Patents

Literature

35results about How to "Avoid Heat Transfer Deterioration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

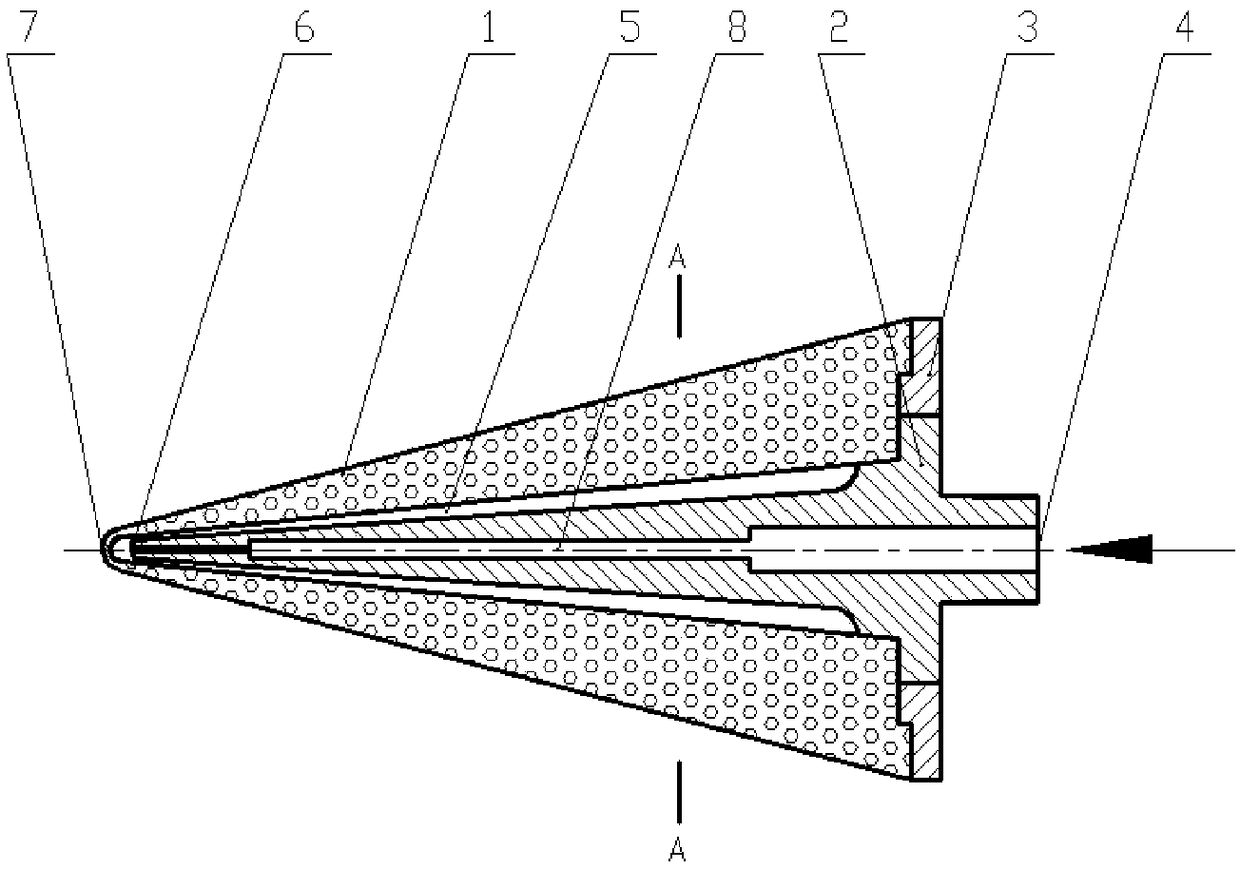

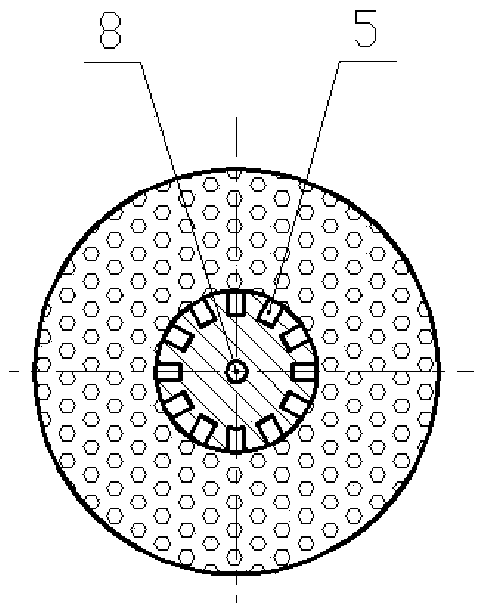

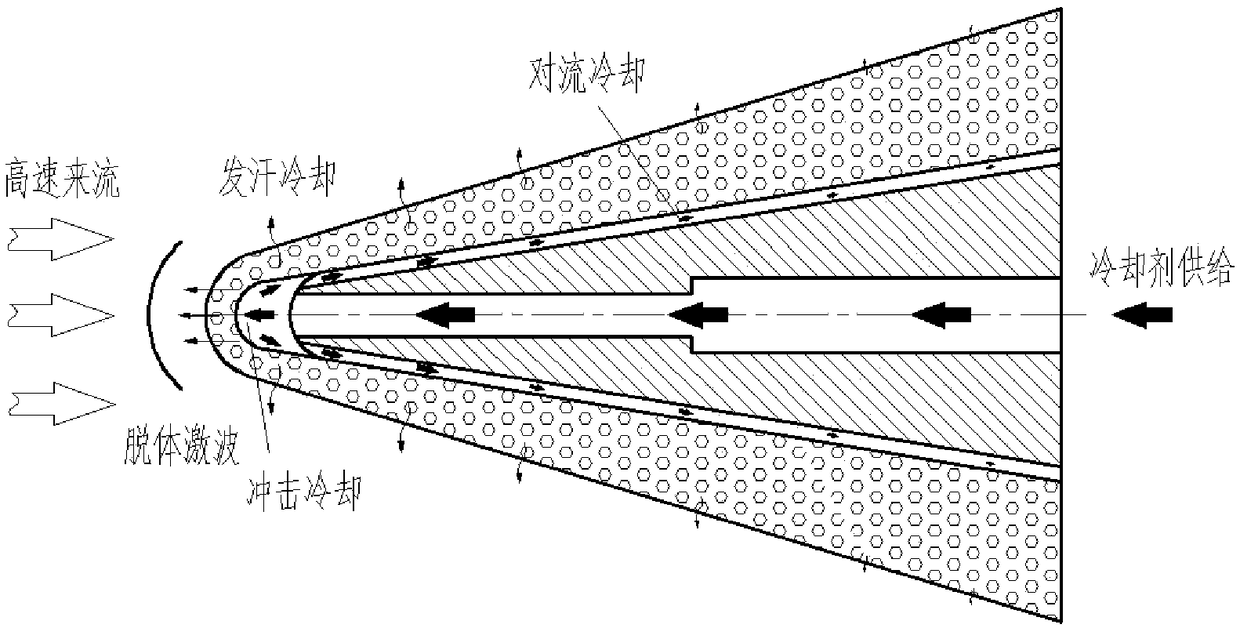

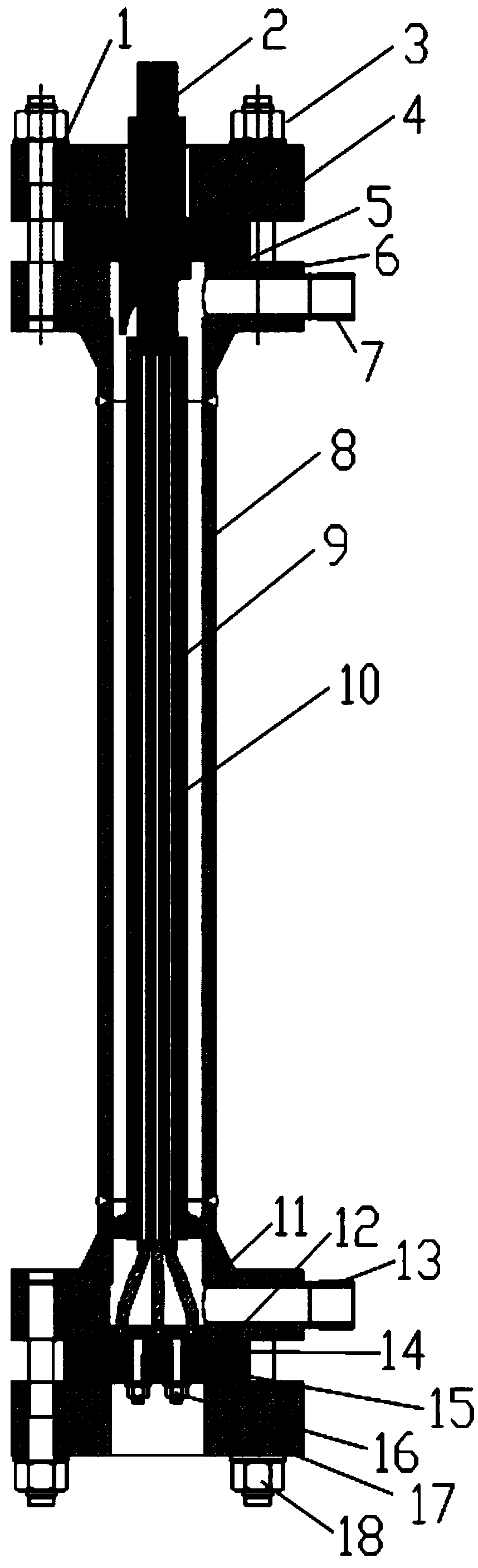

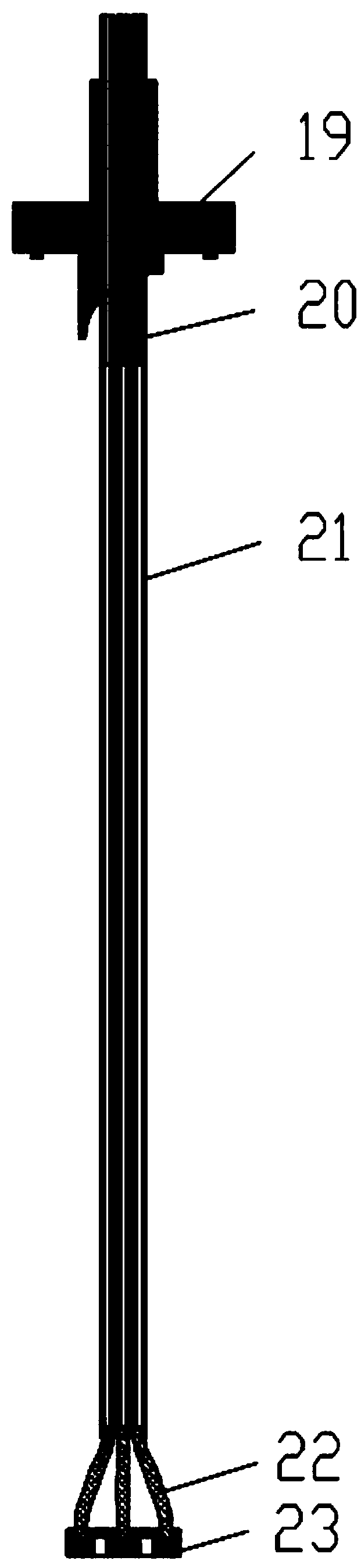

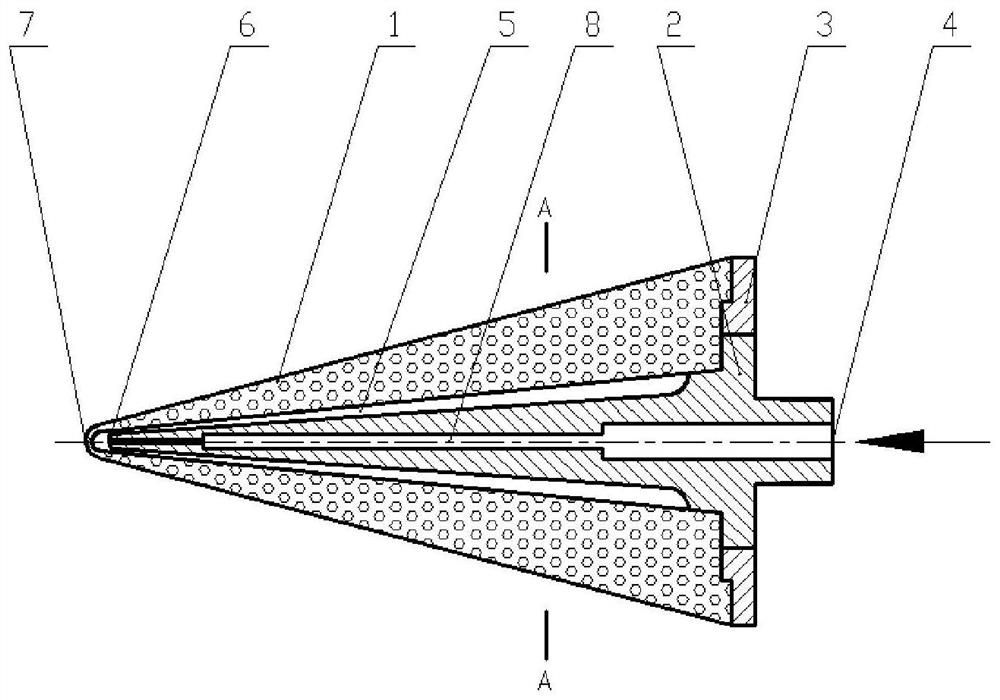

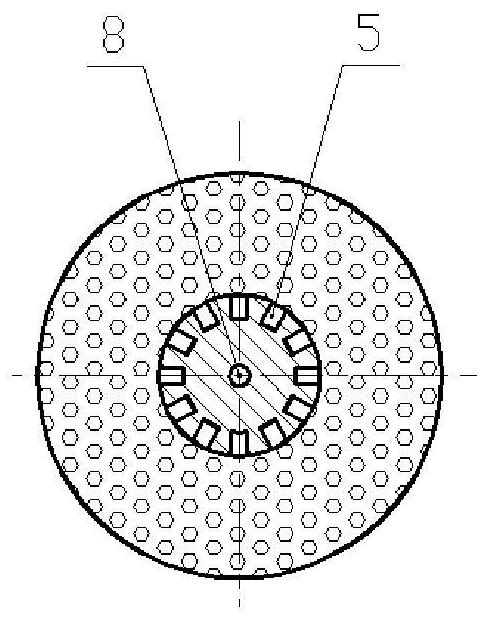

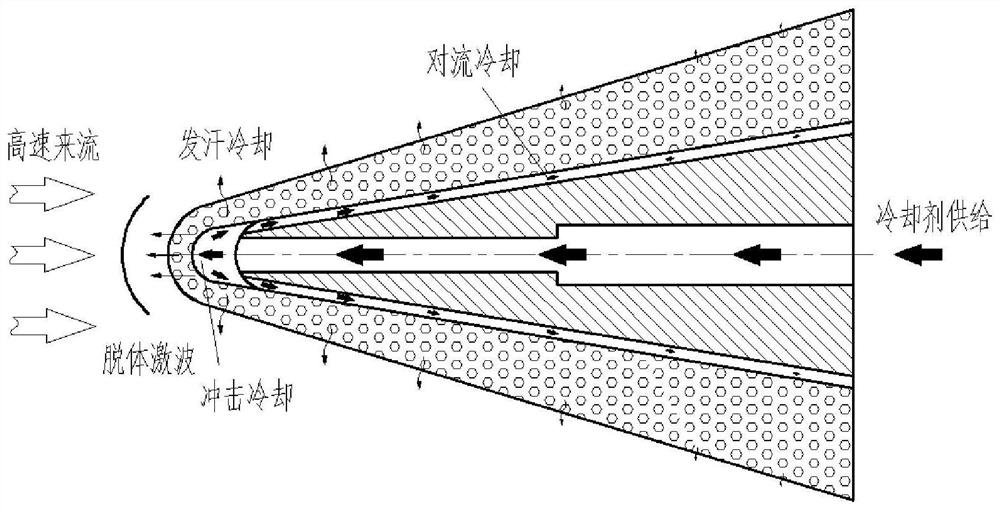

Flow control type impact transpiration cooling nose cone

ActiveCN109334974AImprove high temperature resistanceImprove insulation performanceFuselagesSupersonic aircraftCircular coneTranspiration

A flow control type impact transpiration cooling nose cone comprises a porous nose cone and a flow control cone core; the porous nose cone is a circular cone; a conical blind hole is formed in the bigend of the porous nose cone; the flow control cone core is a circular cone; the flow control cone core is inserted into the conical blind hole of the porous nose cone; a cavity is formed between thehead of the flow control cone core and the bottom of the conical blind hole of the porous nose cone; a through hole is formed in the flow control cone core in the axis direction and used for enablinga coolant to flow into the through hole from the big end of the circular cone of the flow control cone core and flow out of the through hole from the small end; and the big end of the flow control cone core is connected with an aircraft downstream cabin section. According to the flow control type impact transpiration cooling nose cone, by using a transpiration cooling and impact cooling principle,the temperature of the nose cone part of an aircraft is reduced so that ablation deformation cannot be generated; and requirements on long-time, long-distance and repeated use of the aircraft are satisfied.

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

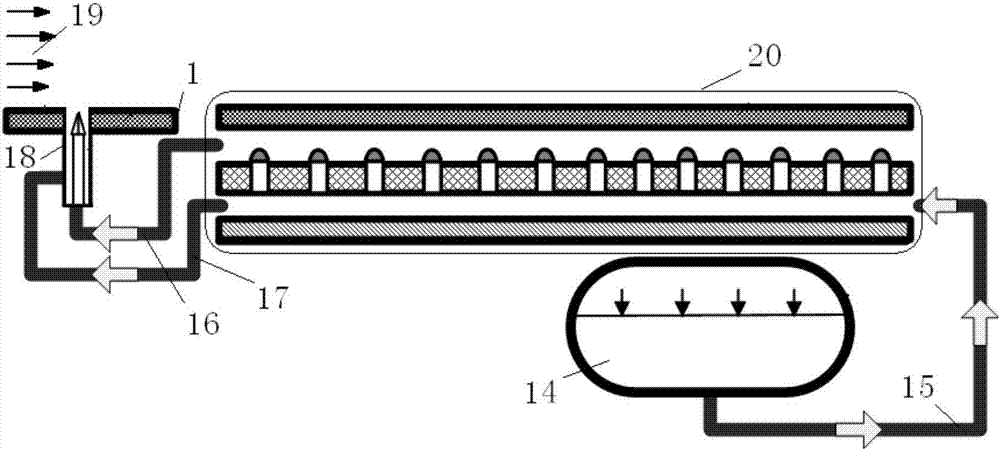

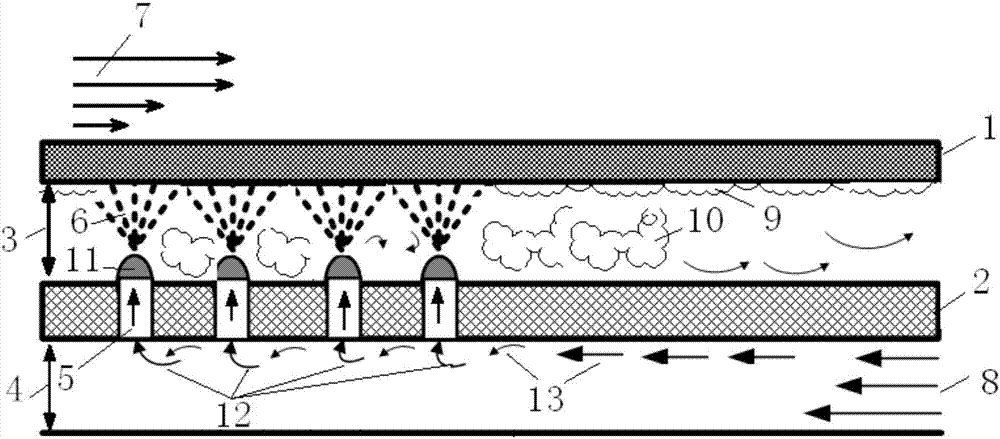

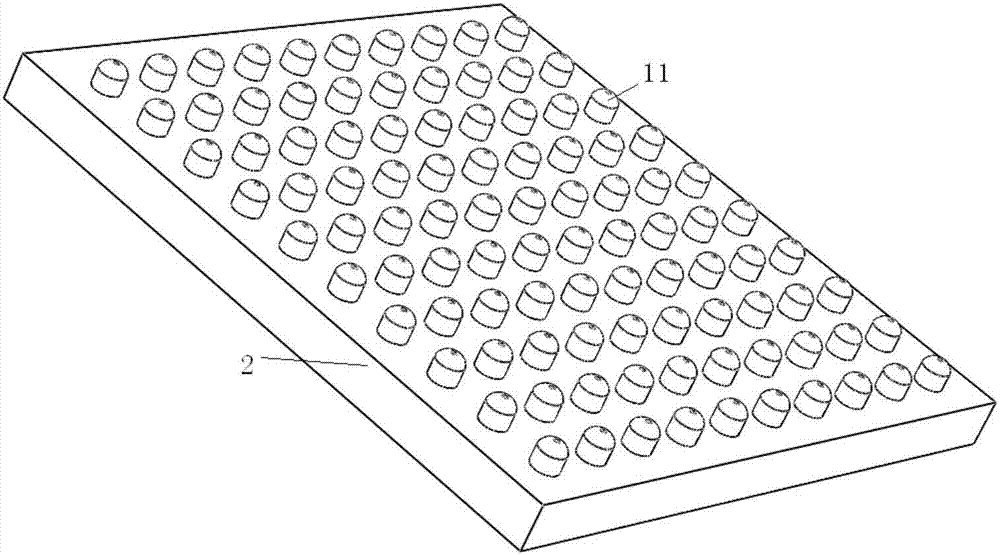

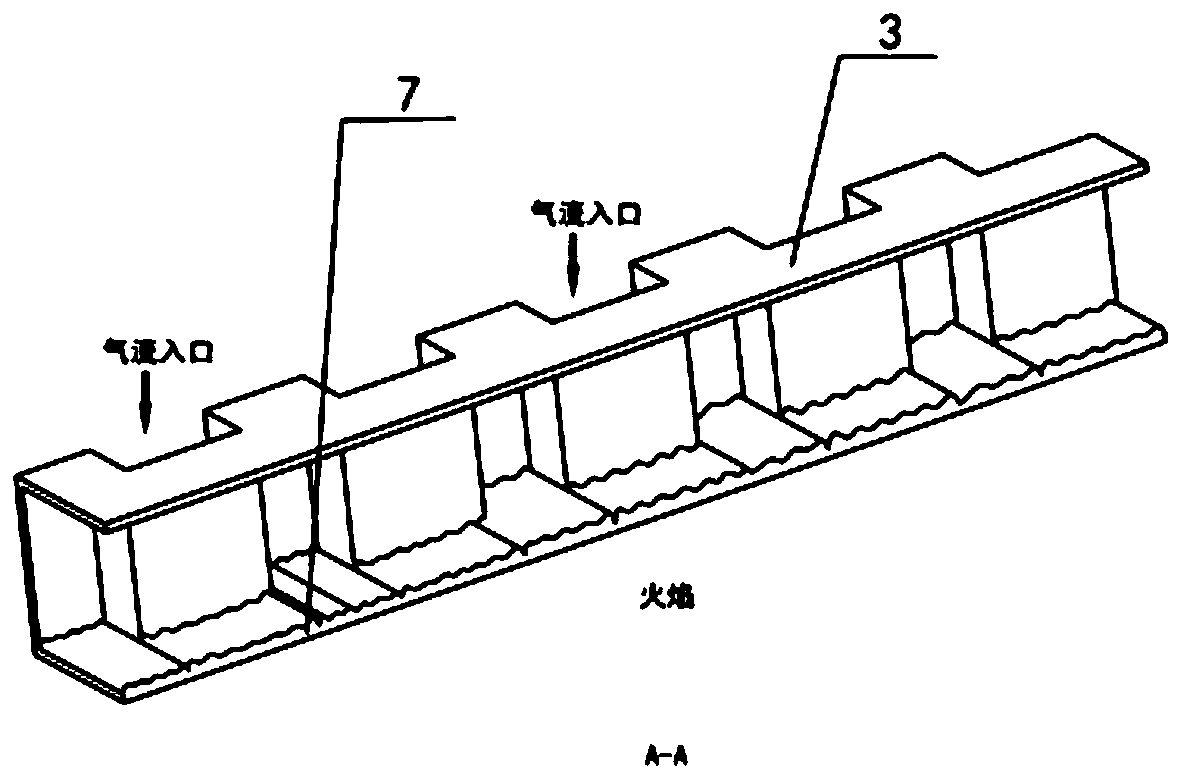

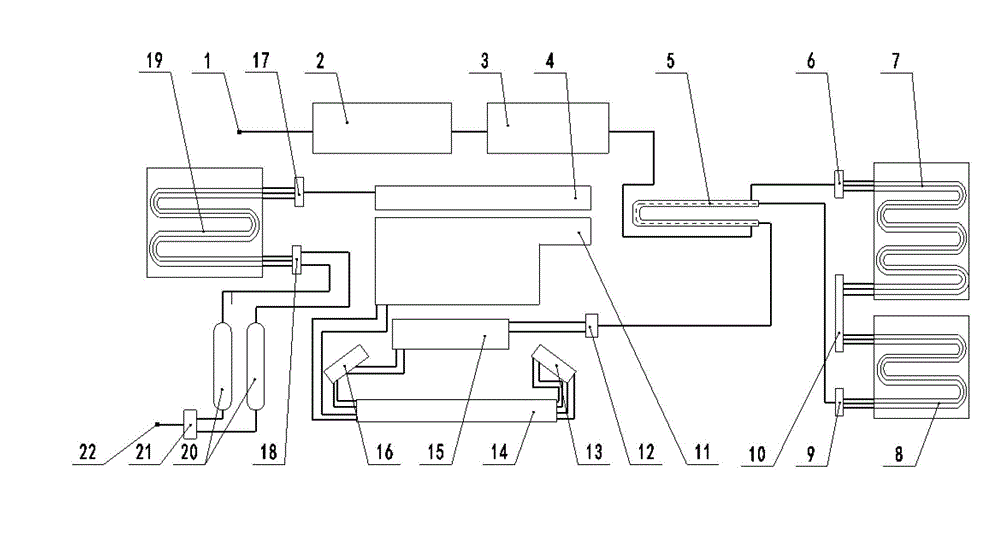

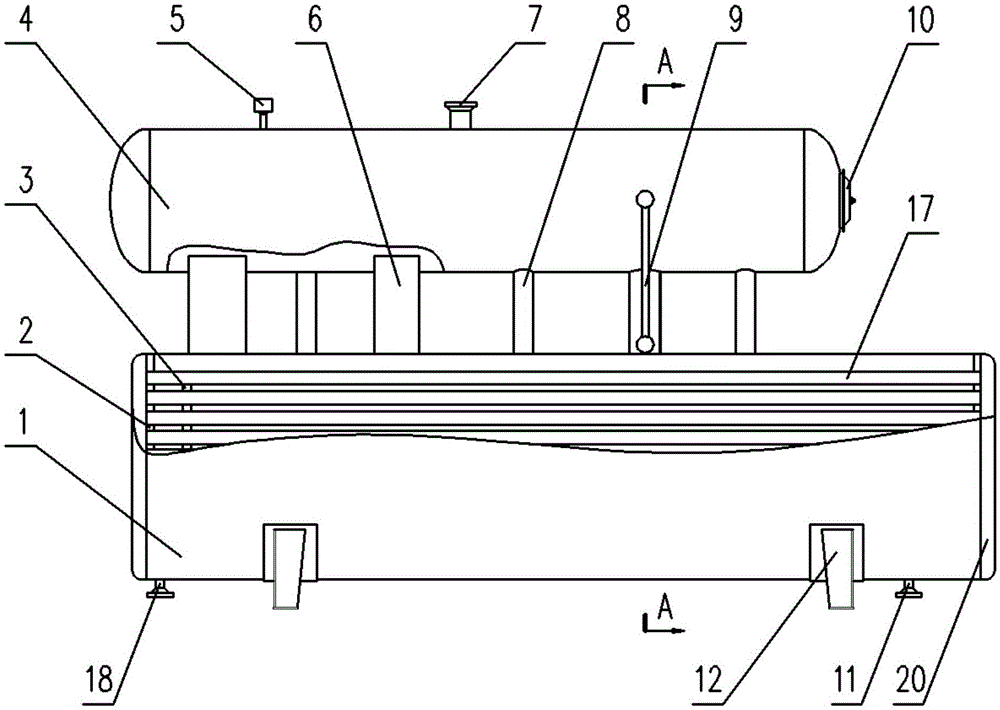

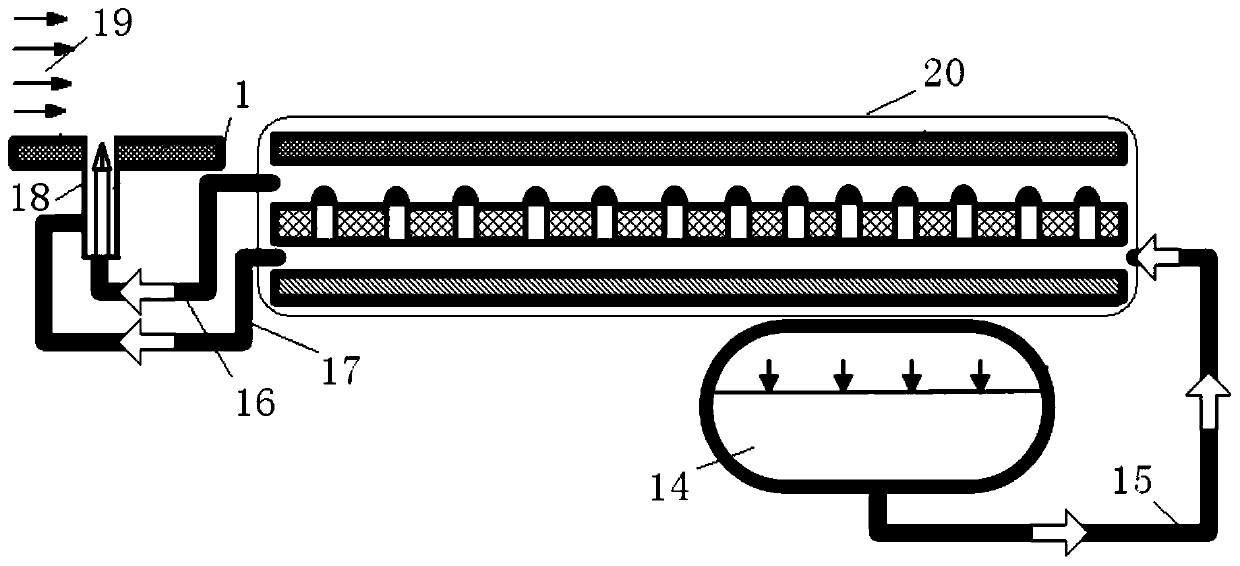

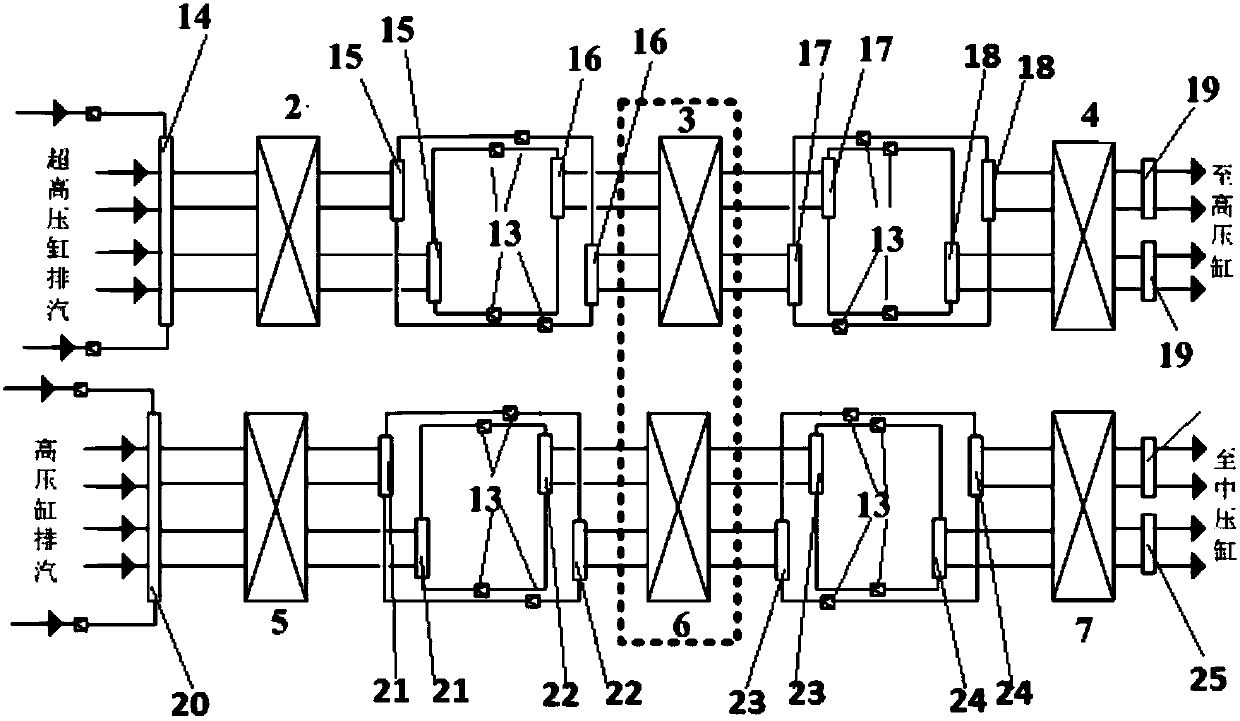

Regenerative cooling double flow channel scheme strengthening heat exchange through spray wall impingement

ActiveCN106949497AImprove heat transfer efficiencyGood choiceContinuous combustion chamberCombustion systemHeat flow

The invention provides a heat exchange strengthening structure used for regenerative cooling of a supersonic combustion chamber through a spraying / convection composite type heat exchange mode. A double flow channel design is adopted, and the characteristic of the large heat flux of a spraying cooling mode is fully utilized to conduct heat exchange strengthening on the wall face of the combustion chamber. A scheme is composed of a double layer heat exchange scheme of the outer layer wall and the inner layer wall. A flow channel formed by partitioning of the outer layer wall and the inner layer wall is used for spray wall impingement strengthening heat exchange. Spraying nozzles are arranged on the inner layer wall. The number and distribution density of the spraying nozzles are determined according to the heat exchange strength and the heat exchange area. Part of heated liquid fuel and gaseous fuel formed by spray heat absorption are supplied to a nozzle of an engine combustion system in different phase states, and the liquid fuel is atomized in a mode of pneumatic atomization assisting. By adopting the design that a gas heat exchange flow channel and a liquid heat exchange flow channel are partitioned, the problem of flow supplying fluctuation caused by nonuniform gas and liquid distribution in the conveying process of the two phase flows of fuel after heat absorption to the combustion system is avoided.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

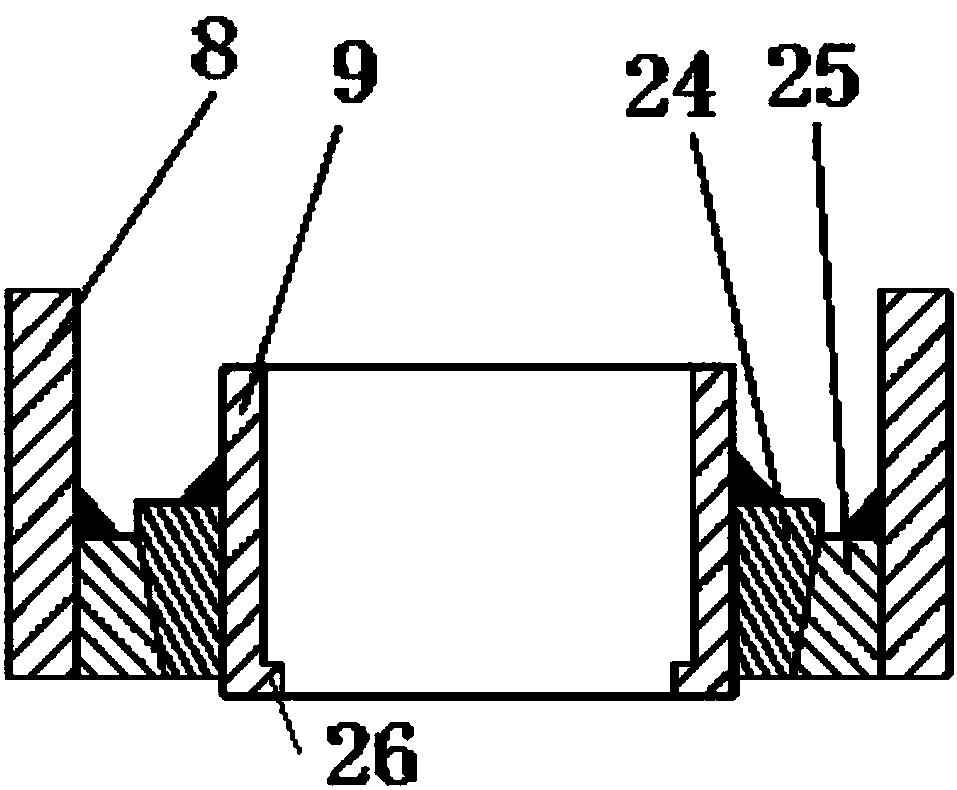

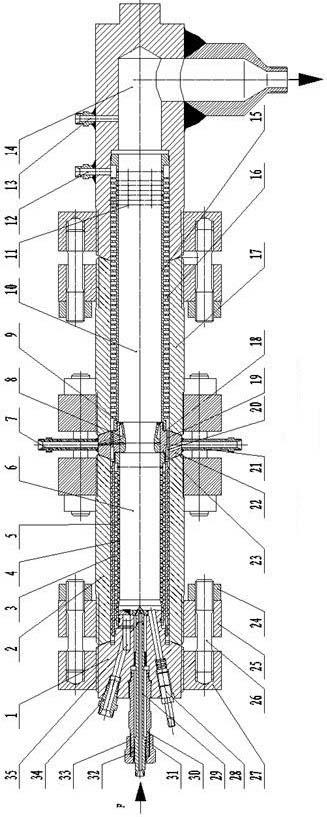

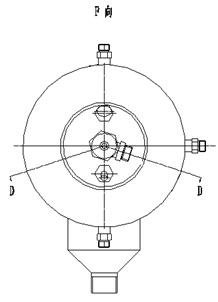

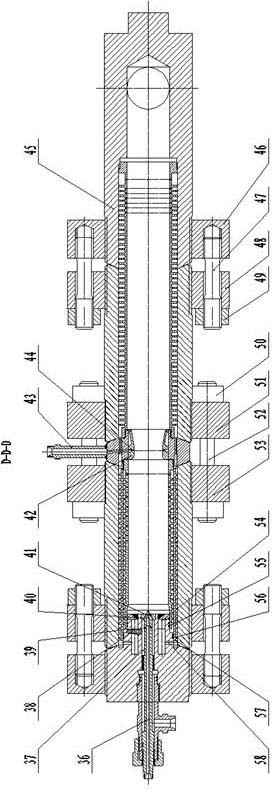

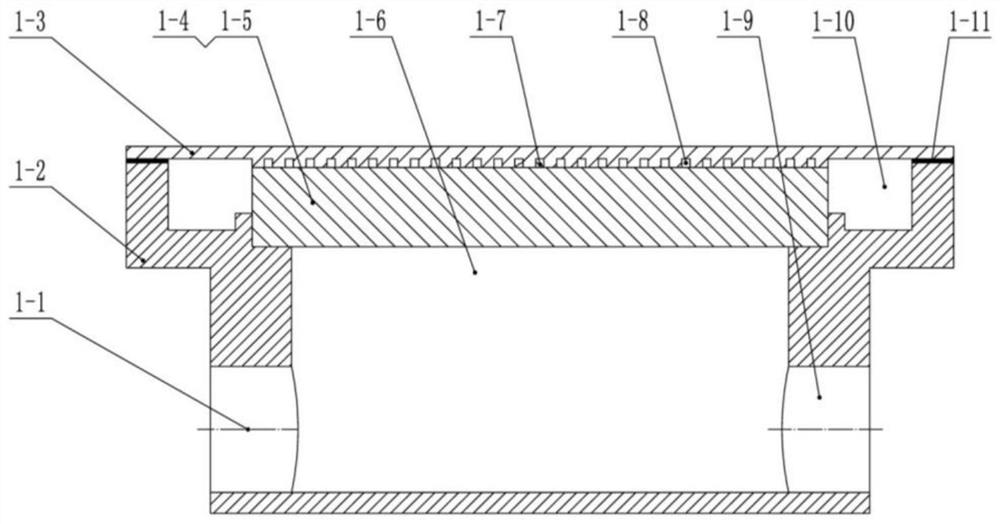

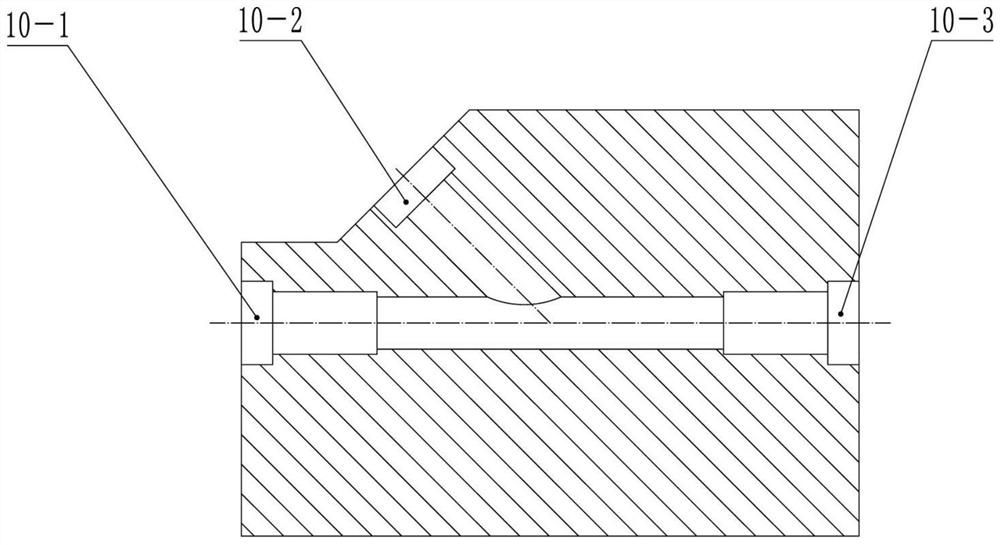

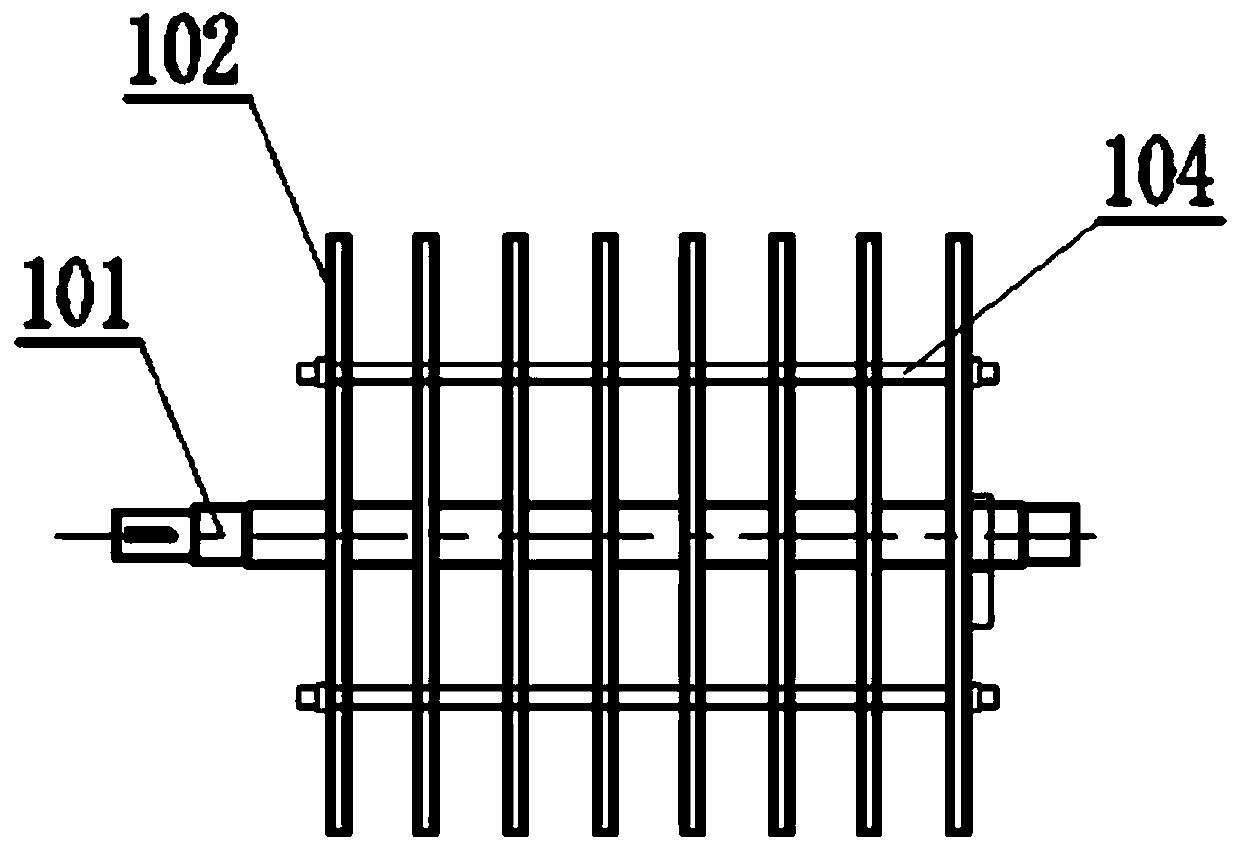

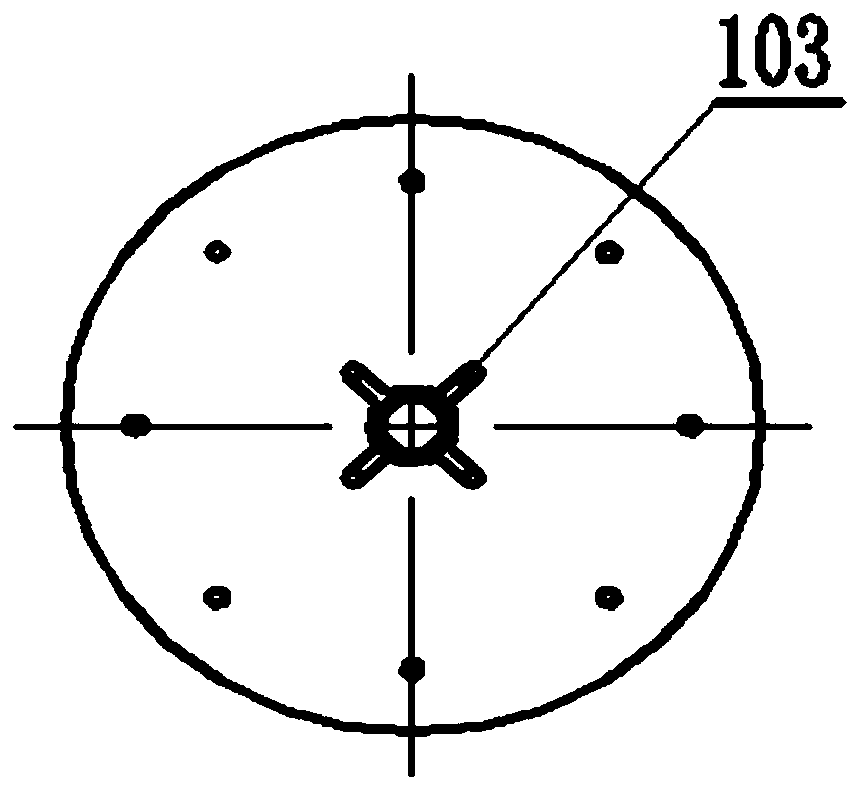

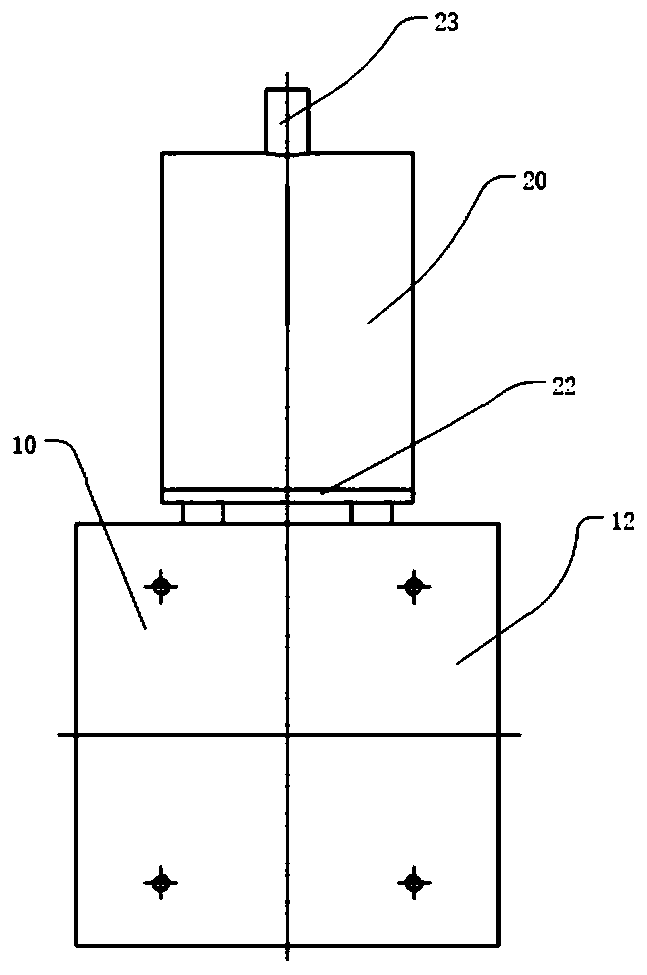

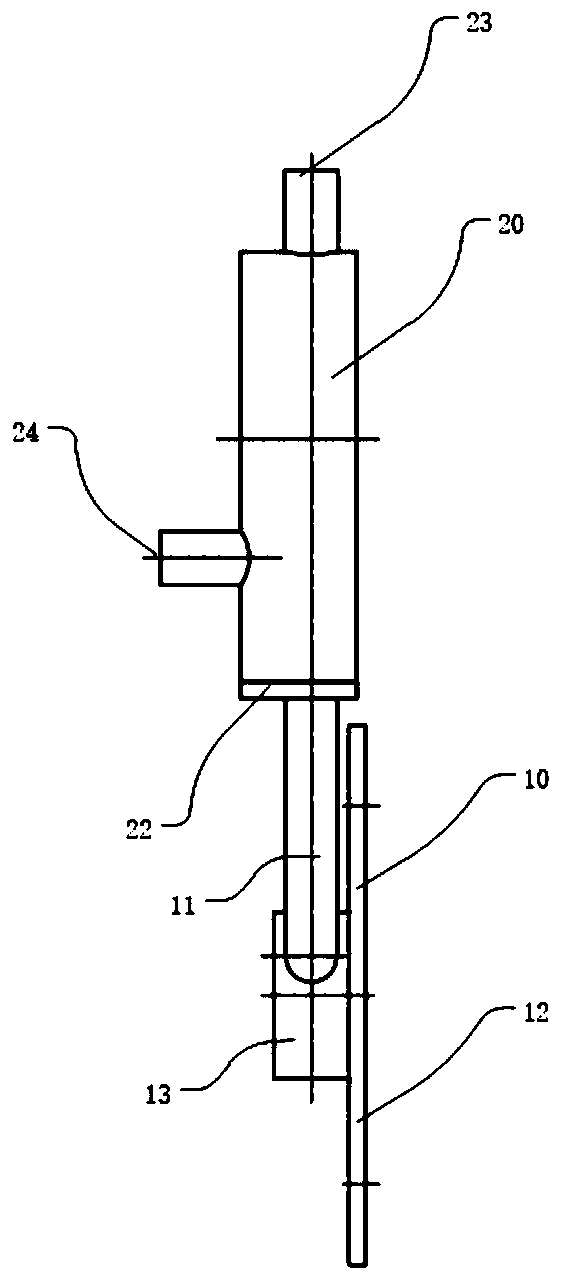

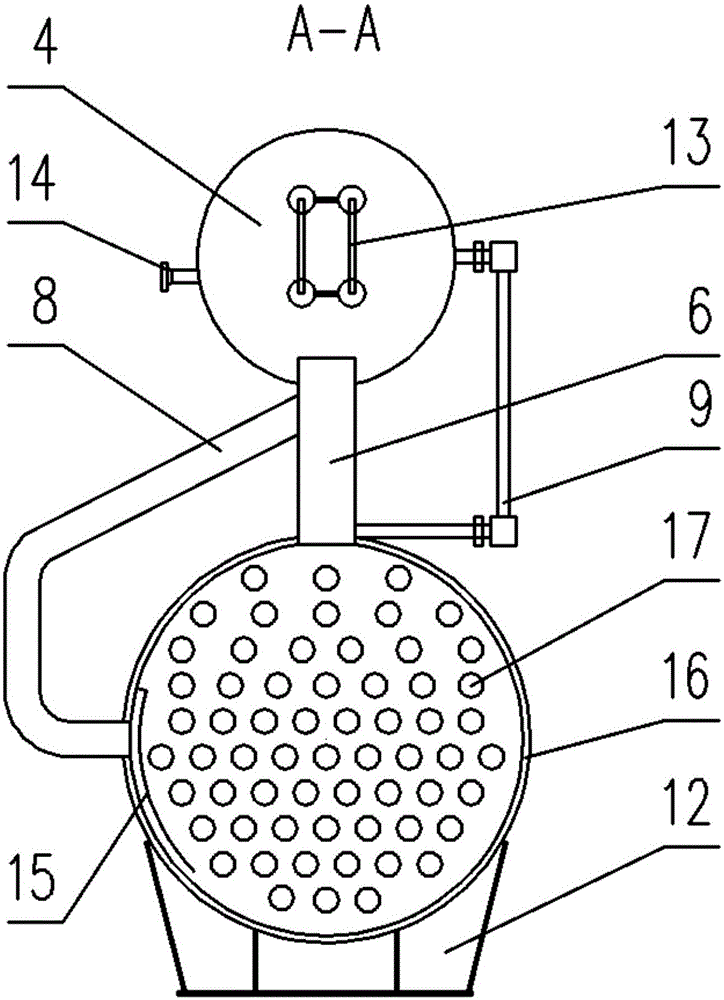

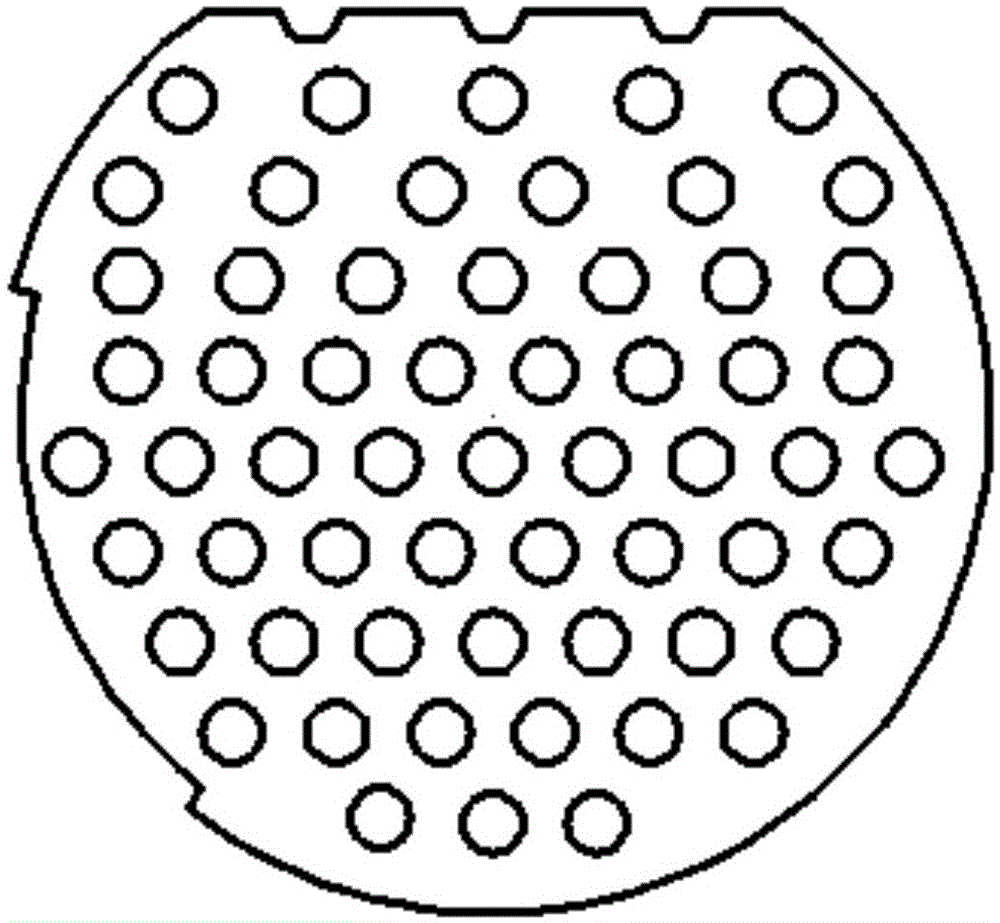

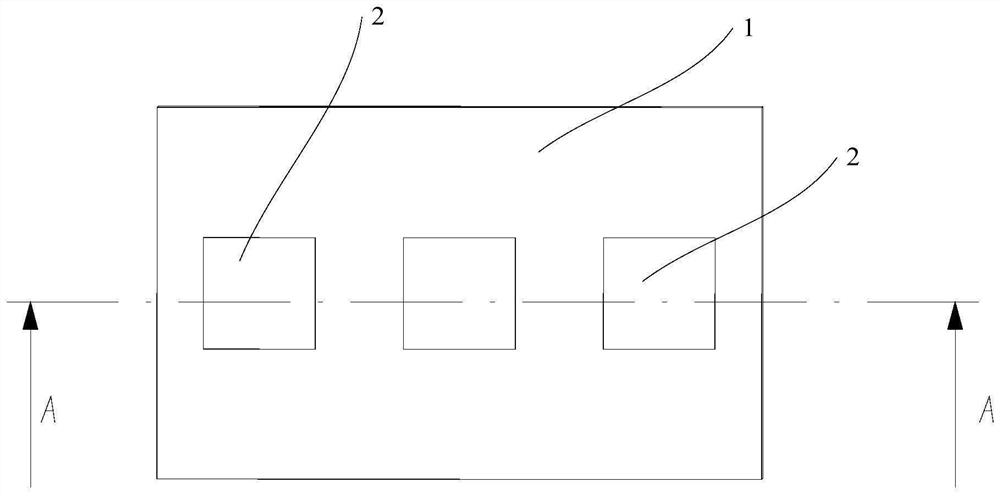

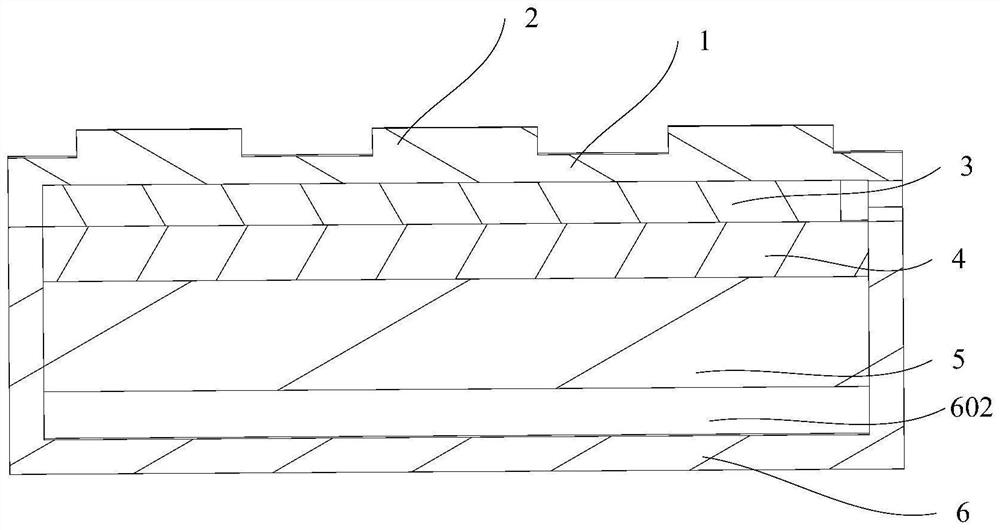

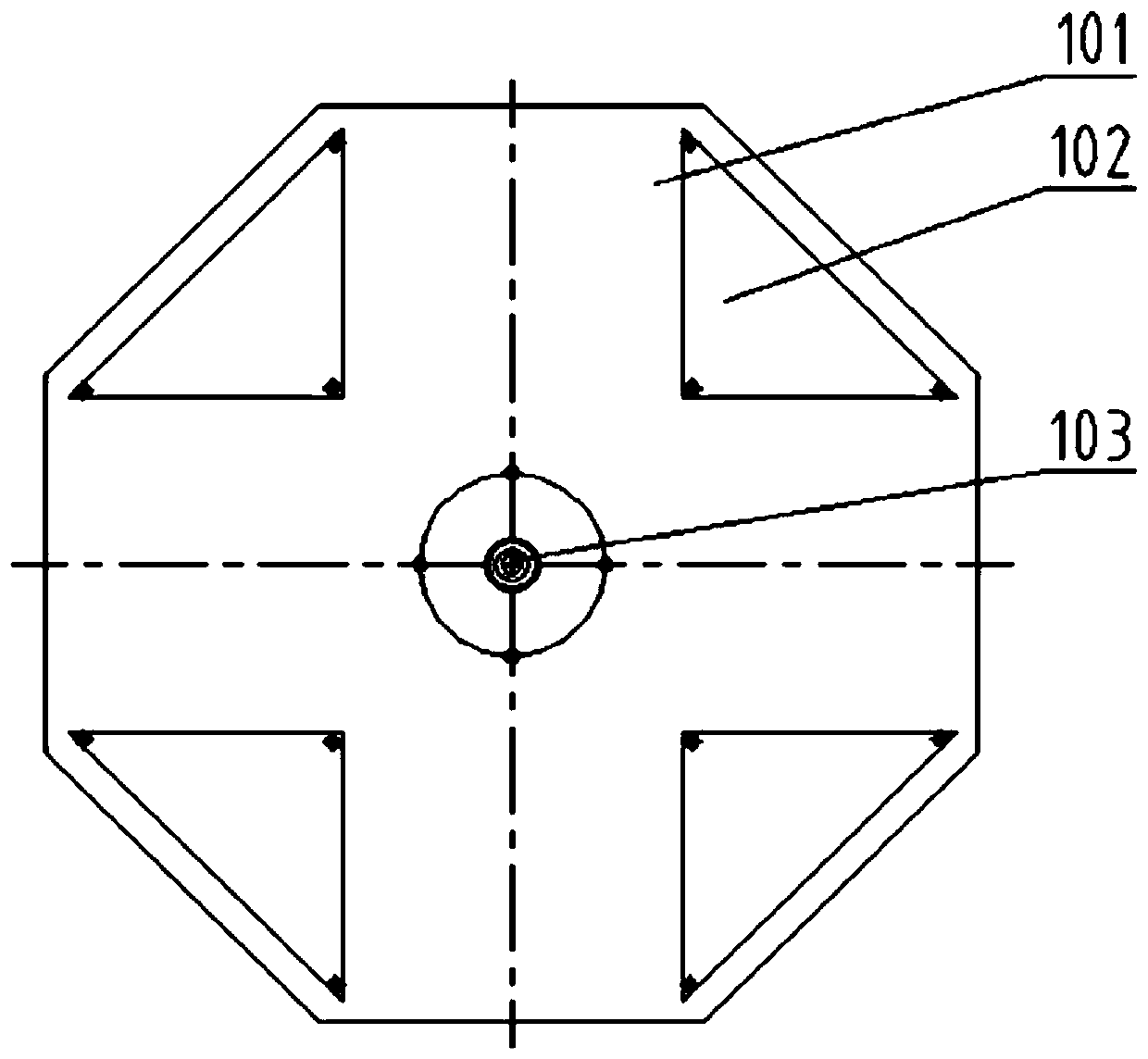

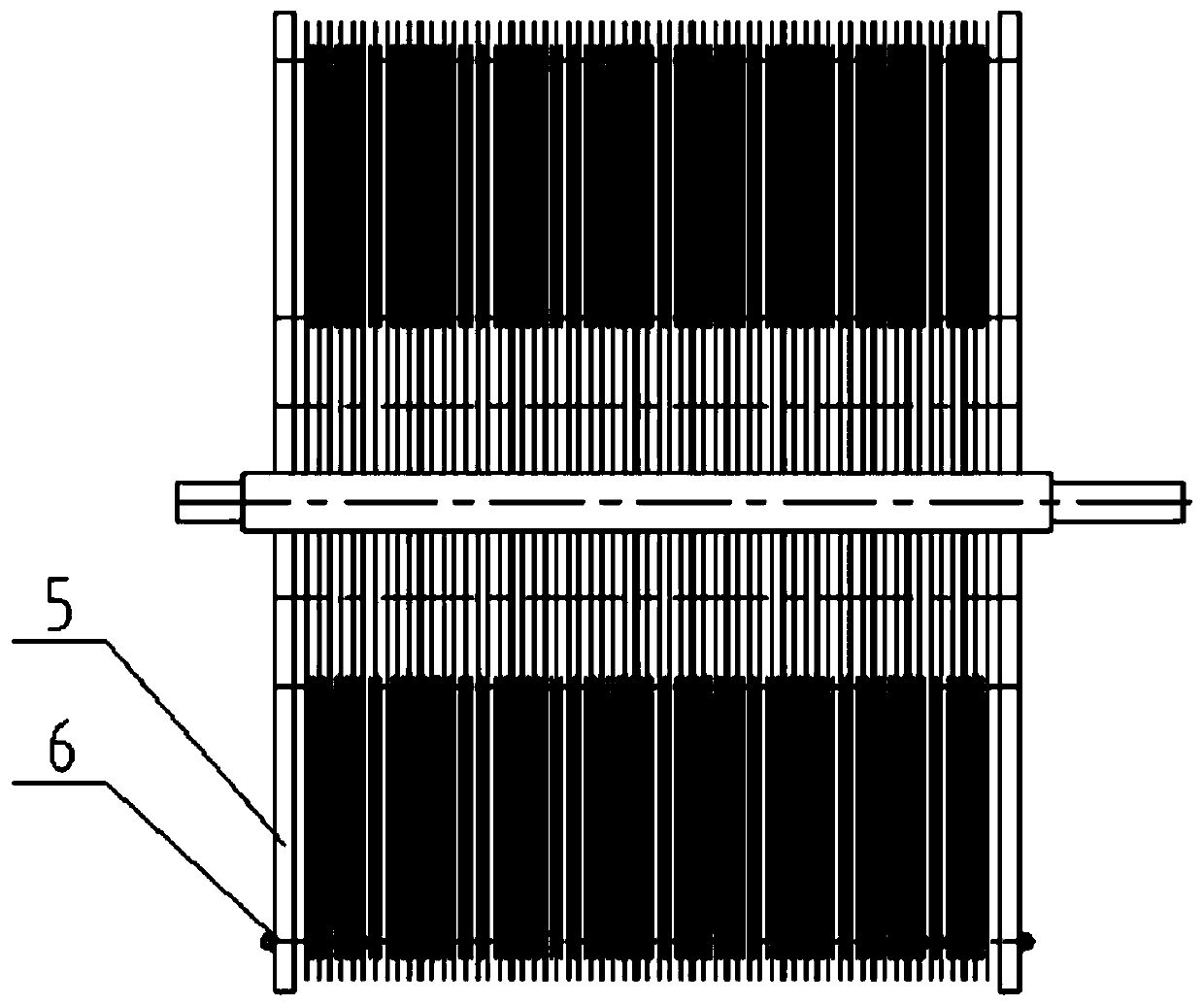

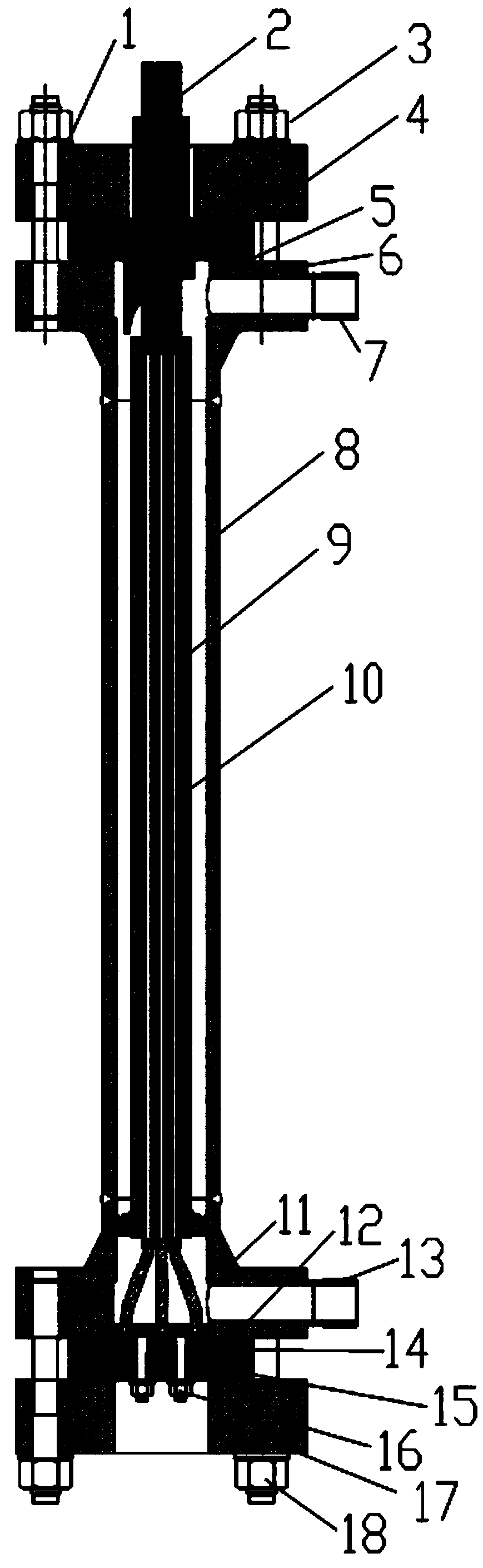

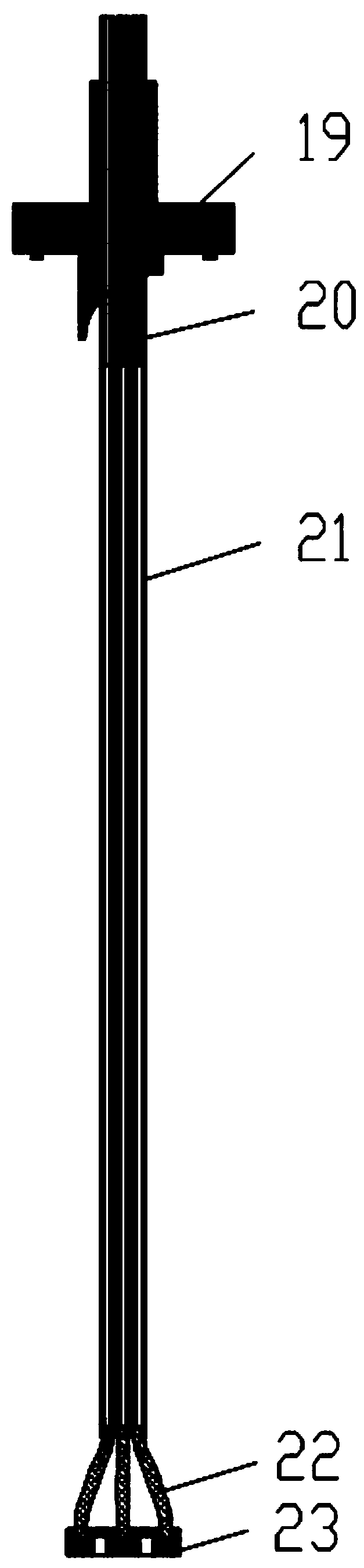

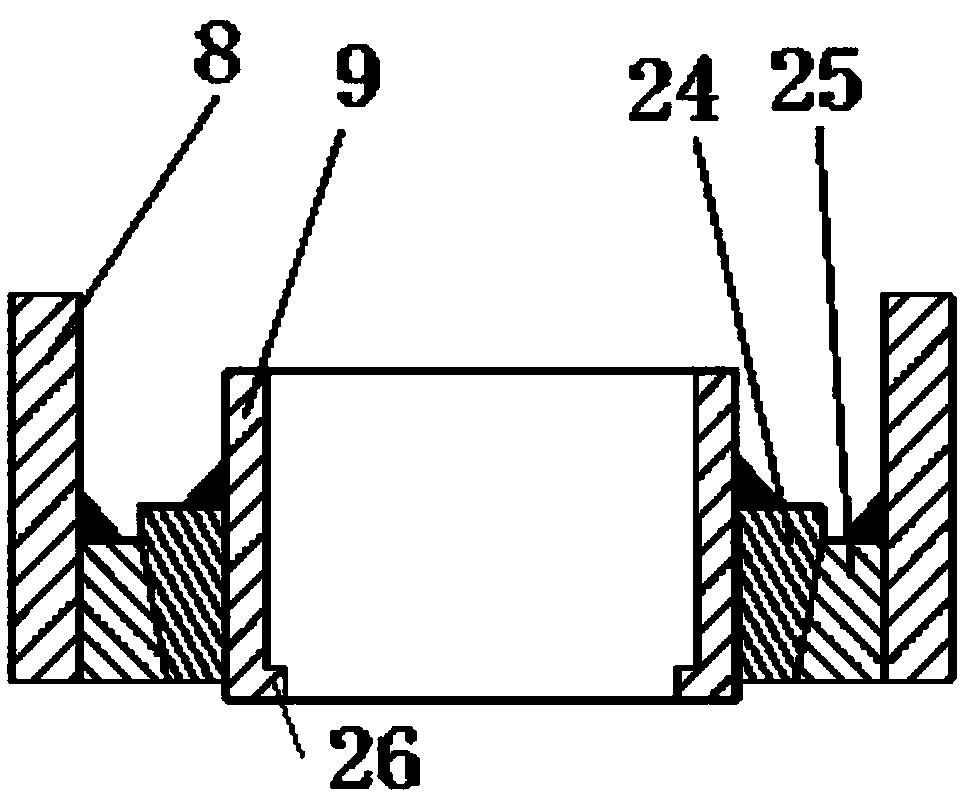

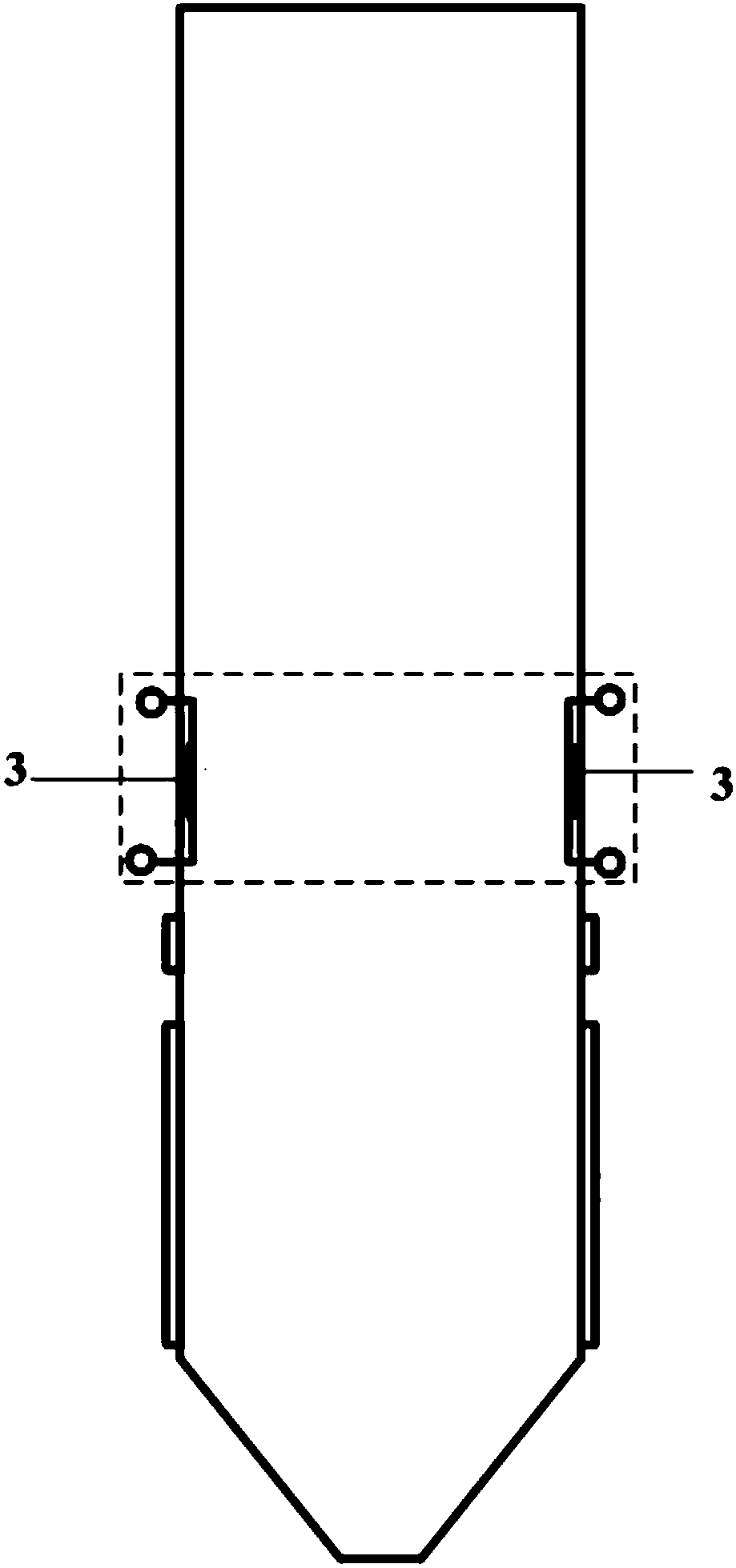

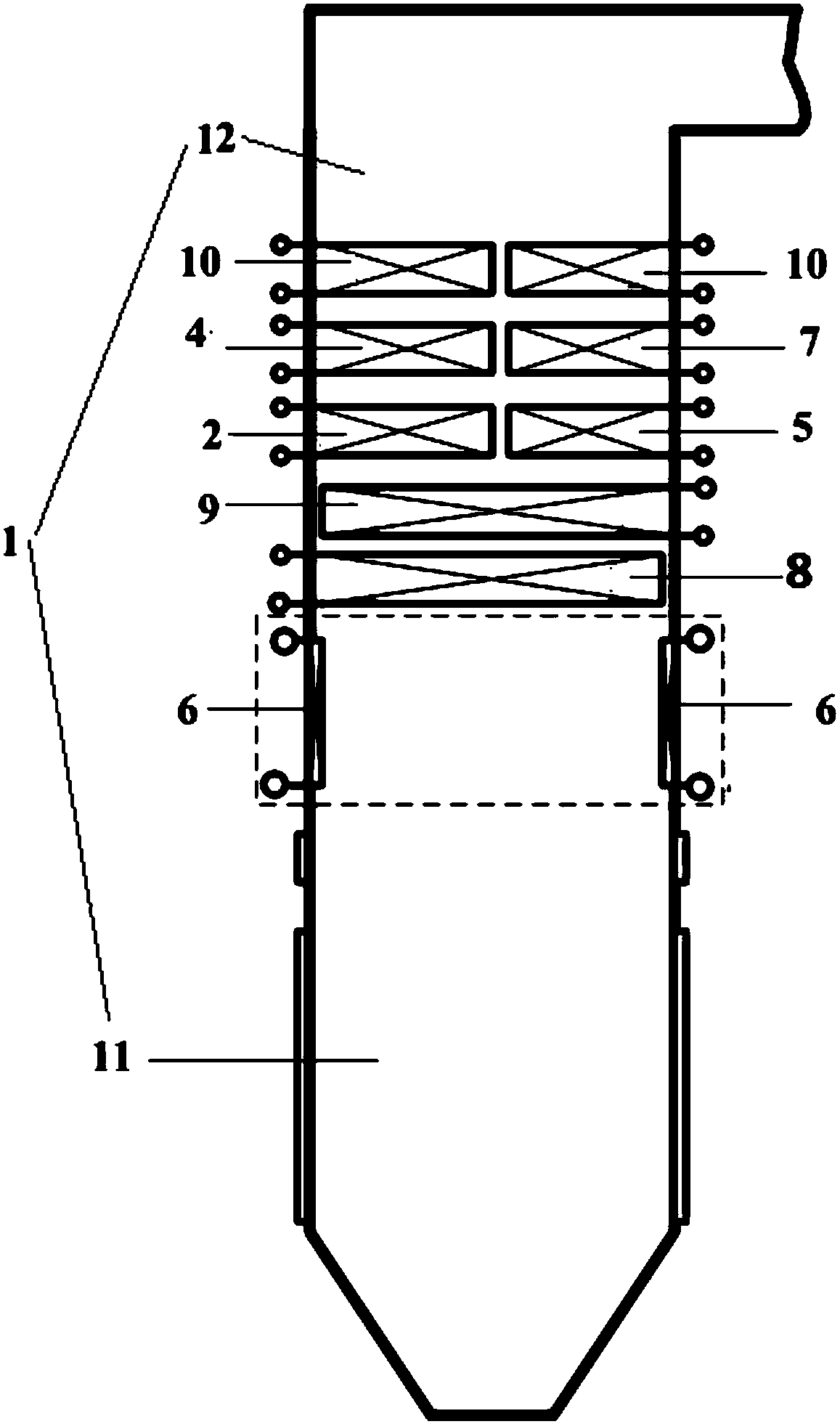

Low-voltage high-power pressurized water reactor fuel assembly simulation device

ActiveCN107799192AEasy to replaceReduce losses and costsNuclear energy generationNuclear monitoringThermal hydraulicsPressurized water reactor

The invention discloses a low-voltage high-power pressurized water reactor fuel assembly simulation device, which comprises a pressure-bearing assembly, an electric heating assembly and a square flowchannel, wherein the square flow channel is arranged in the pressure-bearing assembly and is hermetically connected with the pressure-bearing assembly; and the electric heating assembly simultaneouslypasses through the square flow channel and the pressure-bearing assembly and is sealed with and fixed to the pressure-bearing assembly. The device meets requirements of a high-temperature and high-pressure experiment, keeps thermal hydraulic characteristic similarity with a reactor fuel assembly, can realize a simulation process of a low-voltage high-power pressurized water reactor fuel assembly,has low energy consumption, simplifies the structure, and is used for the critical heat flux and flow instability experiments of the pressurized water reactor fuel assembly so as to verify the thermal safety performance of a reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

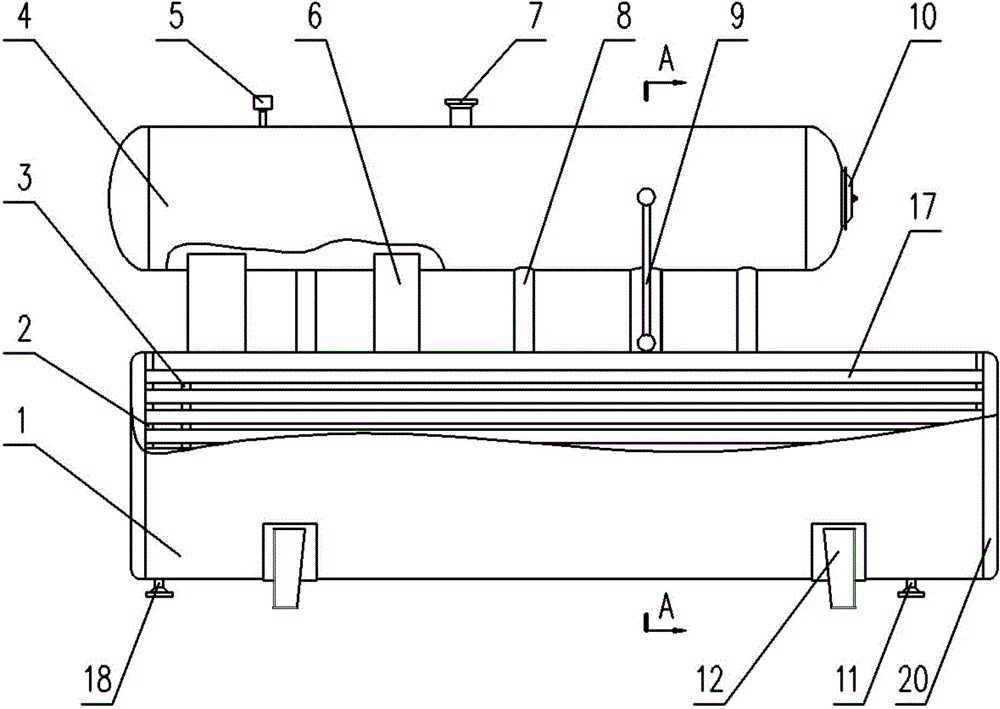

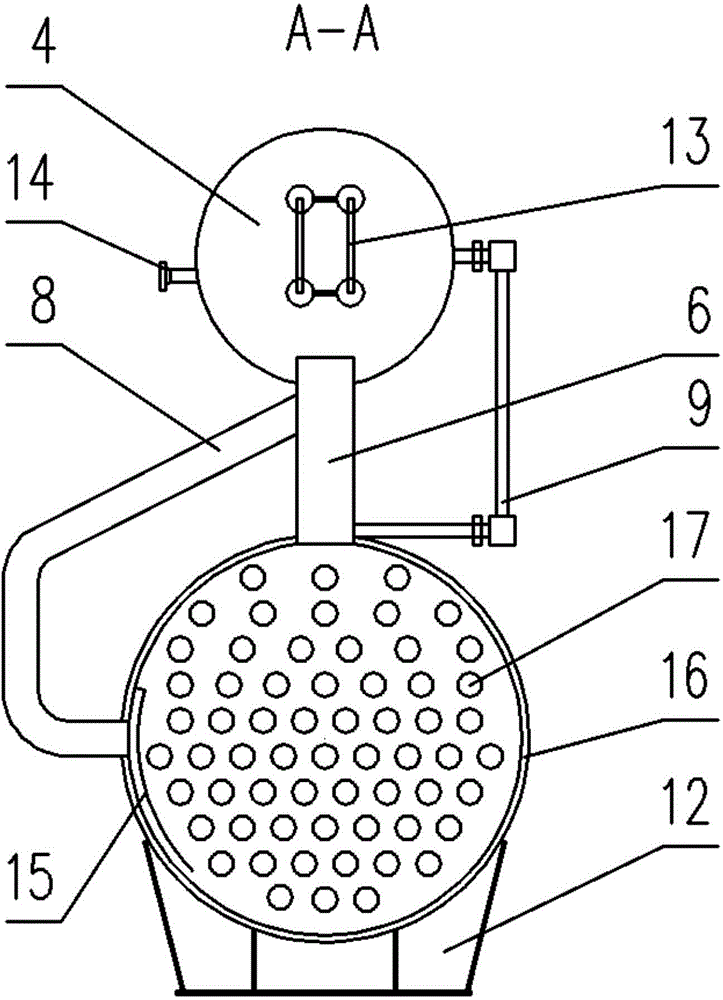

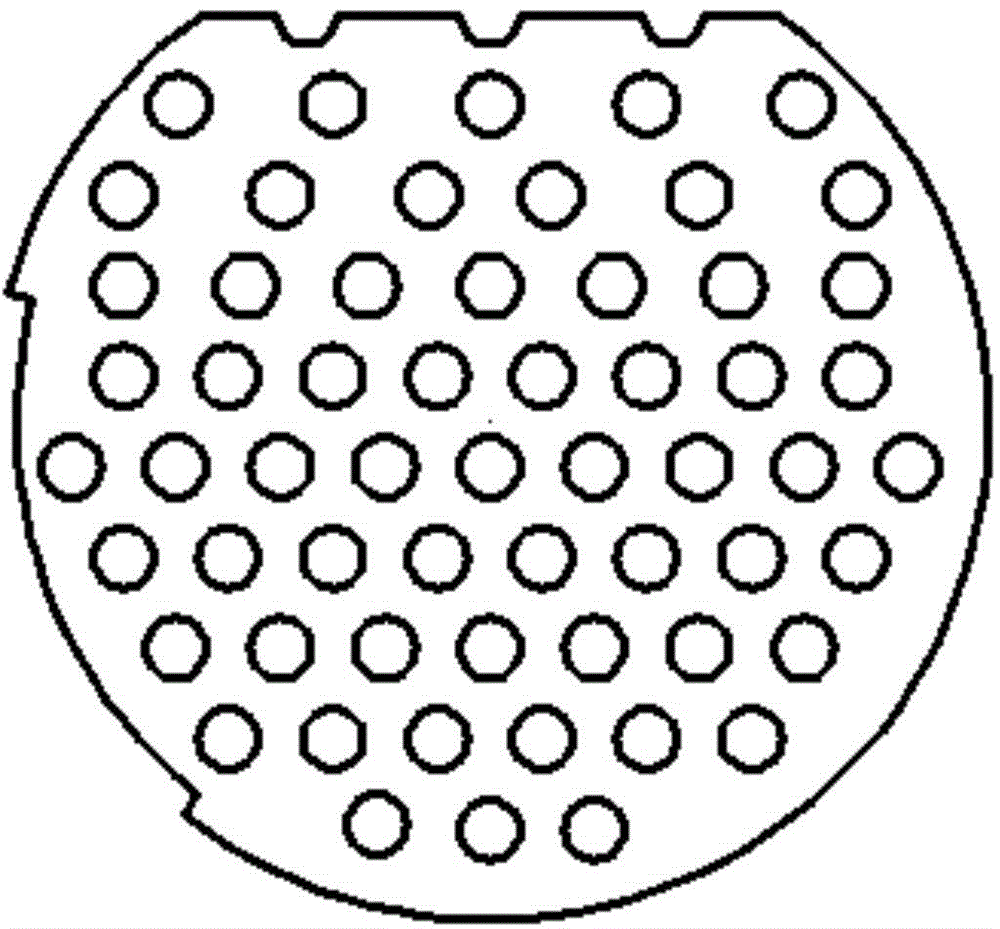

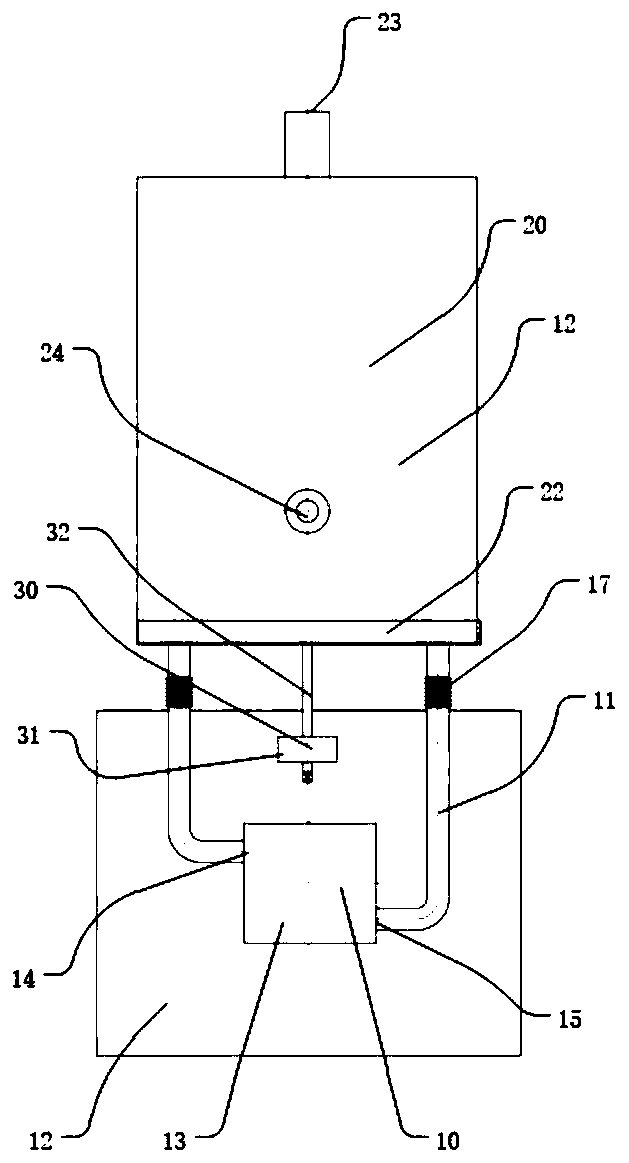

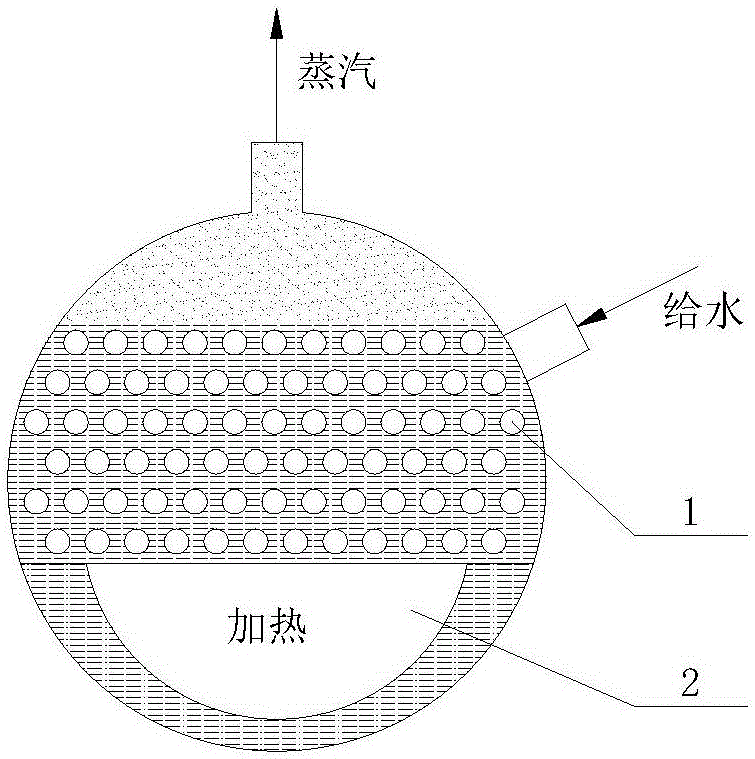

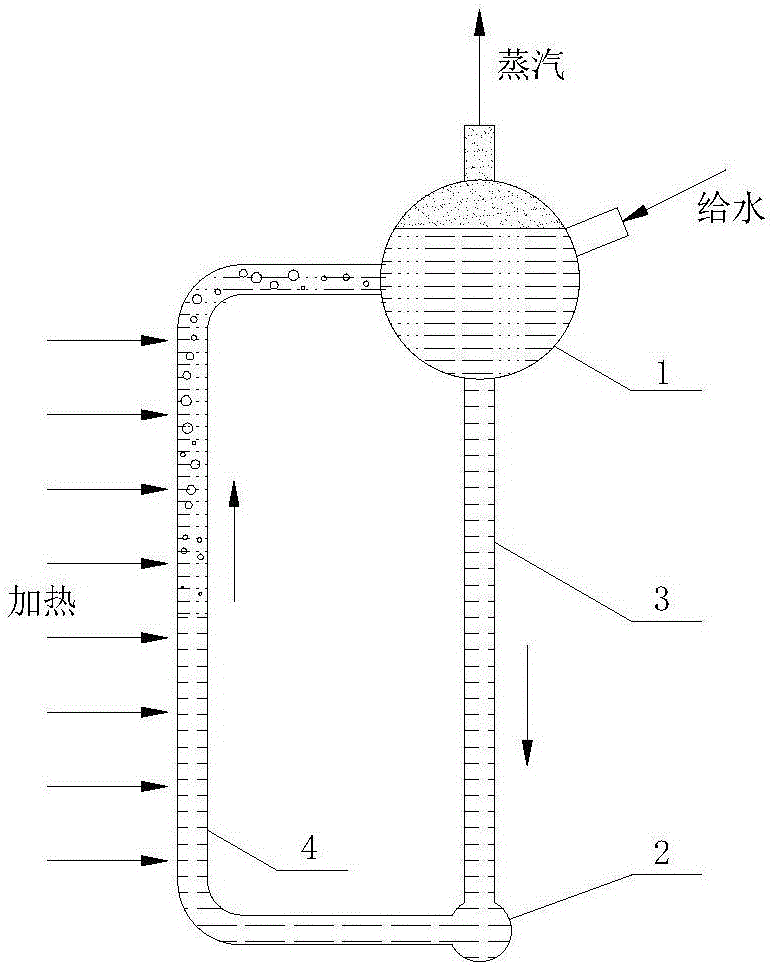

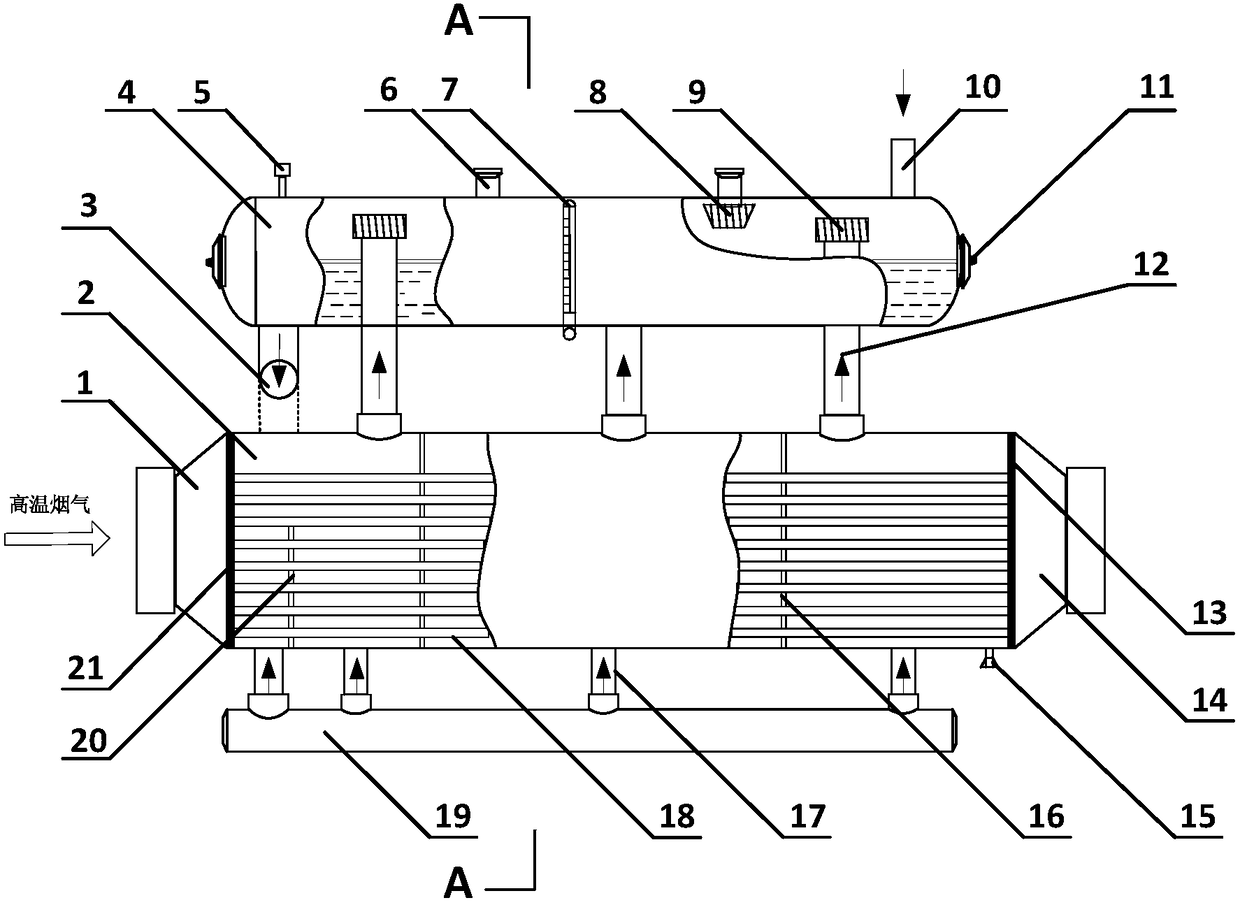

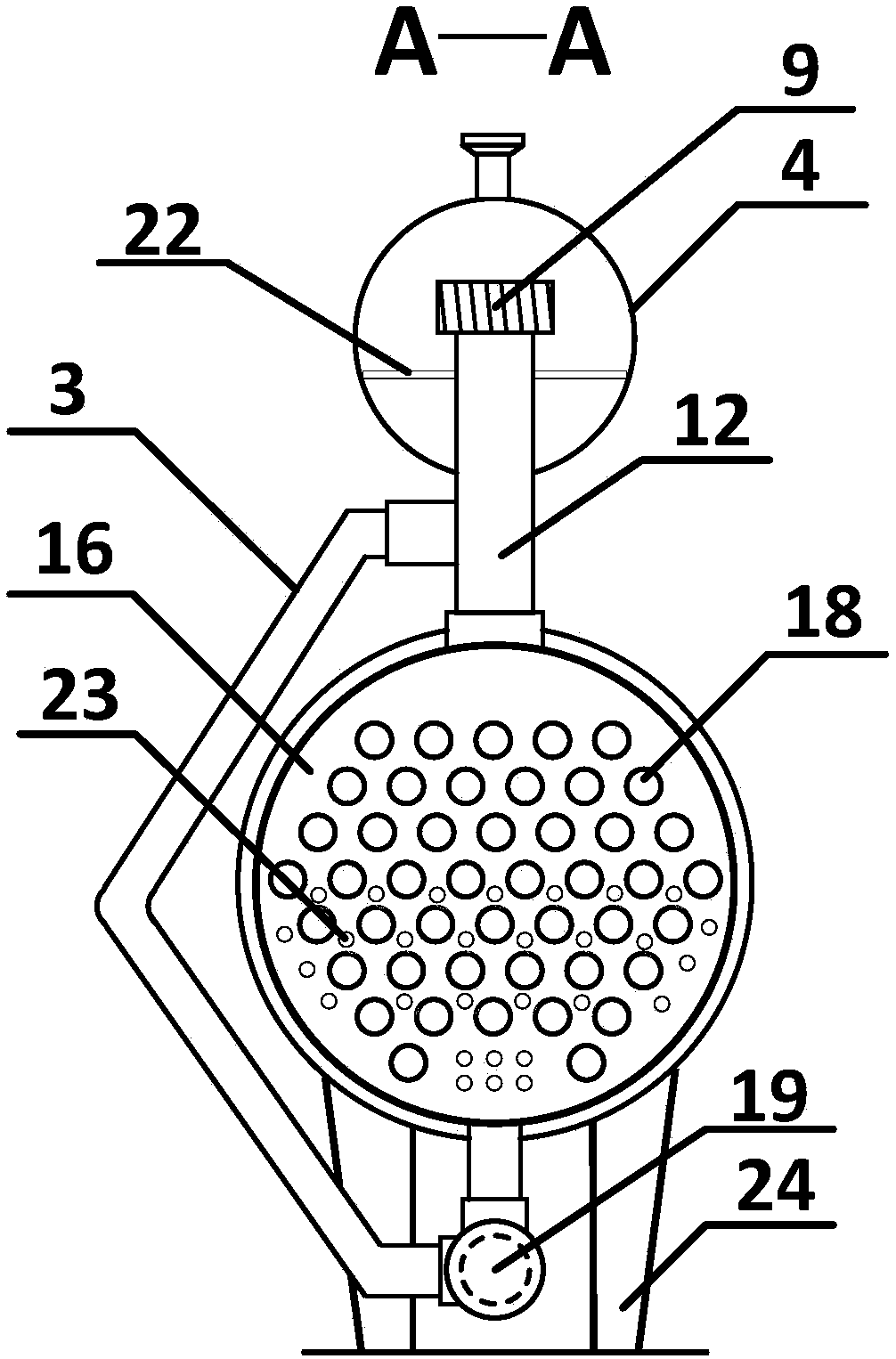

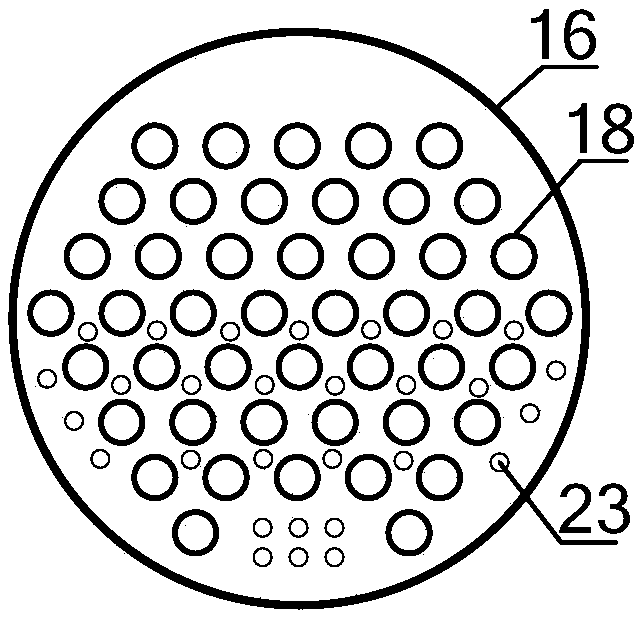

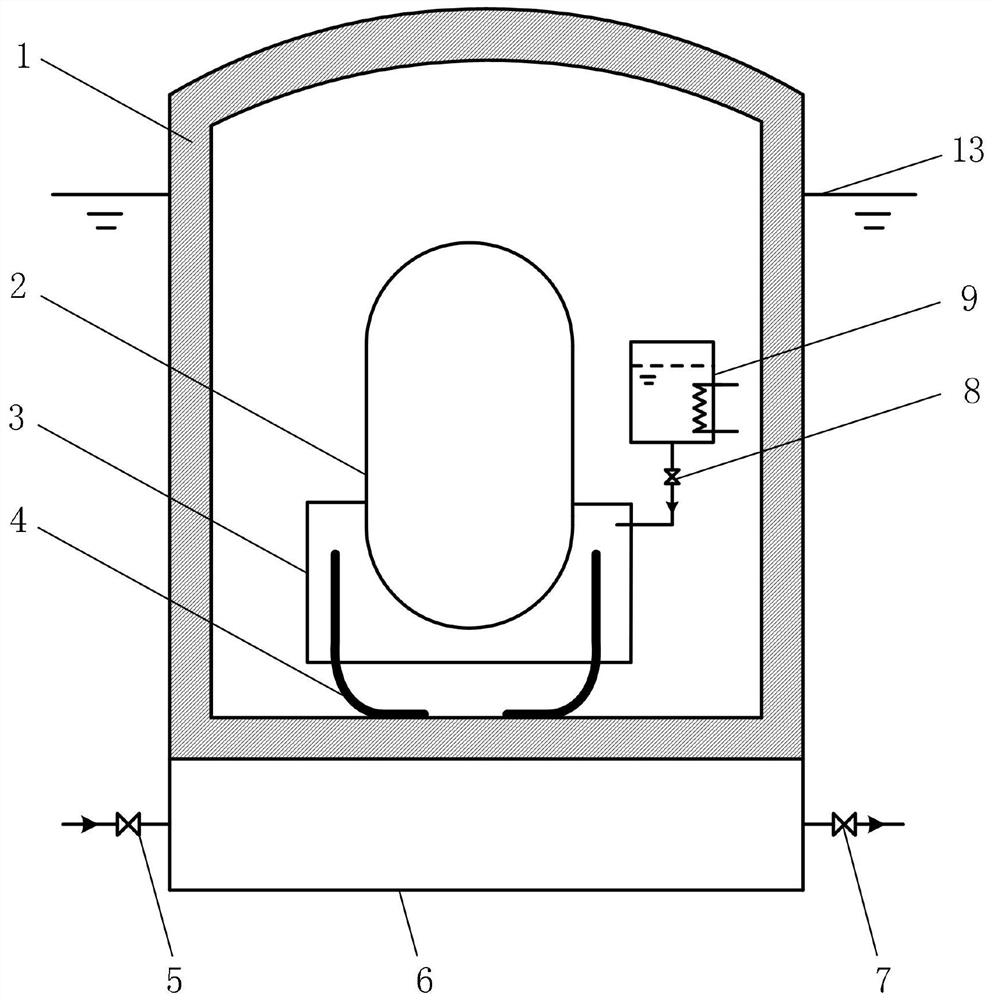

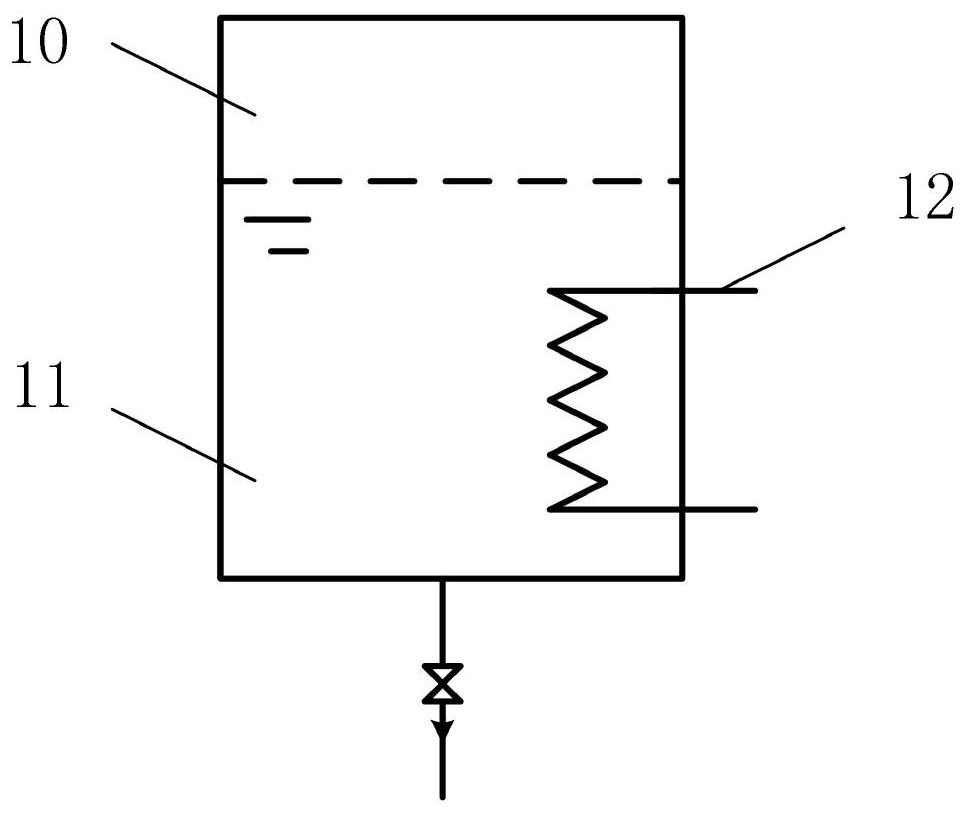

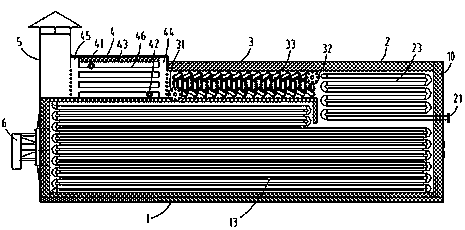

Partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler

ActiveCN103982886AImprove uniformityLow flow resistanceChemical industryStationary tubular conduit assembliesFlue gasEvaporation

The invention discloses a partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler. The partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler comprises a boiler cylinder and a pipe casing type evaporation heat exchanger which are vertically arranged; the boiler cylinder and the pipe casing type evaporation heat exchanger are arranged in a horizontal type; the boiler cylinder and the pipe casing type evaporation heat exchanger are connected through an ascending pipe assembly and a declining pipe assembly; the boiler cylinder is connected with a water inlet connecting opening formed in the pipe casing type evaporation heat exchanger through a high temperature high pressure water pipe; a high temperature high pressure water pump is arranged on the high temperature water pipe. The partial jet flow small circulating ratio pipe casing type high temperature waste heat steam boiler has the advantages of being small in circulating ratio, efficient and energy saving, long in service life, small in occupied space, benefited to site installation and original facility reconstruction and reasonably utilizing high temperature flue gas waste heat in the chemical engineering field.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD +1

Supplementary combustion type supercritical pressure gas-liquid two-phase fuel generator combustion chamber

ActiveCN102287801AExtend your lifeFixing Air LeaksFluid removalSteam boilersInspiratorCombustion chamber

The invention provides a supplementary combustion chamber of a supercritical pressure gas-liquid fuel generator, and relates to oil extraction equipment in an oil field. The supplementary combustion chamber is characterized by comprising a pre-combustion chamber (6), a secondary combustion chamber (10) and a vaporizing chamber (14). A spouting mode of fuel of the supplementary combustion chamber is as follows: the pre-combustion chamber (6) only sprays part of the fuel and full air for oxygen-enriched combustion; the remaining fuel is sprayed into the secondary combustion chamber (10) from a supplementary combustion inspirator and completely combusted with oxygen-enriched gas from the pre-combustion chamber in the secondary combustion chamber (10). By the combustion chamber, simultaneous combustion of gas fuel and liquid fuel is realized, and heat transfer deterioration is prevented due to various cooling modes.

Owner:刘殿玺 +2

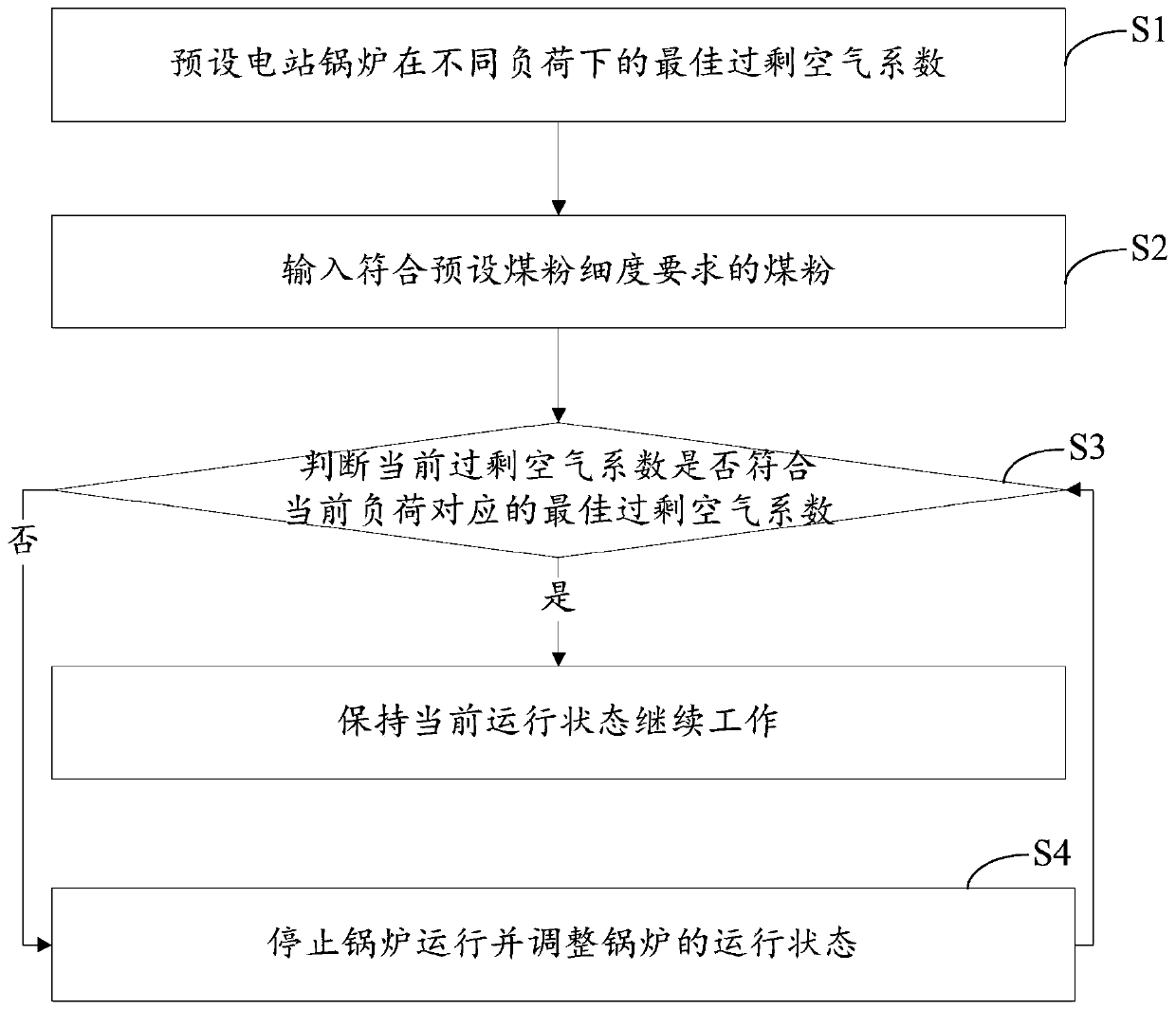

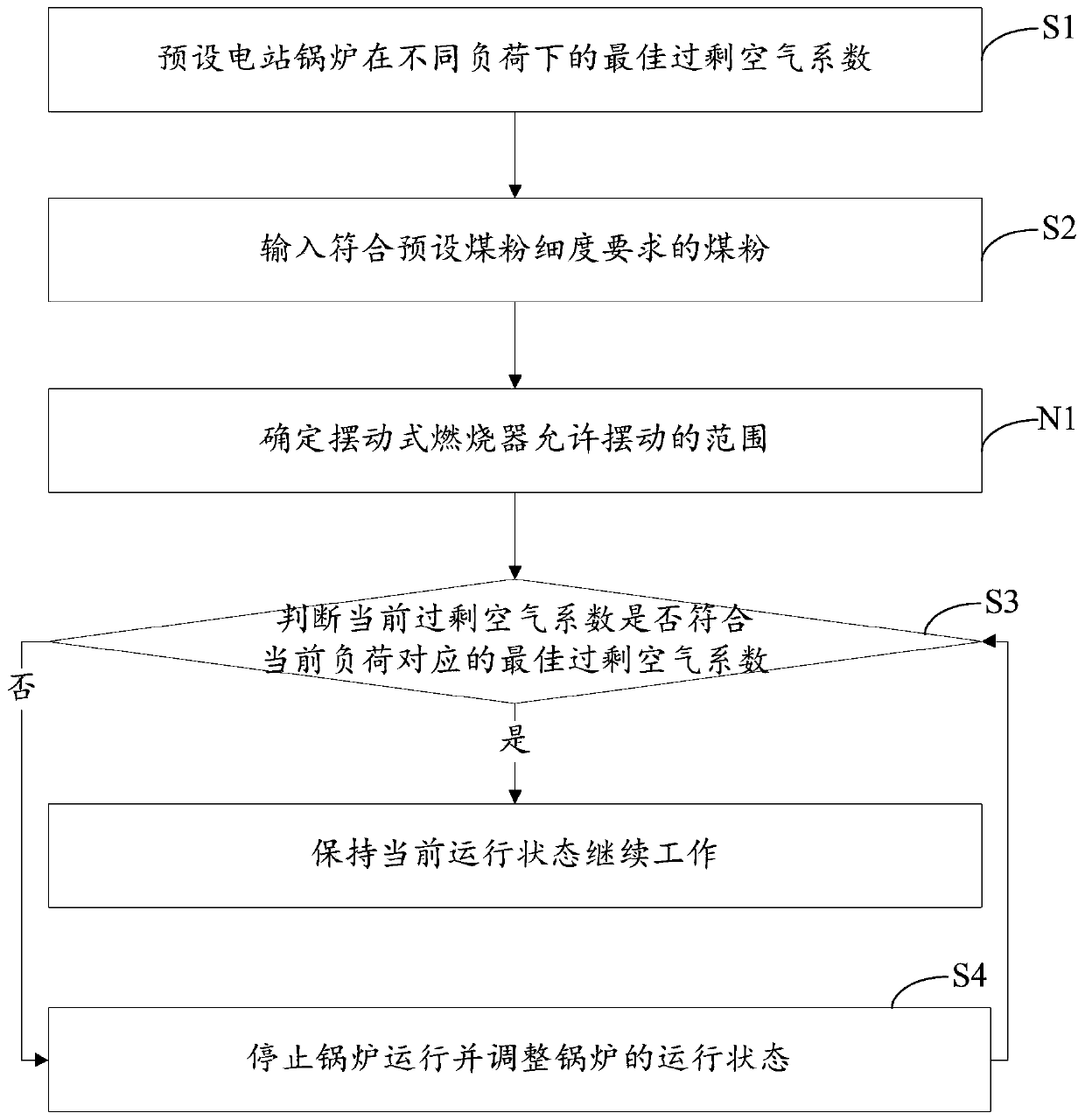

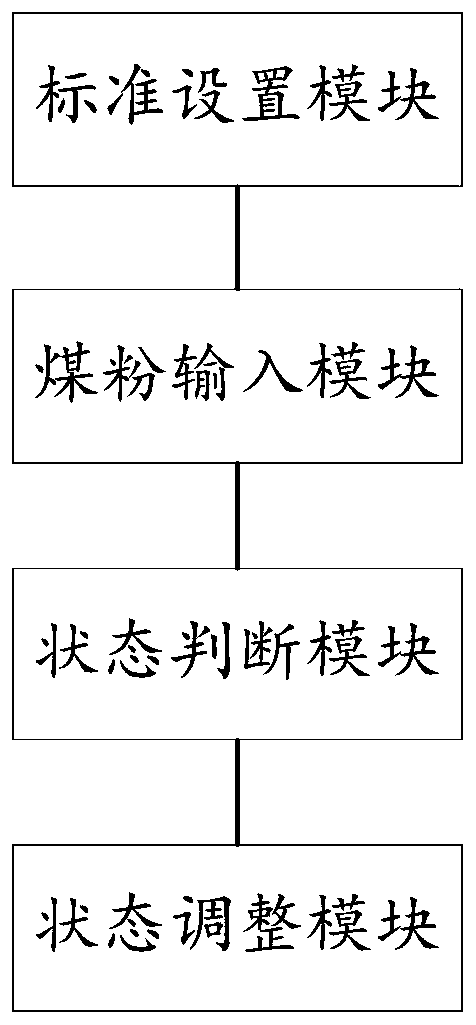

Method and device capable of preventing power station boiler slagging

ActiveCN109855113AAvoid cokingIncrease coal consumptionCombustion regulationLump/pulverulent fuel preparationCurrent loadLoop control

The invention discloses a method and device capable of preventing power station boiler slagging. The method capable of preventing power station boiler slagging comprises the steps of S1, presetting optimal excess air coefficients of a power station boiler under different loads; S2, inputting pulverized coal l meeting the preset pulverized coal fineness need; S3, judging whether the current excessair coefficient meets the optimal excess air coefficient corresponding to the current load in the power station boiler running process, if yes, continuing work with the current running state, and if not, the S4 is executed; S4, stopping boiler running, and adjusting the running state of the boiler, starting the power station boiler and executing the S3. Generation of boiler coking can be prevented, heat transfer resistance of the boiler heating face is reduced, coal consumption is reduced, the boiler heat economy is improved, meanwhile, through online analysis of the change tendency of the outlet pulverized coal finenesses of a coal grinding machine, the pulverized coal fineness is subjected to closed-loop control within the preset range, and pulverized coal fineness and uniformity stableoutput is achieved.

Owner:XINAO SHUNENG TECH CO LTD

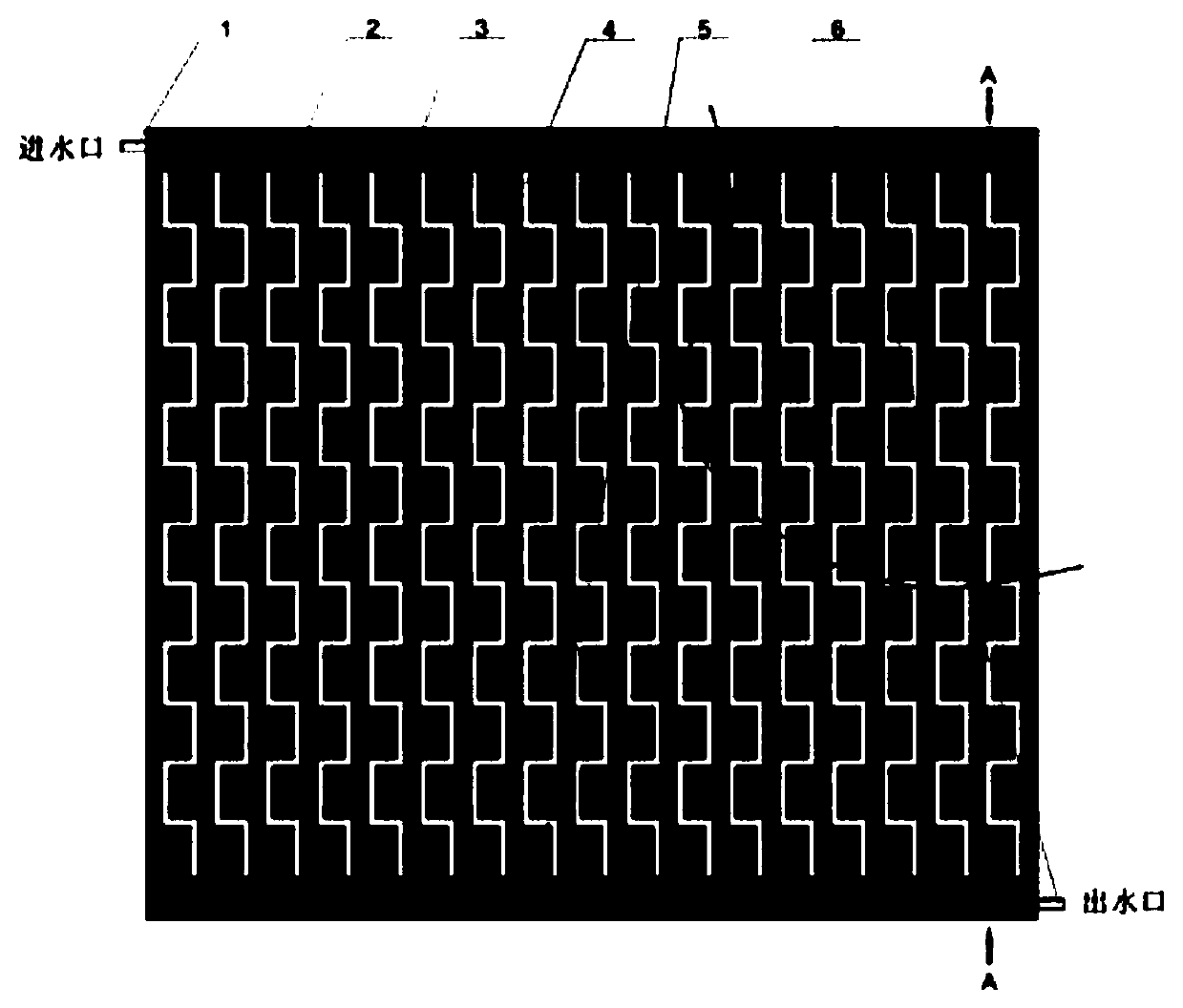

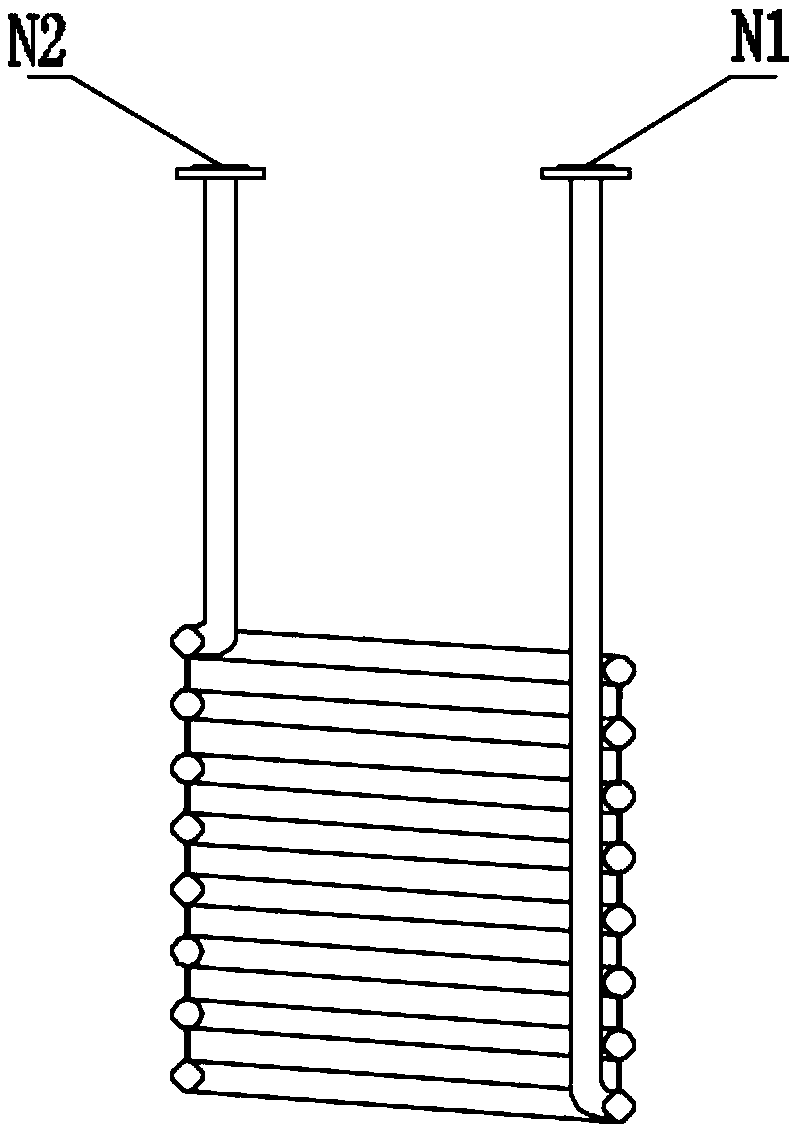

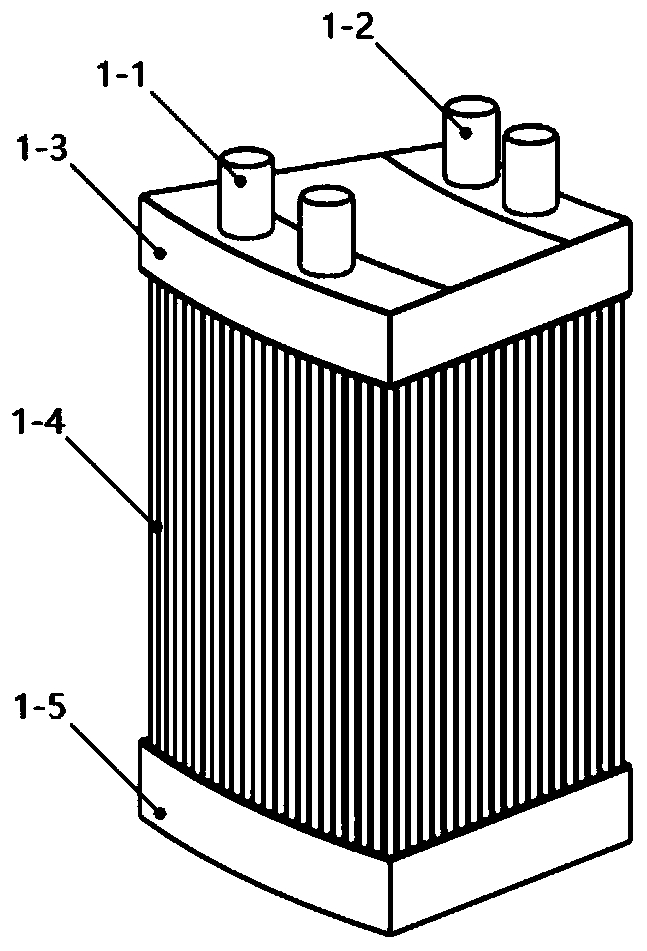

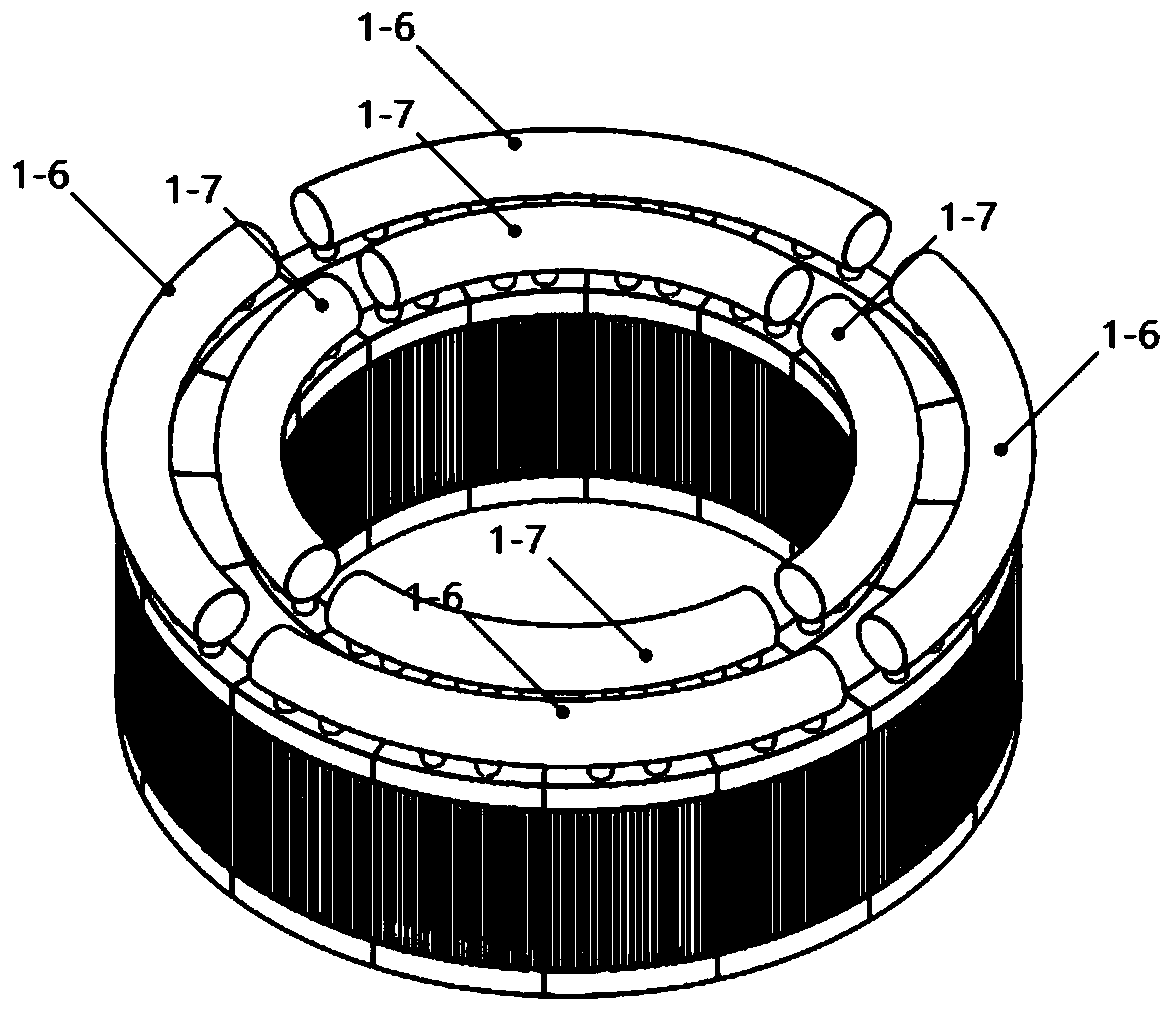

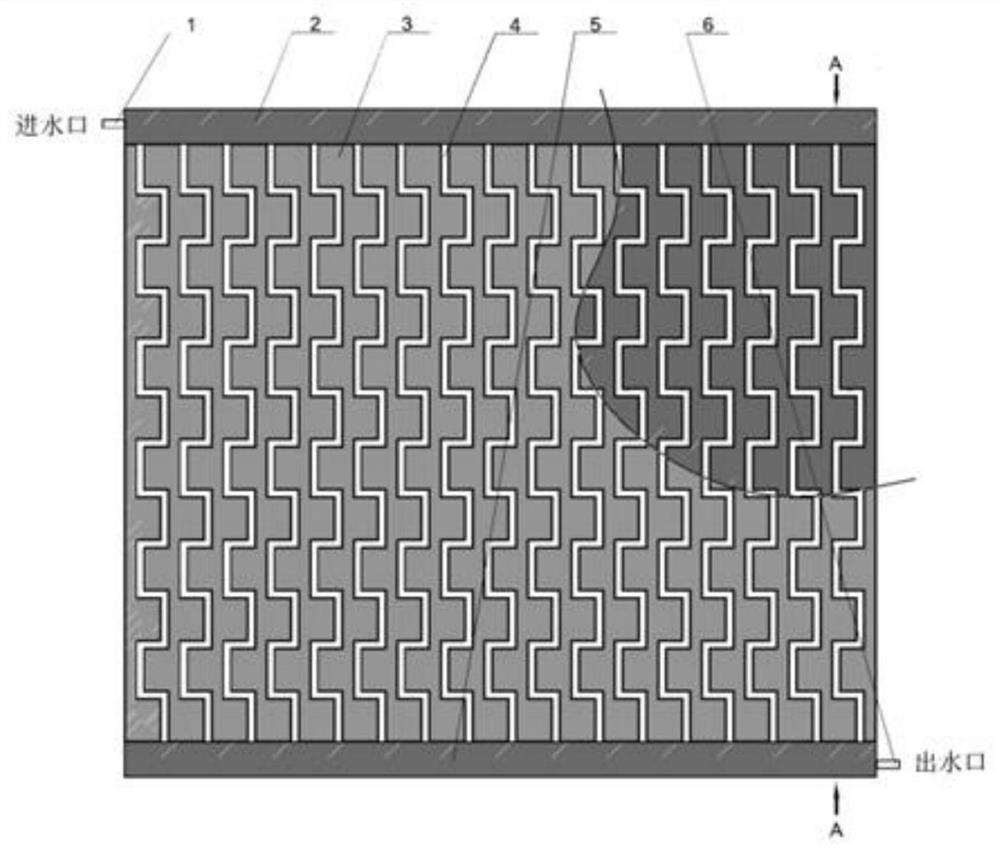

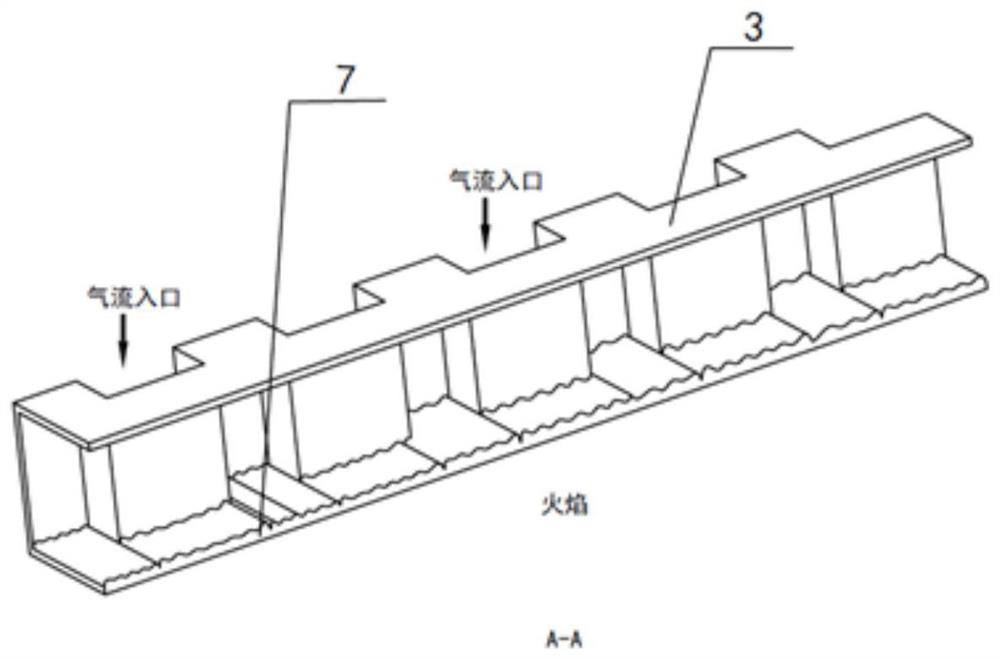

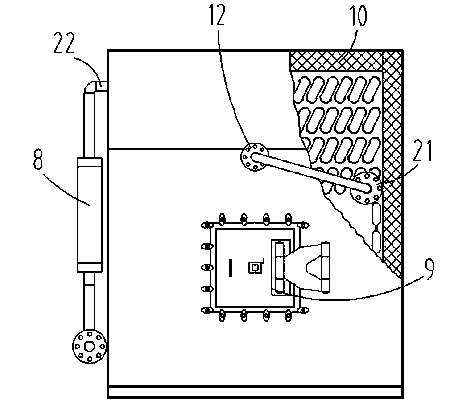

Variation microchannel cooling type surface flame low NOx gas device

ActiveCN110822426APromote gas ignition and efficient combustionEliminate local high temperature phenomenonGaseous fuel burnerEngineeringEnvironmental geology

The invention discloses a variation microchannel cooling type surface flame low NOx gas device. The variation microchannel cooling type surface flame low NOx gas device comprises an upper header, a lower header, variation structure water cooling components, a plurality of compact variation airflow microchannels constructed by the upper header, the lower header and the multiple groups of parallel variation structure water cooling components, a water inlet and a water outlet, wherein the water inlet and the water outlet are connected with the upper header and the lower header separately. Gas andair mixed airflow is ignited and combusted after flowing through the compact variation airflow microchannels, but because the variation structure water cooling components absorb heat, the low-temperature surface combustion of the airflow flame front at outlets of the variation airflow microchannels and the surfaces of the variation structure water cooling components is realized, the airflow combustion temperature is obviously reduced, and the low-temperature low-NOx combustion is further realized; meanwhile, the variation structures of the airflow microchannels remarkably promote disturbanceof flame air flow, and are combined with the compact variation structure water cooling components and the variation airflow microchannels, so that backfire and deflagration are effectively prevented,low-temperature and low-NOx surface combustion is realized, meanwhile, the local high-temperature phenomenon is eliminated, and combustion stability, safety and high efficiency are guaranteed.

Owner:XI AN JIAOTONG UNIV

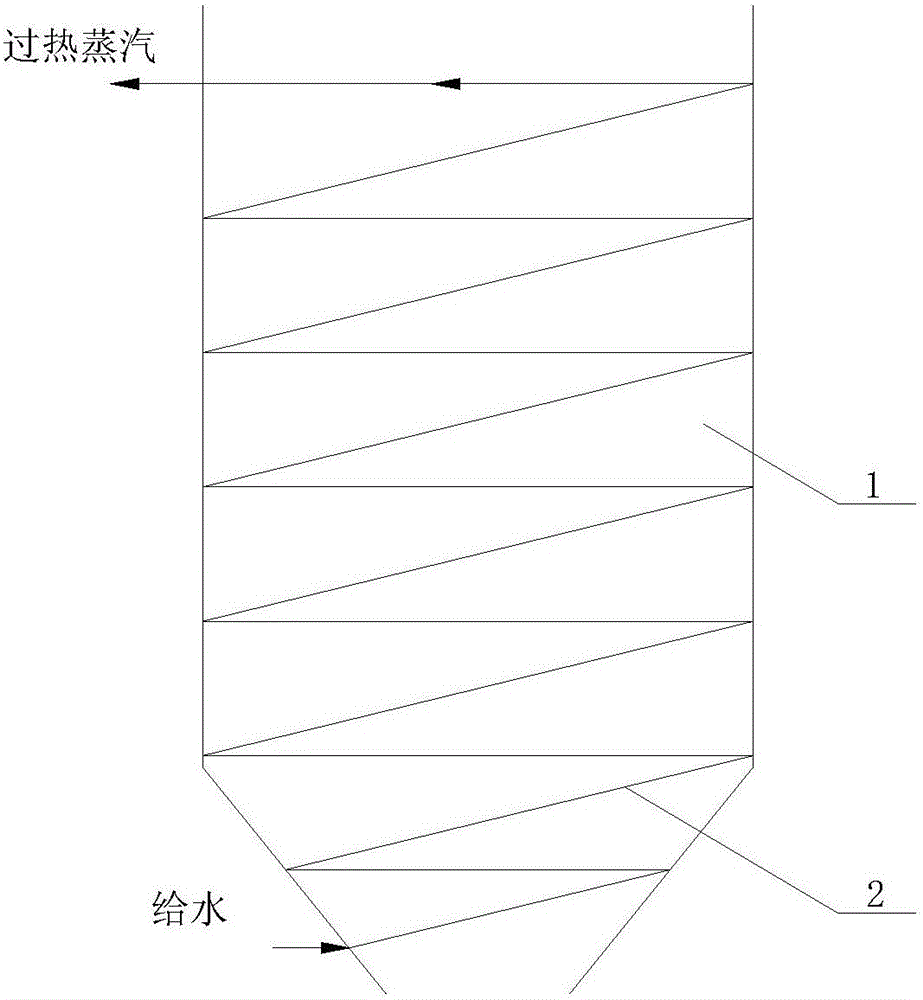

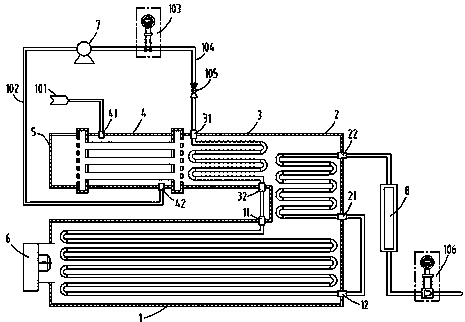

Supercritical pressure coal-fired steam-injection boiler

InactiveCN102980167AIncrease temperatureAvoid Heat Transfer DeteriorationFluid removalSteam boilersEngineeringPlunger pump

The invention relates to a steam-injection boiler for thermal recovery of heavy oil, in particular to a supercritical pressure coal-fired steam-injection boiler. A flexible fin membrane water-cooled wall is adopted by a hearth of the device; both a radiation section tube bundle and an overheating section tube bundle are threaded tubes; a water treatment device is connected with a plunger pump; the plunger pump is connected with a water supply heat exchanger outer tube; the water supply heat exchanger outer tube is connected with a header A; the header A, a first-stage convection section, a header C, a second-stage convection section and a header B are connected in sequence; the header B is connected with a water supply heat exchanger inner tube; the water supply heat exchanger inner tube is connected with a header D; and the header D, a middle arch tube and a front arch tube are connected in sequence. According to the supercritical pressure coal-fired steam-injection boiler, migration of a high-temperature steam region from a radiation section to an overheating section is realized, the phenomenon of heat transfer degradation is avoided, and further the steam exit temperature is improved, so that the steam exit pressure reaches the range of the supercritical pressure, effective exploitation of deep heavy oil and even extra and super heavy oil reservoir is realized, and the steam-injection exploitation effect is improved.

Owner:CNPC BOHAI EQUIP MFG

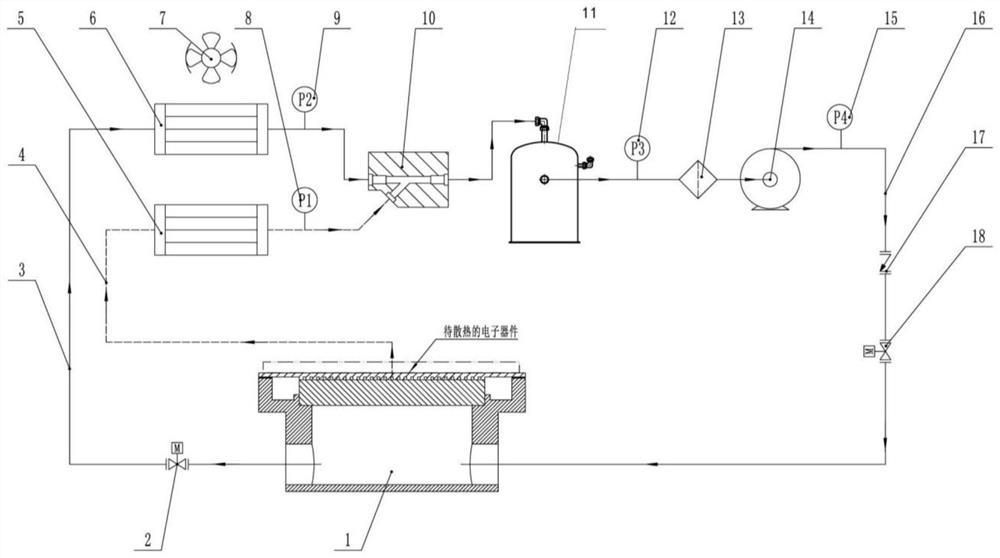

Heat dissipation system based on pump-driven capillary phase change loop

PendingCN112000206AGreat driving forceIncrease heat transfer distanceDigital data processing detailsEnergy efficient computingHeat flowEngineering

The invention discloses a heat dissipation system based on a pump drive capillary phase change loop. The heat dissipation system comprises a first liquid pipeline, a second liquid pipeline, a steam pipeline, an ejector and an evaporator. The first end of the second liquid pipeline is communicated with the first end of the first liquid pipeline through the ejector, and the second end of the secondliquid pipeline is communicated with the second end of the first liquid pipeline through the evaporator; the first end of the steam pipeline is communicated with the first end of the first liquid pipeline through an ejector; the second end of the steam pipeline is communicated with the second end of the first liquid pipeline through the evaporator; an active heat dissipation technology and a passive heat dissipation technology are combined; the heat exchange capability is improved by utilizing phase change latent heat of the working medium; the heat dissipation system meets the heat dissipation requirement of high heat flow density, has high heat transfer efficiency, improves the power of electric power and electronic devices, improves the working efficiency of the electric power and the electronic devices. The defects that a loop heat pipe and a capillary pump loop are small in transmission distance, difficult to start and the like are overcome, and the heat dissipation system adaptsto heat dissipation of the electronic devices with different heat flow densities.

Owner:包文隆 +1

A flow control type impact sweating cooling head cone

ActiveCN109334974BImprove high temperature resistanceImprove insulation performanceFuselagesSupersonic aircraftFlight vehicleCircular cone

Owner:BEIJING LINJIN SPACE AIRCRAFT SYST ENG INST +1

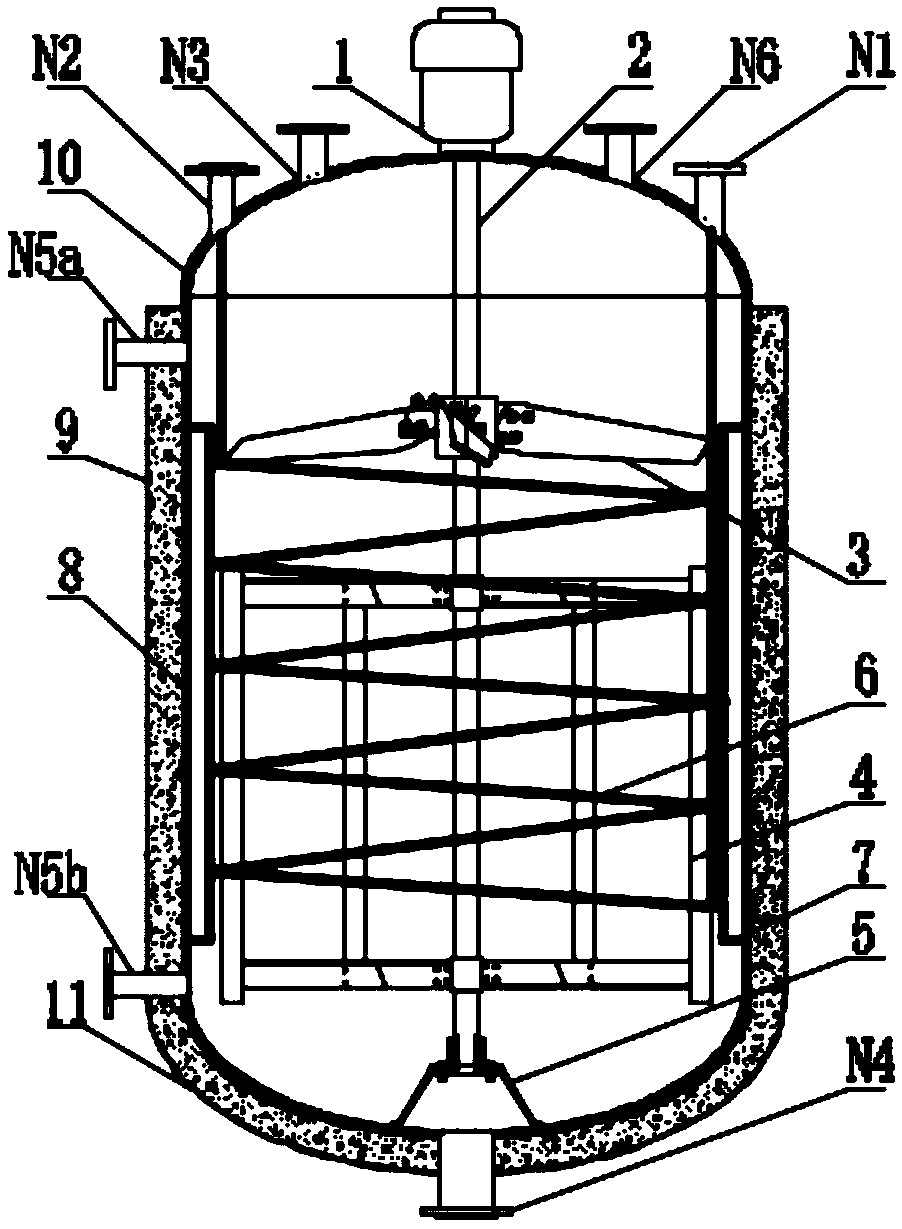

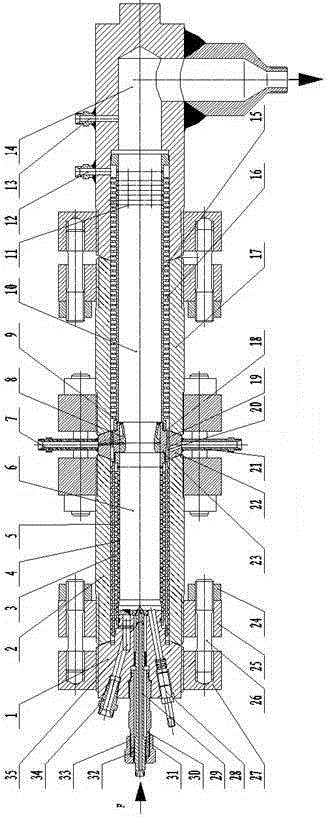

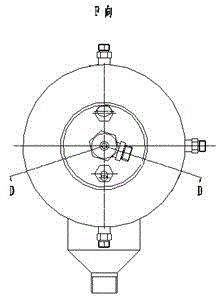

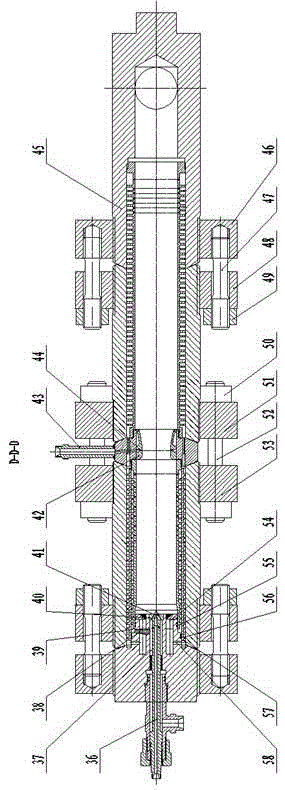

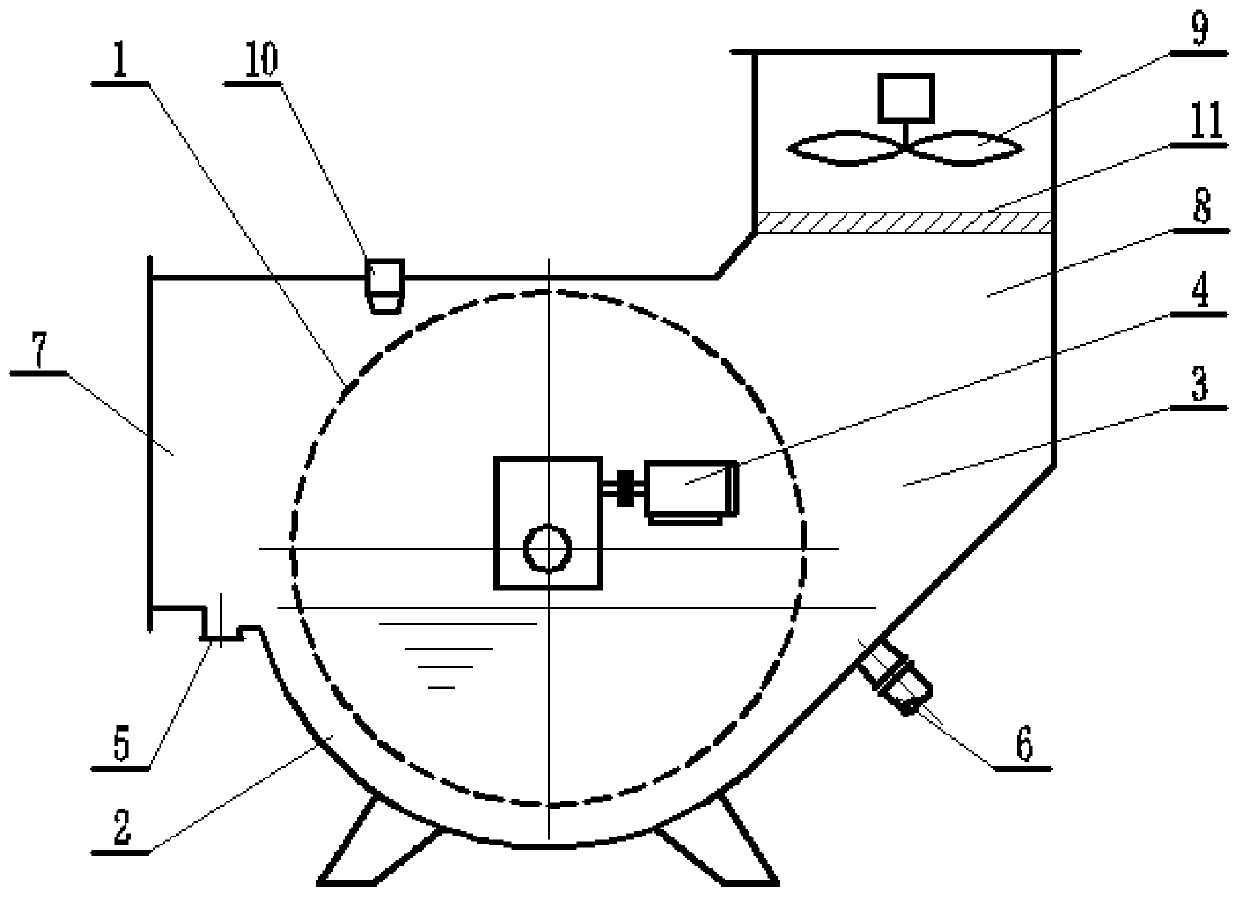

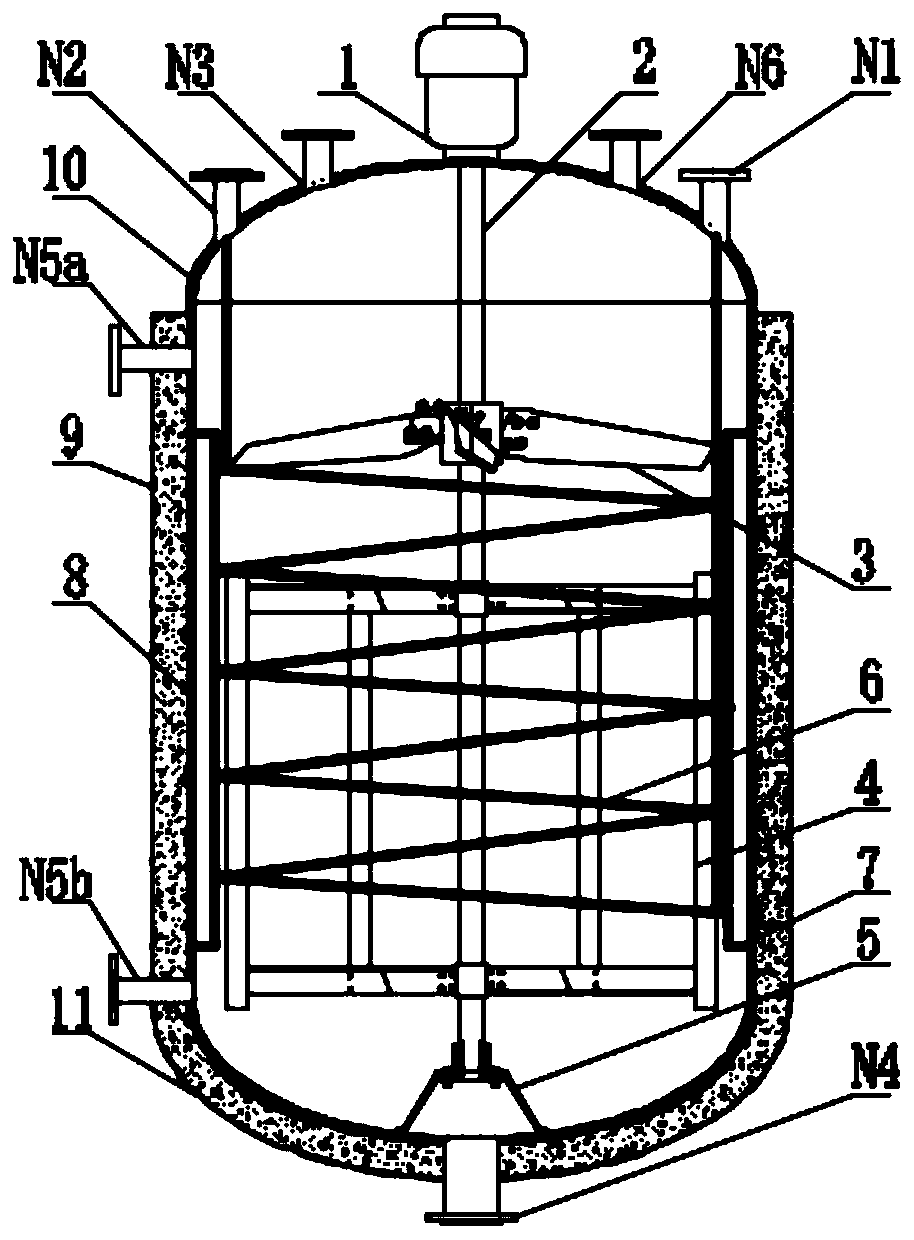

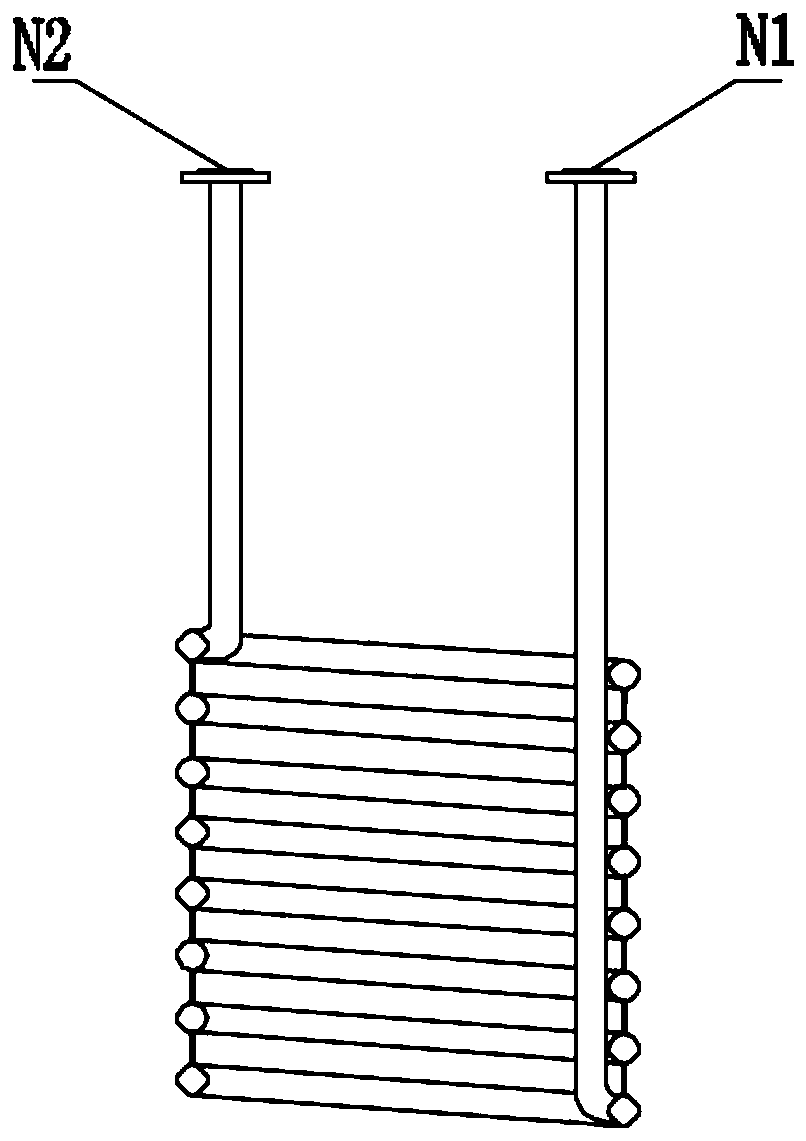

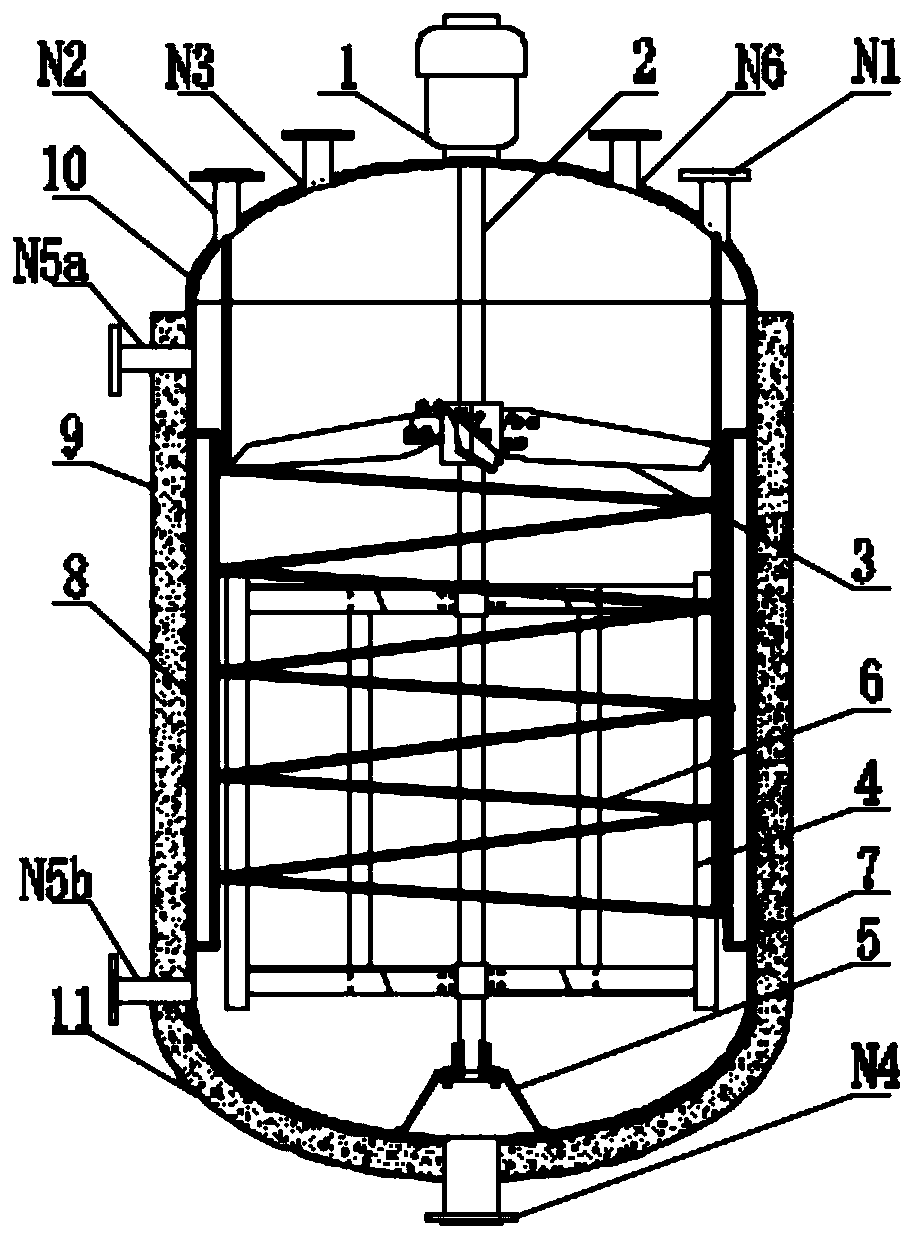

Sludge continuous thermal hydrolysis membrane type wall reactor for supercritical water oxidization system

ActiveCN109399892AImprove heat transfer efficiencyAvoid Heat Transfer DeteriorationSludge treatment by thermal conditioningSludge treatment by oxidationEngineeringSludge

The invention discloses a sludge continuous thermal hydrolysis membrane type wall reactor for a supercritical water oxidization system and belongs to the technical field of supercritical water oxidization. The sludge continuous thermal hydrolysis membrane type wall reactor comprises a barrel body, wherein an upper sealing head is arranged at the top of the barrel body and a lower sealing head is arranged at the bottom of the barrel body; a motor is mounted outside the upper sealing head; the barrel body is internally provided with a rotary shaft driven by the motor; the bottom of the rotary shaft is fixed on the lower sealing head; a sludge inlet is arranged on the upper sealing head and a sludge outlet is arranged at the bottom of the lower sealing head; the barrel body is internally further provided with a membrane type wall heat exchanger which is coaxial with the barrel body and is clung to a side wall of the barrel body; the rotary shaft is provided with a stirring device; the stirring device penetrates through a cavity of the membrane type wall heat exchanger; the upper sealing head is further provided with a hot fluid inlet and a hot fluid outlet; the hot fluid inlet and thehot fluid outlet are communicated with the membrane type wall heat exchanger. The sludge continuous thermal hydrolysis membrane type wall reactor is used for providing heat for sludge to raise the temperature of the sludge; thermal hydrolysis reaction occurs so that the viscosity is reduced; the technical problems in the aspects of sludge conveying, heat exchange and the like in the background technology are solved, so that the sludge continuous thermal hydrolysis membrane type wall reactor can be widely applied to the SCWO (Supercritical Water Oxidation) system for continuously treating thehigh-viscosity sludge.

Owner:XI AN JIAOTONG UNIV

Supplementary combustion chamber of supercritical pressure gas-liquid fuel generator

The invention provides a supplementary combustion chamber of a supercritical pressure gas-liquid fuel generator, and relates to oil extraction equipment in an oil field. The supplementary combustion chamber is characterized by comprising a pre-combustion chamber (6), a secondary combustion chamber (10) and a vaporizing chamber (14). A spouting mode of fuel of the supplementary combustion chamber is as follows: the pre-combustion chamber (6) only sprays part of the fuel and full air for oxygen-enriched combustion; the remaining fuel is sprayed into the secondary combustion chamber (10) from a supplementary combustion inspirator and completely combusted with oxygen-enriched gas from the pre-combustion chamber in the secondary combustion chamber (10). By the combustion chamber, simultaneous combustion of gas fuel and liquid fuel is realized, and heat transfer deterioration is prevented due to various cooling modes.

Owner:刘殿玺 +2

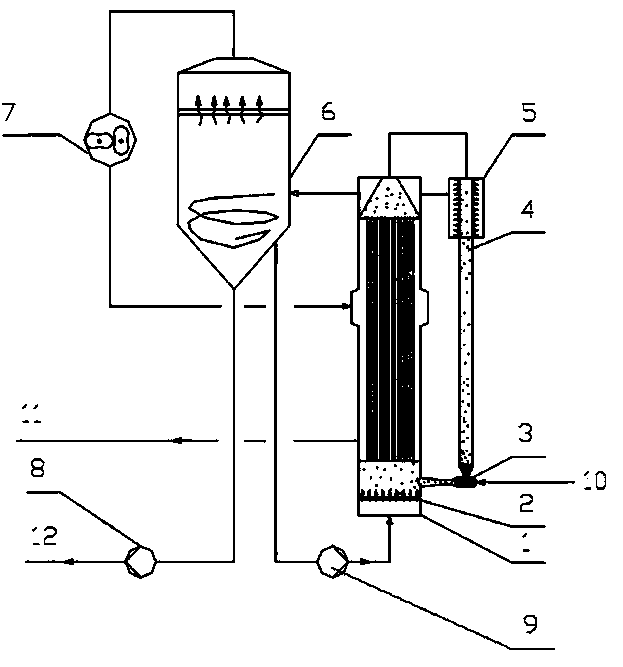

Self-cleaning high-salt wastewater evaporative crystallization device

ActiveCN103101989BTo achieve the purpose of self-cleaningAvoid badHollow article cleaningSolution crystallizationWastewaterSewage

The invention relates to a self-cleaning high-salt wastewater evaporative crystallization device. The evaporative crystallization device comprises a heater (1), an injection pump (3), a self-cleaning medium (4), a solid-liquid separating chamber (5), an evaporative crystallization chamber (6), a steam compressor (7), a strong brine pump (8) and a material water pump (9). By adopting the evaporative crystallization device, because the self-cleaning medium flows continuously in a heat transfer pipe of the heater and rubs and crashes the inner wall of the heat transfer pipe continuously, the dirt deposited on the inner wall of the heat transfer pipe is peeled off, and the self-cleaning medium is drained out of a heating chamber together with the material water, and thus the purpose of self-cleaning of the device is achieved; with the adoption of the evaporative crystallization device, the problem of scaling of the heat transfer pipe can be solved, and thus the heat transfer deterioration of the heat transfer pipe can be avoided, the heating exchanging property of the heater is enhanced, the usage rate of the wastewater evaporative crystallization device is improved, the work load of on-site maintenance is reduced, the dosage of chemicals is reduced, and meanwhile the pressure of environment pollution is reduced; and the wastewater evaporative crystallization is simple in structure, low in machining and manufacturing cost, and easy and convenient to mount and demount.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

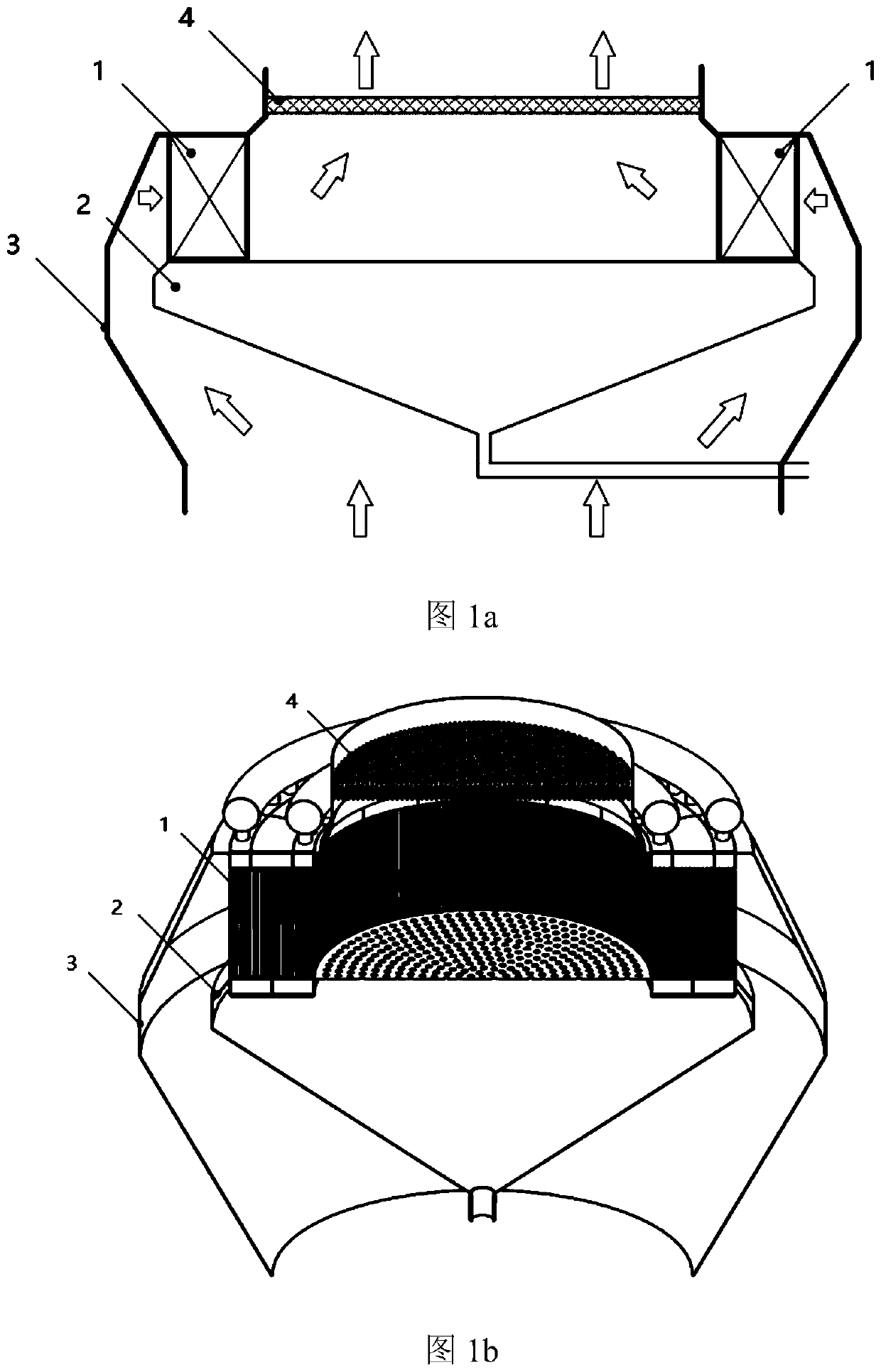

Flue gas condensation heat exchanger with profiling flue gas flow channel structure

PendingCN110631044ALow overall resistanceShorten the lengthSteam/vapor condensersCombustion technology mitigationCondensed waterProcess engineering

The invention discloses a flue gas condensation heat exchanger with a profiling flue gas flow channel structure. The flue gas condensation heat exchanger is composed of flue gas condensing units, a conical air distribution disc, a profiling outer shell and a demister; a plurality of arc units form the annular flue gas condensing units, flue gas is evenly distributed to the inlet surface of each flue gas condensing unit under the common guidance of the conical air distribution disc and the profiling outer shell, and condensed water is collected in the conical air distribution disc; the flue gascondensing units can use laser welding spiral fin tubes to weaken the crevice corrosion of the condensate water and expand the heat exchange surface, so that the weight of the heat exchanger is remarkably reduced. According to the flue gas condensation heat exchanger, a traditional design is eliminated by traversing a tray of the cross-section of a desulfurization tower, and the flue gas whitening can be achieved by matching an external or built-in flue gas reheater; the shape of the heat exchanger is similar to the shape of an original flue, the flue gas condensation heat exchanger can be installed by replacing part of the original flue, the problem that the occupied space of a condensation reheating system is large and the installation space is stressed is solved, and the important requirements of low cost, low resistance and efficient and compact flue gas condensation and whitening are achieved.

Owner:XI AN JIAOTONG UNIV

Rotating disc type thin film evaporative cooling tower

InactiveCN109696063ALow ventilation resistanceReduce the temperatureHeat storage plantsTrickle coolersLiquid temperatureEvaporation heat transfer

The invention relates to a rotating disc type thin film evaporative cooling tower. The rotating disc type thin film evaporative cooling tower is characterized in that the rotating disc type thin filmevaporative cooling tower comprises a heat storage element driven by a driving device to rotate, the upper half part of the heat storage element is located n a cooling environment, the lower half partof the heat storage element is soaked in liquid needing to be cooled, the ambient temperature of the cooling environment is lower than the liquid temperature of the liquid needing to be cooled, whenthe heat storage element rotates, the upper half part and the lower half part of the heat storage element alternatively conduct forced-convection heat transfer with the liquid to absorb heat of the liquid, and meanwhile, the lower half part and the upper half part of the heat storage element with the liquid alternatively conduct thin film evaporation heat transfer with the cooling environment to release the absorbed heat. The purpose of lowering the temperature of circulating water is achieved by two times of heat transfer.

Owner:朱玲燕

A high-magnification concentrated photovoltaic thermal control device

ActiveCN108809253BReasonable structureEfficient deliveryPhotovoltaicsPhotovoltaic energy generationTemperature controlElectrical battery

The invention discloses a high-power concentrating photovoltaic thermal control device. The high-power concentrating photovoltaic thermal control device comprises a radiator and a water tank, whereina circulating pipeline arranged on the radiator is arranged inside the water tank, and heat exchange is carried out between a heat-carrying working medium in the circulating pipeline and water in thewater tank; the high-power concentrating photovoltaic thermal control device is characterized in that the radiator further comprises a heat absorption surface and a heat dissipation part, wherein theheat dissipation part is arranged on one side of the heat absorption surface, and a medium inlet and a medium outlet are formed in the heat dissipation part; the circulating pipeline is connected to the medium inlet and the medium outlet; and fins are arranged in the radiator and gaps formed by the adjacent fins are equal. The technical scheme provided by the invention is used for temperature control of a concentrating photovoltaic power generation battery; the high-power concentrating photovoltaic thermal control device is reasonable in structure, and the heat-carrying working medium is usedfor taking away heat from the heat absorbing surface so as to achieve the purpose of temperature control, so that the service life of the battery is guaranteed, and the reliability and the efficiencyof concentrating photovoltaic power generation are improved; and in addition, the heat taken away by the heat-carrying working medium is stored in water in the water tank, so that waste is reduced, and the utilization rate of energy is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

A Variation Micro-Channel Cooling Type Surface Flame Low NOx Gas Device

The invention discloses a variation micro-channel cooling type surface flame low NOx gas device, which comprises an upper and lower header, a variation structure water-cooling component, and a plurality of compact gas-cooling components constructed by the upper and lower headers and multiple groups of variation structure water cooling components arranged in parallel. Variation airflow microchannel, and water inlet and water outlet respectively connected with the upper and lower headers. The gas and air mixture flows through the dense variable airflow microchannel and then ignites and burns. However, due to the heat absorption of the variable structure water cooling component, the flame front of the gas flow burns at the low temperature surface of the variable airflow microchannel outlet and the surface of the variable structure water cooling component, significantly reducing the airflow combustion temperature , and then achieve low-temperature and low-NOx combustion; at the same time, the variation structure of the gas flow microchannel significantly promotes the disturbance of the flame gas flow, and is combined with the dense variation structure water-cooling component and the variation gas flow microchannel to effectively prevent tempering and defiring, thereby achieving low temperature At the same time, low NOx surface combustion eliminates local high temperature phenomenon and ensures stable, safe and efficient combustion.

Owner:XI AN JIAOTONG UNIV

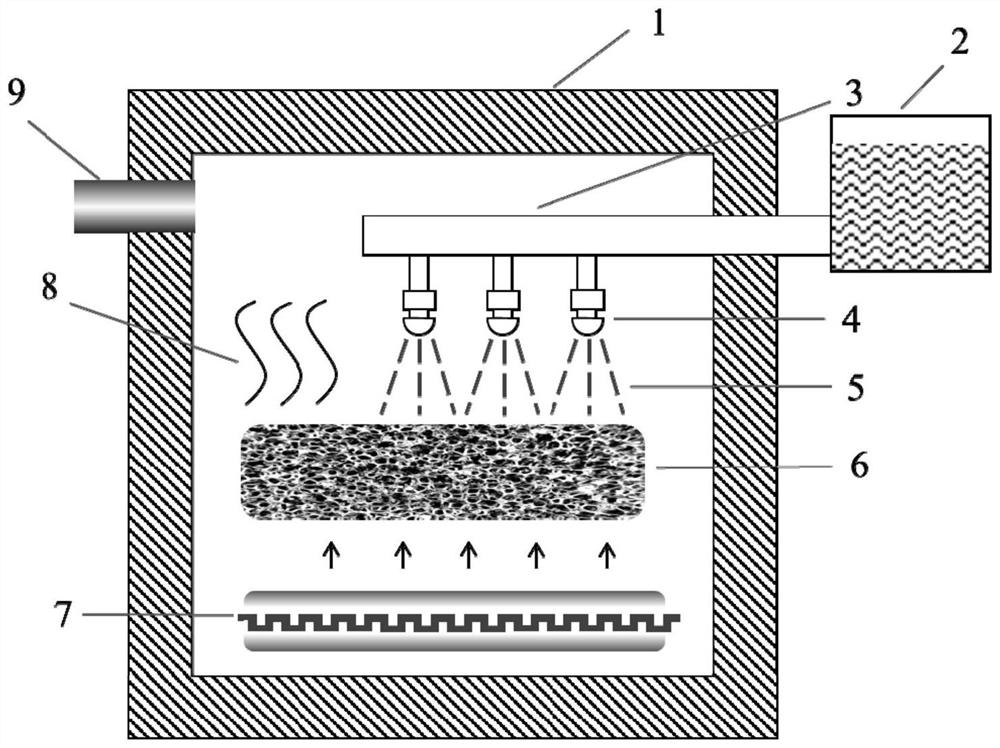

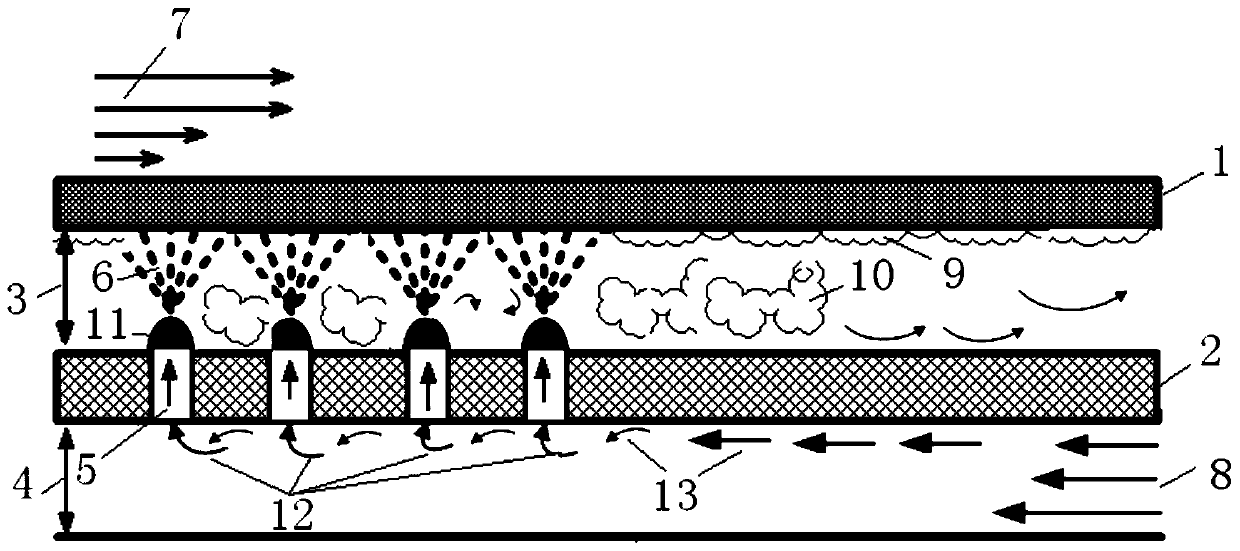

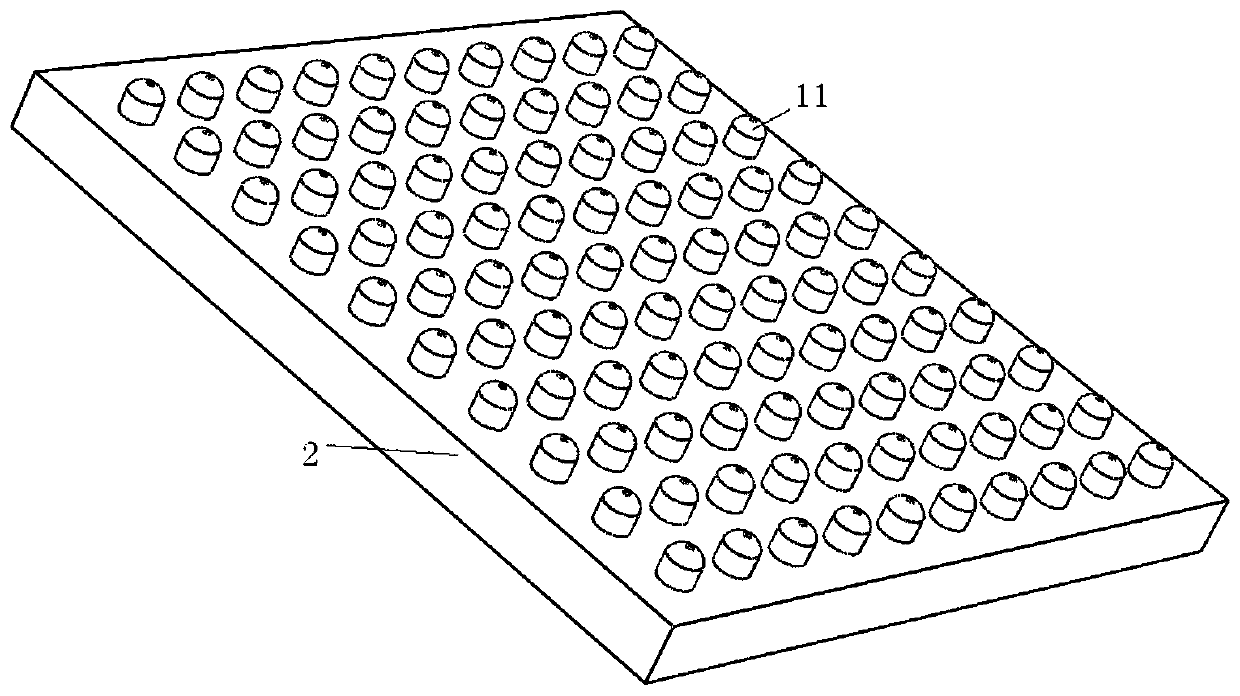

Spraying adsorption type steam generating device and application thereof

PendingCN113464914ANo preheating requiredAvoid Heat Transfer DeteriorationSteam generation heating methodsSteam boilersPorous mediumRadiative heating

The invention relates to a spraying adsorption type steam generating device, which comprises a working bin, a water mist spraying unit, a metal porous adsorption unit and a high-temperature radiation heating unit, wherein the water mist spraying unit is used for forming atomized liquid drops; the metal porous adsorption unit is used for capturing the atomized liquid drops and absorbing heat radiation; the high-temperature radiation heating unit is arranged opposite to the water mist spraying unit; the atomized liquid drops formed by the water mist spraying unit collide with the surface of the metal porous adsorption unit and are diffused to the whole metal porous adsorption unit; and after heat radiation is absorbed, the water is evaporated into steam. The device provided by the invention can quickly obtain steam including high-temperature steam and low-temperature steam; the steam quantity can be controlled by the flow of a nozzle as required, and no water is accumulated; boiling phase change occurs in a metal porous medium layer, so that heat transfer deterioration caused by membrane boiling is avoided; liquid is not in direct contact with a heating surface, and water scale deposits in the metal porous medium layer and does not cover the heating surface, so heat transfer is not affected.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Shell-and-tube high-temperature waste heat steam boiler with small circulation ratio of partial jet flow

ActiveCN103982886BImprove uniformityLow flow resistanceChemical industryStationary tubular conduit assembliesJet flowFlue gas

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD +1

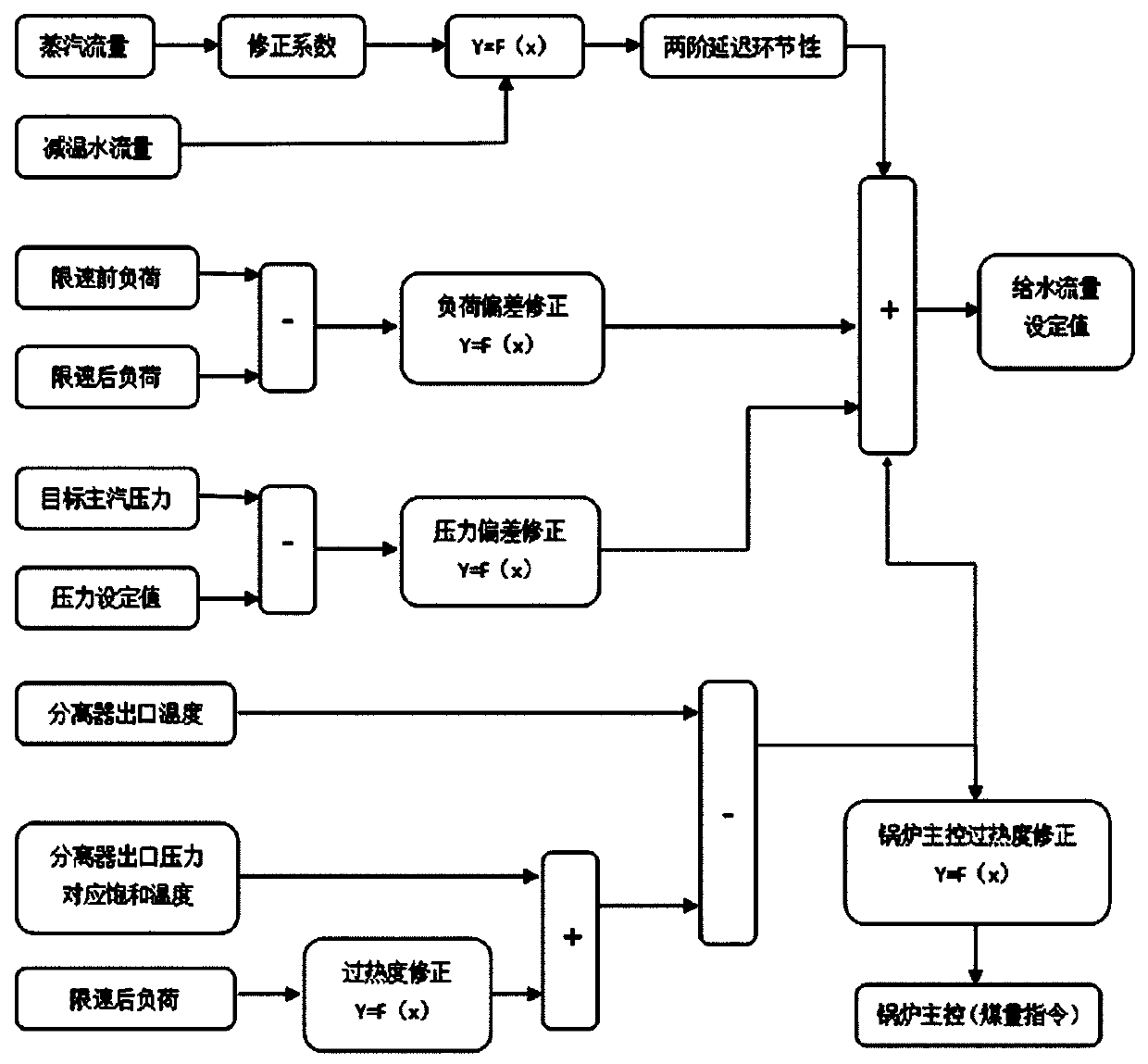

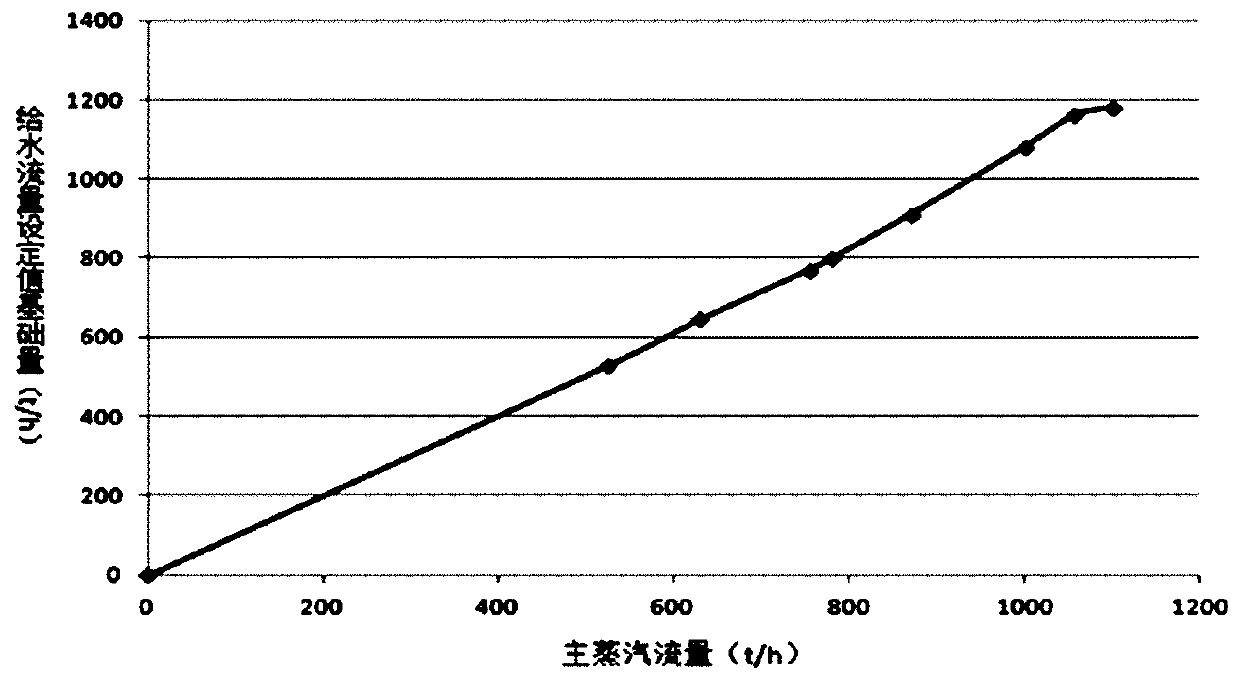

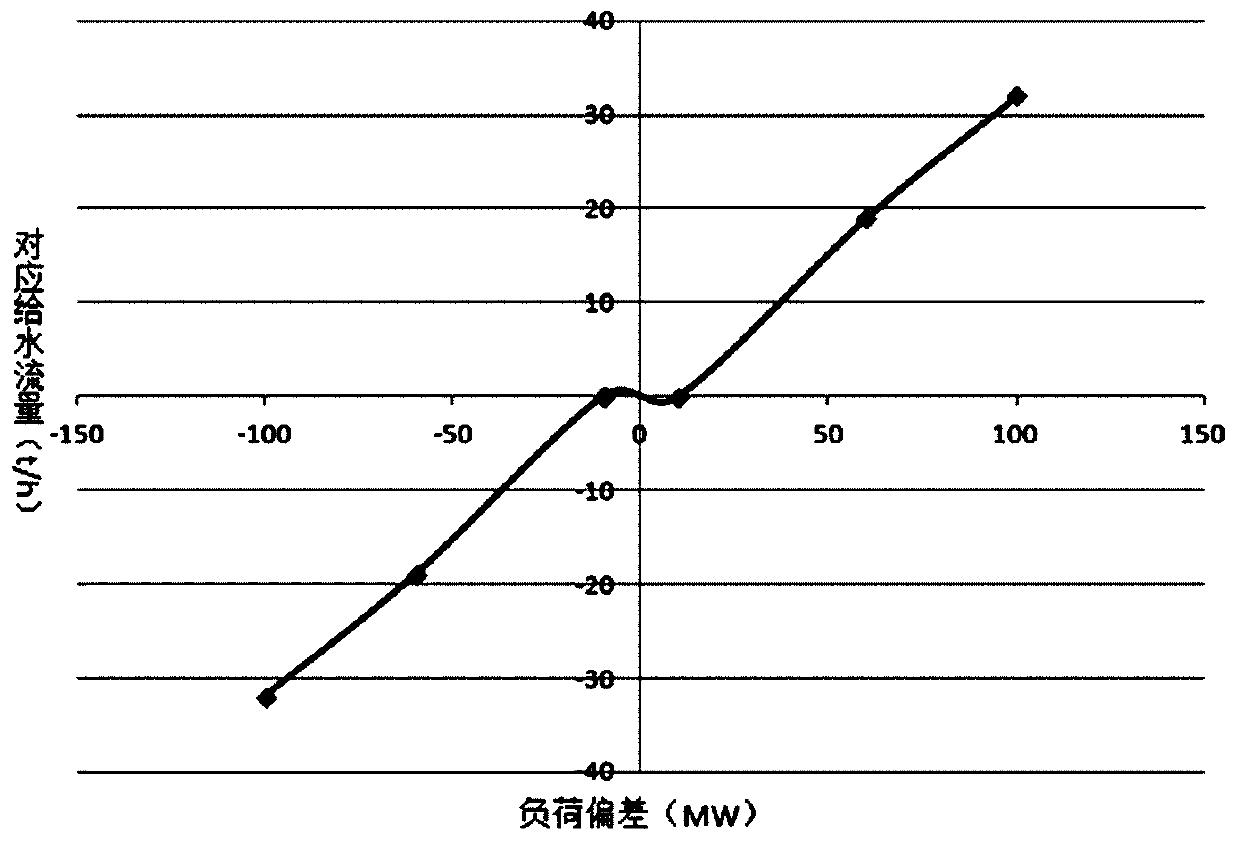

A Feedwater Flow Control Method Adapting to Rapid Load Fluctuation

The invention relates to the technical field of water supplying control of supercritical units, and specifically relates to a rapid load fluctuation adapting type water supplying flow rate control method. The method is characterized in that the main steam flow rate is treated as a main input signal of water supplying control; the difference between target load of the unit and the target load afterspeed limitation, the deviation between the target main steam pressure and the actual main steam pressure, and the deviation between the target temperature and the actual temperature of an outlet ofa separator are overlapped and act on the set water supplying flow rate value; the coal quantity change and the water supplying quantity change are relatively independent; and intermediate point temperature deviation is added to correct the water supplying quantity. According to the method, sufficient water supplying flow rate and pressure are supplied by a water supplying system in running, so that the problems such as large main steam pressure fluctuation and high overshoot of a supercritical pressure circulating fluidized bed boiler can be solved; the cooling water quality of all heated surfaces and the power circulating stability of water in water cooling walls are protected; and the unit can work in an area under a pressure setting working condition. Therefore, the purpose of increasing the economic benefit of the unit is achieved.

Owner:山西格盟安全生产咨询有限公司

Self-adjusting evaporator

The invention relates to the technical field of evaporation equipment, in particular to a self-adjusting evaporator, which comprises: a heat source; a liquid storage component disposed facing the heat source; and an evaporation component arranged between the heat source and the liquid storage component, wherein the evaporation component is attached to the liquid storage component, the liquid storage component is provided with a liquid storage core capable of sucking a cooling liquid, the evaporation component is provided with an evaporation core, and the evaporation core makes contact with the liquid storage core, so that the evaporation core can suck liquid in the liquid storage core. According to the self-adjusting evaporator, a cooling liquid can be continuously and appropriately provided for main evaporation components of the evaporator, so that the evaporation efficiency can be ensured, and the working condition of variable heat loads can be coped; and the smoothness of the escape process of bubbles generated by liquid boiling can be improved, so that heat transfer deterioration can be avoided.

Owner:北京微焓科技有限公司 +1

Film type steam generator

ActiveCN106838852AUniform heating effectUniform cooling effectSteam generation heating methodsBoiler cleaning apparatusEvaporationWater flow

The invention relates to a film type steam generator. The film type steam generator comprises water supply pipelines, a film type evaporation pipe and steam outlet and water return pipelines, wherein the water supply pipelines comprise a main water supply pipeline and a water supply branch pipeline, and supplied water flows to the tail end of the water supply branch pipe from an inlet end of the main water supply pipe; the steam outlet and water return pipelines comprise a main steam outlet and water return pipe and a steam outlet and water return branch pipe; one end of the film type evaporation pipe is connected with the main water supply pipeline or the water supply branch pipeline, and the other end of the film type evaporation pipe is connected with the main steam outlet and water return pipe or the steam outlet and water return branch pipe; steam in the steam outlet and water return branch pipe moves upwards, is output from a high-position steam outlet end and is merged into the main steam outlet and water return pipe, and returned water moves downwards and is merged into the main steam outlet and water return pipe from a low-position water return end; steam in the main steam outlet and water return pipe further moves upwards and is separated from the returned water and finally output from a steam output port, the returned water further moves down and is separated from the steam and finally output from a returned water outlet and merged into a water supply circulation tank, and circular water supply is realized after supplement. The film type steam generator combines advantages of a drum-type boiler and a once-through boiler, overcomes defects of the drum-type boiler and the once-through boiler and has popularization value.

Owner:高峰

A regenerative cooling dual-channel scheme for enhancing heat transfer by spraying against the wall

ActiveCN106949497BImprove heat transfer efficiencyGood choiceContinuous combustion chamberCombustion systemCombustion chamber

The invention provides a heat exchange strengthening structure used for regenerative cooling of a supersonic combustion chamber through a spraying / convection composite type heat exchange mode. A double flow channel design is adopted, and the characteristic of the large heat flux of a spraying cooling mode is fully utilized to conduct heat exchange strengthening on the wall face of the combustion chamber. A scheme is composed of a double layer heat exchange scheme of the outer layer wall and the inner layer wall. A flow channel formed by partitioning of the outer layer wall and the inner layer wall is used for spray wall impingement strengthening heat exchange. Spraying nozzles are arranged on the inner layer wall. The number and distribution density of the spraying nozzles are determined according to the heat exchange strength and the heat exchange area. Part of heated liquid fuel and gaseous fuel formed by spray heat absorption are supplied to a nozzle of an engine combustion system in different phase states, and the liquid fuel is atomized in a mode of pneumatic atomization assisting. By adopting the design that a gas heat exchange flow channel and a liquid heat exchange flow channel are partitioned, the problem of flow supplying fluctuation caused by nonuniform gas and liquid distribution in the conveying process of the two phase flows of fuel after heat absorption to the combustion system is avoided.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

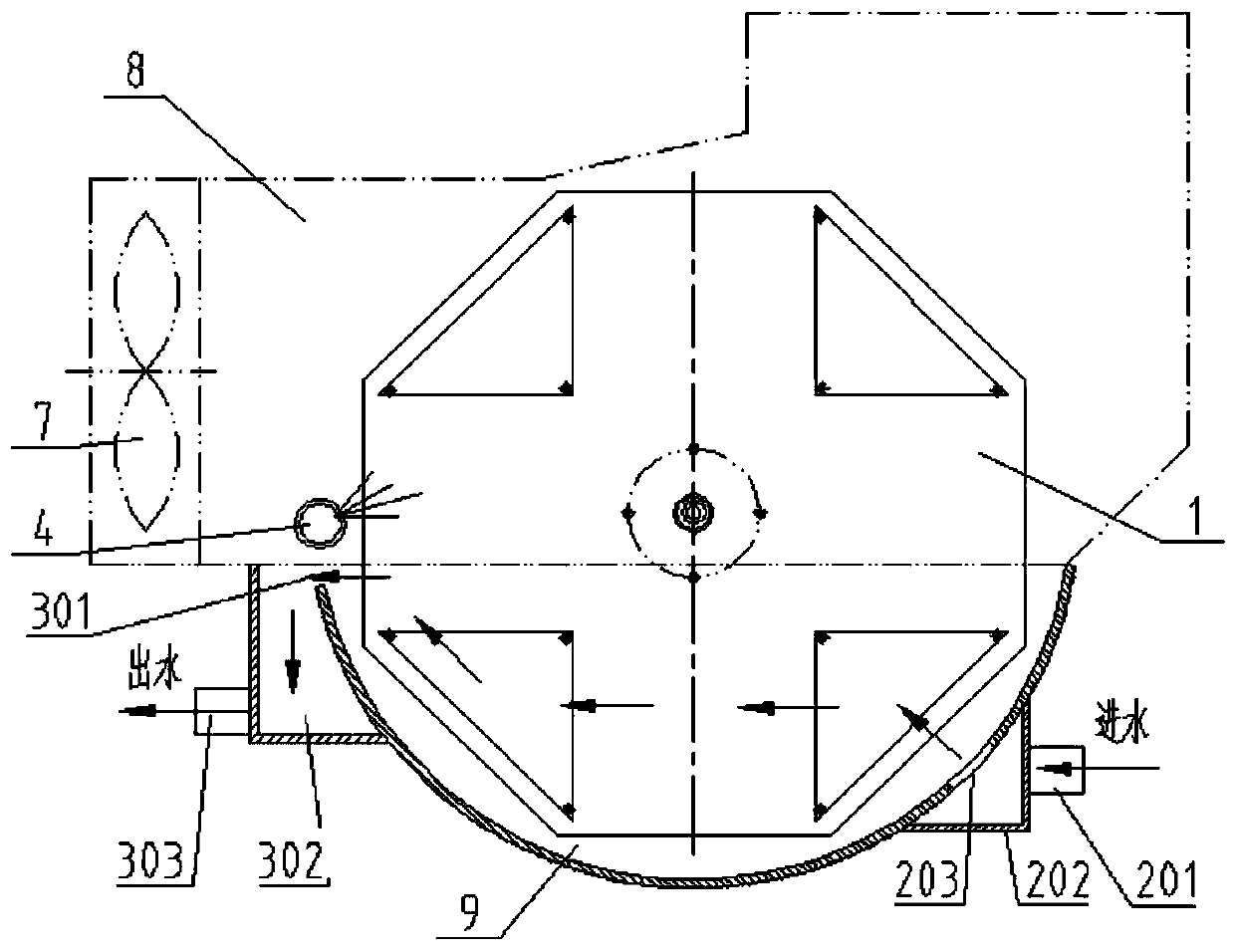

A Natural Circulation Split Tube Shell Waste Heat Boiler with Optimized Flow Field Arrangement

ActiveCN106287627BAvoid flow turbulenceResolve disorderSteam separation arrangementsWater-tube boilersThermodynamicsFlue gas

The invention relates to a natural circulation split shell-and-tube waste heat boiler with optimized flow field layout, which includes a drum and a steam drum. The drum is divided into a flue gas inlet, a heat exchange chamber and a flue gas outlet; The water pipe is connected to the water collection pipe; the heat exchange chamber is arranged with a heat exchange tube bundle; the heat exchange chamber is divided into several heat exchange units by arranging vertical support baffles, and each heat exchange unit is connected to the steam drum through a riser pipe. The upper ends of the ascending tubes extend into the steam drum and are always above the liquid level in the steam drum; there are tube holes on the support baffle for the passage of the heat exchange tube bundle, and there are holes between the tube holes on the lower part of the support baffle. The baffle hole; the steam drum is provided with a steam drum water supply port and several steam outlets; the steam drum is connected with the water collection pipe through the downpipe. The invention can solve the problem that the vapor-liquid two-phase flow in the middle and lower drum of the split-tube shell type waste heat boiler is disordered and the vapor-liquid two-phase flow in the rising pipe is stagnant or even reversed.

Owner:XI AN JIAOTONG UNIV

Novel cooling tower turntable and matched system thereof

InactiveCN110530193AAvoid Heat Transfer DeteriorationReduce the difficulty of production processTrickle coolersRotational axisCooling tower

The invention relates to a novel cooling tower turntable. The turntable is characterized in that the turntable comprises a rotating shaft; n blade parts are arranged along the axial direction of therotating shaft; each blade part comprises a regular polygon blade or each blade mechanism comprises a triangular blade group consisting of a regular polygon blade and M triangular blades; the regularpolygon blades are arranged on the rotating shaft in a penetrating mode, and when the blade parts further comprise triangular blades, the M triangular blades in each blade part are symmetrically and circumferentially distributed with the main shaft as the circle center. A channel is formed between two adjacent regular polygon blades or between the adjacent regular polygon blades and the triangularblades. Another technical scheme of the invention is to provide an auxiliary water spraying system. The innovative points of the invention are as follows: the blades on the rotating shaft are a combination of regular polygons and triangles or a single regular polygon, and the regular polygon can be formed by cutting a thin plate or splicing a plurality of thin plates. The blade structure can greatly reduce the production process difficulty and the manufacturing cost.

Owner:朱玲燕

A pressure vessel external cooling system for floating nuclear power plants

ActiveCN113345609BNo risk of cooling failureAvoid blockingNuclear energy generationCooling arrangementNuclear reactorNuclear power

The invention discloses an external cooling system for a pressure vessel used in a floating nuclear power plant, which belongs to the technical field of nuclear reactor engineering and includes a containment vessel, a pressure vessel, a liquid gallium collection box, a heat pipe, a cooling cabin and a gallium storage box; the containment vessel is arranged in the sea environment, the containment vessel has a containment chamber; the pressure vessel and the liquid gallium collection tank are arranged up and down, and are located in the containment chamber of the containment vessel; one end of the heat pipe is inserted in the liquid gallium collection box, and the other end is arranged outside the liquid gallium collection box; The gallium tank is located in the containment chamber of the containment vessel; the gallium storage tank communicates with the liquid gallium collection tank through the liquid gallium release valve; the cooling cabin is set at the lower end of the containment vessel and is located below the sea level in the sea environment. The invention does not face the risk of failure of the external cooling of the reactor vessel due to the loss of the heat sink, does not generate a large amount of steam inside the containment, avoids the problems of flow channel blockage and containment overpressure, and has the advantages of safety, stability and long-term operation.

Owner:HARBIN ENG UNIV

A PWR Fuel Assembly Simulation Device with Low Voltage and High Power

ActiveCN107799192BAvoid Heat Transfer DeteriorationGuaranteed similarityNuclear energy generationNuclear monitoringPressurized water reactorLow voltage

The invention discloses a low-voltage and high-power pressurized water reactor fuel assembly simulation device, which comprises a pressure-bearing assembly, an electric heating assembly and a square flow channel. The square flow channel is arranged in the pressure-containing assembly and is sealed with the pressure-containing assembly. The electric heating component passes through the square flow channel and the pressure-bearing component at the same time, and is sealed and fixed with the pressure-bearing component. The device meets the requirements of high-temperature and high-pressure experiments, and maintains the thermal-hydraulic characteristics similarity with the reactor fuel assembly. It can realize the simulation process of the pressurized water reactor fuel assembly with low voltage and high power. It consumes less energy and simplifies the structure. It is used in pressurized water reactors. Fuel assembly critical heat flux and flow instability experiments to verify the thermal safety performance of the reactor.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

A membrane wall reactor for continuous thermal hydrolysis of sludge for supercritical water oxidation system

ActiveCN109399892BImprove heat transfer efficiencyAvoid Heat Transfer DeteriorationSludge treatment by thermal conditioningSludge treatment by oxidationSludgeElectric machine

The invention discloses a sludge continuous thermal hydrolysis membrane type wall reactor for a supercritical water oxidization system and belongs to the technical field of supercritical water oxidization. The sludge continuous thermal hydrolysis membrane type wall reactor comprises a barrel body, wherein an upper sealing head is arranged at the top of the barrel body and a lower sealing head is arranged at the bottom of the barrel body; a motor is mounted outside the upper sealing head; the barrel body is internally provided with a rotary shaft driven by the motor; the bottom of the rotary shaft is fixed on the lower sealing head; a sludge inlet is arranged on the upper sealing head and a sludge outlet is arranged at the bottom of the lower sealing head; the barrel body is internally further provided with a membrane type wall heat exchanger which is coaxial with the barrel body and is clung to a side wall of the barrel body; the rotary shaft is provided with a stirring device; the stirring device penetrates through a cavity of the membrane type wall heat exchanger; the upper sealing head is further provided with a hot fluid inlet and a hot fluid outlet; the hot fluid inlet and thehot fluid outlet are communicated with the membrane type wall heat exchanger. The sludge continuous thermal hydrolysis membrane type wall reactor is used for providing heat for sludge to raise the temperature of the sludge; thermal hydrolysis reaction occurs so that the viscosity is reduced; the technical problems in the aspects of sludge conveying, heat exchange and the like in the background technology are solved, so that the sludge continuous thermal hydrolysis membrane type wall reactor can be widely applied to the SCWO (Supercritical Water Oxidation) system for continuously treating thehigh-viscosity sludge.

Owner:XI AN JIAOTONG UNIV

1000mw ultra supercritical double reheat boiler with high reheat steam temperature and wide adjustment ratio

ActiveCN105953217BIncrease metal temperature marginAlleviate the problem that the wall temperature is easy to overheatSuperheating controlEngineeringWater cooling

The invention provides a 1000MW ultra-supercritical secondary reheat boiler with a high reheat steam temperature and width regulation ratio. The 1000MW ultra-supercritical secondary reheat boiler comprises a boiler body, a primary reheat low-temperature reheater, primary reheat wall type reheaters, a primary reheat high-temperature reheater, a secondary reheat low-temperature reheater, secondary reheat wall type reheaters and a secondary reheat high-temperature reheater, wherein the primary reheat low-temperature reheater, the primary reheat wall type reheaters and the primary reheat high-temperature reheater are sequentially connected, and the secondary reheat low-temperature reheater, the secondary reheat wall type reheaters and the secondary reheat high-temperature reheater are sequentially connected. The boiler body comprises a hearth and an outlet flue. The primary reheat wall type reheaters are symmetrically arranged on a front wall and a rear wall of a vertical water cooling wall section in the hearth. The secondary reheat wall type reheaters are symmetrically arranged on a left wall and a right wall of the vertical water cooling wall section in the hearth. The boiler is simple in structure and low in cost; the reheat steam temperature is greatly improved; the outlet exhaust temperature of an air pre-heater is reduced; exhaust heat losses are reduced; and therefore the efficiency of the boiler is improved, power supply coal consumption is reduced, and the economic efficiency and safety of running of a unit are guaranteed.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

Gradual vapouration type high-energy-efficiency direct-flow steam injection boiler and method

InactiveCN102635846BReduce the temperatureIncrease profitFluid removalSteam boilersHeat transmissionHigh energy

The invention relates to a gradual vapouration type high-energy-efficiency direct-flow steam injection boiler and a method. The technical scheme of the invention is that the steam injection boiler mainly consists of four modules and an accessory, wherein the four modules comprise a radiation water-cooled module, a gradual vapouration module, a water pipe convection module and a smoke pipe water bath module; the radiation water-cooled module is placed on the bottom of the center of the boiler in a horizontal manner, a front-end opening of the water-cooled module is butted with a burner, and a tail-end upper opening is connected with the bottom of the gradual evapouration module; a front-side opening in the horizontal direction of the gradual vapouration module is connected with the water pipe convection module, and the rear side of the water pipe convection module is connected with the smoke pipe water bath module by a front smoke box; and the smoke pipe water bath module is of a square structure, and is connected with a chimney by a rear smoke box. The boiler and the method have the beneficial effects of preventing a heat transmission exacerbation phenomenon from being generated from fundamentality, greatly reducing tube exploding probability, promoting safety and stability, solving the problem that the heat transmission exacerbation easily exists in a large specific heat region under supercritical pressure, and the energy is saved and the consumption is reduced so as to be beneficial for environmental protection.

Owner:JUNMA PETROLEUM EQUIP MFG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com