Patents

Literature

145 results about "Regenerative cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Regenerative cooling is a method of cooling gases in which compressed gas is cooled by allowing it to expand and thereby take heat from the surroundings. The cooled expanded gas then passes through a heat exchanger where it cools the incoming compressed gas.

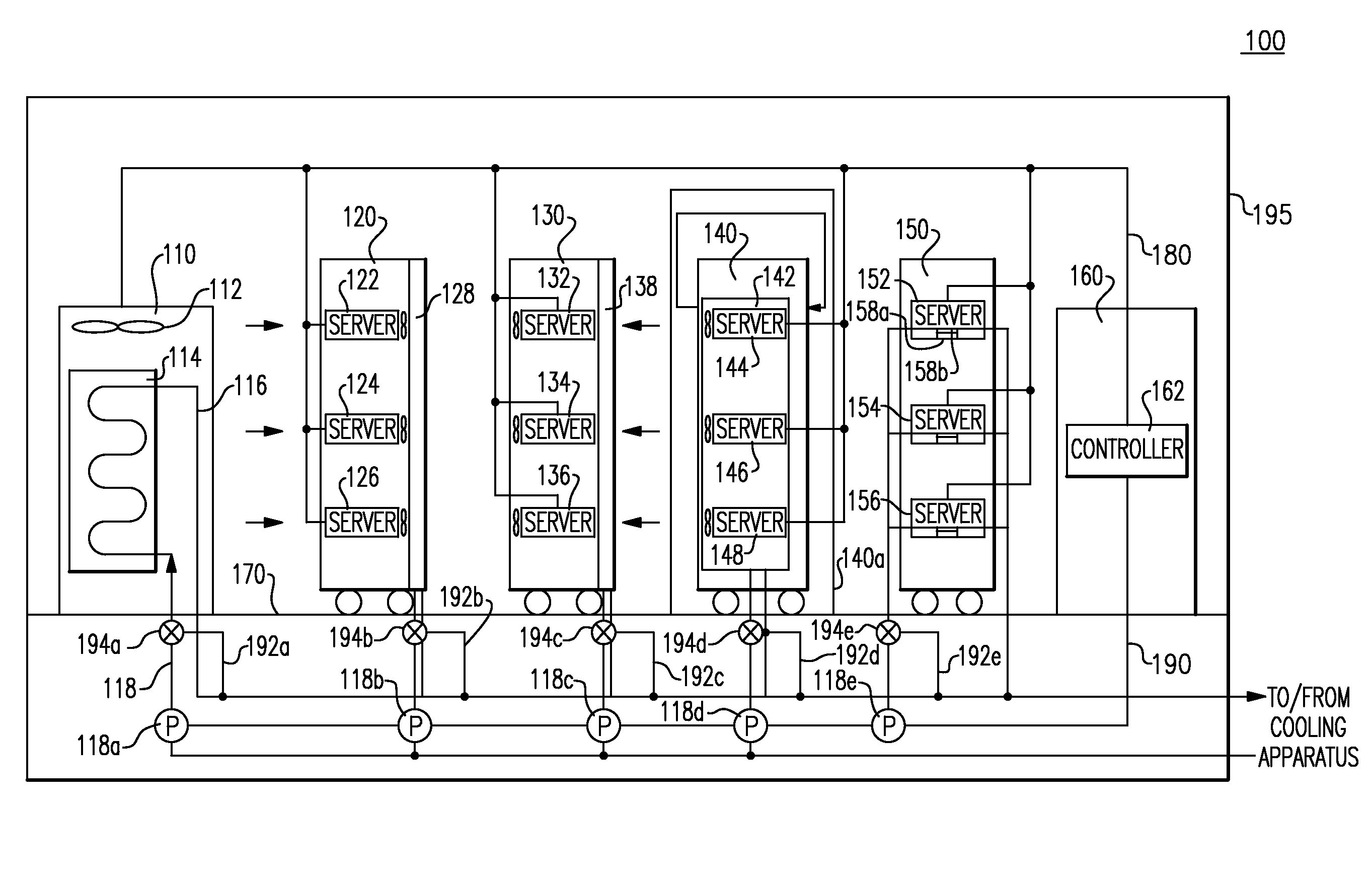

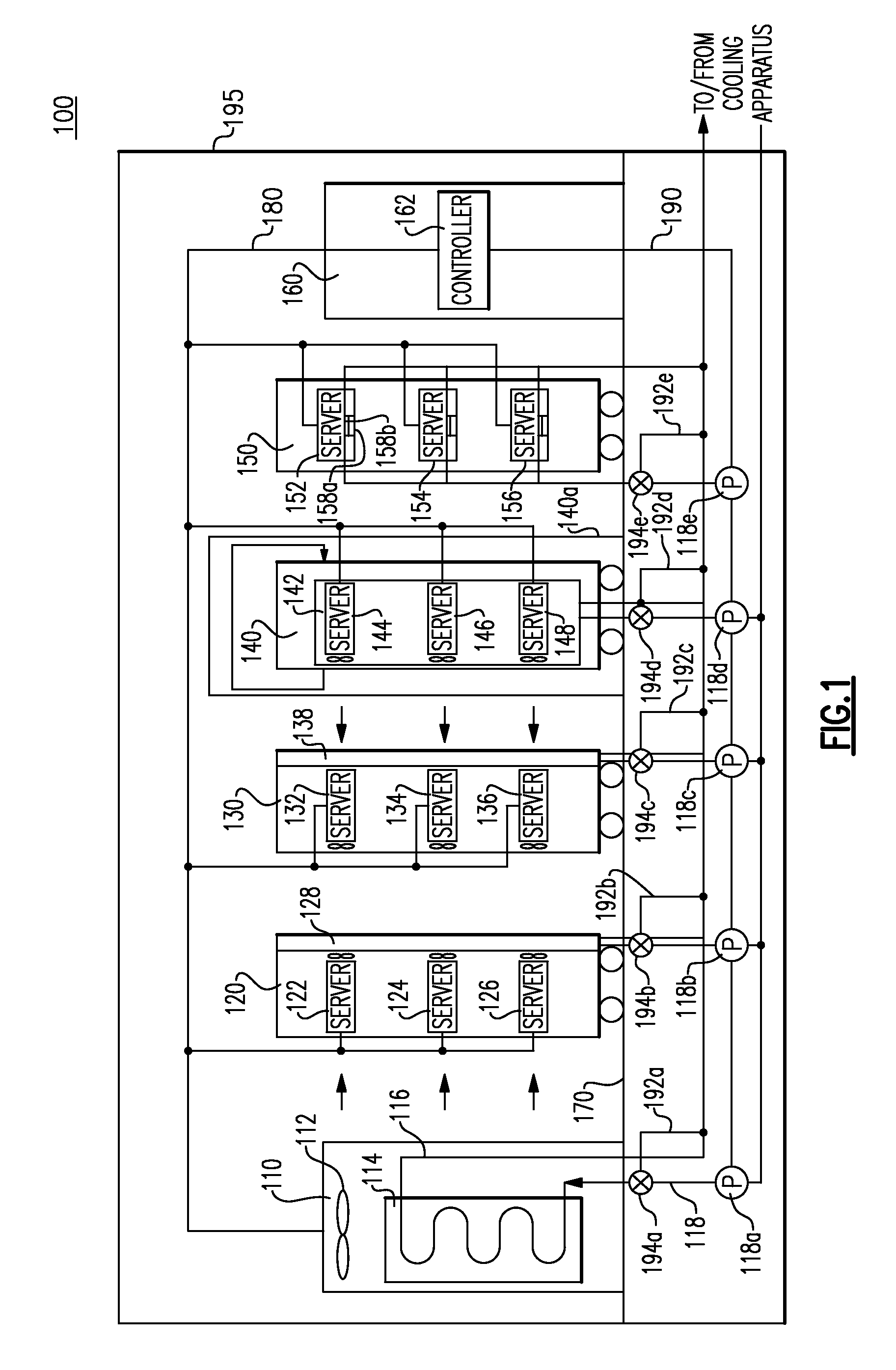

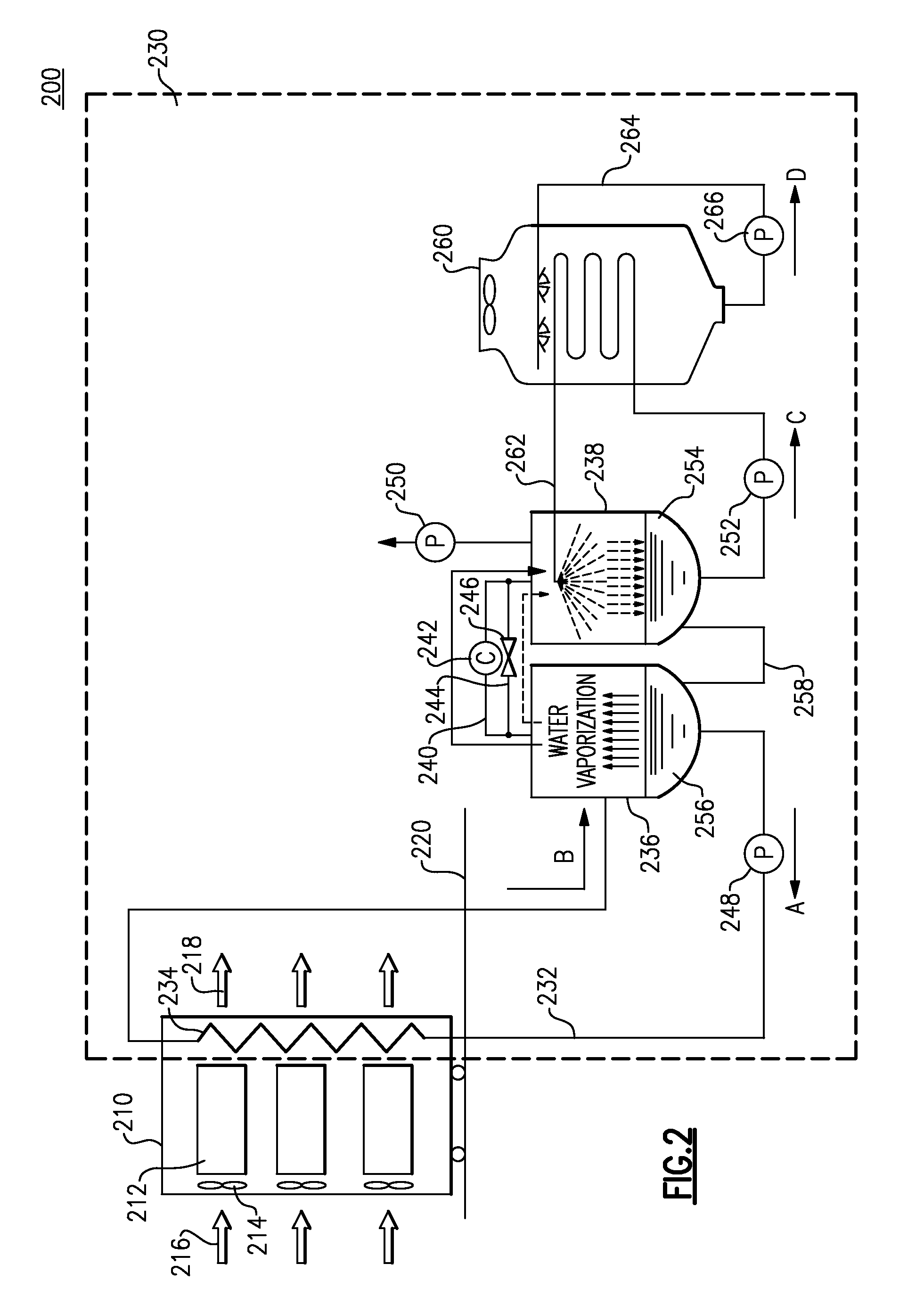

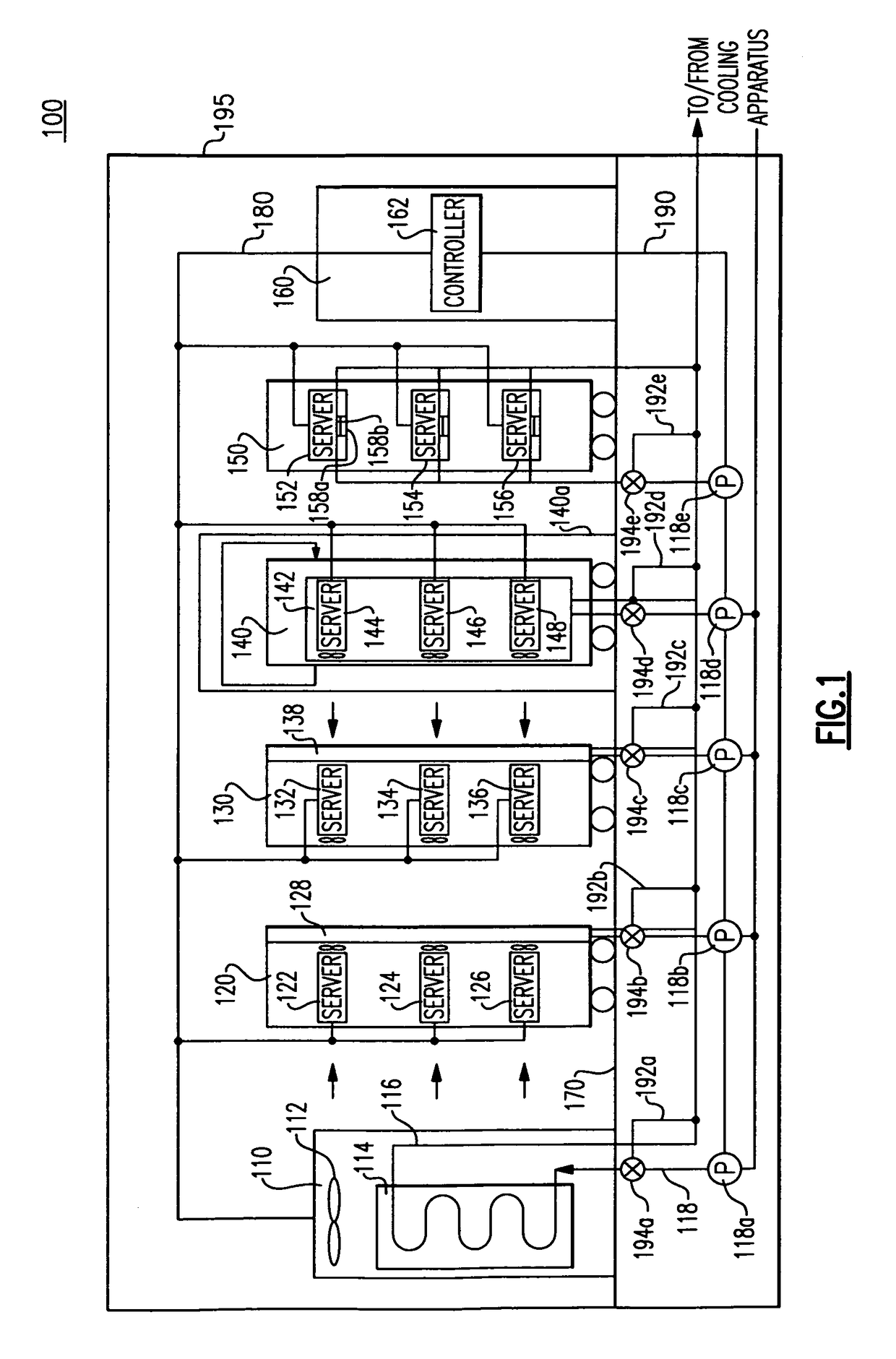

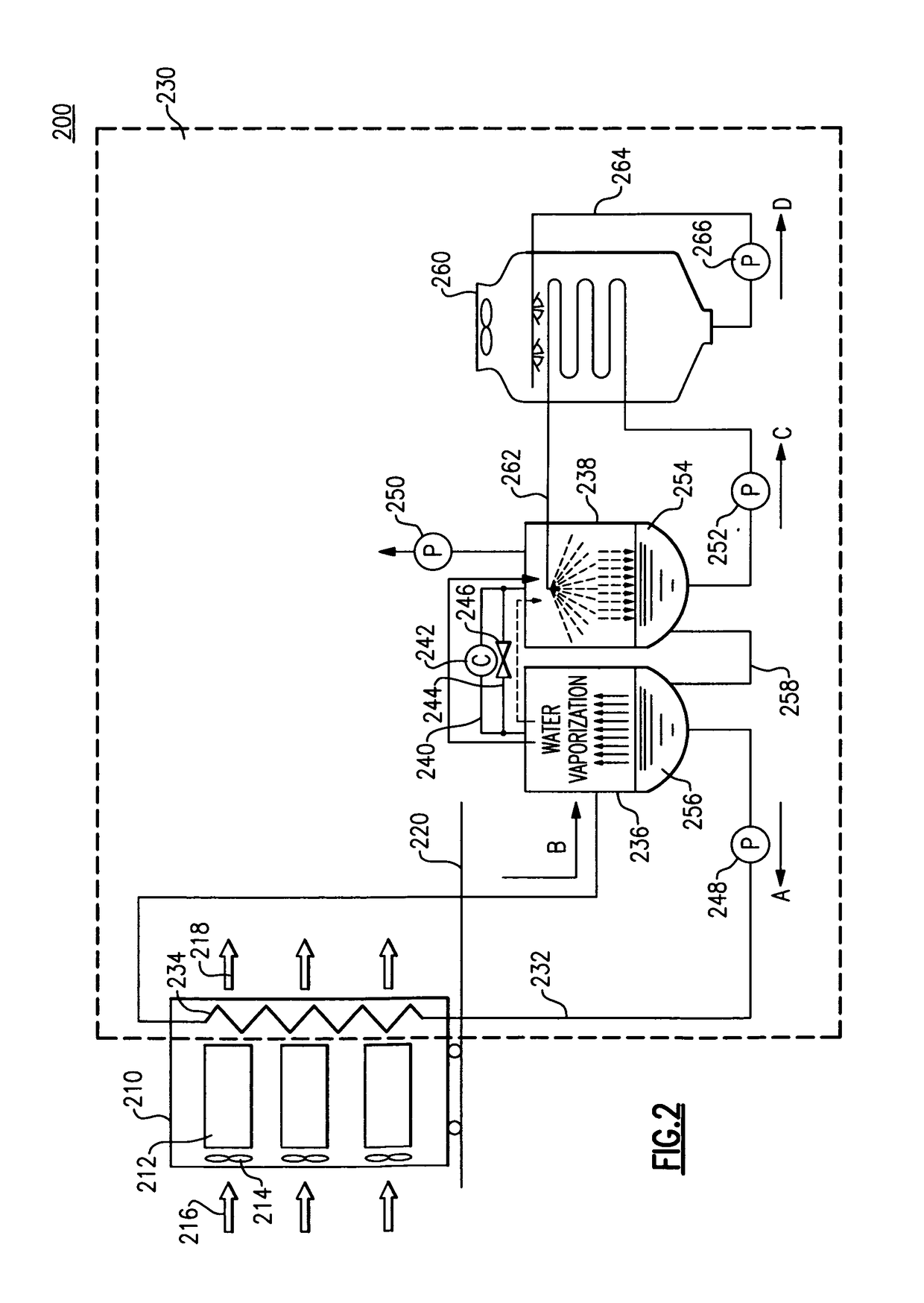

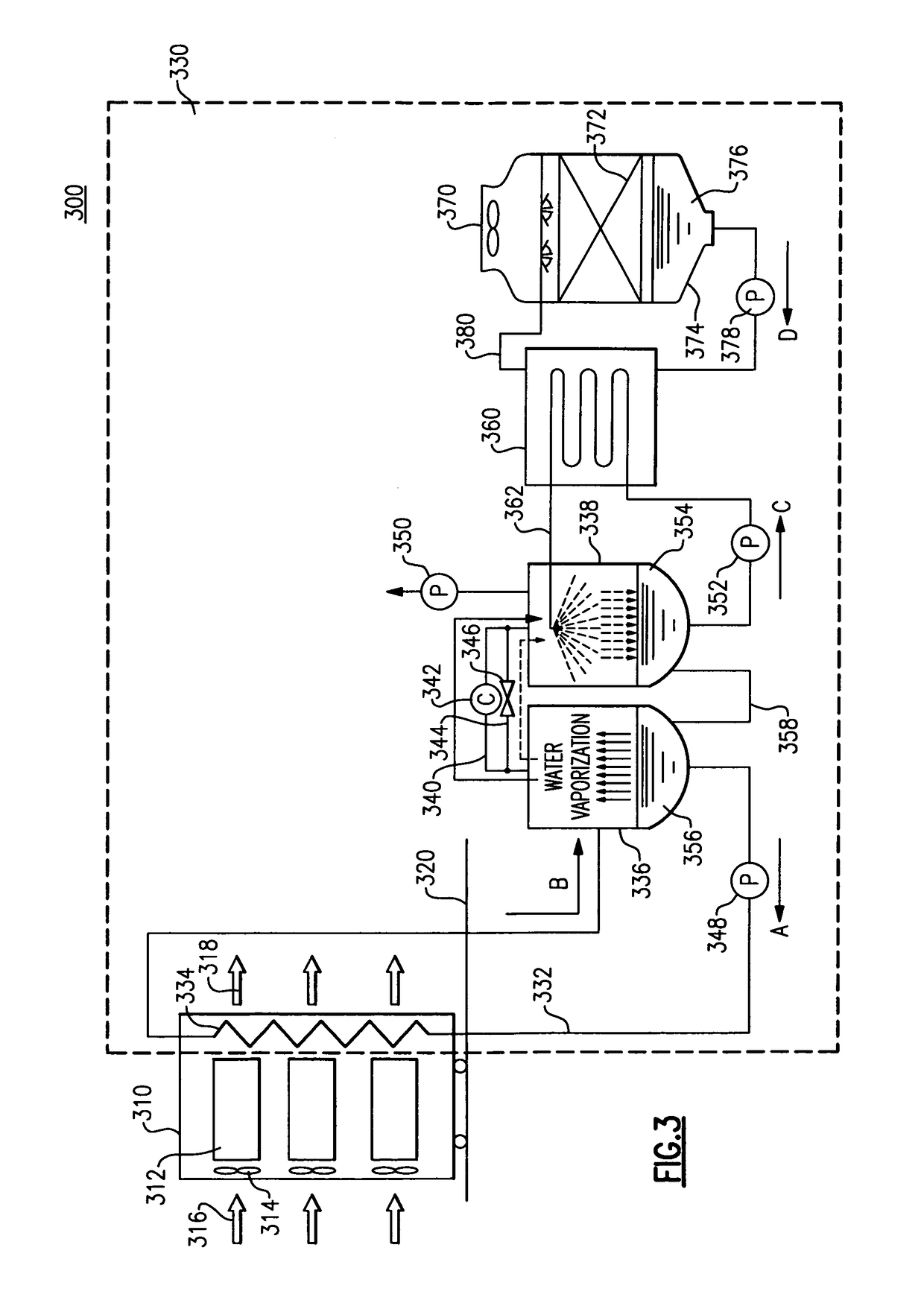

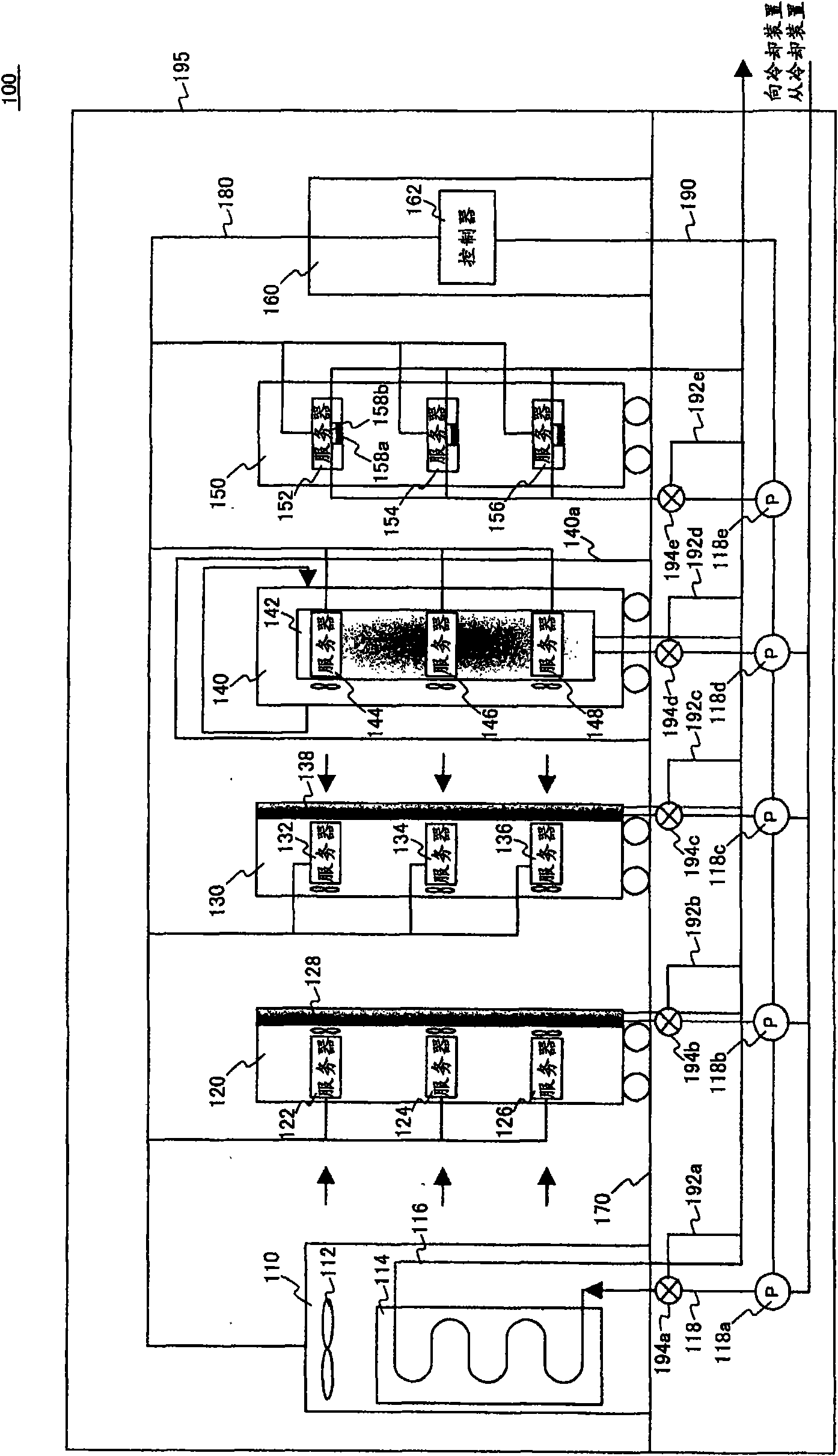

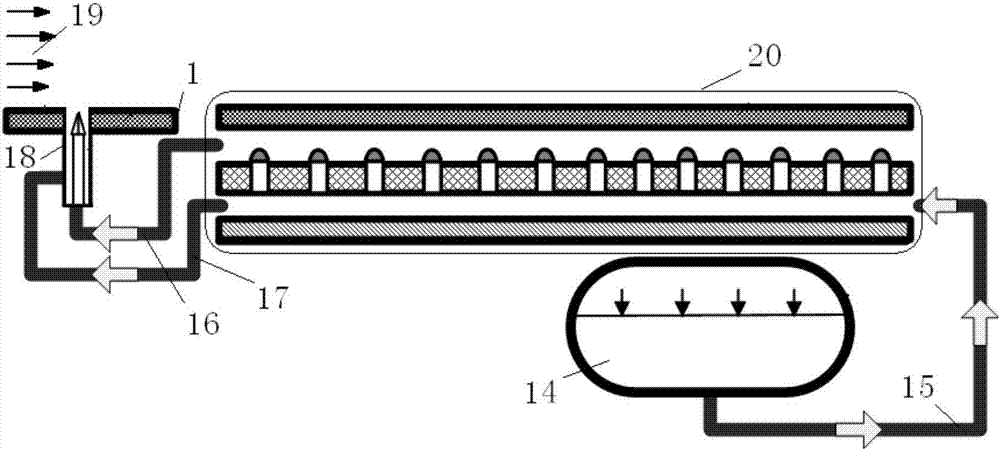

Facilitating Cooling Of An Electronics Rack Employing Water Vapor Compression System

InactiveUS20110063792A1Reduce environmental loadSafe and effective removalDigital data processing detailsSemiconductor/solid-state device detailsWater vaporNuclear engineering

Owner:IBM CORP

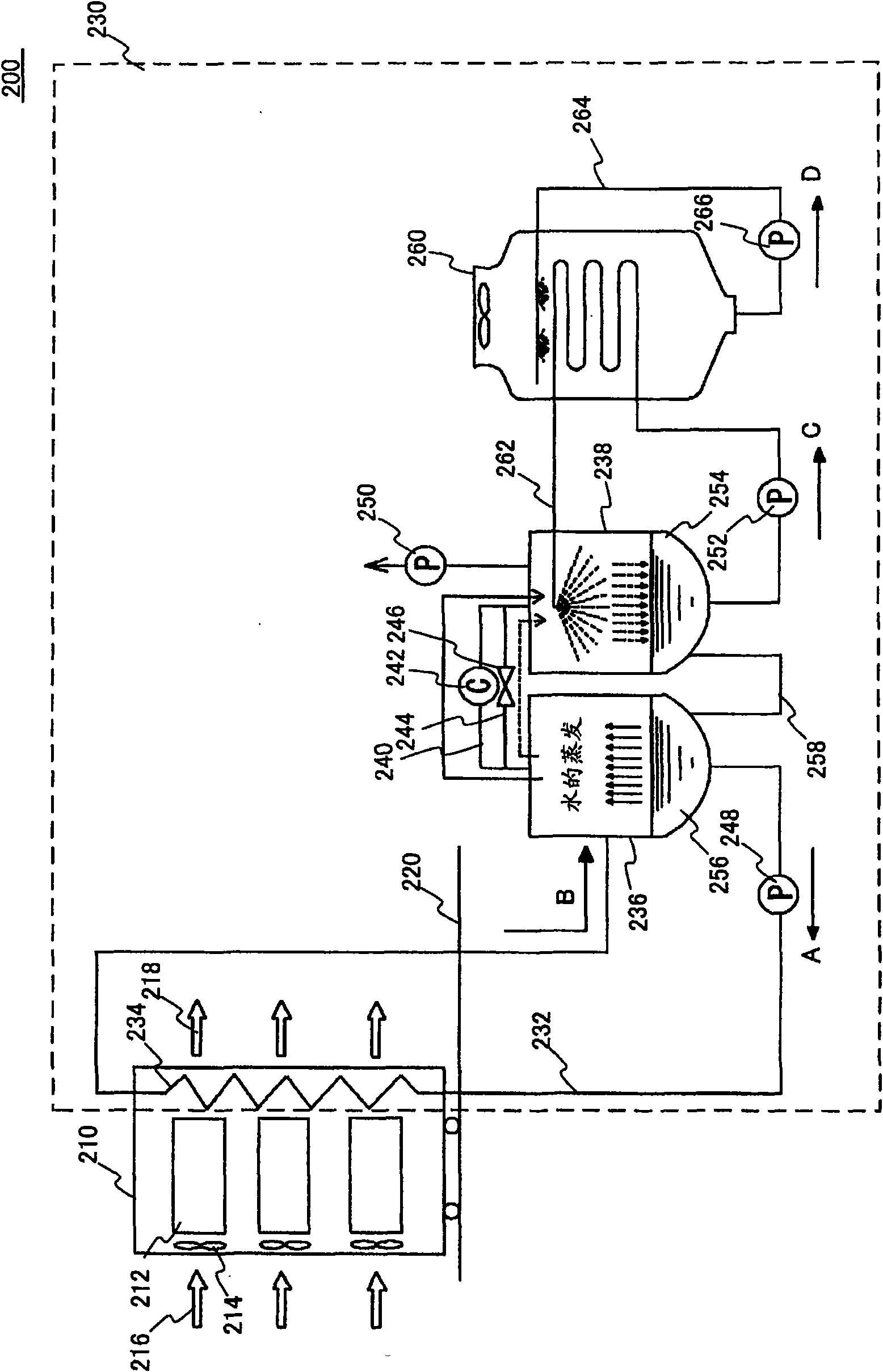

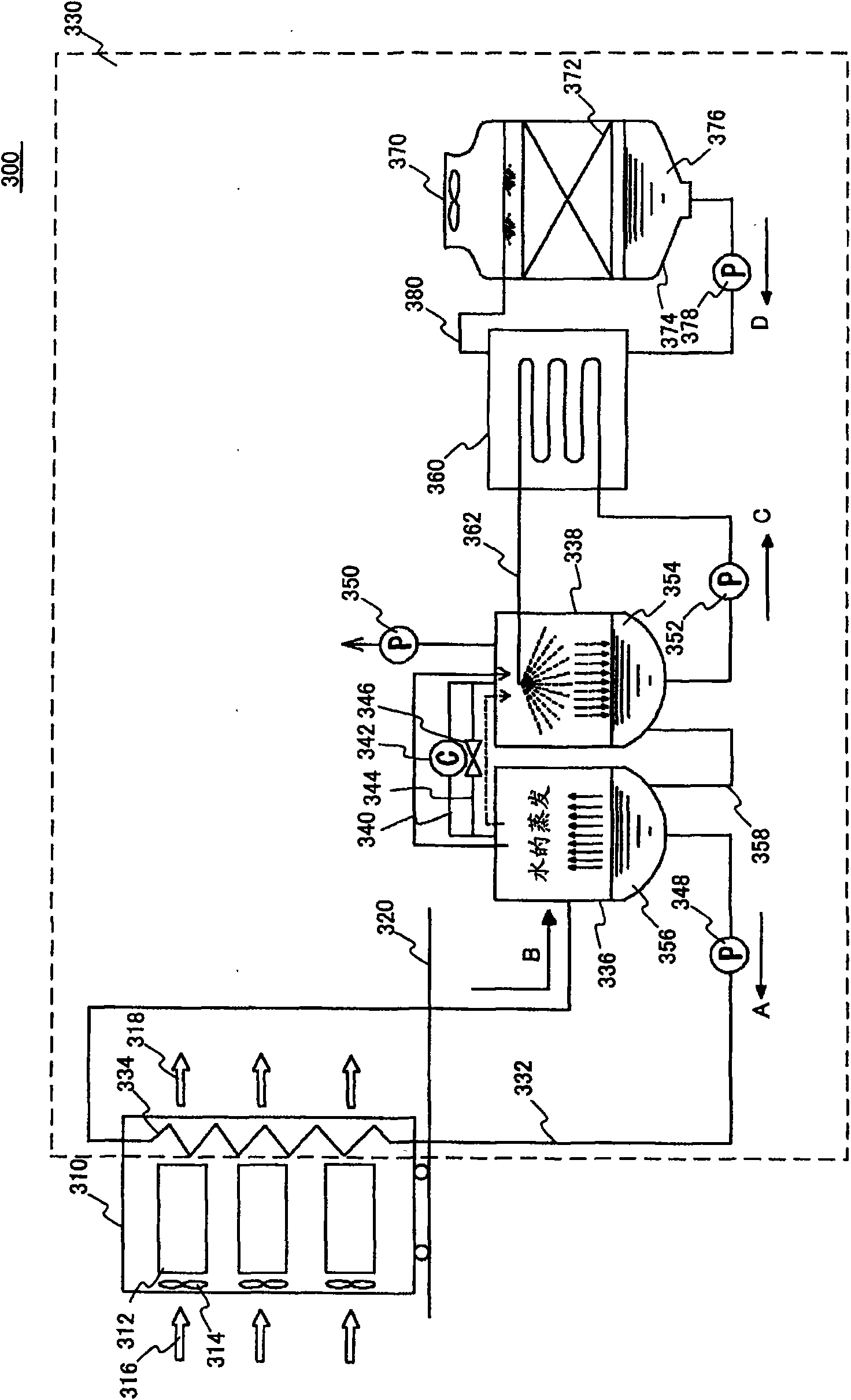

Facilitating cooling of an electronics rack employing water vapor compression system

InactiveUS8120916B2Reduce environmental loadSafe and effective removalDigital data processing detailsSemiconductor/solid-state device detailsWater vaporNuclear engineering

A cooling apparatus and method are provided for facilitating cooling of an electronic apparatus that includes a semiconductor element. The cooling apparatus includes an evaporator containing a coolant and evaporating the coolant under a reduced pressure lower than an ambient pressure to generate a chilled coolant, a condenser regenerating the coolant from a vapor of the coolant and being fluid-communicated with the evaporator through a bypass line, and a circulating pump and a line supplying the chilled coolant to a heat exchange area of the electronic apparatus to conduct a heat exchange with an air flow passing though the semiconductor element at a hot side of the electronic apparatus and returning the coolant after the heat exchange to the condenser.

Owner:INT BUSINESS MASCH CORP

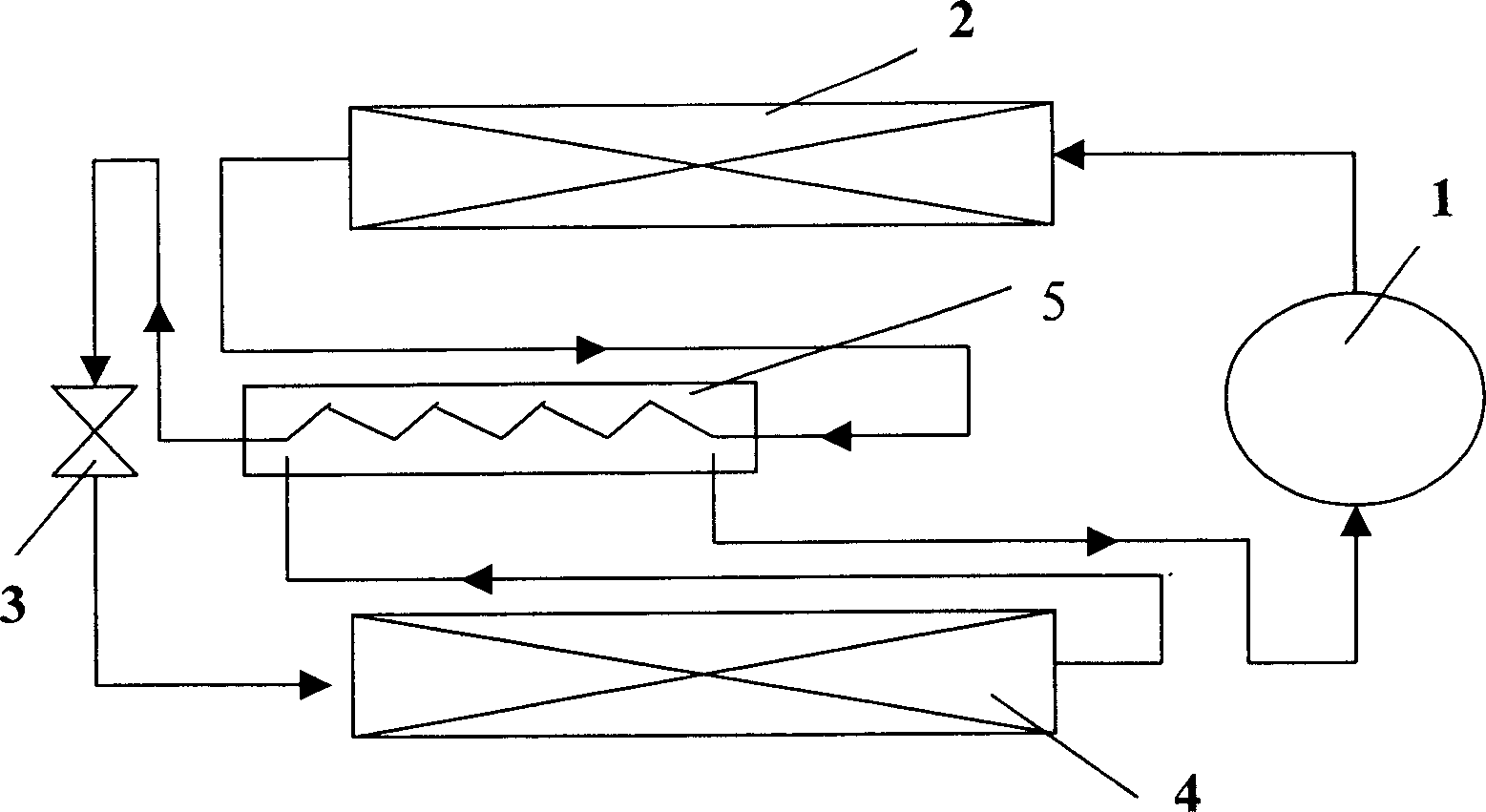

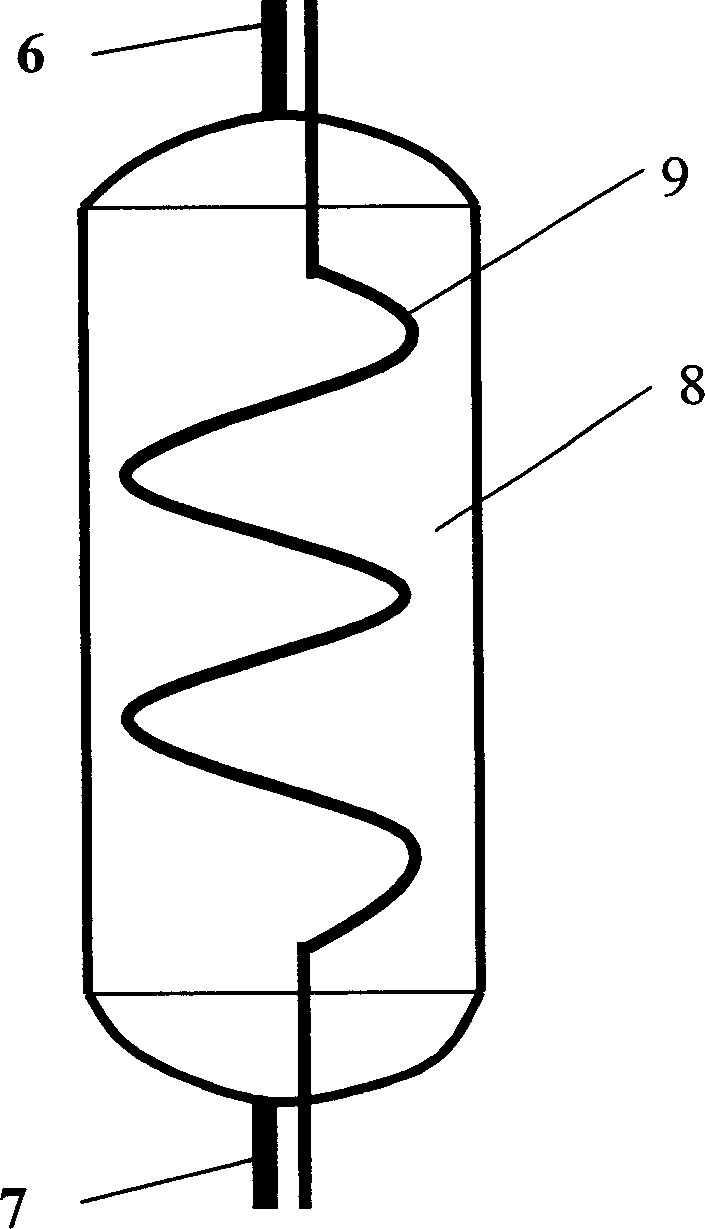

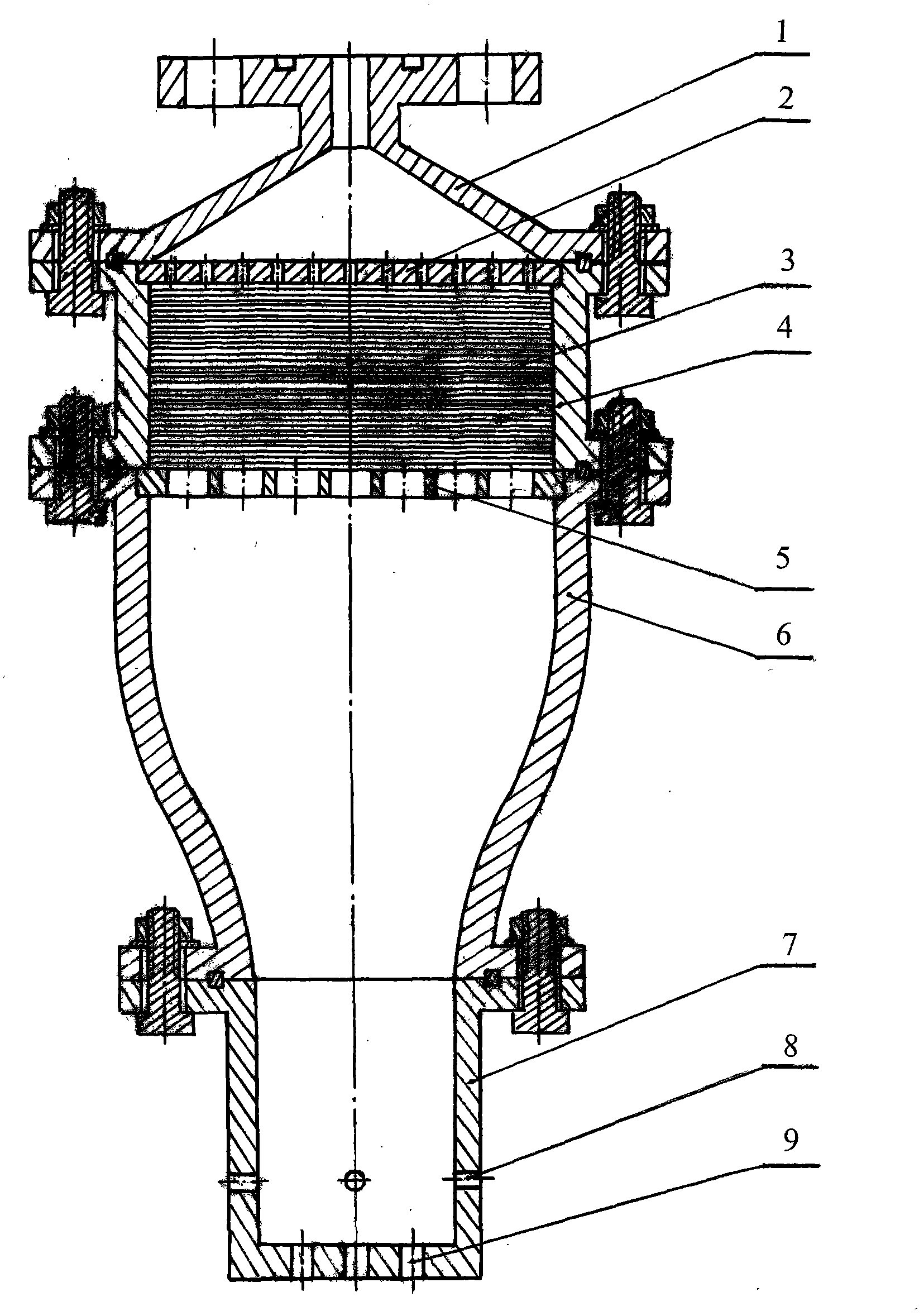

Air conditioner for regenerative cooling circulation system

InactiveCN1862151AReduce volumeReduce the impactCompression machines with non-reversible cycleSuperheatersStraight tubeEngineering

The present invention discloses a regenerative refrigeration cycle system air conditioner. It includes compressor, condenser, throttle device, evaporator and recuperative heat exchanger. The described recuperative heat exchanger includes a cylindrical tank body whose top portion and bottom portion are respectively equipped with low-pressure refrigerant outlet and inlet connected with compressor suction pipe and evaporator outlet, a straight tube which is placed in the interior of tank body along vertical direction and whose upper and lower ends are respectively connected with condenser outlet and throttle device and a heat-exchanging coiled tube, said coiled tube and straight tube are integrally formed into one body.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

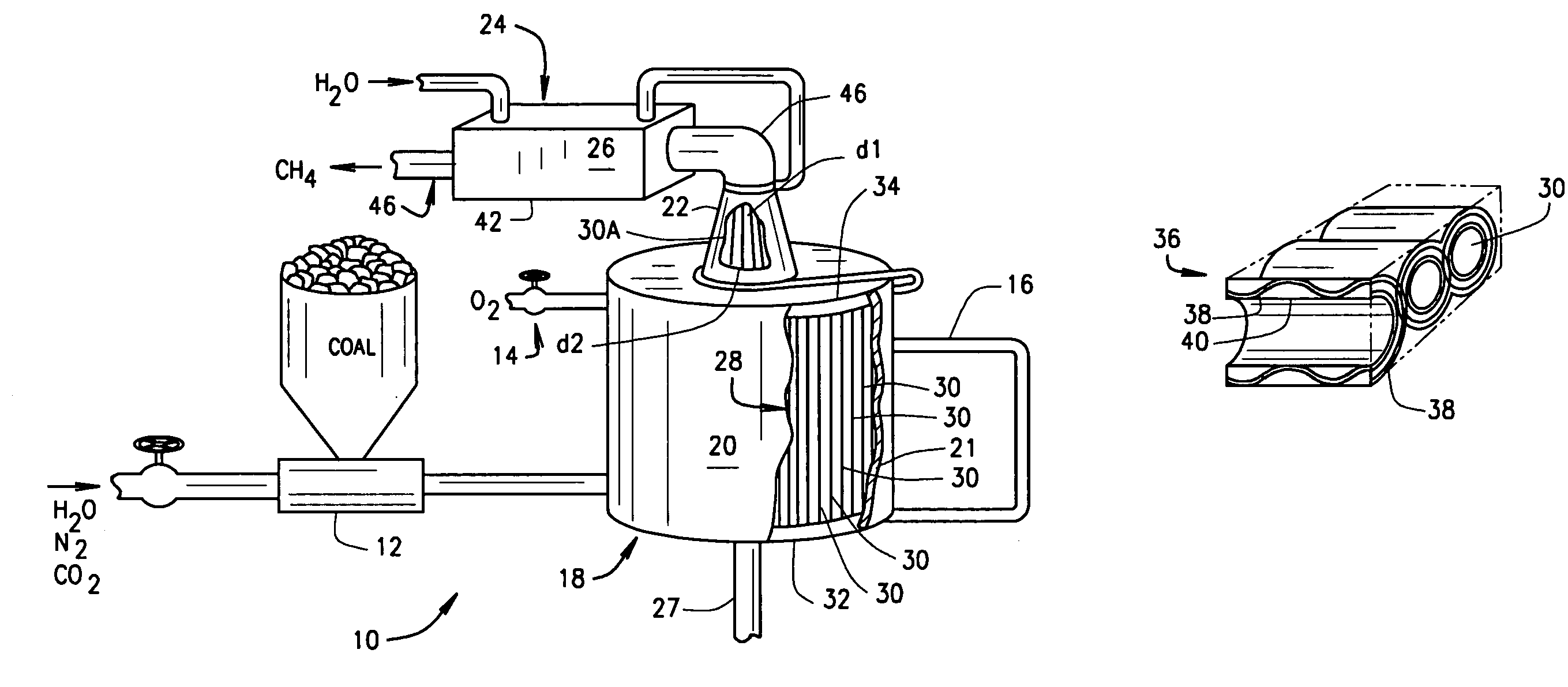

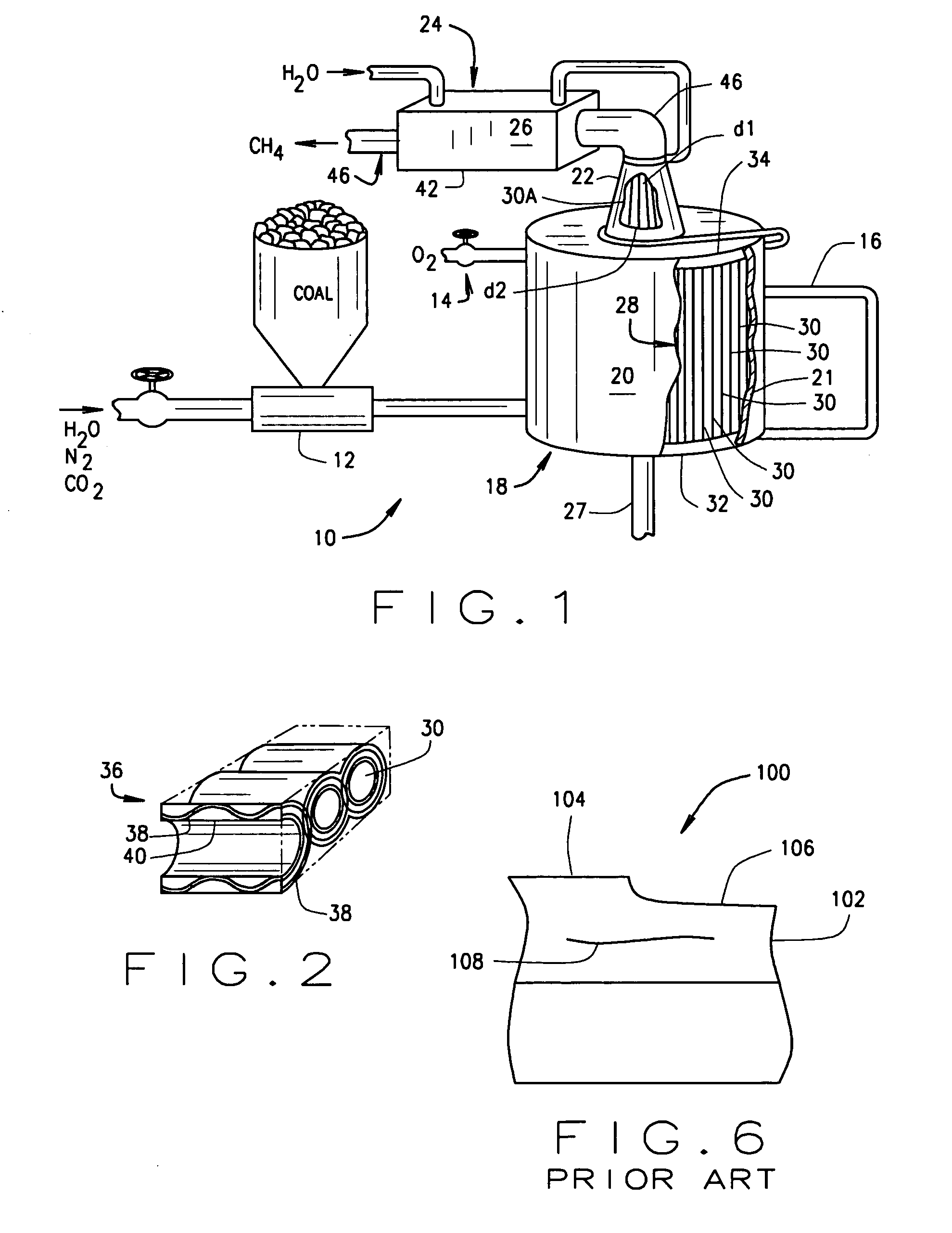

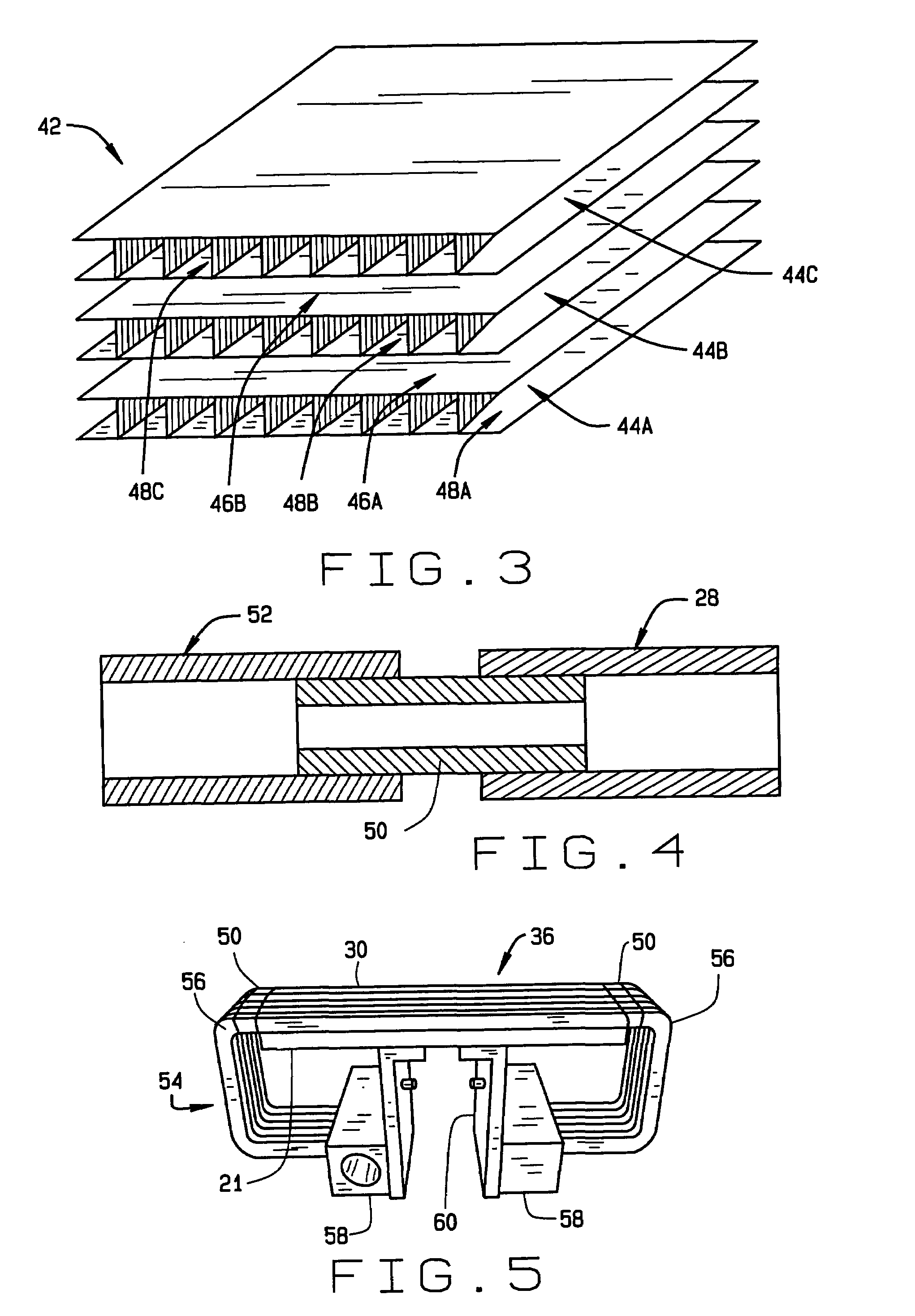

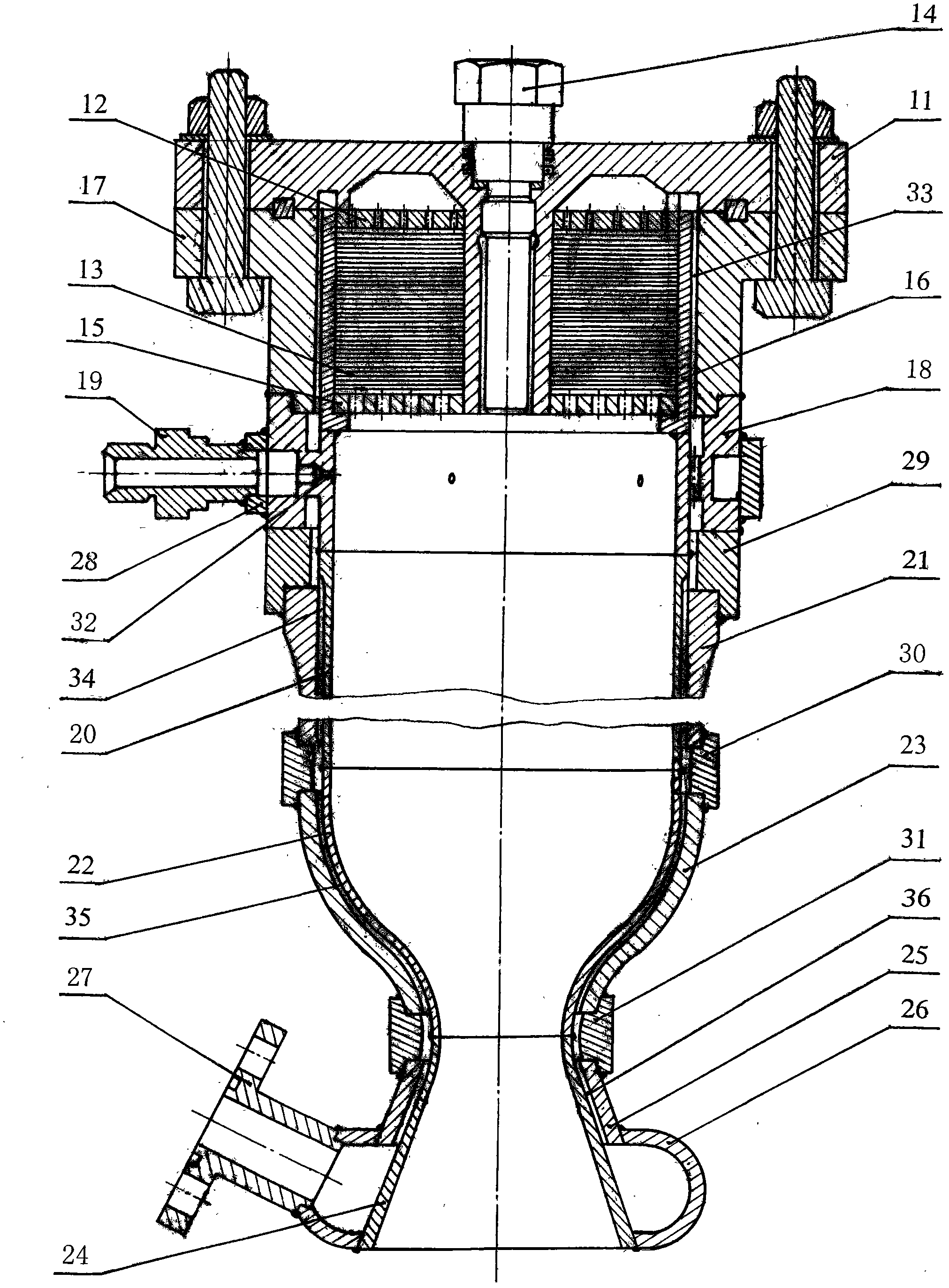

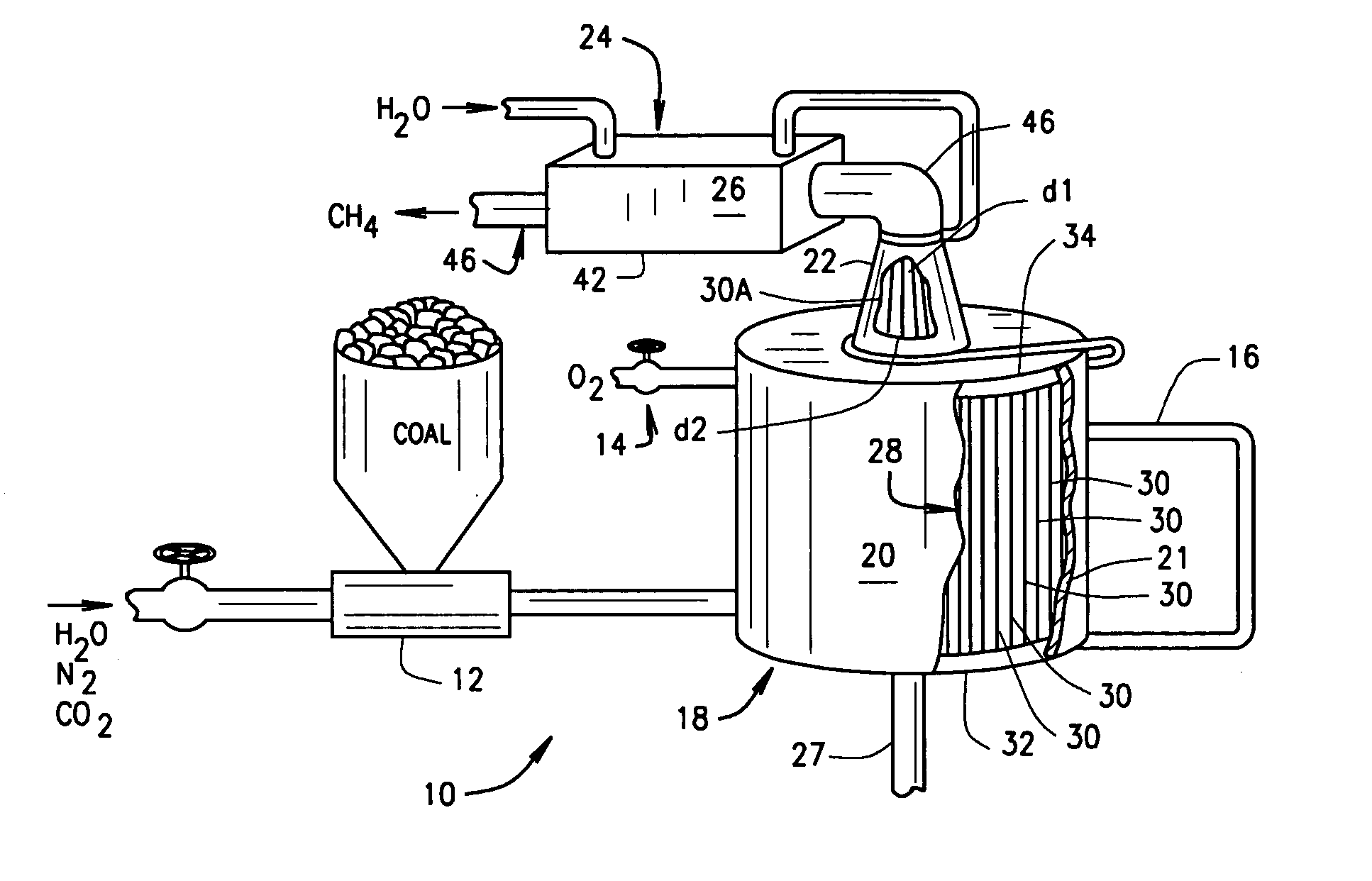

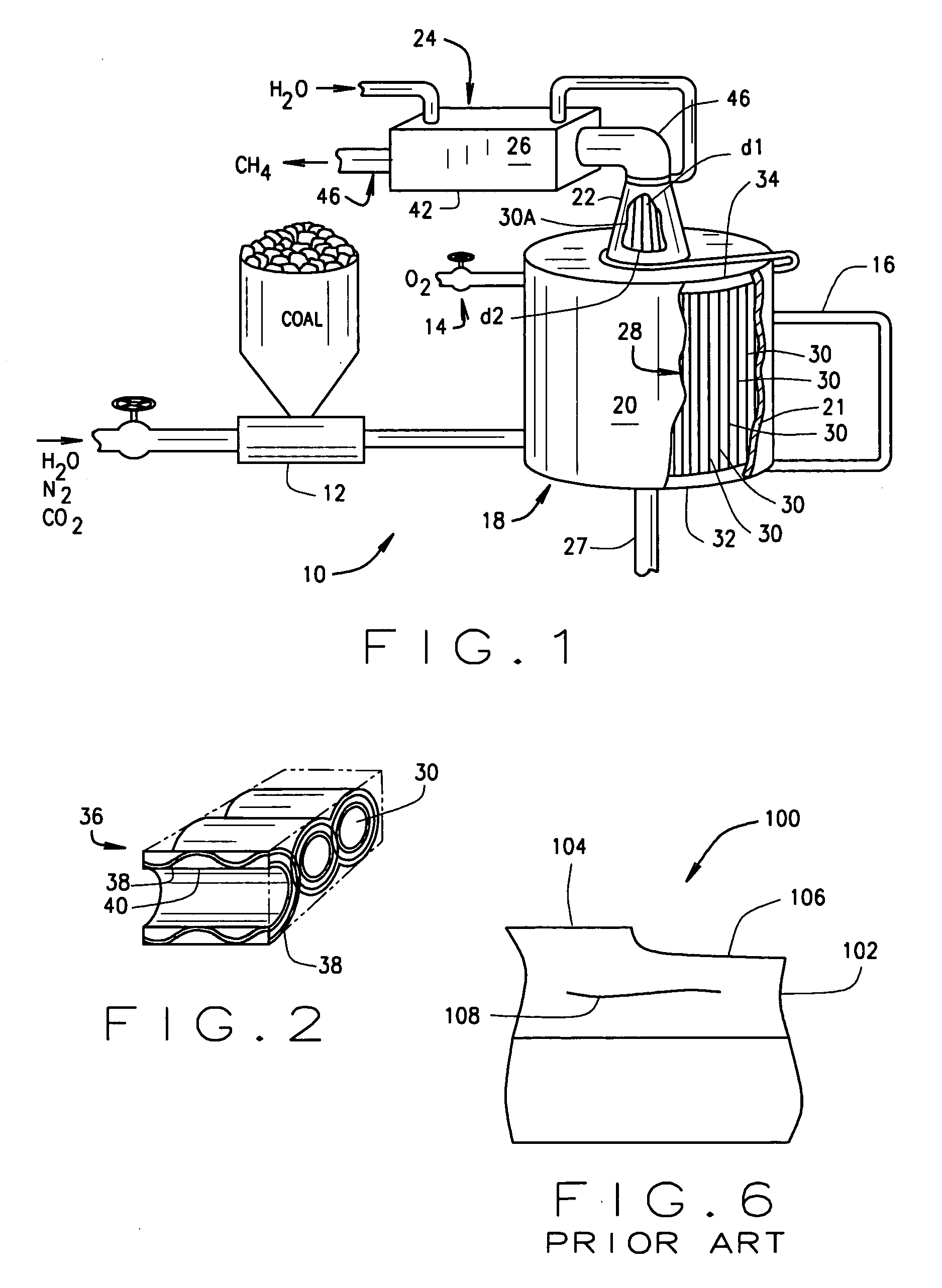

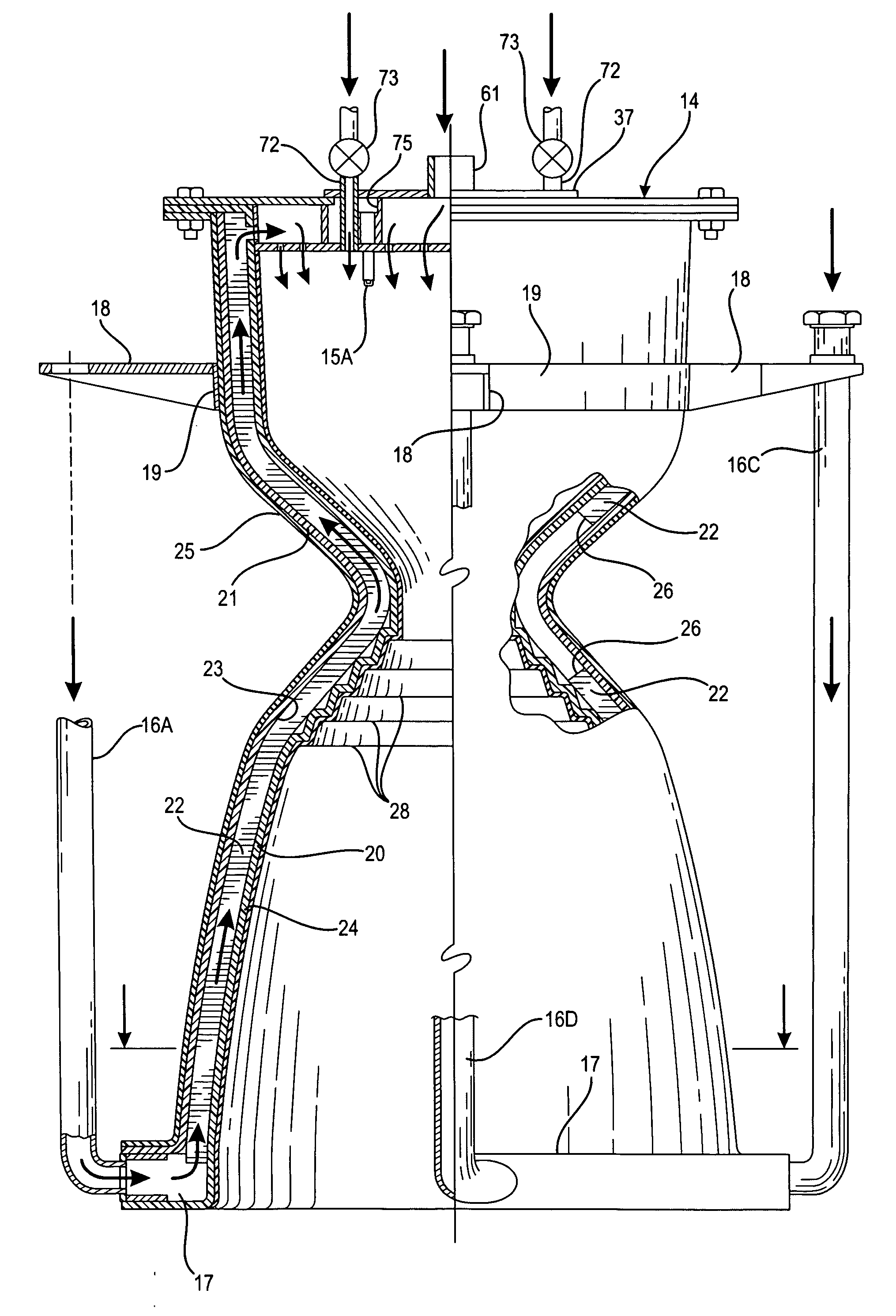

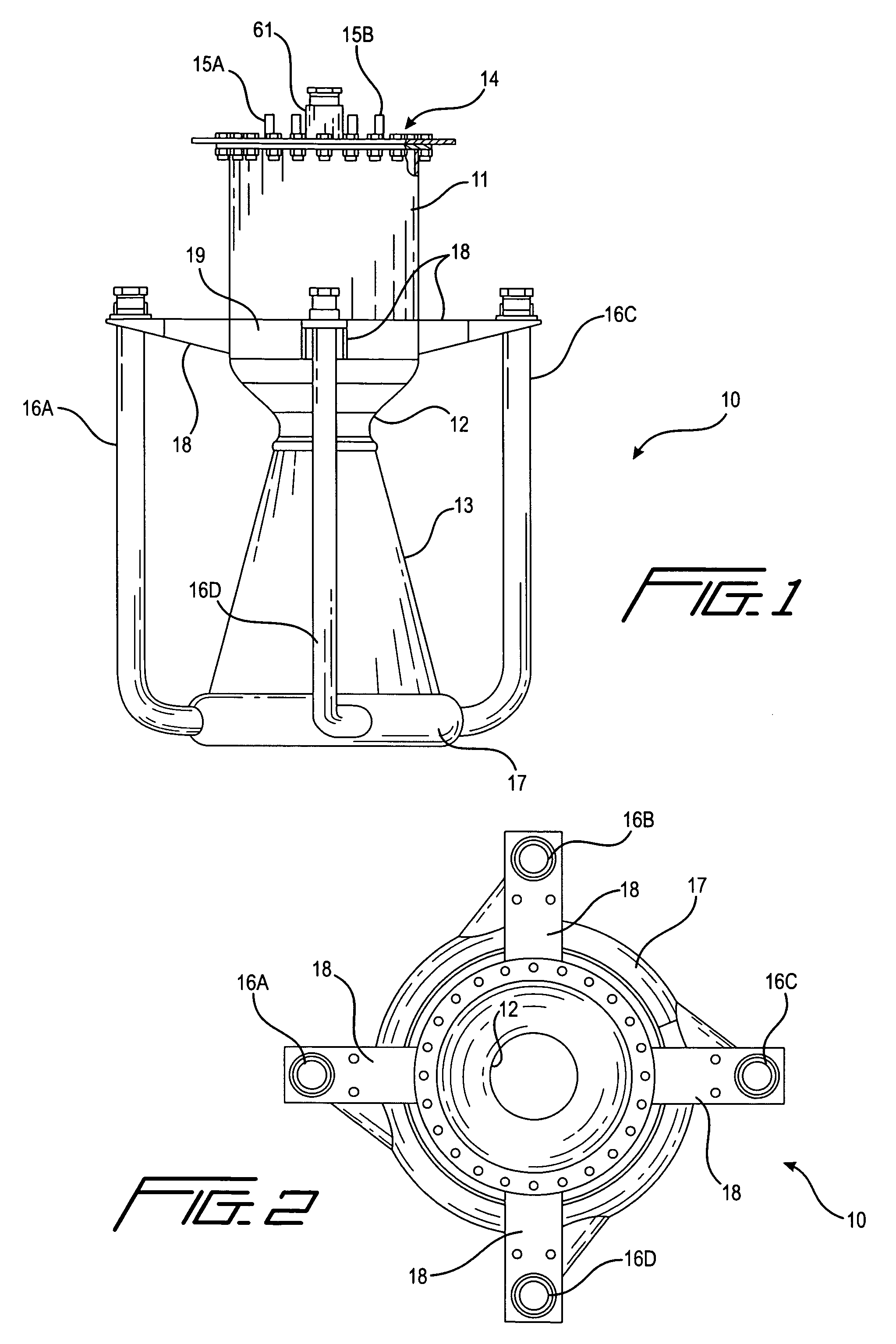

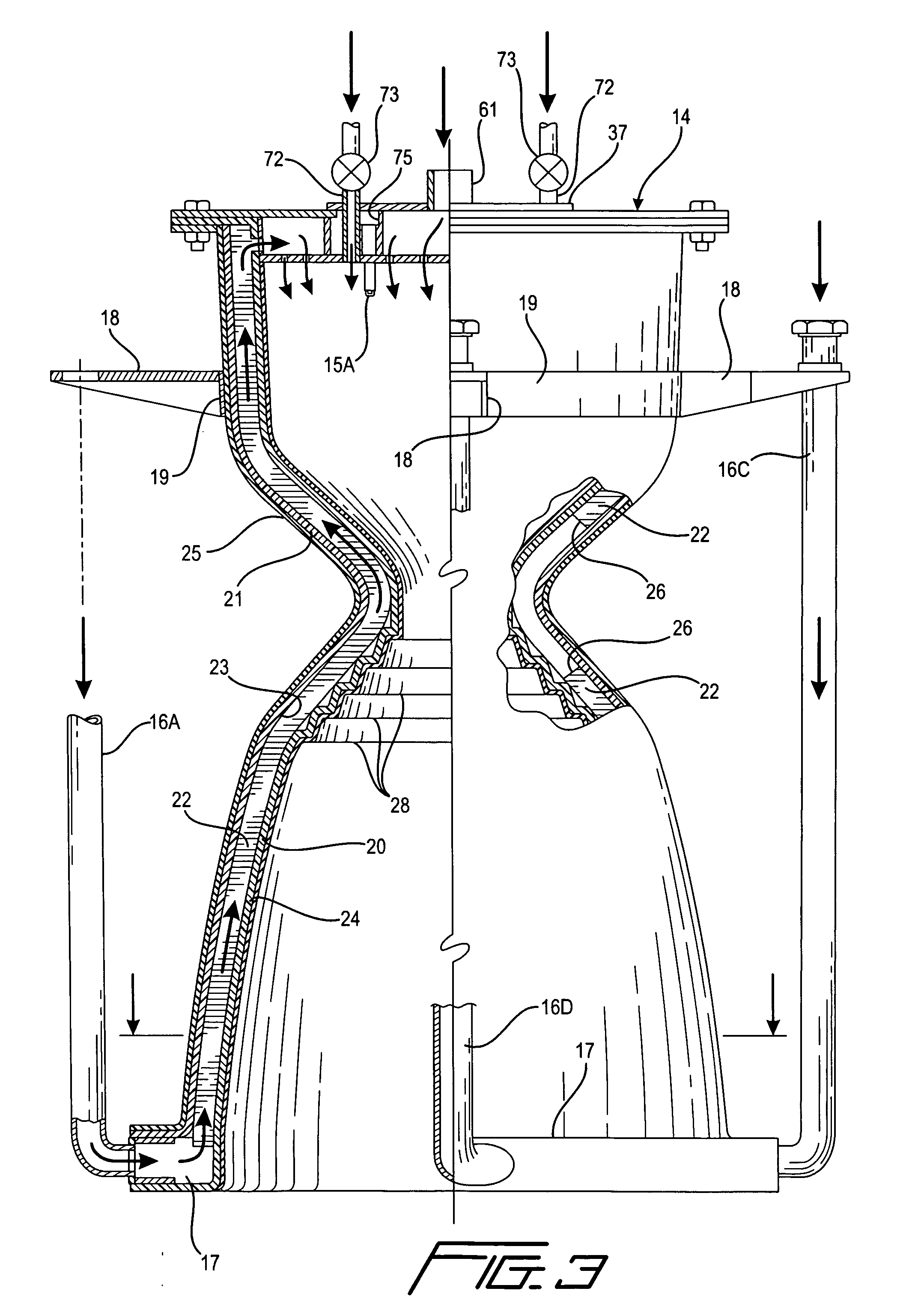

Regeneratively cooled synthesis gas generator

InactiveUS6920836B2Low costImprove reliabilityGasifier mechanical detailsCorrosion preventionYarnFiber

A coolant liner for a carbonaceous fuel (coal or petcoke) gasification vessel including a ceramic composite panel and a method of cooling a vessel. The panel includes at least two layers of woven yarns of fibrous material and walls extending between the layers. Accordingly, the layers and the walls define coolant channels that extend in a warp direction. Moreover, one of the layers may be less than about 0.08 inches thick. Materials used to create the composite panel may include alumina, chromia, silicon carbide, and carbon. Additionally, the liners may be shaped in an arc or have coolant channels which vary in diameter in the warp direction. Additionally, the liner may abut a structural closeout of the vessel. The coolant liner provides a significantly more durable component than previously employed liners and is especially well suited to demanding service environments.

Owner:GAS TECH INST +1

Catalytic decomposition low-concentration hydrogen peroxide reactor, combustion chamber and application thereof

InactiveCN102658066ALow priceImprove securityRocket engine plantsChemical/physical processesCombustion chamberKerosene

The invention relates to a catalytic decomposition low-concentration hydrogen peroxide reactor and a combustion chamber, which solve the problem that in the prior art, price is expensive, safety is not high, freezing point is high, decomposition temperature and ignition temperature are high, purpose is single and the like. A multilayer low-bed-load and pre-contact fine silver net catalysis bed for catalytic decomposition of 40%-70% of hydrogen peroxide is adopted, and service life is greatly prolonged. Radial holes or / and axial holes are arranged on a laryngeal casing of the catalytic decomposition low-concentration hydrogen peroxide reactor for using in underground reactor oil recovery by heating, mining and marine accident self rescuing and a life support system of spaceships and rocket oxidizer storage tank supercharging. The catalytic decomposition low-concentration hydrogen peroxide combustion chamber is provided with a plurality of radial spraying holes for spraying diesel oil or kerosene, an electronic spark plug for ignition, a combustion chamber body with the 40%-70% of hydrogen peroxide serving as a regeneration cooling agent and two kinds of spraying tubes, and the catalytic decomposition low-concentration hydrogen peroxide combustion chamber can be used for thrust chamber gas spraying thrust of a plurality of military projects and road ice and snow removal by heat and crude oil pollution.

Owner:葛明龙

Regeneratively cooled synthesis gas generator

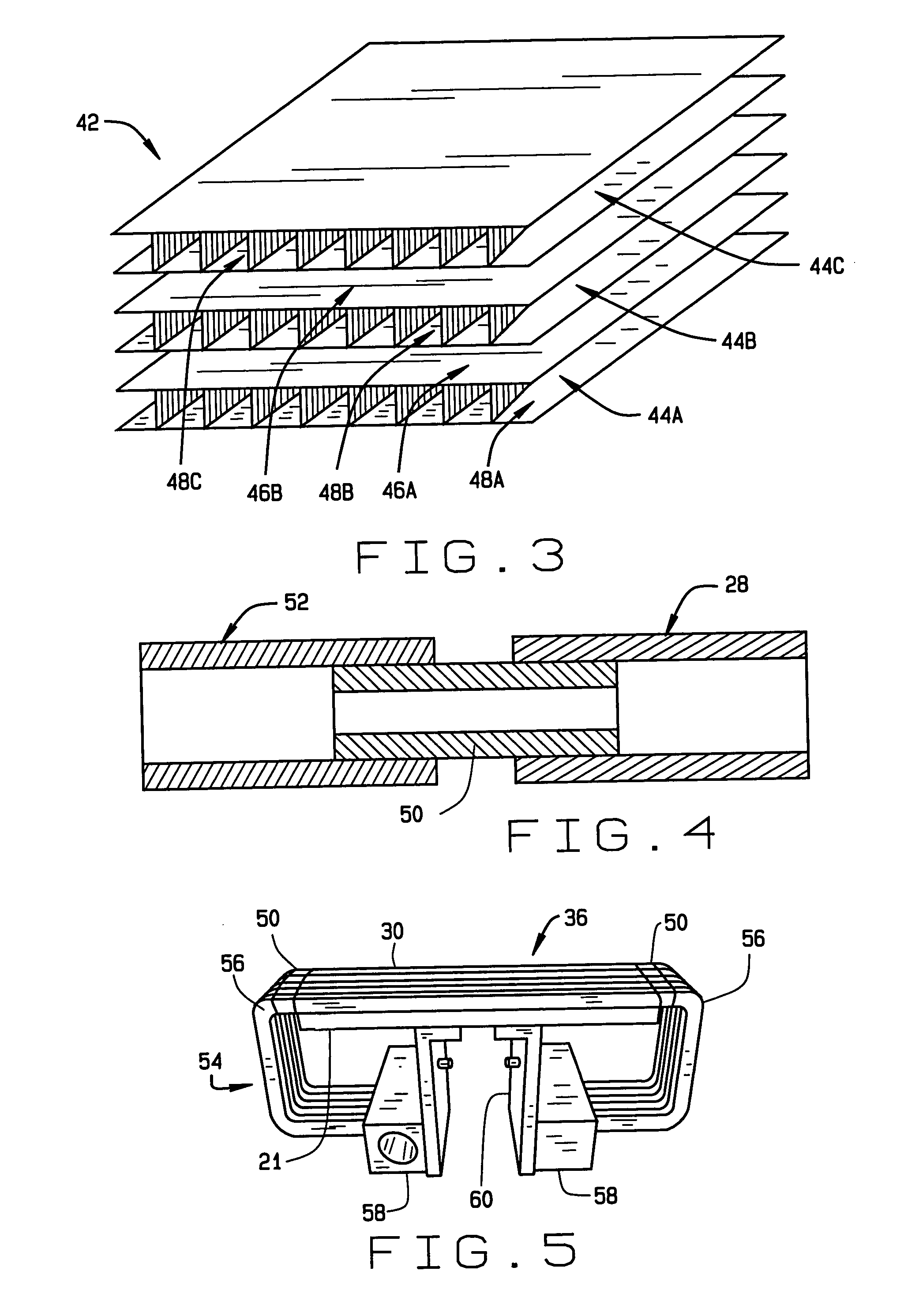

InactiveUS20050072341A1Low costImprove reliabilityGasifier mechanical detailsFurnace cooling arrangementsYarnFiber

A coolant liner for a carbonaceous fuel (coal or petcoke) gasification vessel including a ceramic composite panel and a method of cooling a vessel. The panel includes at least two layers of woven yarns of fibrous material and walls extending between the layers. Accordingly, the layers and the walls define coolant channels that extend in a warp direction. Moreover, one of the layers may be less than about 0.08 inches thick. Materials used to create the composite panel may include alumina, chromia, silicon carbide, and carbon. Additionally, the liners may be shaped in an arc or have coolant channels which vary in diameter in the warp direction. Additionally, the liner may abut a structural closeout of the vessel. The coolant liner provides a significantly more durable component than previously employed liners and is especially well suited to demanding service environments.

Owner:GAS TECH INST +1

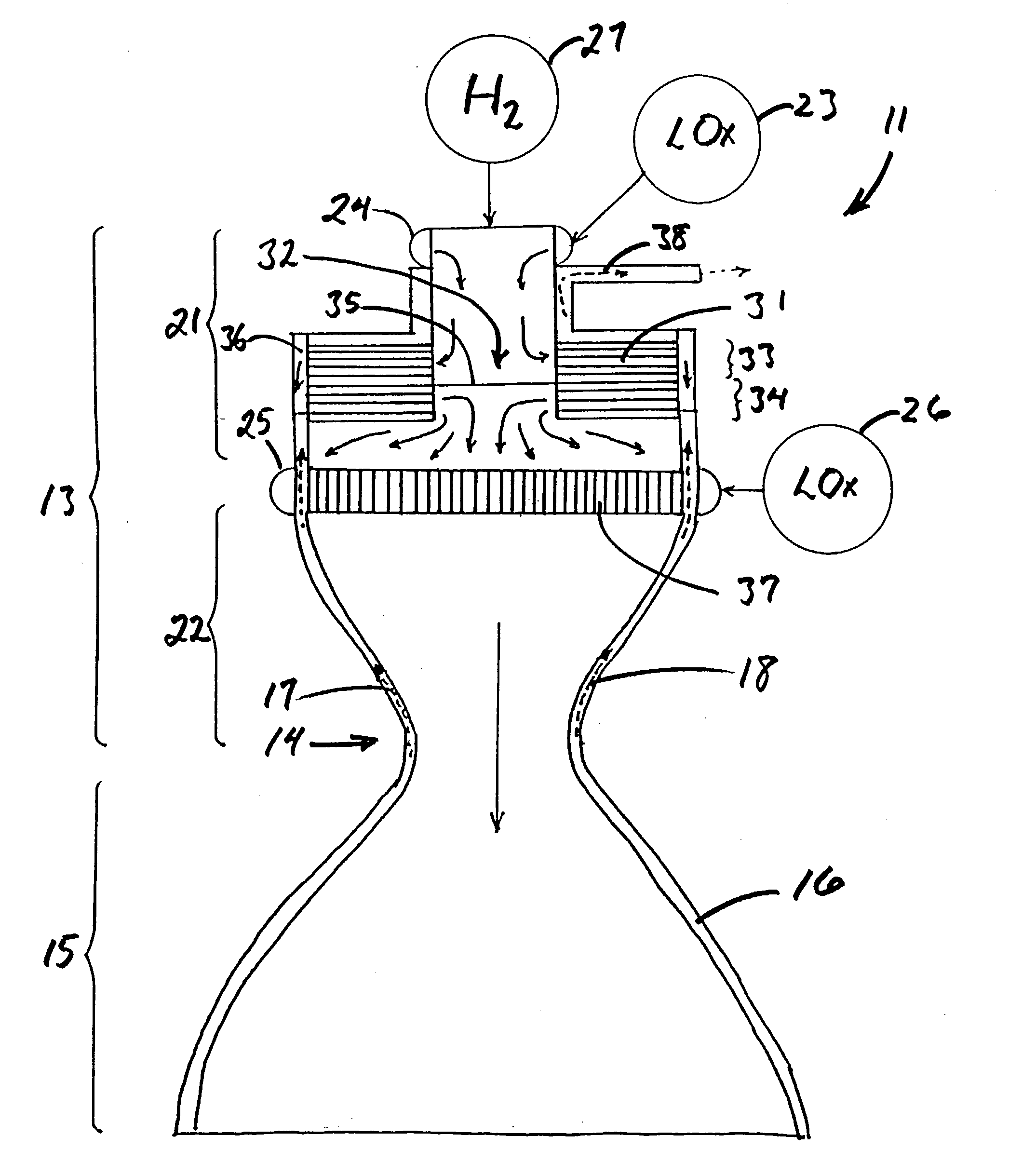

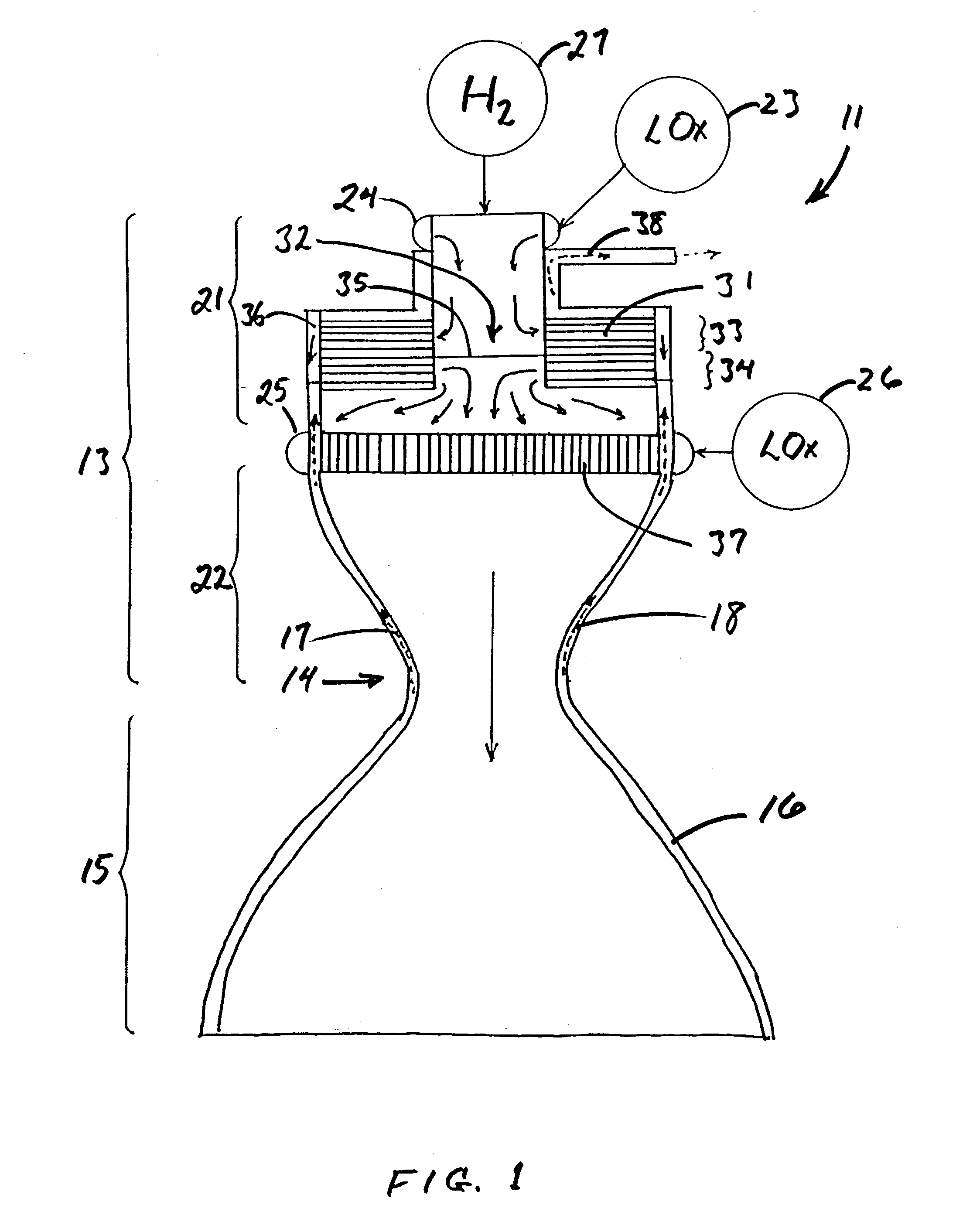

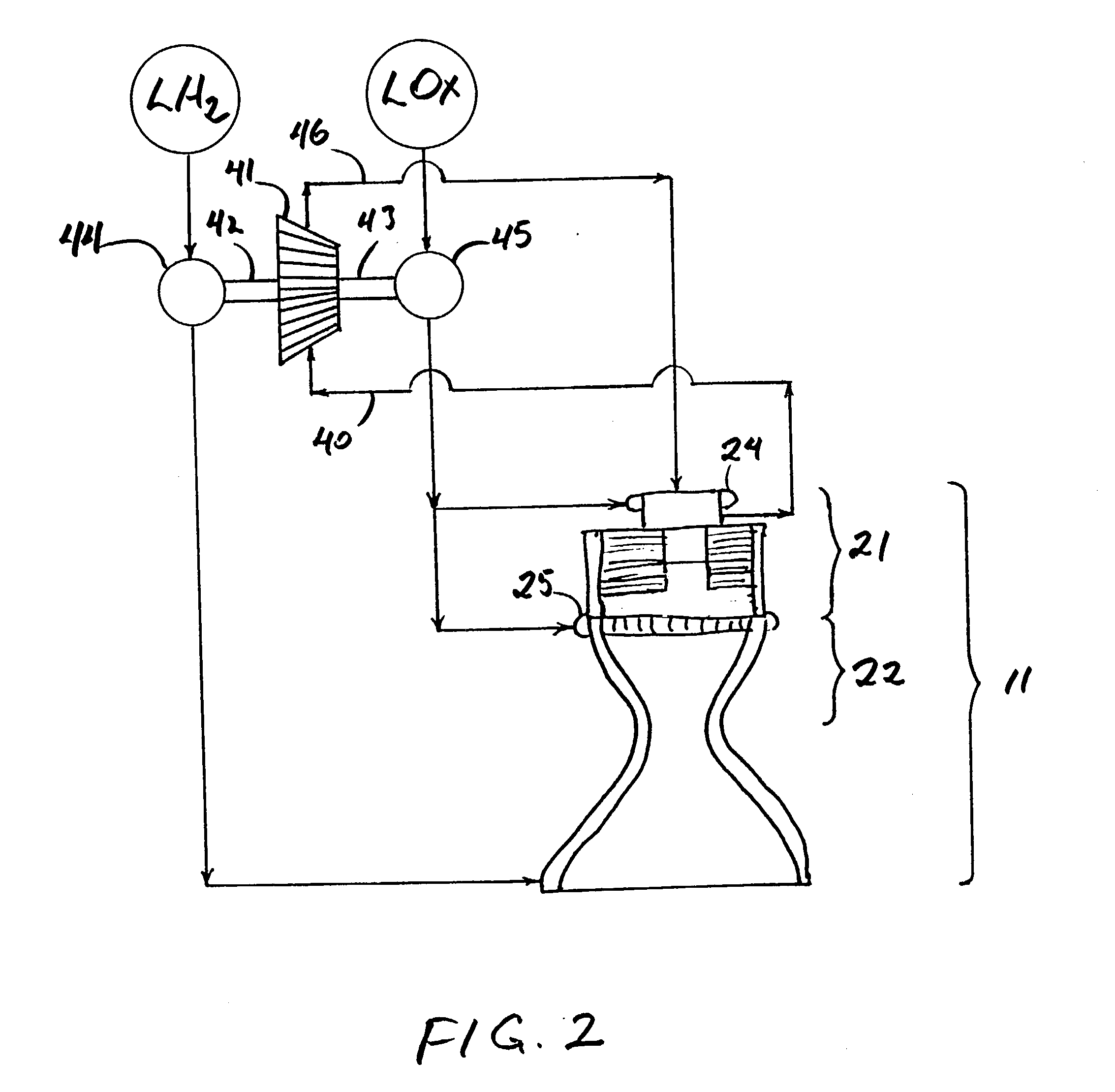

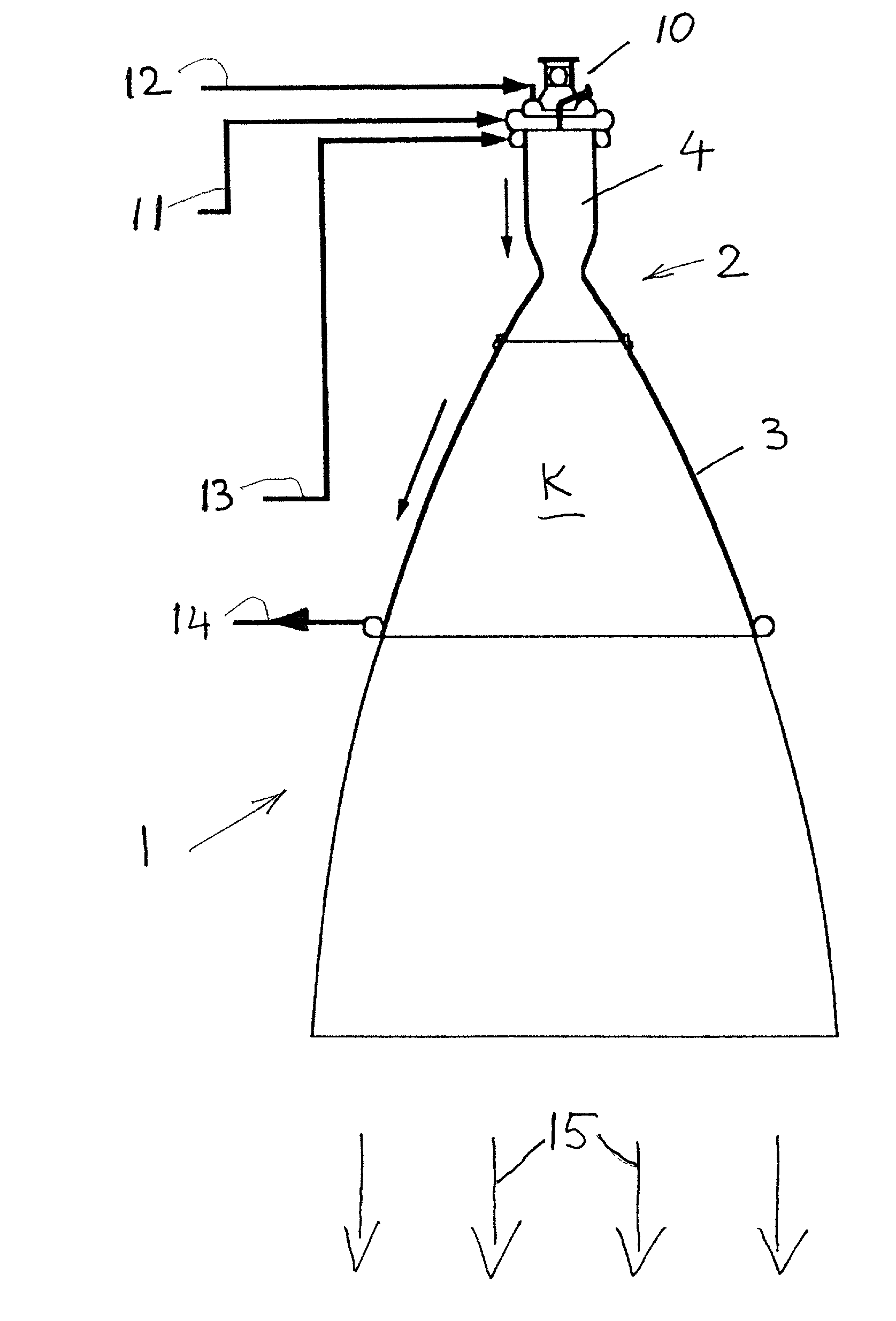

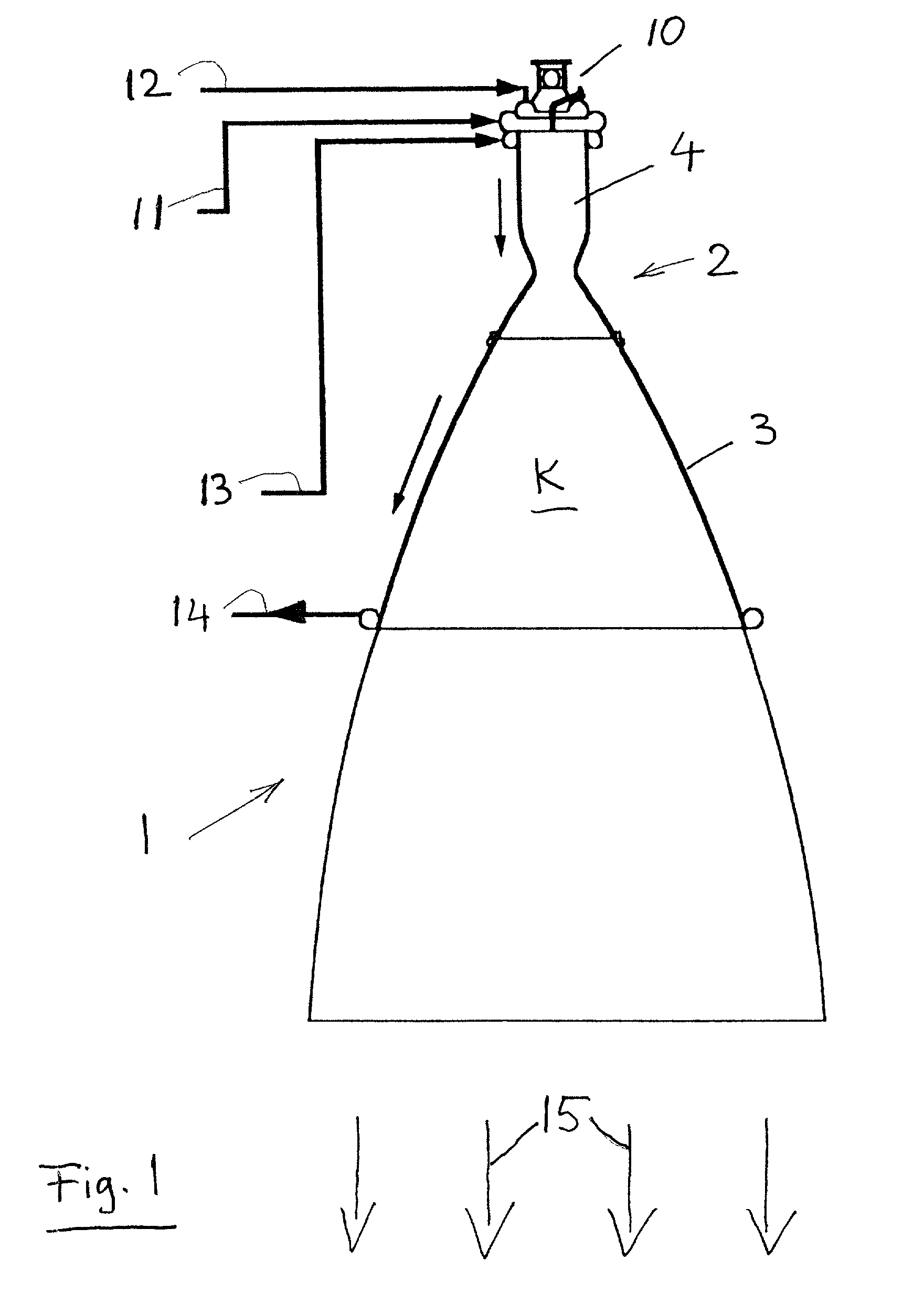

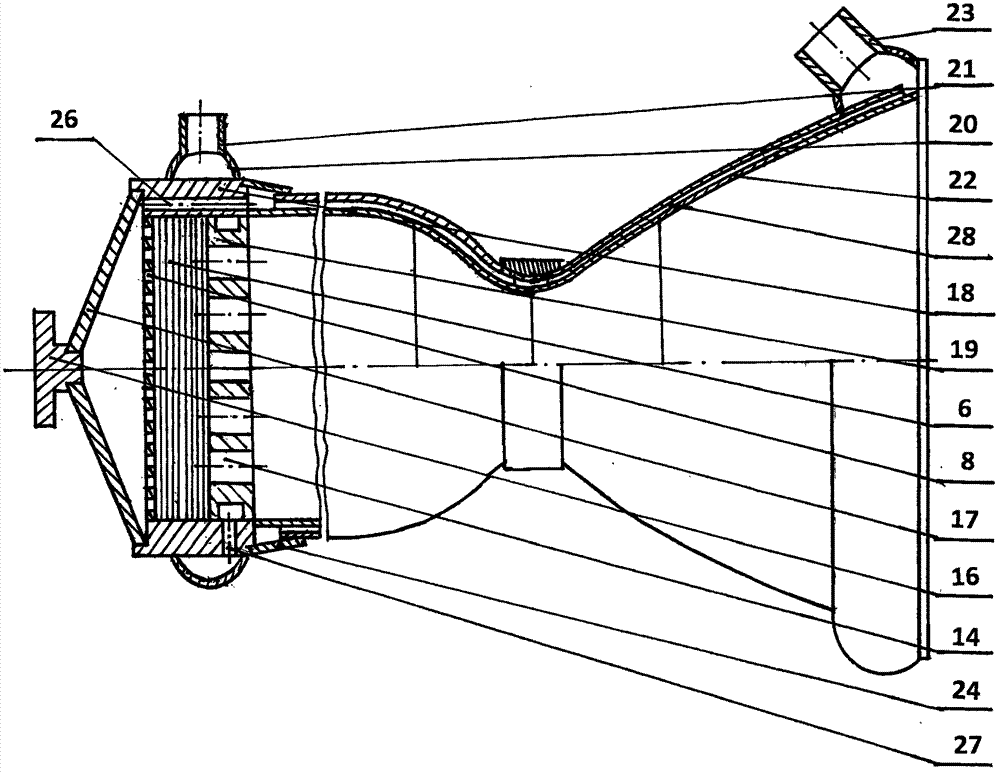

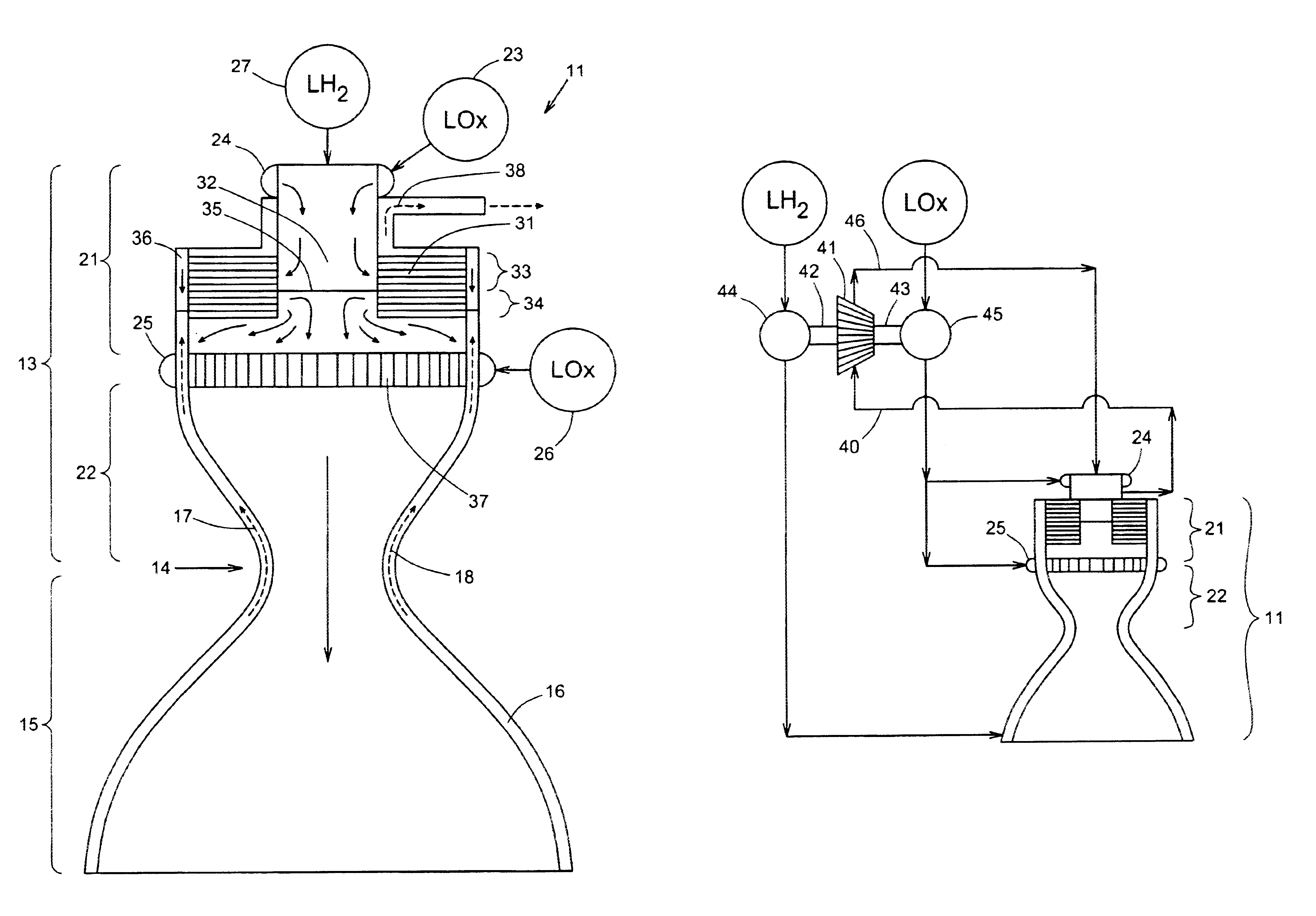

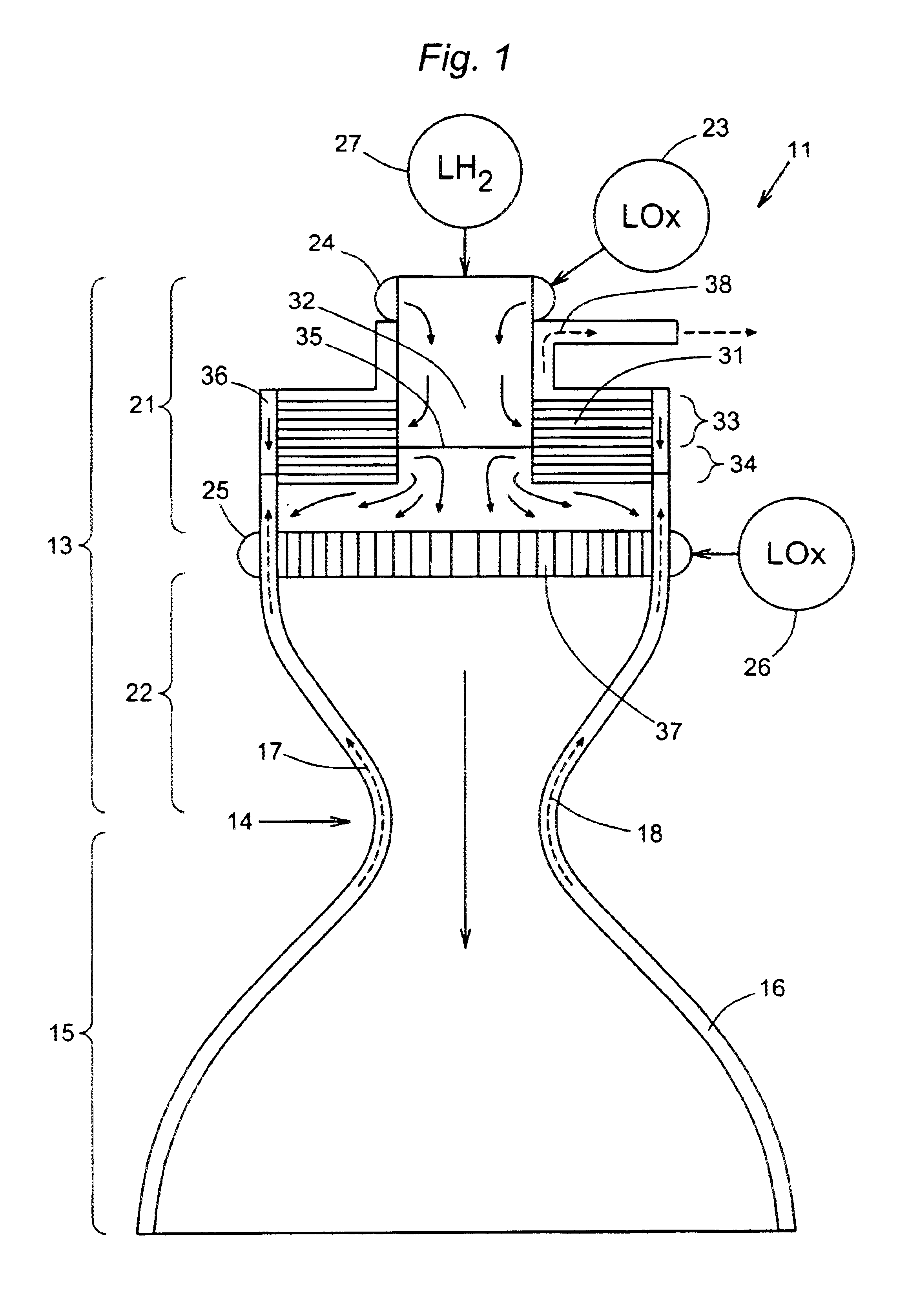

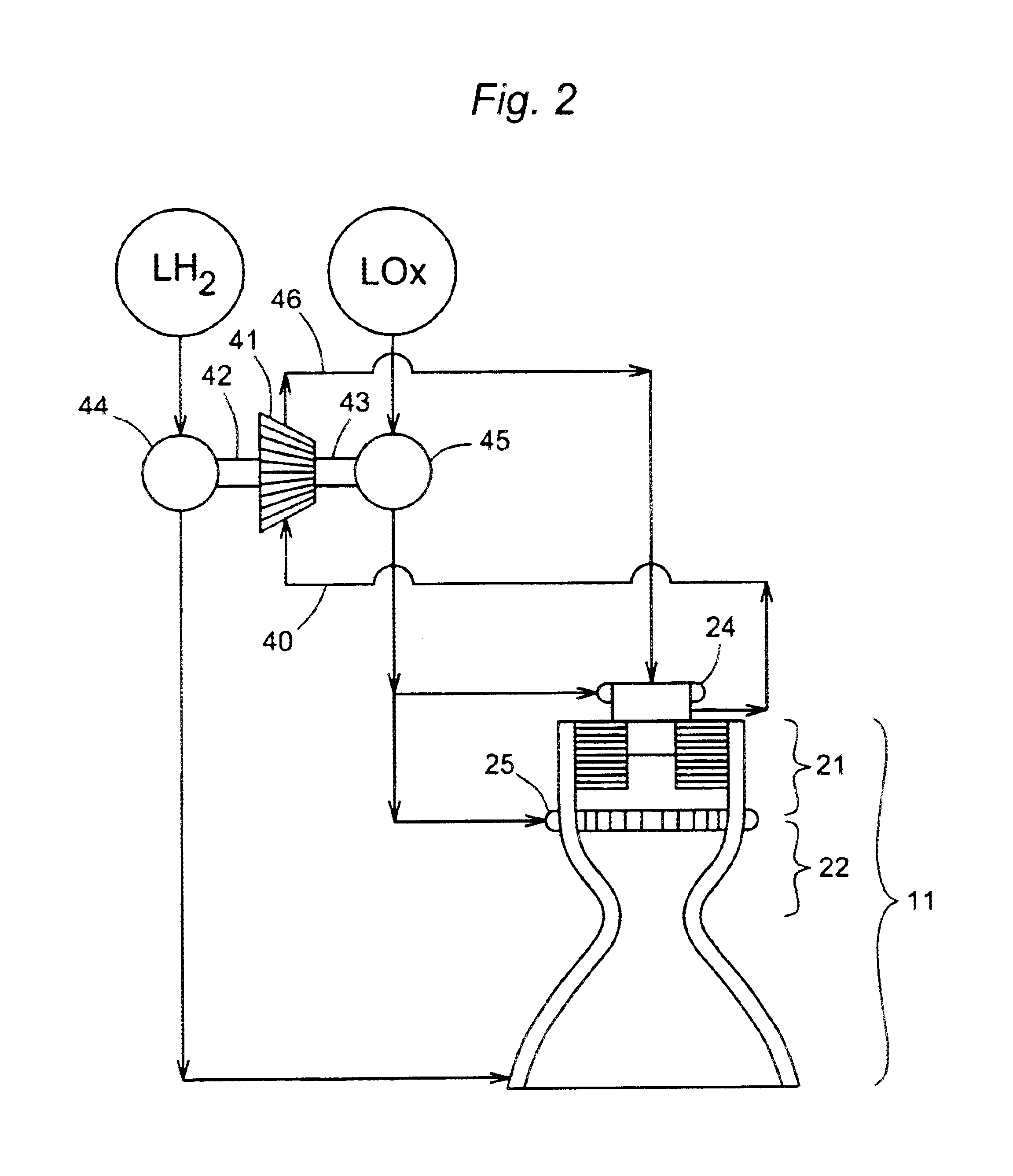

Expander cycle rocket engine with staged combustion and heat exchange

In a supersonic nozzle incorporating injectors and a combustion chamber as part of an expander cycle rocket engine, the oxidizer is injected in two streams. One of the streams, preferably a small fraction of the total, is injected into an upstream or preburner section of the combustion chamber and the other to a downstream or main section of the chamber. The preburner combustion gas is cooled in a substantially uniform manner to a moderate temperature by cooling the bulk of the gas rather than cooling only the gas in a boundary layer adjacent to the chamber wall. The combustion gas produced in the downstream section is hotter, and heat from that gas is drawn through the chamber wall into a jacket. The limited combustion in the preburner permits the use of a cooling element with highly intimate heat exchange construction, extracting a high level of energy from the preburner gas without damage to the cooling element and an overall improvement in the regenerative cooling.

Owner:AEROJET ROCKETDYNE INC

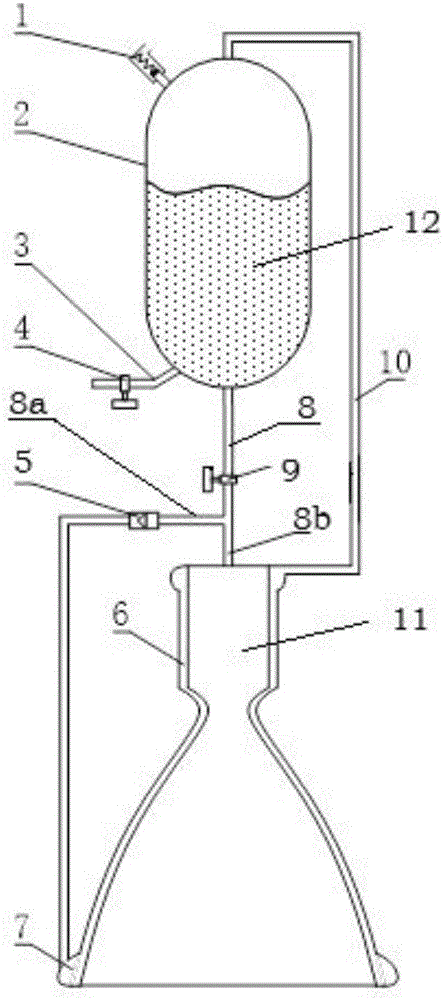

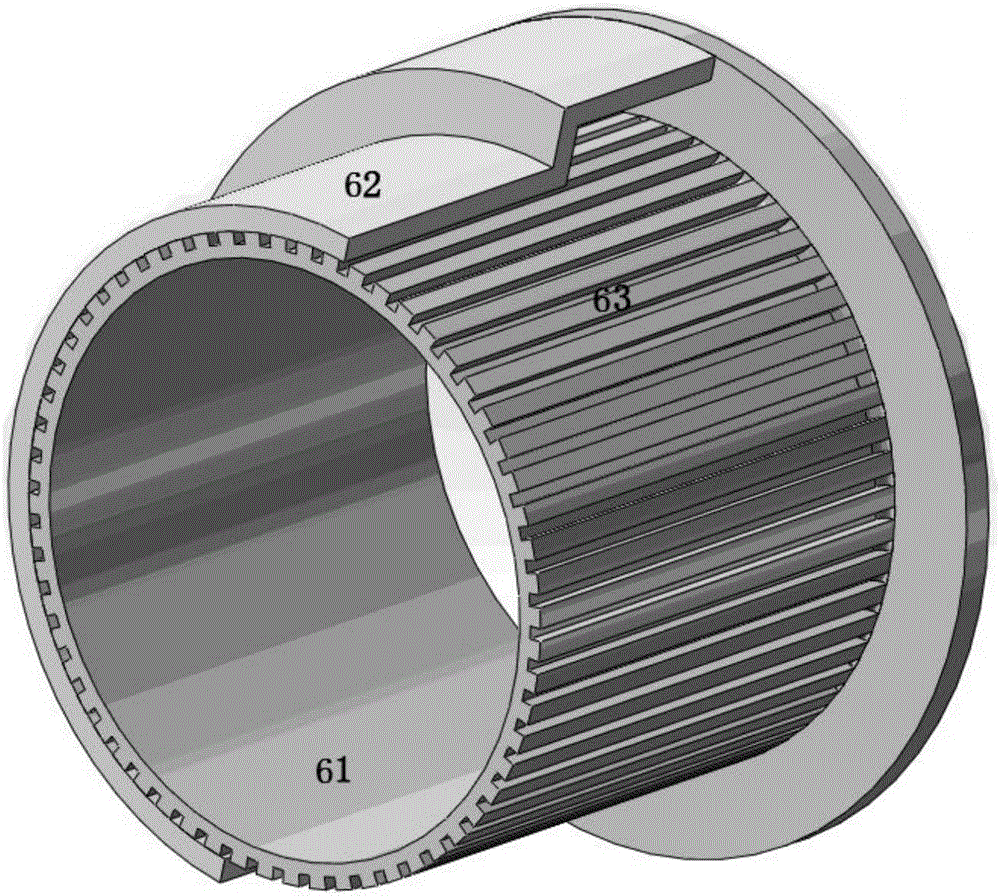

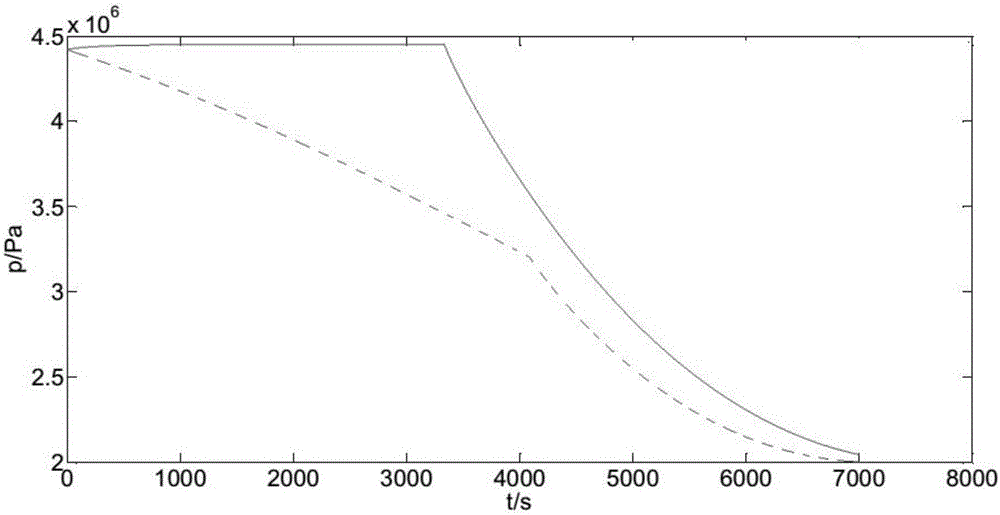

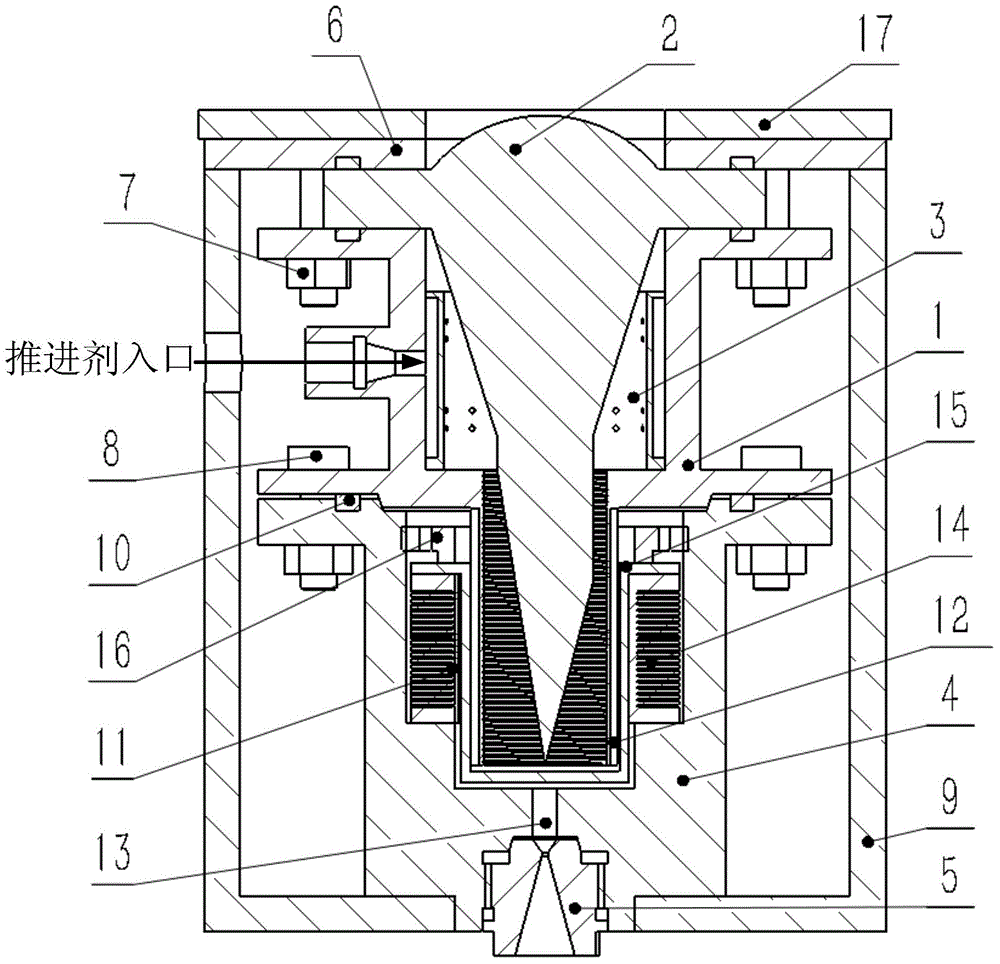

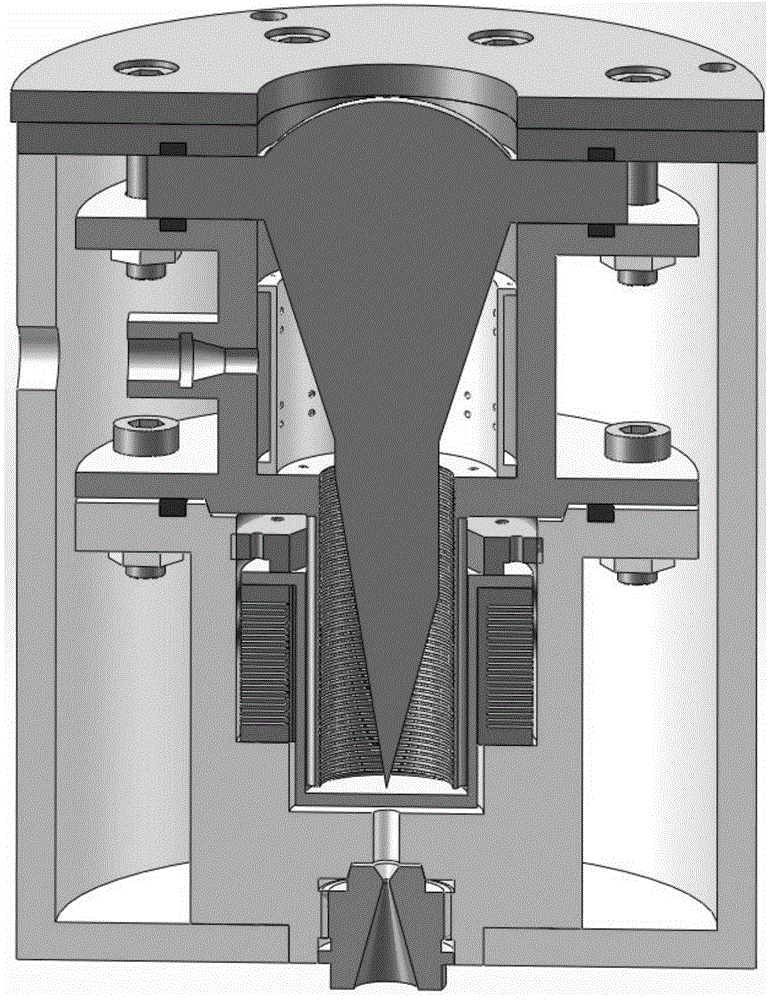

Self-pressurization supply system based on regenerative cooling

The invention belongs to the technical field of spacecraft systems and is mainly applied to liquid propulsion systems or solid-liquid mixing propulsion systems adopting high-saturated vapor pressure propulsive agents. In order to solve the problems that the temperature of propulsive agents and the pressure in a storage box are seriously reduced in the working process of a self-pressurization supply system, a self-pressurization scheme based on regenerative cooling is provided. The self-pressurization supply system is composed of a safety valve, a storage box, a filling pipeline, a filling valve, a one-way valve, a cooling channel, a liquid accumulating cavity, a main supply pipeline, a coolant pipeline, a burning agent pipeline, a main valve, a pressurization pipeline and the like. Propulsive agents cool the wall of a combustor and acquire heat at the same time. The propulsive agents subjected to heat exchange and vaporization return to the storage box to pressurize the storage box. According to the self-pressurization supply system based on regenerative cooling, the pressure intensity of the storage box can be basically maintained to be stable before the liquid propulsive agents in the storage box are completely discharged, and accordingly the effect that the thrust is basically stable is ensured.

Owner:NAT UNIV OF DEFENSE TECH

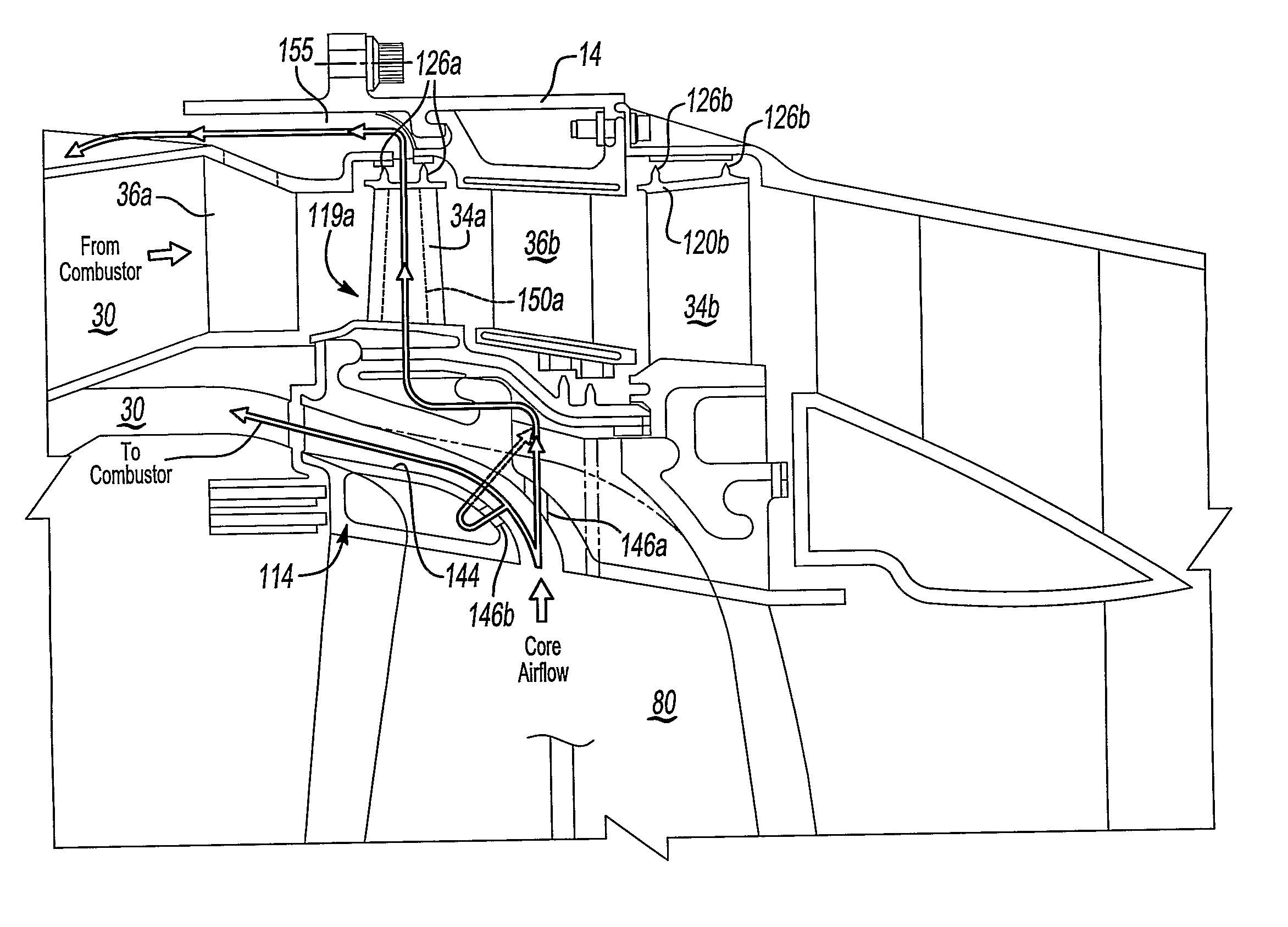

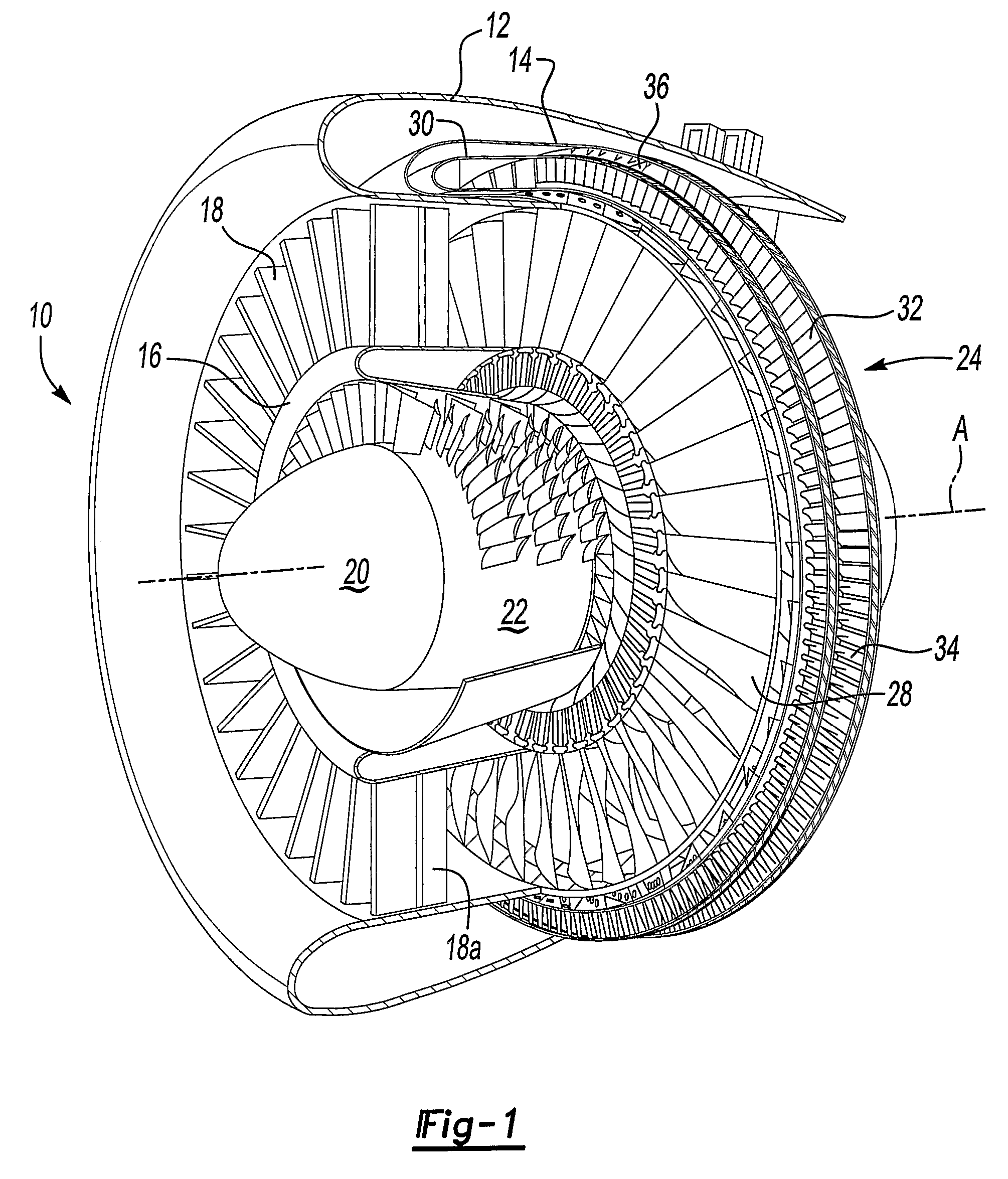

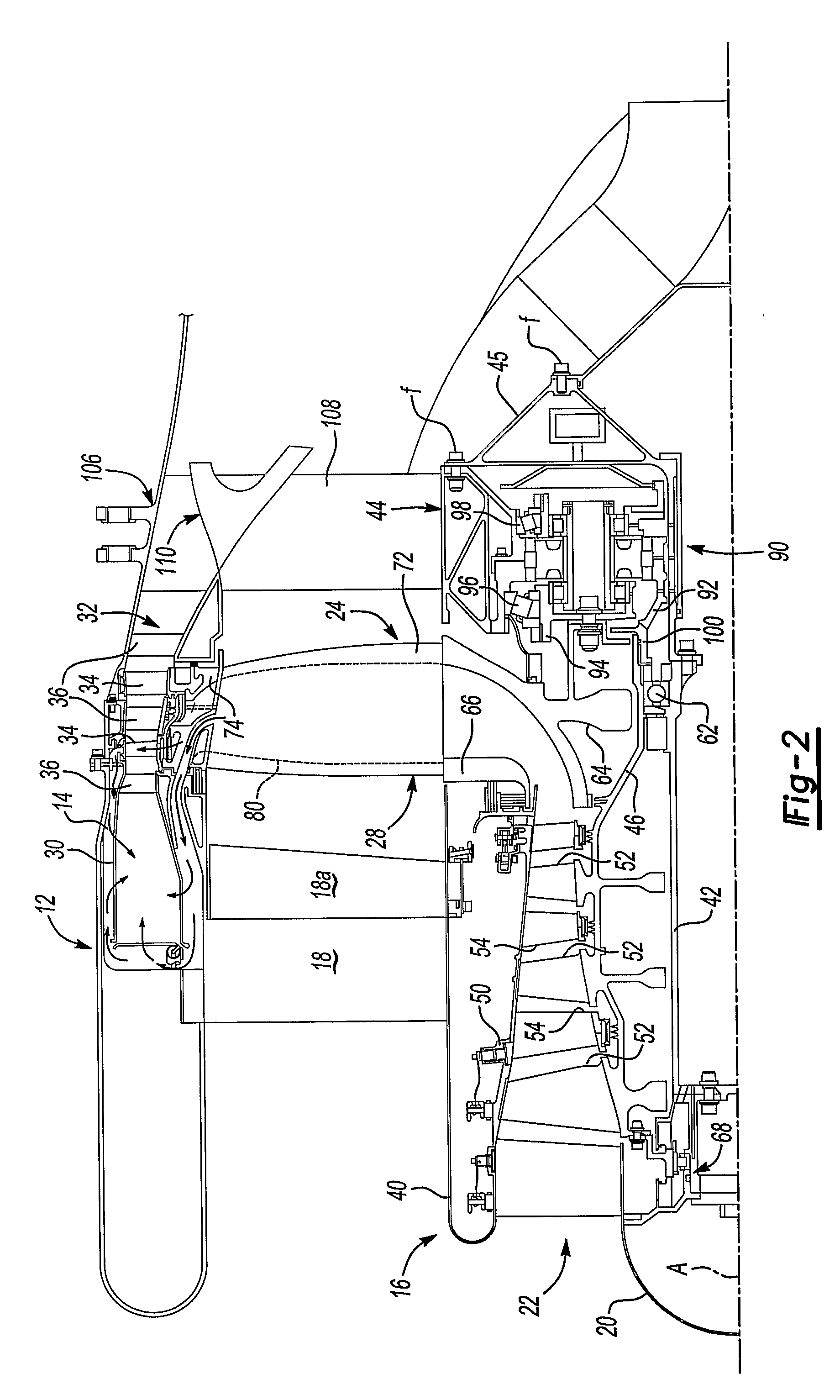

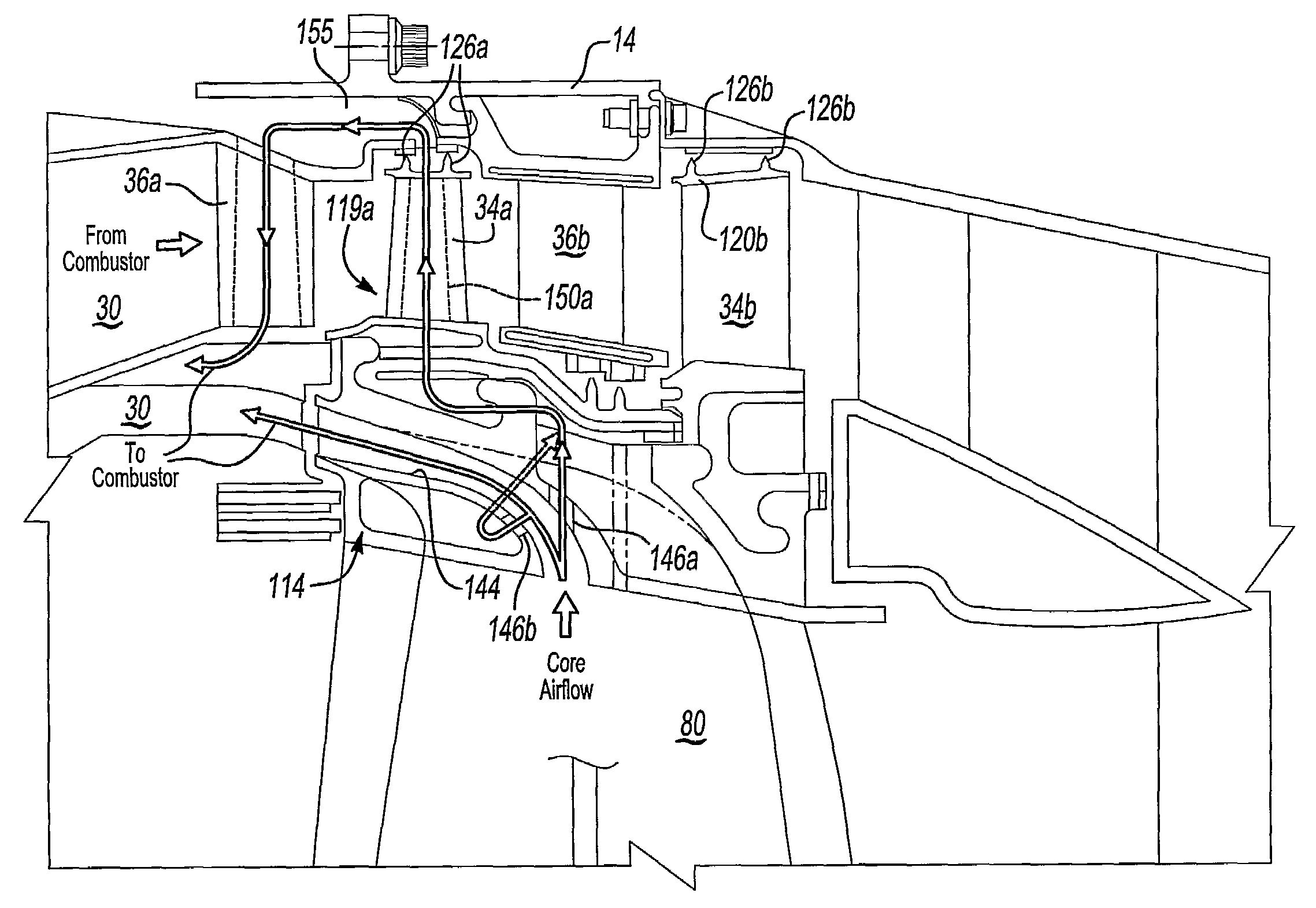

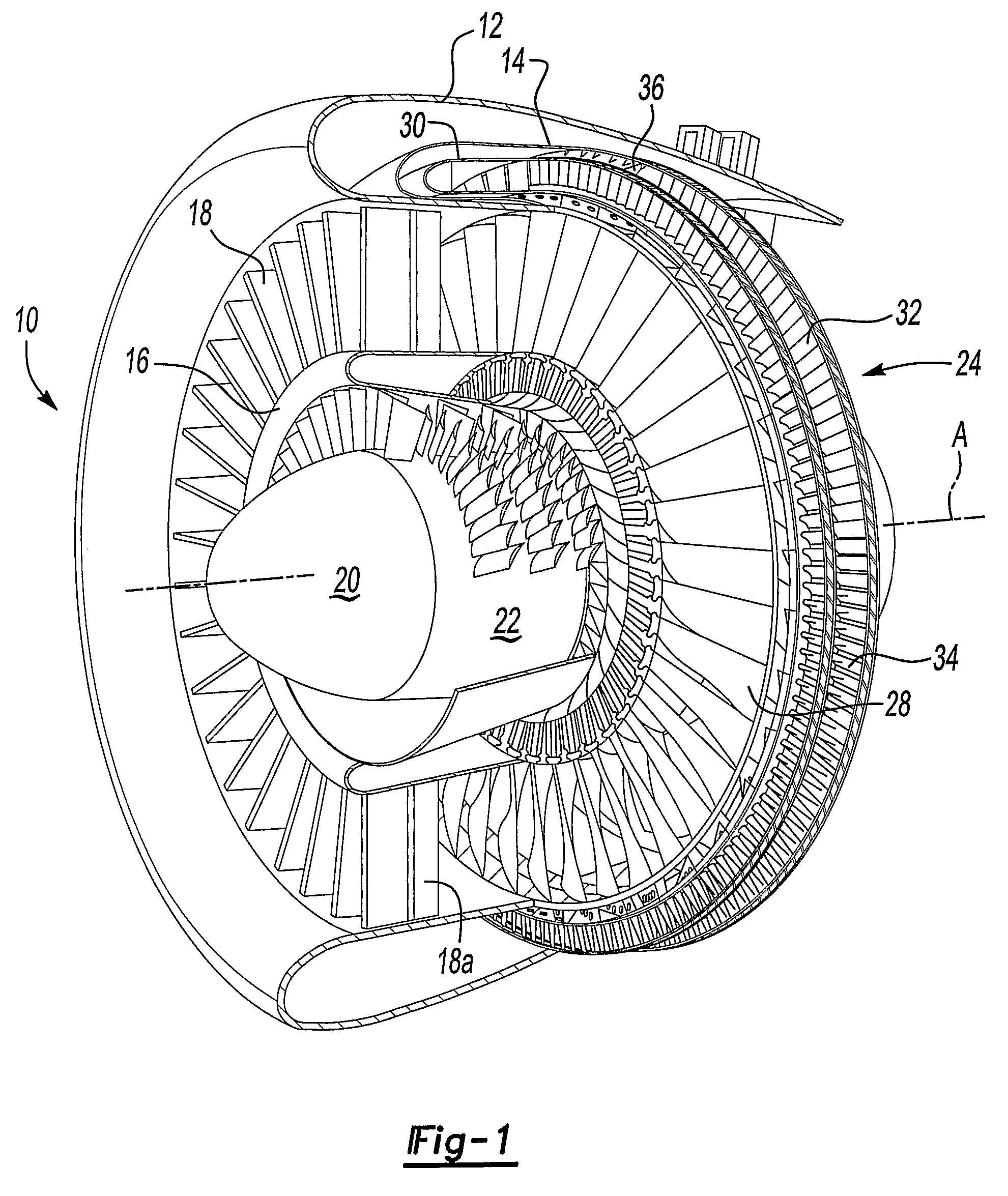

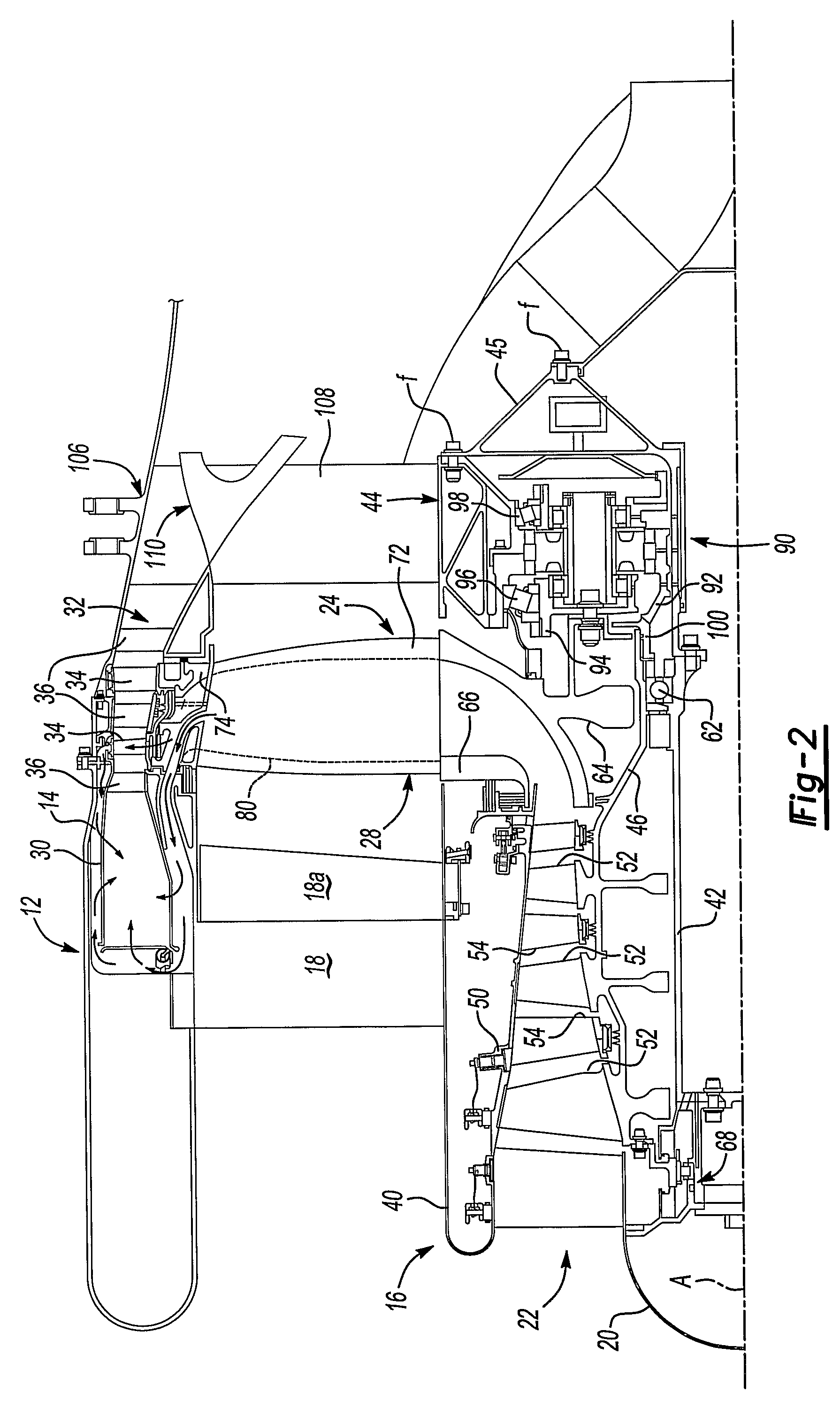

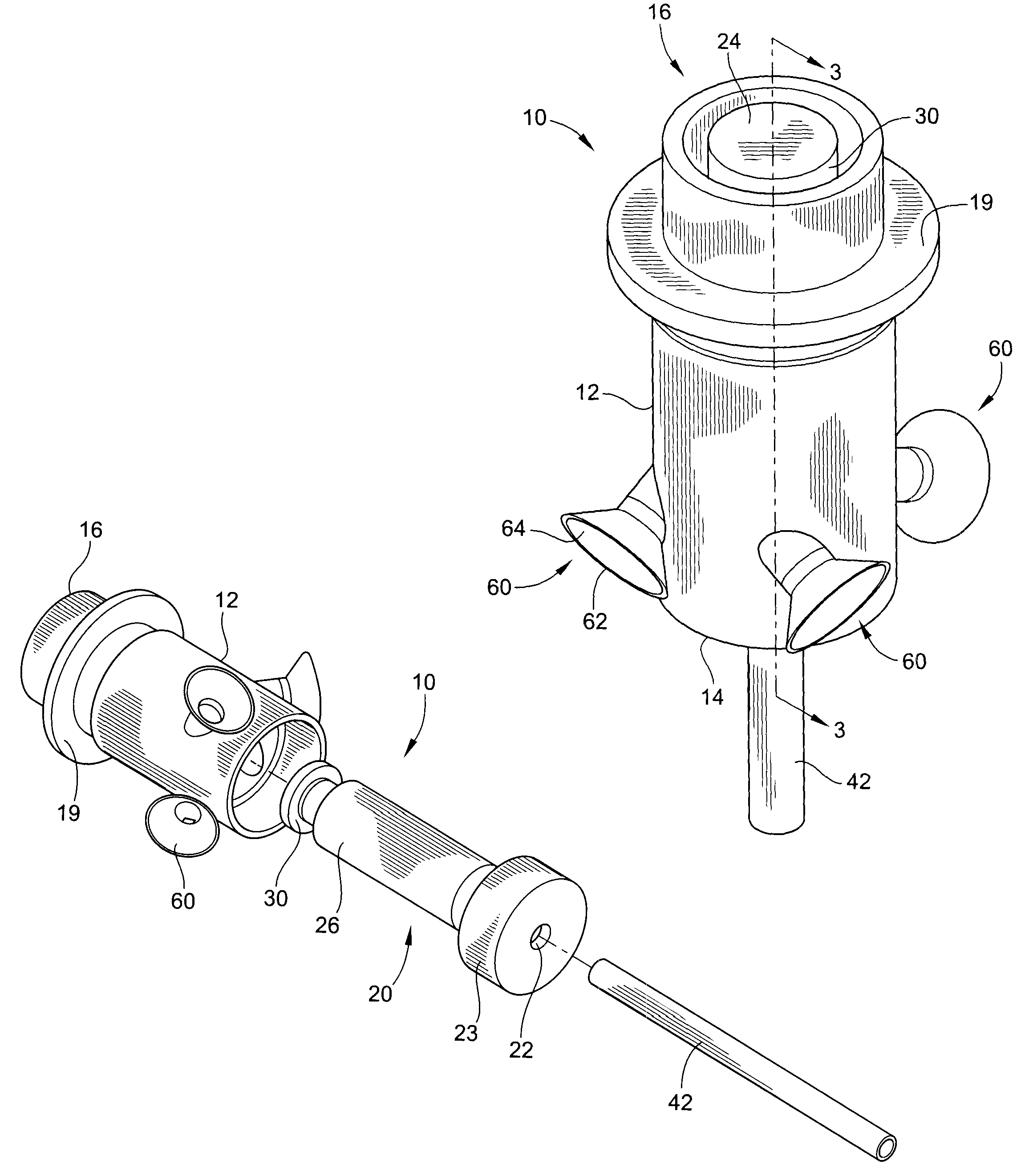

Regenerative Turbine Blade and Vane Cooling for a Tip Turbine Engine

InactiveUS20070295011A1Minimize impactDelayed air separationPump componentsEngine fuctionsThermal energyCombustor

A fan-turbine rotor assembly (24) includes a multitude of turbine blades (34) which each define a turbine blade passage which bleed air from a diffuser section (74) to provide for regenerative cooling. Regenerative cooling airflow is communicated from the radial core airflow passage (80) through the diffuser passages (144), through diffuser aspiration passages (146A, 146B) and into the turbine blade passages (150a). The regenerative cooling airflow exits from the turbine blade passage (150a) and transfers received thermal energy into an annular combustor (30). The received thermal energy is recovered at the highest temperature in the cycle.

Owner:RAYTHEON TECH CORP

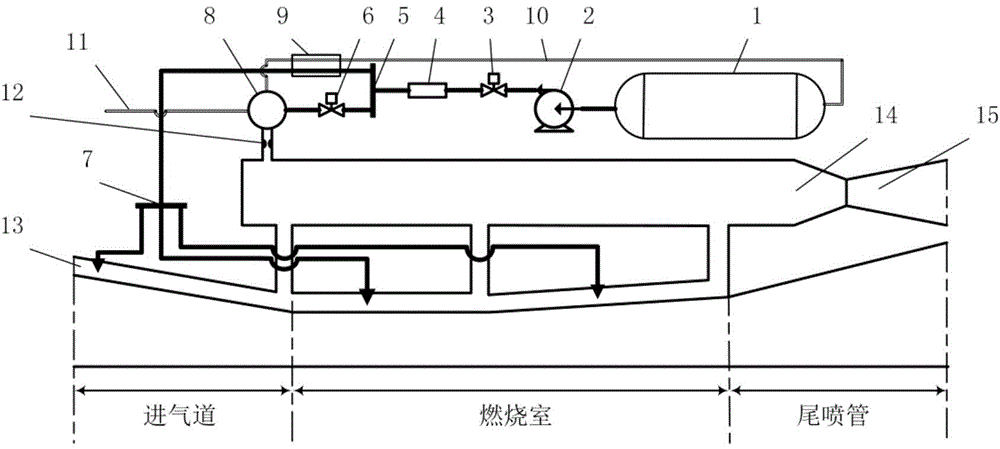

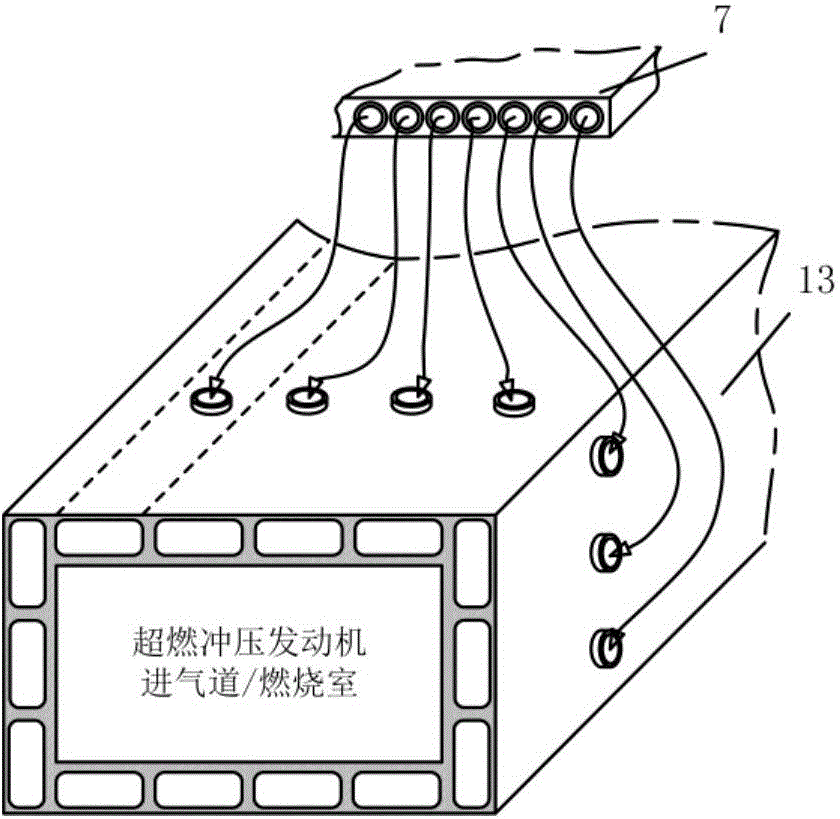

Liquid-nitrogen cooling system of scramjet engine

InactiveCN104989550ASolve the cooling problemImprove securityRam jet enginesLiquid nitrogen coolingAttitude control

The invention discloses a liquid-nitrogen cooling system of a novel scramjet engine. The liquid-nitrogen cooling system is combined with the scramjet engine through a heat structure, and the system mainly comprises a liquid nitrogen supply device, a high-pressure air source generation device, an engine casing pipe type heat exchange panel, a high-pressure gas collection chamber and a movable spraying pipe. The liquid-nitrogen system mainly executes three masks including (1) solving the problems in heat dissipation of the scramjet engine; (2) serving as a secondary power device so as to assist a hypersonic vehicle in acceleration and attitude control; and (3) providing low-temperature high-pressure nitrogen for subsystems of cabin environment control, fire prevention and the like. The liquid nitrogen serves as a low-temperature refrigerant so as to have the higher heat sink capacity, the wall face of the engine can be fully cooled, and in the cooling process of the liquid nitrogen, chemical cleavage does not exist; compared with a traditional system, refrigeration cooling is easily achieved; and the reliability and safety of the system are higher. The ultrahigh heat flow of the wall face of the scramjet engine will make the liquid nitrogen to achieve phase changes and expansion sufficiently, and the efficient auxiliary power is provided for an aircraft.

Owner:BEIHANG UNIV

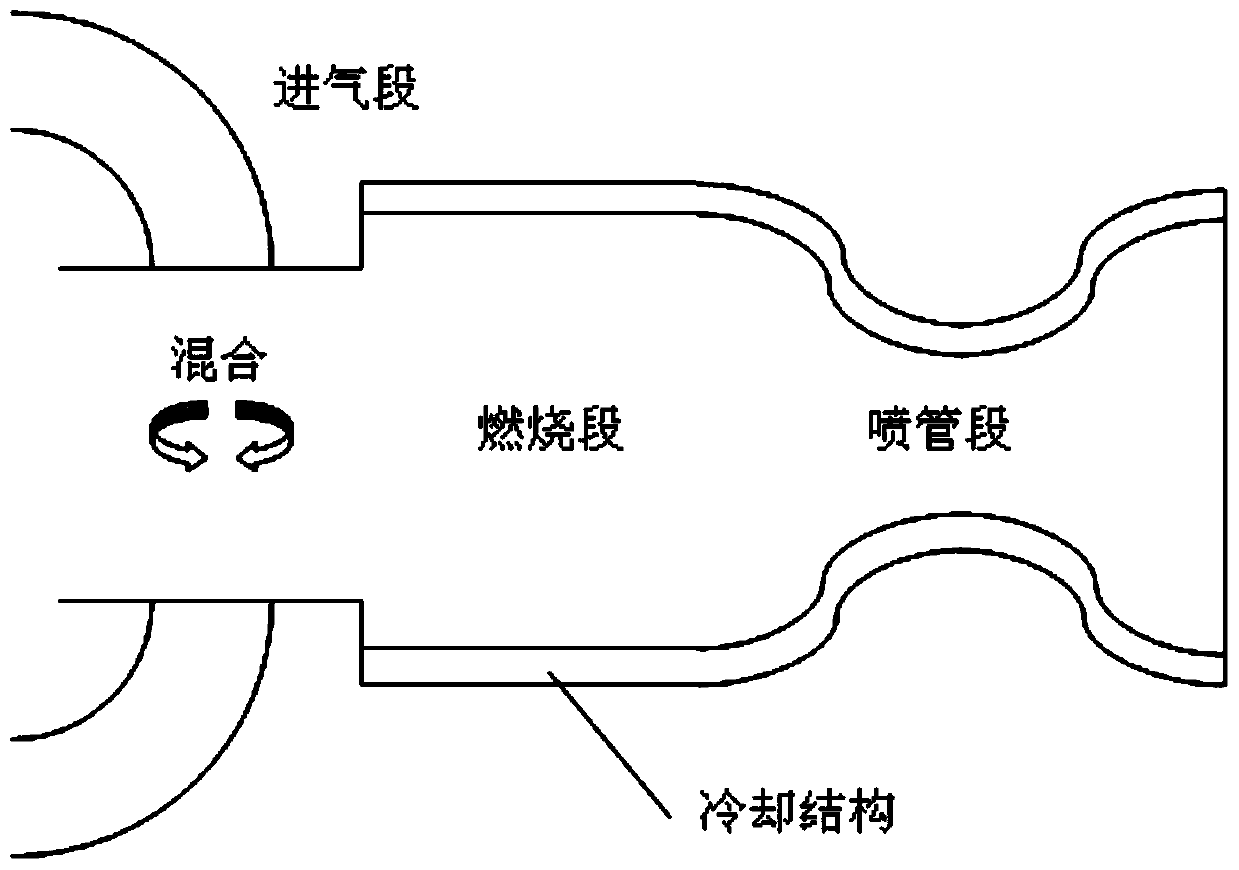

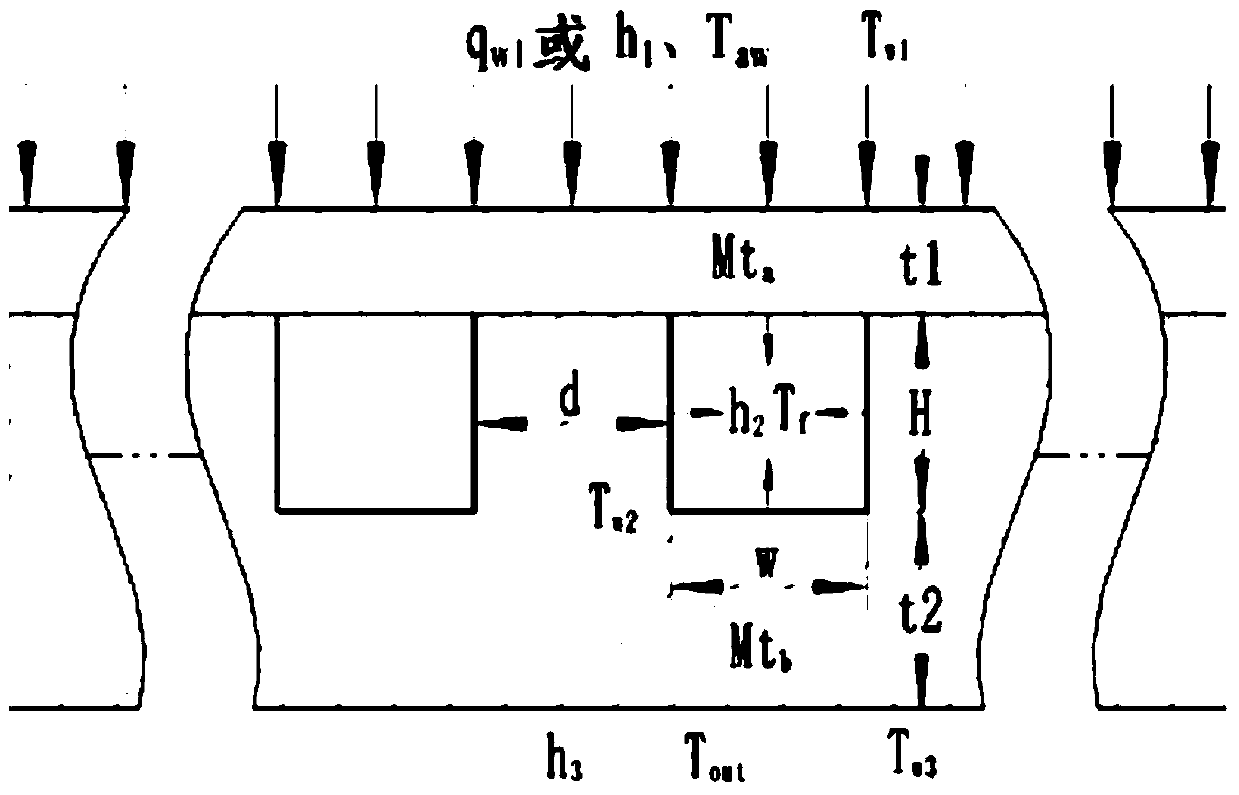

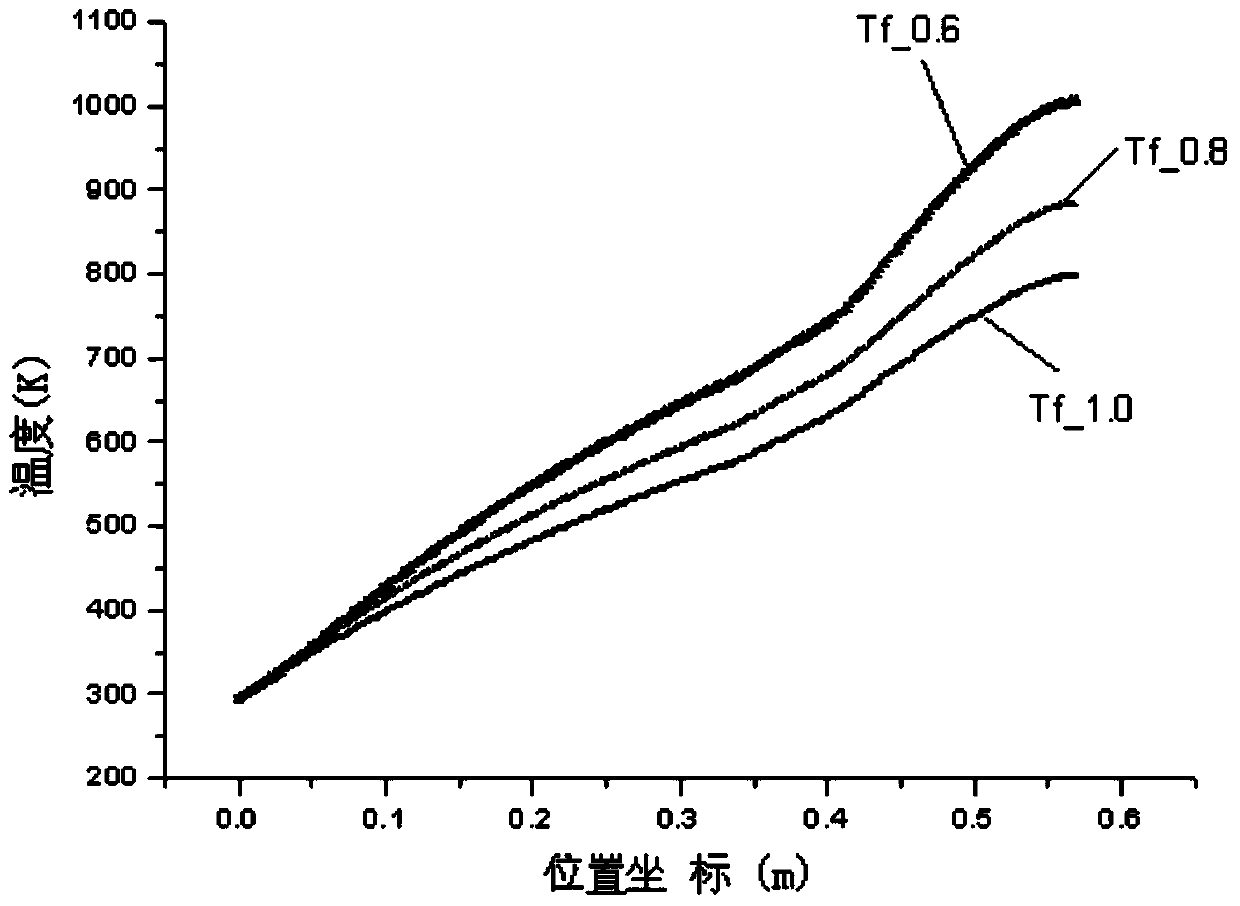

Subsonic velocity combustion ramjet combustion chamber and regenerative cooling method thereof

The invention discloses a subsonic velocity combustion ramjet combustion chamber and a regenerative cooling method of the subsonic velocity combustion ramjet combustion chamber. The subsonic velocity combustion ramjet combustion chamber comprises an air inlet segment, a combustion segment and a spray pipe segment. A regenerative cooling structure is arranged inside an outer shell of the combustion segment and the spray pipe segment. The regenerative cooling structure comprises multiple cooling channels. Hydrocarbon fuel cools the combustion chamber through the cooling channels first, and then enters the combustion chamber for combustion. By means of the regenerative cooling method and the cooling structure, the temperature of an engine body can be lowered greatly to be below the allowable temperature of an engine manufacturing material, thermal balance of a whole system can be realized quickly, and therefore the effect of long-time effective thermal protection of the subsonic velocity combustion ramjet combustion chamber is achieved; moreover, the fuel after absorbing heat is higher in combustion efficiency and sufficient in combustion, and therefore the thrust and endurance of a subsonic velocity combustion ramjet can be effectively increased.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

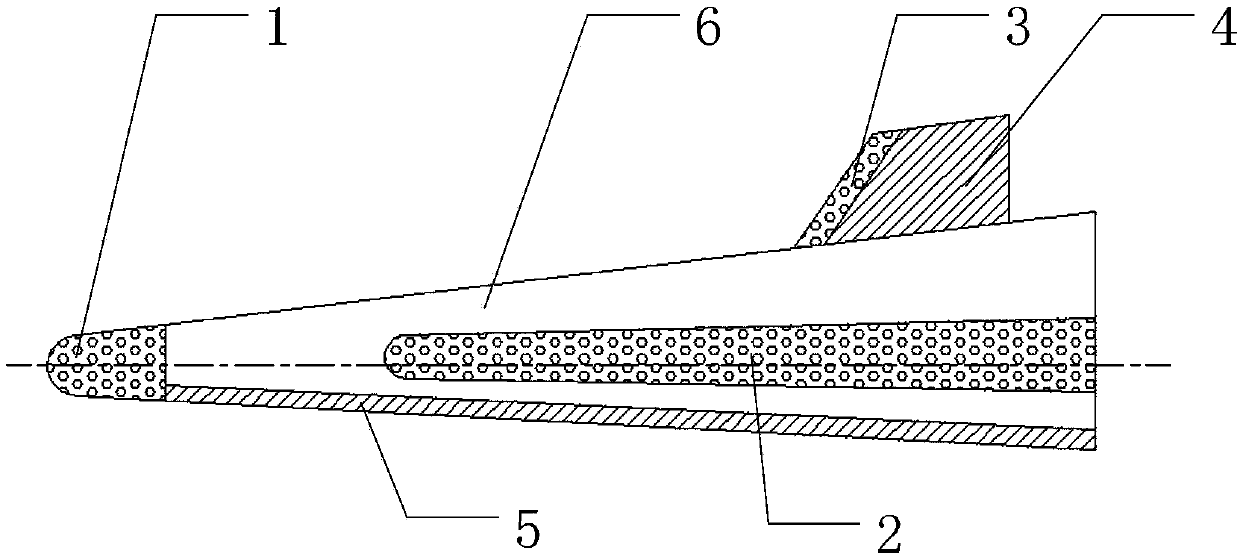

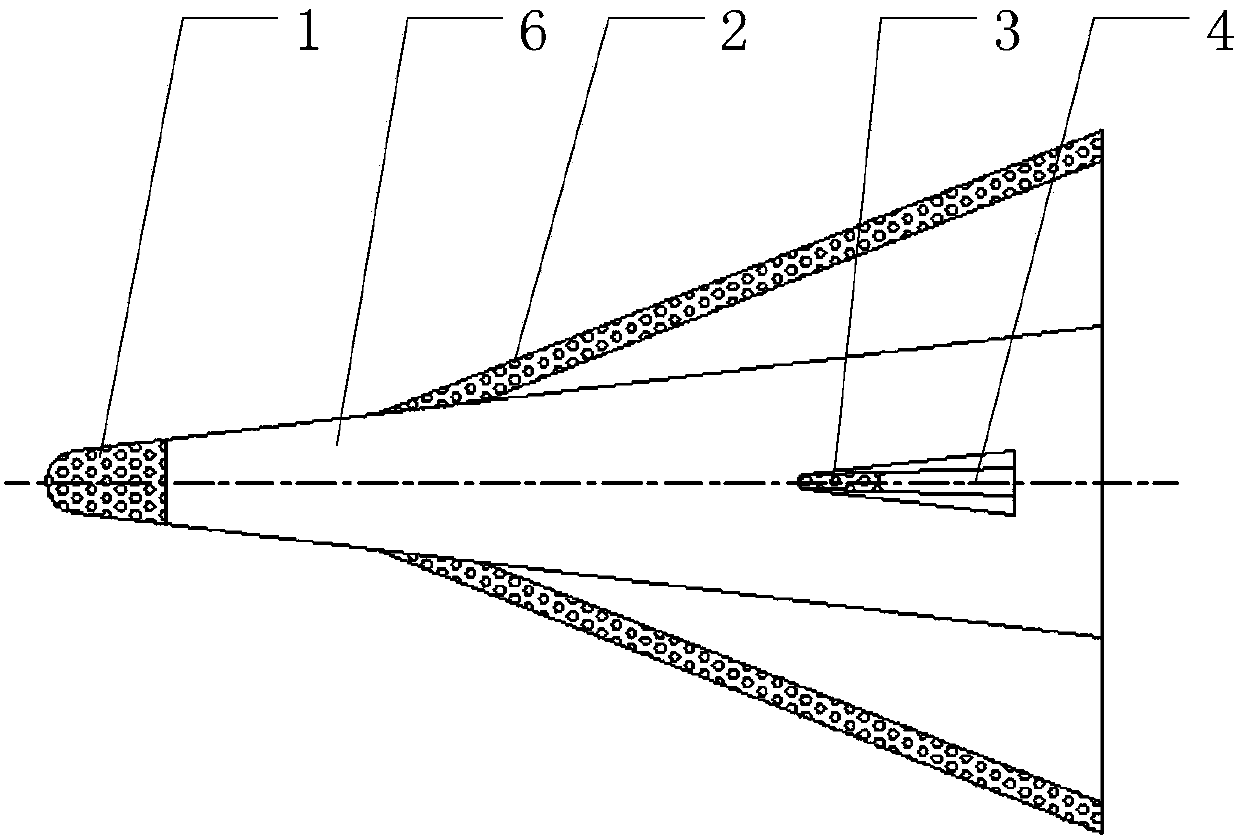

Full-active cooling hypersonic flight vehicle

ActiveCN107914862AAvoid thermal structural thermal matching problemsGuaranteed aerodynamic shapeBoundary layer controlsFuselage insulationFlight vehicleTranspiration

The invention discloses a full-active cooling hypersonic flight vehicle which comprises a transpiration cooling end, a transpiration cooling wing front edge, a transpiration cooling rudder front edge,a regenerative cooling rudder surface, a regenerative cooling windward side and a flight vehicle leeside, wherein porous structures are formed in the transpiration cooling end, the transpiration cooling wing front edge and the transpiration cooling rudder front edge, and the interiors of the porous structures are filled with liquid cooling media; the liquid cooling media can be supplied outwardsfrom the porous structures, flow through the porous structures to perform heat exchange, are heated and then flow out of the outer surface of the end in a gaseous form; and the regenerative cooling rudder surface and the regenerative cooling windward side are respectively used for cooling the rudder surface and the windward side of the flight vehicle in a regenerative cooling manner, and the liquid cooling media carried inside the flight vehicle are used for blocking, cooling and taking away pneumatic heating volume of the flight vehicle transferred into the flight vehicle in the hypersonic flight process, so that thermal protection requirements of the flight vehicle on high-speed, long-term and long-distance flight in the atmosphere are met.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

Regenerative turbine blade and vane cooling for a tip turbine engine

InactiveUS7607286B2Delayed air separationEasy to compressPump componentsTurbine/propulsion engine coolingThermal energyCombustor

A fan-turbine rotor assembly (24) includes a multitude of turbine blades (34) which each define a turbine blade passage which bleed air from a diffuser section (74) to provide for regenerative cooling. Regenerative cooling airflow is communicated from the radial core airflow passage (80) through the diffuser passages (144), through diffuser aspiration passages (146A, 146B) and into the turbine blade passages (150a). The regenerative cooling airflow exits from the turbine blade passage (150a) and transfers received thermal energy into an annular combustor (30). The received thermal energy is recovered at the highest temperature in the cycle.

Owner:RAYTHEON TECH CORP

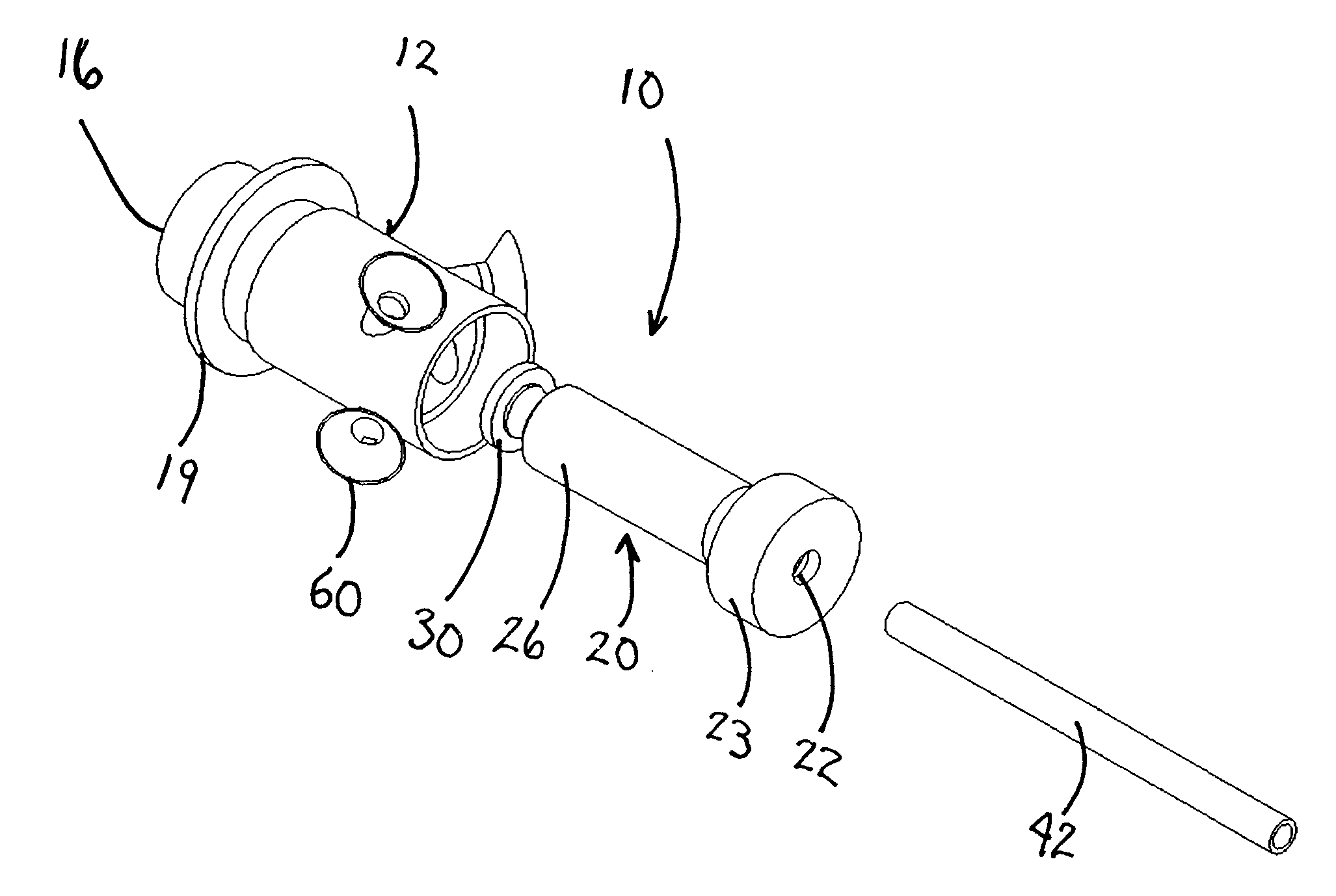

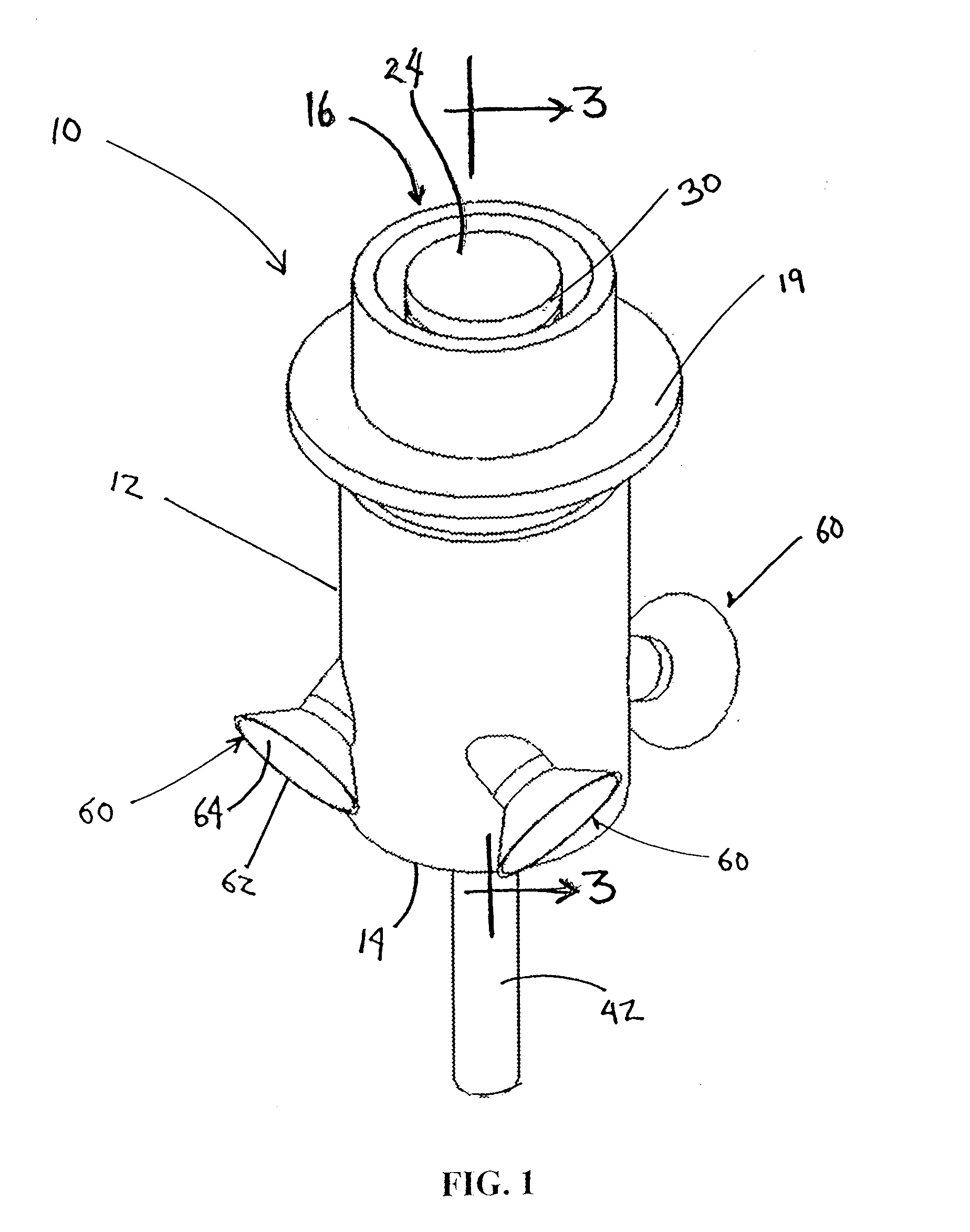

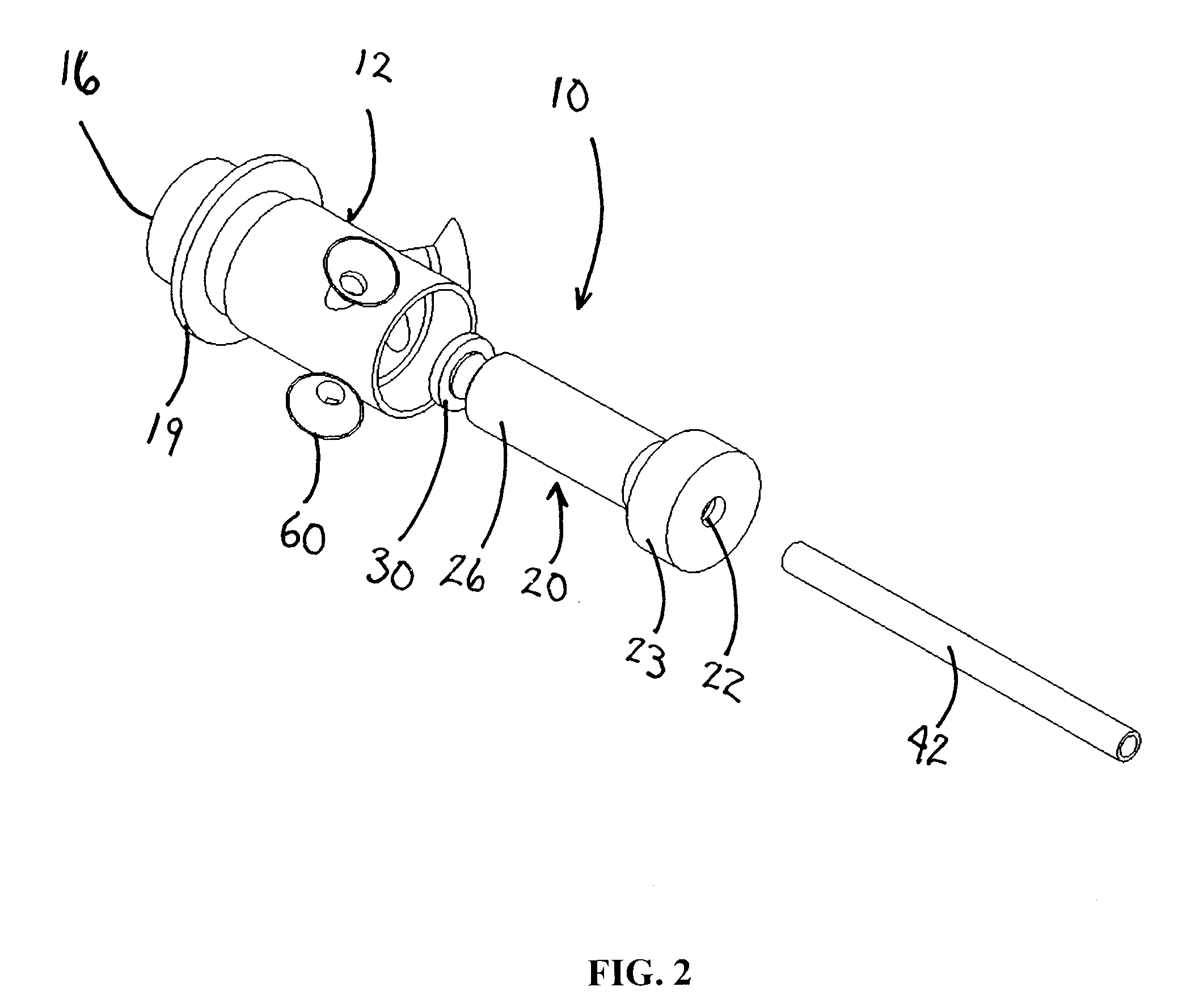

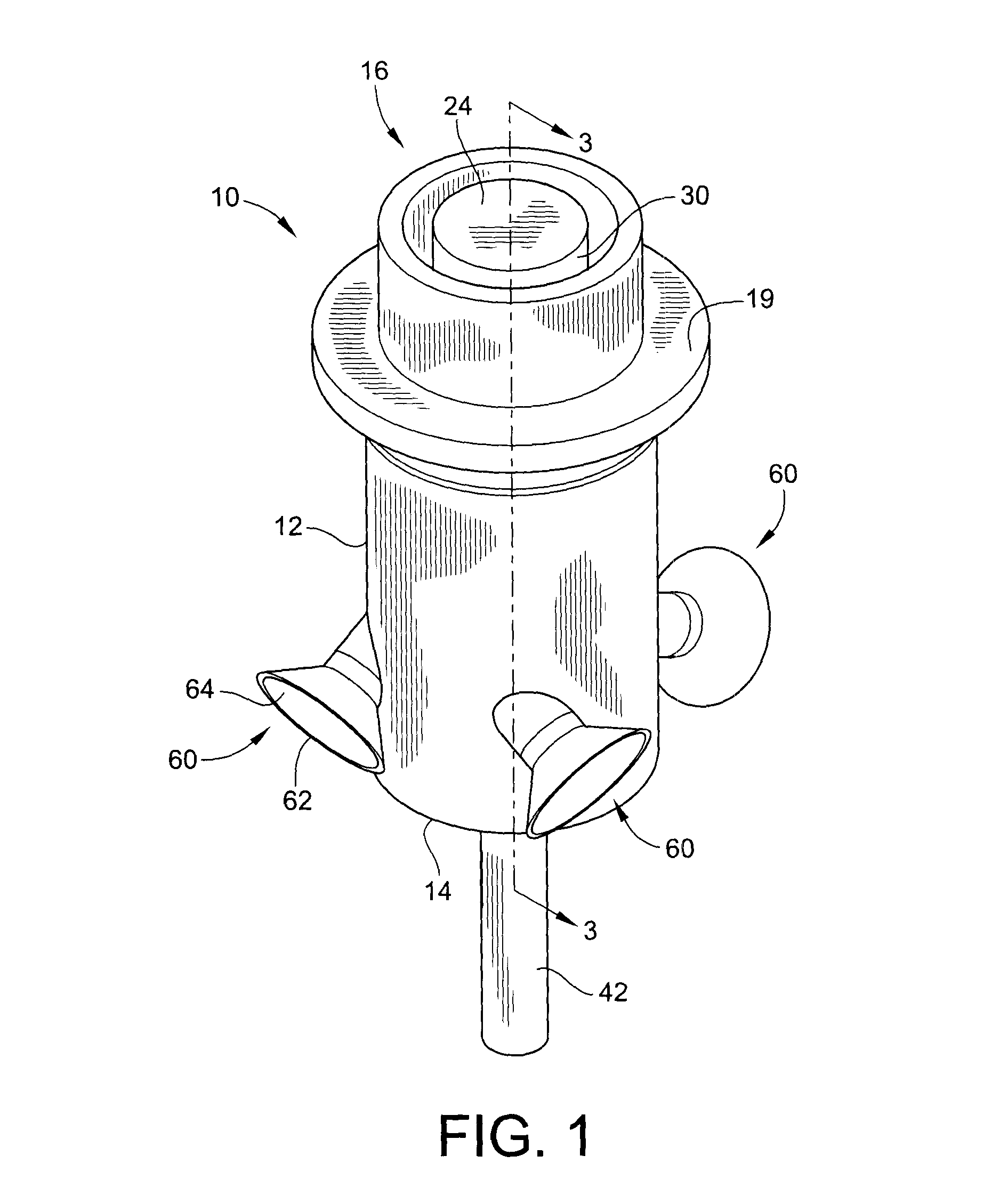

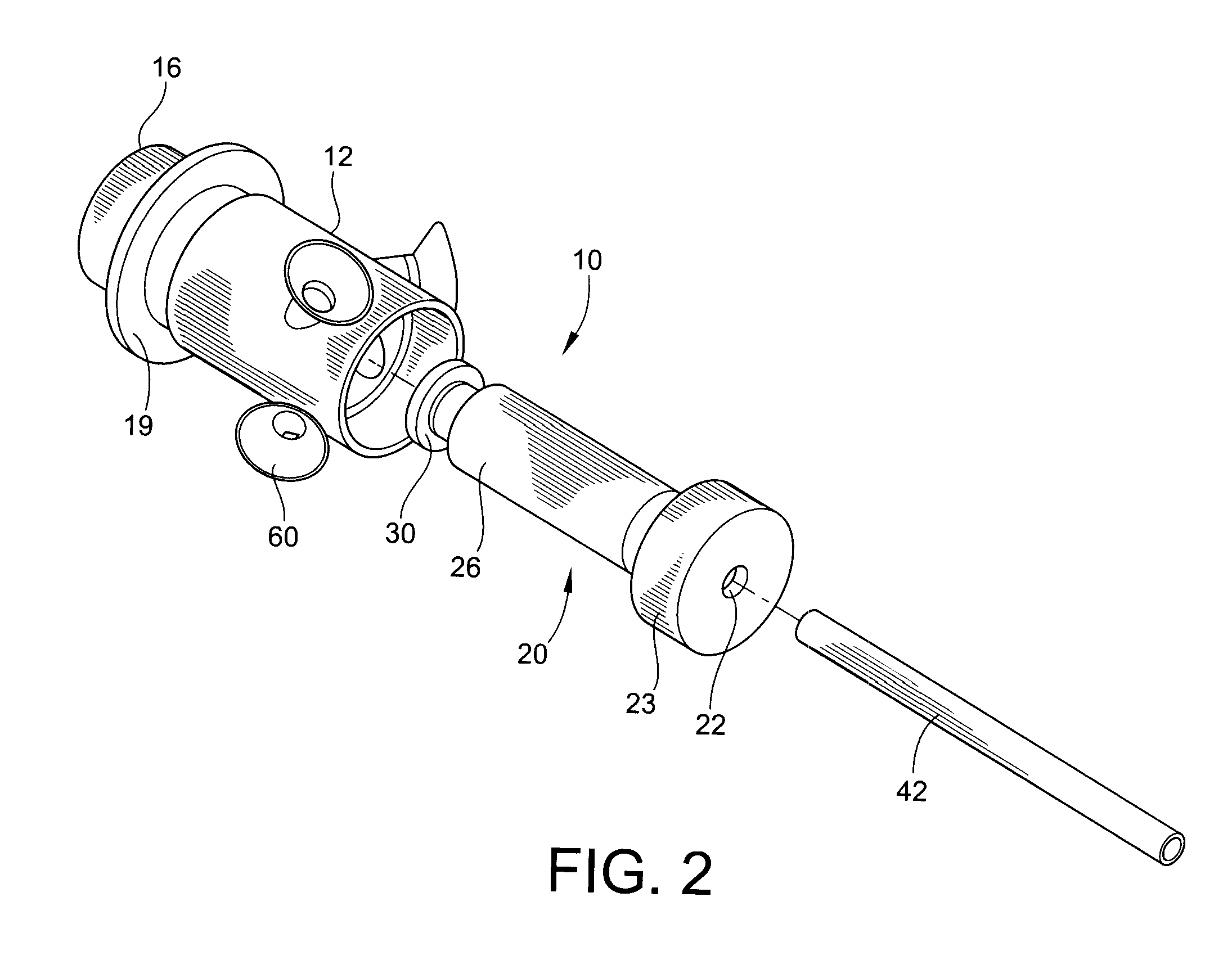

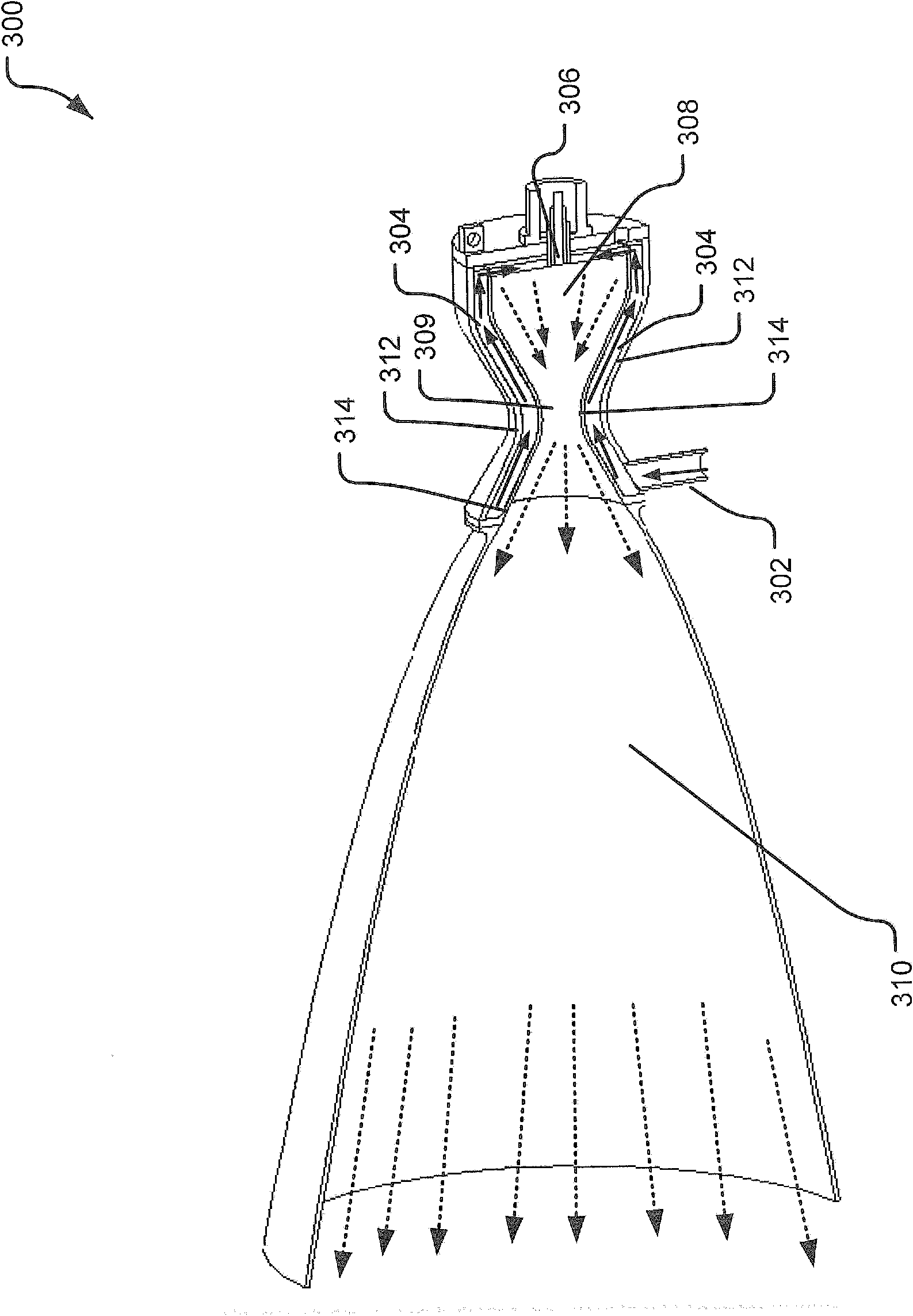

Premixing injector for gas turbine engines

InactiveUS20070277528A1Extend your lifePreserve longevity of premixingBurner safety arrangementsContinuous combustion chamberCombustion instabilityCombustion chamber

A premixing injector for use in gas turbine engines assists in the lean premixed injection of a gaseous fuel / air mixture into the combustor of a gas turbine. The premixing injector is designed to mix fuel and air at high velocities to eliminate the occurrence of flashback of the combustion flame from the reaction zone into the premixing injector. The premixing injector includes choked gas ports, which allow the fuel supply to be decoupled from any type of combustion instability which may arise in the combustor of the gas turbine and internal passages to provide regenerative cooling to the device.

Owner:VIRGINIA TECH INTPROP INC +1

Reinforced, regeneratively cooled uni-body rocket engine

InactiveUS20090235636A1Enabling useEliminate pointRocket engine plantsRam jet enginesFiberCombustion chamber

A rocket engine having a combustion chamber, a throat, and an exhaust bell is made with spaced apart inner and outer skins each unitarily formed in one piece of carbon fiber fabric. Longitudinal ribs in the space between the skins reinforce the engine and divide the space into a plurality of flow channels. An oxidizer ring at the bottom of the exhaust bell is in fluid flow communication with the flow channels, and one or more oxidizer tubes are connected tangentially at one end to the ring to supply oxidizer to the ring and thence to the flow channels. The oxidizer tubes are connected at their other end to the engine above the throat, further reinforcing the engine. An igniter is in the combustion chamber, and ignition fuel ports are directed toward the igniter to provide a soft start ignition.

Owner:OEHRLEIN ROBERT

Premixing injector for gas turbine engines

InactiveUS7870736B2Reduce equivalence ratioBurner safety arrangementsContinuous combustion chamberCombustion instabilityHigh velocity

A premixing injector for use in gas turbine engines assists in the lean premixed injection of a gaseous fuel / air mixture into the combustor of a gas turbine. The premixing injector is designed to mix fuel and air at high velocities to eliminate the occurrence of flashback of the combustion flame from the reaction zone into the premixing injector. The premixing injector includes choked gas ports, which allow the fuel supply to be decoupled from any type of combustion instability which may arise in the combustor of the gas turbine and internal passages to provide regenerative cooling to the device.

Owner:VIRGINIA TECH INTPROP INC +1

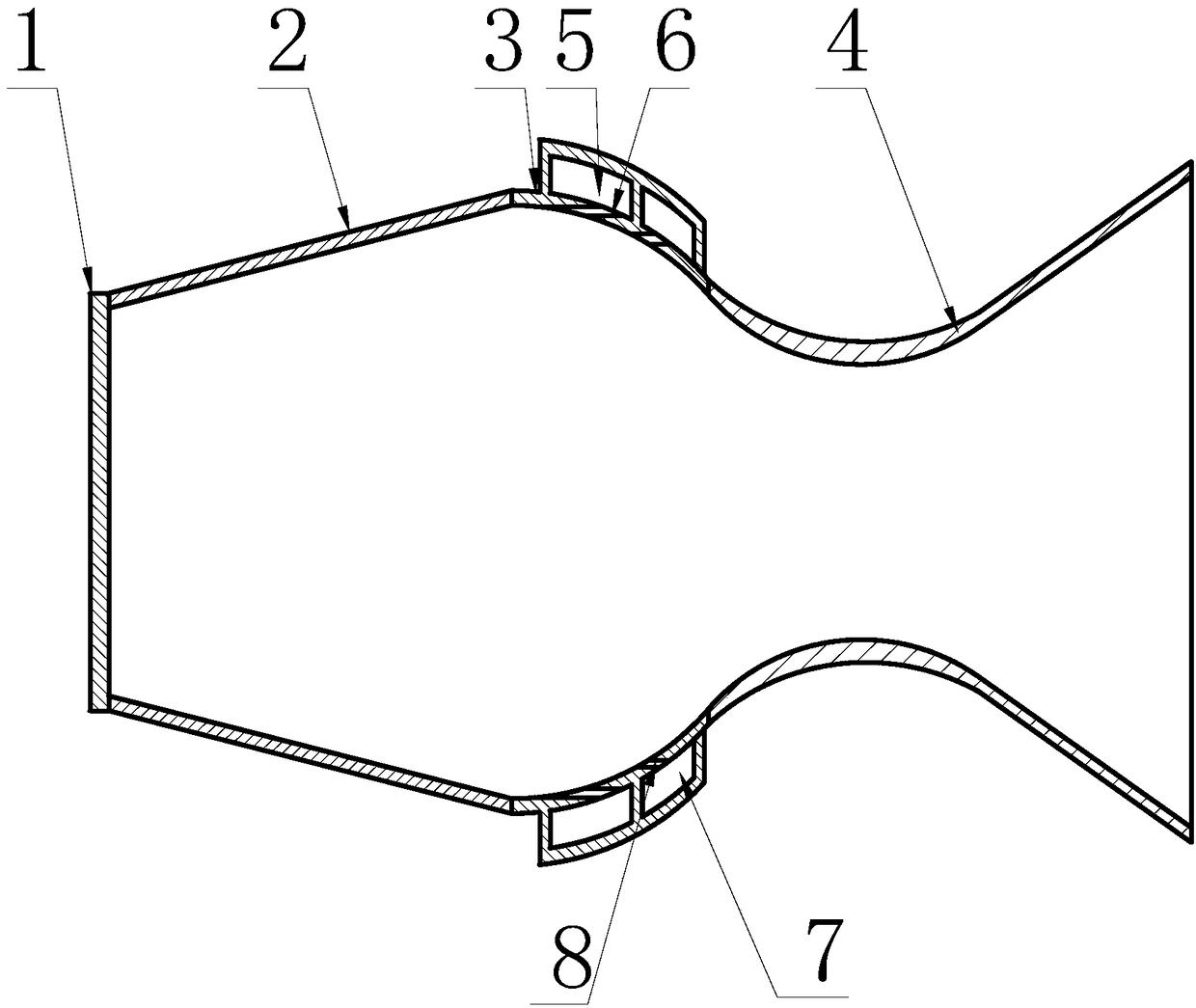

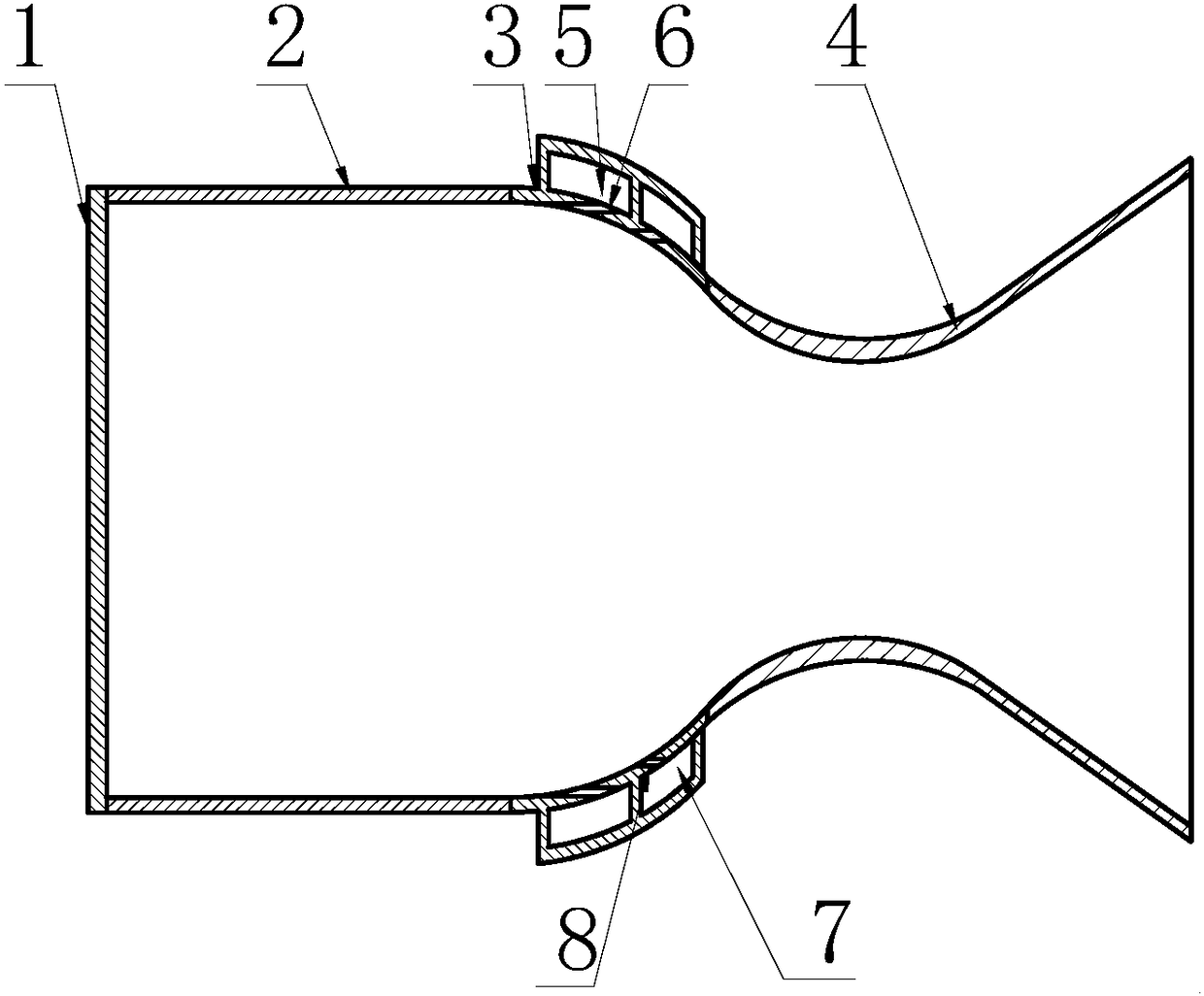

Coolable nozzle and method for producing such a nozzle for a rocket engine

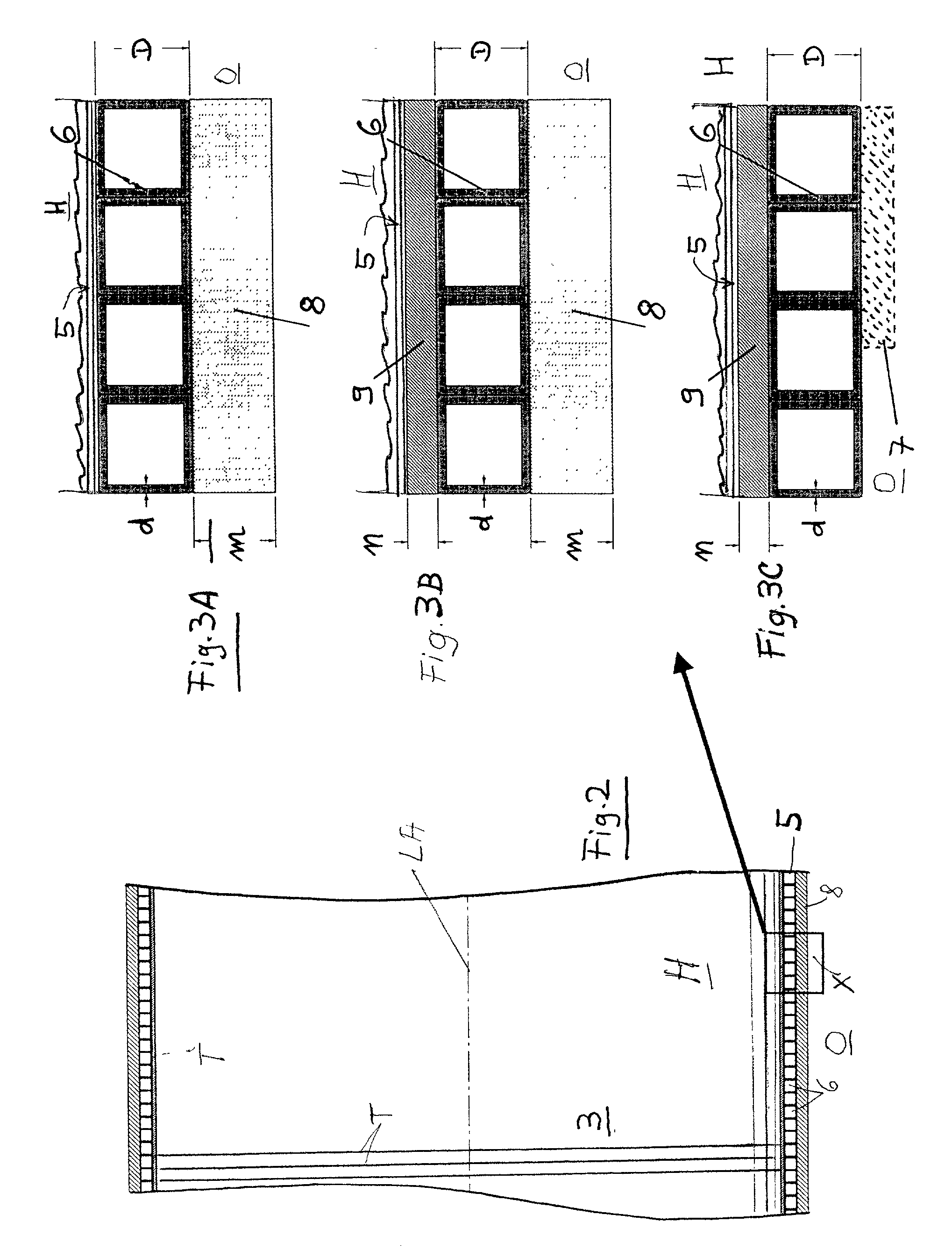

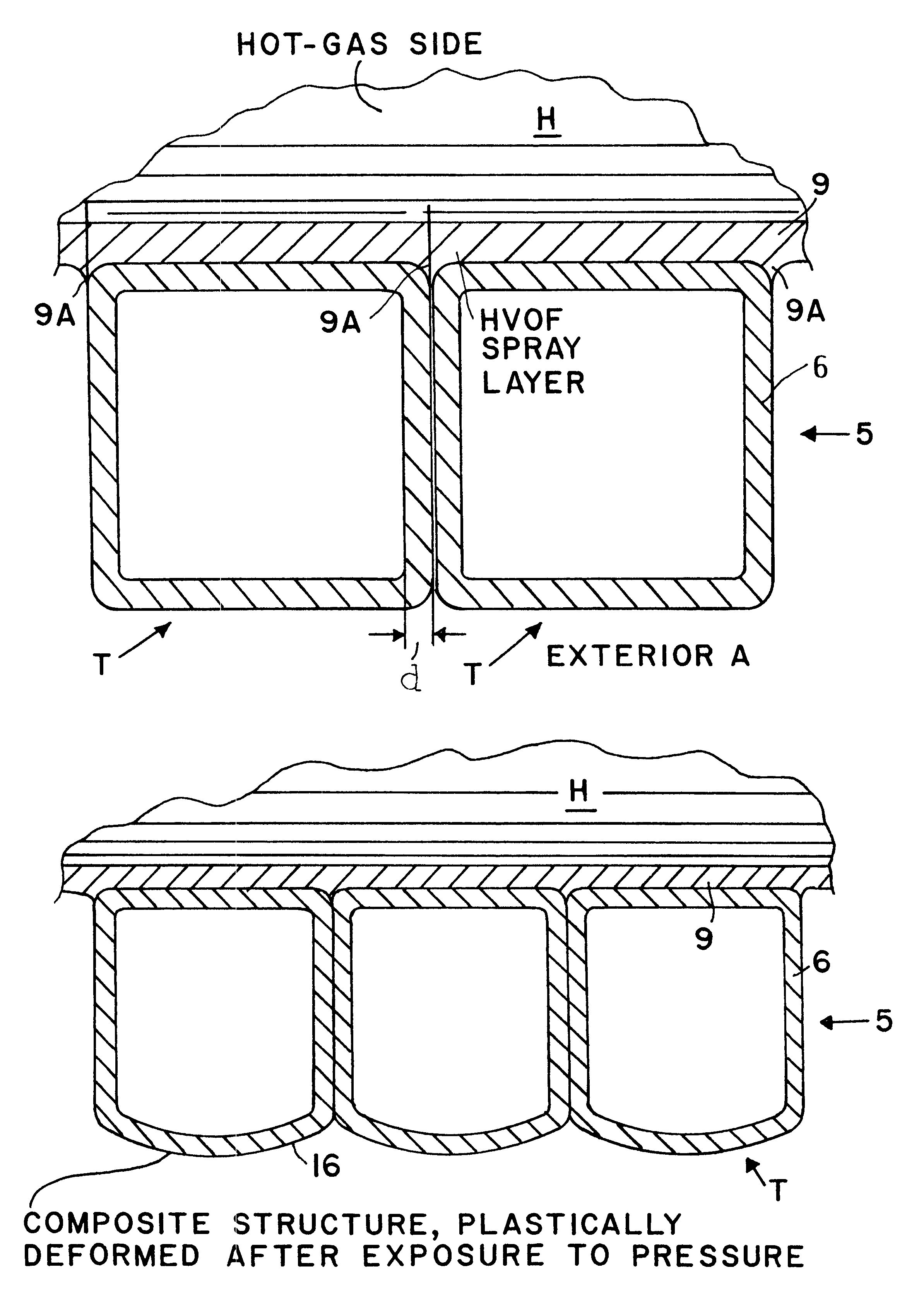

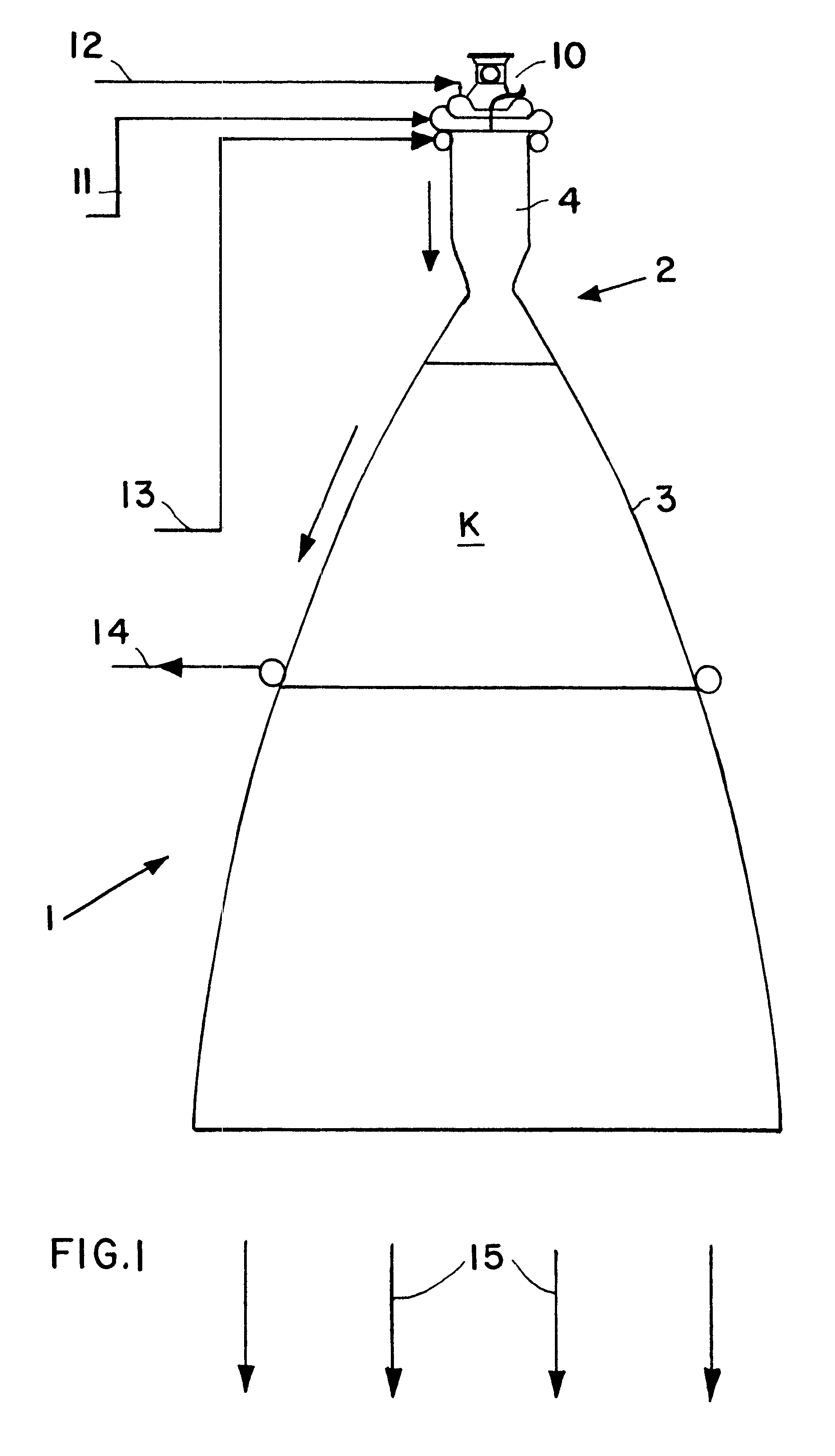

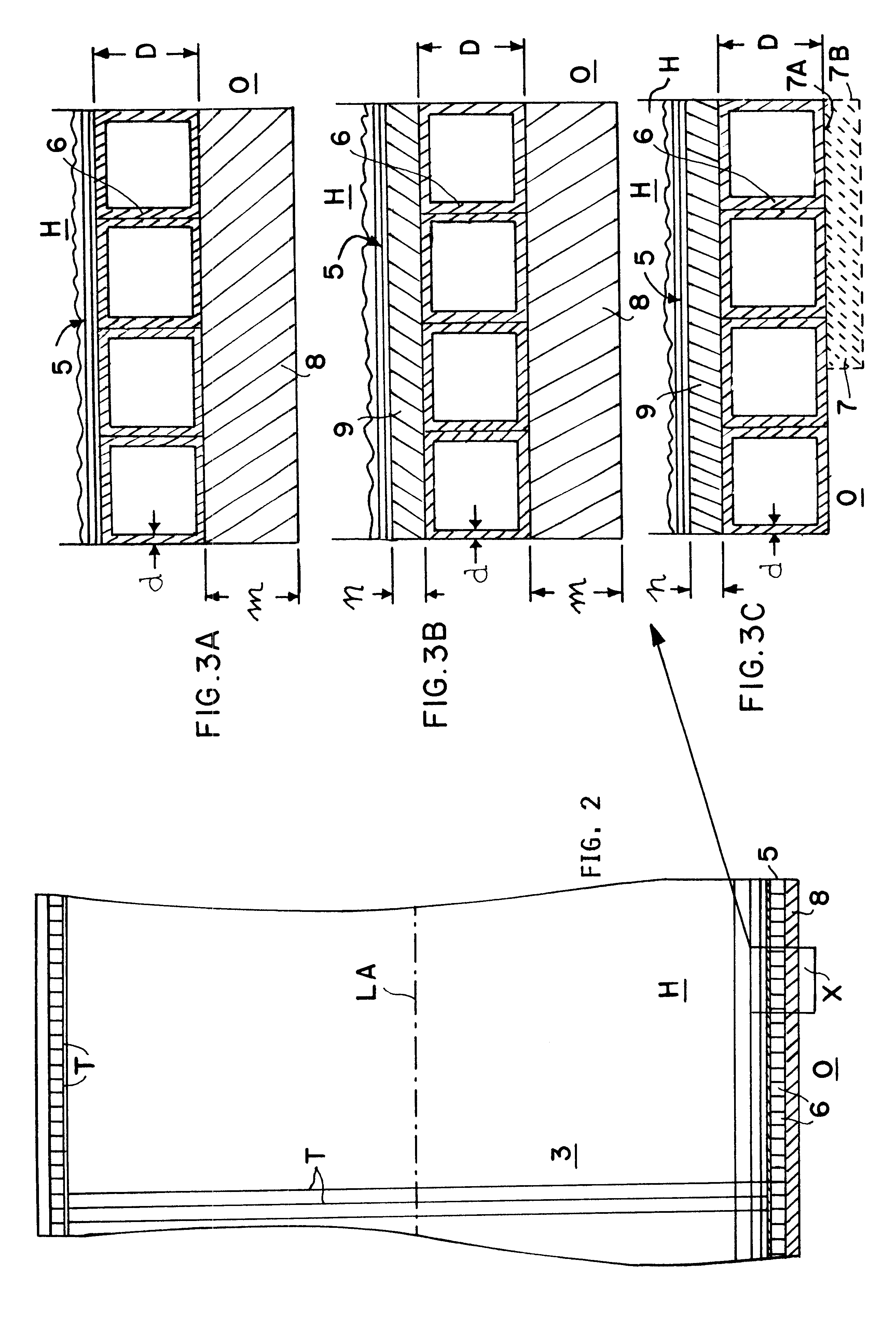

InactiveUS20020056762A1Improve smoothnessHigh trafficMolten spray coatingPower plant exhaust arrangementsComposite structureCoolant

A regeneratively coolable nozzle for a rocket engine is formed by winding a tubular material (6) onto a winding mandrel to produce a helical composite structure (5), through which a coolant can flow during operation of the nozzle. The spiral composite structure (5) is fixed temporarily and the fixed composite structure (5) is removed from the winding mandrel. Then an inner heat resistant, load bearing layer (9) is applied to the radially inner hot-gas facing surface (H) of the fixed composite structure (5). The present nozzle is lightweight and withstands a high coolant pressure.

Owner:ASTRIUM GMBH

Novel series of hydrogen peroxide thrust chambers used for rockets and airships

InactiveCN107152353AEasy to useHigh working reliabilityRocket engine plantsSemi openAttitude control

The invention relates to novel series of hydrogen peroxide thrust chambers used for rockets and airships. The novel series of hydrogen peroxide thrust chambers comprise micro attitude control types, small-sized orbit control types, middle-sized acoustic cavity types, large-sized partition types and ultra-large types; industrial 79.1%-84.9% hydrogen peroxide is used as an oxidizing agent and a regenerative coolant; a non-toxic homogeneous miscible fuel (NHMF), kerosene or liquid hydrogen is taken as a fuel; non-toxic storable components account for 95%-100% of a propellant, so that the use is convenient; the decomposition rate of a catalyst bed is controlled within 75%-95%, the development and service life prolonging of the catalyst bed are facilitated; and novel structures such as a high strength head, a regenerative cooling nineteen-zone partition, a semi-opening acoustic cavity, a gas-liquid impinging injector, a multihole conical shell are adopted. According to the novel series of hydrogen peroxide thrust chambers used for rockets and airships, the combustion temperature, decomposition temperature and regenerative cooling temperature rise are low, so that the working conditions are improved at lot; besides, the density-specific impulse is higher, the propulsive performance is better, and therefore the thrust chambers are applicable to boosters, first-stage and second-stage engines as well as first-stage core engines, which are capable of being used for over 25 times, of novel manned Moon and Mars landing rockets and airships.

Owner:葛明龙 +1

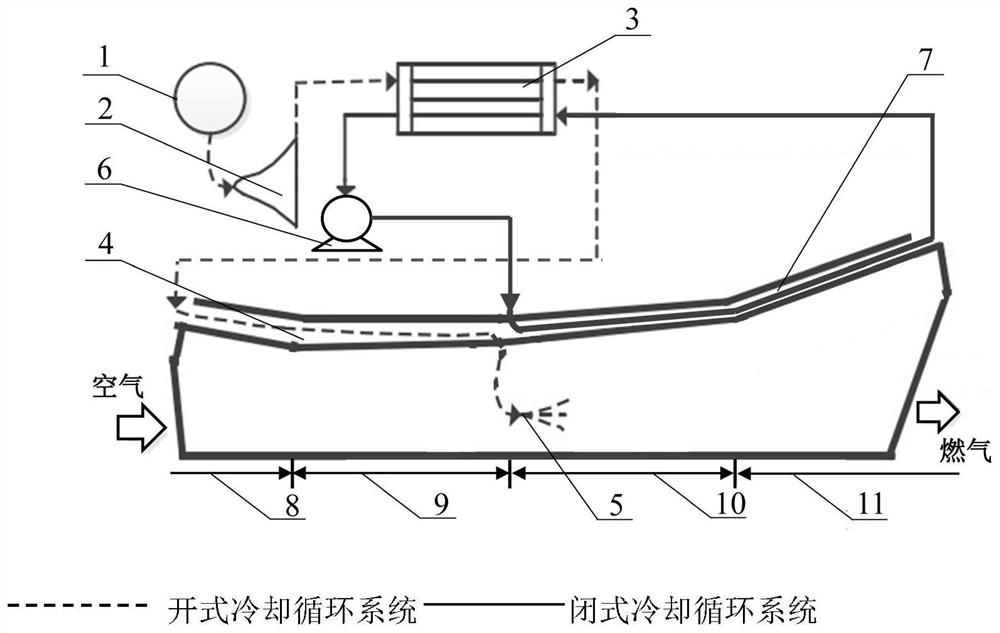

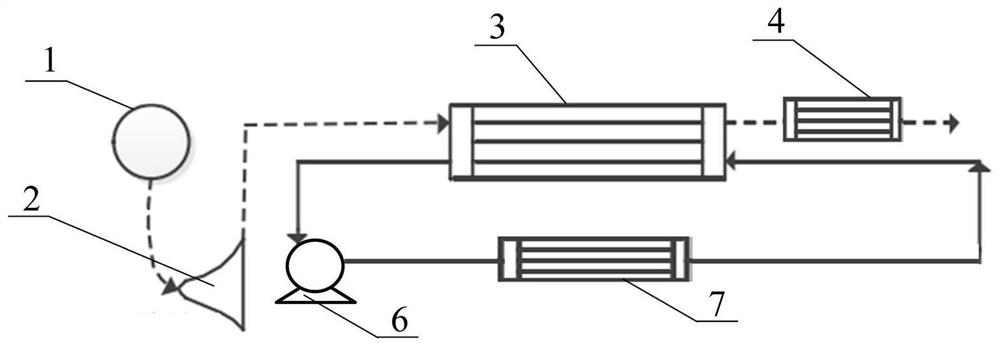

Combined type scramjet engine cooling circulation system

ActiveCN112431675ASmall Prandtl numberAvoid blocking cooling passagesContinuous combustion chamberTurbine/propulsion engine coolingCombustion chamberFuel tank

The invention discloses a combined type scramjet engine cooling circulation system, and belongs to the technical field of air suction type scramjet engine thermal protection. The system comprises a fuel tank, a fuel pump, a heat exchanger, a first cooling channel, a second cooling channel, a fuel injector and an electromagnetic pump; an annular cavity is formed between the inner wall face and theouter wall face of an engine outer shell and divided into the first cooling channel and the second cooling channel; the fuel tank, the fuel pump, the heat exchanger, the first cooling channel and thefuel injector are sequentially connected through pipelines to form an open cooling circulation system, and kerosene serves as a working medium; and the electromagnetic pump, the second cooling channeland the heat exchanger are sequentially connected through pipelines to form a closed cooling circulation system, and the working medium is liquid metal. According to the combined type scramjet enginecooling circulation system, waste heat of the wall face of an engine combustion chamber is utilized, the advantages of an active regeneration cooling system are reserved, the problems of heat transfer deterioration, cracking coking and the like of a traditional cooling working medium are solved, and an efficient energy management circulating system is constructed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

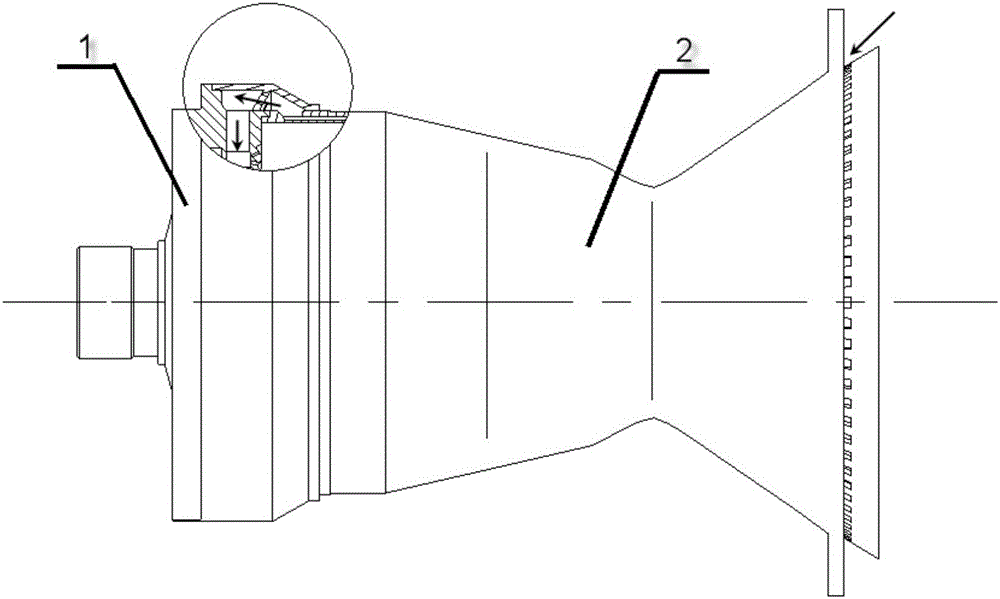

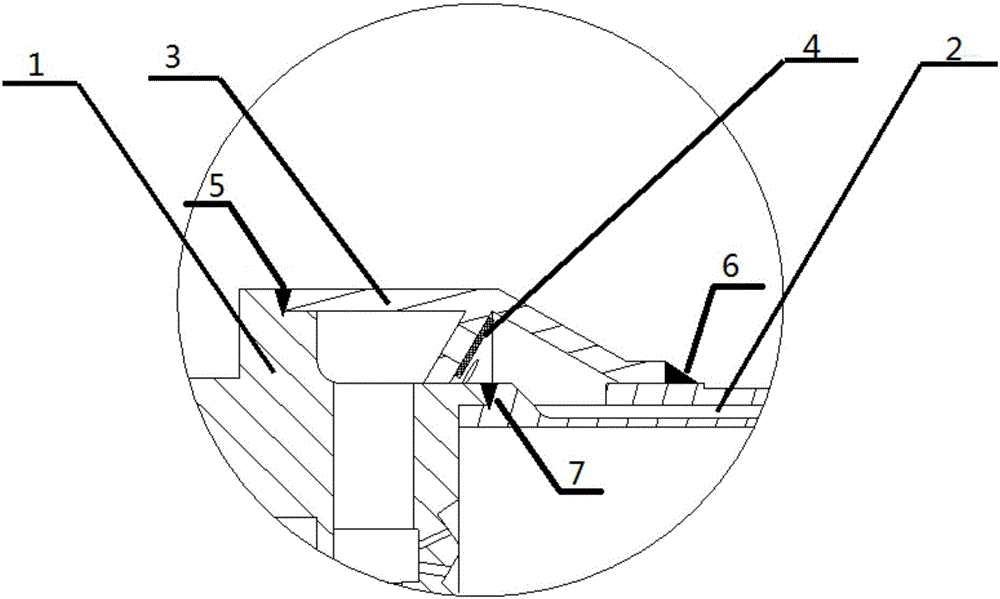

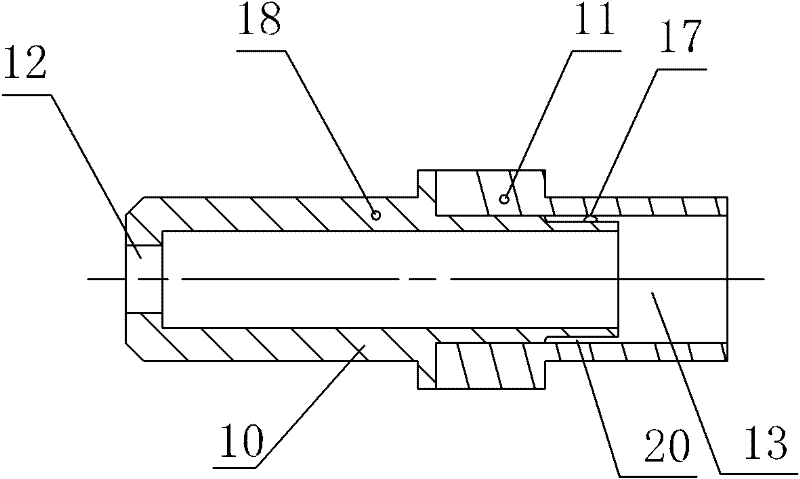

Novel connecting structure for head and regenerative cooling body of rocket engine

ActiveCN106050474AImprove reliabilityImprove appearance qualityRocket engine plantsNumerical controlCombustion chamber

The invention discloses a novel connecting structure for a head and a regenerative cooling body of a rocket engine. The novel connecting structure for the head and the regenerative cooling body of the rocket engine comprises the head, the regenerative cooling body, a connecting ring and a filter screen. An installation groove is formed in the head in the direction of an injection panel and used for positioning a combustion chamber section of the regenerative cooling body. A first weld joint is arranged on the outer side of the head and used for welding the big end of the connecting ring through a high energy beam. A second weld joint is arranged on the outer side of the inner wall of the combustion chamber section of the regenerative cooling body and used for welding the head through the high energy beam. A third weld joint is arranged on the outer side of the outer wall of the regenerative cooling body and used for argon arc welding of the small end of the connecting ring. The filter screen is fixed to the inner side of the connecting ring in a spot welded mode through a filter framework. A plurality of unthreaded holes are evenly formed in the filter framework. According to the novel connecting structure for the head and the regenerative cooling body of the rocket engine, the number of the weld joints is small, overlapped weld joints are avoided, and the connecting structure is high in reliability; numerical-control welding can be achieved easily, and the weld penetration consistency is good; through the arrangement of the coolant filter screen, the capacity to resist redundant pollutants of the engine is improved; and in addition, the appearance quality of the engine is good, and the expansibility is high.

Owner:SHANGHAI INST OF SPACE PROPULSION

Coolable nozzle and method for producing such a nozzle for a rocket engine

InactiveUS6470671B1Reduce weightHigh strengthMolten spray coatingPower plant exhaust arrangementsCoolantComposite structure

A regeneratively coolable nozzle for a rocket engine is formed by winding a tubular material (6) onto a winding mandrel to produce a helical composite structure (5), through which a coolant can flow during operation of the nozzle. The spiral composite structure (5) is fixed temporarily and the fixed composite structure (5) is removed from the winding mandrel. Then an inner heat resistant, load bearing layer (9) is applied to the radially inner hot-gas facing surface (H) of the fixed composite structure (5). The present nozzle is lightweight and withstand a high coolant pressure.

Owner:ASTRIUM GMBH

Expander cycle rocket engine with staged combustion and heat exchange

In a supersonic nozzle incorporating injectors and a combustion chamber as part of an expander cycle rocket engine, the oxidizer is injected in two streams. One of the streams, preferably a small fraction of the total, is injected into an upstream or preburner section of the combustion chamber and the other to a downstream or main section of the chamber. The preburner combustion gas is cooled in a substantially uniform manner to a moderate temperature by cooling the bulk of the gas rather than cooling only the gas in a boundary layer adjacent to the chamber wall. The combustion gas produced in the downstream section is hotter, and heat from that gas is drawn through the chamber wall into a jacket. The limited combustion in the preburner permits the use of a cooling element with highly intimate heat exchange construction, extracting a high level of energy from the preburner gas without damage to the cooling element and an overall improvement in the regenerative cooling.

Owner:AEROJET ROCKETDYNE INC

Direct-current cold-wall type engine combustor

ActiveCN108457768AImprove atomization effectImprove thermal protection performanceRocket engine plantsCombustion chamberCombustor

The invention discloses a direct-current cold-wall type engine combustor. The direct-current cold-wall type engine combustor comprises a combustor upper cover, a combustor linear section, a jet section and a spray pipe convergence and expansion section which are connected in sequence. An oxidizing agent liquid collection cavity, an oxidizing agent jet hole, a fuel liquid collection cavity and a fuel jet hole are formed in the outer wall of the jet section in the circumferential direction. An oxidizing agent enters the oxidizing agent liquid collection cavity via an oxidizing agent regenerativecooling channel and then flows out from the oxidizing agent jet hole to form a jet flow, fuel enters the fuel liquid collection cavity via a fuel regenerative cooling channel and then flows out fromthe fuel jet hole to form a jet flow, the jet flows are close to the inner wall of the combustor linear section but being not in contact with the wall, and the jet flows impact for atomization, mixingand combustion on the combustor upper cover, and are discharged out of the combustor through the spray pipe convergence and expansion section. By means of the combustor, the propellant combustion efficiency and the thermal protection capacity of the combustor can be improved, and the combustor is simple in overall structure and easy to machine and obtain.

Owner:SHANGHAI INST OF SPACE PROPULSION

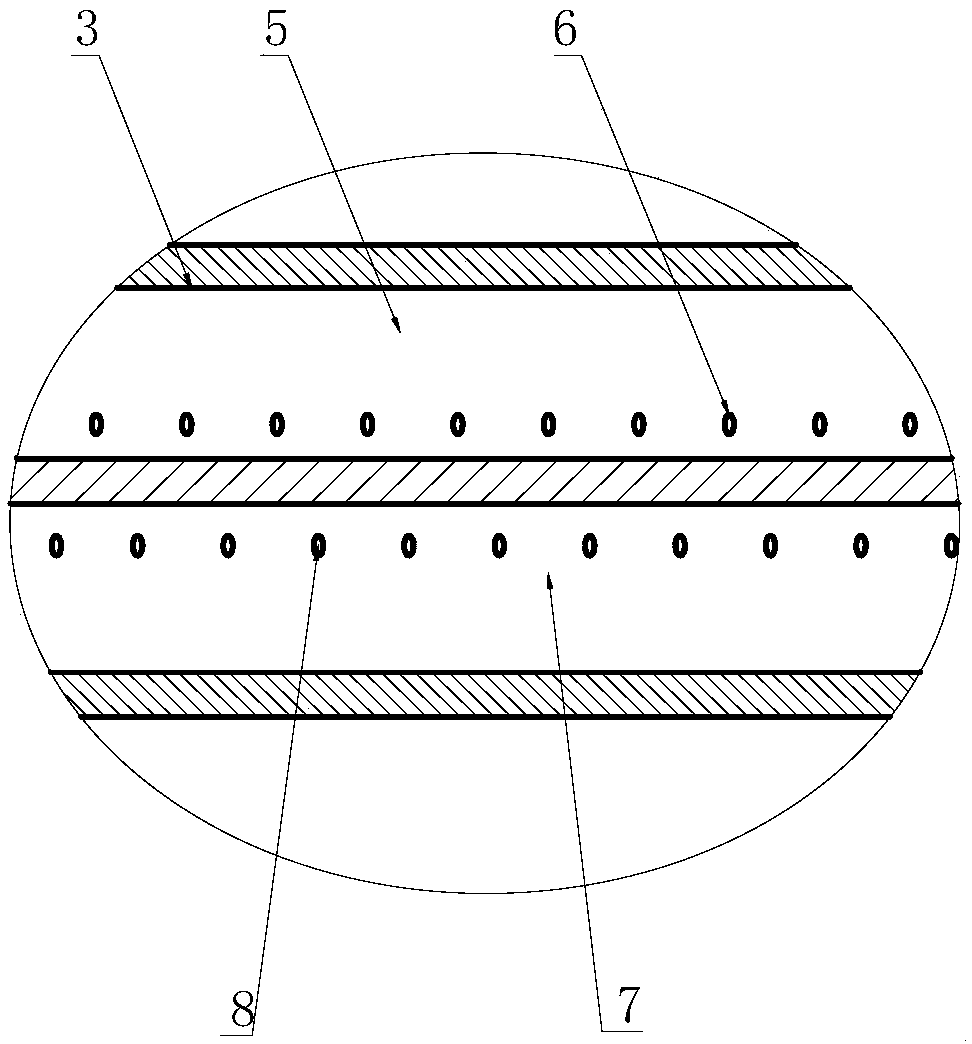

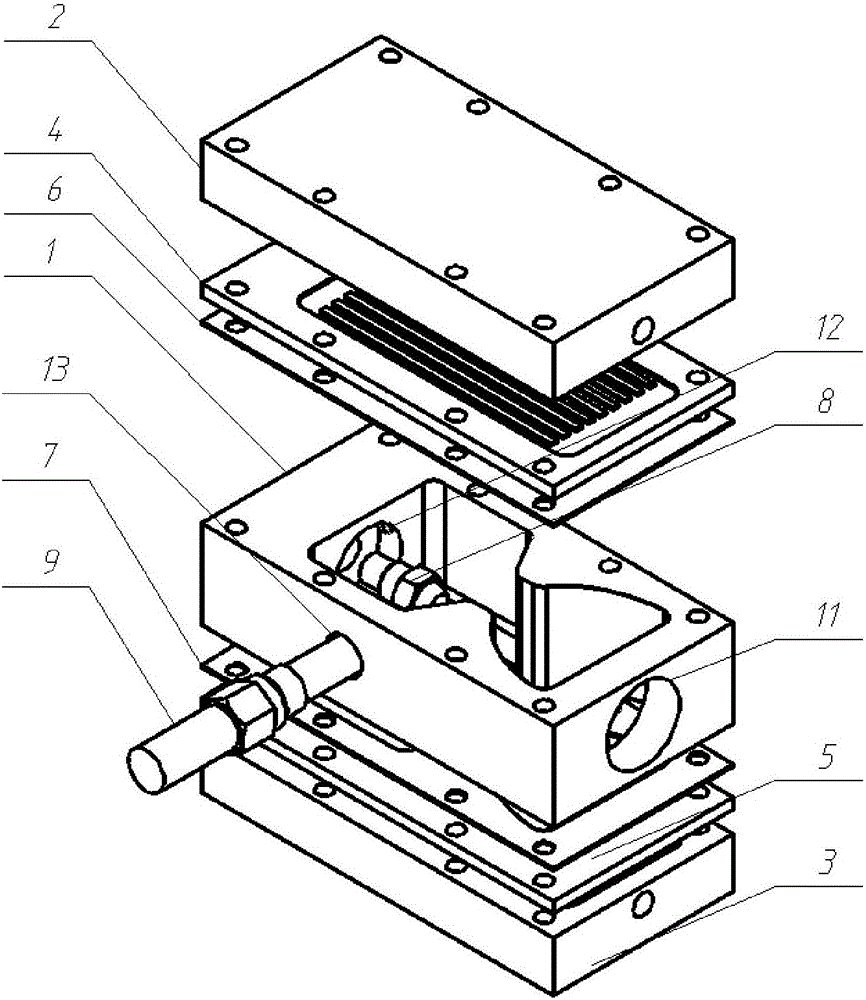

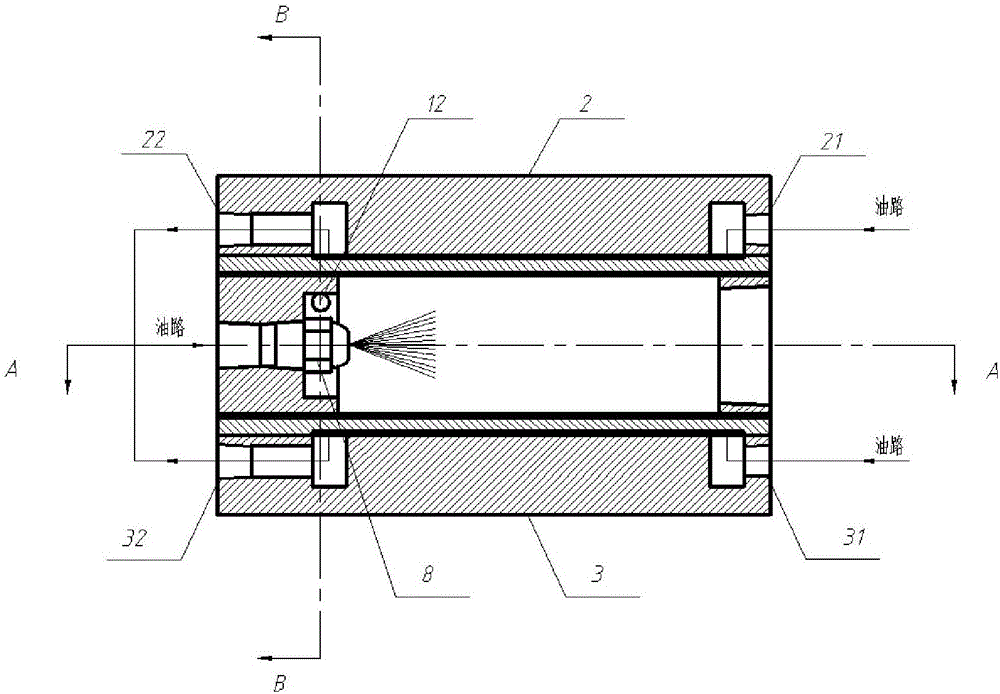

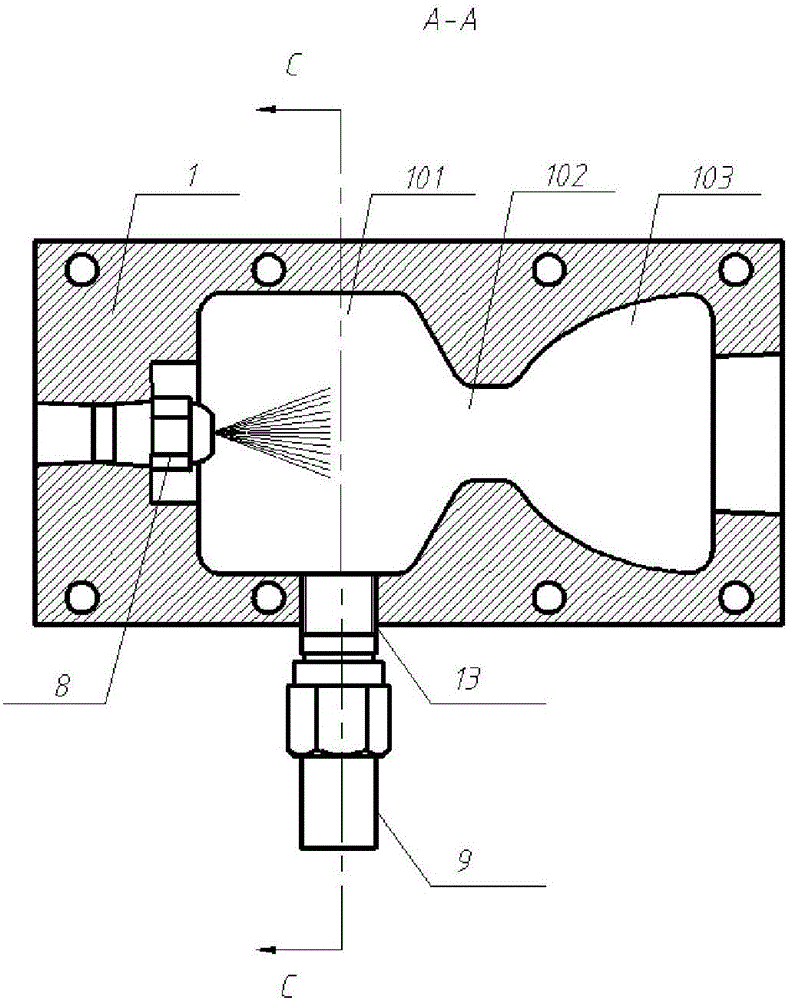

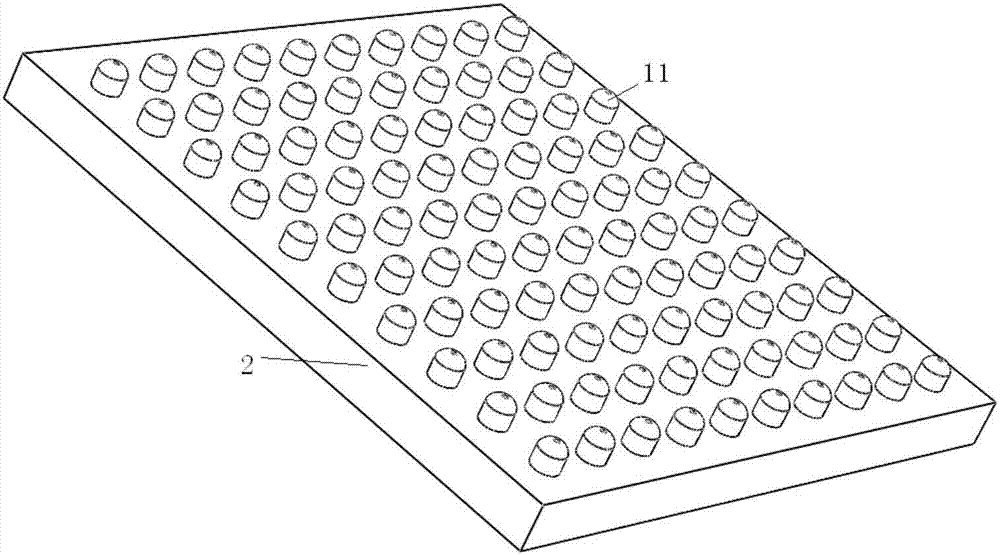

Micro-channel regenerative cooling micro-combustor

ActiveCN106322436AEffective heat protectionReduce the temperatureContinuous combustion chamberCombustorCombustion chamber

The invention discloses a micro-channel regenerative cooling micro-combustor. By the aid of a combustion cavity body, a middle base plate, a micro-channel plate and a top cover plate, the combustion cavity, the middle base plate and the micro-channel plate form a closed combustion cavity, wherein the middle base plate, the micro-channel plate and the top cover plate are sequentially arranged on the upper side and the lower side of the combustion cavity in a laminated manner. Fuel oil flows through the micro-channel plate and then is sprayed into the combustion cavity body through a fuel oil atomizing nozzle, the fuel oil is ignited after mixed with air entering an air inlet, the fuel oil simultaneously serves as a coolant, heat released by the combustor is absorbed by a micro-channel, and the wall of the combustor is cooled while combustion efficiency is improved, so that regenerative cooling is realized. By taking the advantages of large surface area and micro-size effect enhanced heat exchange of the micro-channel, the wall temperature and the temperature gradient of the combustor are reduced, the problem of excessive heat stress is solved, and effective heat protection of the combustor is realized. Besides, preheated fuels are cracked, ignition performance is improved, and extinction limit and combustion efficiency are increased.

Owner:XIAMEN UNIV +1

Device and method for promotion of cooling electronic device rack by using a vapor compression system

InactiveCN101677091AEffective and Safe RemovalReduce environmental burdenDigital data processing detailsSemiconductor/solid-state device detailsWater vaporCirculator pump

The present invention provides a device and method for the promotion of cooling electronic device rack by using a vapor compression system. A cooling device used to cool the electronic device including semiconductor elements is provided with an evaporator, a condenser, a circulating pump and tubing, wherein the evaporator stores coolant which will be evaporated when the pressure is lower than thesurrounding pressure so as to generate cooled coolant; the condenser is communicated with with the evaporator by a bypass pipleline to regenerate the coolant from coolant steam; the circulating pump and piping are used to supply the cooled coolant to a heat exchange area of the electronic device, so as to exchange heat with an air flow passing through the semiconductor elements and return the coolant after heat exchange to the condenser on a high-temperature side of the electronic device; In the heat exchange area of the air flow, the pressure of the coolant is ensured to be lower than the surrounding pressure.

Owner:IBM CORP

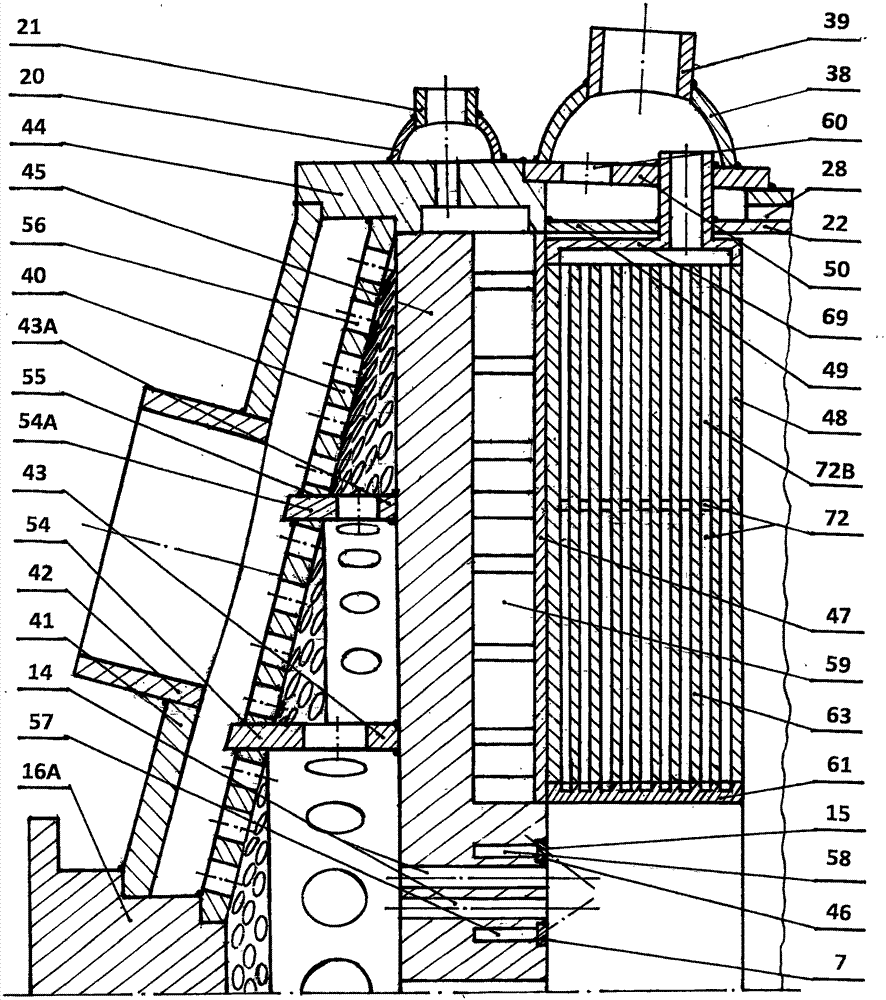

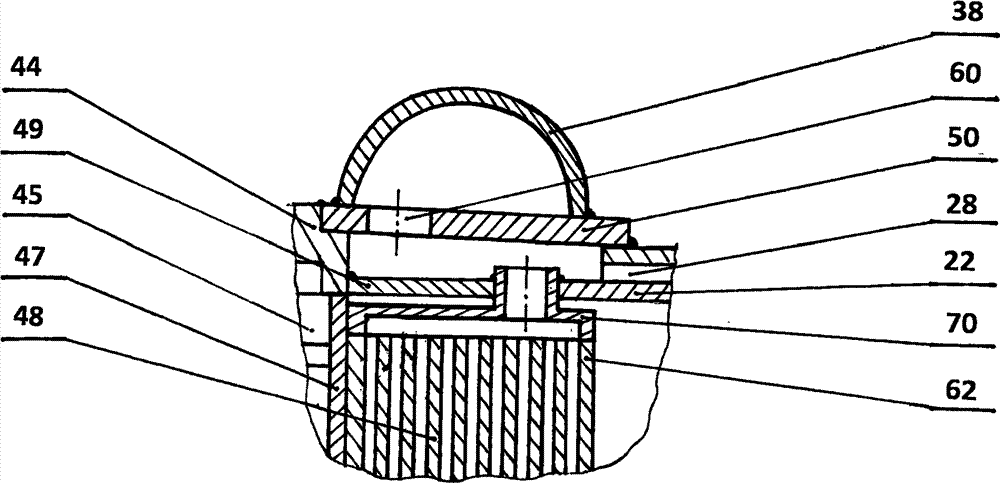

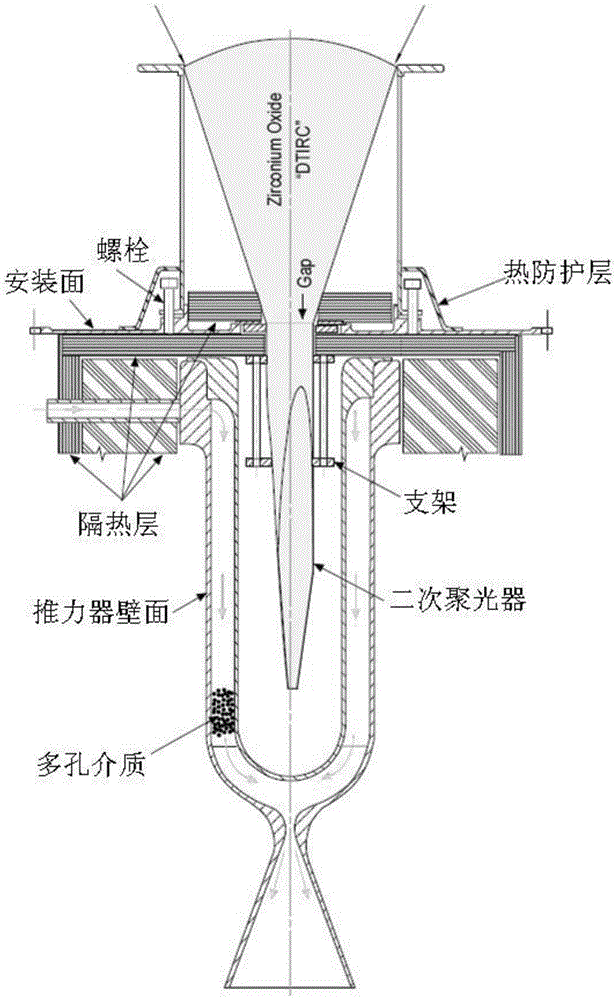

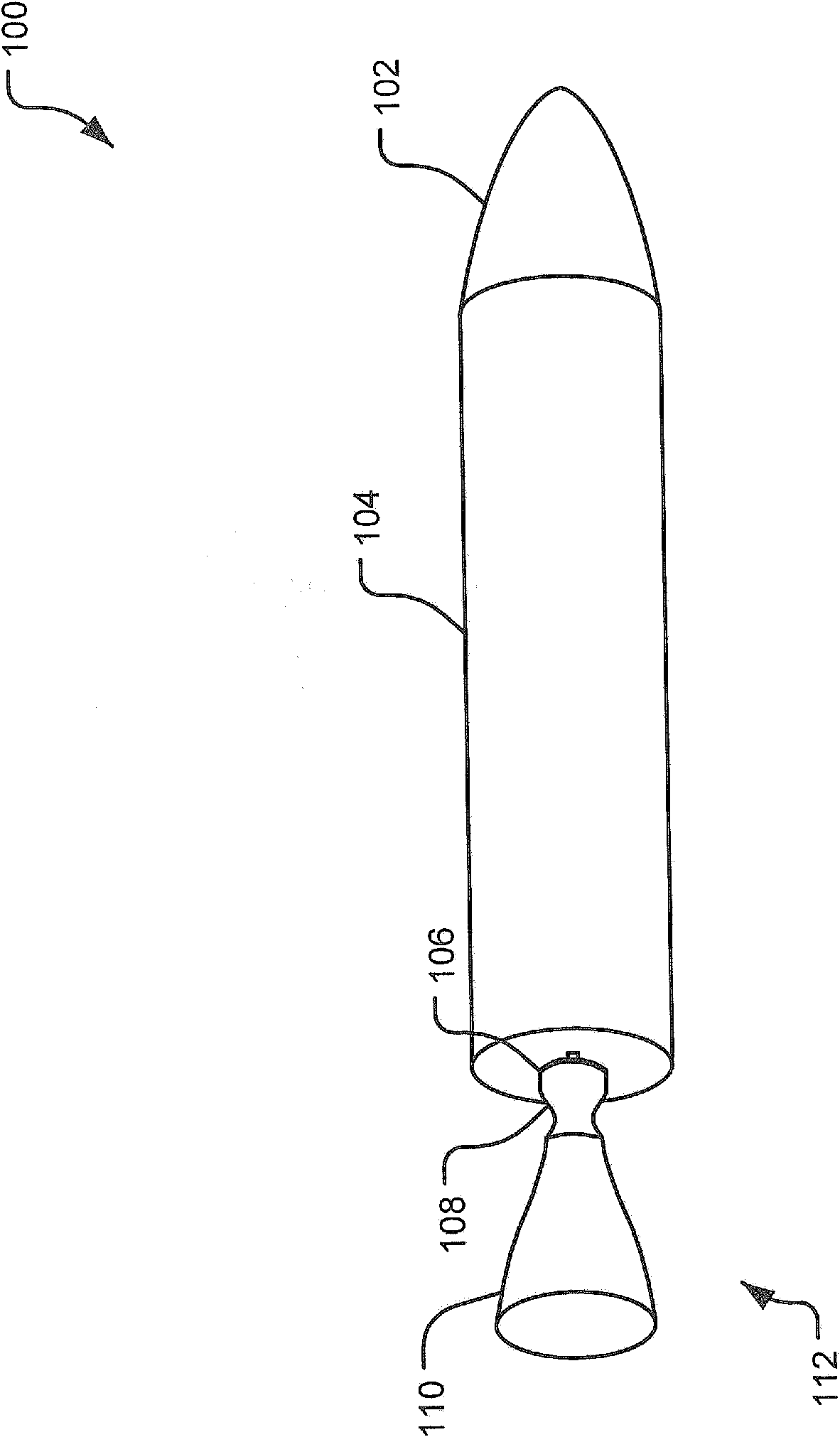

Solar heat thruster

ActiveCN104005923ASmall sizeIncrease the heat exchange areaFrom solar energyRocket engine plantsStress concentrationHeating temperature

The invention discloses a solar heat thruster with high efficiency and high specific impulse, and belongs to the technical field of spacecraft space propulsion. According to the solar heat thruster, the secondary condenser regenerative cooling technology and the laminate heating efficient heat exchange core technology are adopted, a propellant is preheated, cracks caused by hot stress concentration of a secondary condenser are avoided, and the solar utilization rate of a system is improved through laminate heating efficient heat exchange. According to the solar heat thruster, under the same solar incident power, the heating efficiency of the solar heat thruster for the propellant is improved, the heating temperature of the propellant is increased, and the solar heat thruster has the advantages of high efficiency and high specific impulse.

Owner:NAT UNIV OF DEFENSE TECH

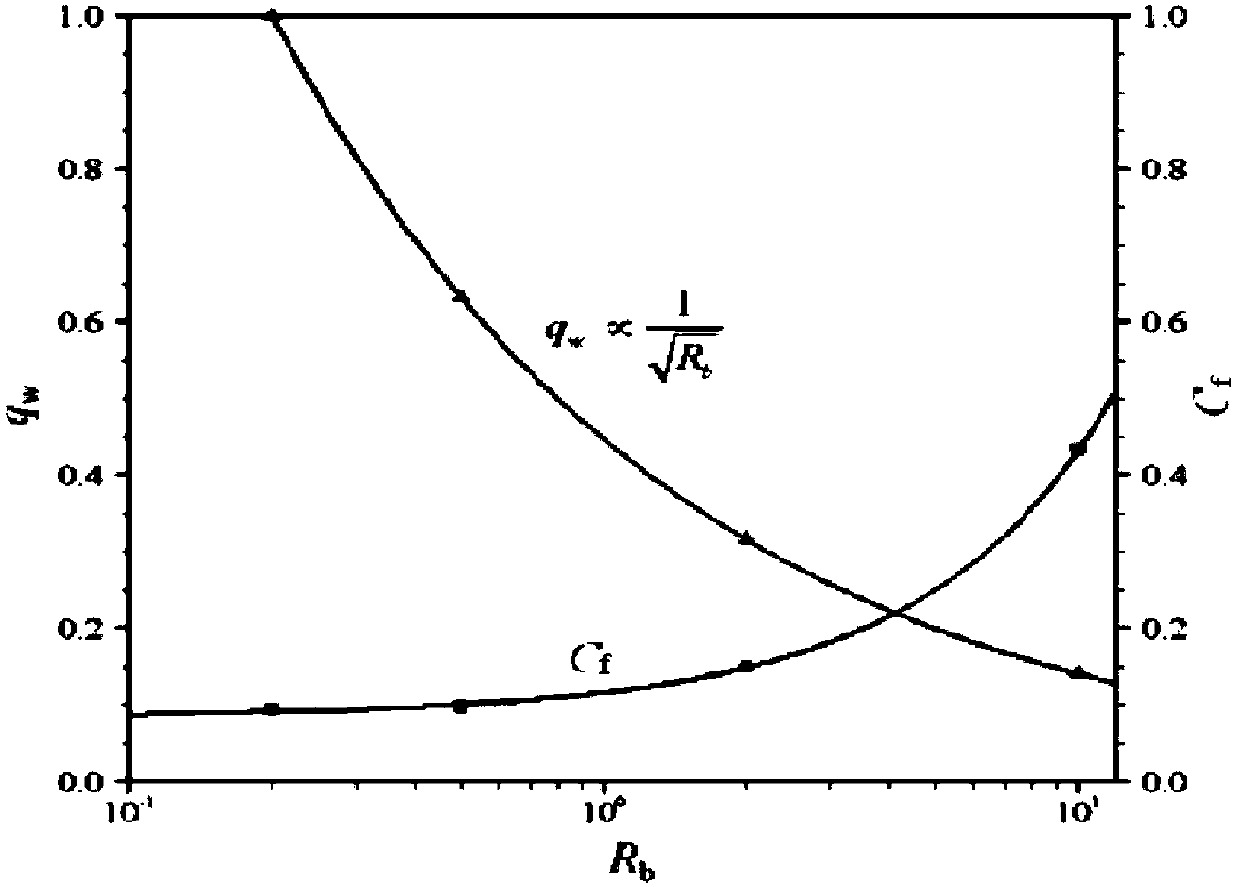

Regeneratively cooled porous media jacket

The fluid and heat transfer theory for regenerative cooling of a rocket combustion chamber with a porous media coolant jacket is presented. This model is used to design a regeneratively cooled rocket or other high temperature engine cooling jacket. Cooling jackets comprising impermeable inner and outer walls, and porous media channels are disclosed. Also disclosed are porous media coolant jackets with additional structures designed to transfer heat directly from the inner wall to the outer wall, and structures designed to direct movement of the coolant fluid from the inner wall to the outer wall. Methods of making such jackets are also disclosed.

Owner:FIRESTAR ENG

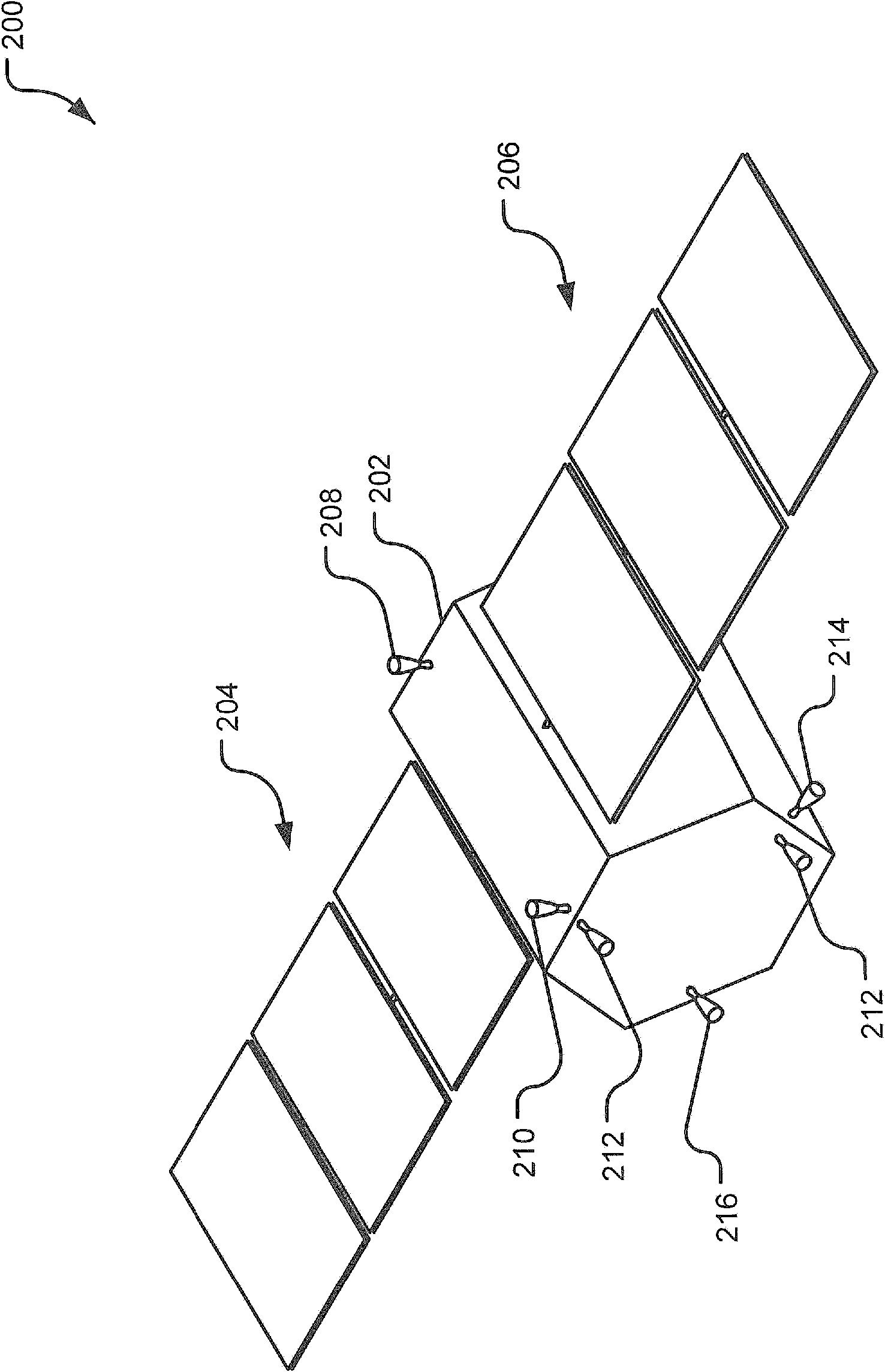

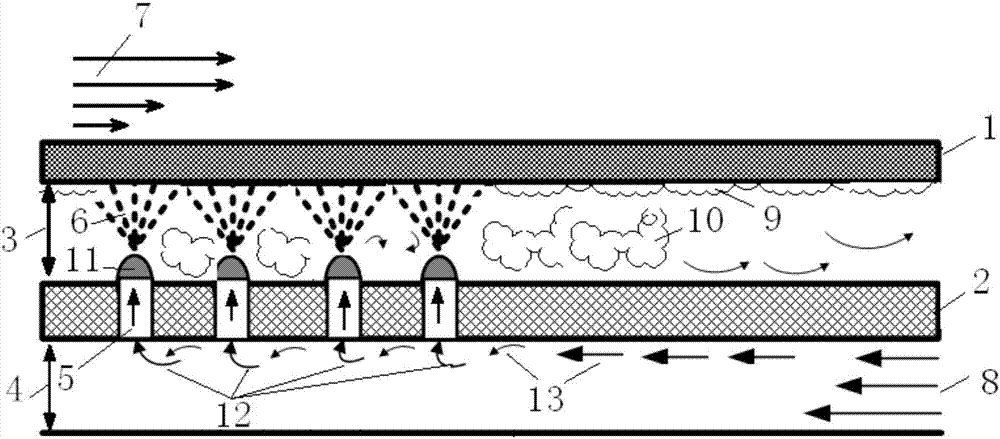

Regenerative cooling double flow channel scheme strengthening heat exchange through spray wall impingement

ActiveCN106949497AImprove heat transfer efficiencyGood choiceContinuous combustion chamberCombustion systemHeat flow

The invention provides a heat exchange strengthening structure used for regenerative cooling of a supersonic combustion chamber through a spraying / convection composite type heat exchange mode. A double flow channel design is adopted, and the characteristic of the large heat flux of a spraying cooling mode is fully utilized to conduct heat exchange strengthening on the wall face of the combustion chamber. A scheme is composed of a double layer heat exchange scheme of the outer layer wall and the inner layer wall. A flow channel formed by partitioning of the outer layer wall and the inner layer wall is used for spray wall impingement strengthening heat exchange. Spraying nozzles are arranged on the inner layer wall. The number and distribution density of the spraying nozzles are determined according to the heat exchange strength and the heat exchange area. Part of heated liquid fuel and gaseous fuel formed by spray heat absorption are supplied to a nozzle of an engine combustion system in different phase states, and the liquid fuel is atomized in a mode of pneumatic atomization assisting. By adopting the design that a gas heat exchange flow channel and a liquid heat exchange flow channel are partitioned, the problem of flow supplying fluctuation caused by nonuniform gas and liquid distribution in the conveying process of the two phase flows of fuel after heat absorption to the combustion system is avoided.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

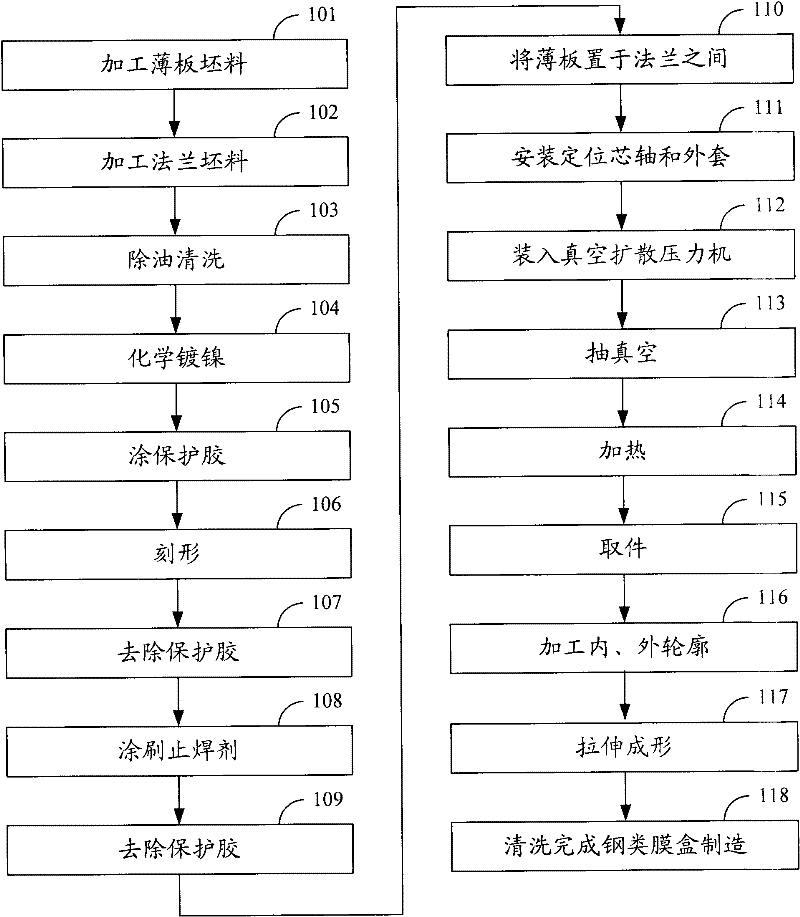

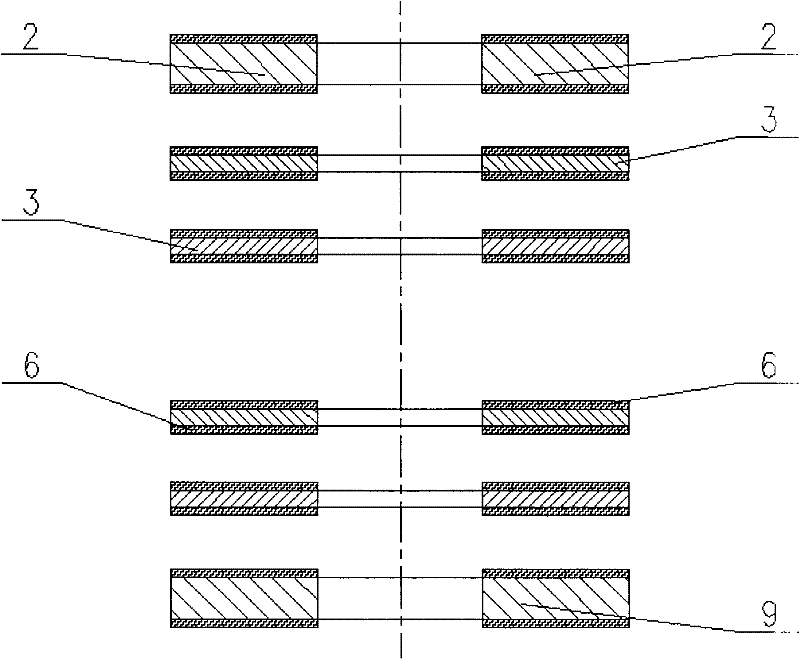

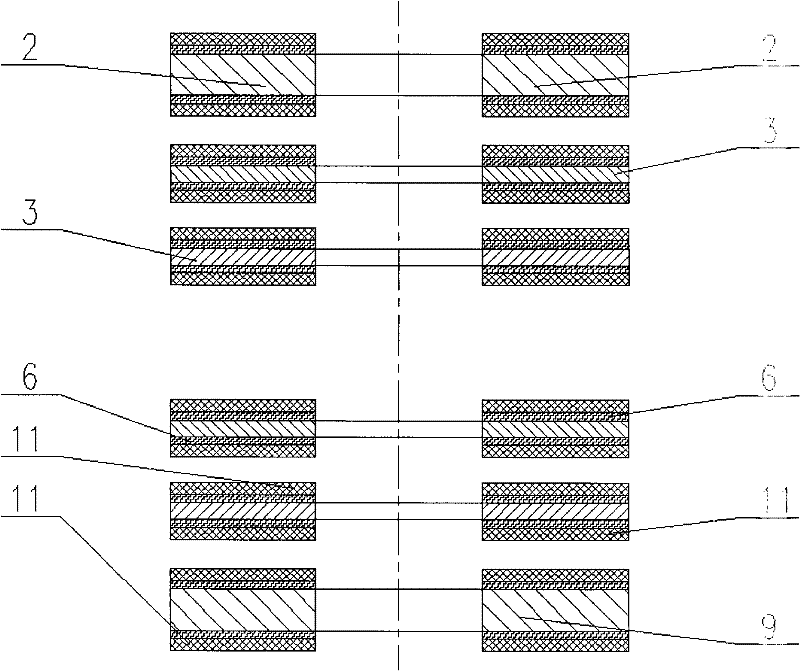

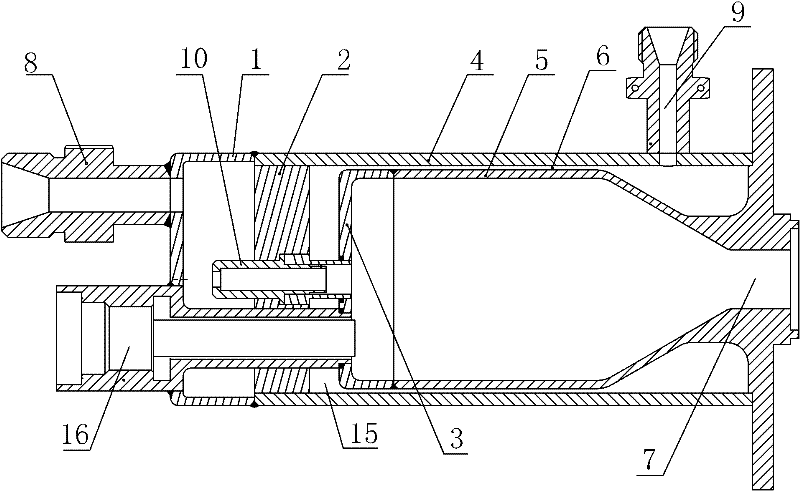

Diffusion welding method and weldment

InactiveCN102441732AHigh elongationImprove plastic indexNon-electric welding apparatusThrust chamberEngineering

The invention relates to the technical field of press welding in mechanical engineering, in particular to a diffusion welding method and a weldment, which are used for solving the problem of high temperature required by diffusion welding in the prior art, providing a novel solution for researching and developing regenerative cooling body parts of space rockets, missile engine diaphragm capsules and rocket thrust chambers, prolonging the fatigue life of the regenerative cooling body parts of the engine diaphragm capsules and the thrust chambers, and enhancing the strength and reliability of the regenerative cooling body parts. The surface of the weldment is plated with a nickel coating which contains nickel and phosphorus. The diffusion welding method provided by the invention comprises the following steps of: tightly jointing the nickel coatings on the surfaces of two weldments; and performing diffusion welding on the two jointed weldments. In the scheme, the nickel coatings containing nickel and phosphorus are added, so that the temperature needed by diffusion welding is lowered.

Owner:北京智创联合科技股份有限公司

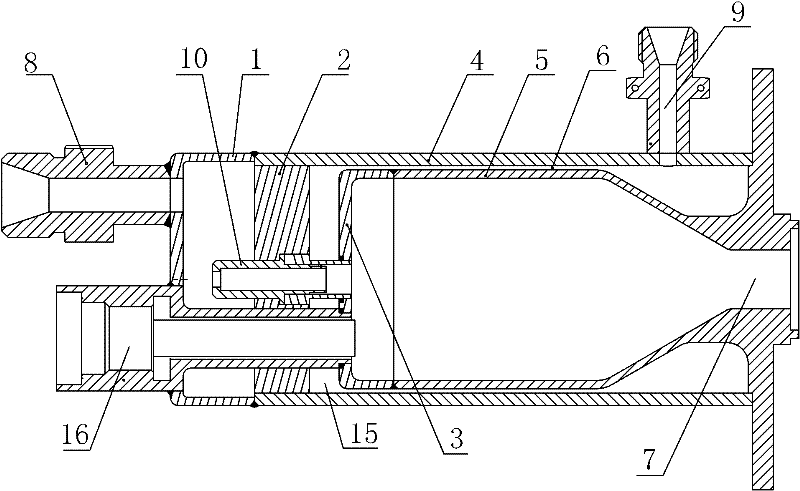

Dividing wall type regenerative cooling air oxygen alcohol torch type igniter

ActiveCN102175041AGuaranteed Cooling ReliabilityMeet ignition requirementsIncandescent ignitionRocket engine plantsAlcoholCombustion chamber

The invention discloses a dividing wall type regenerative cooling air oxygen alcohol torch type igniter which comprises an oxidant shell, a middle bottom, an inner bottom, a cooling jacket, a combustion chamber, a nozzle, a sparking plug, an oxidant inlet pipe mouth and a fuel inlet pipe mouth, wherein oxygen and alcohol are adopted as a propellent, and ignition is carried out by adopting the electric sparking plug. The nozzle comprises a straight-flow nozzle and an eccentric type nozzle, the straight-flow nozzle is an oxidant nozzle, the eccentric nozzle is a fuel nozzle, a cavity from the outlet of the straight-flow nozzle to the outlet of the eccentric nozzle is a reducing chamber; oxidant enters the reducing chamber from the straight-flow nozzle, fuel enters a fuel before-spraying liquid collecting cavity through a regenerating cooling chamber and then rotates through eccentric nozzle tangential holes and enters the reducing chamber, and the oxidant and the fuel are atomized and mixed in the reducing chamber and stably combusted at the outlets of the nozzles. High-temperature fuel is uniformly mixed in the combustion chamber and then sprayed through the throat part of the combustion chamber to form a stable torch. The invention ensures ignition and cooling reliability of an igniter and stable combustion of the torch at the outlet.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com