Spraying adsorption type steam generating device and application thereof

A steam generating device and adsorption technology, applied in steam generation, steam generation methods, steam boilers, etc., can solve the problems of heat transfer deterioration, lower efficiency, easy scale deposition, etc., and achieve the effect of avoiding heat transfer deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

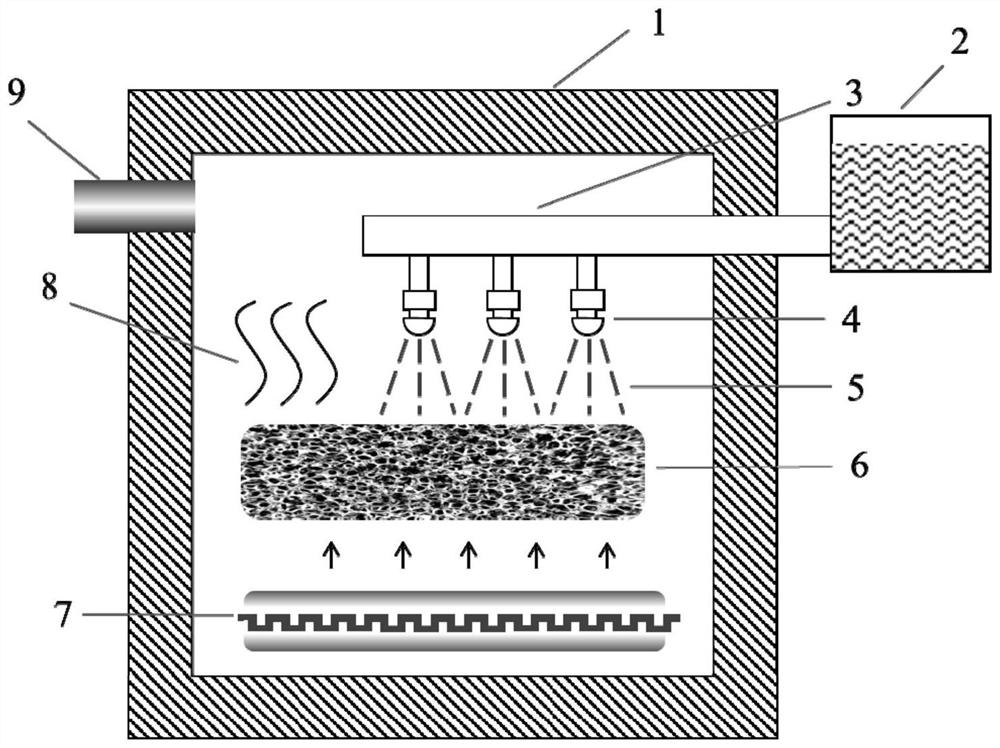

[0034] Such as figure 1 , a spray adsorption steam generating device, the device includes a working chamber 1 and a water mist spraying unit located in the working chamber for forming atomized droplets; a metal porous adsorption unit for capturing atomized droplets and absorb heat radiation; the high-temperature radiation heating unit is set opposite to the water mist spray unit, and heats the liquid in the metal porous adsorption unit through heat radiation. The atomized liquid droplets formed by the water mist spray unit hit the surface of the metal porous adsorption unit and spread to the whole metal porous adsorption unit. After absorbing heat radiation, this part of water evaporates into water vapor8.

[0035] As a specific embodiment, the water mist spray unit includes a water tank 2, a water delivery pipe 3 connected to the water tank 2, and a plurality of groups of nozzles 4 installed on the water delivery pipe 3 for producing mist droplets. Above 200, the pore size r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com