Cleaing method of polyurethane filter leaf or filter core

A technology of filter element and filter sheet, which is applied in the fields of filament forming treatment, textile and paper making, fiber treatment, etc., and can solve the problems of high cost, long processing time, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

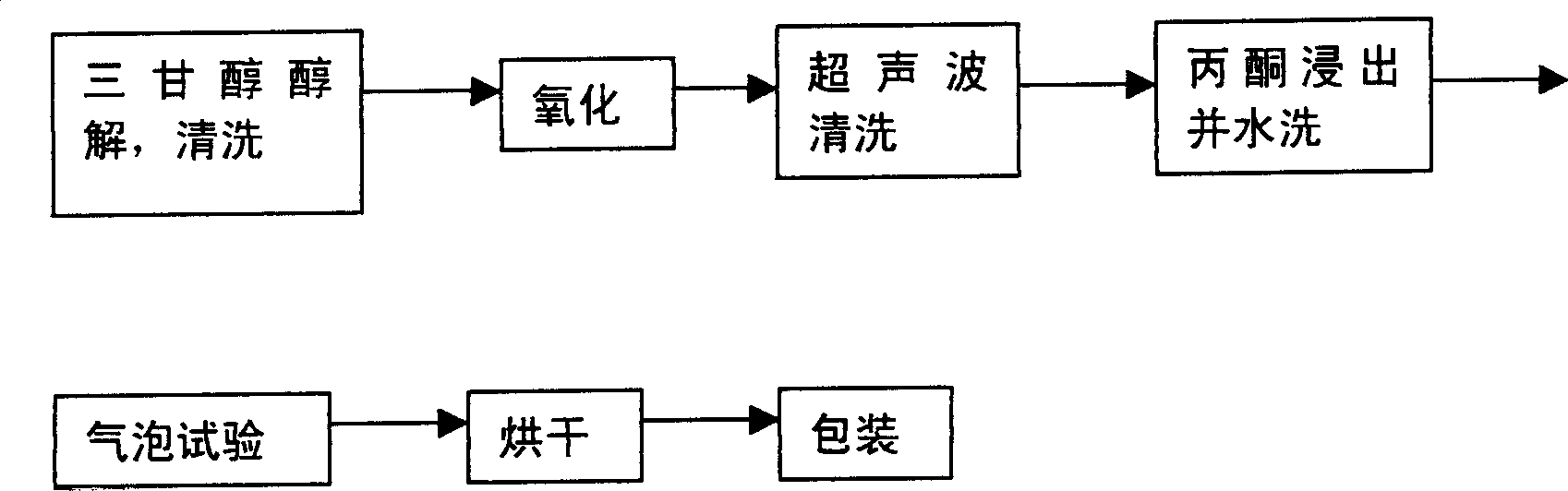

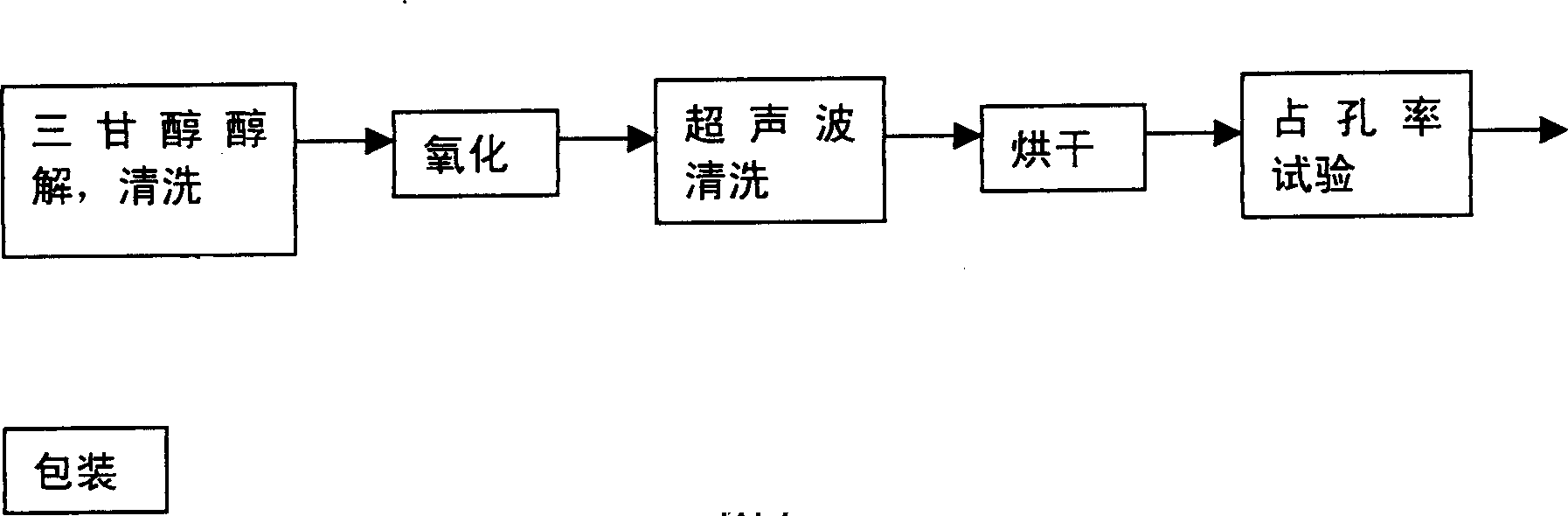

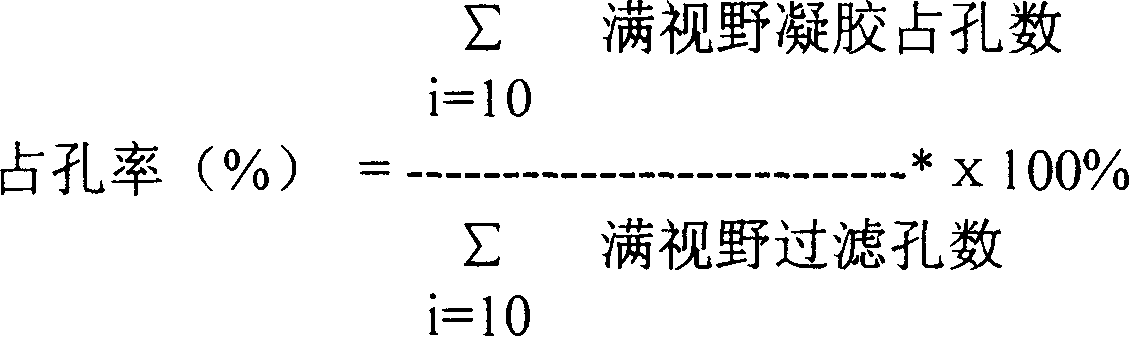

[0015] An efficient and energy-saving cleaning method for filter discs or filter elements coated with polyurethane. It is characterized in that: the high-efficiency and energy-saving cleaning method of the polyurethane-stained filter sheet or filter core comprises the combination of the following steps: A, triethylene glycol cleaning is carried out at high temperature; B, oxidation cleaning is carried out in an aqueous solution containing an oxidant Carry out; C, soaping liquid is the aqueous solution of composite surfactant and builder; Washing; D, ultrasonic cleaning; drying; H, packing.

[0016] During the specific implementation of triethylene glycol cleaning, first place the filter sheet or filter element in a triethylene glycol furnace for alcoholysis at 240-280 degrees for 8-24 hours. The cleaning after alcoholysis with triethylene glycol includes rinsing, soaping, and water washing, and oxidation is carried out in an aqueous solution containing an oxidizing agent, and...

example 1

[0027] Example 1 (alcoholysis-hydrogen peroxide oxidation method):

[0028] Put the polluted filter in a triethylene glycol furnace, heat it up to 250°C for 23 hours, take it out after cooling down, rinse it with water, put it in a soaping furnace equipped with forced convection at 30°C, and soap it for 5 hours; then Water washing; triethylene glycol pretreatment can remove 97% of polyurethane, creating good conditions for subsequent catalytic alcoholysis. After the pre-treated filter sheet or filter element is drained, put it in hydrogen peroxide solution, raise it to 100°C, and keep it warm for 2 hours; cool down, take it out and rinse it; then enter the soaping furnace for soaping and keep it warm for 5 hours; then use pure water Rinse well; drain. Ultrasonic treatment in 3% phosphoric acid solution; on the one hand, to further shake out impurities, and on the other hand, to remove inorganic impurities and complexes formed on the surface of the filter element. Finally, ri...

example 2

[0029] Example 2 (alcoholysis-hydrogen peroxide oxidation method):

[0030] Put the polluted filter element in a triethylene glycol furnace, heat it up to 270°C for 13 hours, take it out after cooling down, rinse it with water, put it in a soaping furnace equipped with forced convection at 70°C, and soap it for 2 hours; Then wash with water; triethylene glycol pretreatment can remove 98% of polyurethane, creating good conditions for subsequent catalytic alcoholysis. After the pre-treated filter sheet or filter core is drained, put it in hydrogen peroxide solution, raise it to 90°C, and keep it warm for 4 hours; cool it down to room temperature, take it out and rinse it; then enter the soaping furnace for soaping and keep it warm for 7 hours; Rinse well with pure water; drain. Ultrasonic treatment in 7% phosphoric acid solution; on the one hand, to further shake out impurities, and on the other hand, to remove inorganic impurities and complexes formed on the surface of the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com