A hand-held hot air output device

An output device, a technology of hot air flow, applied in hair drying devices, devices for washing hair or scalp, heating element materials, etc. The effect of fast heating rate and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

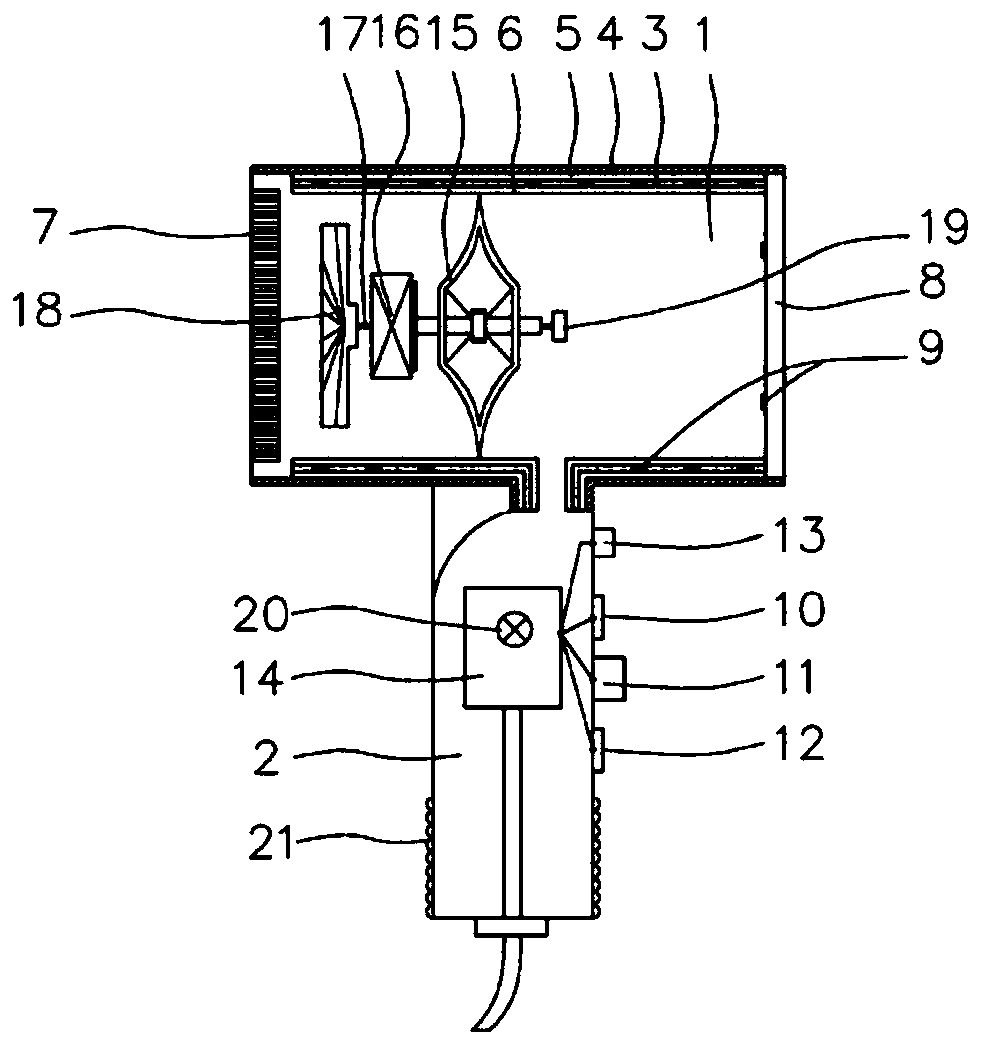

[0026] This embodiment describes a hand-held hot air output device, such as figure 1 As shown, the output device includes a housing 1 and a handle 2, the lower part of the housing 1 is connected to the handle 2, and the inner cavity communicates.

[0027] The left and right ends of the housing 1 are respectively provided with an air inlet cover 7 and an air outlet cover 8, and a heating part is provided on the side wall of the inner cavity of the housing 1 to radiate heat, and the air enters the inner cavity of the housing 1 through the air inlet cover 7 , is blown out by the air outlet cover 8 after being heated by the heating part. Shell 1 is made of high temperature resistant ABS (acrylonitrile-styrene-butadiene copolymer), PPS (polyphenylene sulfide), PC (polycarbonate), PA (polyamide), PP (polypropylene), HDPE (High-density polyethylene) and a series of polymer composite materials.

[0028] The heating part includes a heating element 3 , a reflection layer 4 , a heat in...

Embodiment 2

[0042] In a preferred embodiment, the heating element 3 adopts the self-made new heating element of the present invention, which is made of high-performance electrothermal material obtained from microcrystalline graphite directly grown on high-temperature-resistant fibers.

[0043] Specifically, the novel heating element of the present invention includes a high temperature resistant fiber layer and a microcrystalline graphite layer coated outside the high temperature resistant fiber layer.

[0044] The preparation method of electrothermal material usually includes the following steps:

[0045] Step 1: Prepare the cleaned fiber material;

[0046] Step 2: Carry out surface coating treatment on the fiber material, and the coated film layer contains a carbon source cracking catalytic material;

[0047] Step 3: Place the coated fiber material in a vacuum reaction chamber;

[0048] Step 4: feeding protective gas and reducing gas into the vacuum reaction chamber, and then feeding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com