Patents

Literature

93results about How to "Flying distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

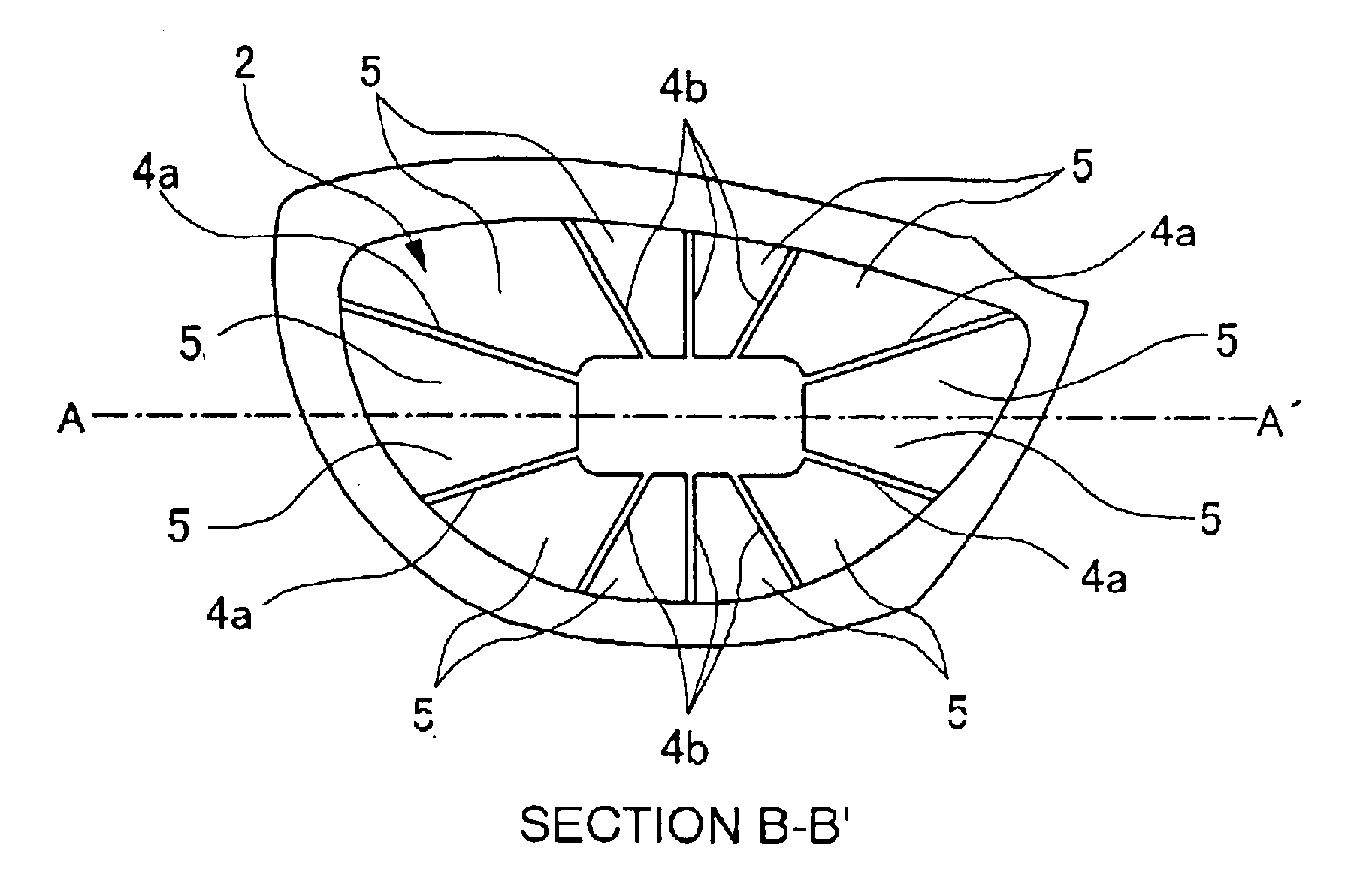

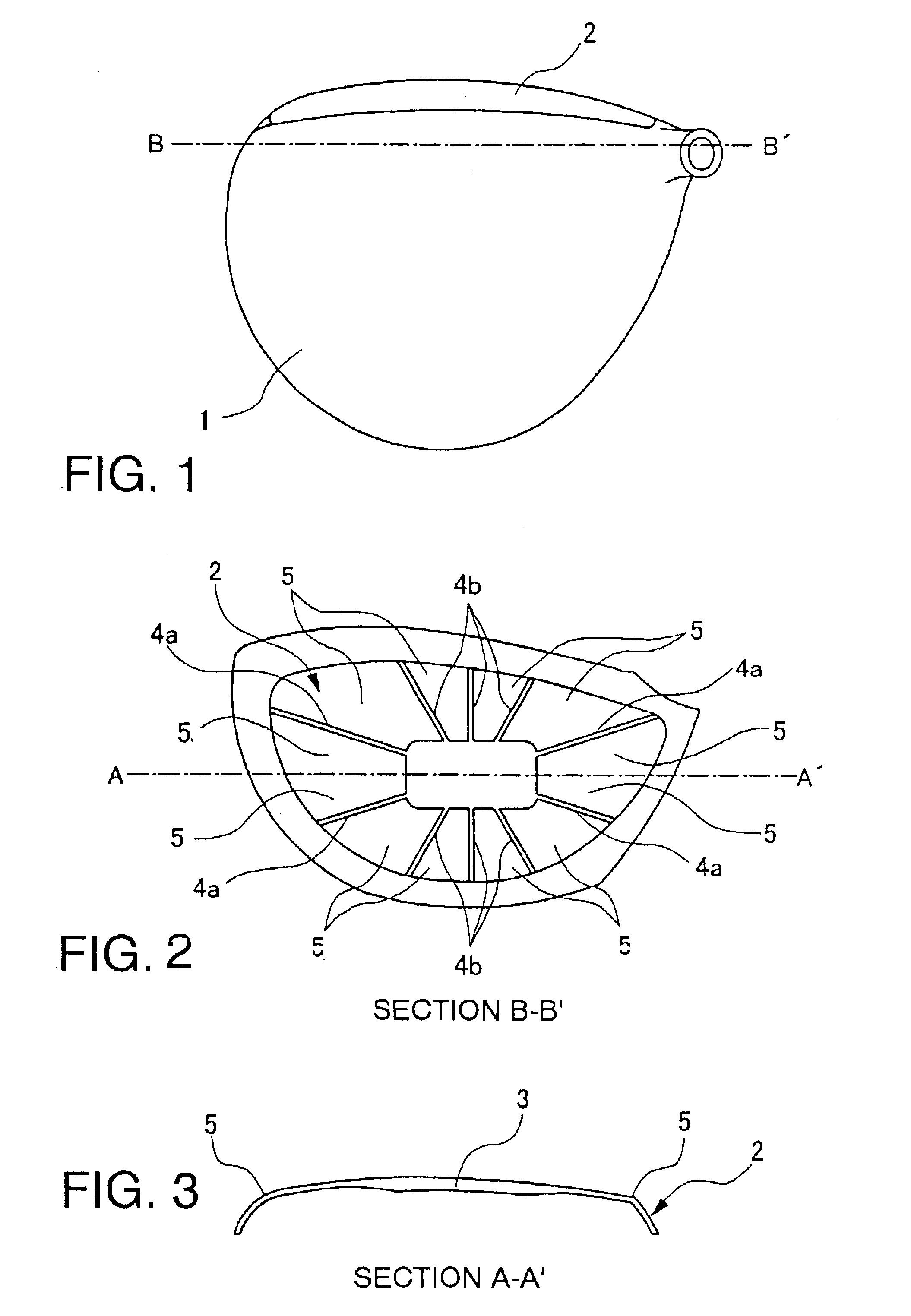

Golf club head

A golf club head has a face plate of high strength and high resilience and which provides excellent directional stability of the ball trajectory. The golf club head comprises a thick-walled portion 3 at the center of the face plate 2, and at least four narrow ribs 4a and 4b. Each of the ribs is formed with a thickness not substantially exceeding the thickness of the thick-walled portion, and extends radially from the thick-walled portion toward the perimeter of the face plate. Thin-walled portions 5 are formed between the thick-walled portion and the narrow ribs.

Owner:YONEX CO LTD

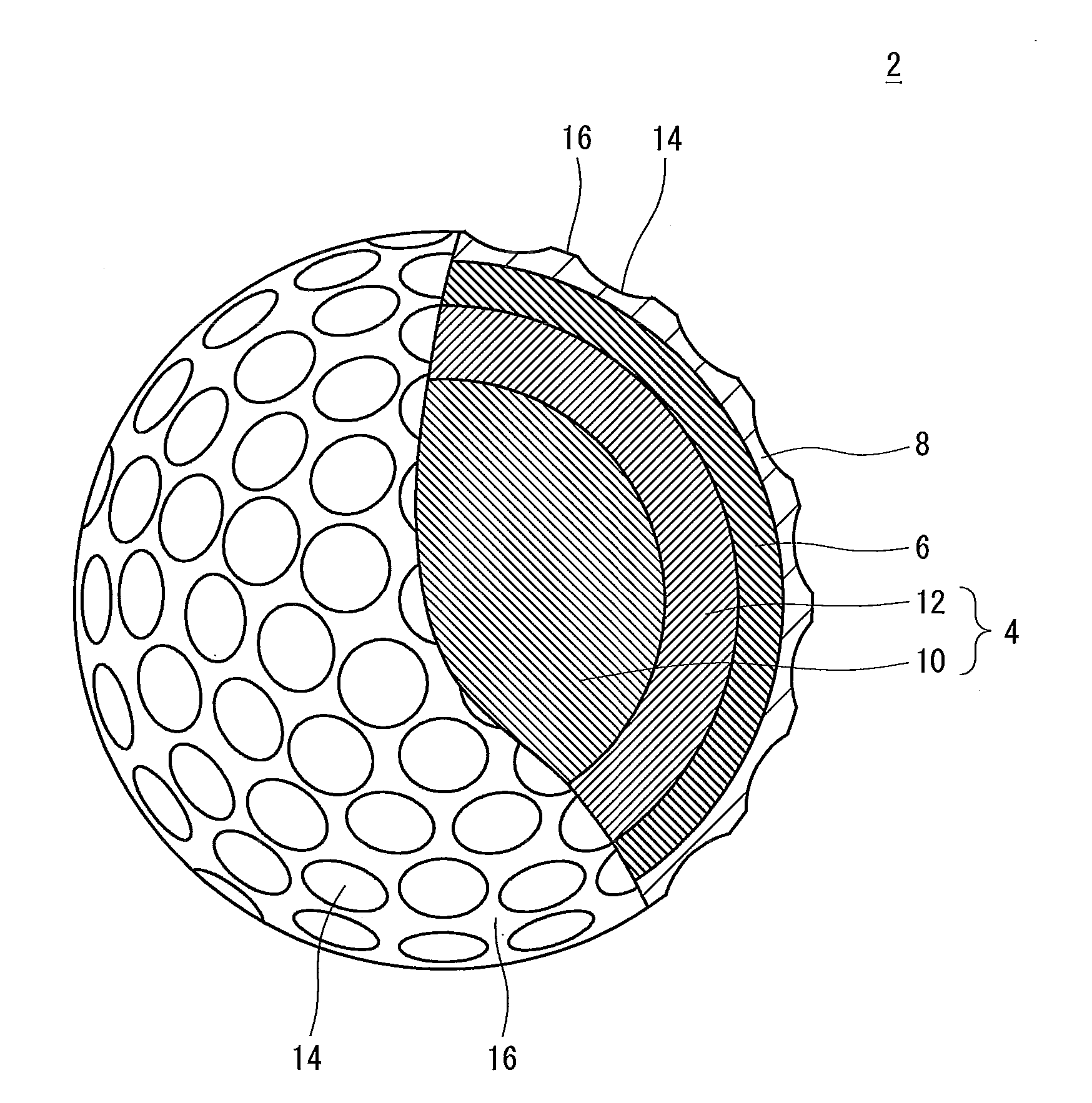

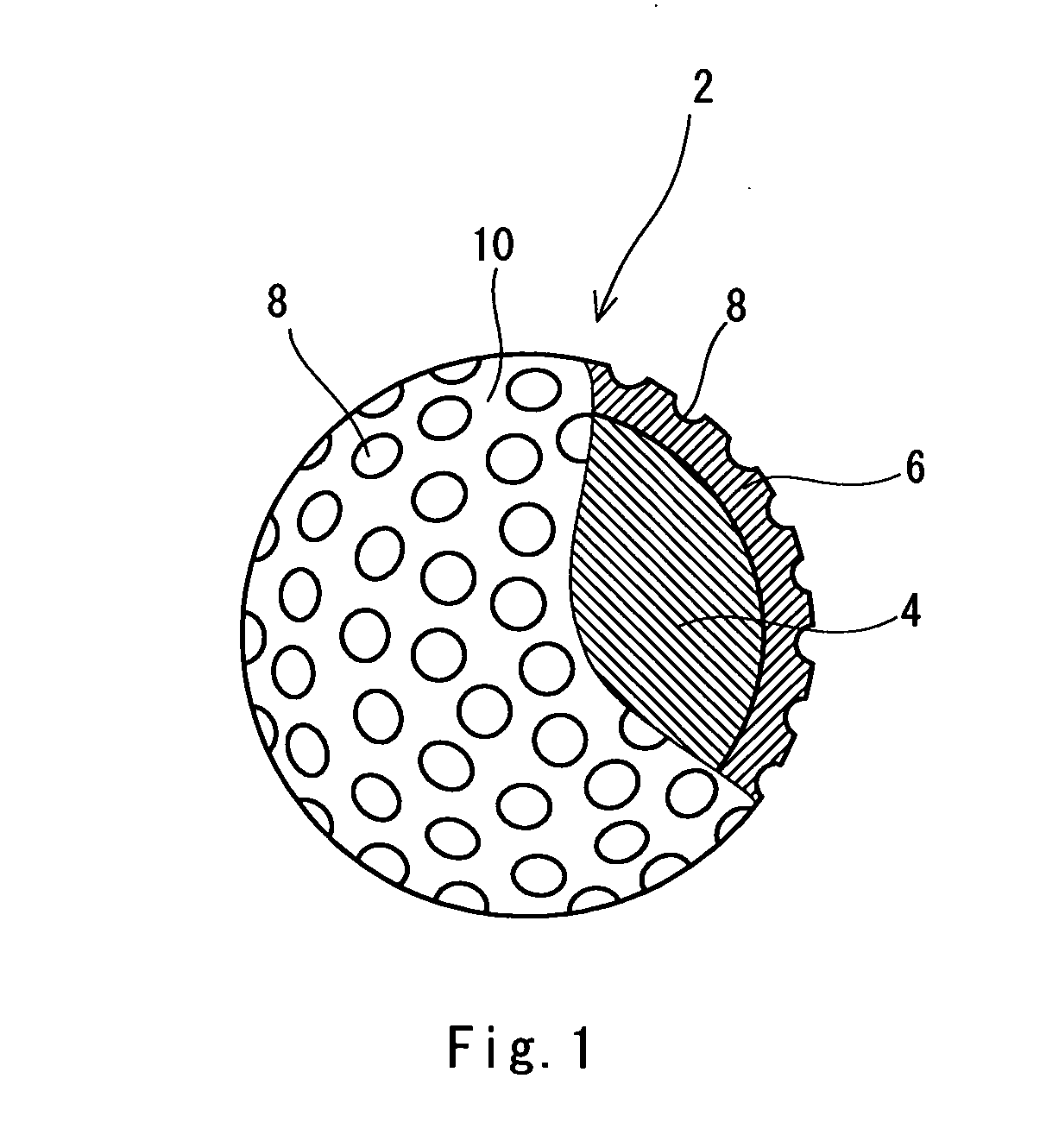

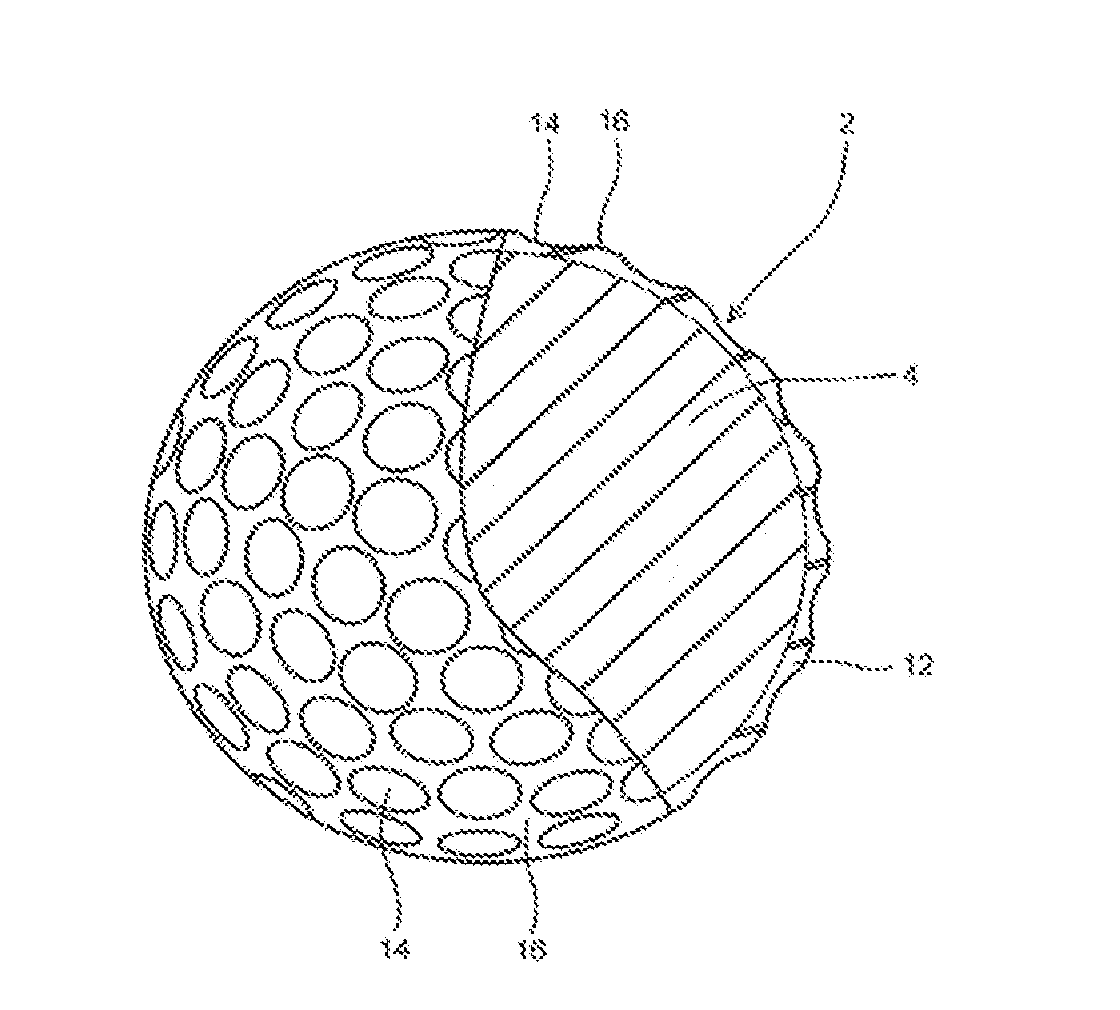

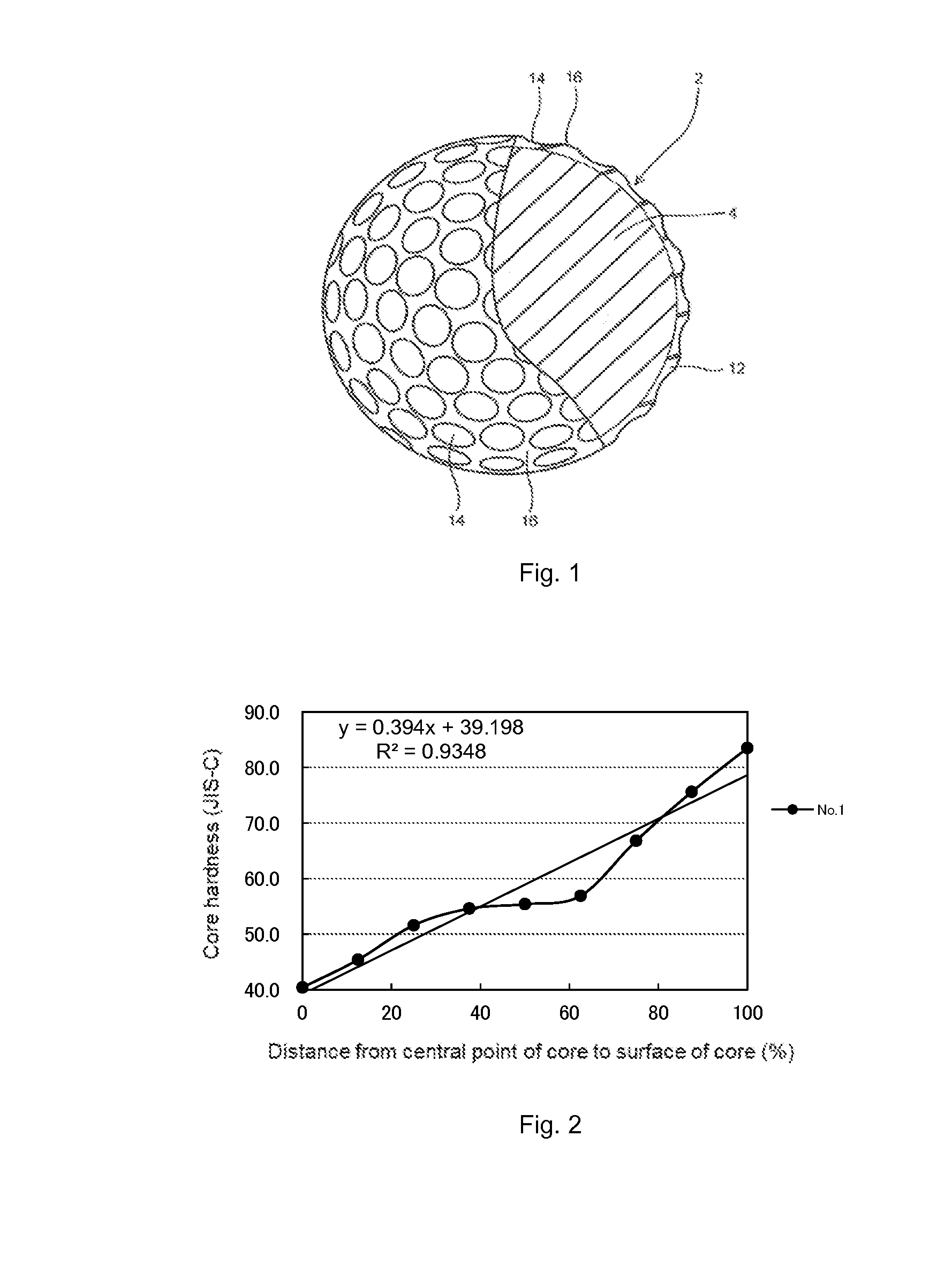

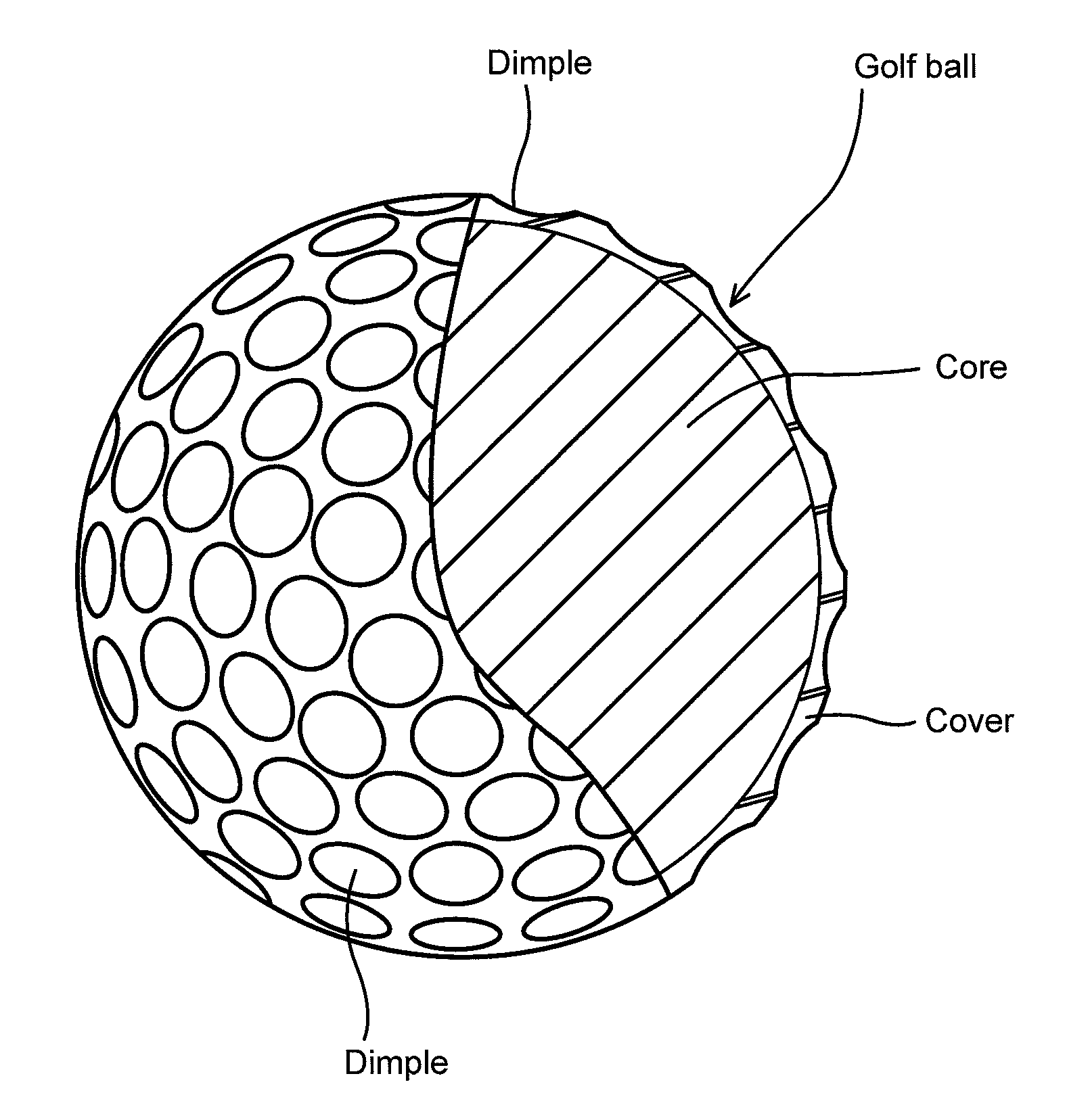

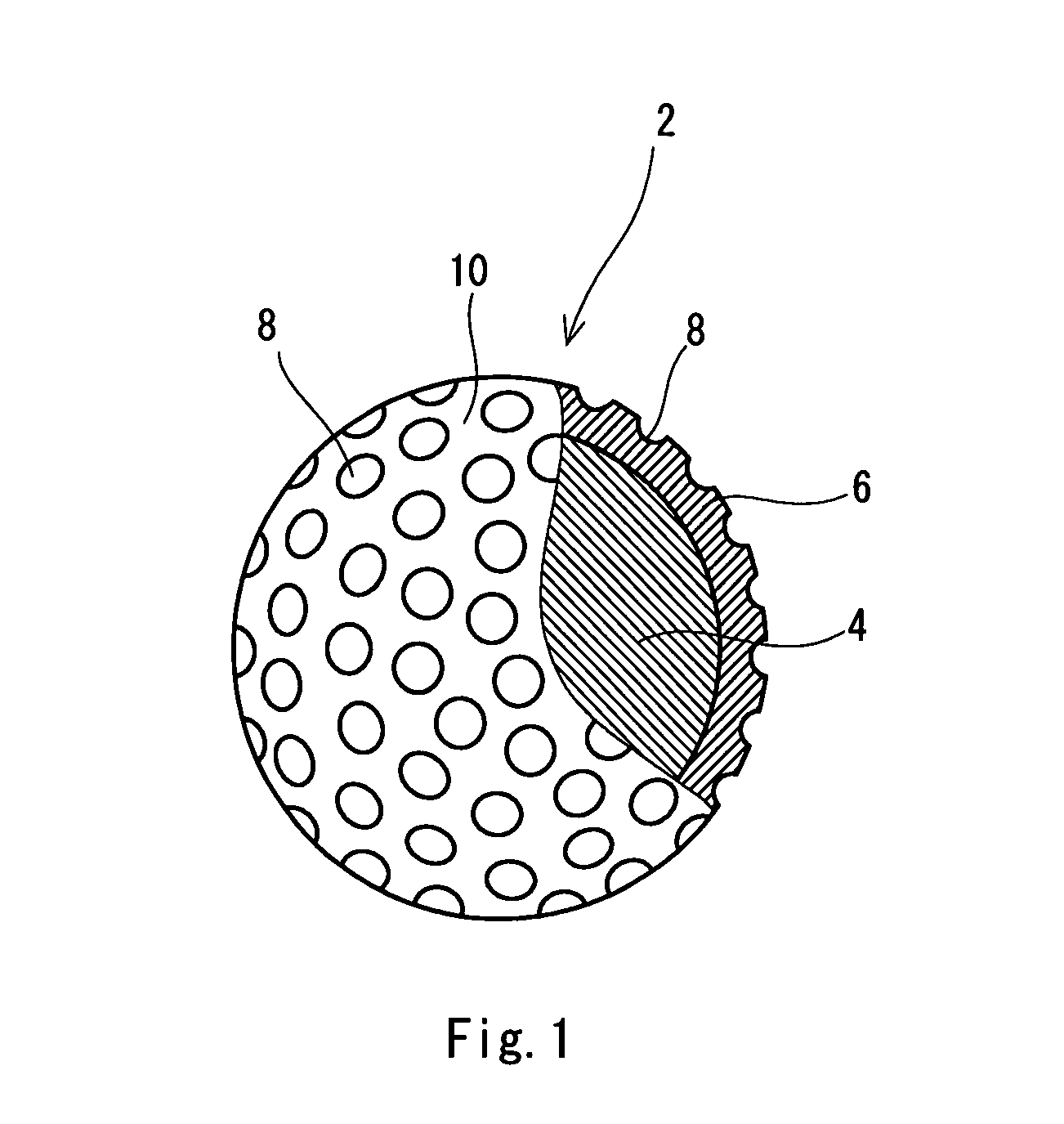

Golf ball

InactiveUS20110159998A1Improve control effectLess energy lossGolf ballsSolid ballsEngineeringGolf Ball

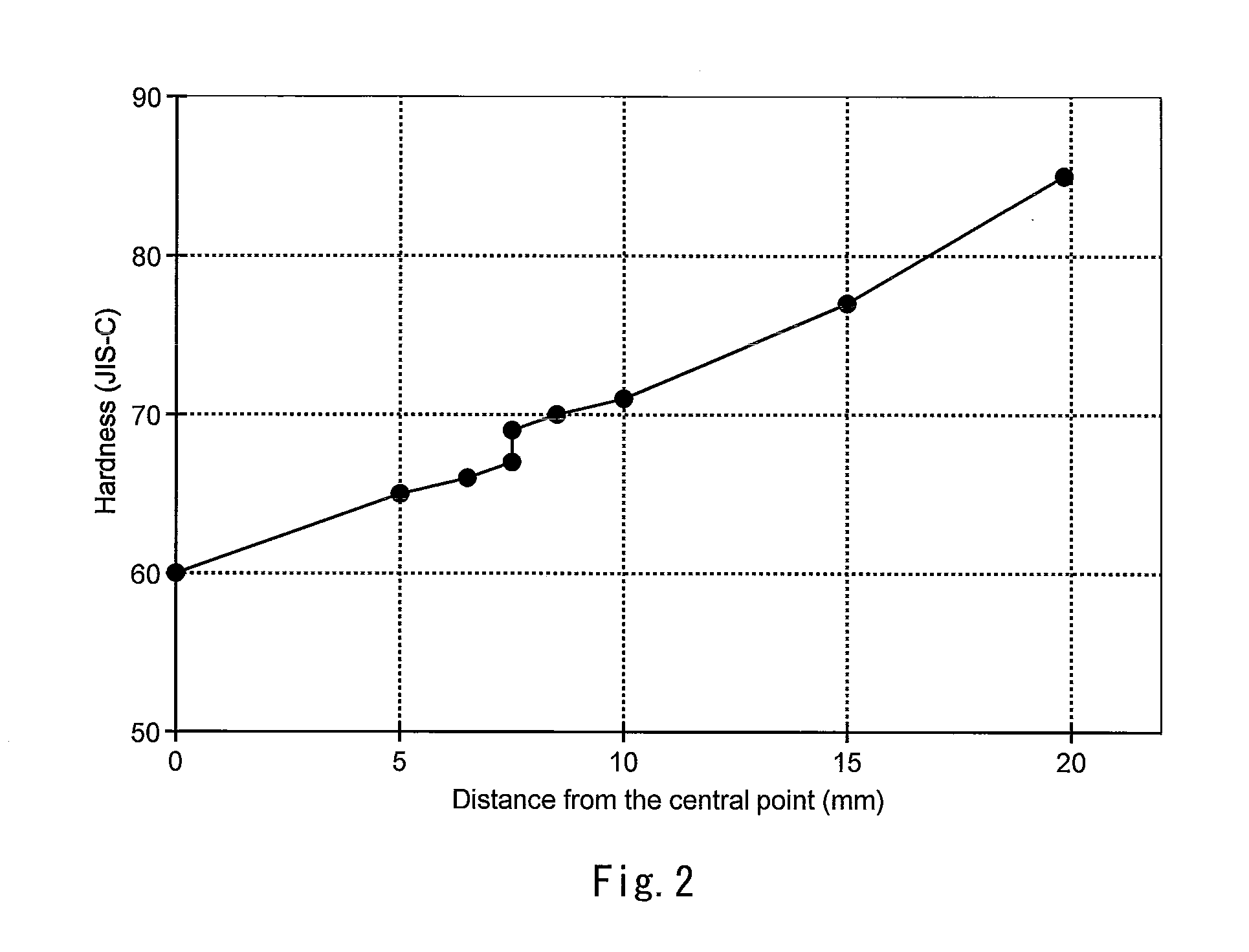

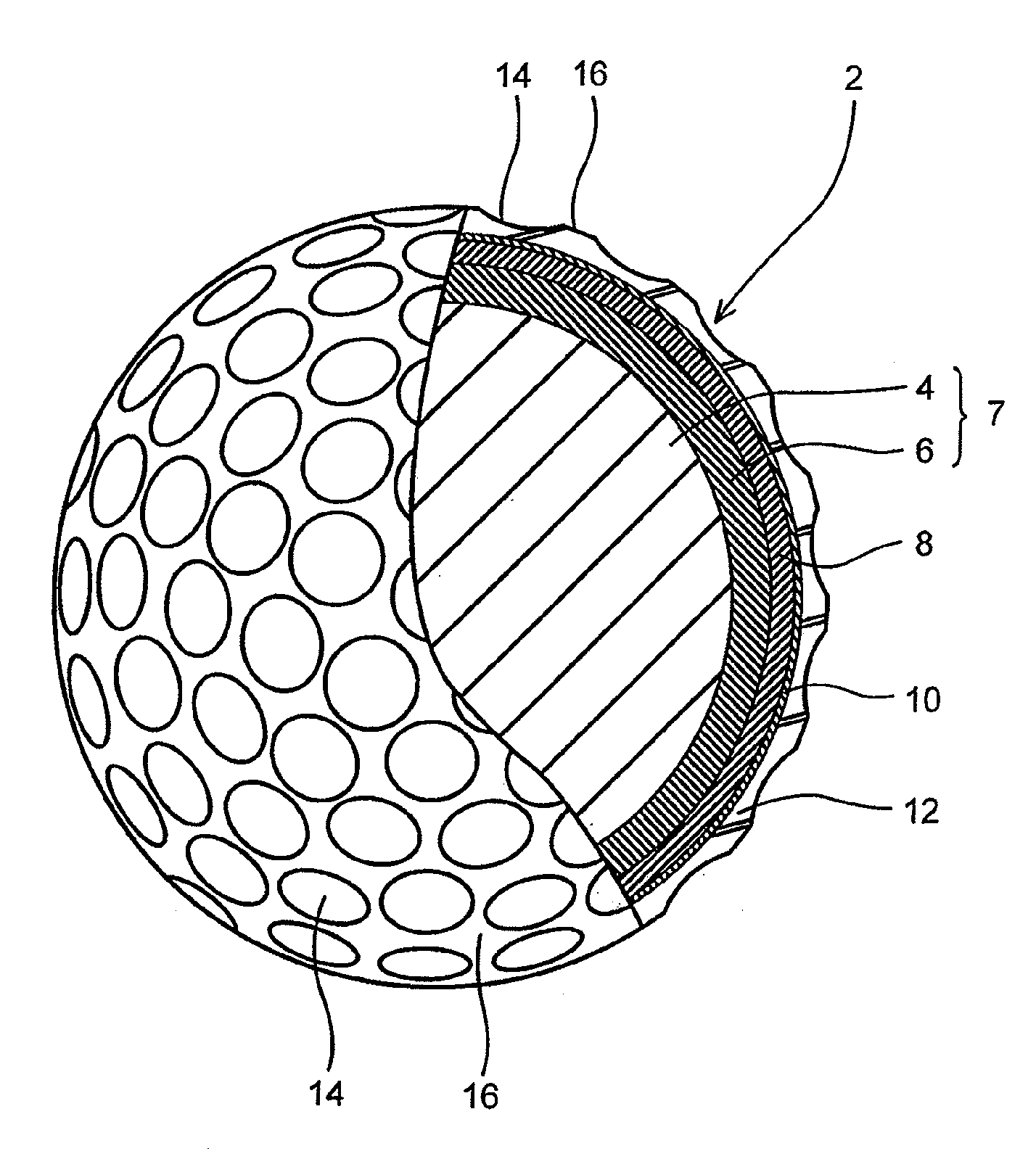

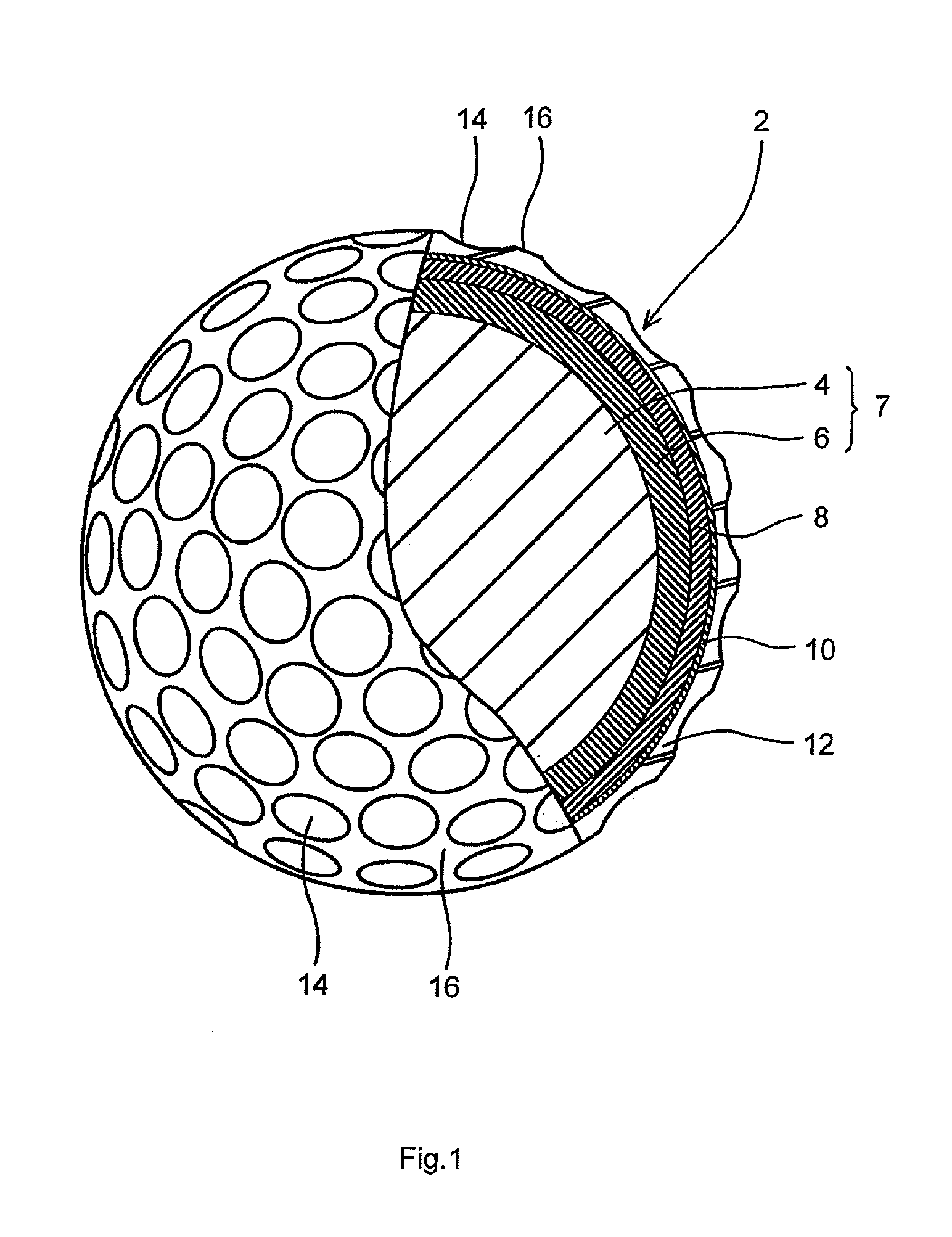

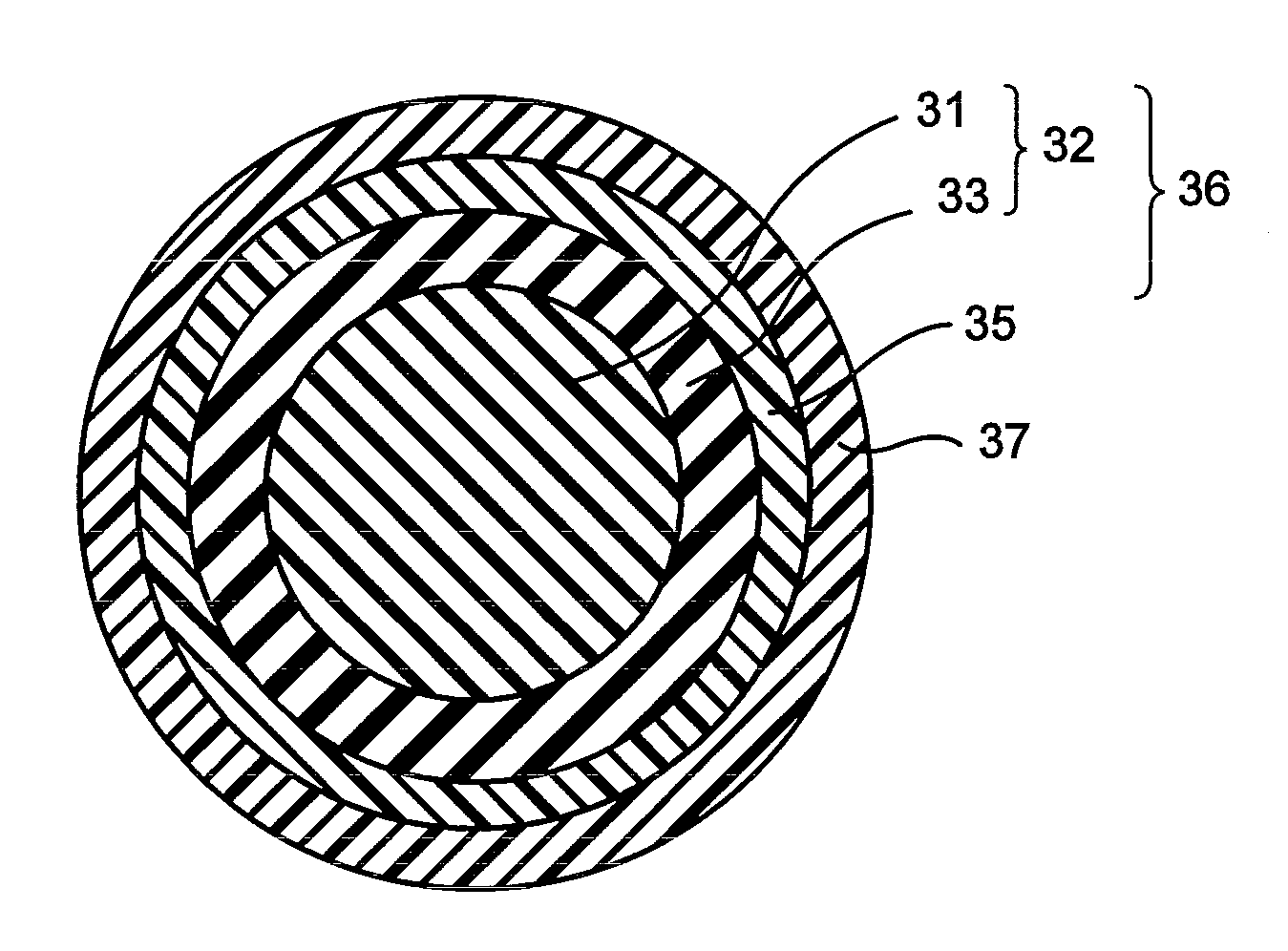

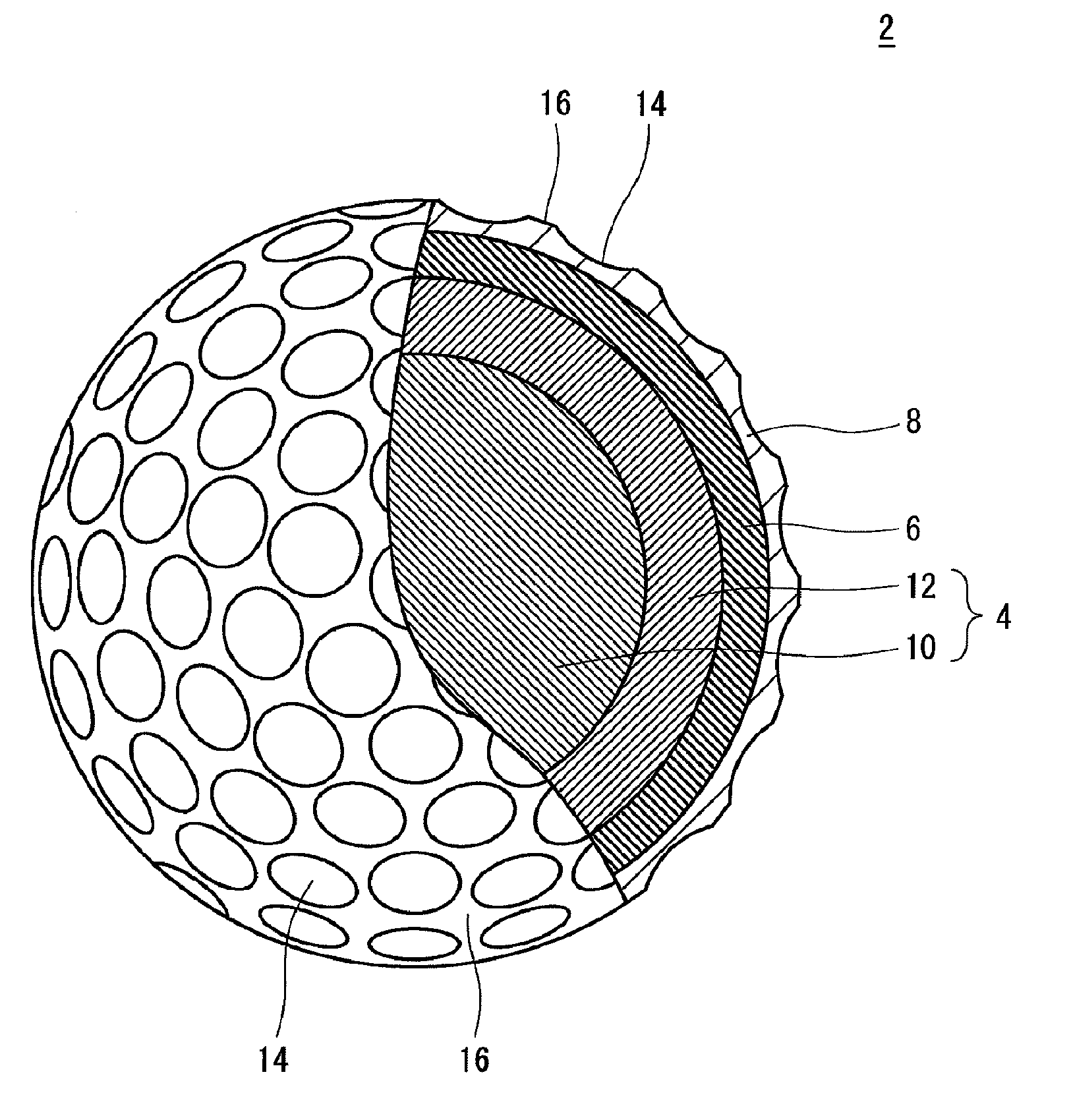

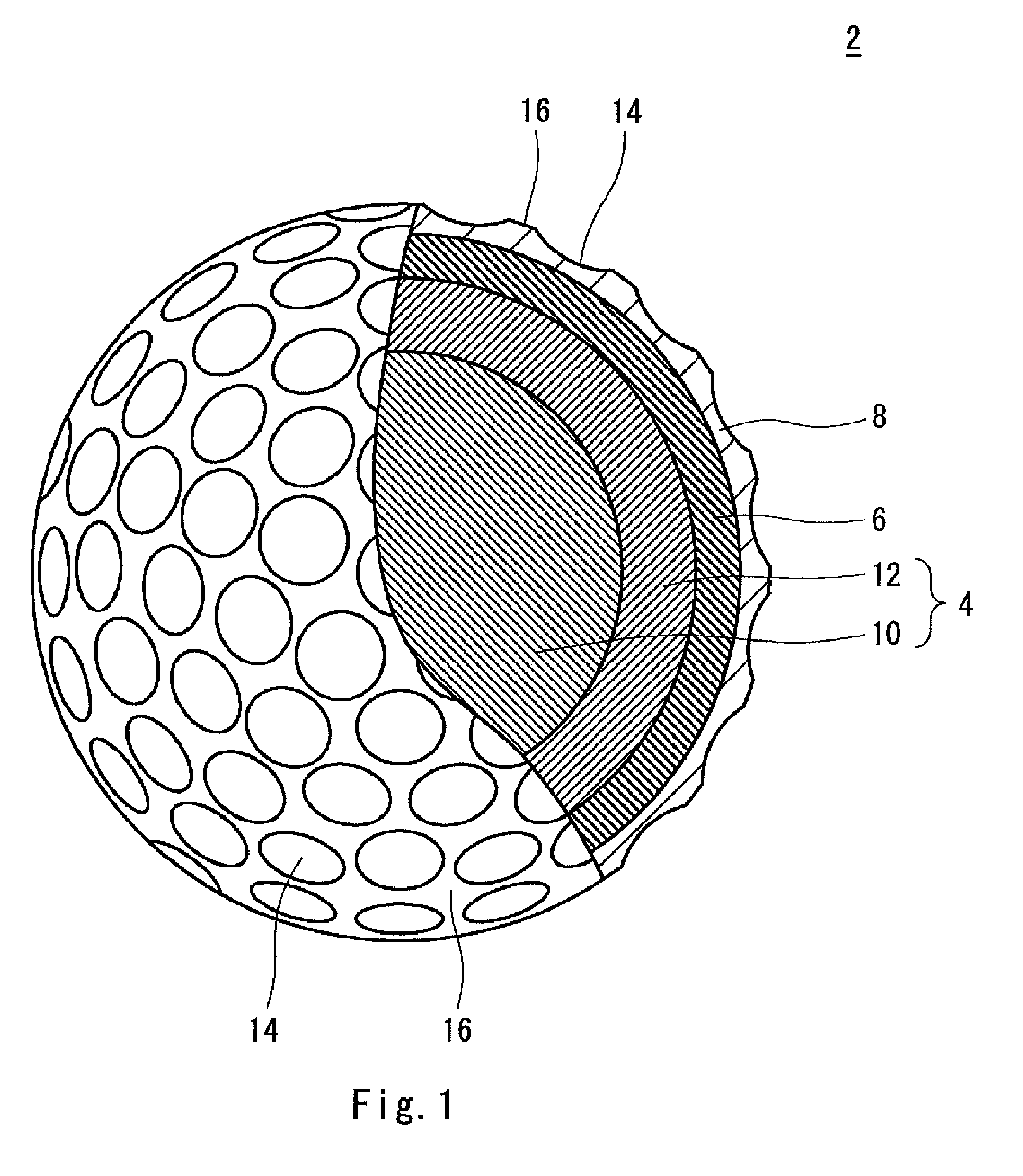

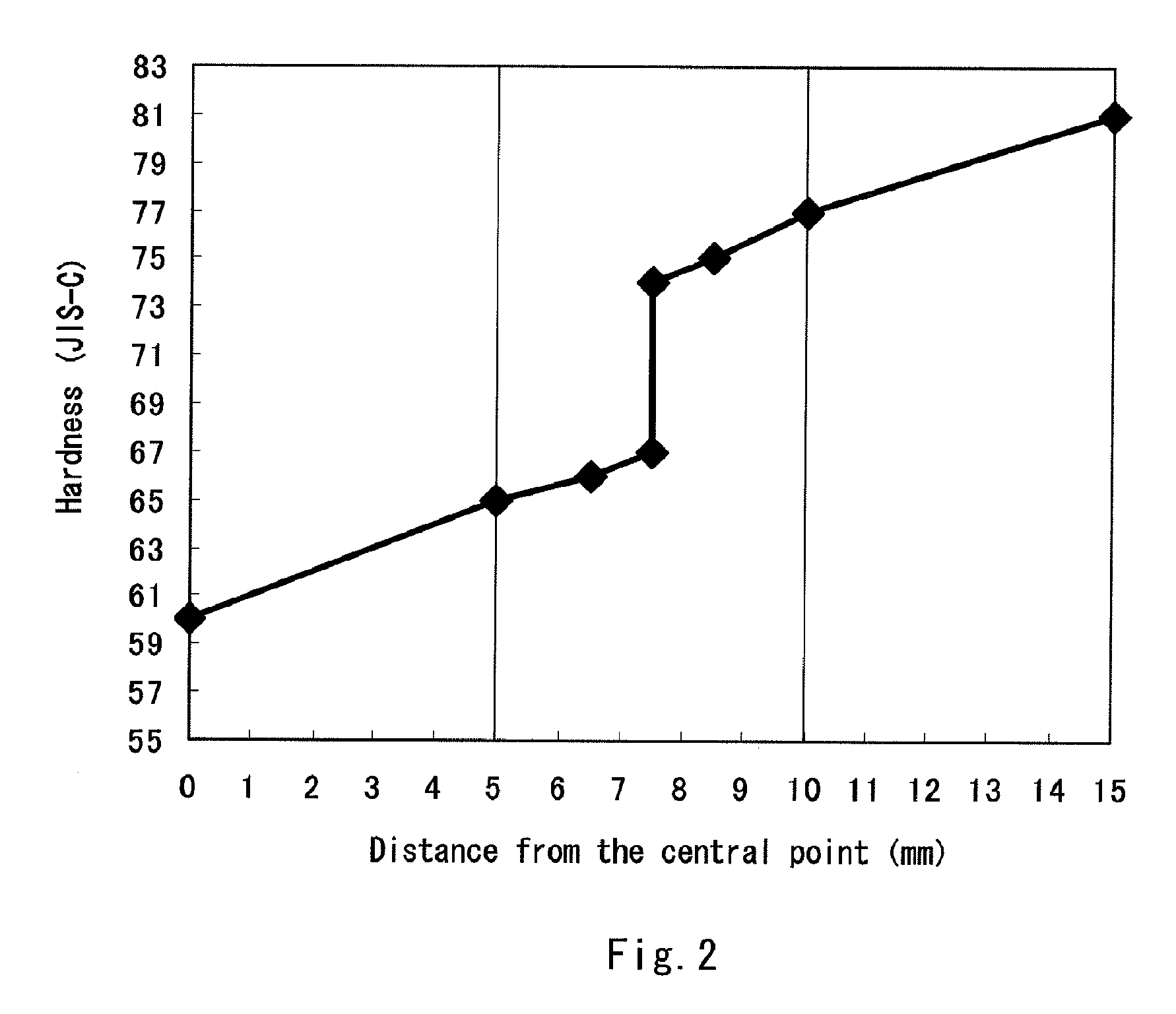

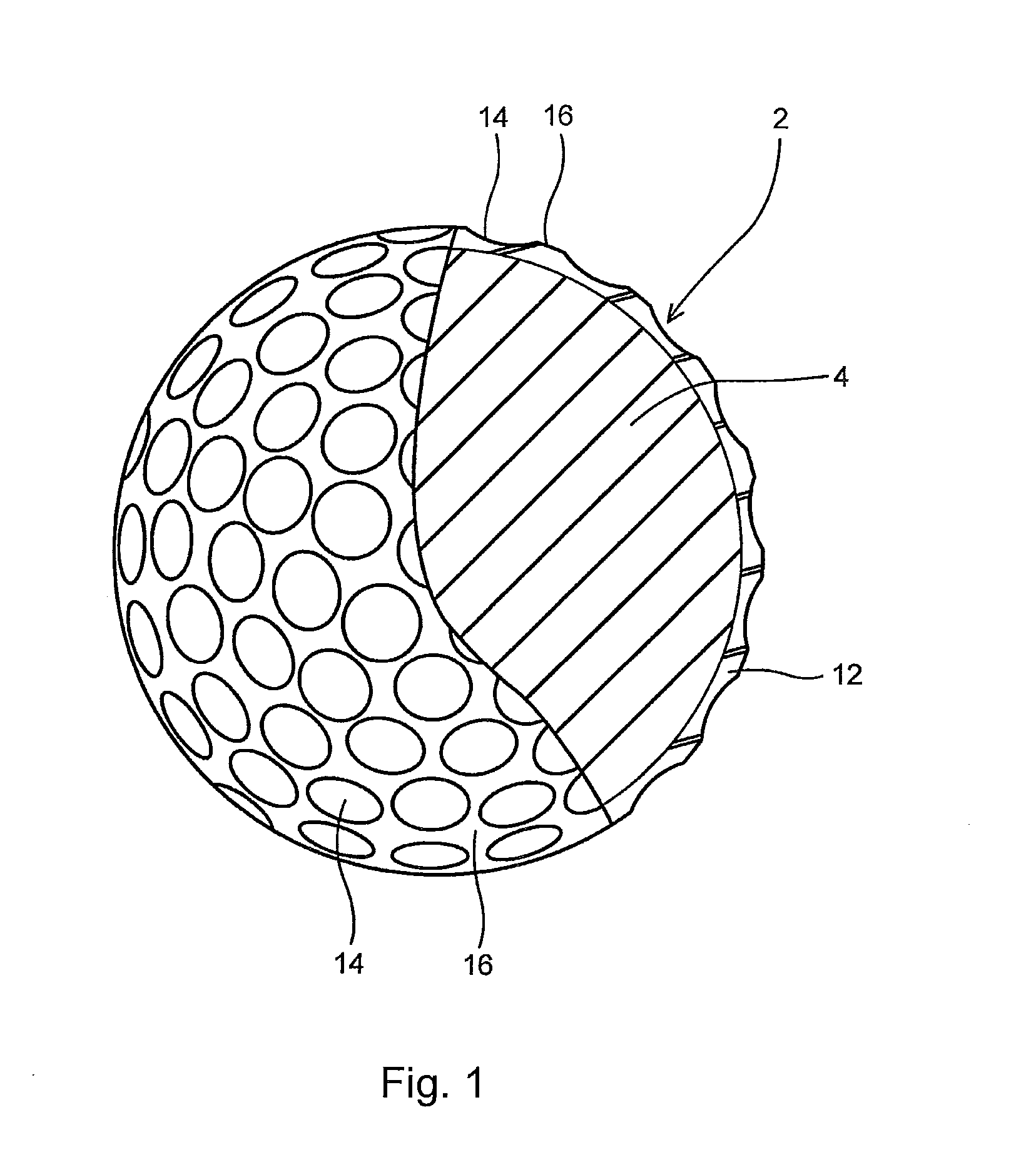

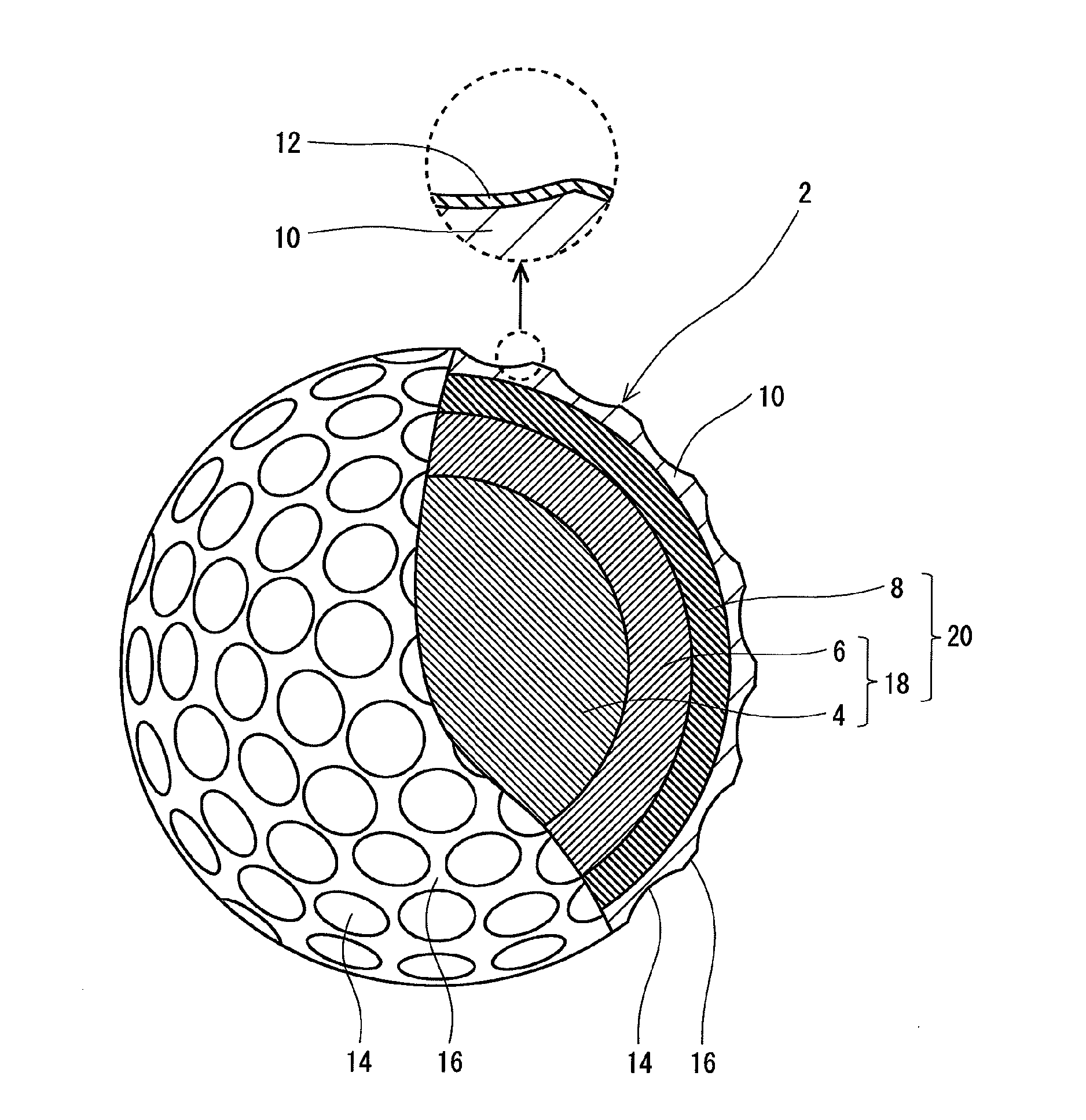

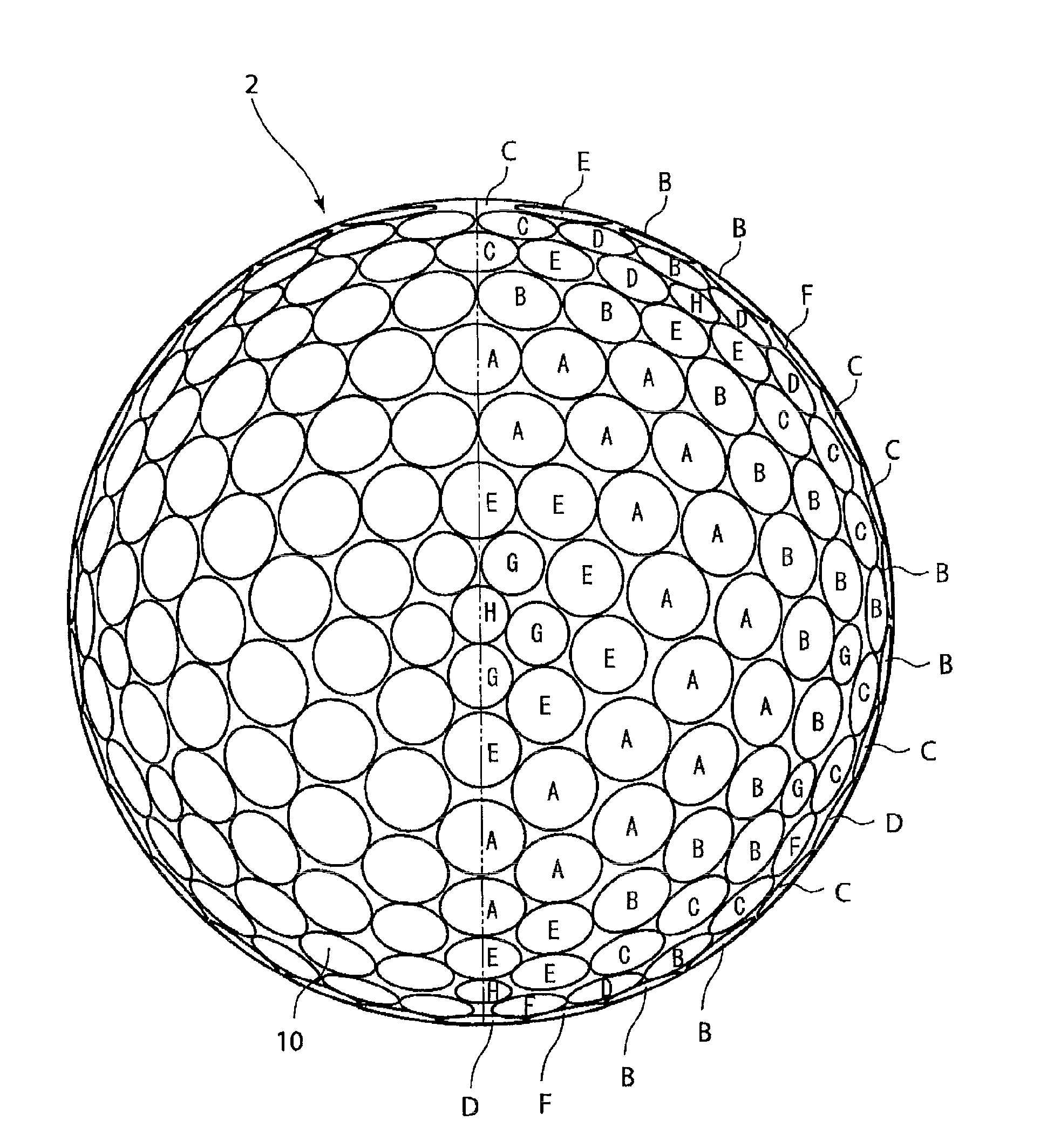

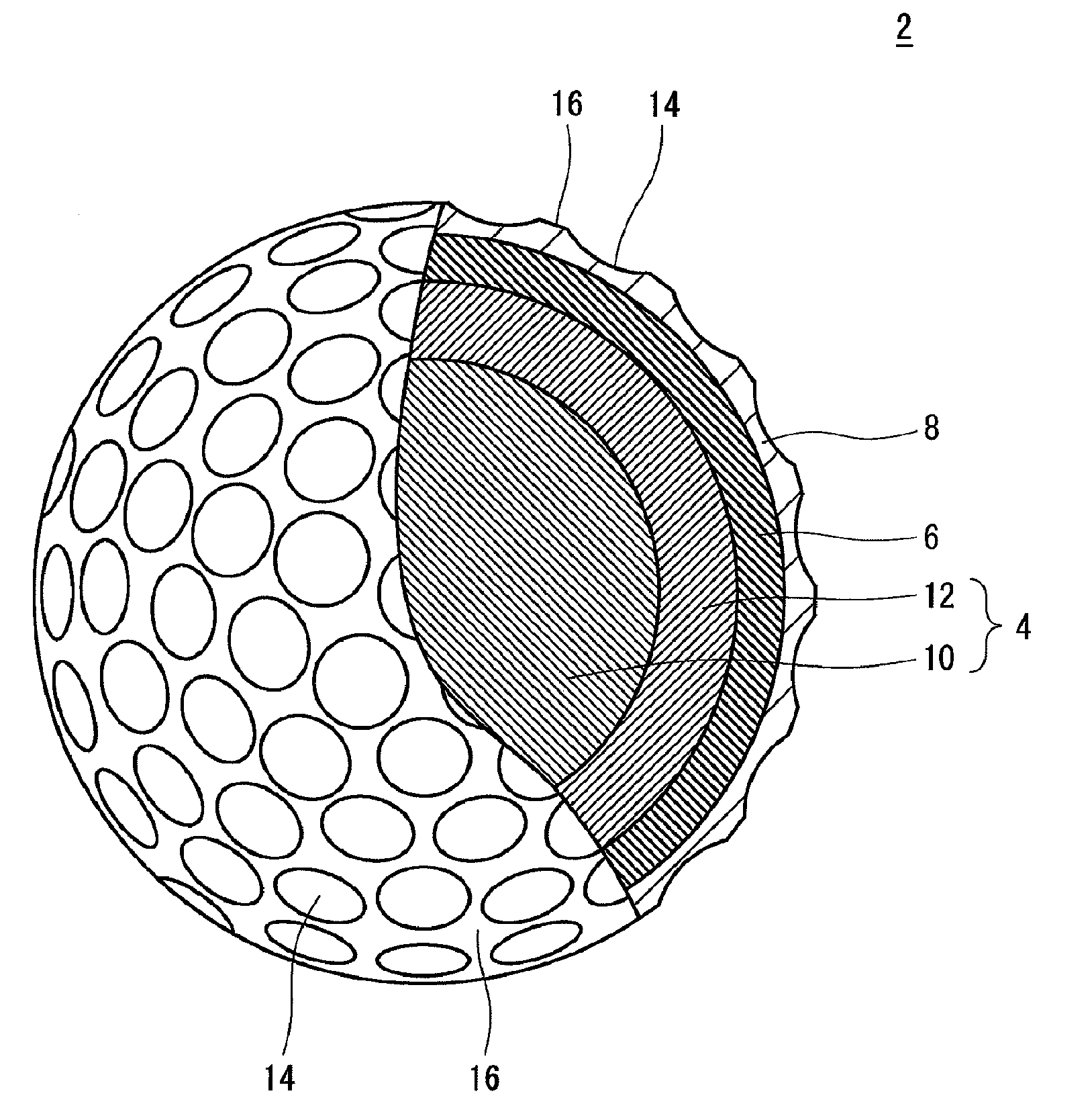

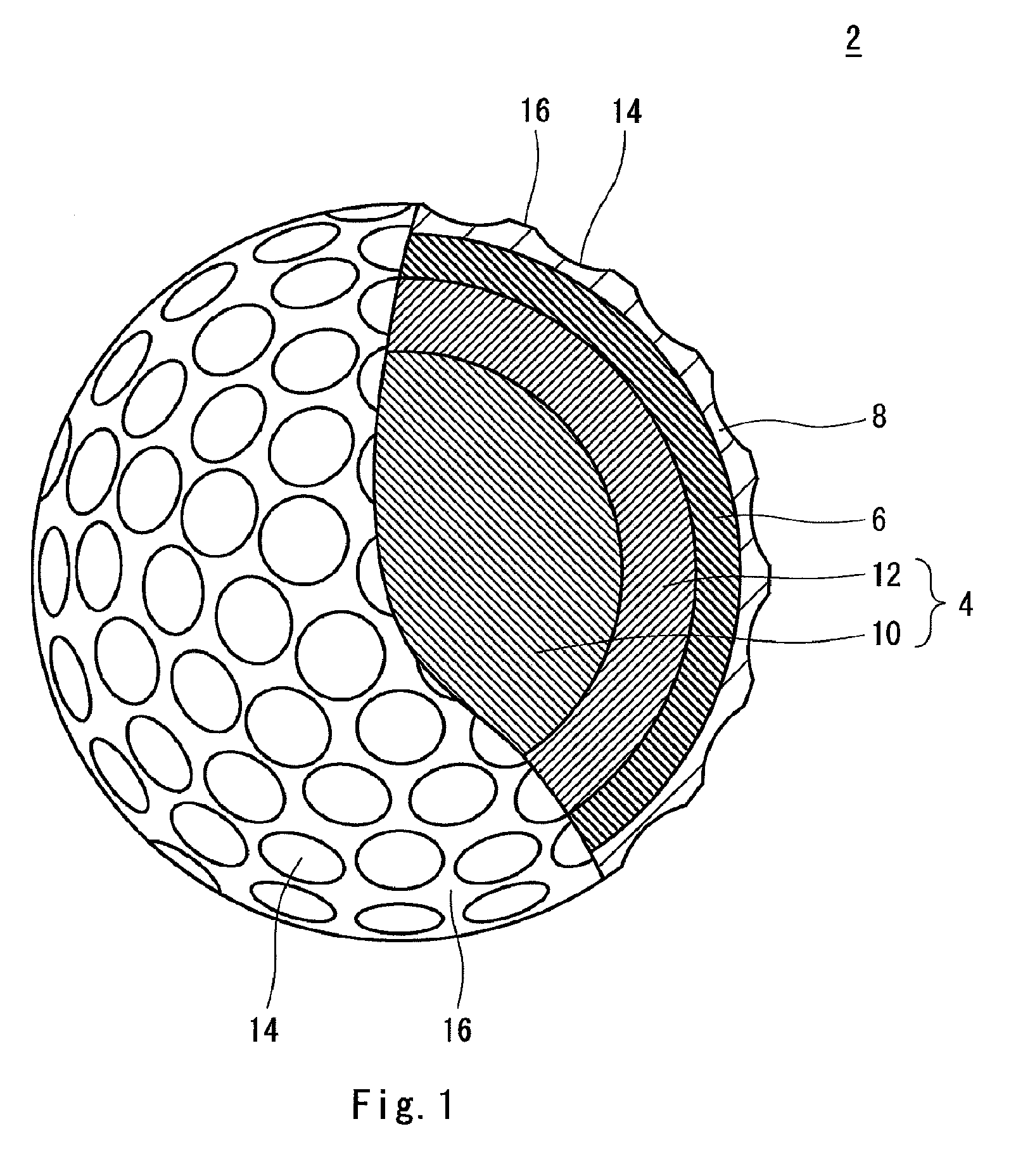

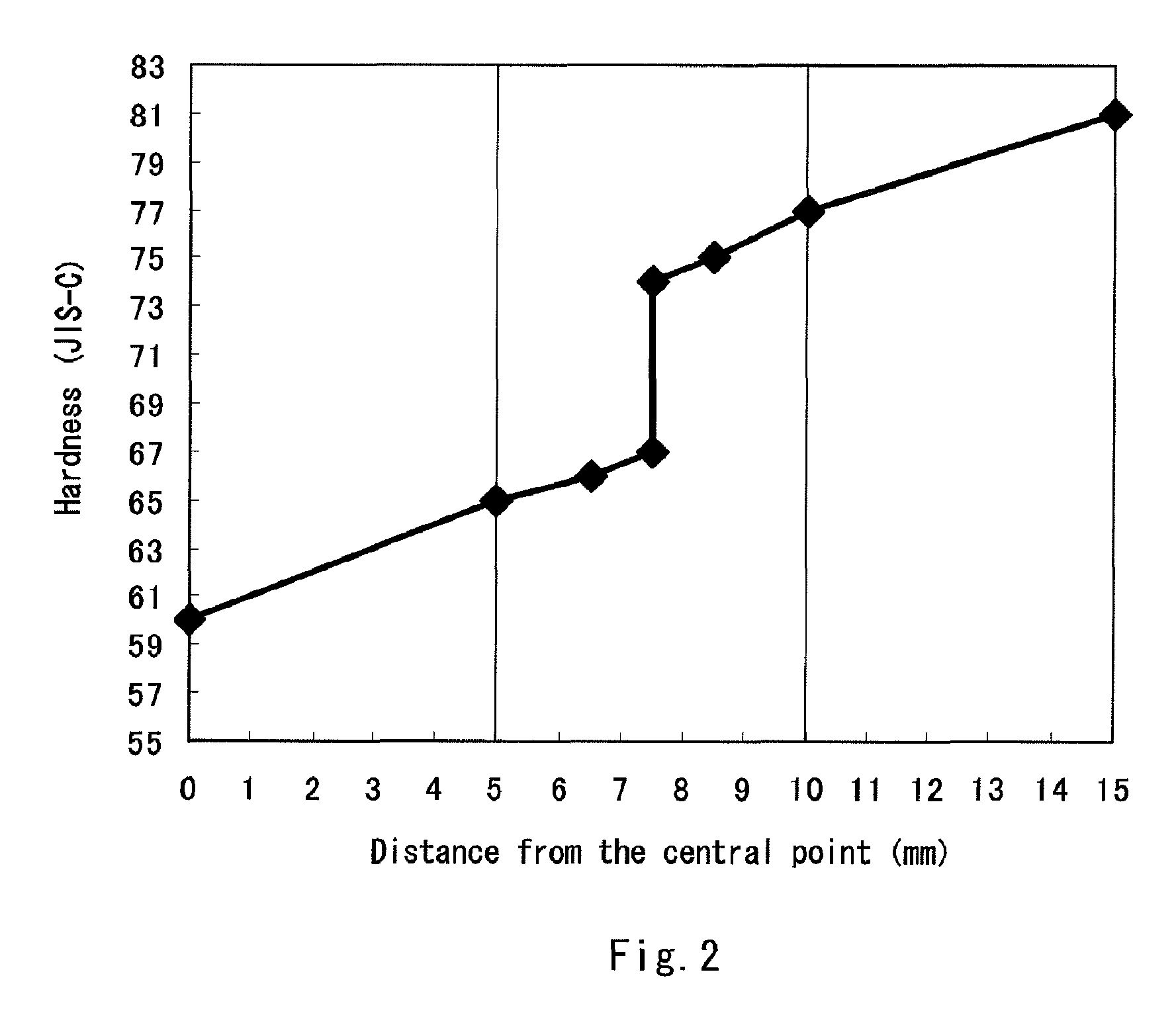

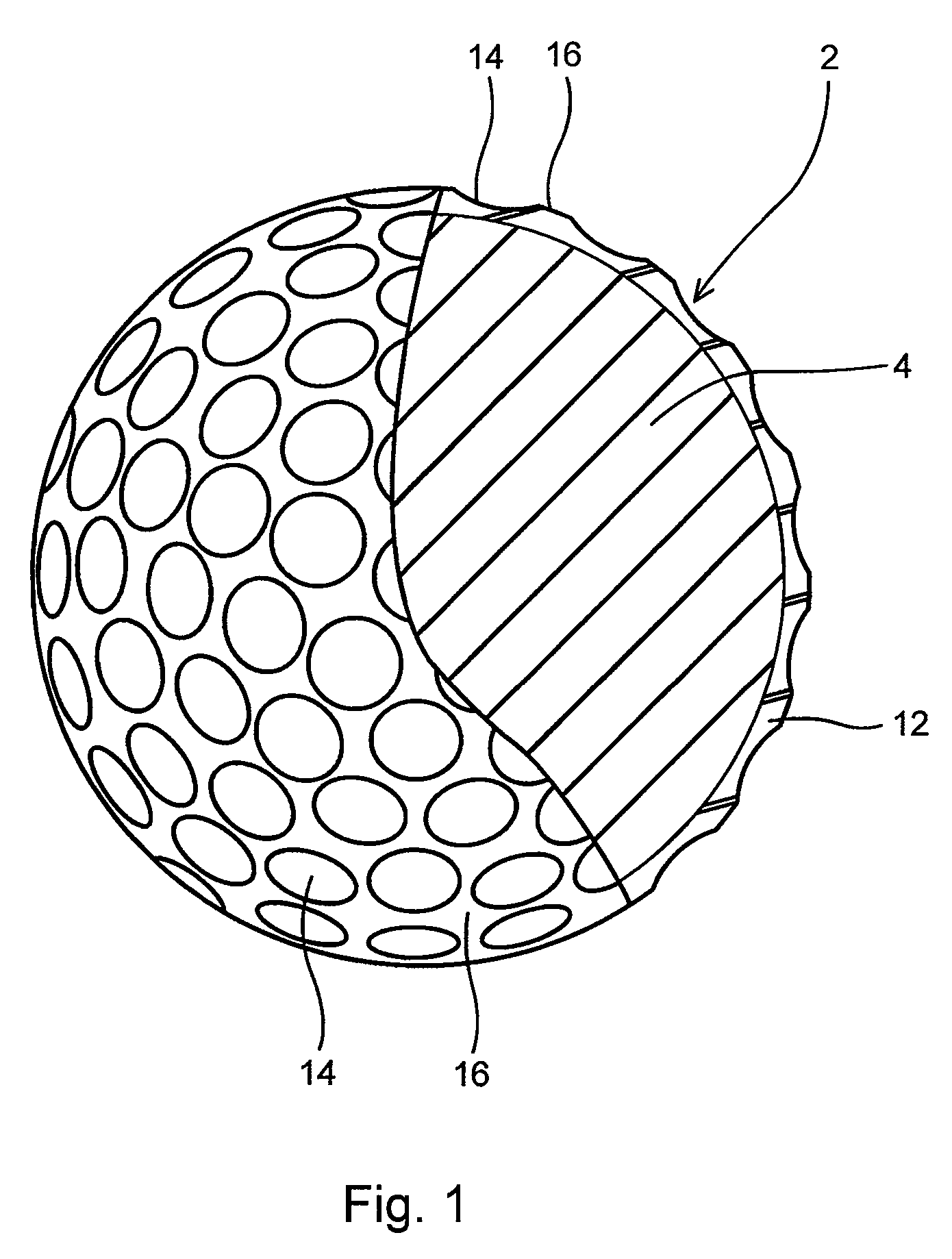

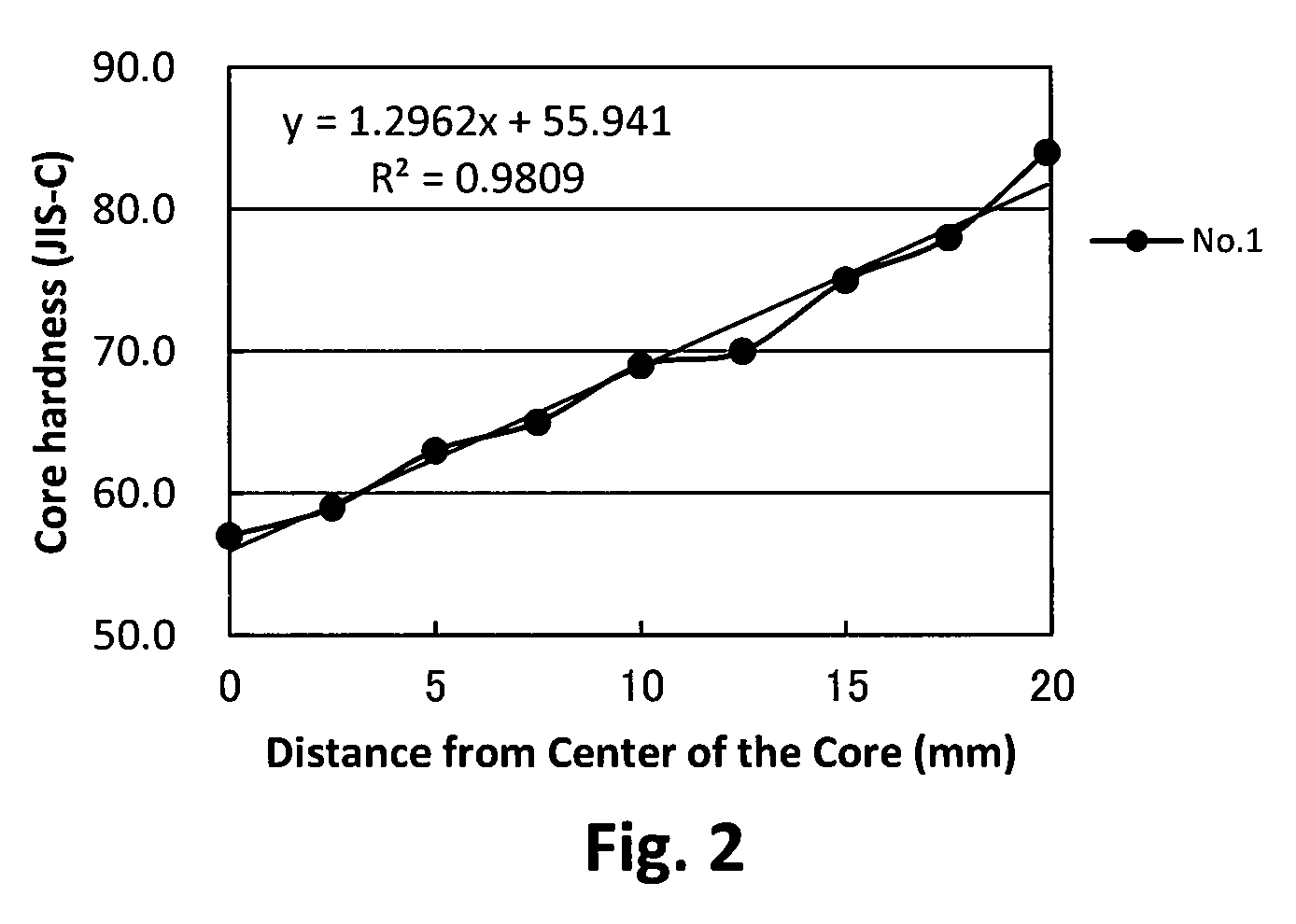

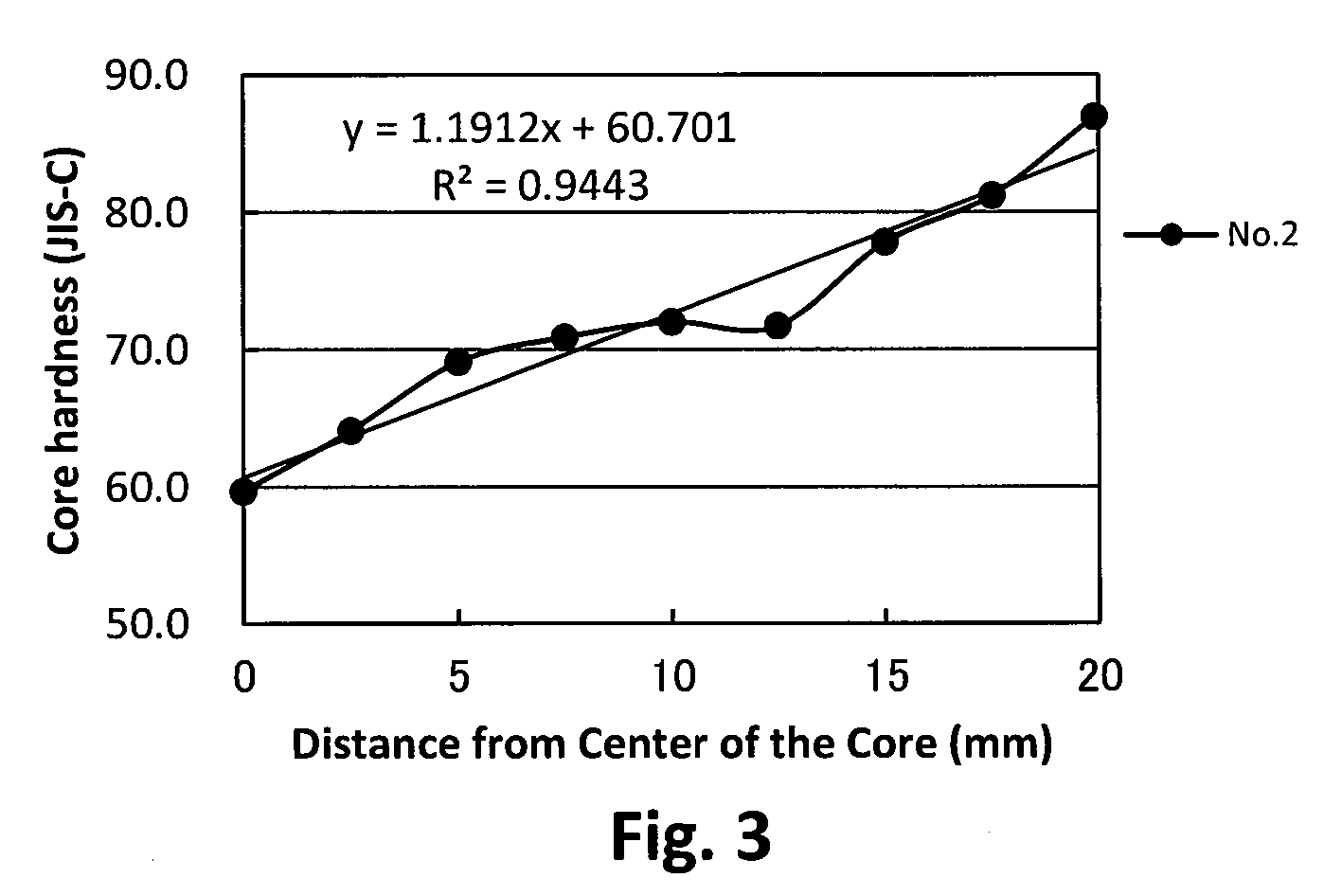

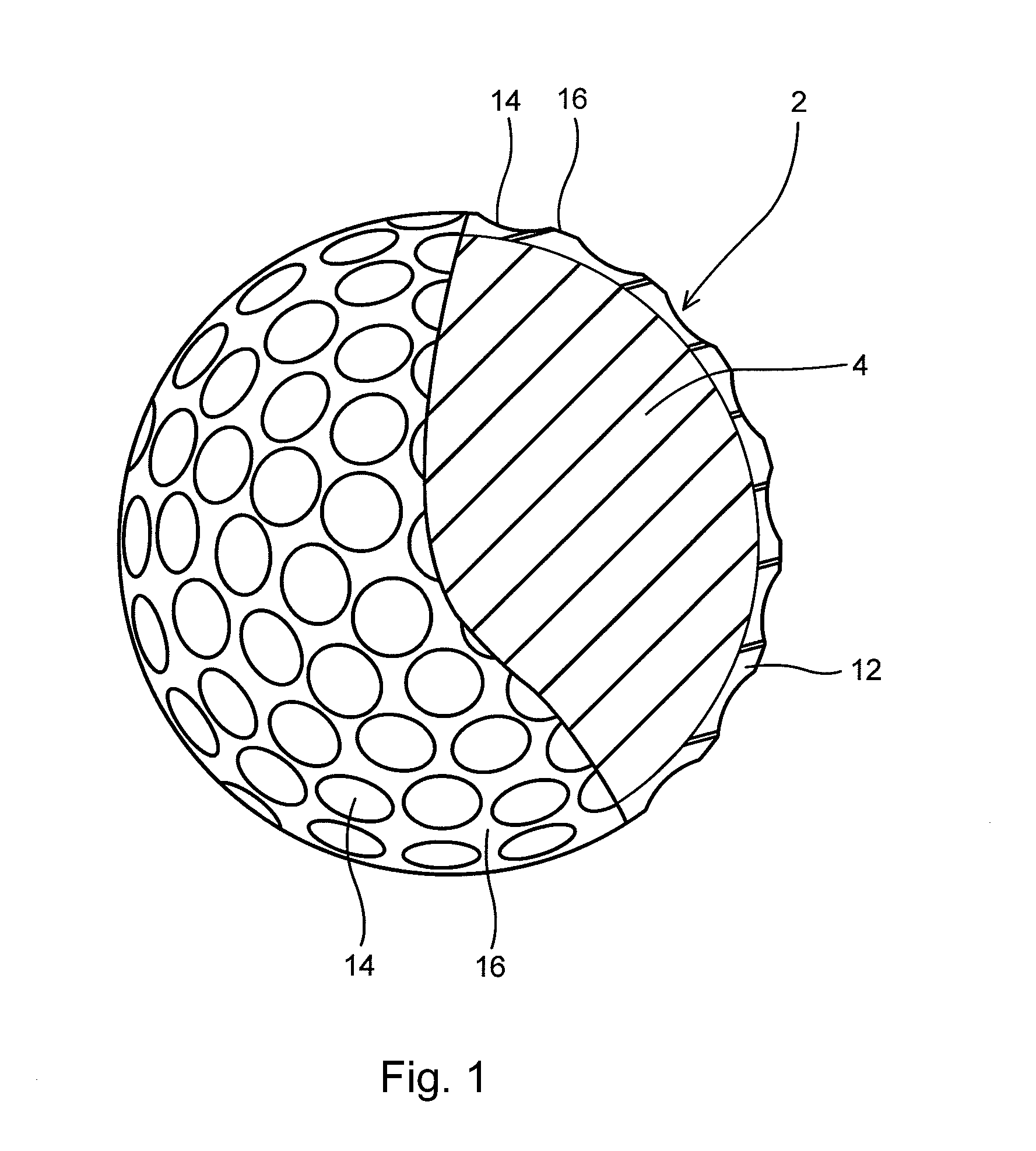

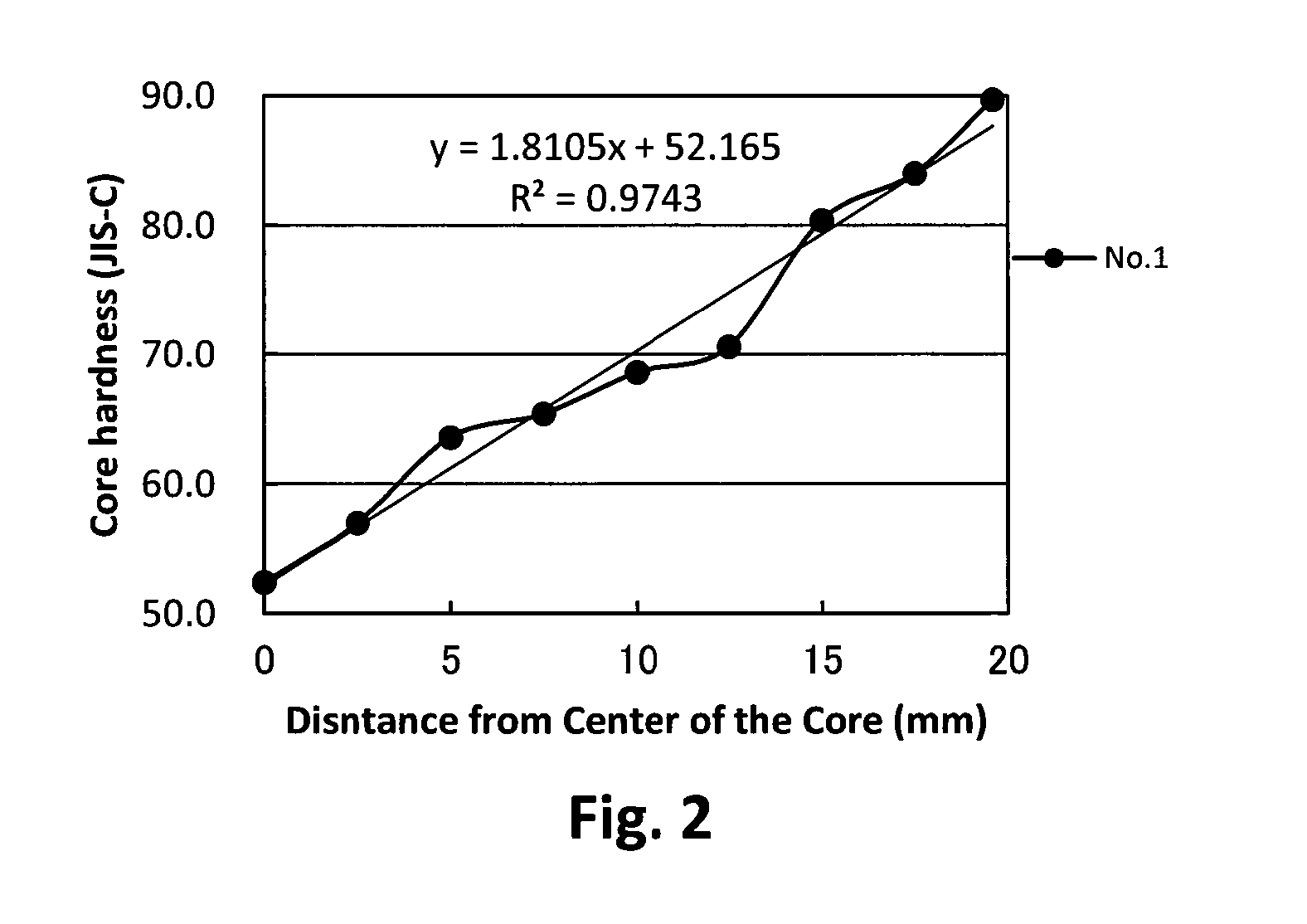

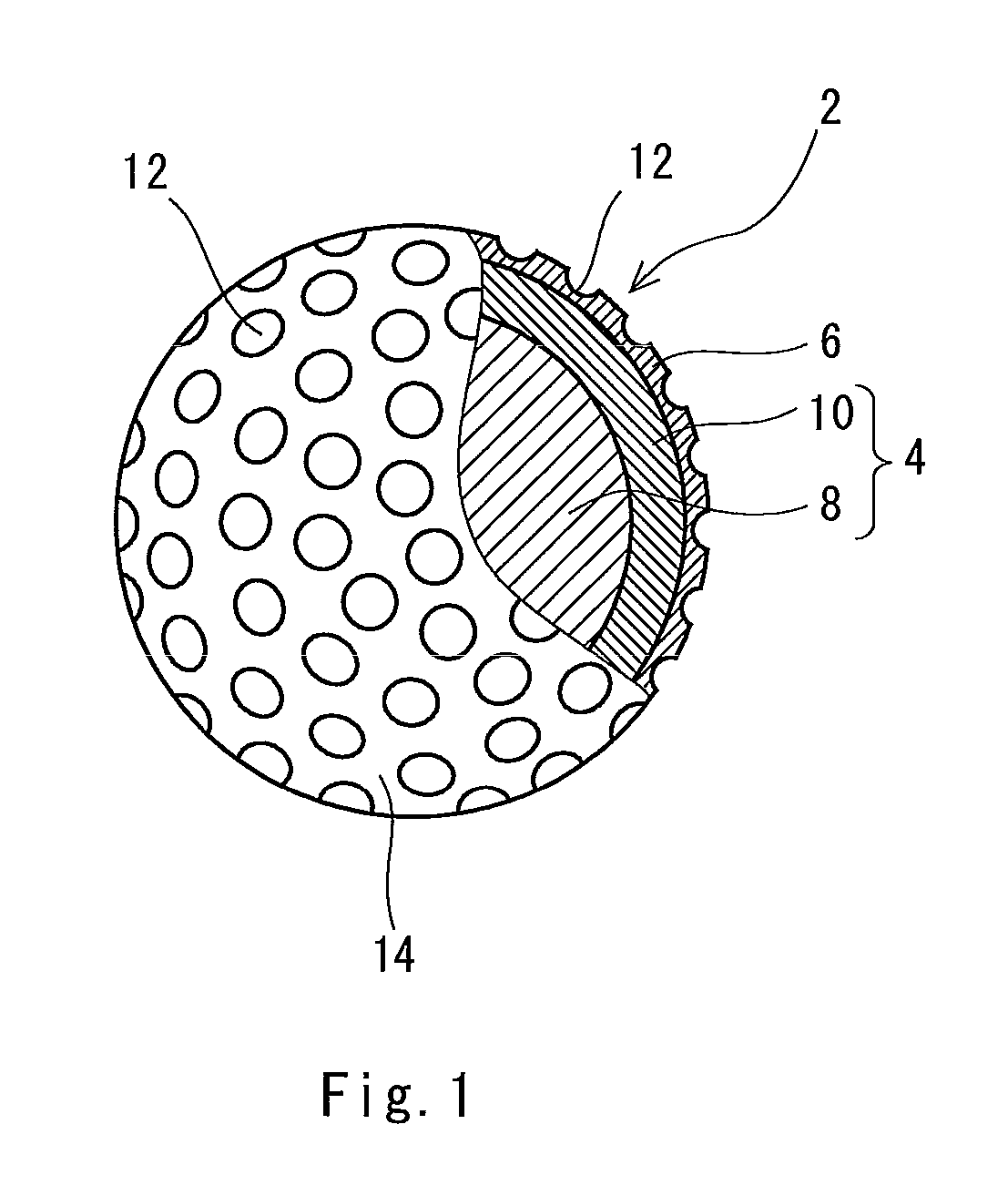

A golf ball 2 has a spherical core 4, a mid layer 6 situated on the external side of the core 4, and a cover 8 situated on the external side of the mid layer 6. The core 4 has a spherical center 10 and an envelope layer 12 situated on the external side of the center 10. At all points P included in a zone away from the central point of the core 4 at a distance of 1 mm or greater and 15 mm or less, the following mathematical expression is satisfied.H2−H1≦5In the above mathematical expression, H1 represents the JIS-C hardness at a point P1 that is located inside the point P along the radial direction and away from the point P at a distance of 1 mm, and H2 represents the JIS-C hardness at a point P2 that is located outside the point P along the radial direction and away from the point P at a distance of 1 mm.

Owner:DUNLOP SPORTS CO LTD

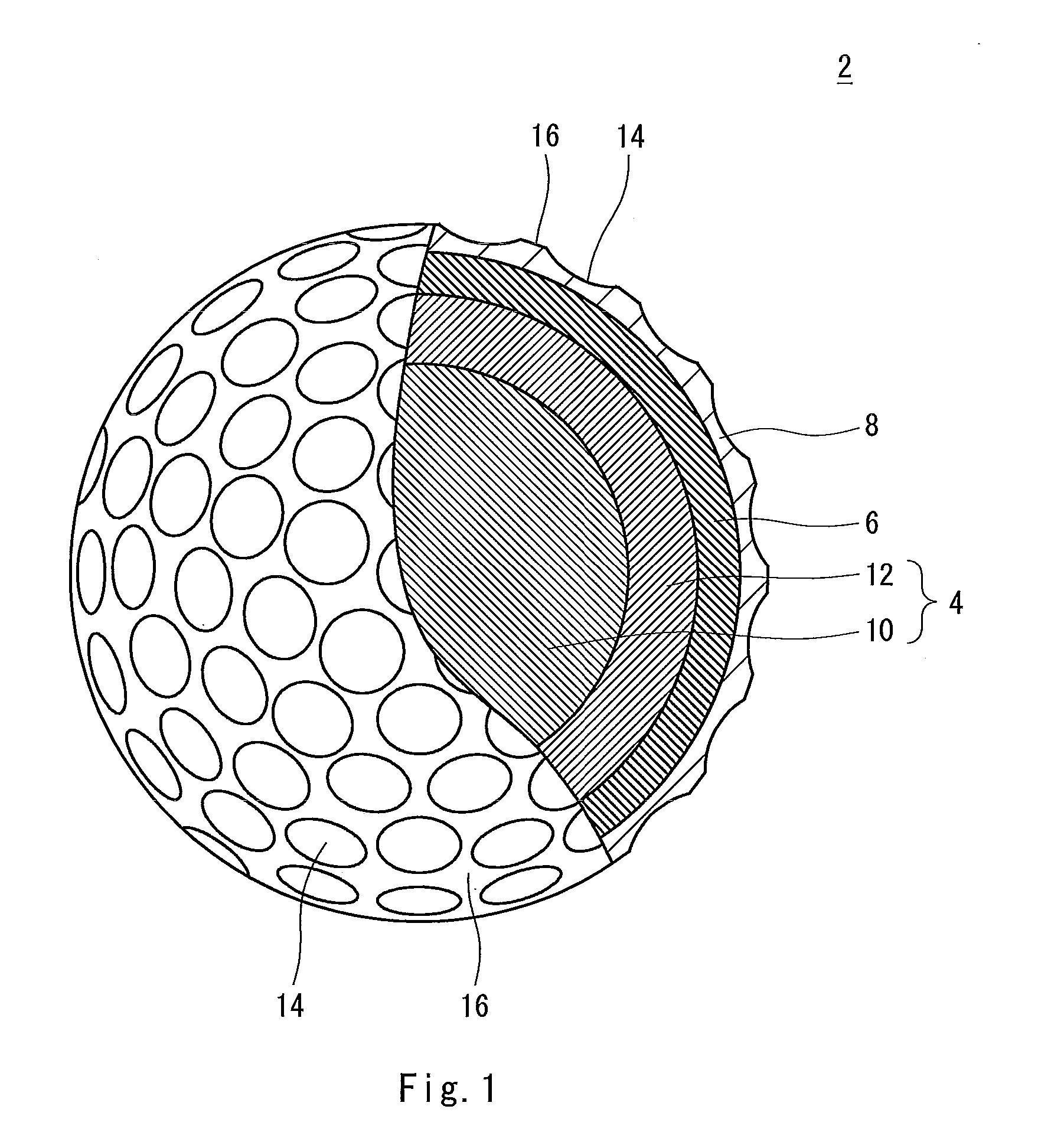

Golf ball

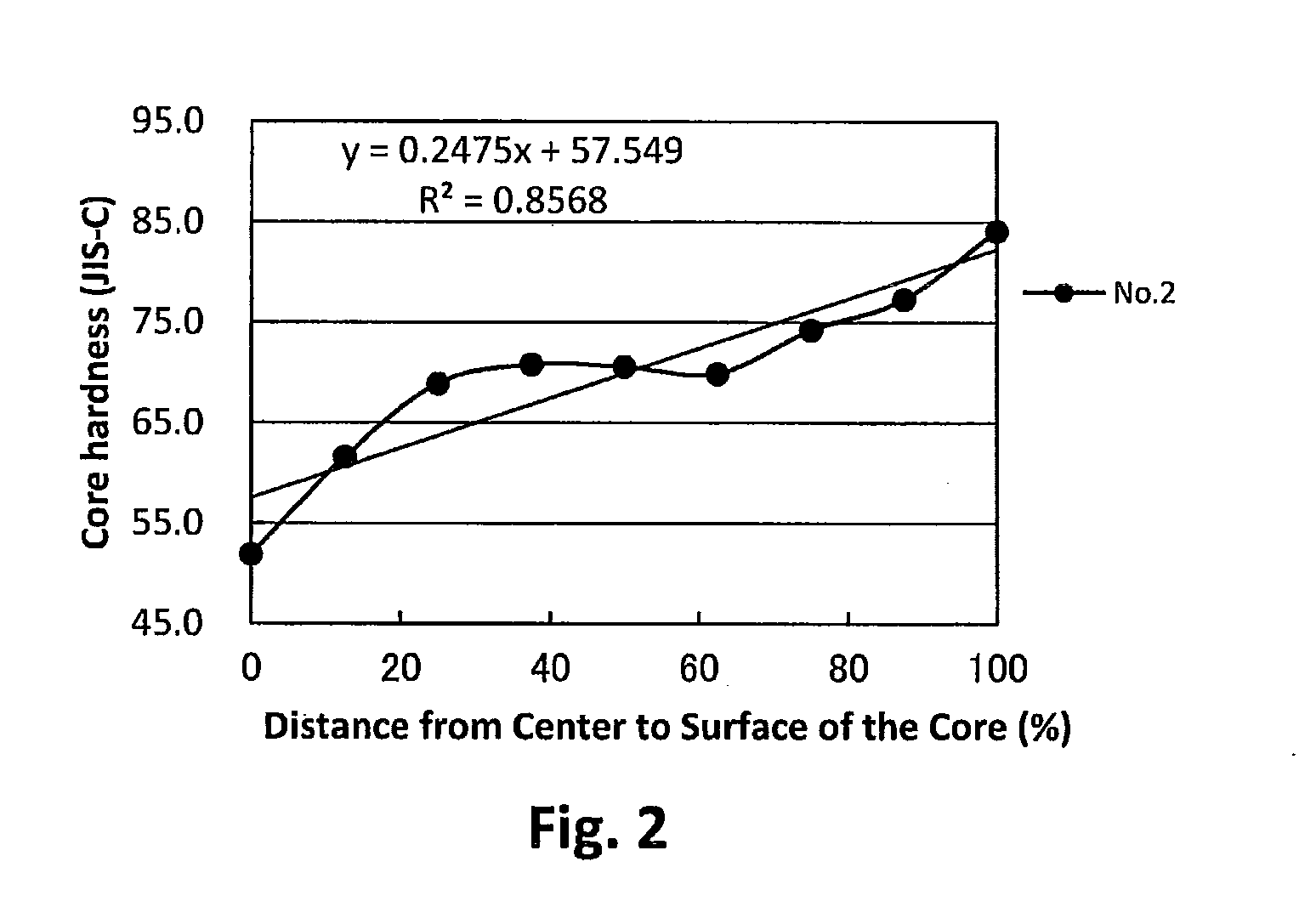

ActiveUS20130324318A1Improve controllabilitySlow down the spin ratePolyurea/polyurethane coatingsGolf ballsHardnessContact force

The present invention provides a golf ball comprising a golf ball body with a spherical core having one or more layers, an intermediate layer disposed outside the spherical core and a cover disposed outside the intermediate layer and a paint film formed on a surface of the golf ball body, and having a friction coefficient calculated using a contact force tester of 0.35 or more and 0.60 or less, wherein the golf ball body has specific plurality of dimples on the surface thereof, at least one layer of the spherical core is a rubber layer having a specific hardness distribution, and the rubber layer has a hardness at the outermost point which is greater than a hardness at the innermost point, and the intermediate layer has a slab hardness (Hm) which is greater than a slab hardness (Hc) of the cover.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

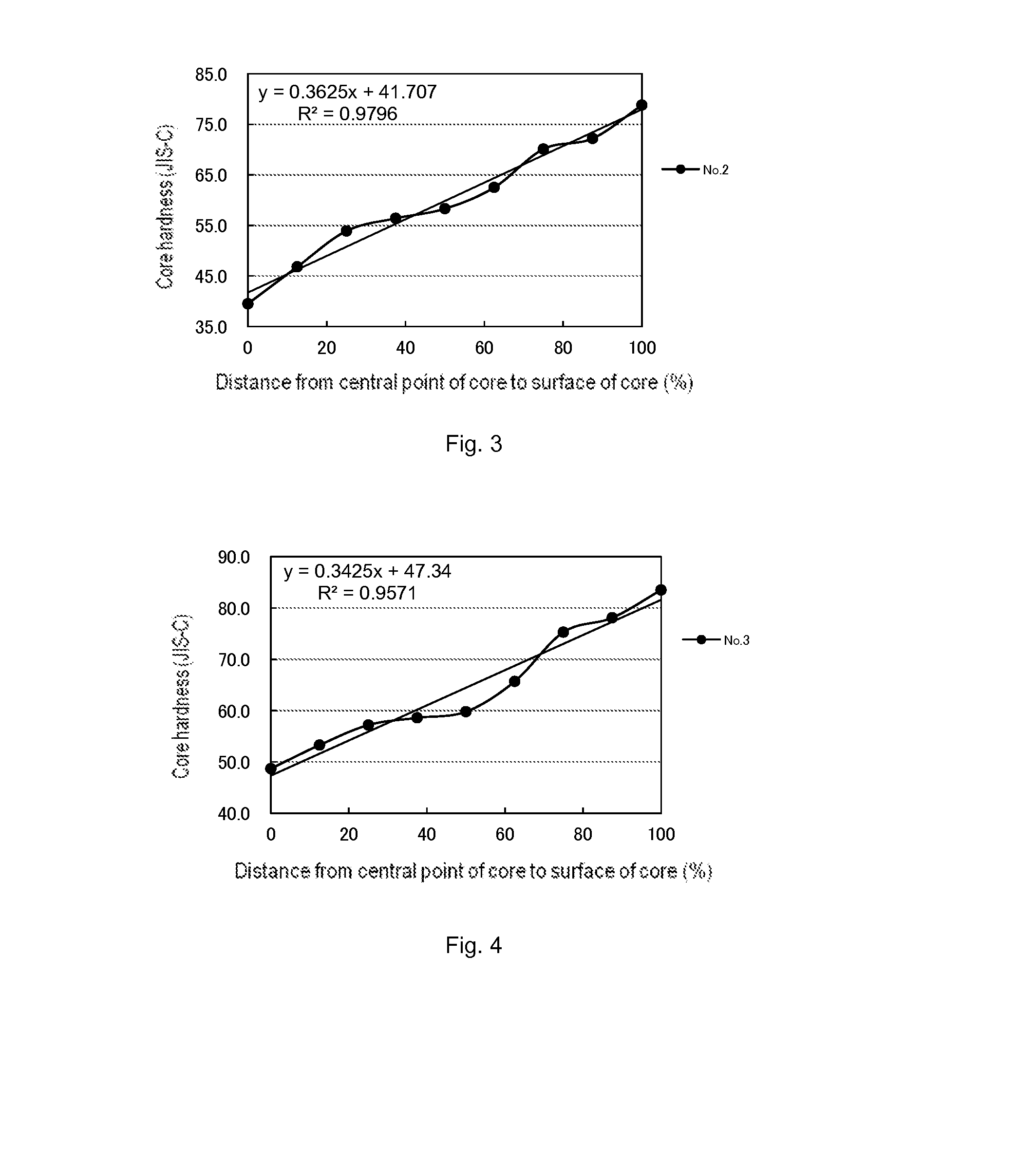

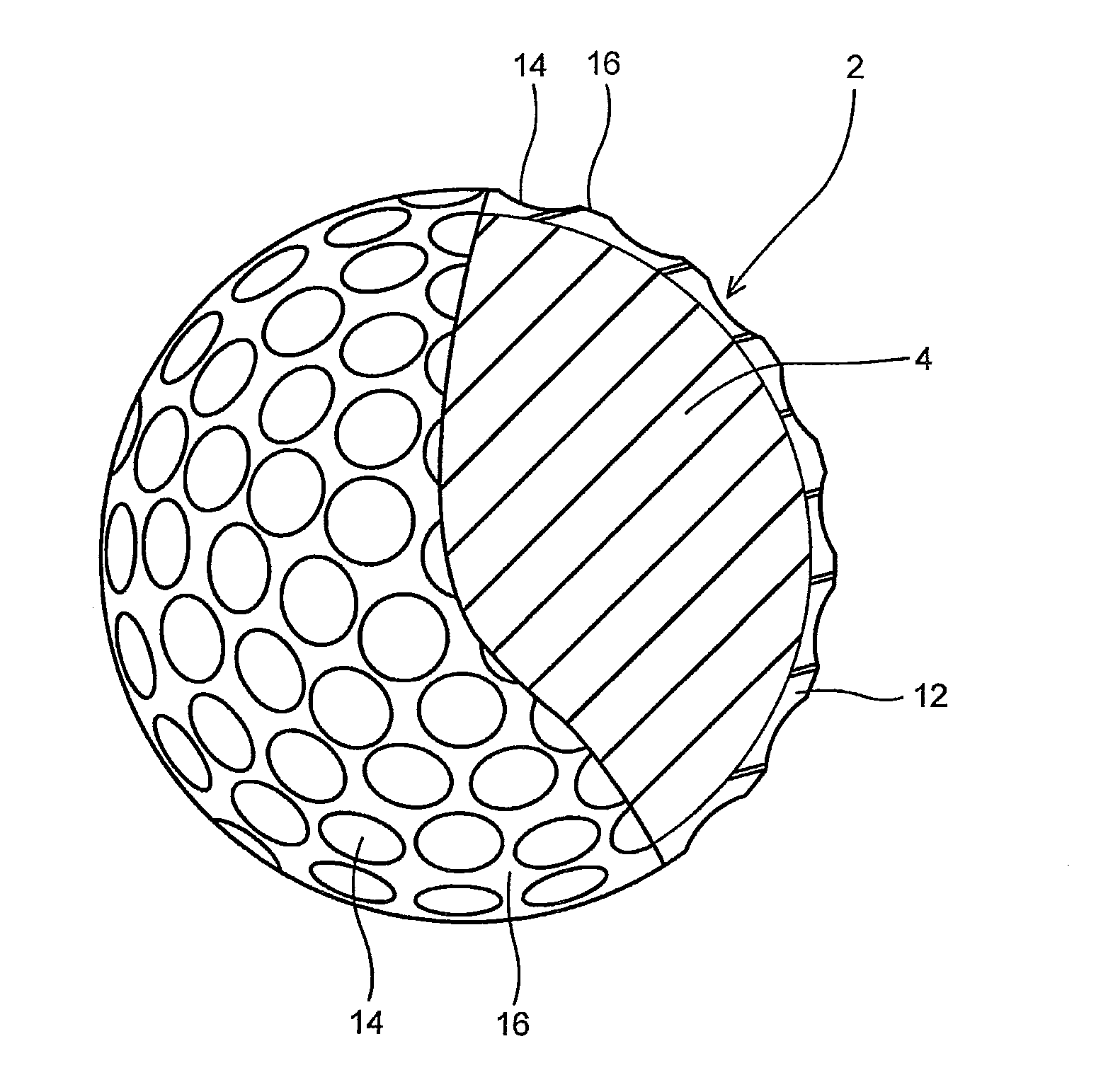

An object of the present invention is to provide a golf ball having an improved controllability and shot feeling while maintaining a flight distance on driver shots. The present invention provides a golf ball having a core, an intermediate layer disposed around the core, and a cover disposed around the intermediate layer, wherein the core has a center and an envelope layer disposed around the center, and has a specific hardness distribution, and the intermediate layer is formed from an intermediate layer composition comprising, as a resin component, (A) a modified polyester elastomer and (B) a binary ionomer resin, and having a flexural modulus ranging from 150 MPa to 450 MPa, a maximum loss factor (tan δ) between −20° C. and 0° C. of 0.08 or less, a repulsive modulus of 55% or more, and a slab hardness ranging from 60 to 90 in JIS-hardness.

Owner:SUMITOMO RUBBER IND LTD

Golf ball and process for preparing the same

ActiveUS20100167841A1Feel goodIncrease elasticityLiquid surface applicatorsGolf ballsDriver/operatorMeth-

An object of the present invention is to provide a golf ball providing a great distance. Another object of the present invention is to provide a golf ball striking a balance between a flight distance on a driver shot and an approach performance on an approach shot while providing an excellent shot feeling. The present invention provides a golf ball comprising: a center, a cover and at least one intermediate layer disposed between the center and the cover, wherein at least one piece or one layer of the intermediate layer is formed from a high fluidity intermediate layer composition that contains (A) a polyamide resin composition having a flexural modulus in a range from 700 MPa to 4,000 MPa; (B) at least one member selected from the group consisting of an ethylene-(meth)acrylic acid binary copolymer, a metal-neutralized product of the binary copolymer, an ethylene-(meth)acrylic acid-(meth)acrylic acid ester ternary copolymer, and a metal-neutralized product of the ternary copolymer, and (C) a fluidity improving agent.

Owner:SUMITOMO RUBBER IND LTD

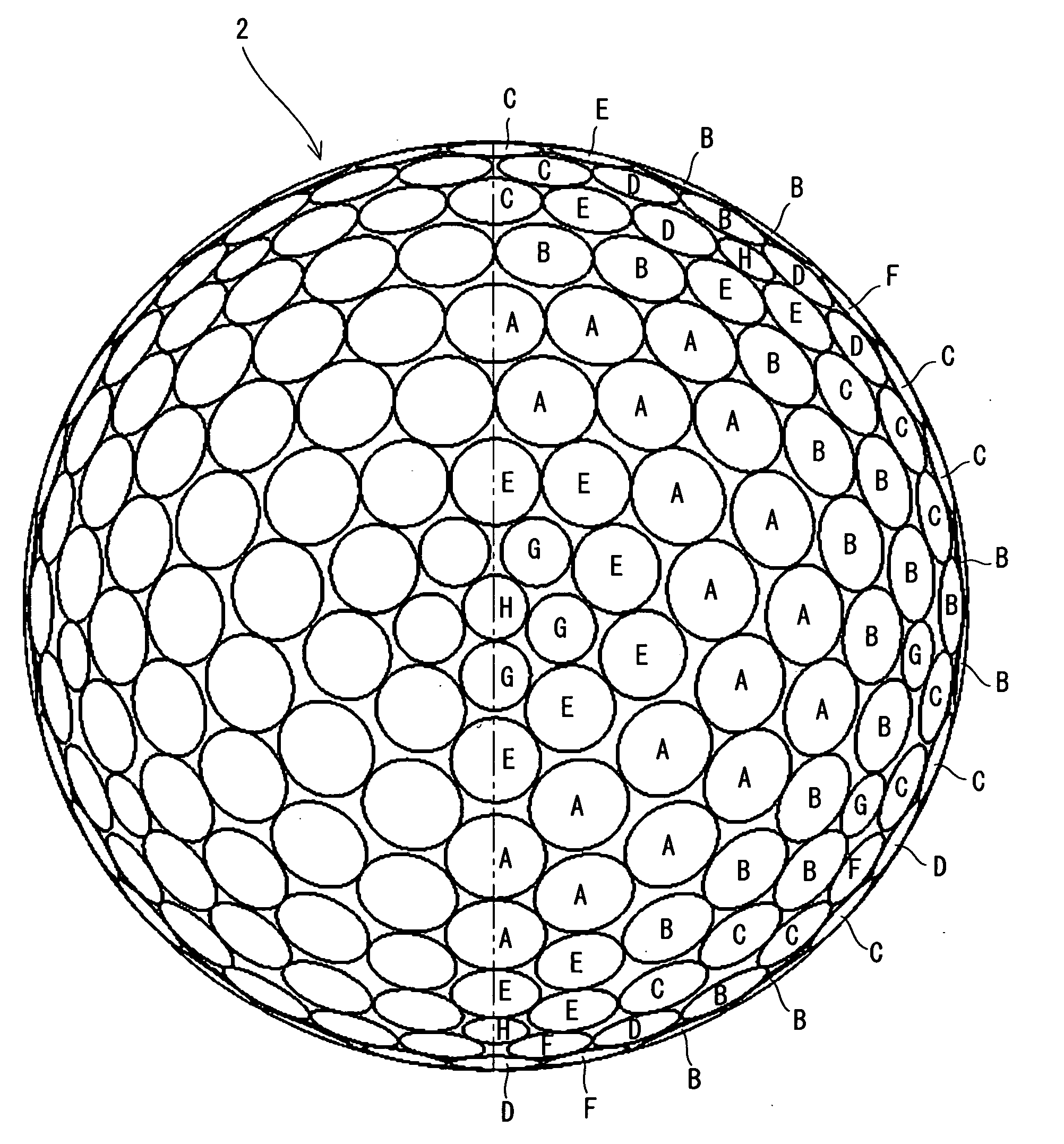

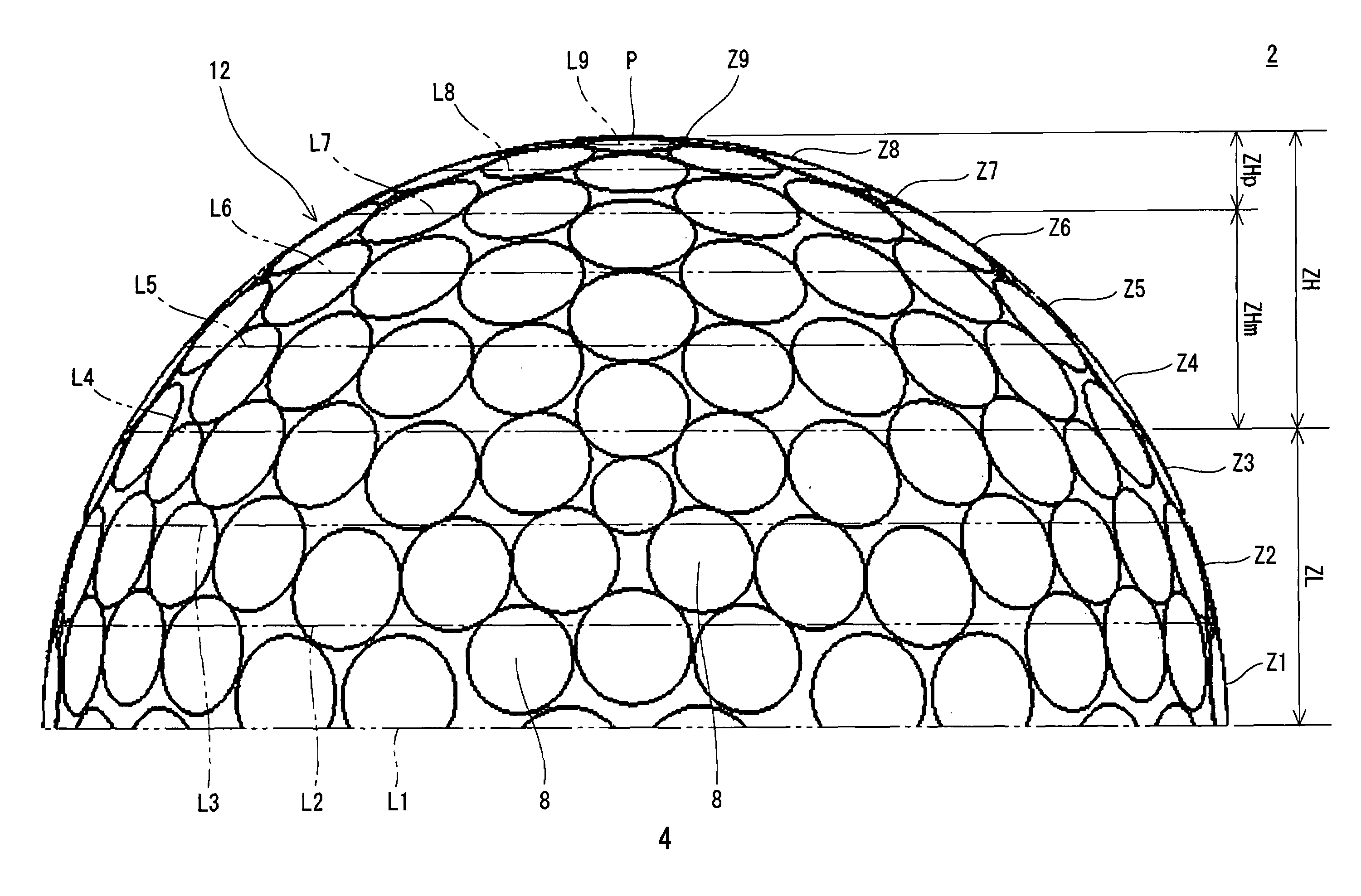

Golf ball

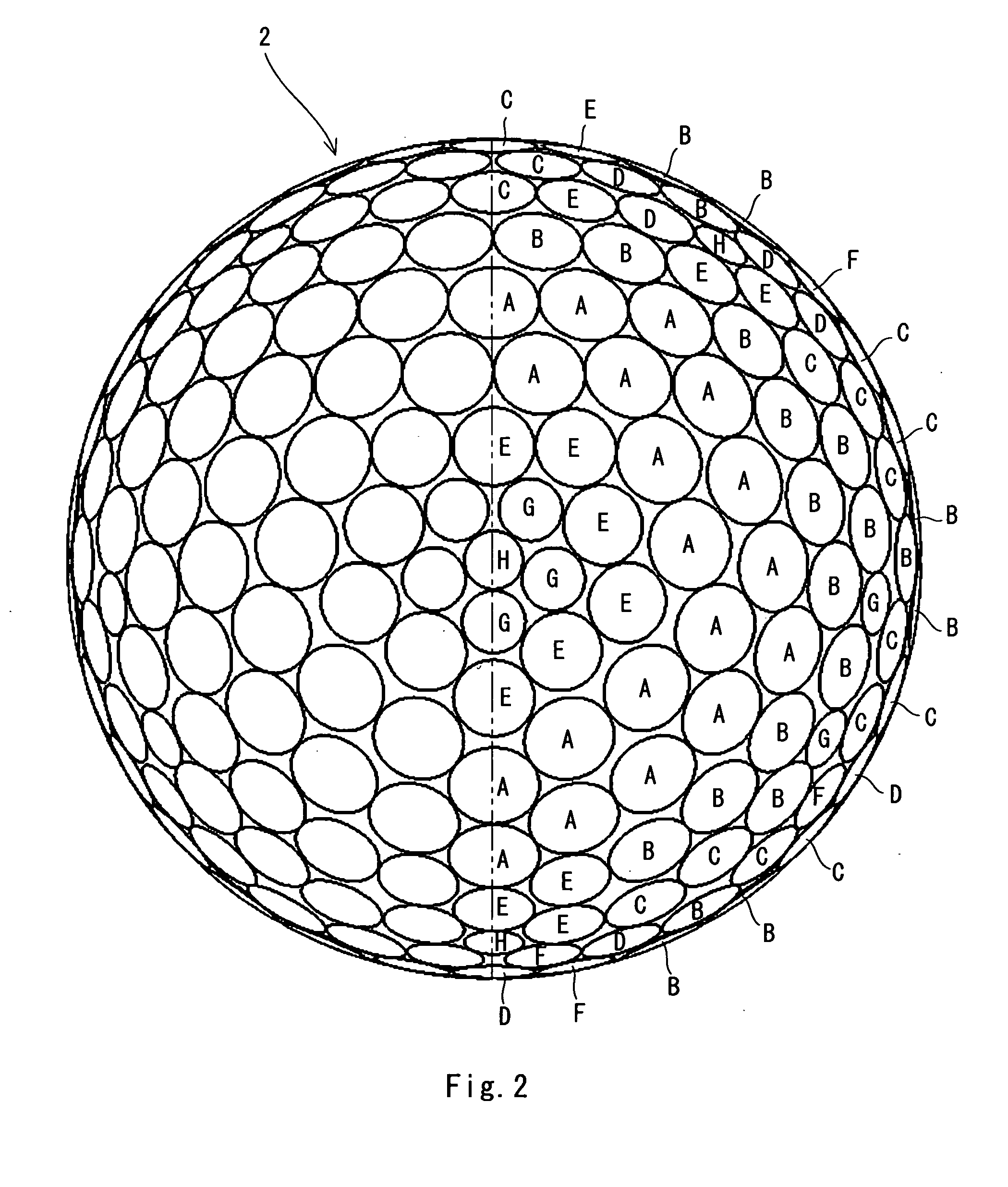

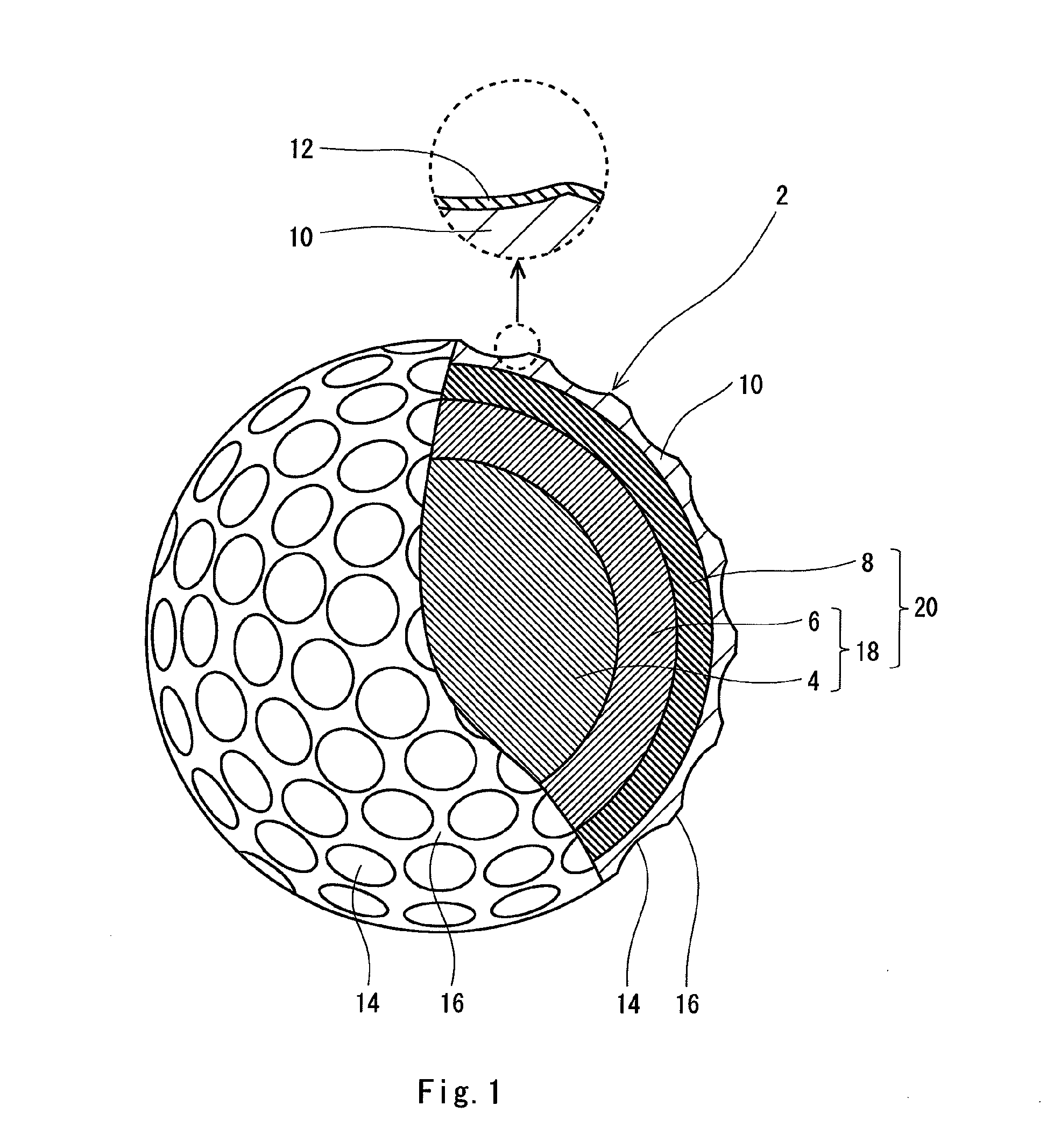

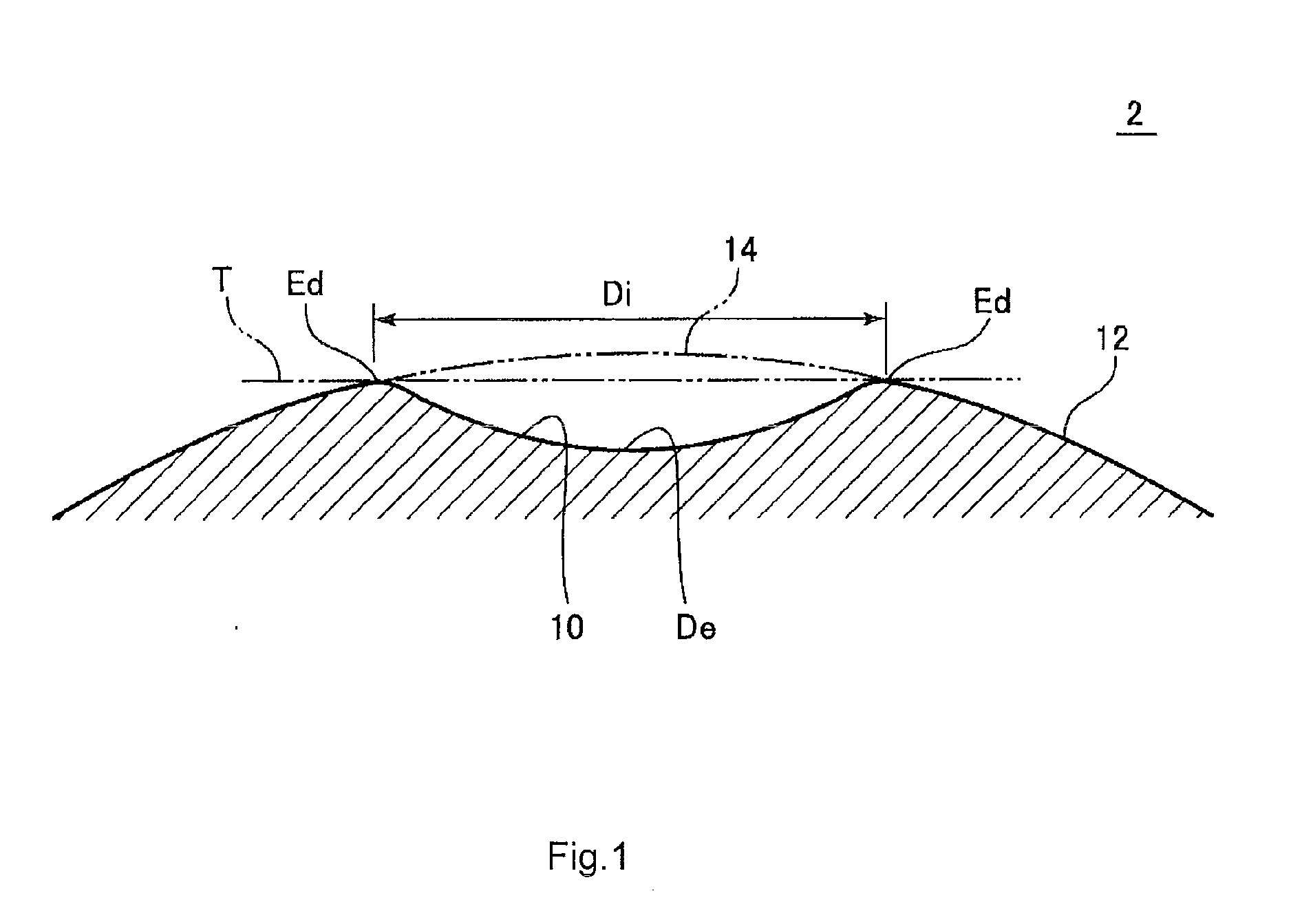

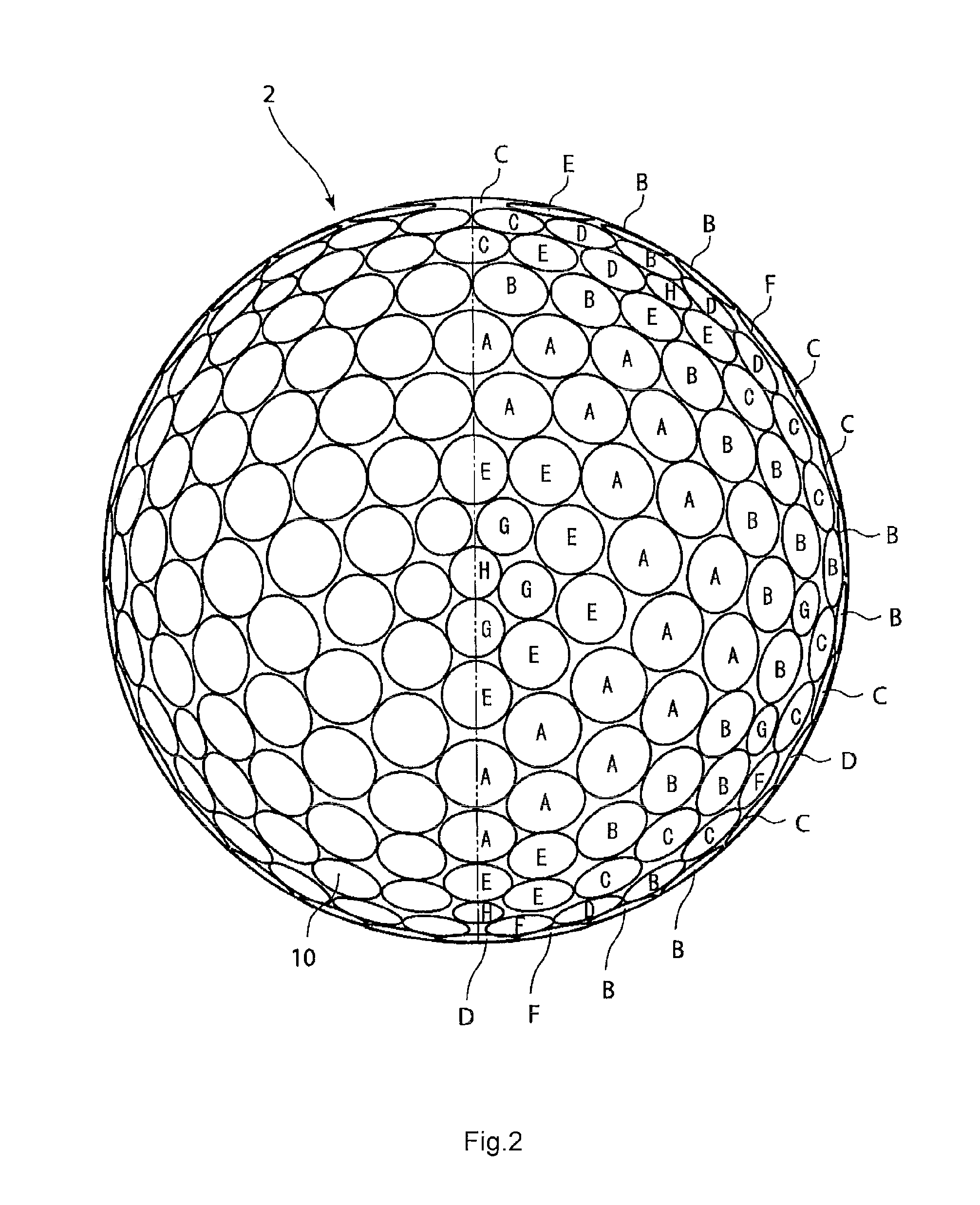

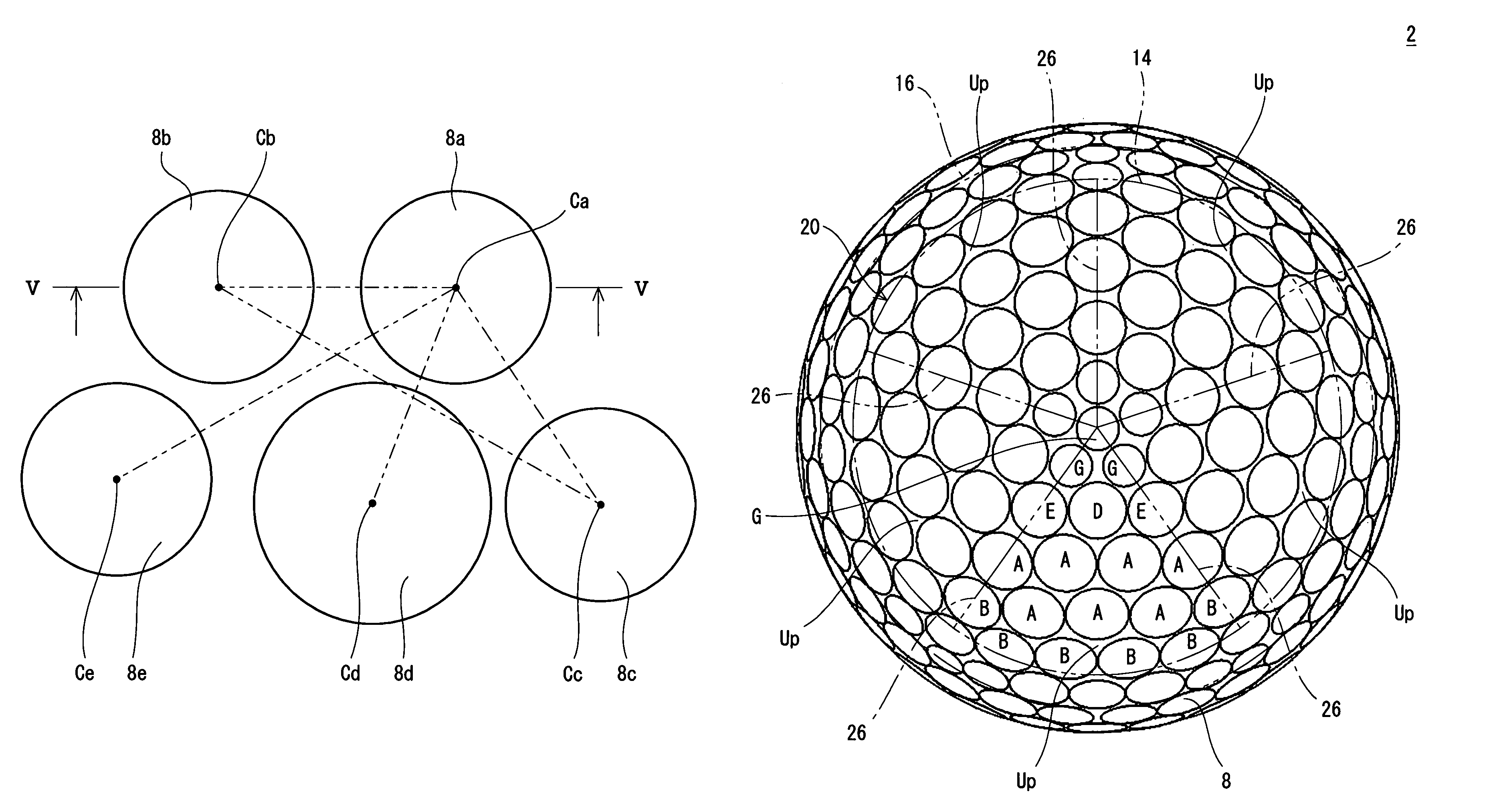

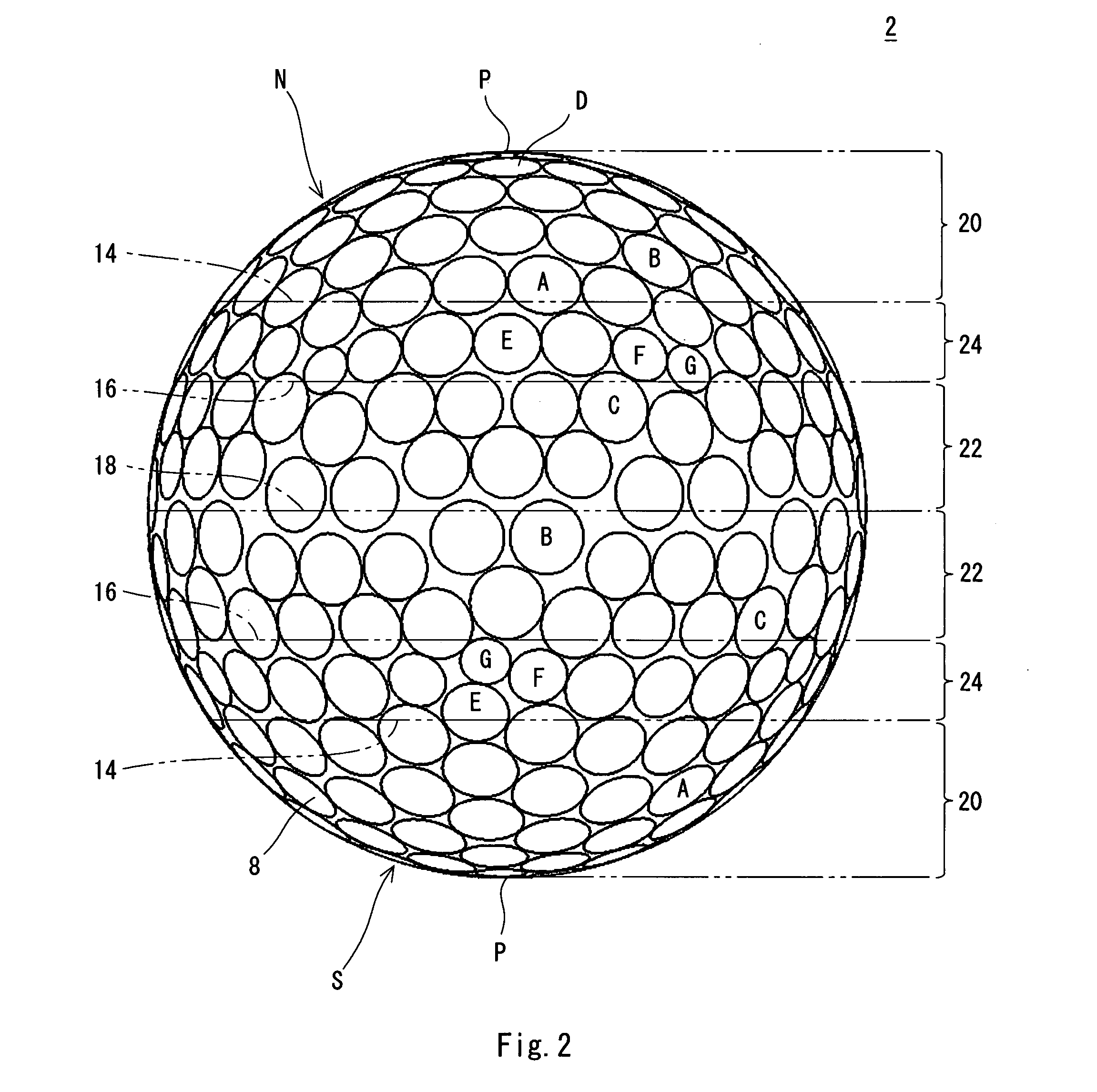

InactiveUS20070173354A1Promotes dimple effectExcellent in aerodynamic symmetryGolf ballsSolid ballsMiddle latitudesLow latitude

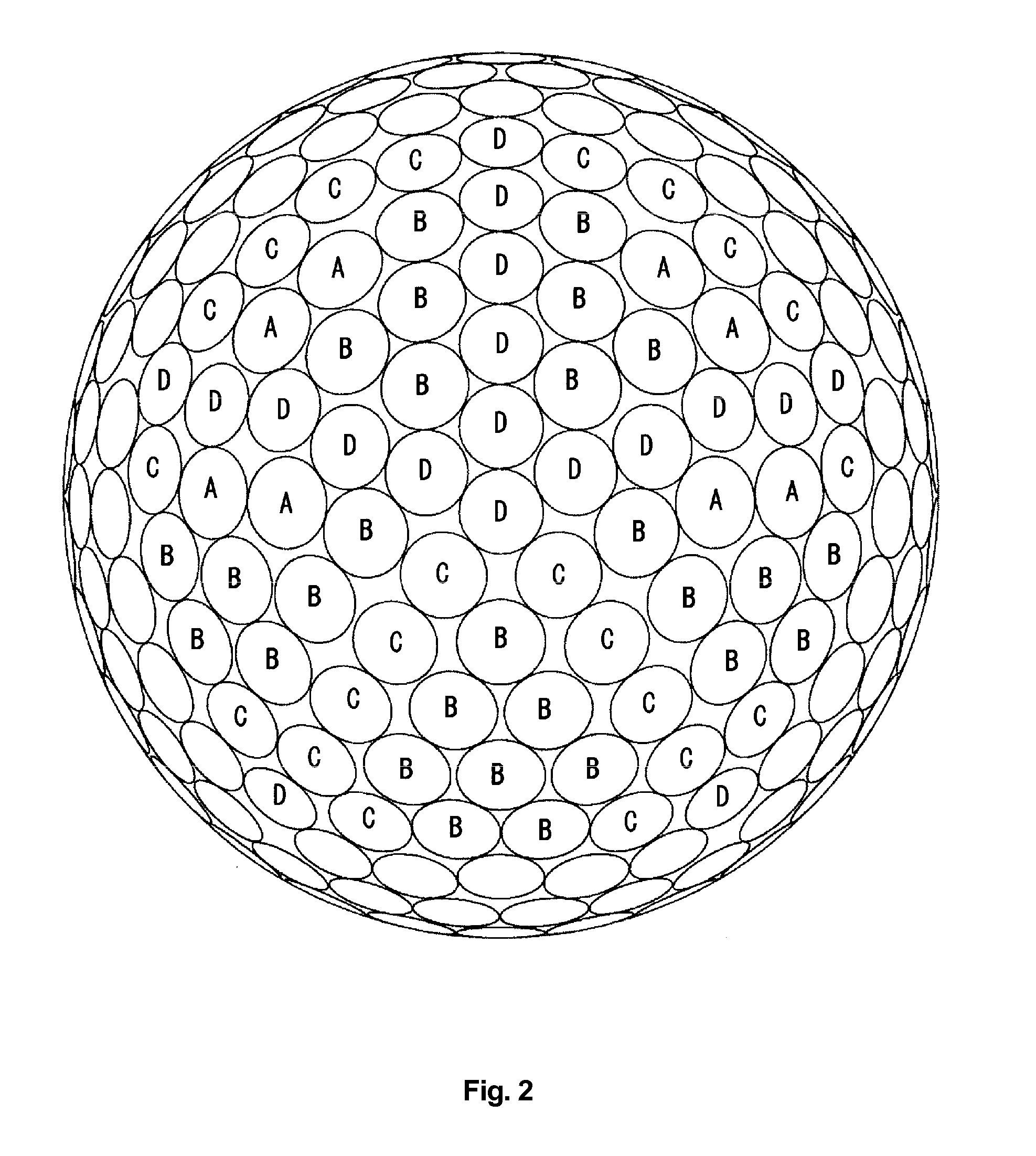

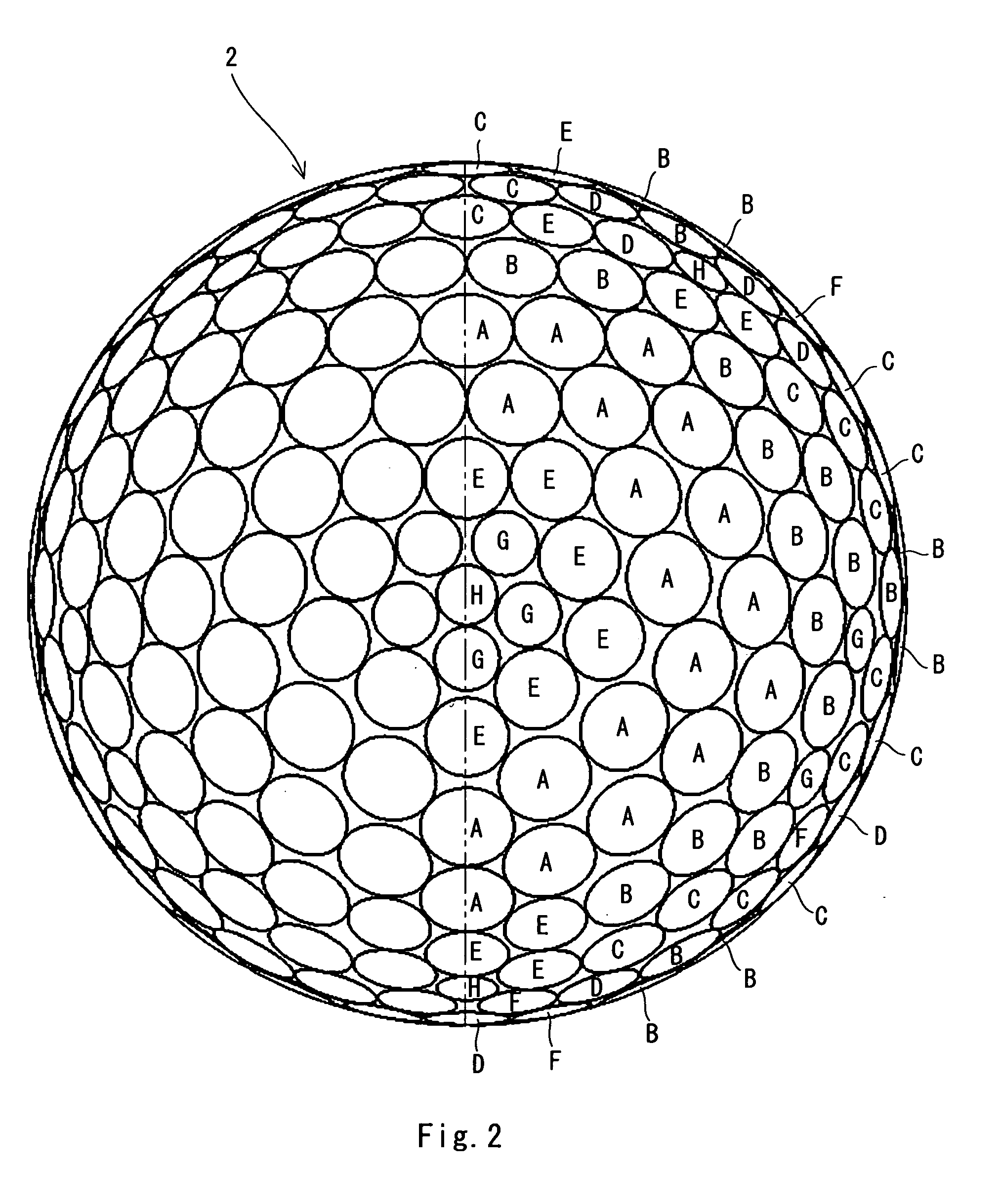

Golf ball 2 has three or more different kinds of dimples 8. The total number of the dimples 8 is 300 or more. A ratio Pn of the number of the dimples 8 with a diameter of equal to or greater than 3.40 mm to the total number is equal to or greater than 90%. The golf ball 2 meet the following formulae (I) and (II).NL−NH≧0 (I)NL>NHm≧NHp (II)NL represents the number of kinds of the dimples being located in a low latitude region ZL and having a diameter of equal to or greater than 3.40 mm, NH represents the number of kinds of the dimples being located in a high latitude region ZH and having a diameter of equal to or greater than 3.40 mm, NHm represents the number of kinds of the dimples being located in a middle latitude region ZHm and having a diameter of equal to or greater than 3.40 mm and NHp represents the number of kinds of the dimples being located in a polar region ZHp and having a diameter of equal to or greater than 3.40 mm.

Owner:SUMITOMO RUBBER IND LTD

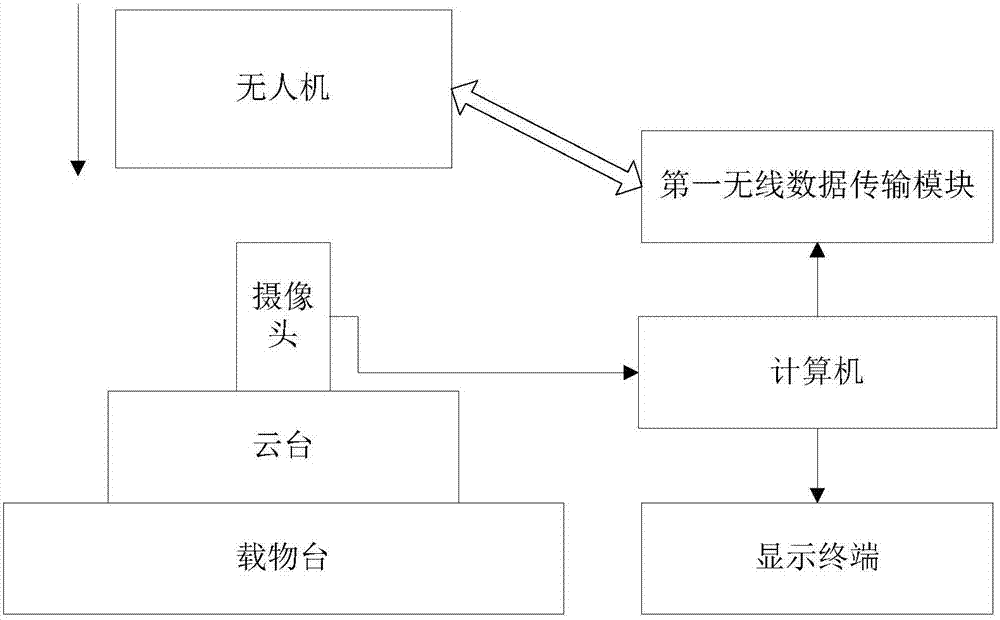

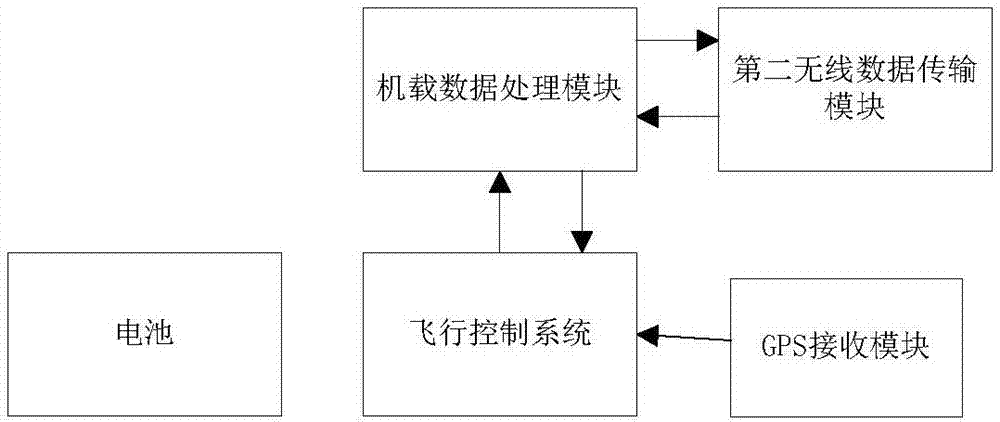

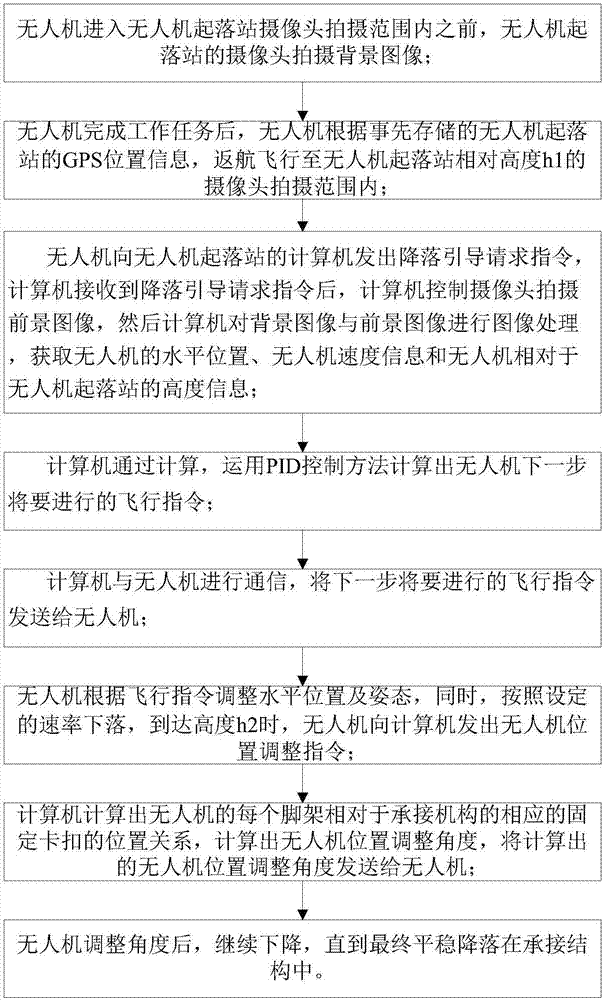

Unmanned aerial vehicle flight landing system and method based on image processing

ActiveCN106864751AFast recognitionFast falling speedAnchoring installationsLanding aidsCamera lensImaging processing

The invention discloses an unmanned aerial vehicle flight landing system and method based on image processing. The system comprises an unmanned aerial vehicle and an unmanned aerial vehicle take-off and landing station. The unmanned aerial vehicle take-off and landing station comprises a carrying table arranged on the ground. A precise positioning and fixing device assisting in landing of the unmanned aerial vehicle is mounted on the carrying table. A holder is mounted on the precise positioning and fixing device assisting in landing of the unmanned aerial vehicle. A camera is mounted on the holder, and a camera lens of the camera faces upward. The camera and the holder are both connected with a computer. The computer controls rotation of the holder to drive the camera to rotate, and accordingly the shooting direction of the camera is adjusted. The computer controls the camera to shoot pictures. The computer is in communication connection with the unmanned aerial vehicle through a first wireless data transmission module. The computer is further connected with a display terminal. The unmanned aerial vehicle flight landing system and method have the beneficial effect that an all-weather centimeter-level precise landing function of the multi-rotor unmanned aerial vehicle is achieved based on image processing by adoption of a multistratum PID control technology.

Owner:SHANDONG UNIV +1

Golf ball

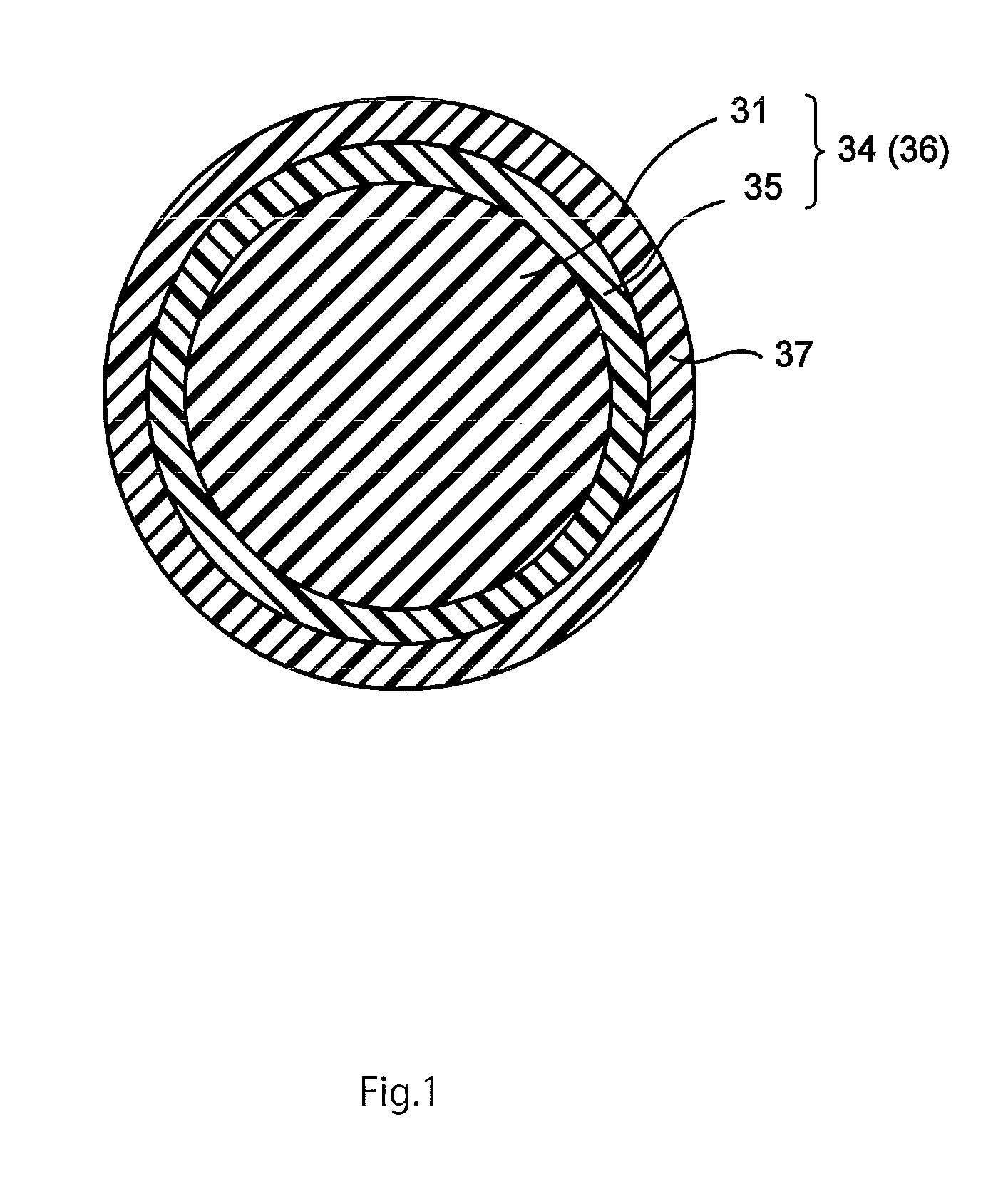

ActiveUS20110159999A1Appropriate hardness distributionLess energy lossGolf ballsSolid ballsMedicineGolf Ball

At all points Pa included in zone “A” away from the central point of the core 4 at a distance of 1 mm or greater and less than 5 mm, the following mathematical expression (I) is satisfied, and at any point Pb included in zone “B” away from the central point of the core 4 at a distance of 5 mm or greater and 10 mm or less, the following mathematical expression (II) is satisfied.Ha2−Ha1<5 (I)Hb2−Hb1≧5 (II)Ha1 represents the hardness at a point Pa1 that is located inside the point Pa along the radial direction and away from the point Pa at a distance of 1 mm, and Ha2 represents the hardness at a point Pa2 that is located outside the point Pa along the radial direction and away from the point Pa at a distance of 1 mm. Hb1 represents the hardness at a point Pb1 that is located inside the point Pb along the radial direction and away from the point Pb at a distance of 1 mm, and Hb2 represents the hardness at a point Pb2 that is located outside the point Pb along the radial direction and away from the point Pb at a distance of 1 mm.

Owner:SUMITOMO RUBBER IND LTD

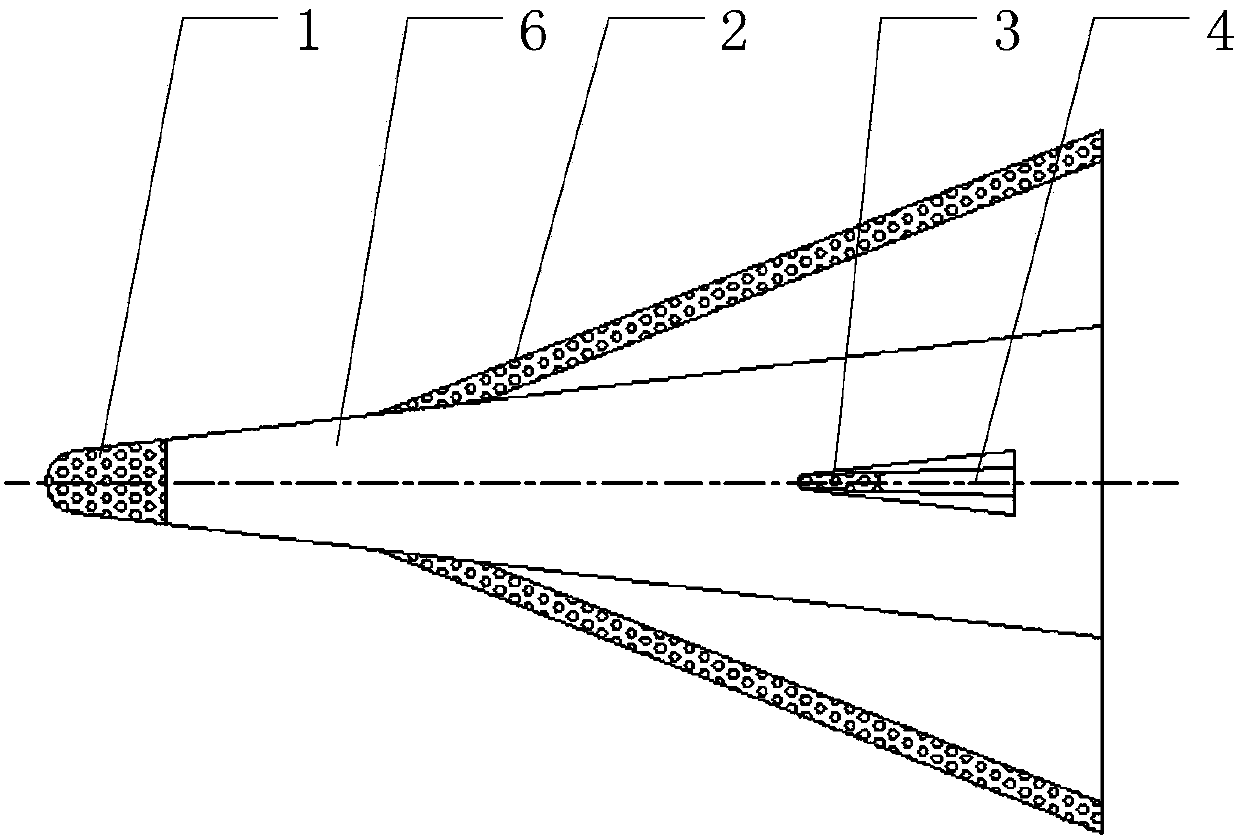

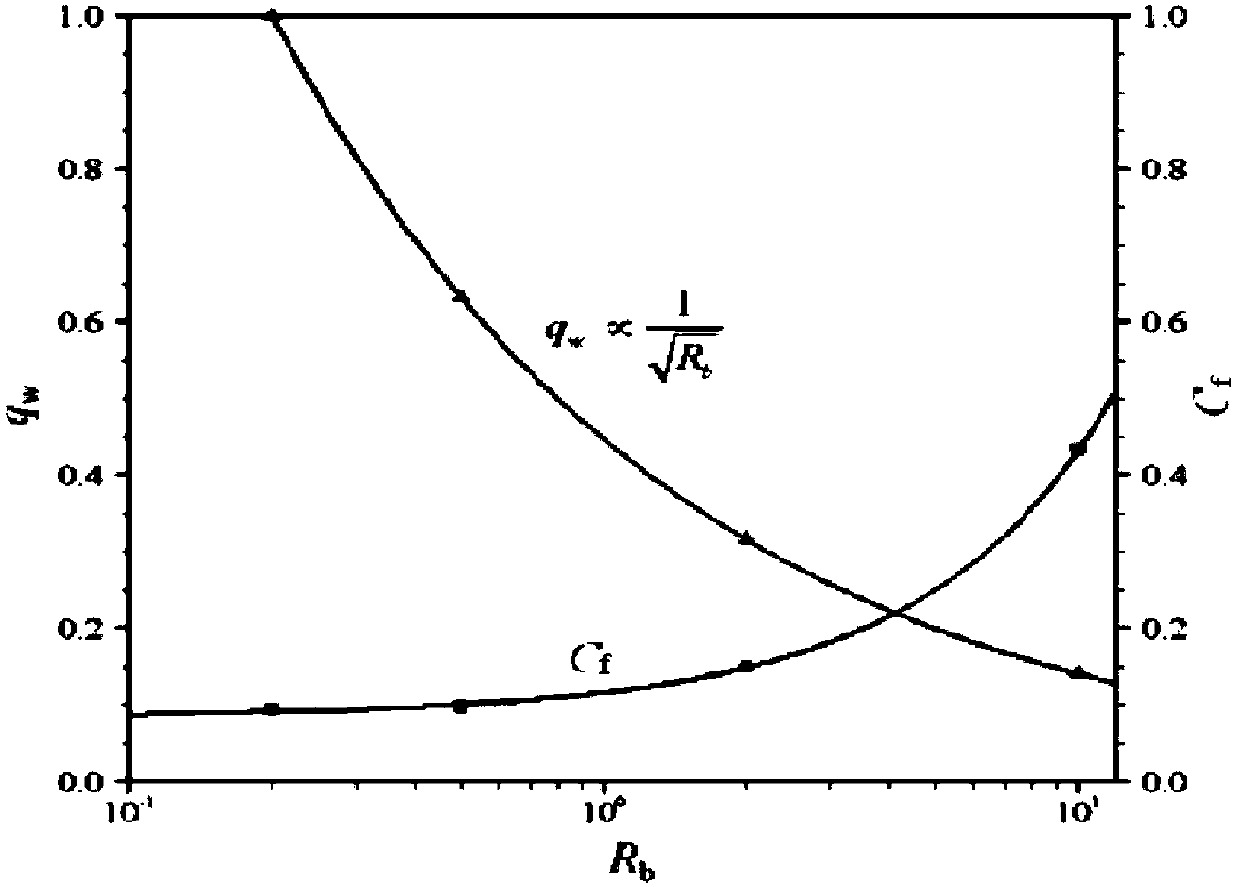

Full-active cooling hypersonic flight vehicle

ActiveCN107914862AAvoid thermal structural thermal matching problemsGuaranteed aerodynamic shapeBoundary layer controlsFuselage insulationFlight vehicleTranspiration

The invention discloses a full-active cooling hypersonic flight vehicle which comprises a transpiration cooling end, a transpiration cooling wing front edge, a transpiration cooling rudder front edge,a regenerative cooling rudder surface, a regenerative cooling windward side and a flight vehicle leeside, wherein porous structures are formed in the transpiration cooling end, the transpiration cooling wing front edge and the transpiration cooling rudder front edge, and the interiors of the porous structures are filled with liquid cooling media; the liquid cooling media can be supplied outwardsfrom the porous structures, flow through the porous structures to perform heat exchange, are heated and then flow out of the outer surface of the end in a gaseous form; and the regenerative cooling rudder surface and the regenerative cooling windward side are respectively used for cooling the rudder surface and the windward side of the flight vehicle in a regenerative cooling manner, and the liquid cooling media carried inside the flight vehicle are used for blocking, cooling and taking away pneumatic heating volume of the flight vehicle transferred into the flight vehicle in the hypersonic flight process, so that thermal protection requirements of the flight vehicle on high-speed, long-term and long-distance flight in the atmosphere are met.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

Golf ball

ActiveUS20140357406A1Enhance degreeHardness be lowGolf ballsSolid ballsSaturated carboxylic acidHeat press

A method for manufacturing a golf ball showing a great flight distance on driver shots for includes the steps of: preparing a rubber composition containing a base rubber, an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and / or a metal salt thereof as a co-crosslinking agent, a crosslinking initiator and a carboxylic acid and / or a salt thereof; heat pressing the rubber composition at a press temperature ranging from t-40° C. to t-15° C. to mold a spherical core, wherein t ° C. is a one-minute half-life temperature of the crosslinking initiator; and forming at least one cover layer covering the spherical core.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

An object of the present invention is to provide a golf ball traveling a great flight distance on driver shots. The present invention provides a golf ball comprising a spherical core and at least one cover layer covering the spherical core, wherein the spherical core is formed from a rubber composition containing (a) base rubber, (b) an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and / or a metal salt thereof as a co-crosslinking agent, (c) a crosslinking initiator, (d) a carboxylic acid having 1 to 14 carbon atoms and / or a salt thereof, and (e) a halogen-substituted thiophenol and / or a metal salt thereof as an organic sulfur compound, provided that the rubber composition further contains (f) a metal compound in the case of containing only (b) the α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms as the co-crosslinking agent.

Owner:SUMITOMO RUBBER IND LTD

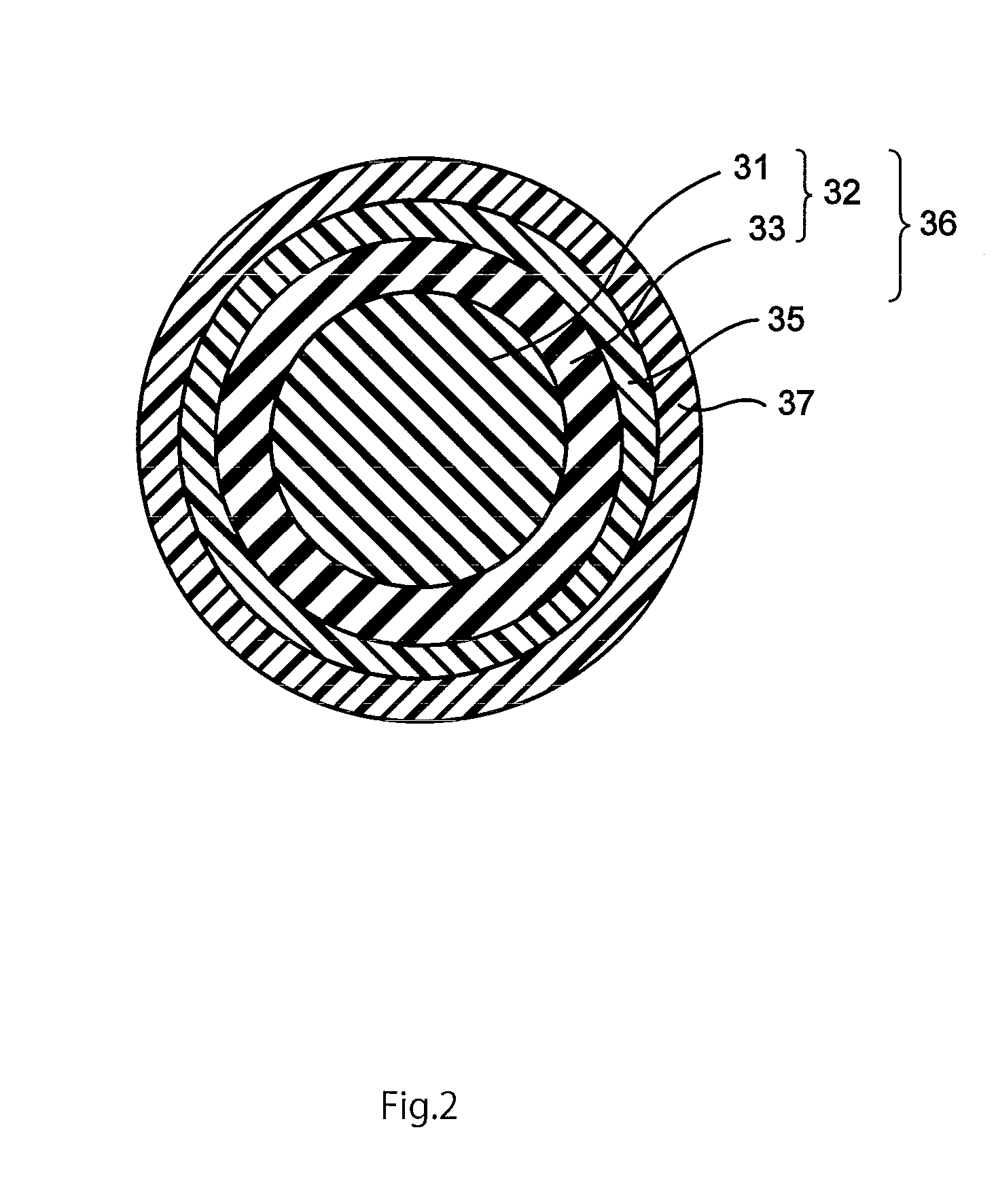

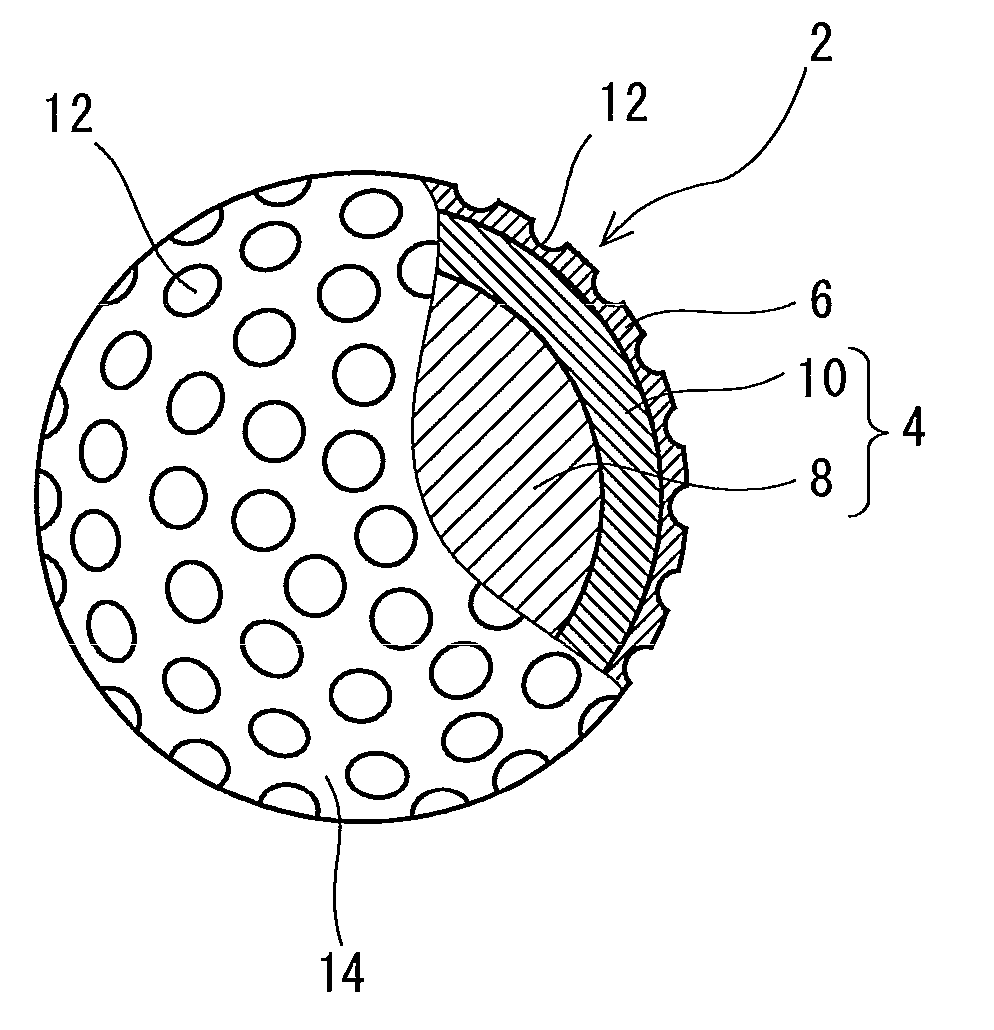

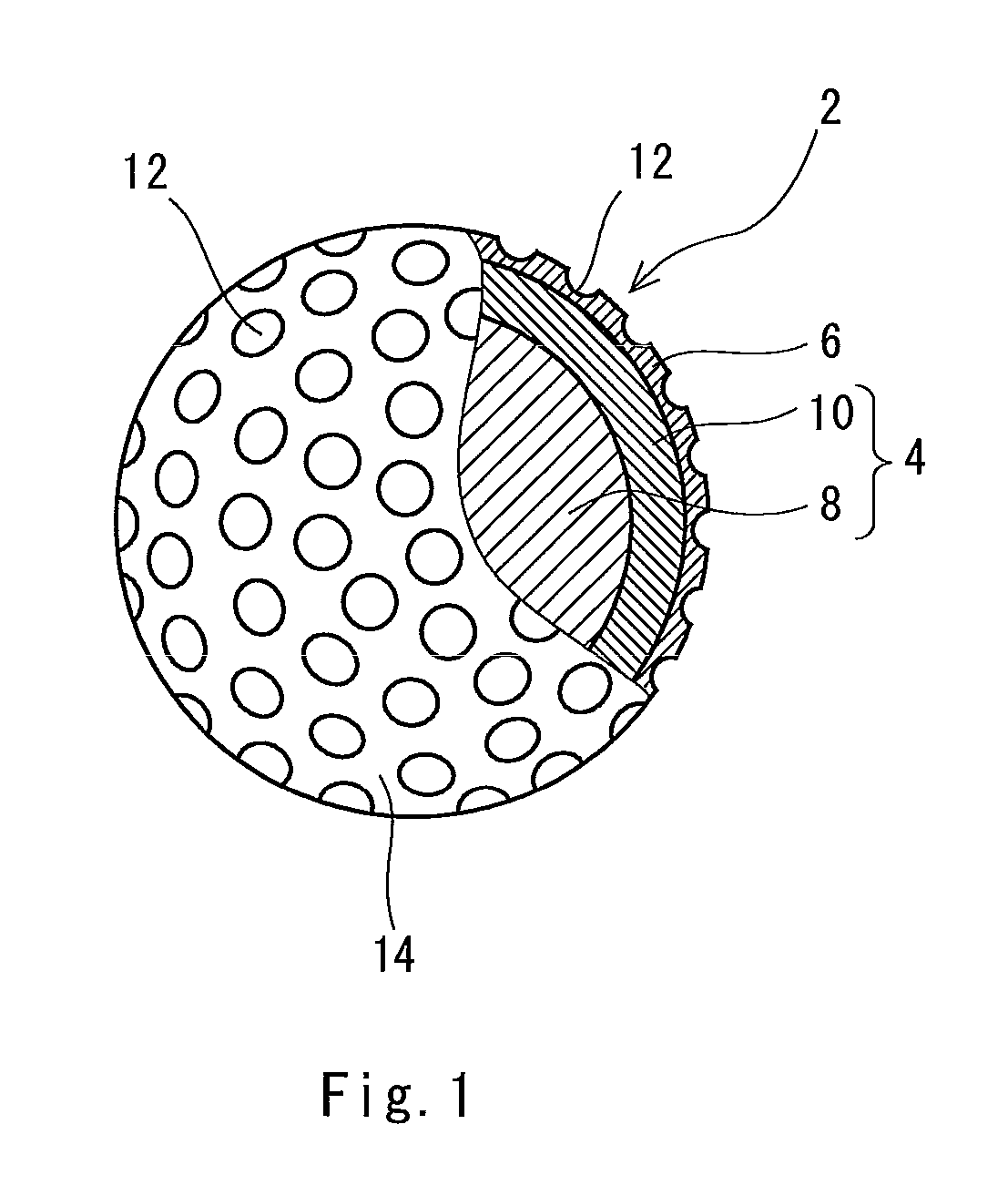

Golf ball

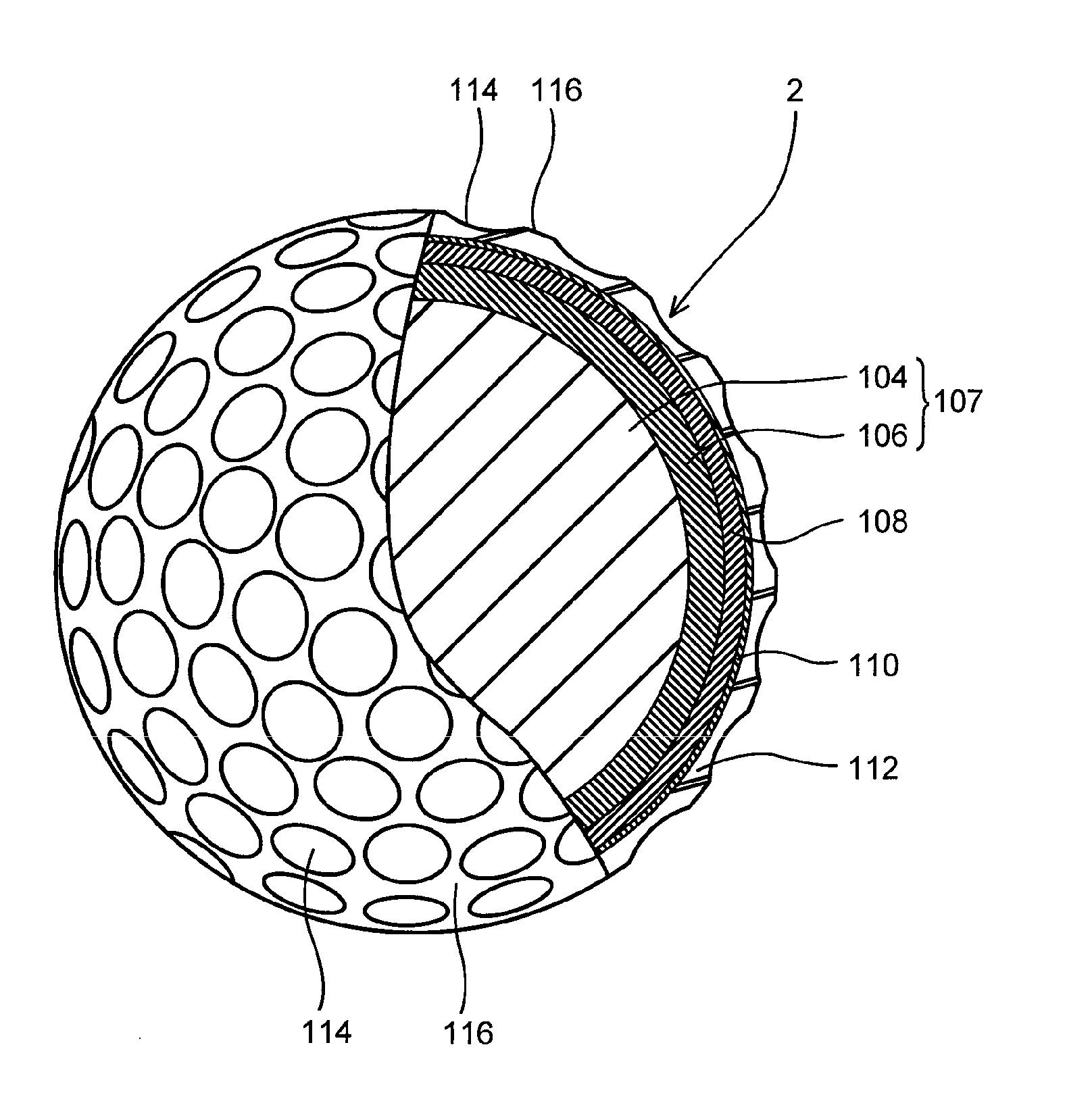

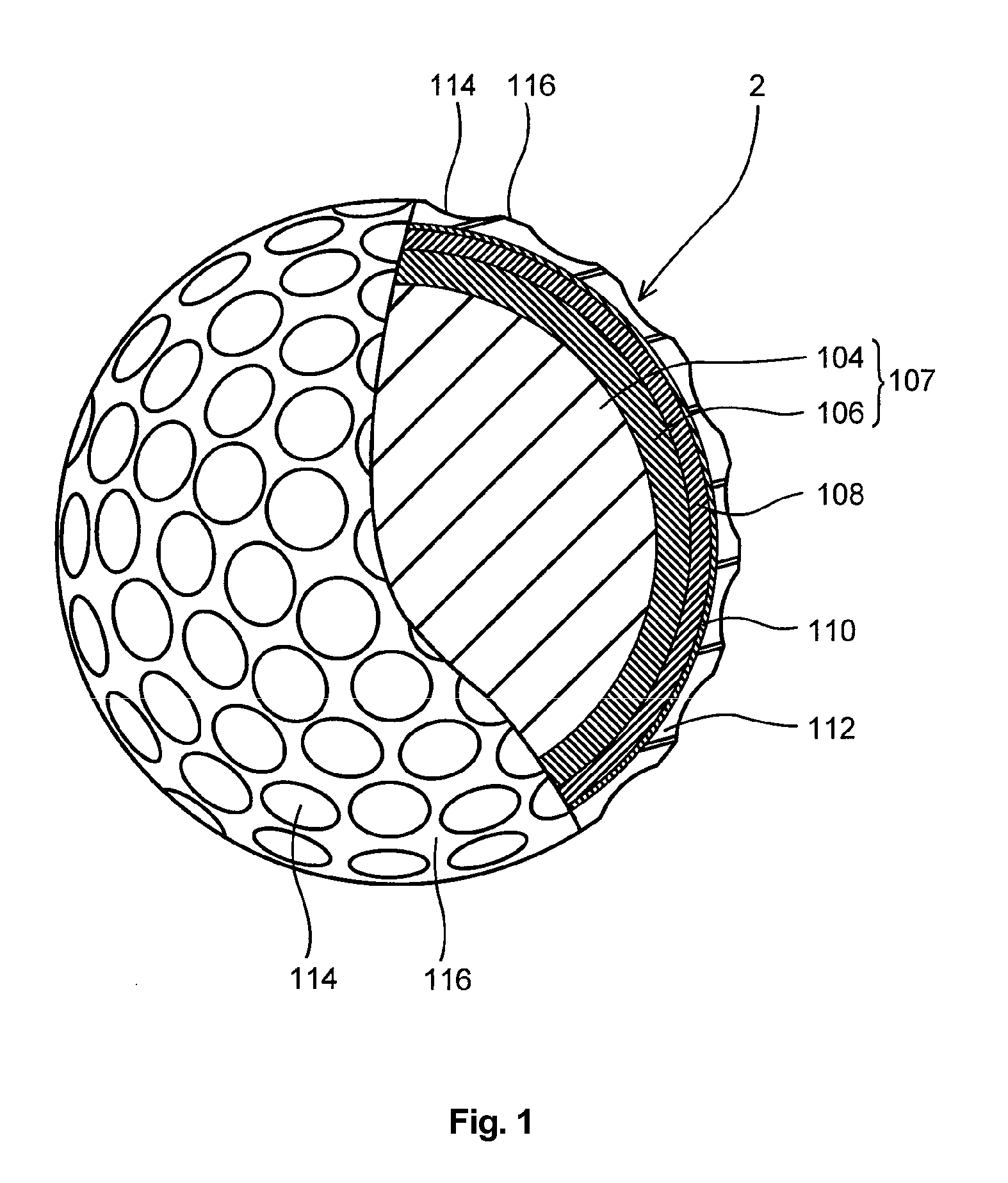

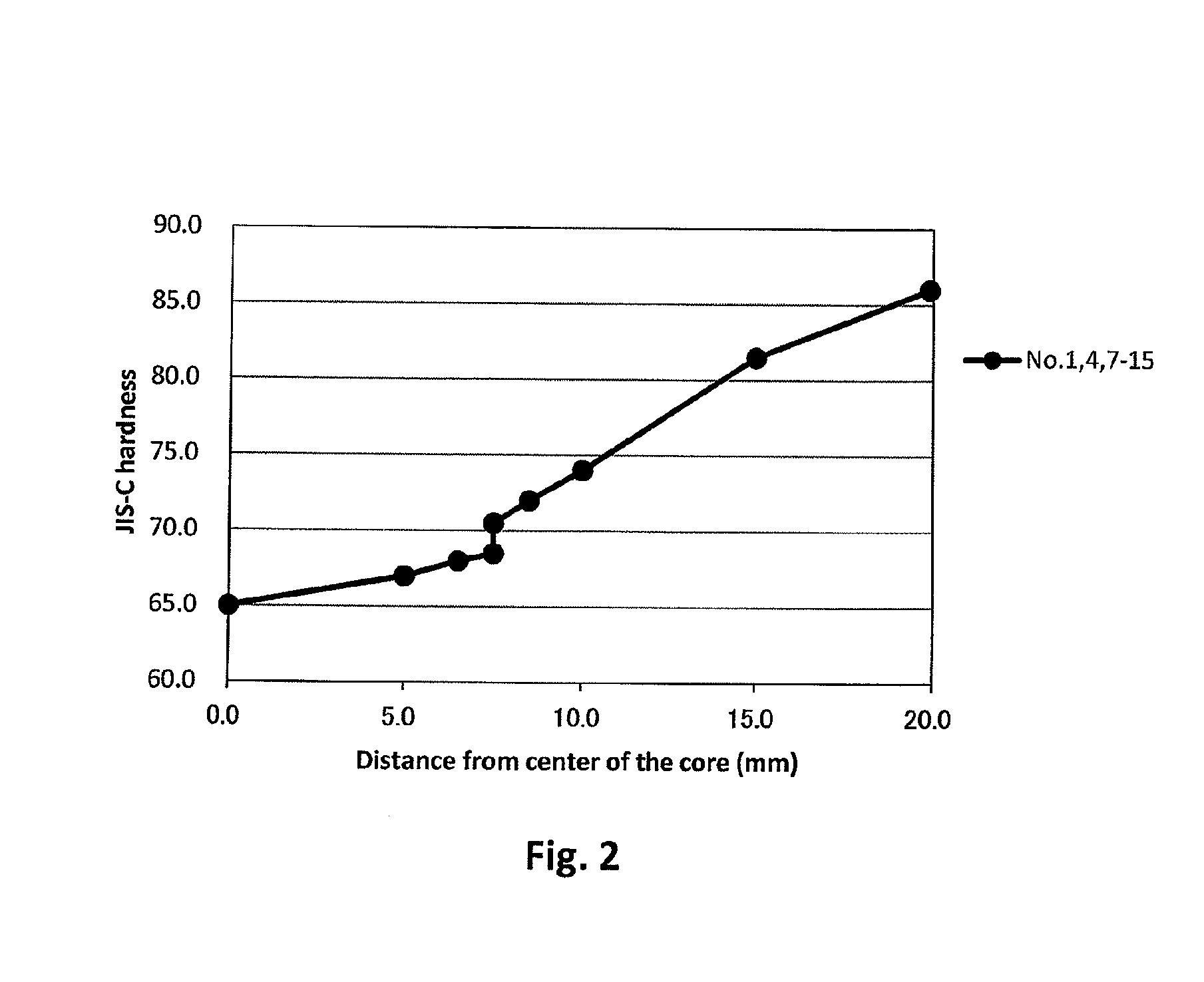

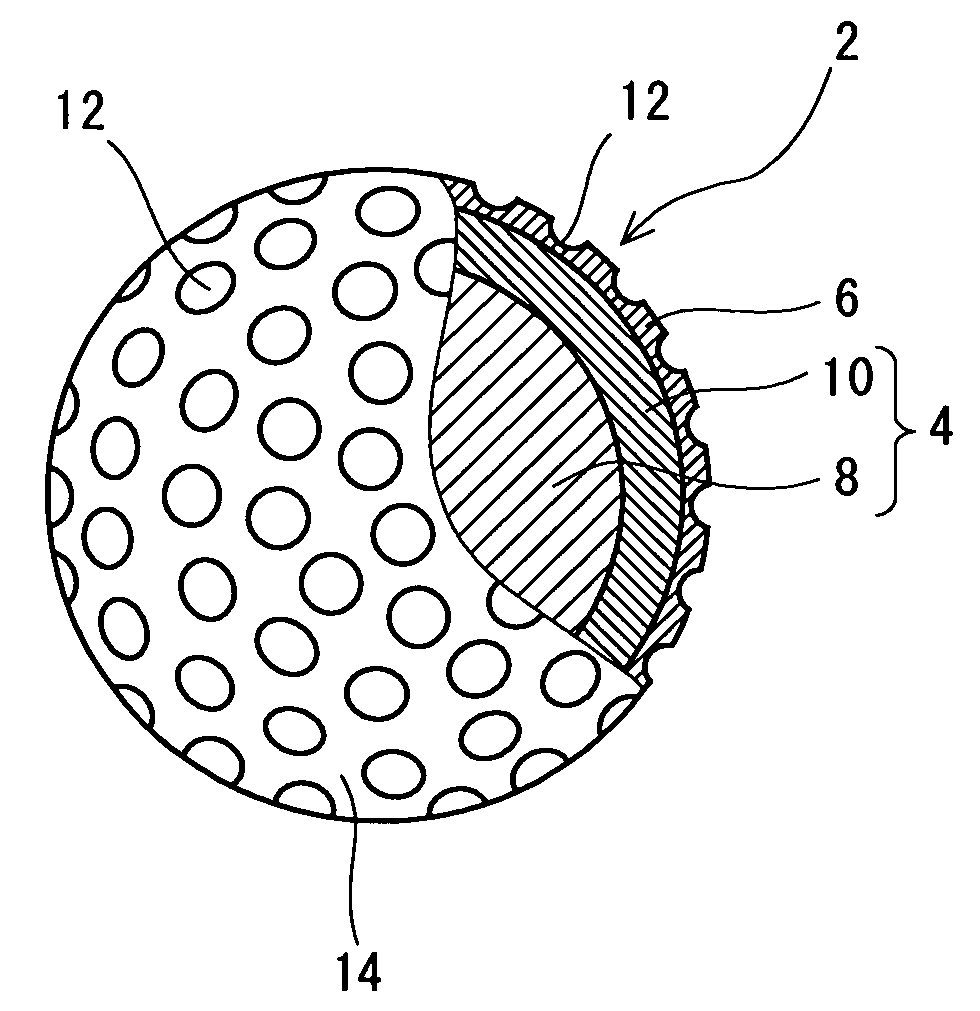

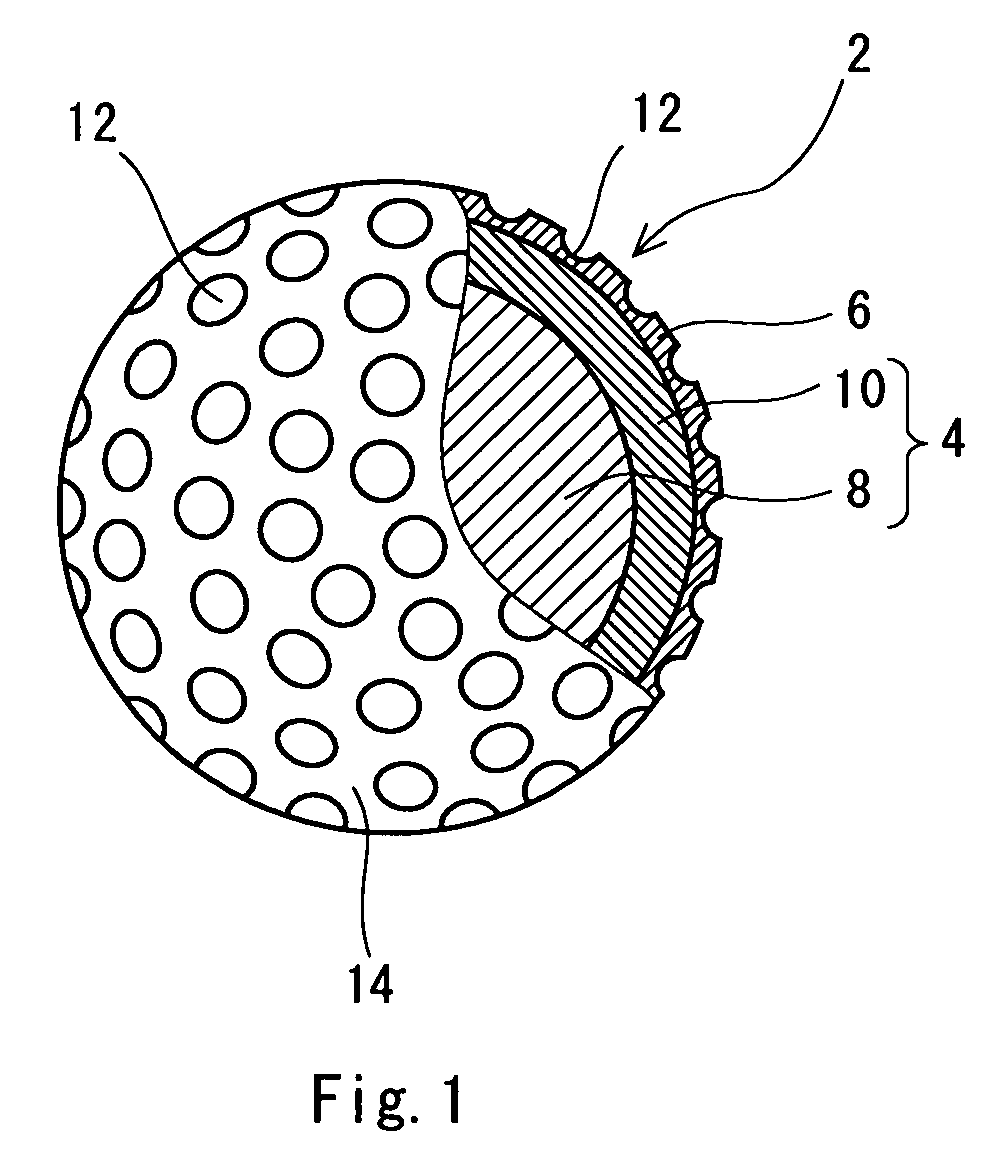

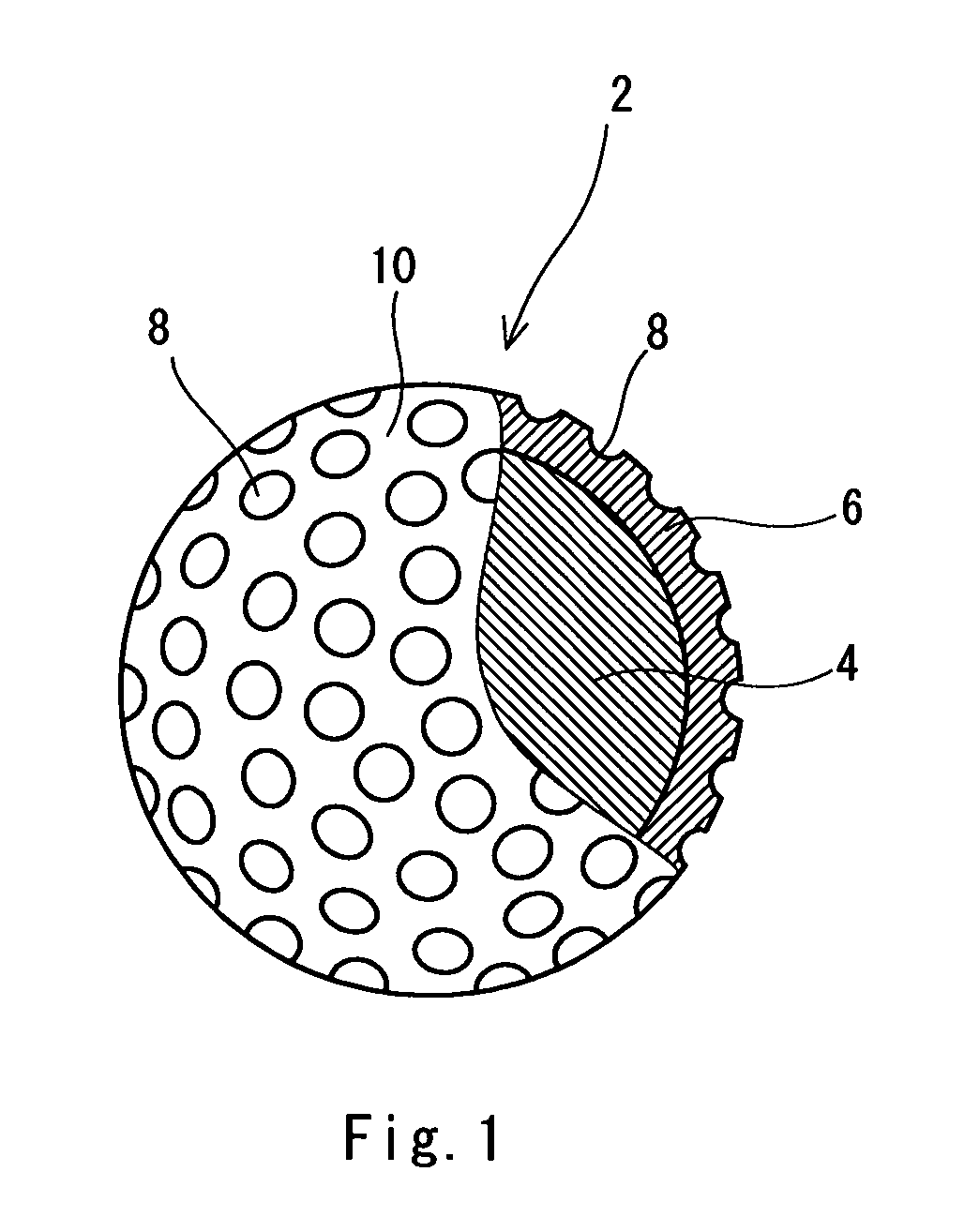

Golf ball 2 has spherical core 4, surrounding layer 6 situated on the external side of the core 4, mid layer 8 situated on the external side of the surrounding layer 6, cover 10 situated on the external side of the mid layer 8, and paint layer 12 situated on the external side of the cover 10. The mid layer 8 has a thickness Tm of 0.1 mm or greater and 1.2 mm or less. The ratio (Tc / Tm) of the thickness Tc of the cover 10 to the thickness Tm of the mid layer 8 is no greater than 0.50. The cover 10 has a Shore D hardness Hc of no greater than 35. The Shore D hardness Hm of the mid layer 8 is greater than the Shore D hardness Hc of the cover 10. The base material of the surrounding layer 6 is an ionomer resin. The base material of the mid layer 8 is a polyurethane. The base material of the cover 10 is a polyurethane.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

ActiveUS20100167840A1Increase elasticityImproved low temperature durabilityFibre treatmentSynthetic resin layered productsMeth-Flexural modulus

An object of the invention is to provide a golf ball excellent in the durability at the normal and low temperatures, flight distance, direction stability and shot feeling on the shots. The present invention provides a golf ball comprising: a core consisting of a center having a diameter of 35 mm or less and a surrounding layer covering the center; at least one intermediate layer covering the core, said intermediate layer having a thickness ranging from 0.5 mm to 1.2 mm and a density of 1.10 g / cm3 or more; and a cover covering the intermediate layer and having a thickness ranging from 0.3 mm to 1.0 mm, wherein the cover is formed of a cover composition that has a slab hardness ranging from 65 to 75 in Shore D hardness and contains as a resin component; (A) a polyamide resin composition having a flexural modulus in a range from 700 MPa to 4,000 MPa and a melt flow rate (240° C., 2.16 kg) of 5.0 g / 10 min or more; (B) at least one member selected from the group consisting of an ethylene-(meth)acrylic acid binary copolymer, a metal-neutralized product of the binary copolymer, an ethylene-(meth)acrylic acid-(meth)acrylic acid ester ternary copolymer, and a metal-neutralized product of the ternary copolymer; and (C) a fluidity improving agent.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

Golf ball wherein, at all points Pa included in zone "A" away from the central point of its core at a distance of >=1 mm and <5 mm, this mathematical expression is satisfied: Ha2-Ha1<5, wherein Ha1 and Ha2 each represents hardness at a point located respectively inside a point Pa and outside the point Pa. Also, at any point Pb included in zone "B" away from the central point of its core at a distance of >=5 mm and @10 mm, this mathematical expression is satisfied: Hb2-Hb1>=5, wherein Hb1 and Hb2 each represents hardness at a point located respectively inside a point Pb and outside the point Pb. This hardness distribution provides a golf ball with reduced energy loss when hit with a driver, and with excellent control performance when hit with a short iron.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

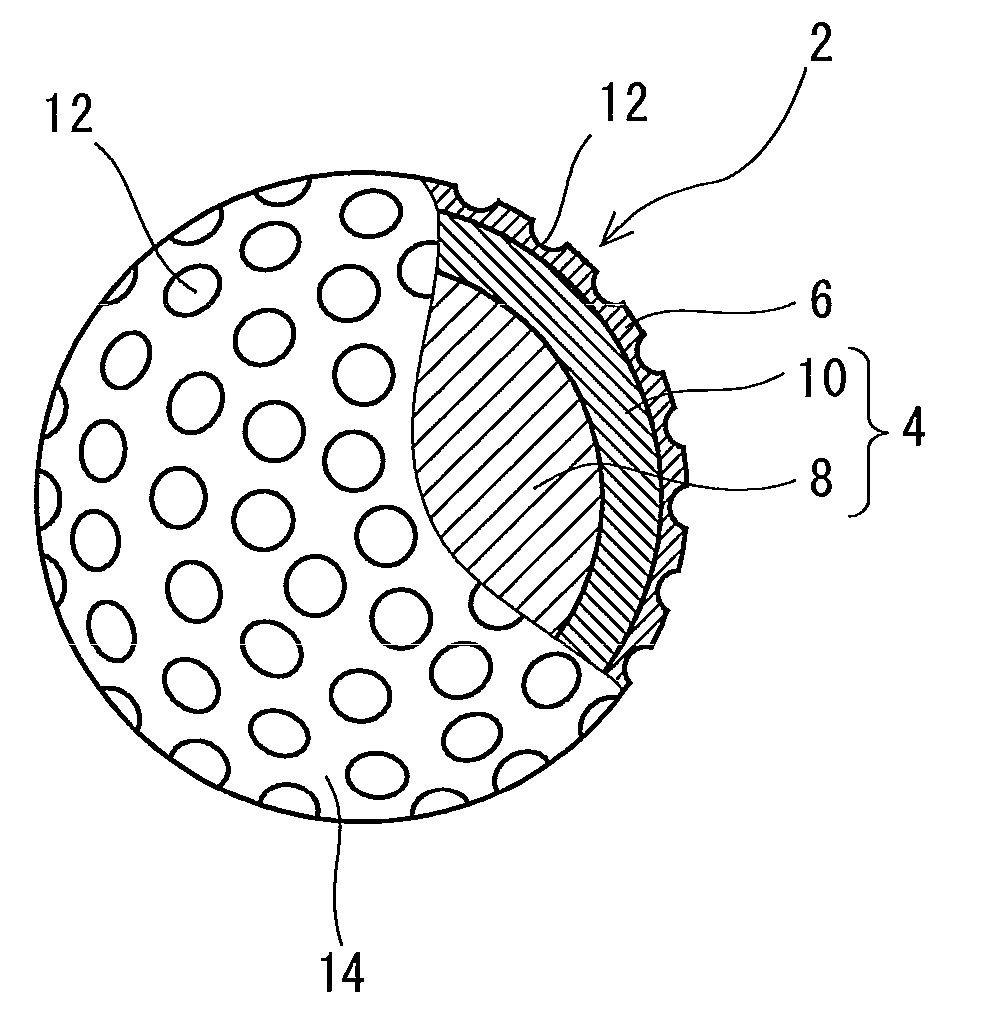

InactiveUS7648427B2Excellent in flight performance and feel at impactSuppresses the spin caused upon shotsGolf ballsSolid ballsThermoplastic elastomerEngineering

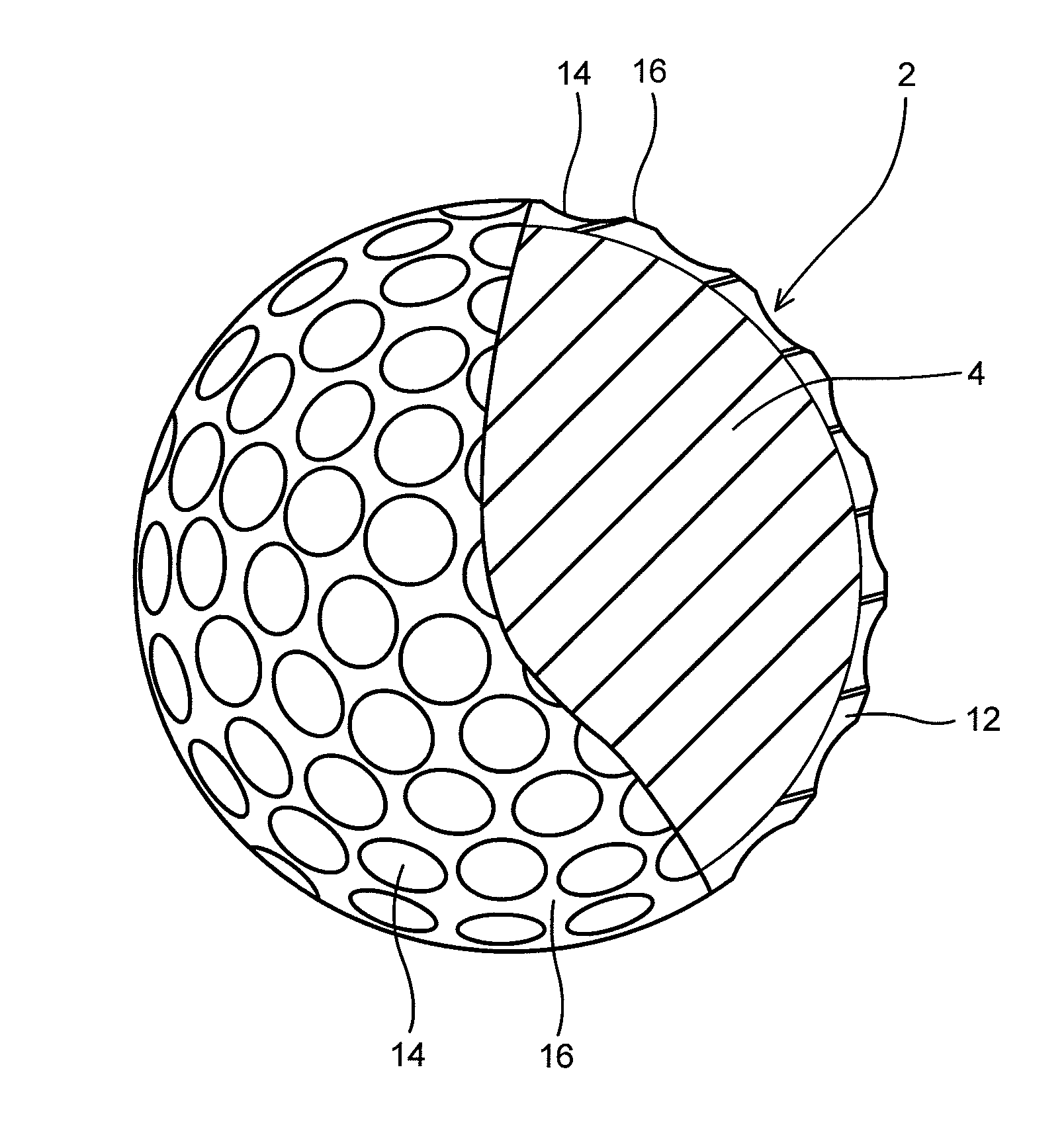

Golf ball 2 has spherical core 4, and cover 6 provided so as to cover this core 4. The core 4 has spherical center 8, and mid layer 10 provided so as to cover this center 8. The center 8 is constituted with a styrene block-containing thermoplastic elastomer. The mid layer 10 is obtained by crosslinking a rubber composition. The cover 6 is constituted with a resin composition. The center 8 has a diameter of 18 mm or greater and 35 mm or less. The center 8 has a hardness H1 of equal to or less than 25. The center 8 has an amount of compressive deformation of 5.0 mm or greater and 10.0 mm or less, as measured with the initial load of 1 kgf and the final load of 10 kgf. The difference (H2−H1) between the surface hardness H2 of the core 4 and the hardness H1 of the center 8 is 25 or greater and 60 or less. The difference (H3−H1) between the hardness H3 of the cover 6 and the hardness H1 of the center 8 is 40 or greater and 65 or less.

Owner:SUMITOMO RUBBER IND LTD

Wind-tracking twin-turbine system

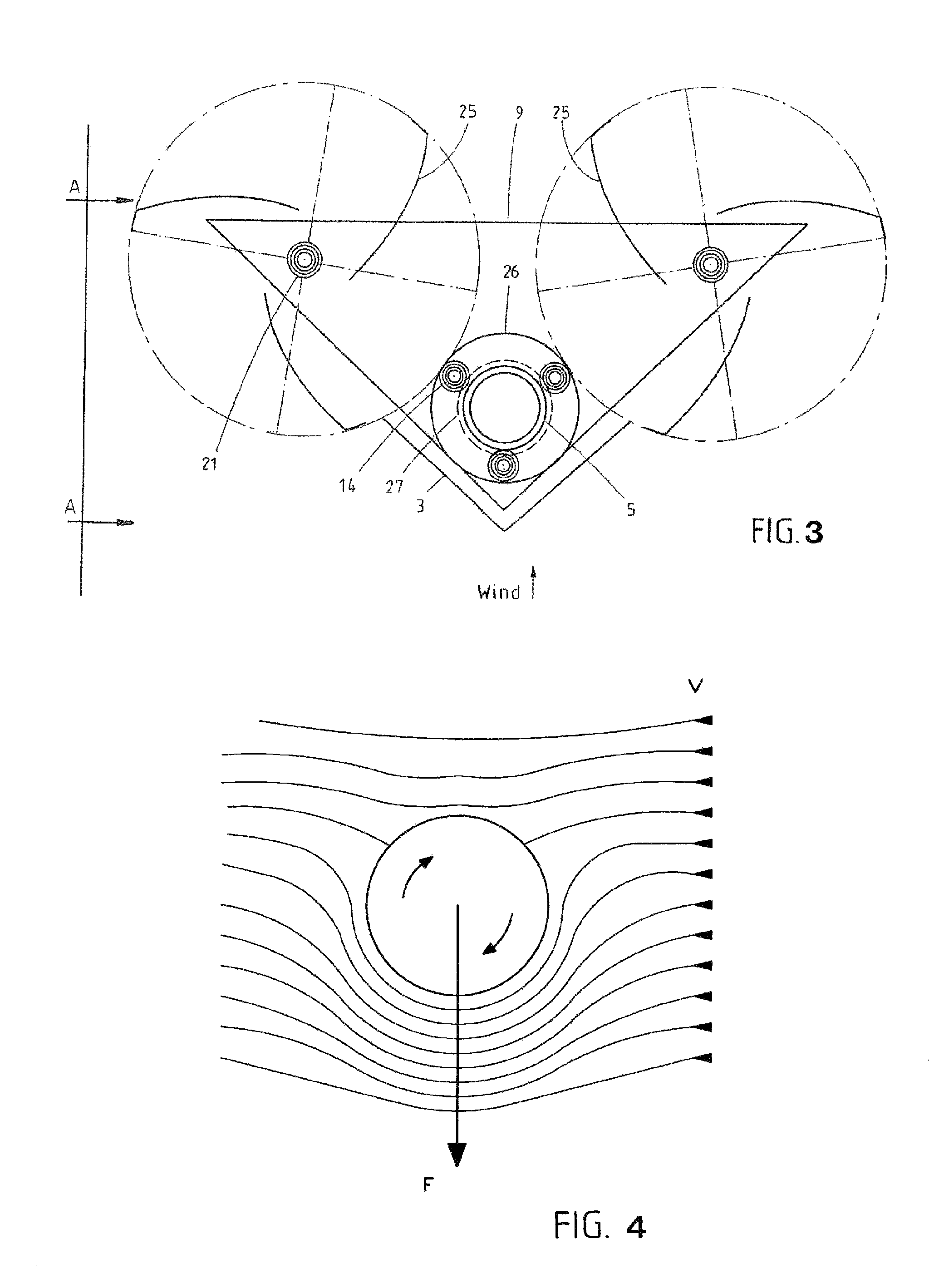

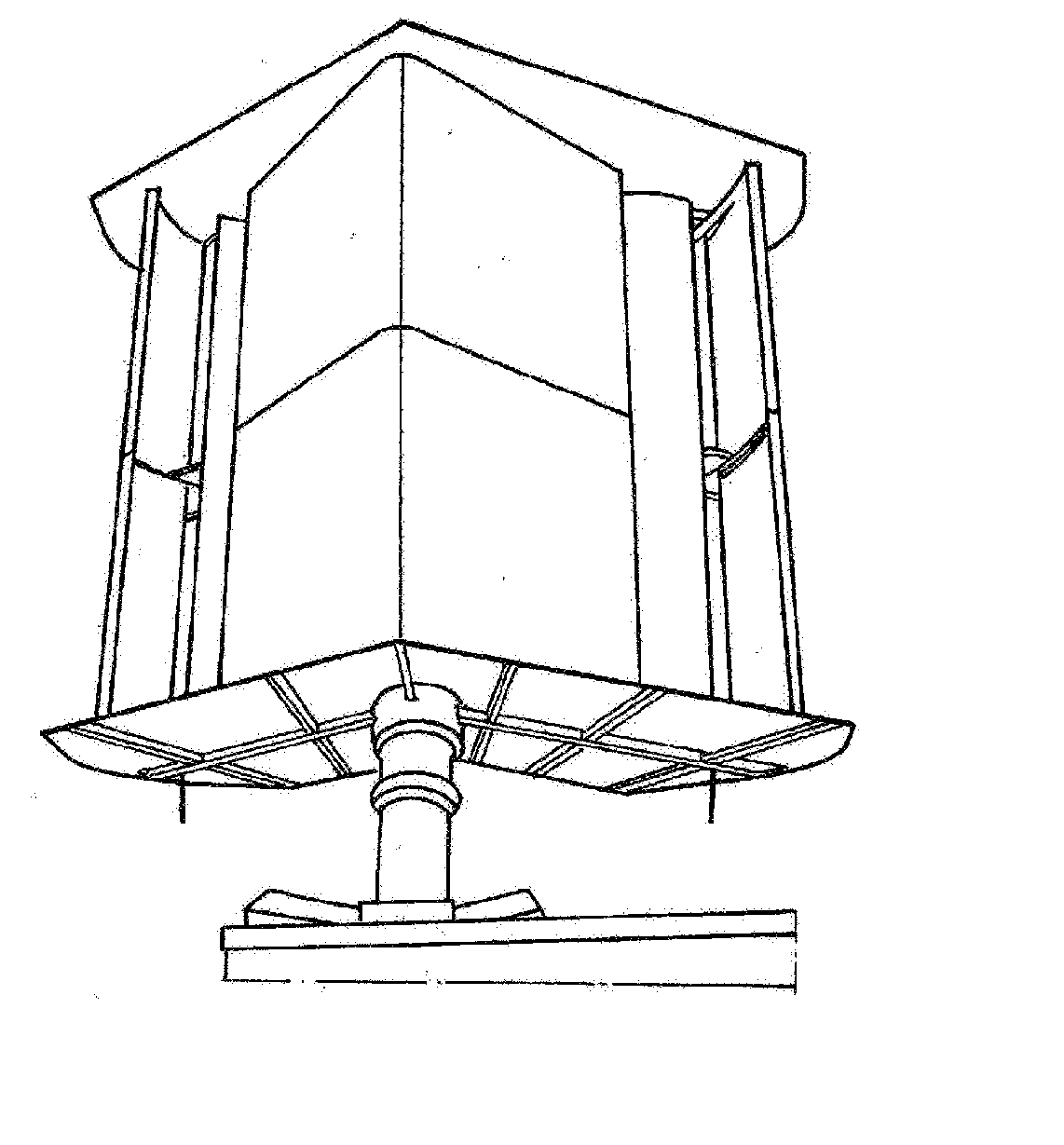

ActiveUS8946923B2Improve adhesionReduce air resistanceWorking fluid for enginesMachines/enginesTurbineRadial turbine

Owner:DIRECTTECH GLOBAL GMBH

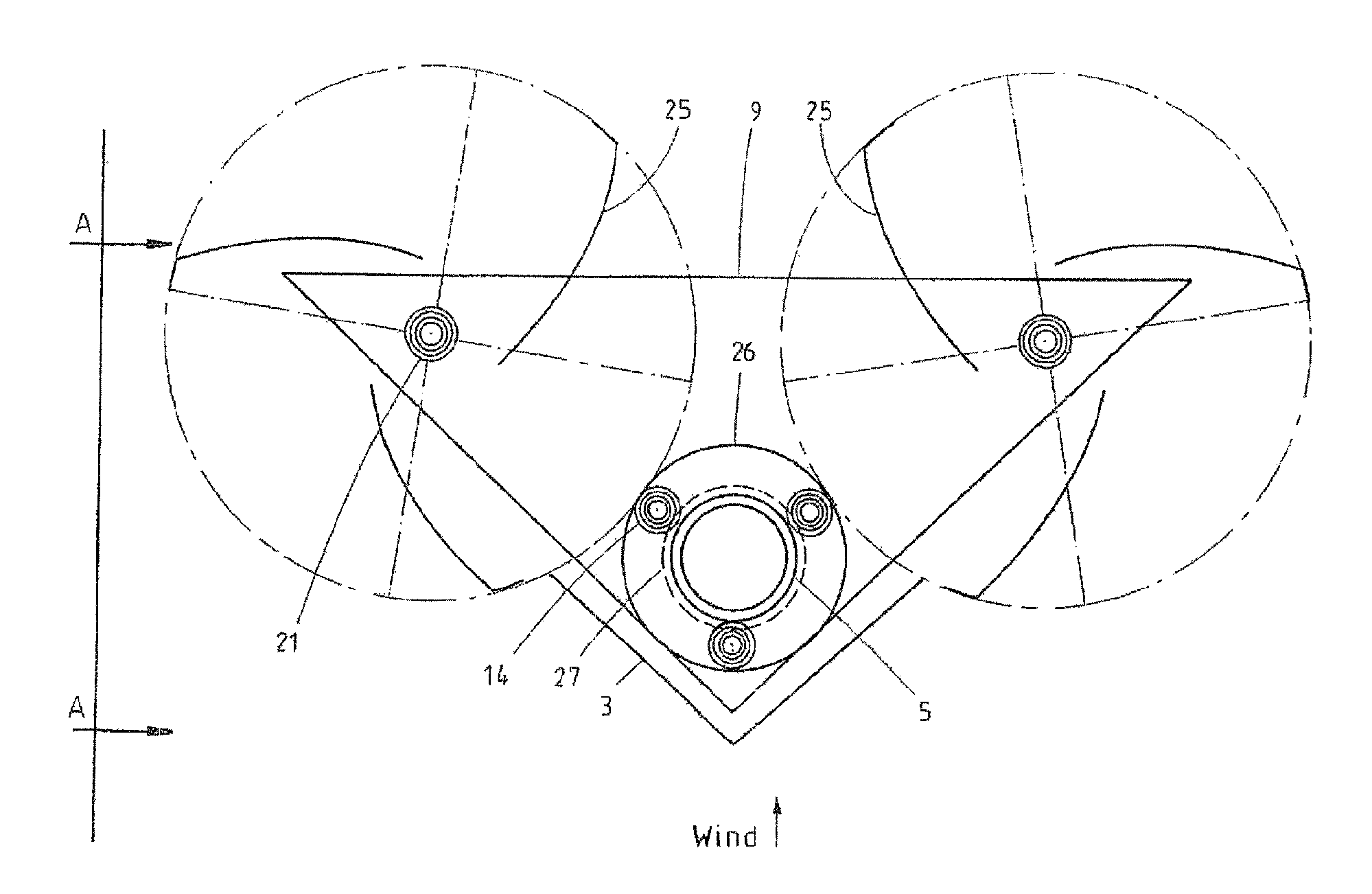

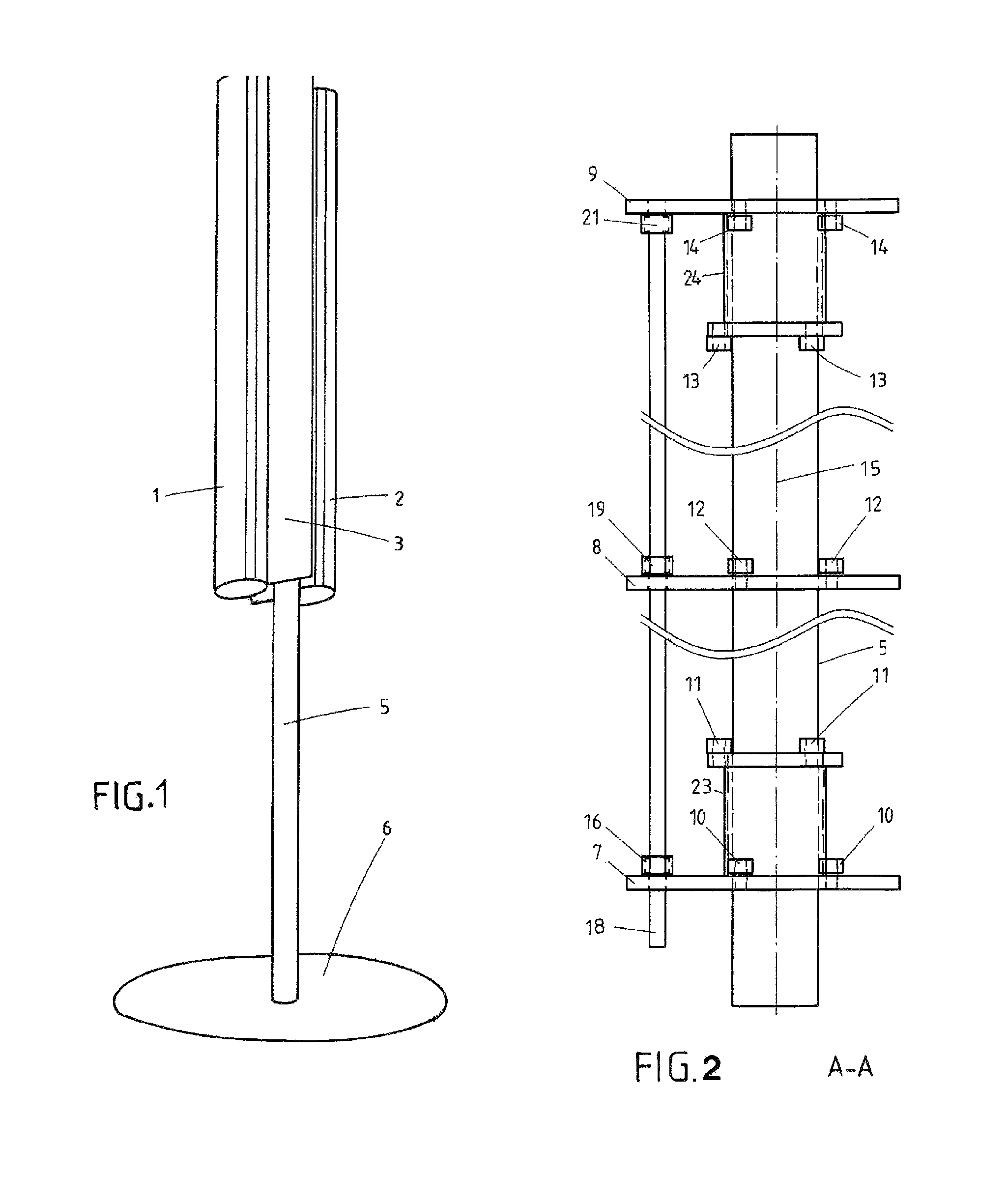

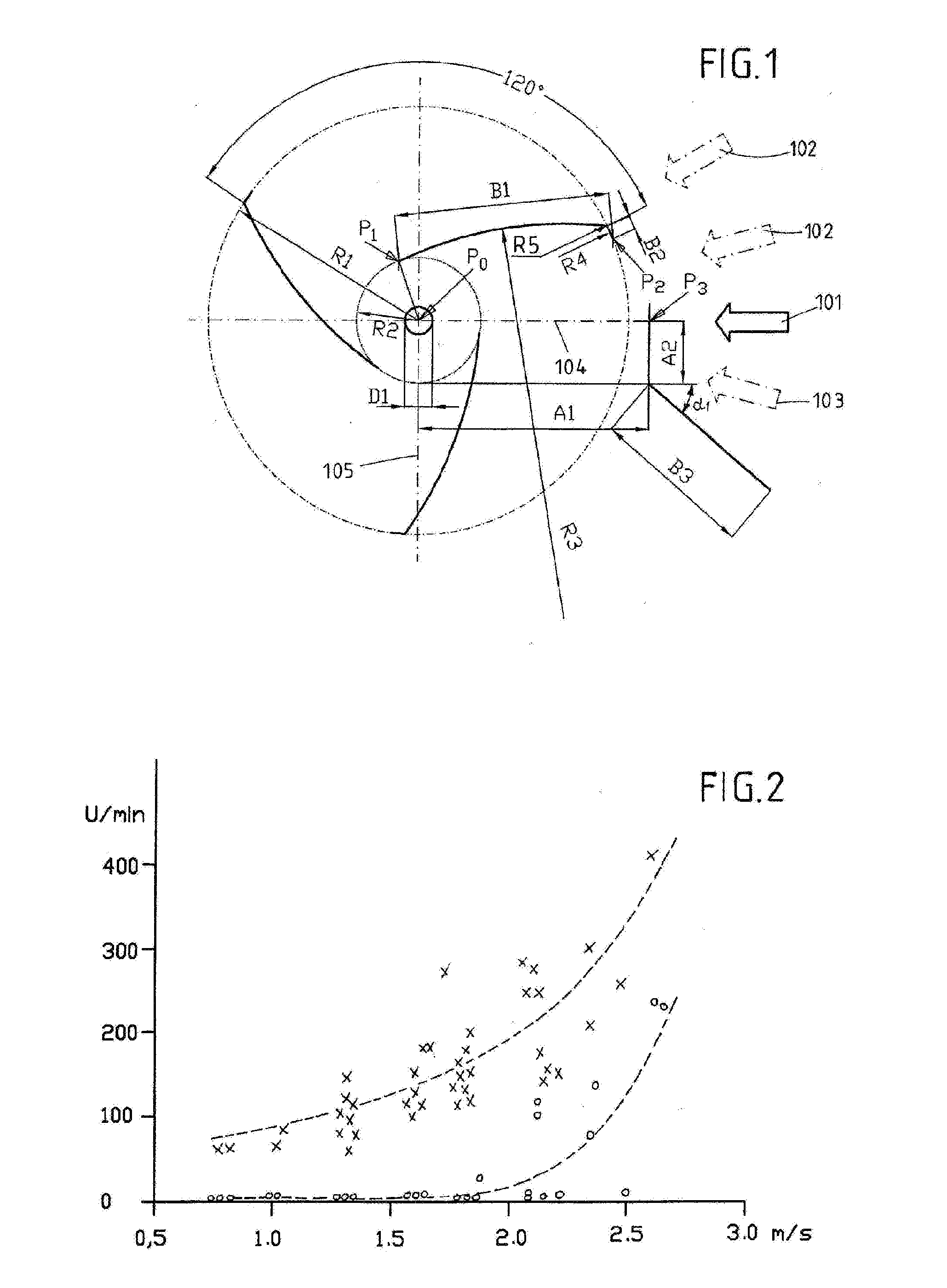

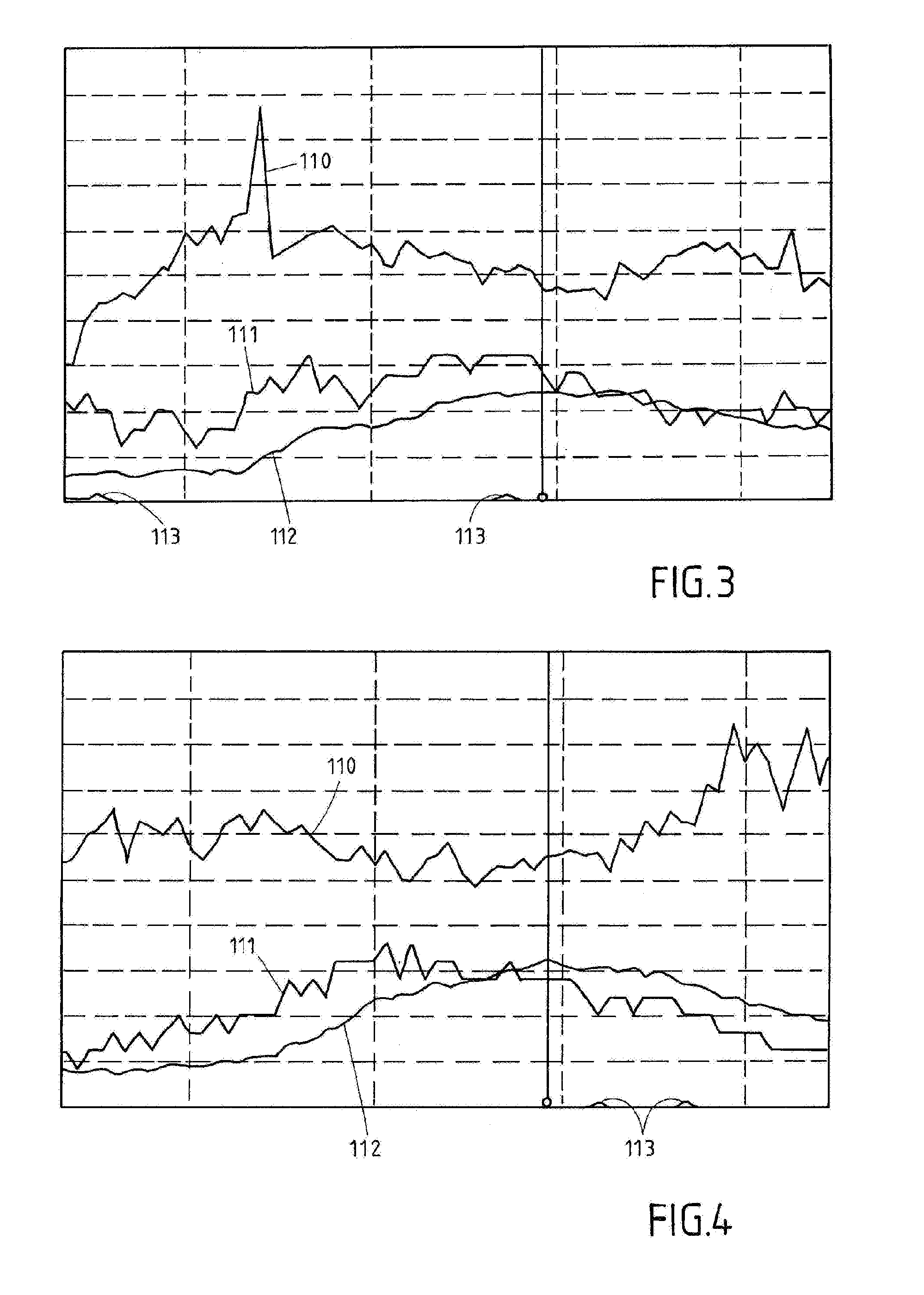

Windtracker twin-turbine system

InactiveUS20130170986A1High yieldImprove adhesionPropellersRotary propellersTurbine bladeRadial turbine

The turbine system for wind and / or water power, wherein the radial turbines have a rotor which can rotate about an axis and comprises one or more turbine blades, wherein the turbine blades are aligned parallel to the rotor, wherein the turbine blades are arranged within a cylindrical shell, which is arranged concentrically around the axis and has an outer radius R1 and an inner radius R2, is characterized in that the turbine blades have a specific geometry and in that two radial turbines (1, 2) which are aligned alongside one another and parallel are arranged, which radial turbines (1, 2) are connected to one another and can pivot about a pivoting axis (15) parallel to the turbine axes (18), wherein the pivoting axis and the guide surfaces (3, 4) are not located on the connecting line between the turbine axes, and are both located on the same side of the connecting line. It is proposed that the abstract be published without any drawing.

Owner:STEEL DENNIS PATRICK

Forest extinguishment rocket projectile

InactiveCN102107049AFlying distanceHigh drop densityAmmunition projectilesRespiratory apparatusFire pointProjectile

The invention provides a forest extinguishment rocket projectile. The forest extinguishment rocket projectile mainly comprises a fuze, an extinguishment device, a solid rocket engine and an empennage, wherein the fuze comprises a proximity module transparent shade, a fuze base, a circuit board, a power supply and a safety mechanism; the extinguishment device comprises a priming port plug, a front plugging cover, a pull rod, a center tube, a throwing ammunition body, a projectile body shell, an extinguishing agent and a rear plug; and in the extinguishment rocket projectile, the solid rocket engine is used as a power device, so the projectile body has a far flying distance and high placement concentration, and can be thrown to a fire point for extinguishment remotely, quickly and accurately. The front plugging cover and the rear plugging cover are connected together by using the pull rod, so that flyoff of the throwing ammunition body during the action can be avoided; meanwhile, the extinguishing agent can be transversely scattered in a large area. As a plurality of thin slots are processed on the projectile body shell, the projectile body is detonated and the shell can be cracked from the thin slots, and the extinguishing agent can be thrown and scattered uniformly.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

Golf ball

ActiveUS20090312121A1Suppresses back spin spinSuppresses spin side spinGolf ballsSolid ballsEngineering

Golf ball 2 has a center 8, a mid layer 10 and a cover 6. The base polymer of the mid layer 10 includes an ionomer resin as a principal component. The surface hardness H1s of the center 8 is greater than the hardness H2 of the mid layer 10. The Shore D hardness H3 of the cover 6 is equal to or greater than 57. The weight W2 of the mid layer 10 is greater than the weight W3 of the cover 6. The total weight (W2+W3) of the weight W2 of the mid layer 10 and the weight W3 of the cover 6 is 8.4 g or greater and less than 12.0 g. The total volume (V2+V3) of the volume V2 of the mid layer 10 and the volume of the cover 6 is equal to or less than 10.0 cm3.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

An object of the present invention is to provide a golf ball having a spherical core with an outer-hard inner-soft structure formed from a rubber composition excellent in kneading workability. Another object of the present invention is to provide a golf ball traveling a great flight distance on driver shots. The present invention provides a golf ball having a spherical core and at least one cover layer covering the spherical core, wherein the spherical core is formed from a rubber composition containing (a) a base rubber, (b) an α,β-unsaturated carboxylic acid having 3 to 8 carbon atoms and / or a metal salt thereof as a co-crosslinking agent, (c) a crosslinking initiator, and (d) a basic metal salt of a fatty acid.

Owner:SUMITOMO RUBBER IND LTD

Golf ball

The present invention provides a golf ball having a center and at least one intermediate layer covering the center and a cover, wherein at least one of the intermediate layer is formed from a composition comprising, as a resin component, (A) a polyamide copolymer containing (a-1) a polymerized fatty acid, (a-2) sebacic acid and / or azelaic acid, (a-3) a polyamine component as an essential component, and (B) at least one member selected from (b-1) a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid, (b-2) a metal ion-neutralized product of a binary copolymer composed of an olefin and an α,β-unsaturated carboxylic acid, (b-3) a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid and an α,β-unsaturated carboxylic acid ester, and (b-4) a metal ion-neutralized product of a ternary copolymer composed of an olefin, an α,β-unsaturated carboxylic acid and an α,β-unsaturated carboxylic acid ester.

Owner:SUMITOMO RUBBER IND LTD

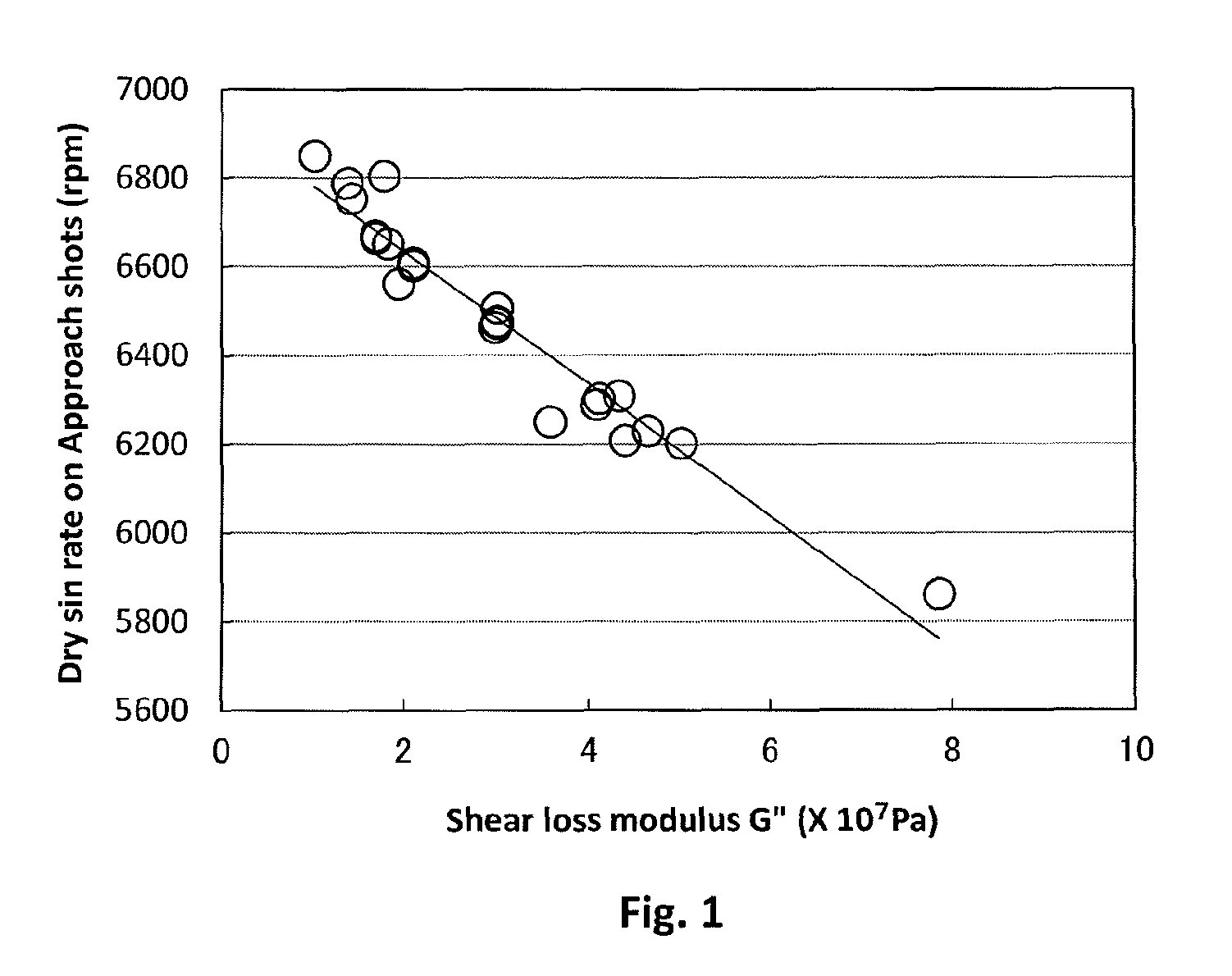

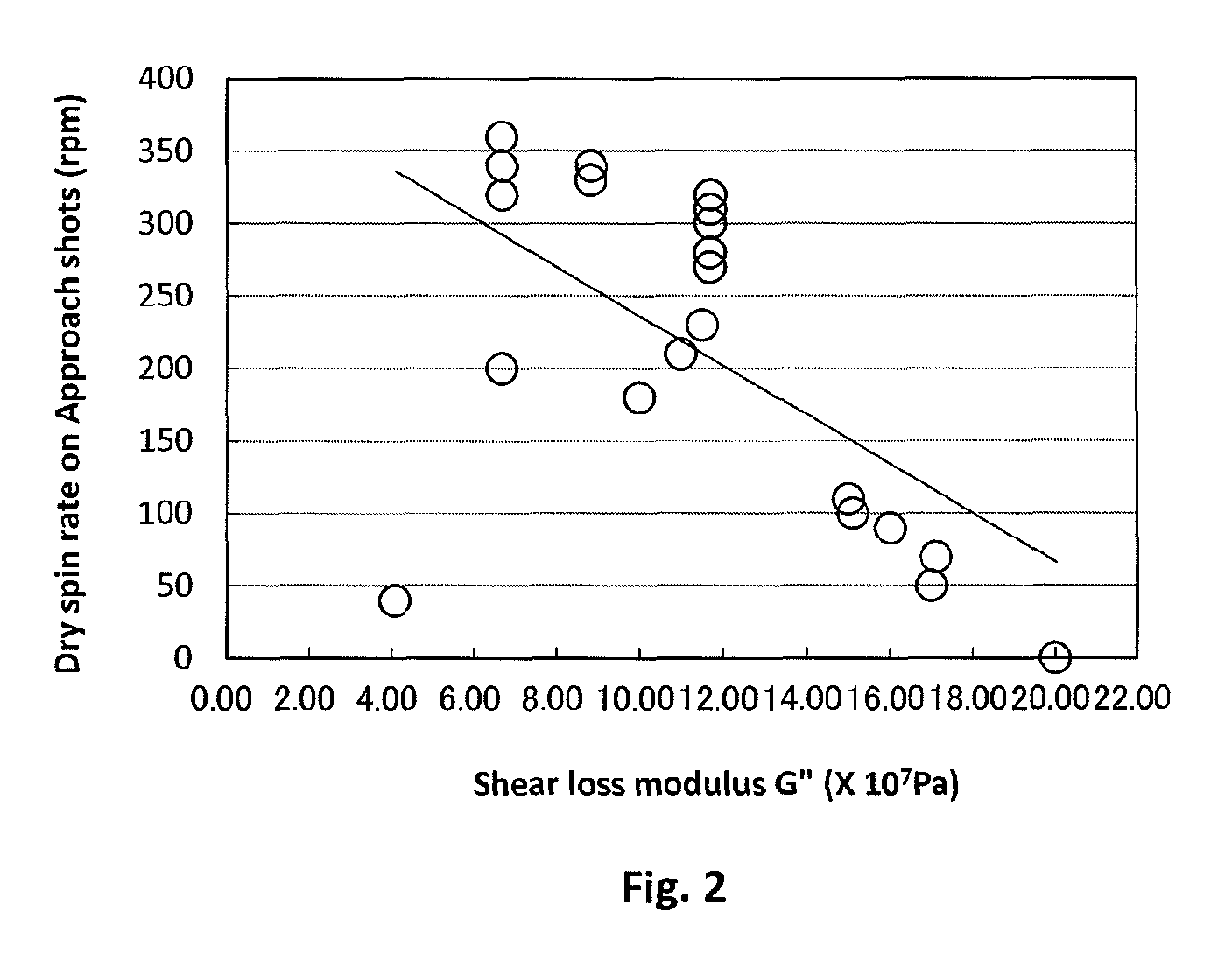

Golf ball

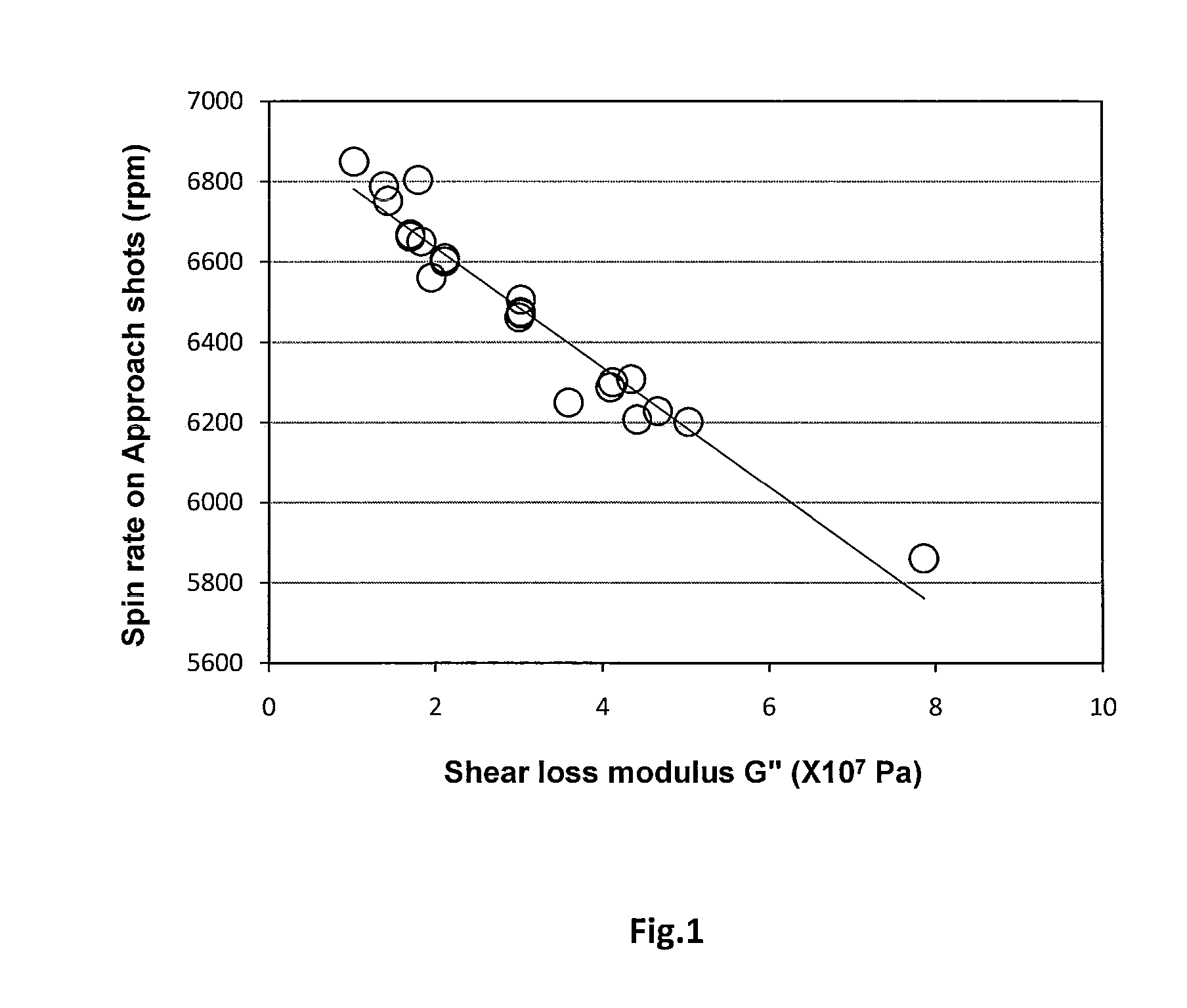

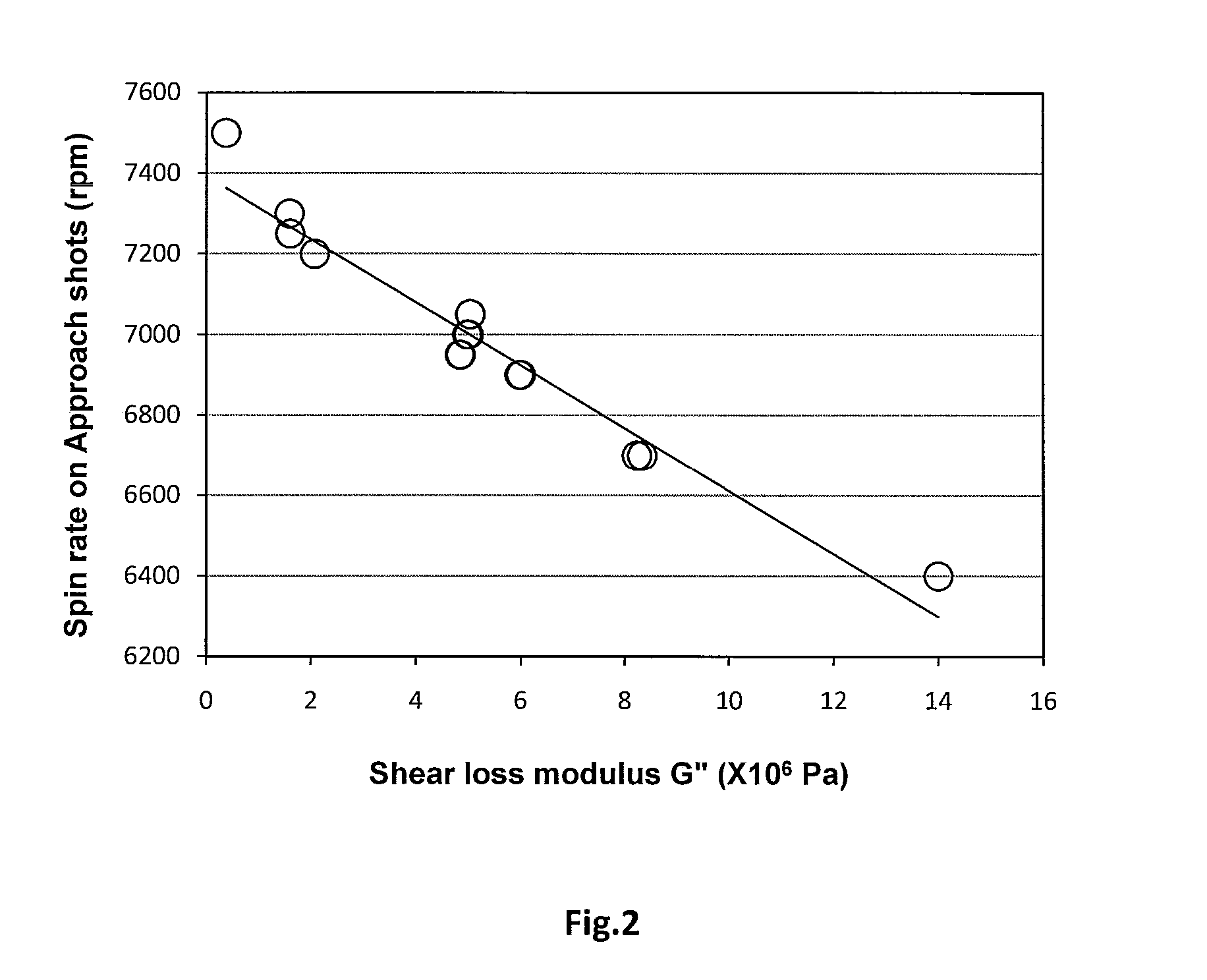

ActiveUS20120021853A1Increase elasticityIncrease speedGolf ballsSolid ballsPolyurethane elastomerDynamic viscoelasticity

An object of the present invention is to provide a golf ball having a high resilience with a high spin rate on the approach shots. The present invention provides a golf ball comprising a constituting member that is formed from a polyurethane composition containing a polyurethane elastomer as a resin component, the polyurethane composition satisfying properties of a rebound resilience of 54% or more and a shear loss modulus G″ of 5.03×106 Pa or less when measured at the conditions of the temperature of 0° C., the oscillation frequency of 10 Hz, and in a shear mode using a dynamic viscoelasticity measuring apparatus.

Owner:SUMITOMO RUBBER IND LTD

Flying disc

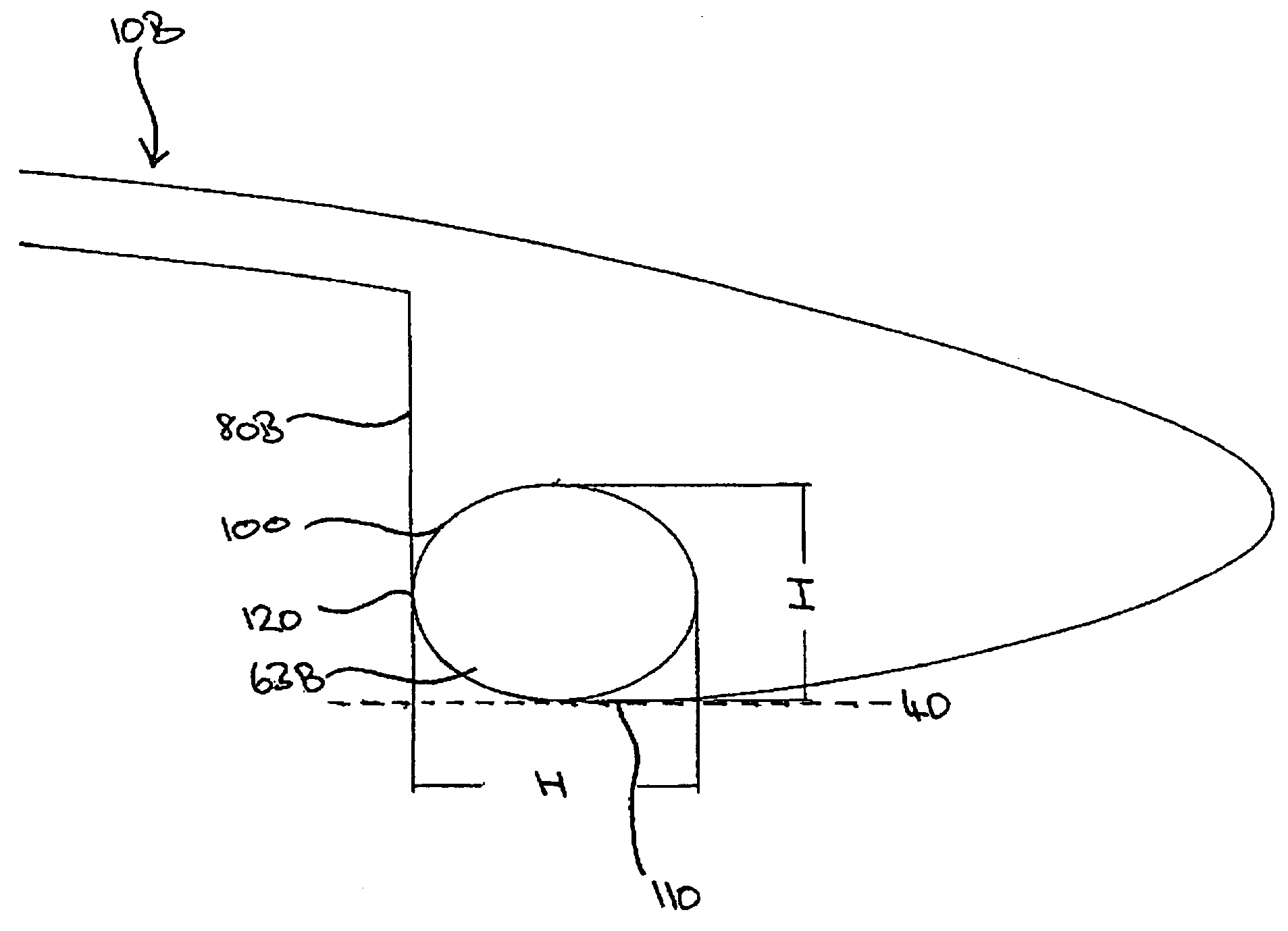

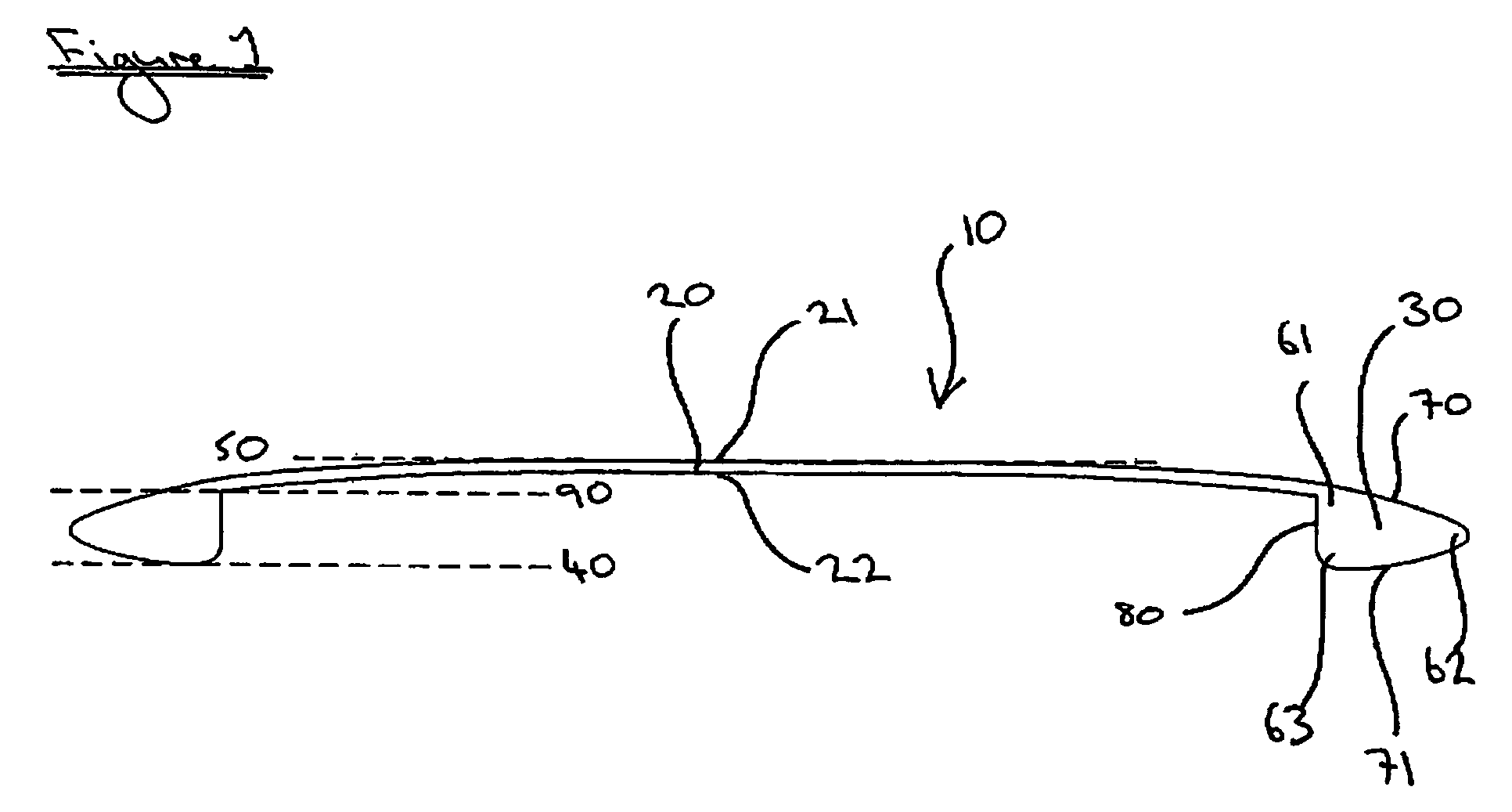

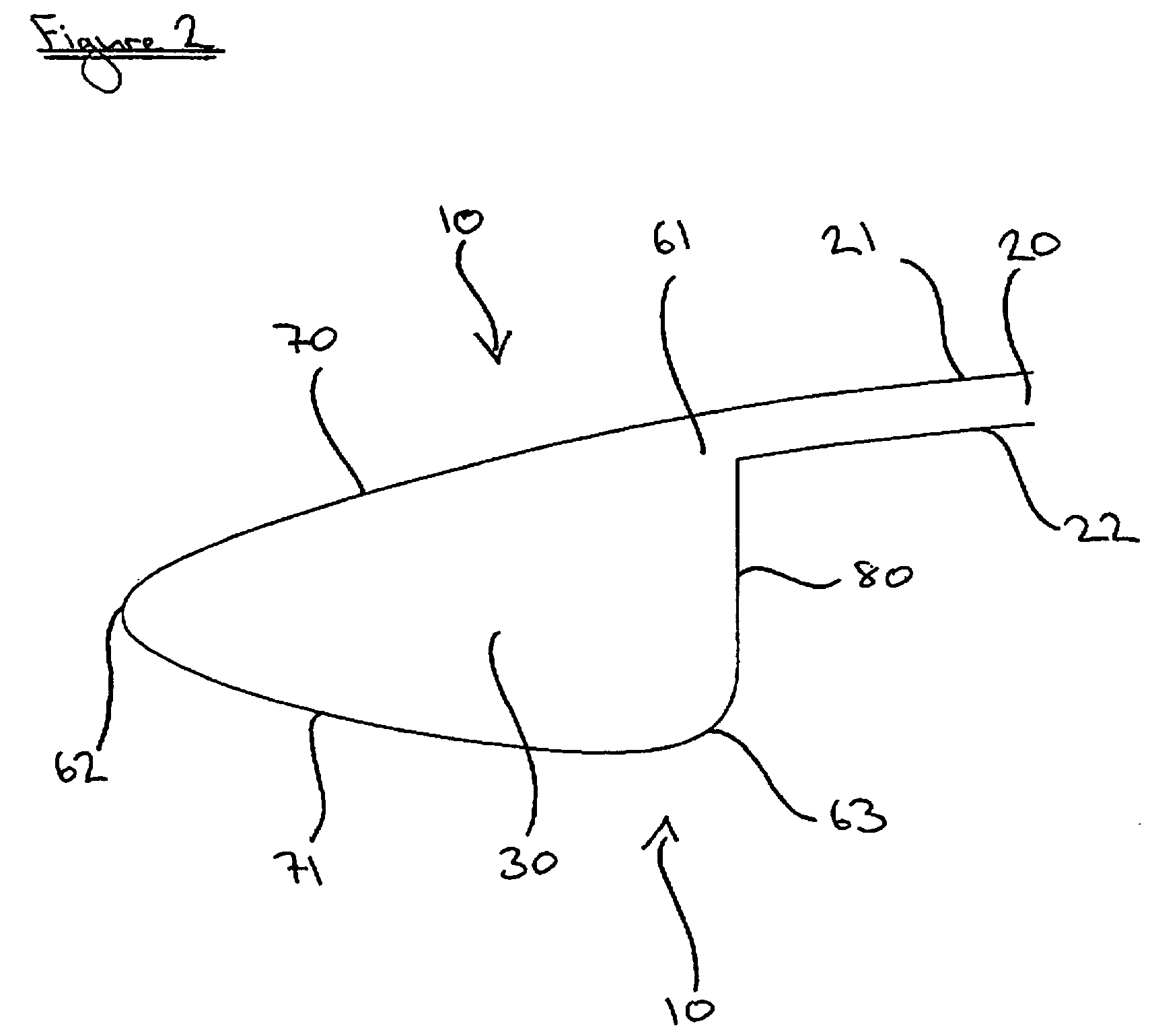

InactiveUS7294036B2Improve flight efficiencyFlying distanceAircraft navigation controlWingsEdge surfaceMechanical engineering

A circular planform wing includes a contiguous thin central plate having top and bottom surfaces. An outer annular rim encompasses the central plate. The rim has a lower edge defining a lower plane of the wing, and the central plate has an upper zone defining an upper plane of the wing. The rim has a cross-section with a lower rounded corner forming the lower edge, an outer rounded corner, and an upper corner merging with the central plate, the outer corner being located between the upper plane and the lower plane. The rim cross-section has a convex upper curve joining the outer rounded corner to the upper corner, an inside rim surface joining the lower rounded corner to the upper corner, and a convex lower curve joining the outer rounded corner to the lower rounded corner.

Owner:POTTS JONATHAN

Golf ball

ActiveUS8998749B2Reduce rateDifficult to stopGolf ballsSolid ballsPolyurethane elastomerDynamic viscoelasticity

Owner:SUMITOMO RUBBER IND LTD

Golf ball

Owner:SUMITOMO RUBBER IND LTD

Method for manufacturing a golf ball

An object of the present invention is to provide a method for manufacturing a golf ball excellent in kneading workability when preparing a core rubber composition containing (d) a carboxylic acid and / or a salt thereof. The present invention provides a method for manufacturing a golf ball comprising the steps of blending (a) a base rubber and at least (b) a carboxylic acid and / or a salt thereof to prepare a first masterbatch; blending (a) a base rubber and at least (c) a crosslinking initiator to prepare a second masterbatch; blending the first masterbatch and second masterbatch to form a core rubber composition; molding the core rubber composition into a spherical core; and forming one or more cover layers covering the spherical core.

Owner:SUMITOMO RUBBER IND LTD

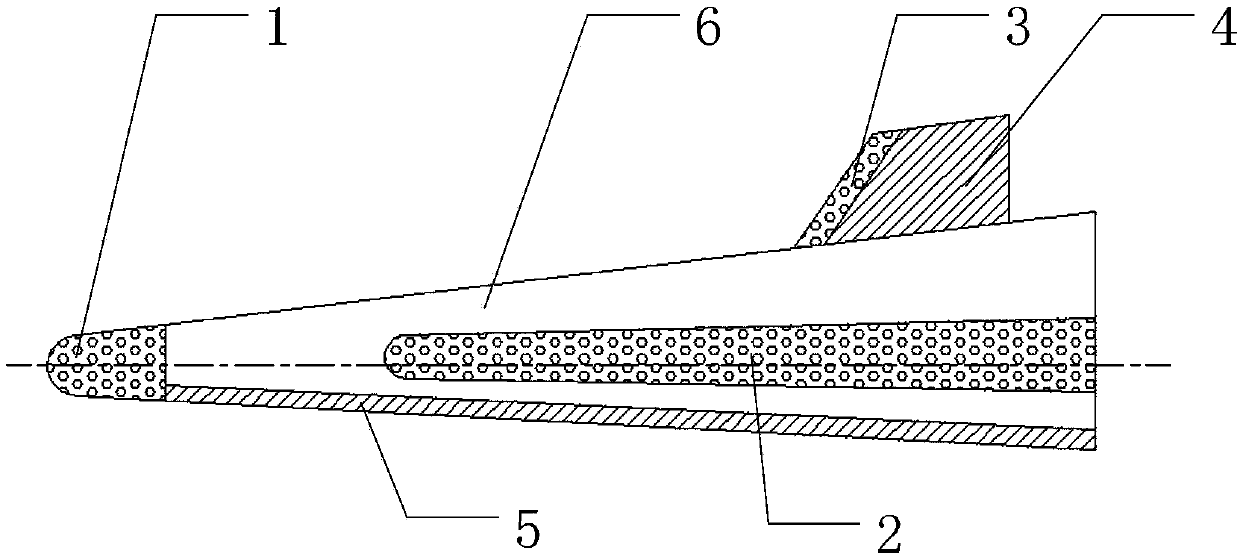

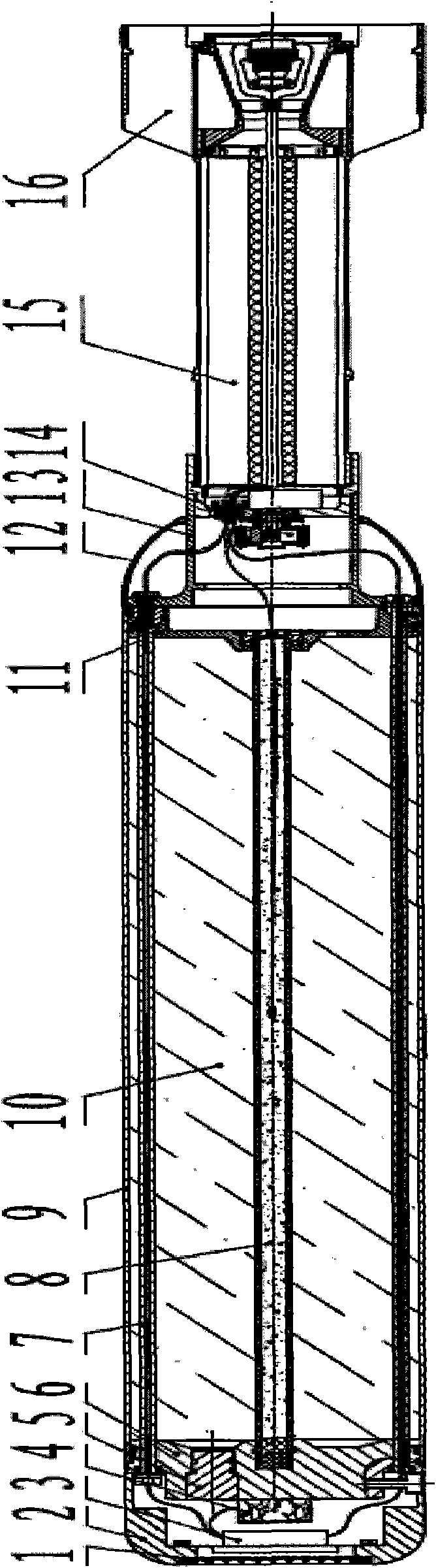

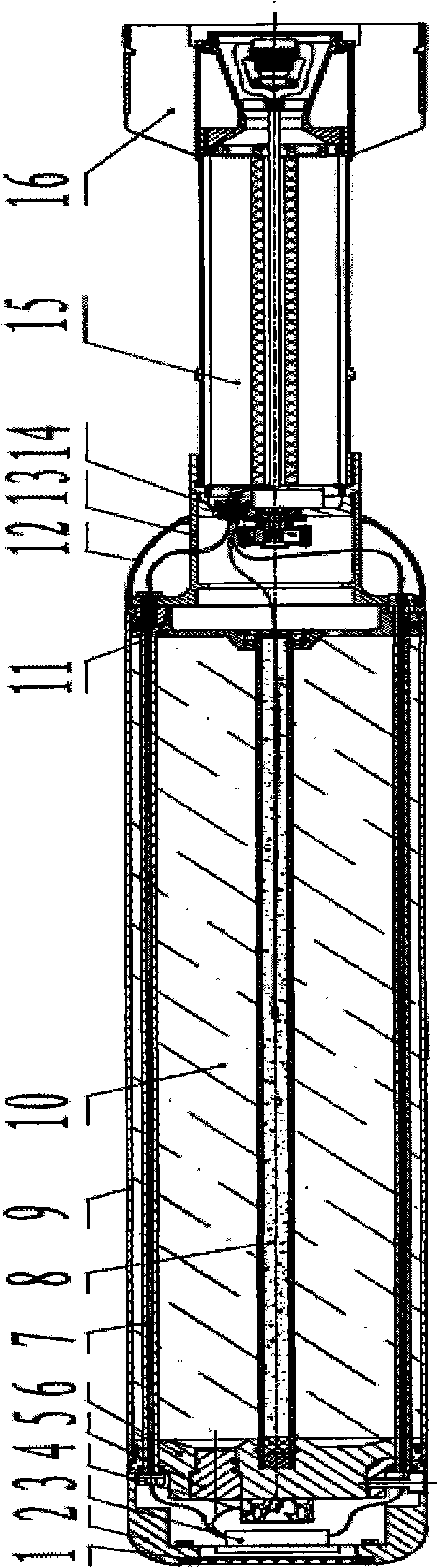

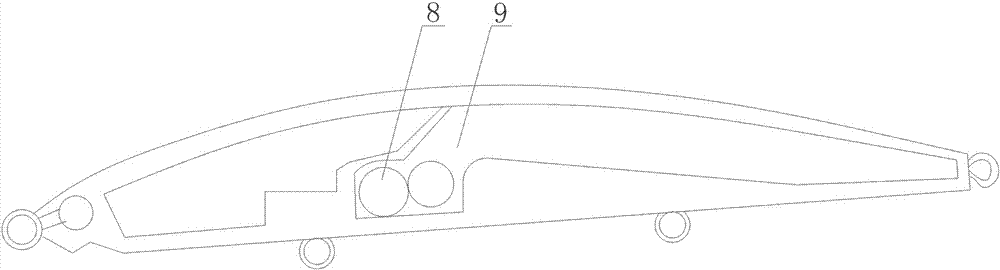

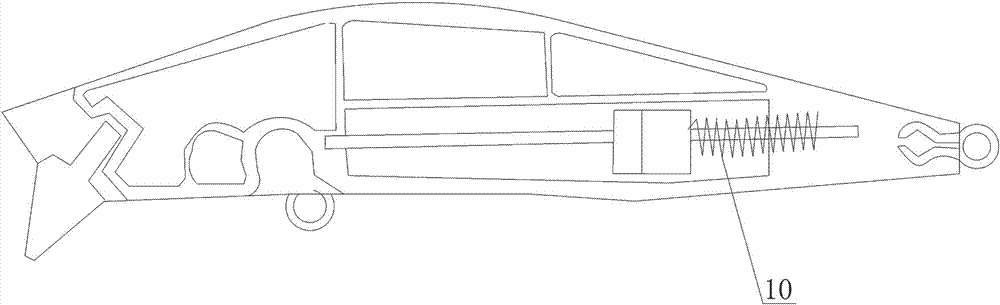

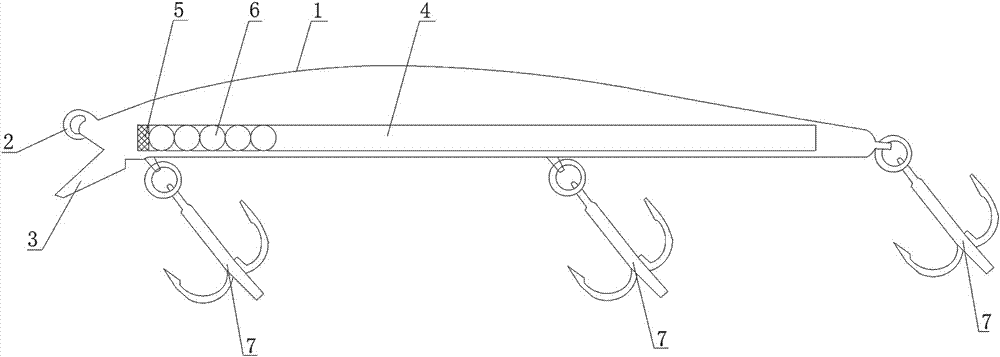

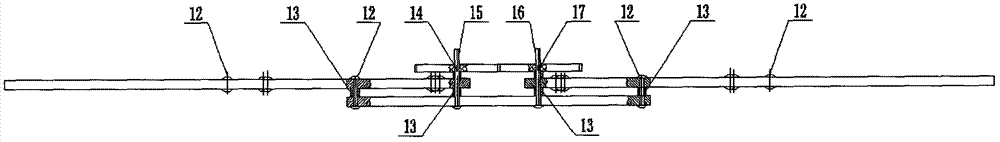

Minnow gravity transferring system and use method of same

The invention discloses a gravity transferring system comprising a lure main body (1). The left end part of the lure main body (1) is provided with a lure head; the lure head part is provided with anear ring (2) and a water press plate (3); the water press plate (3) inclines to left and downward; the right end part of the lure main body is provided with a lure tail; a straight slide path (4) is formed in the lure main body (1); the straight slide path (4) is horizontally arranged; one end of the straight slide path (4) extends into the lure head; the other end of the straight slide path (4) extends to the lure tail; a magnet (4) is disposed in the straight slide path (4) and on the left side of the same; a plurality of tungsten beads (6) moving along the straight slide path (4) are disposed in the straight slide path (4); and treble hooks (7) are arranged under the water press plate (3), on the bottom of the lure main body (1) and on the bottom of the lure tail. The beneficial effectsare that the minnow gravity transferring system has a compact structure; fish targeting efficiency can be improved by 50%; lures can stably return; and further flying distance of the lure can be guaranteed.

Owner:四川省眉山市风语者渔具有限公司

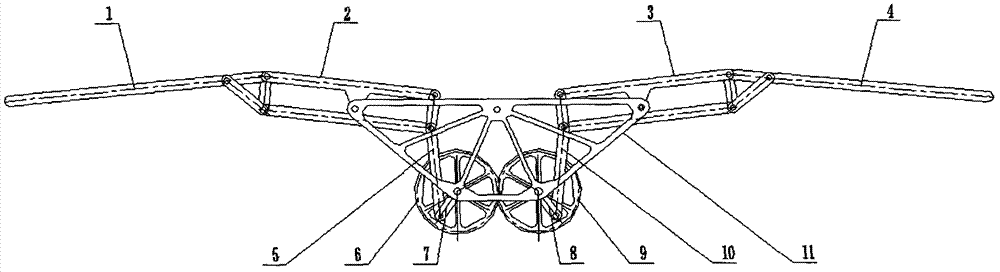

Efficient flapping wing device

The invention relates to a flapping wing device, in particular to a novel high-performance bionic bird flapping wing device capable of being applied to sports, entertainment and military science. The novel high-performance bionic bird flapping wing device comprises two sets of devices on the left and right sides, wherein each set of devices is composed of a gear, a crank, a connecting rod, a main wing and a stander. When the novel high-performance bionic bird flapping wing device works, the left gear rotates, the right gear meshed with the left gear also rotates; the rotating left gear drives the left crank to rotate, the left connecting rod swings along with the rotation, and the left main wing is then driven to swing vertically; a left auxiliary wing swings vertically under the driving of a left main wing side rod; the rotating right gear drives the right crank to rotate, the right connecting rod swings along with the rotation, and the right main wing is driven to swing vertically; a right auxiliary wing swings vertically under the driving of a right main wing side rod, and thus the integral flapping movements of the left and right wings are realized. For the novel high-performance bionic bird flapping wing device, the auxiliary wings and the main wings are organically combined, so that the size is small, the structure is compact, and the flying distance is long. The novel high-performance bionic bird flapping wing device is particularly suitable for the industries of sports, entertainment, military science and the like.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Golf ball

Golf ball 2 has a core 4, a cover 6 and numerous dimples 8. The cover 6 has a thickness of less than 3.0 mm and a hardness H4 of equal to or greater than 90. A difference (H2−H1) of a surface hardness H2 of the core 4 and a central hardness H1 of the core 4 is 10 or greater and 25 or less. A difference (H4−H1) of the hardness H4 of the cover 6 and a surface hardness H1 of the core 4 is equal to or greater than 25. A difference (H4−H2) of the hardness H4 of the cover 6 and a surface hardness H2 of the core 4 is 10 or greater and 20 or less. Provided that mean diameter of all the dimples 8 is Da, a ratio (N1 / N) of number N1 of adjacent dimple pairs having a pitch of (Da / 4) or less to total number N of the dimples 8 is equal to or greater than 2.70. A ratio (N2 / N1) of number N2 of adjacent dimple pairs having a pitch of (Da / 20) or less to the number N1 is equal to or greater than 0.50.

Owner:DUNLOP SPORTS CO LTD

Golf ball

Owner:SUMITOMO RUBBER IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com