Regenerative cooling double flow channel scheme strengthening heat exchange through spray wall impingement

A technology for regenerative cooling and enhanced heat exchange, which is applied in combustion methods, lighting and heating equipment, combustion chambers, etc., and can solve problems such as large thermal load gradient on the combustion chamber wall, unstable fuel nozzle flow supply, and difficult fuel supply system design. , to solve the problem of instability and fuel fluctuation, enhance the overall atomization effect, and prevent the deterioration of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

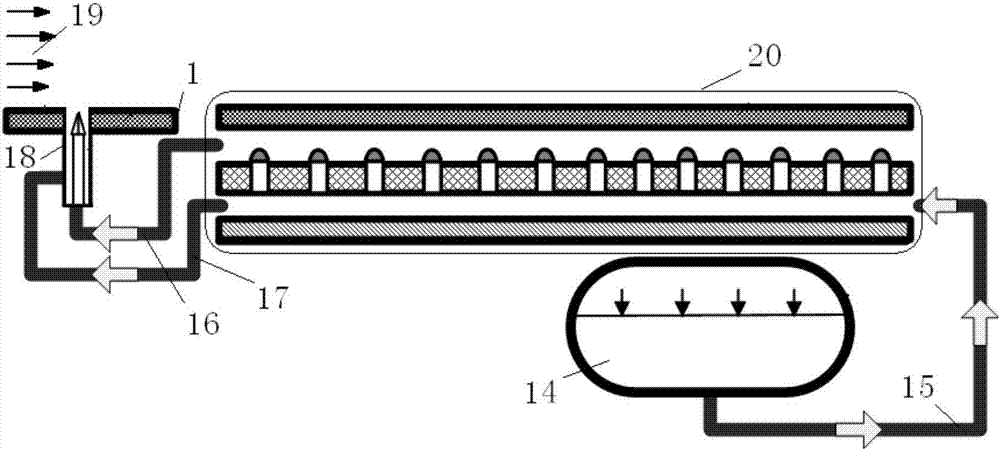

[0022] Such as figure 1 Schematic diagram of the self-generating cooling process of the endothermic hydrocarbon fuel of the scramjet engine shown. After the fuel stored in the storage tank 14 is extruded, it enters the nozzle 18 of the engine combustion system in gaseous and liquid forms respectively through the fuel supply pipeline to absorb heat on the double-layer heat exchange channel in the wall of the combustion chamber, and realizes Atomized, blended and combusted with supersonic air flow. The overall structure of the combustion chamber of the combined spray / convection cooling structure can choose a circular wall or a flat wall according to the overall configuration of the engine combustion chamber. Only the local structure of the combustion chamber is shown in the figure.

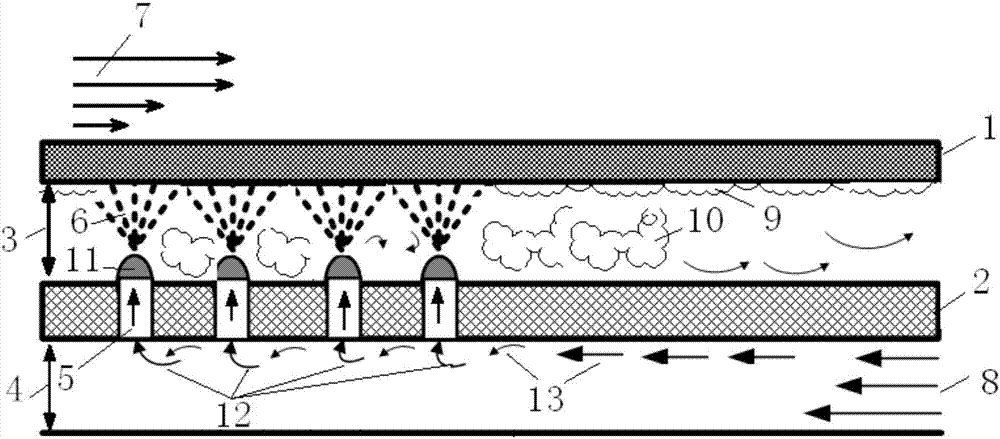

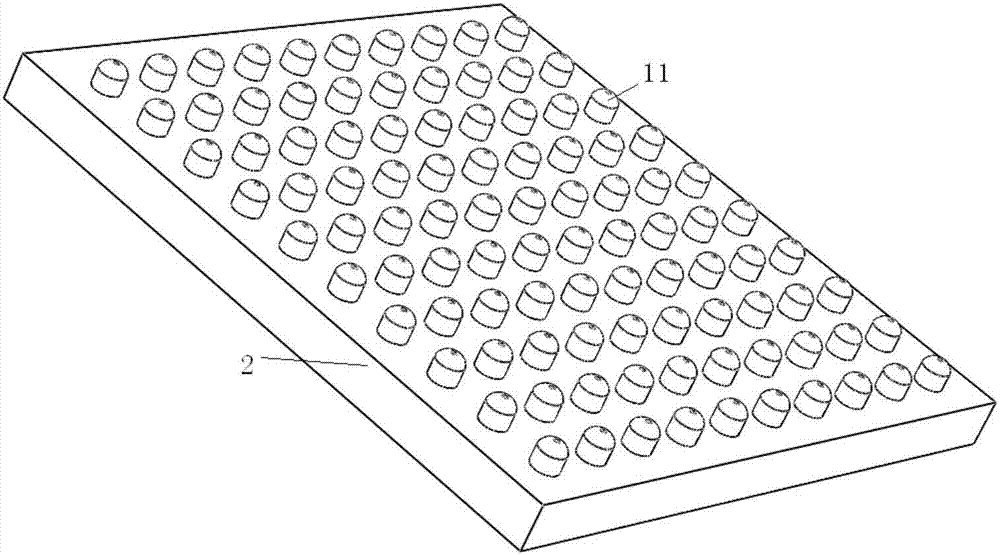

[0023] Such as figure 2 As shown, the combustion chamber wall structure of the spray / convection composite cooling structure is composed of an outer wall 1 and an inner wall 2, which are separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com