High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

A technology of sulfurized calcium alkyl phenolate and high base value, applied in the preparation of sulfide, hydrogenated polysulfide/polysulfide, organic chemistry, etc., can solve the problems of increased production of finished products, harsh reaction conditions and high reaction temperature, Achieve improved flexibility, low viscosity, light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

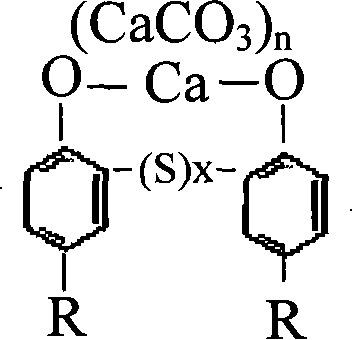

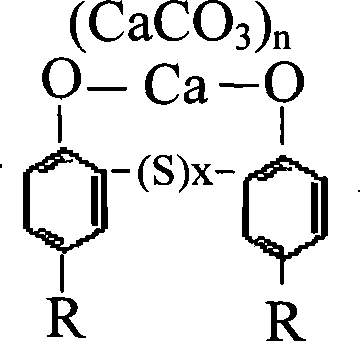

[0031] The chemical structure of the high base number (TBN400) sulfurized calcium alkylphenate is as follows:

[0032]

[0033] In the formula: R group - is C 9 -C 21 straight-chain or branched-chain saturated hydrocarbon structure.

[0034] X-1-4.

[0035] n-10-14.

[0036] The R group of the compound has at least nine carbon atoms, and may be nine, twelve, fifteen, eighteen and twenty-one carbon atoms. The R group is a straight-chain or branched saturated hydrocarbon structure, which is derived from nonylphenol, dodecylphenol, and up to 21-carbon alkylphenol.

[0037] In the -S(x)-bond in the compound, the number of its x includes 1, 2 up to 4, (CaCO in the compound 3 The value of n in the )n structure is 10-14.

example 2

[0039] The high alkali value (TBN400) sulfurized alkyl phenate calcium preparation process is:

[0040] In a system containing solvent and diluent oil, combine (a) alkylphenolic compound, (b) shielded phenolic compound with (c) calcium oxide and / or calcium hydroxide, (d) sulfur, (e) alkyl The mixture of polyhydric alcohol and (f) long-chain carboxylic acid undergoes vulcanization and neutralization reaction to generate phenate intermediate. Among them, the alkylphenol compound is a monosubstituted phenol, the R group of the alkylphenol contains at least nine carbon atoms, including nine carbon atoms to twenty-one carbon atoms, and the R group is a straight-chain or branched saturated hydrocarbon structure. Nonylphenol, dodecylphenol, pentadecylphenol, octadecylphenol or behenylphenol can be used, and dodecylphenol is selected in this example. Shielded phenolic compounds refer to compounds with branched chain substituents from three to twelve carbons on at least one ortho pos...

example 3

[0044] The high alkali value (TBN400) sulfurized alkyl phenate calcium preparation process is:

[0045] In a system containing solvent and diluent oil, combine (a) alkylphenolic compound, (b) shielded phenolic compound with (c) calcium oxide and / or calcium hydroxide, (d) sulfur, (e) alkyl The mixture of polyhydric alcohol and (f) long-chain carboxylic acid undergoes vulcanization and neutralization reaction to generate phenate intermediate. Among them, the alkylphenol compound is a monosubstituted phenol, the R group of the alkylphenol contains at least nine carbon atoms, including nine carbon atoms to twenty-one carbon atoms, and the R group is a straight-chain or branched saturated hydrocarbon structure. Nonylphenol, dodecylphenol, pentadecylphenol, octadecylphenol or behenylphenol can be used, and dodecylphenol is selected in this example. Shielded phenolic compounds refer to compounds with branched chain substituents from three to twelve carbons on at least one ortho pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com