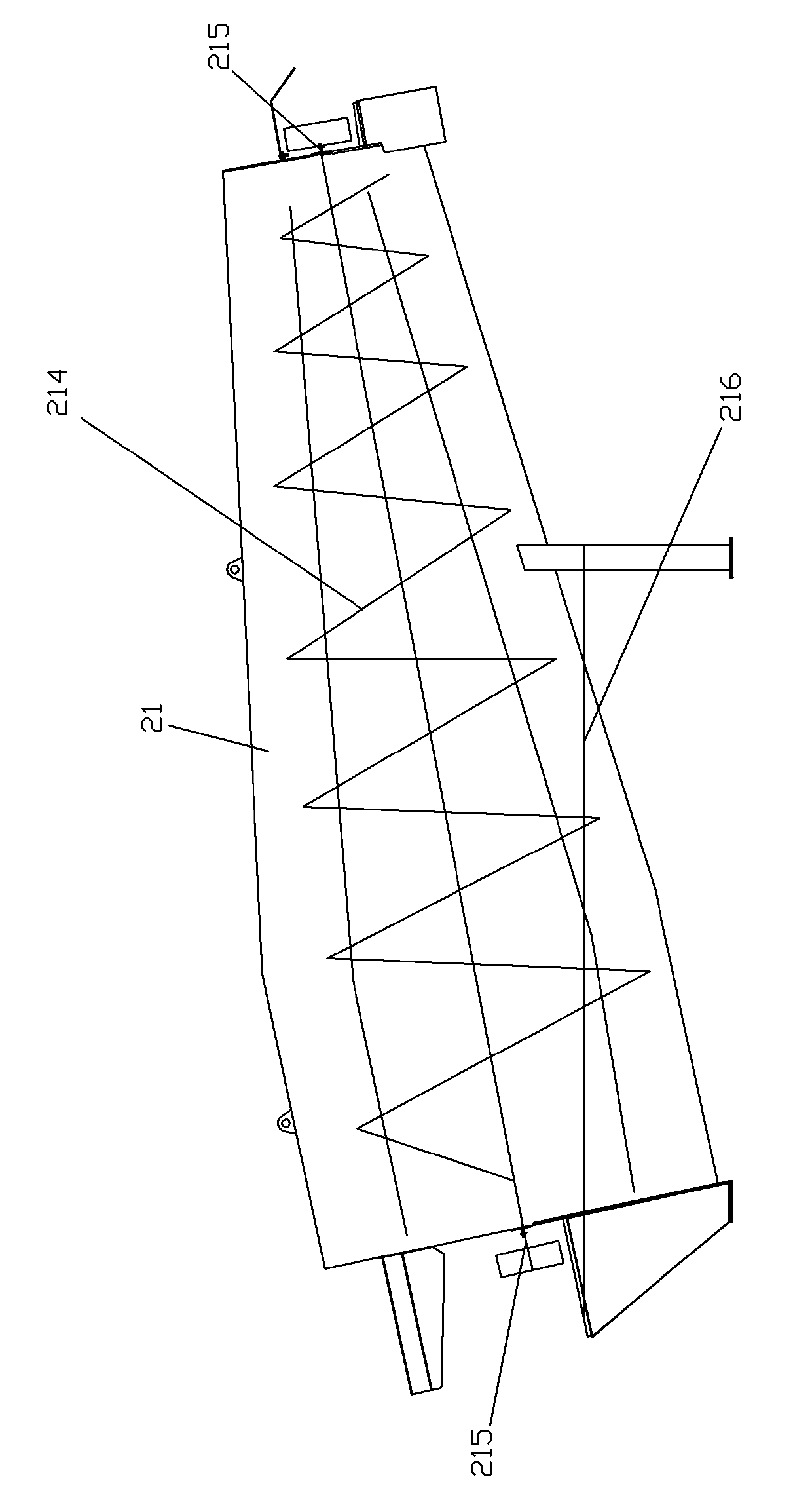

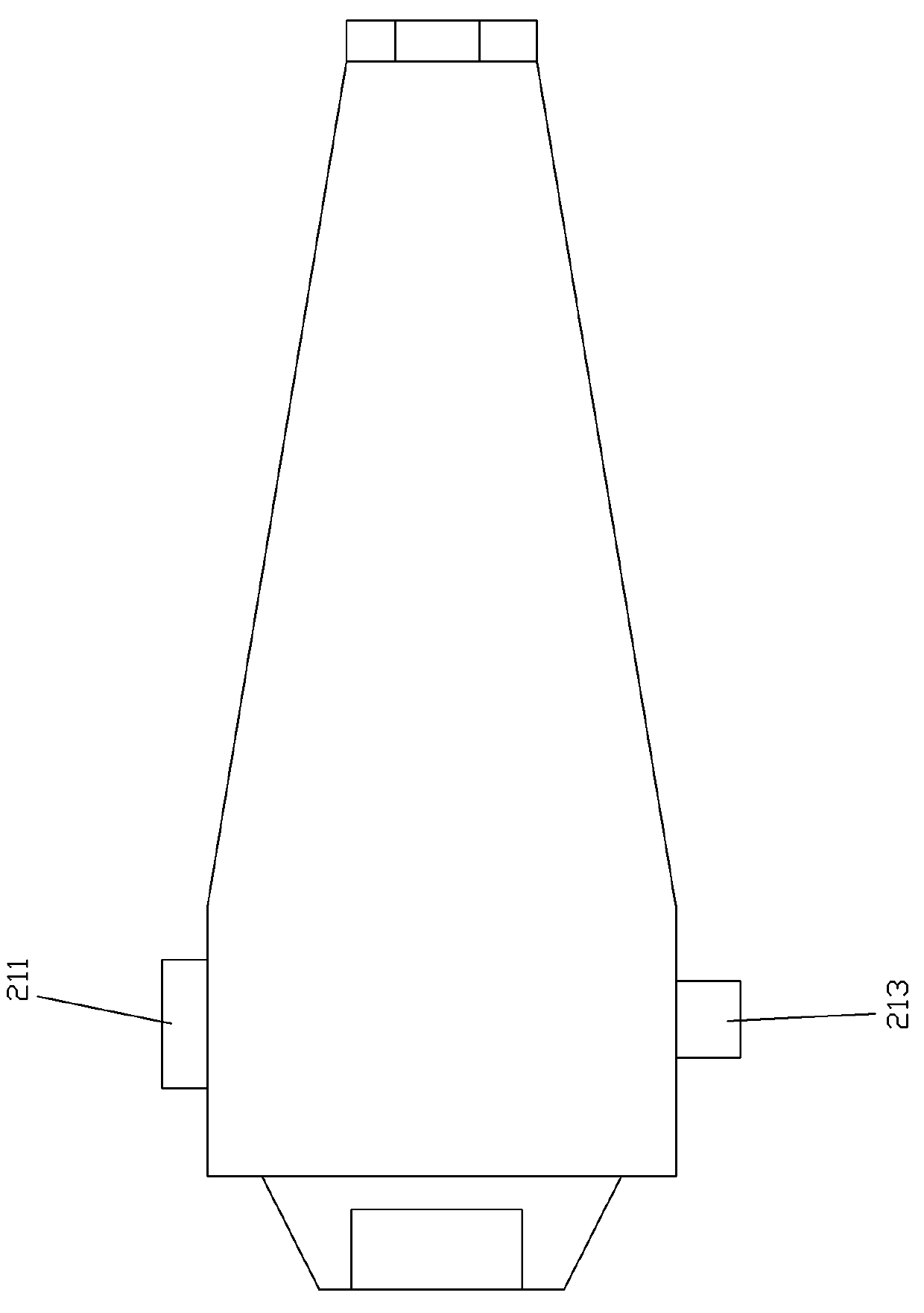

[0028] refer to figure 1 , figure 2 and image 3 , a residual wet concrete recovery system of the present invention includes a car washing tank 10, a sand separation unit 20, a hydrocyclone 30, a stirring tank 50, an automatic control unit 40 and a sedimentation tank 60. The sand and gravel separation unit 20 includes a wet concrete recovery machine 21 and a sand and gravel separation vibrating screen 22. The feed port 211 of the wet concrete recovery machine 21 is connected to the car wash tank 10, and the sand and gravel separation vibrating screen 22 is connected to the wet concrete recovery machine 21. The discharge port 212, the wet concrete recovery machine 21 is provided with an overflow port 213, the inlet 31 of the hydrocyclone 30 is connected to the overflow port 213 of the wet concrete recovery machine 21, the low concentration mud of the hydrocyclone 30 The water outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com