Patents

Literature

53results about How to "High base number" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

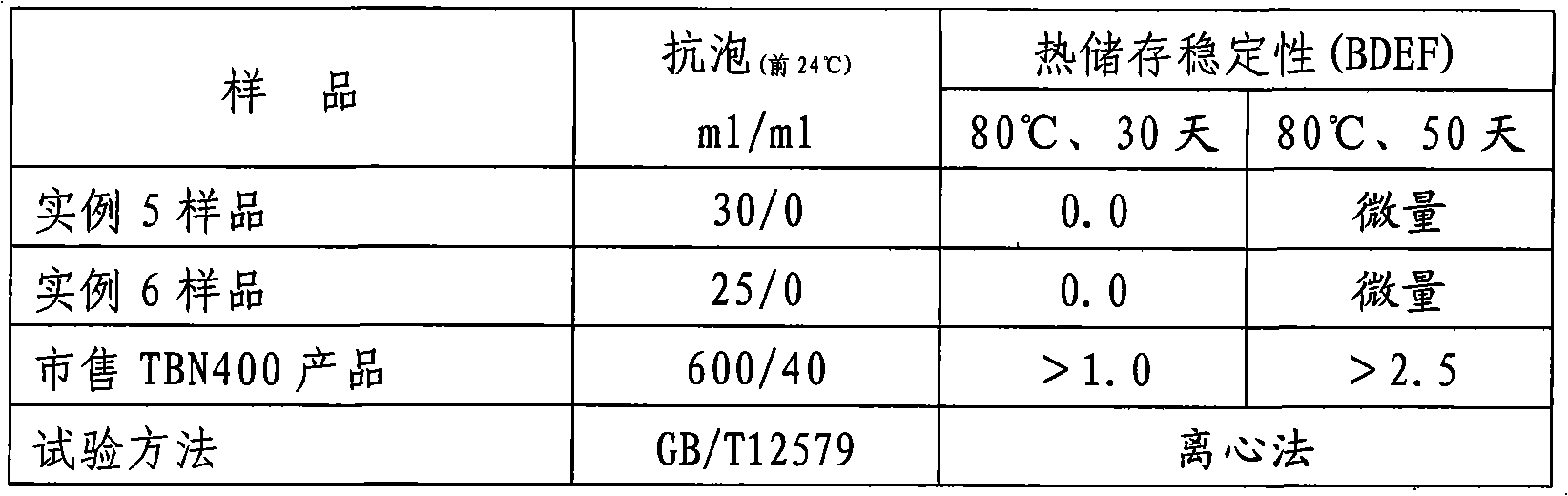

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

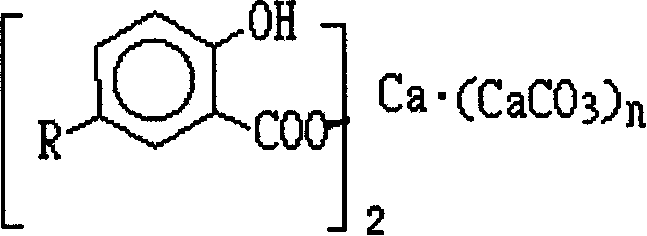

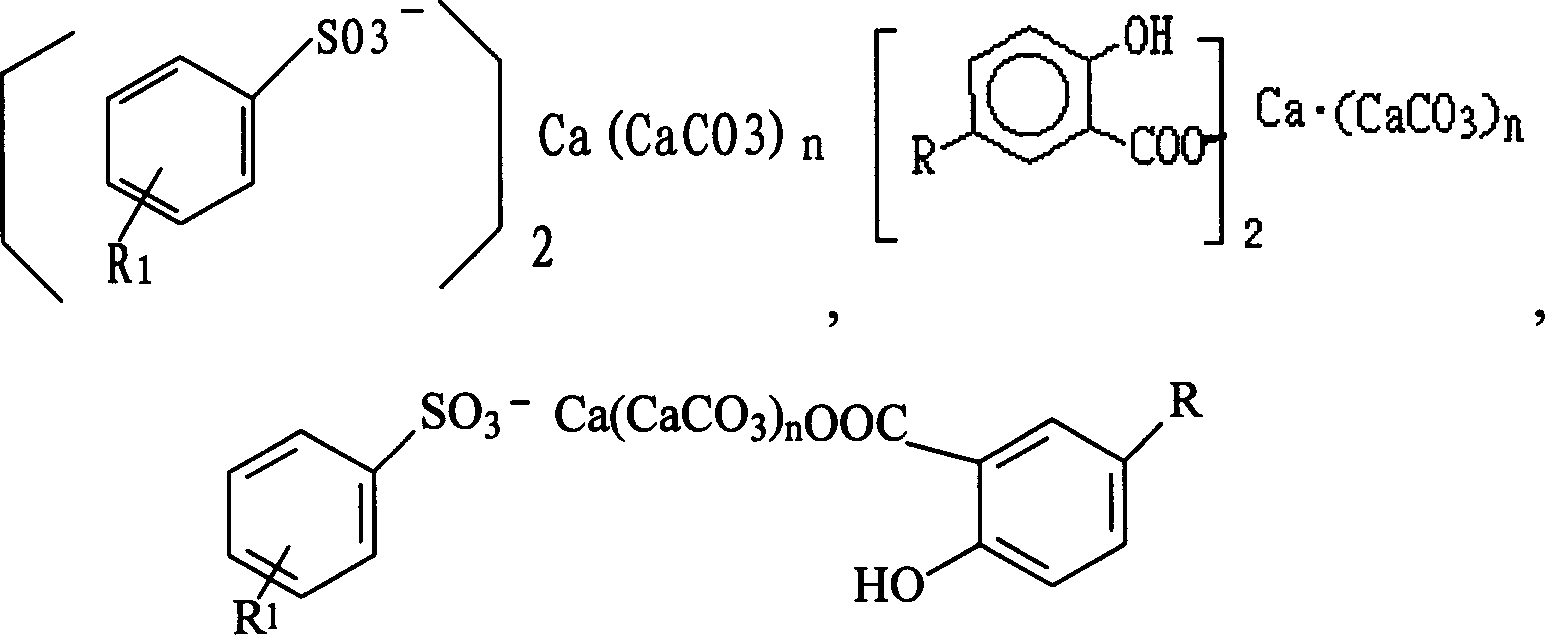

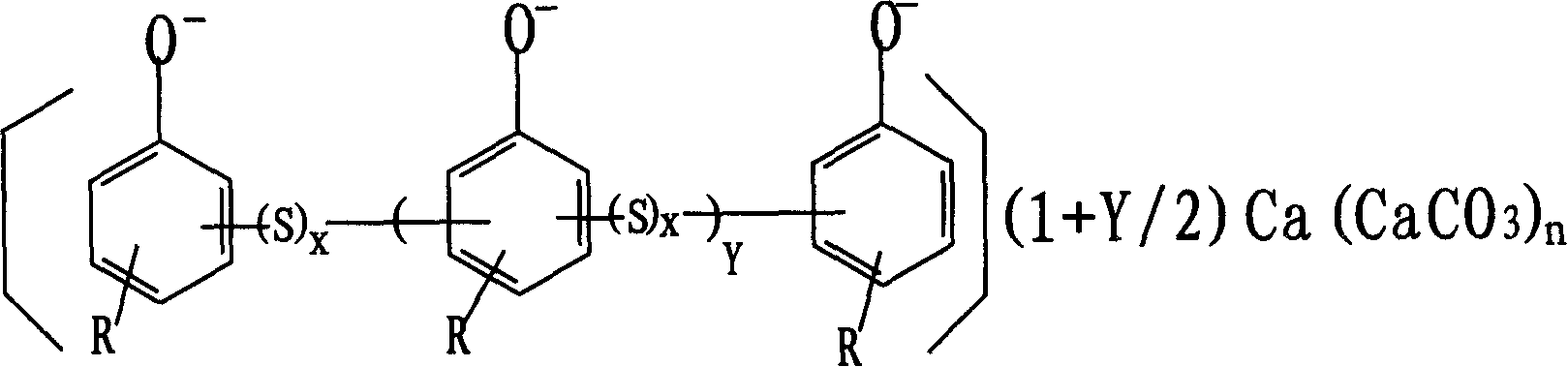

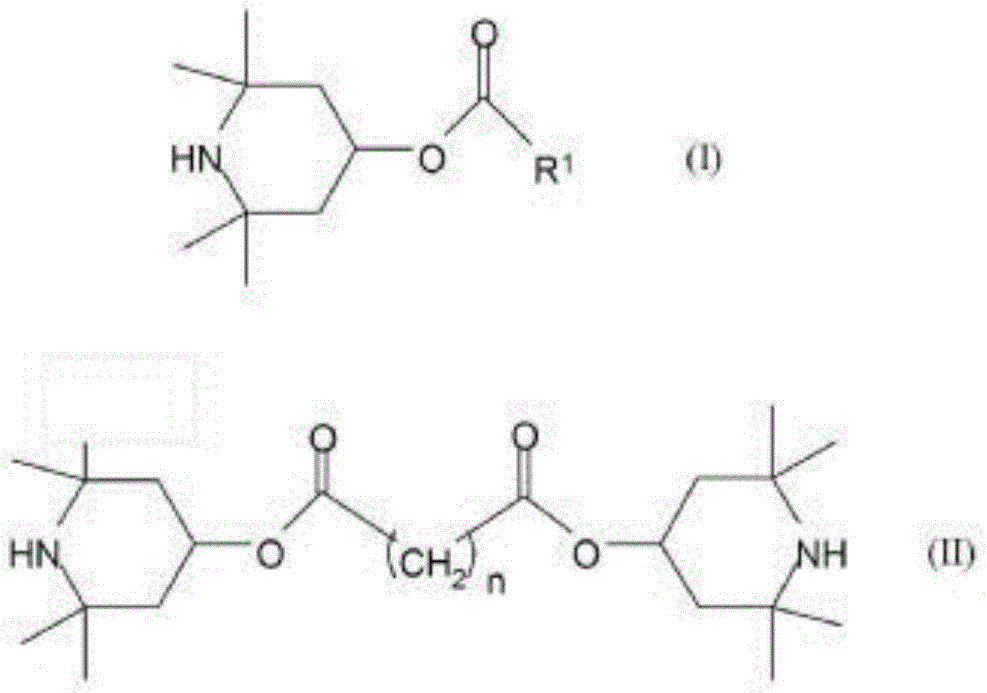

High basic value (TBN400) sulfurized calcium alkyl and preparation method thereof

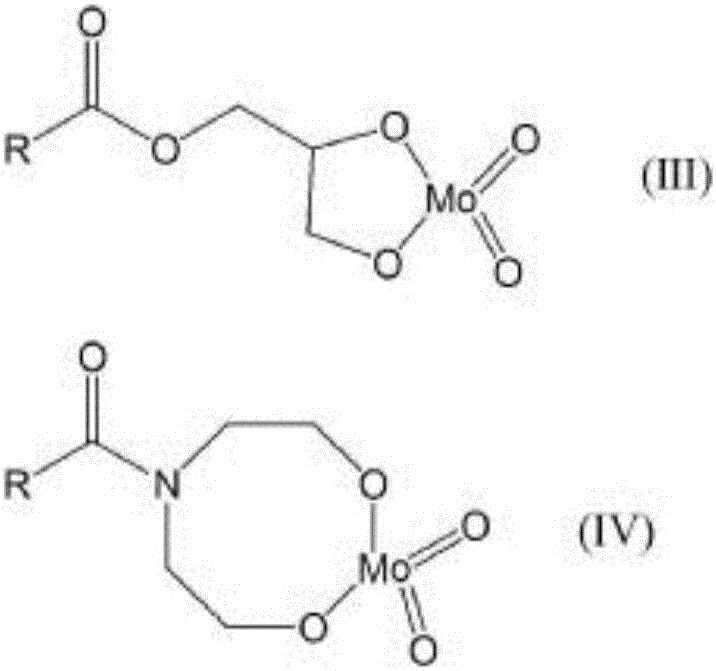

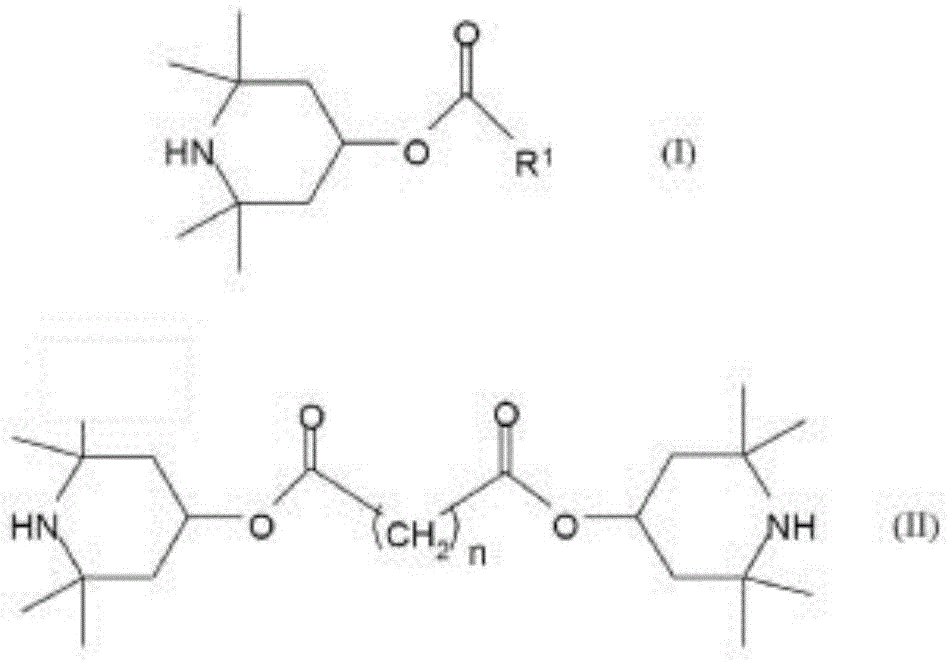

ActiveCN101423483AWide range of usesImprove performanceAdditivesHydropoly/poly sulfide preparationChemical structureCarboxylic acid

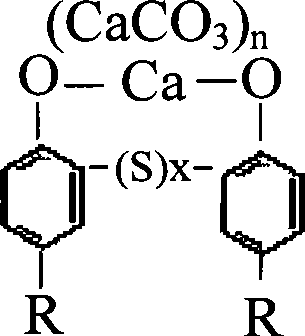

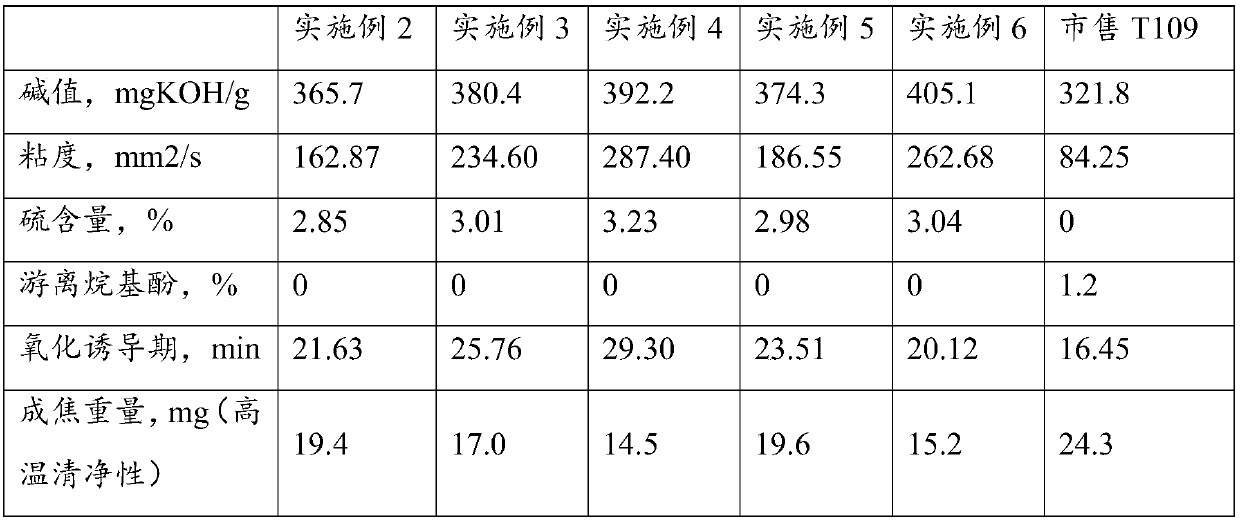

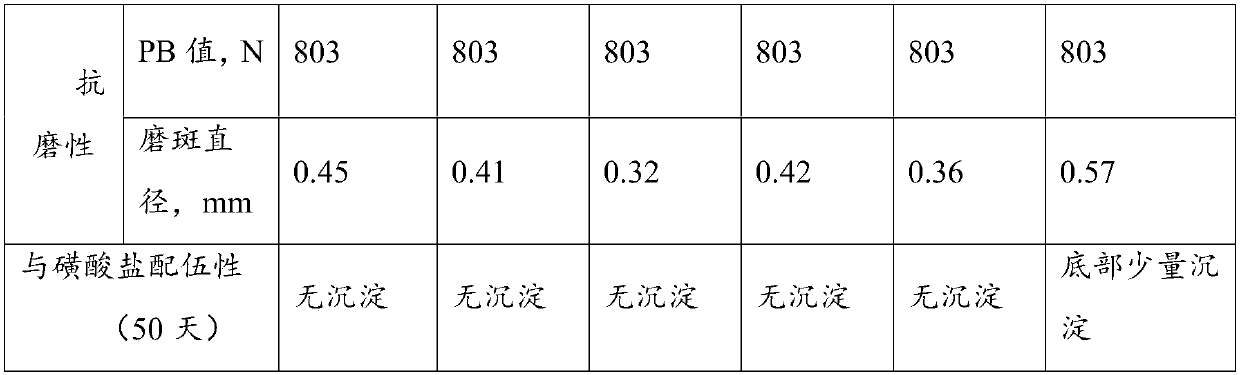

The invention relates to high base number (TBN400) vulcanized alkyl phenol calcium and a preparation method thereof. The vulcanized alkyl phenol calcium has a chemical structure as right. The preparation method is as follows: in a system containing solvent and diluent oil, alkyl phenol compound, shielded phenol compound, calcium oxide and / or calcium hydroxide and sulfur are subjected to sulfonation / neutralization reaction at a temperature of between 60 and 180 DEG C to generate phenolate intermediate; balanced calcium oxide and / or calcium hydroxide are added into the mixture, carbon dioxide is introduced, and the mixture is subjected to carbonation reaction; and alkyl polylol is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, long-chain carboxylic acid is added into the mixture at the sulfonation / neutralization reaction or respectively at the sulfonation / neutralization reaction and the carbonation reaction to participate in the reaction, and products are obtained through refining. The vulcanized alkyl phenol calcium has the characteristics of high base number, low viscosity, low precipitation number, good heat storage stability, and the like, and has excellent combination property, does not cause environmental protection problem during use, and belongs to an environment-friendly product, and adopts a one-stage process, has mild reaction conditions, and is easy to filter.

Owner:JINZHOU DPF TH CHEM CO LTD

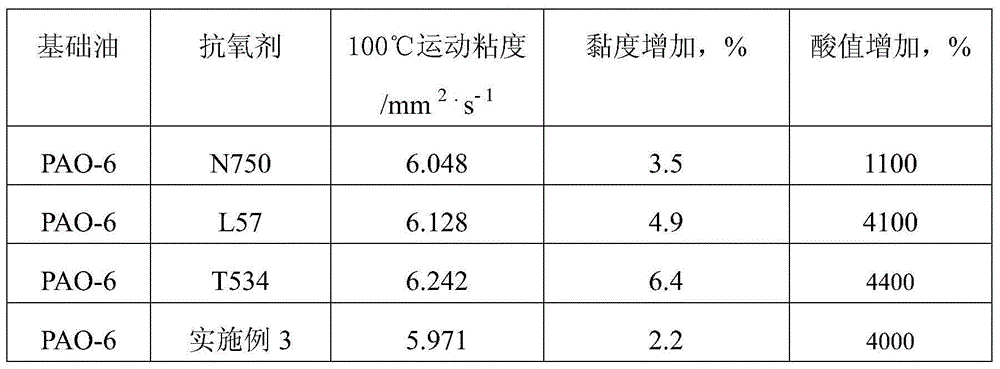

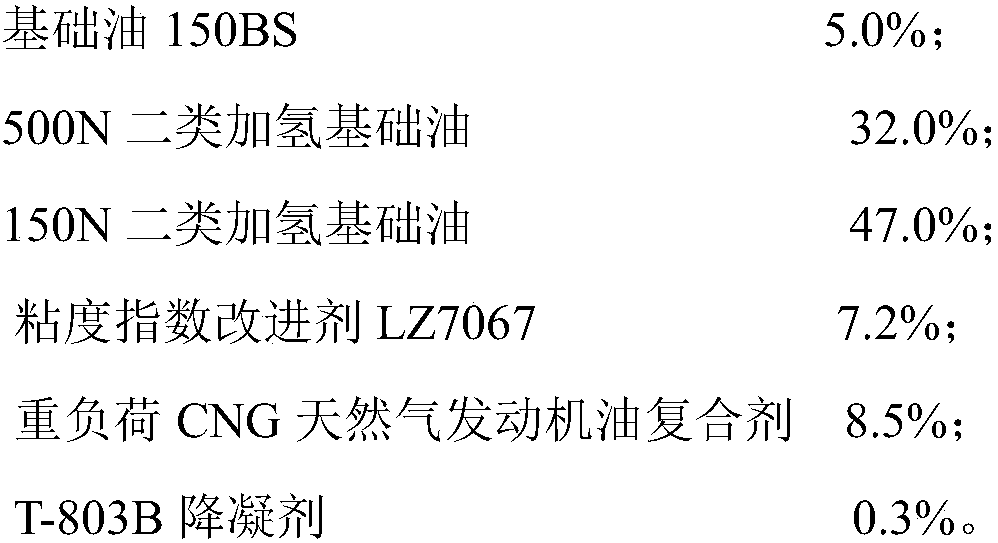

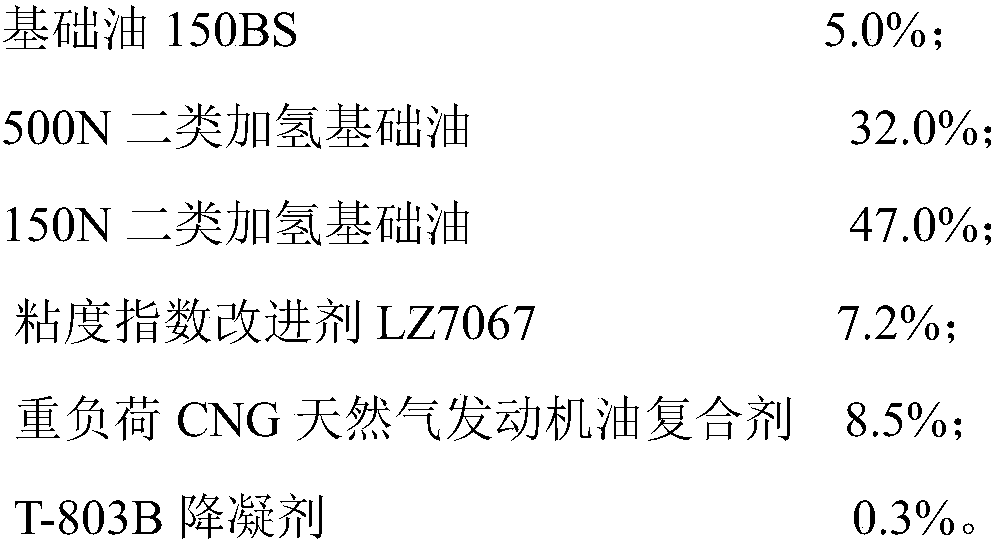

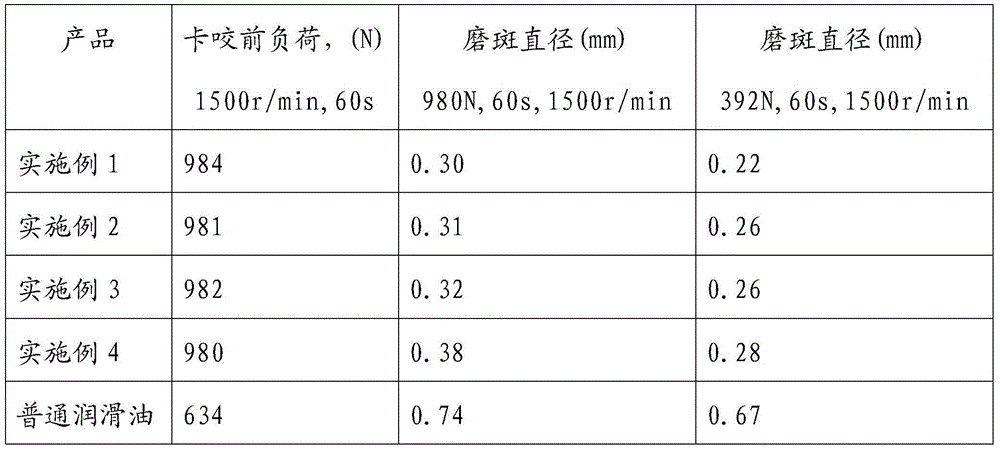

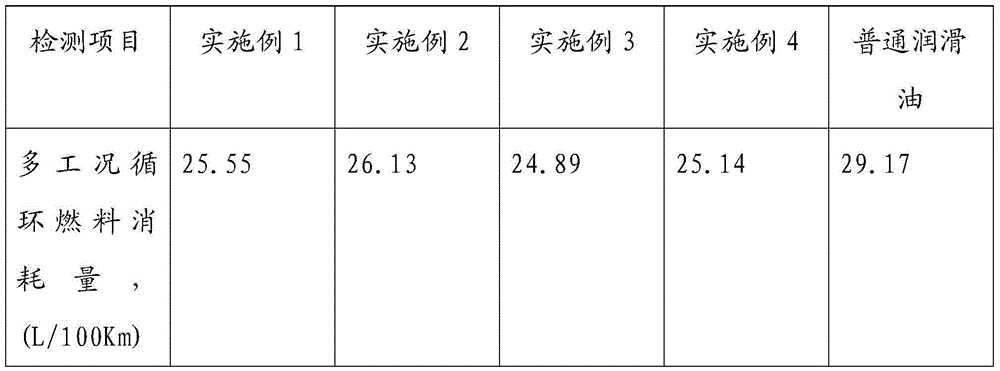

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

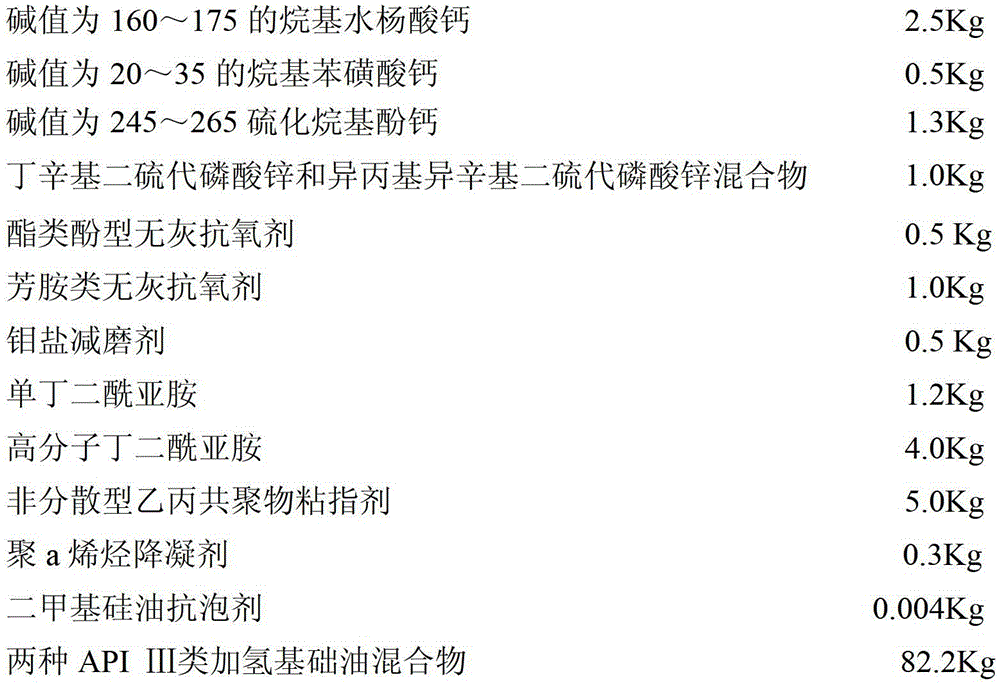

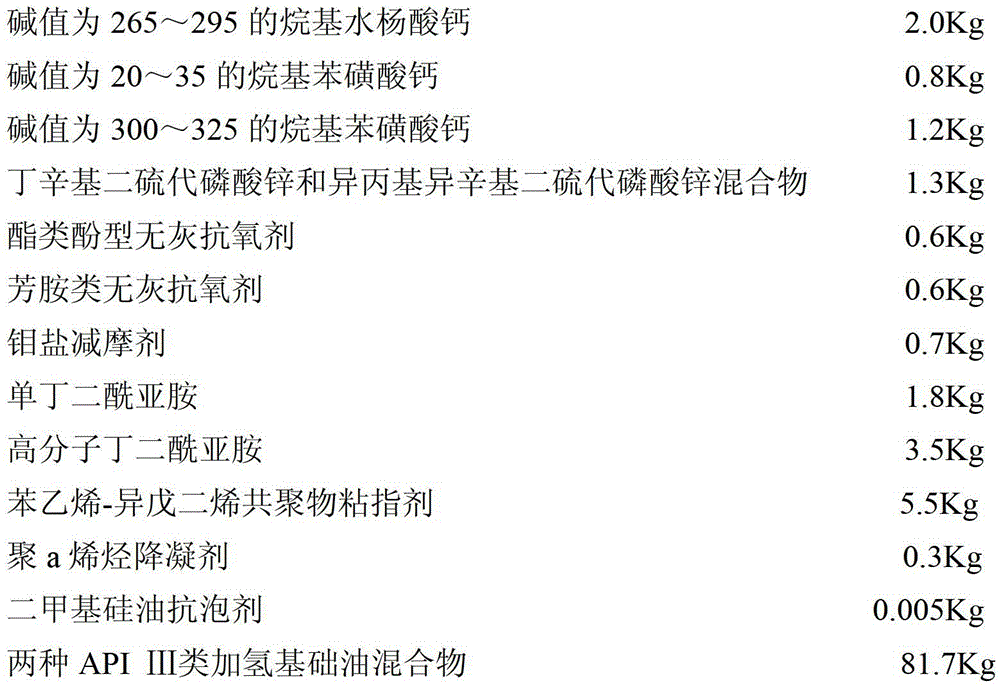

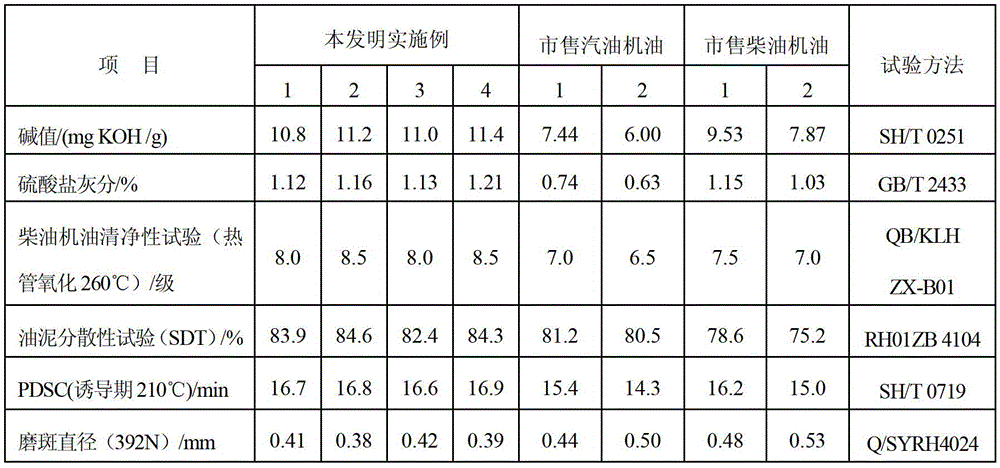

Light-duty diesel oil/gasoline car engine lubricating oil composition

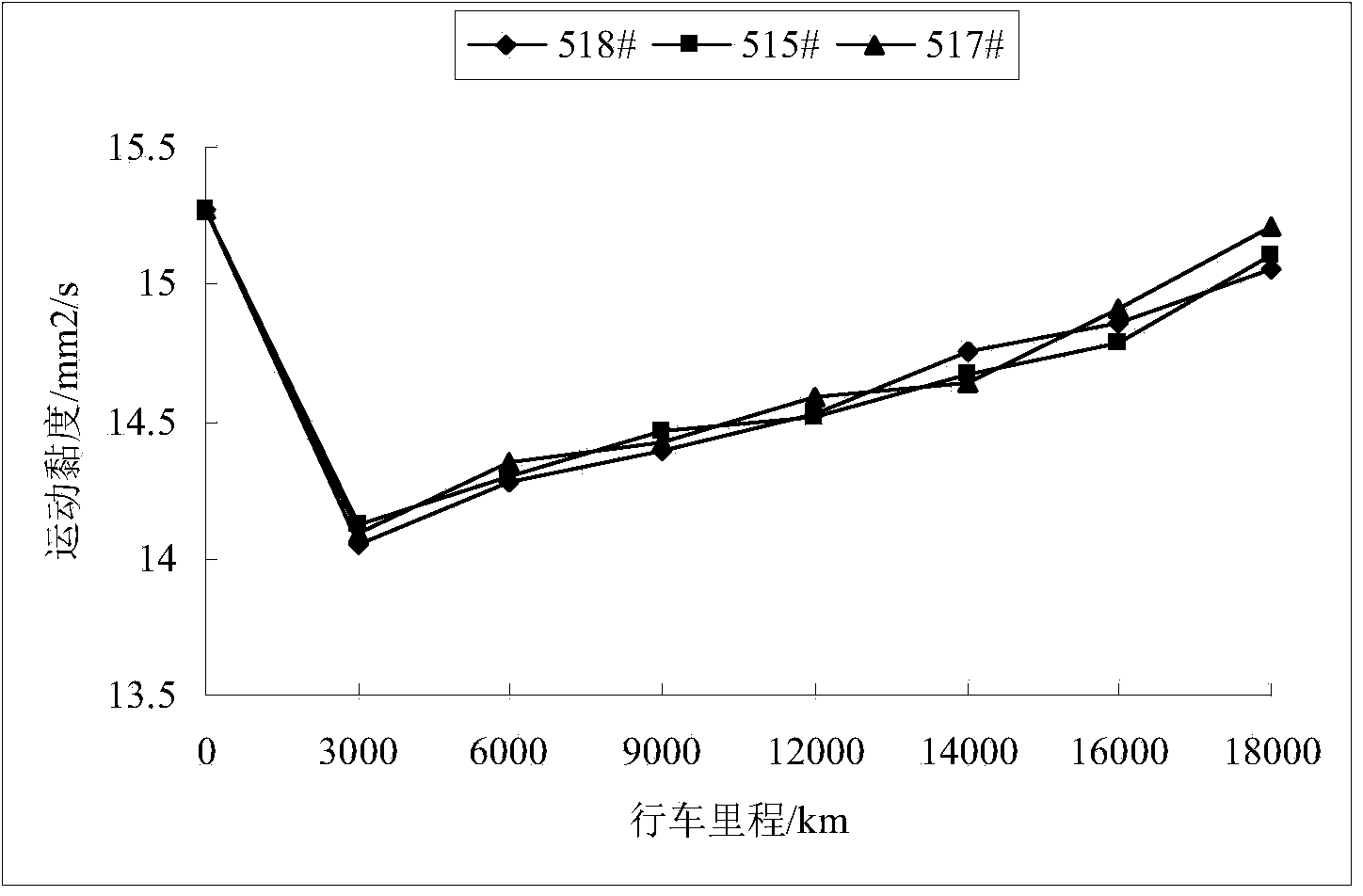

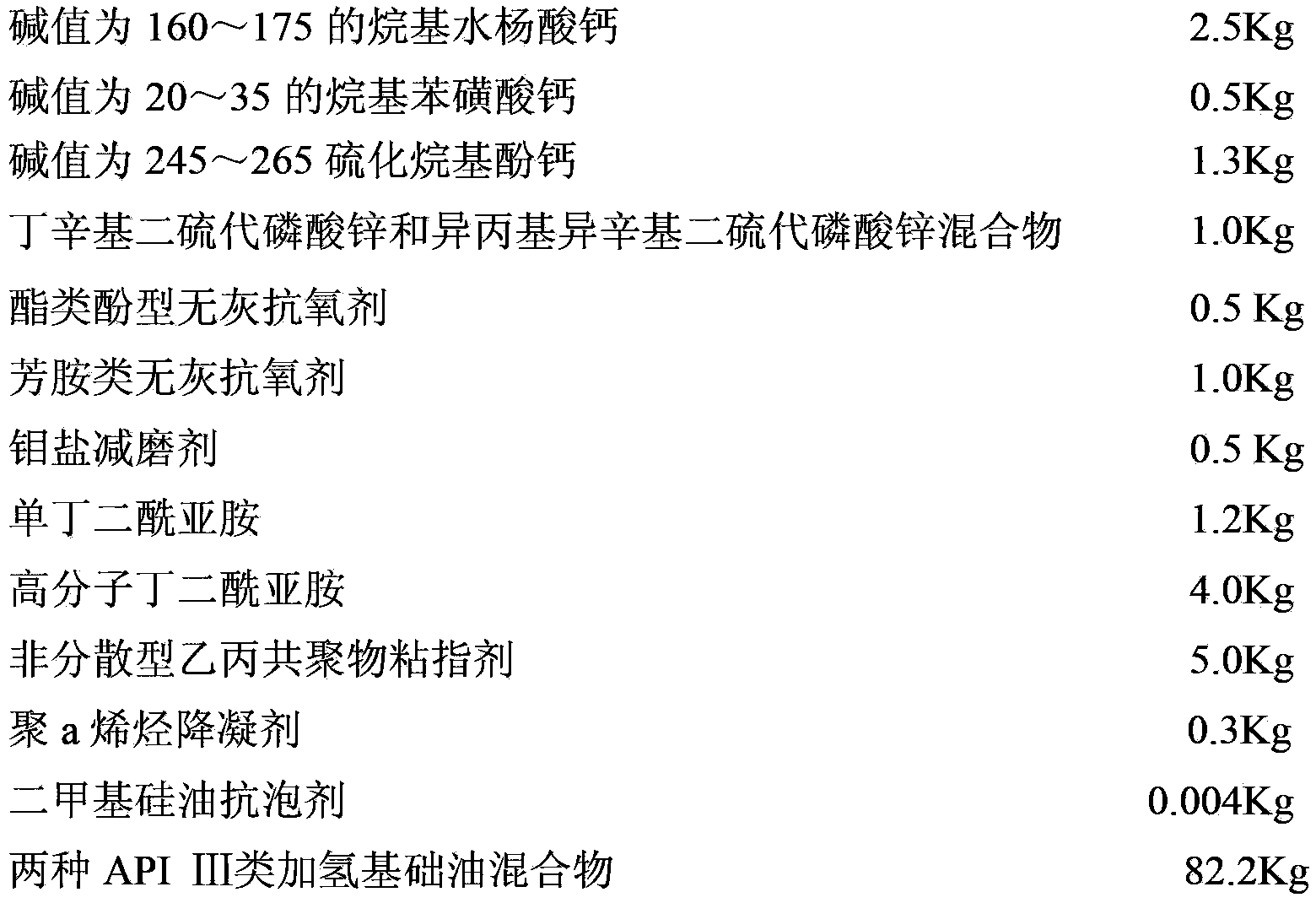

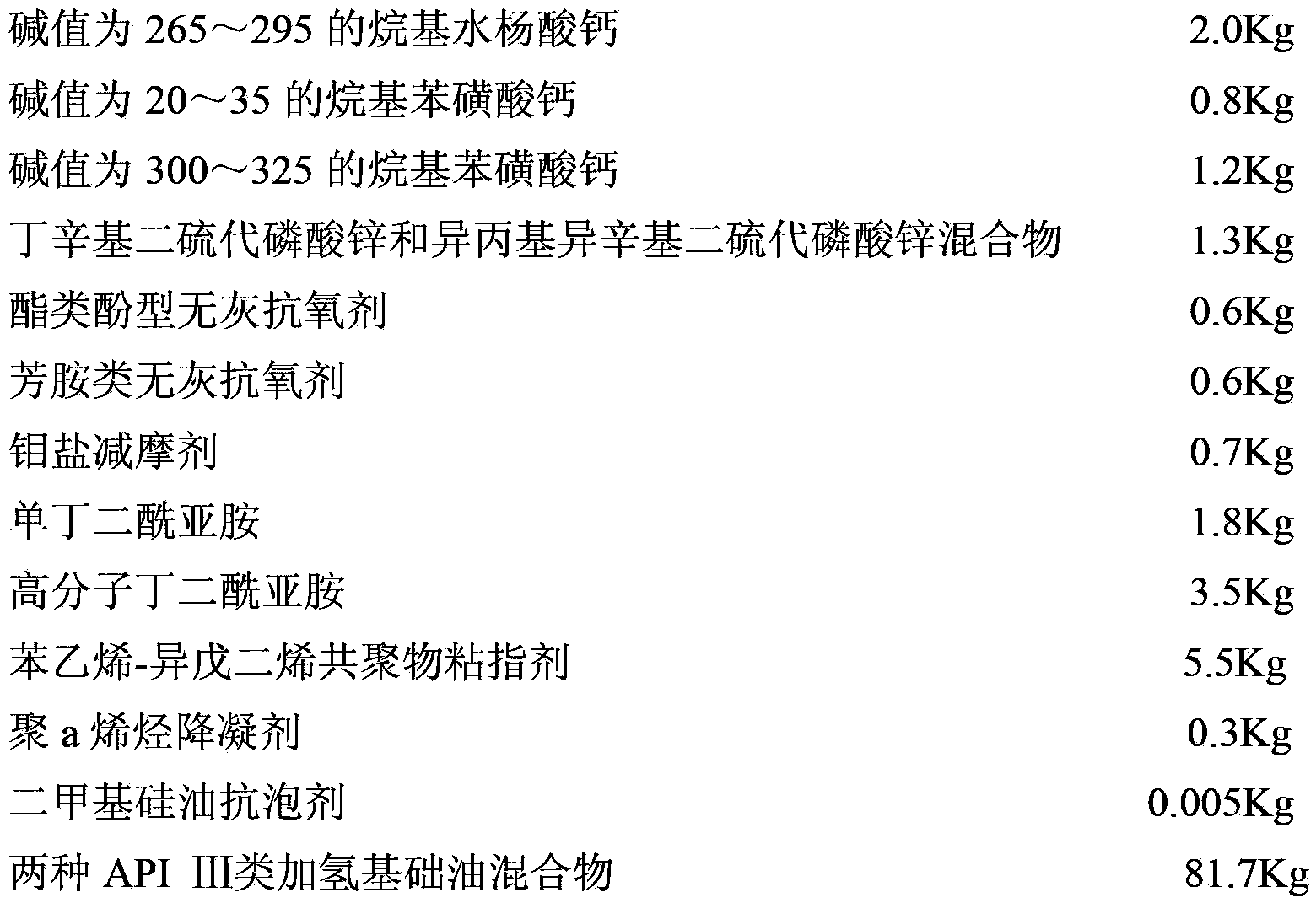

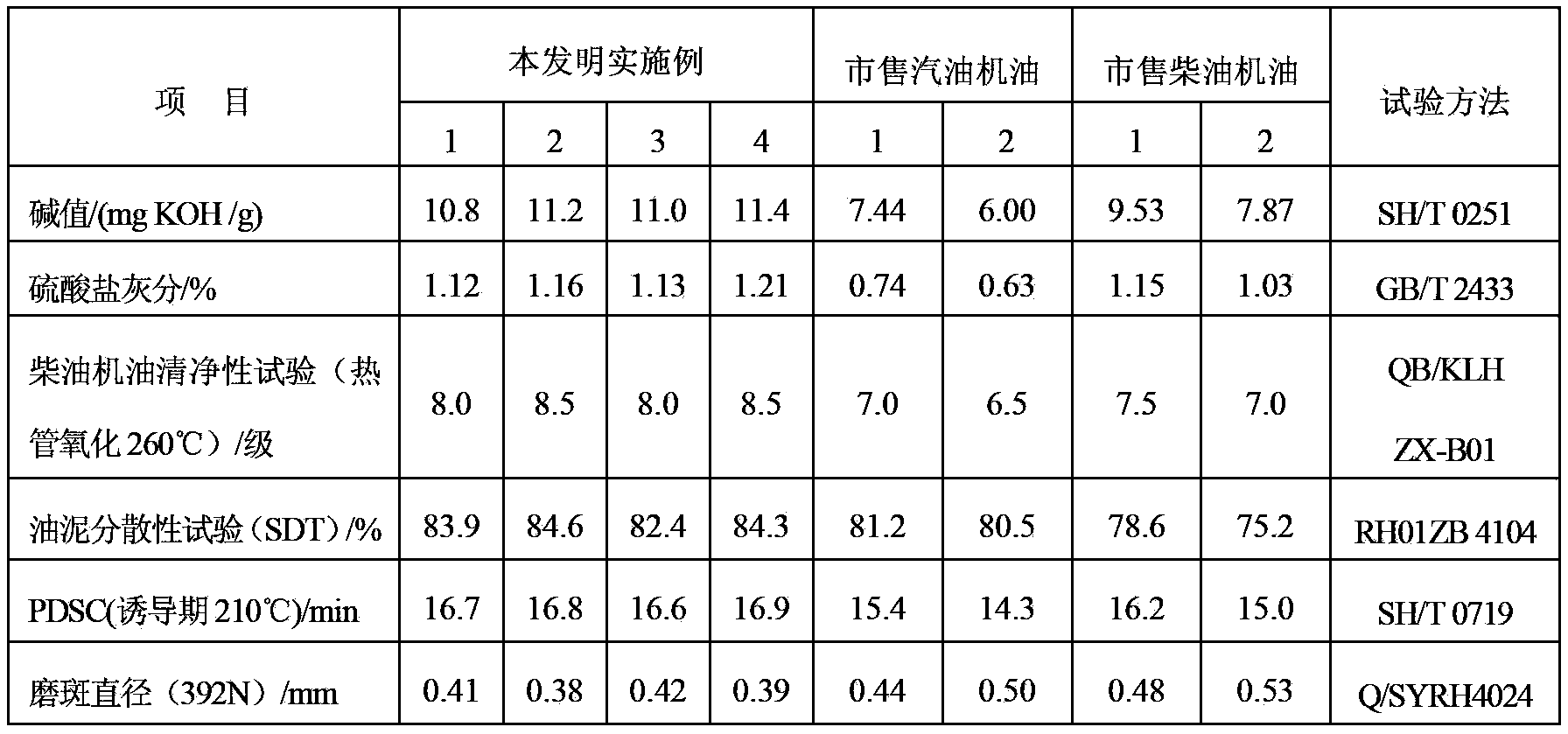

ActiveCN104046418AExcellent anti-oxidation and anti-wear propertiesExcellent medium and low temperature dispersibilityLubricant compositionFoaming agentChemical composition

The invention discloses an engine lubricating oil composition. The engine lubricating oil composition has quality satisfying ACEA-2010A3 / B4 and SAEJ300 specification requirements, is suitable for lubricating a light-duty diesel oil / gasoline car engine under harsh conditions and is especially suitable for lubricating a direct injection light-duty diesel oil / gasoline engine having turbocharging. The engine lubricating oil composition has excellent oxidation and wear resistance, middle / low temperature dispersibility and high temperature detergency, a high base number and strong alkali maintenance capability, can effectively inhibit high-temperature piston deposit generation, can prevent piston adhesion to a ring, has a long oil change period and can provide full lubricating protection on the engine. The engine lubricating oil composition comprises at least two metal detergents, two ashless dispersants, three antioxidant, anticorrosive and antiwear agents, a viscosity index improver, a pour point depressant, an anti-foaming agent and two base oil.

Owner:PETROCHINA CO LTD

High-base number metal detergent and preparation method thereof

ActiveCN102071085AExcellent antioxidant stabilityWide range of usesAdditivesCalcium hydroxideHydrocarbon solvents

The invention relates to a high-base number metal detergent and a preparation method thereof. The preparation method comprises the following steps of: mixing and performing a neutralization reaction on a hydrocarbon solvent, neutral oil, naphthenic acid, water, alkylphenol and calcium hydroxide and / or calcium oxide; and adding methanol and the calcium hydroxide and / or the calcium oxide; introducing carbon dioxide to perform a carbonation reaction twice; and obtaining a product through an aftertreatment process. The product has an ultra-high base number and better anti-oxidation stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

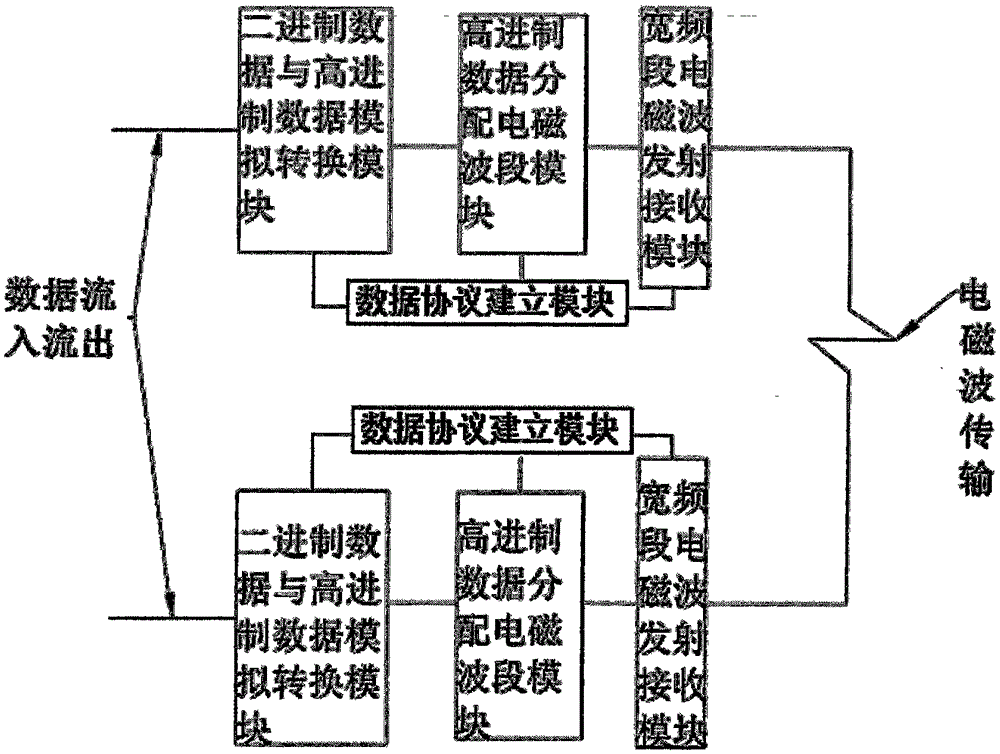

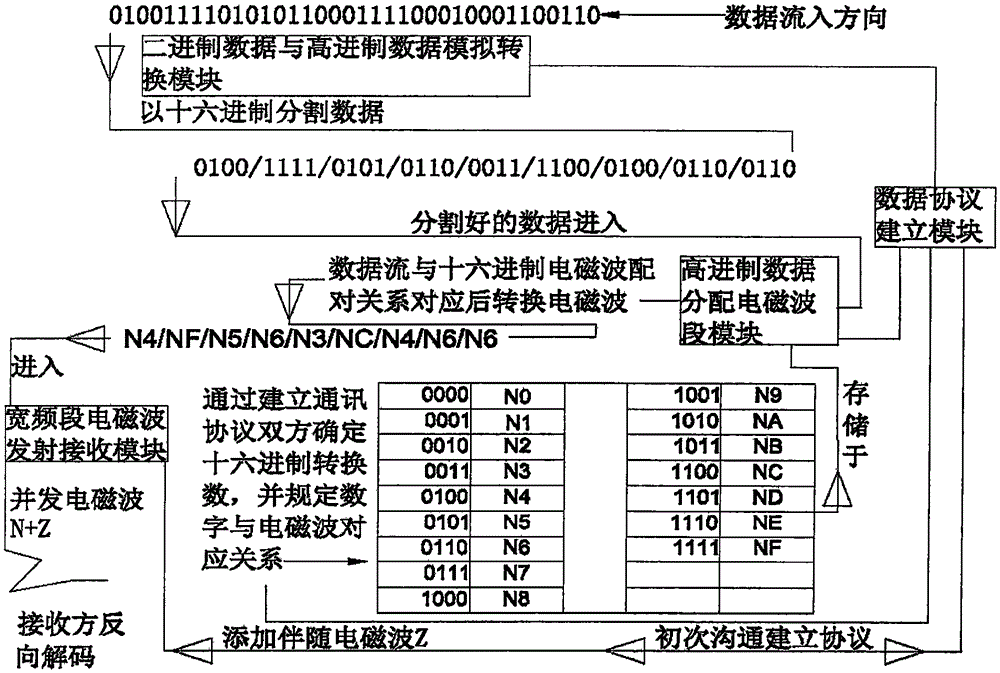

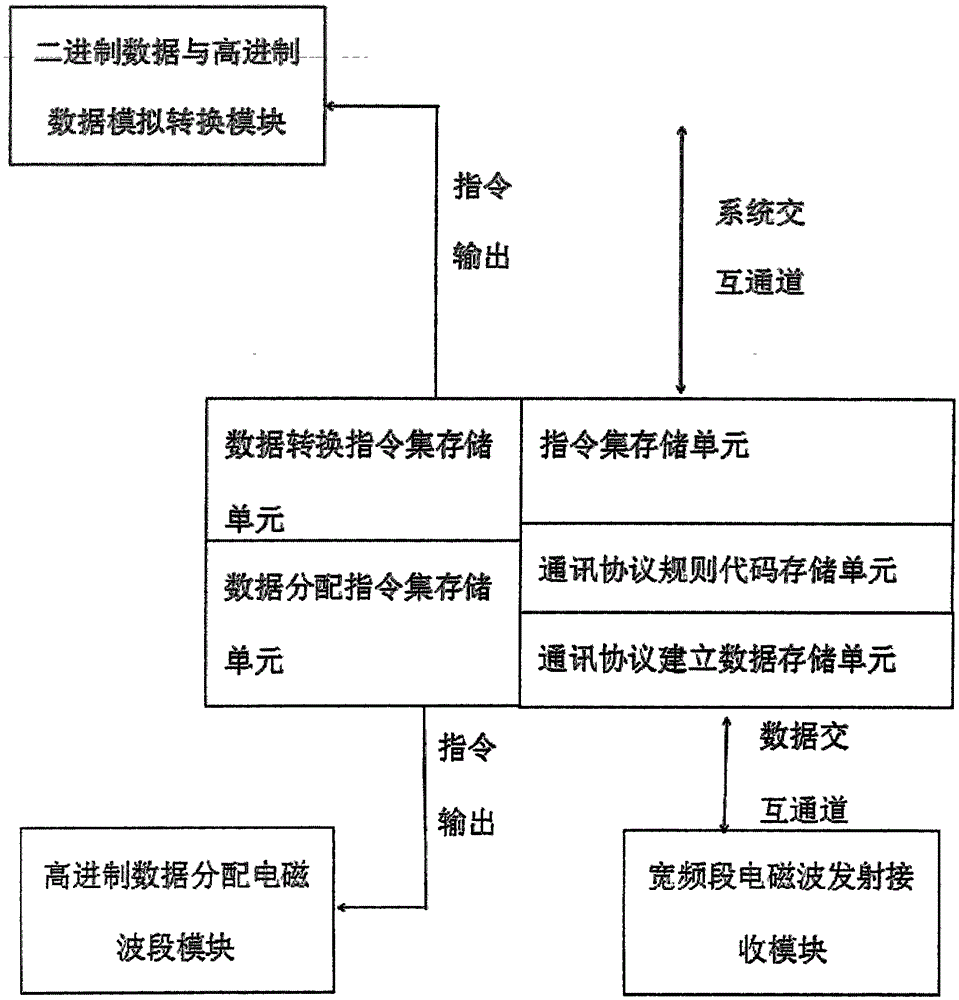

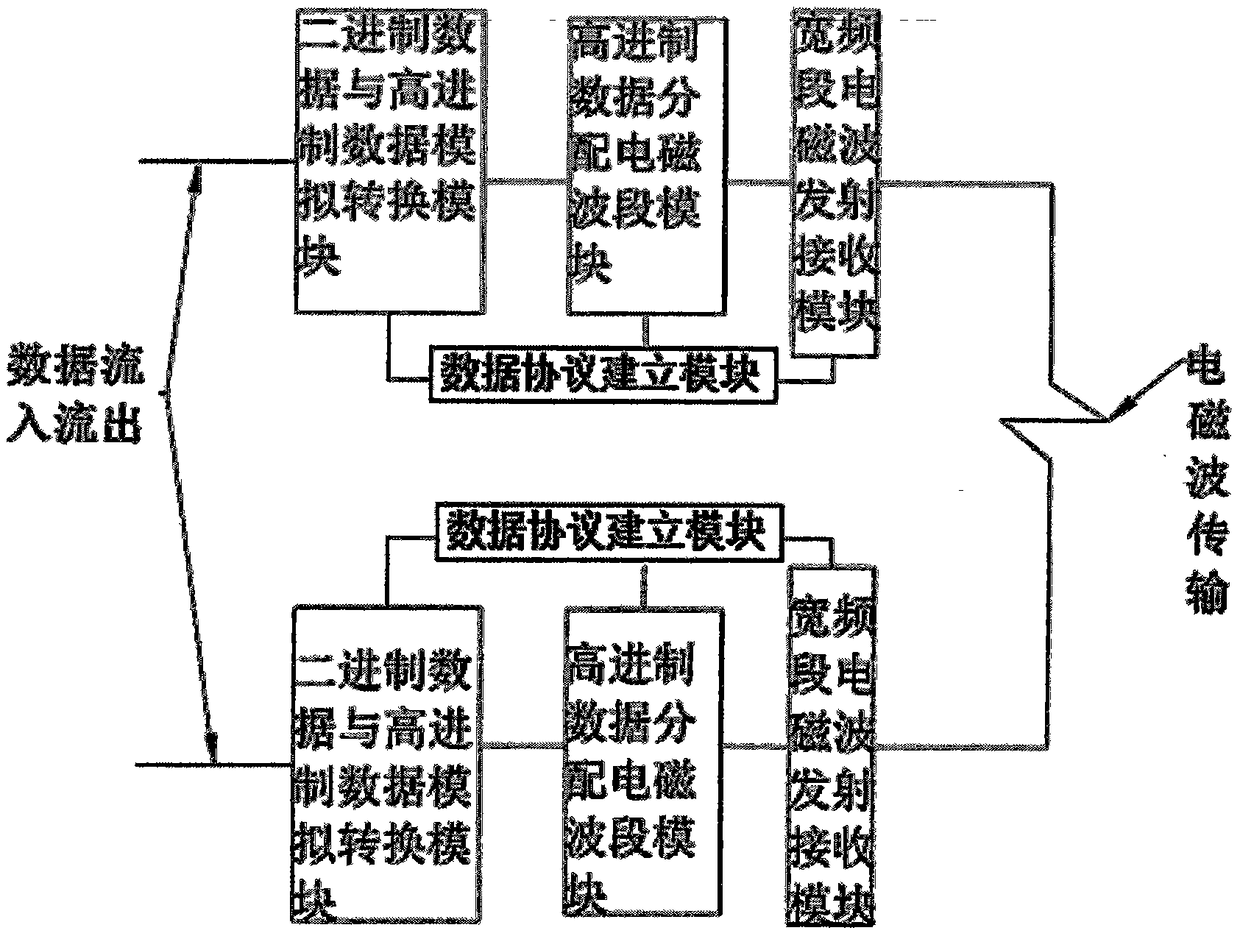

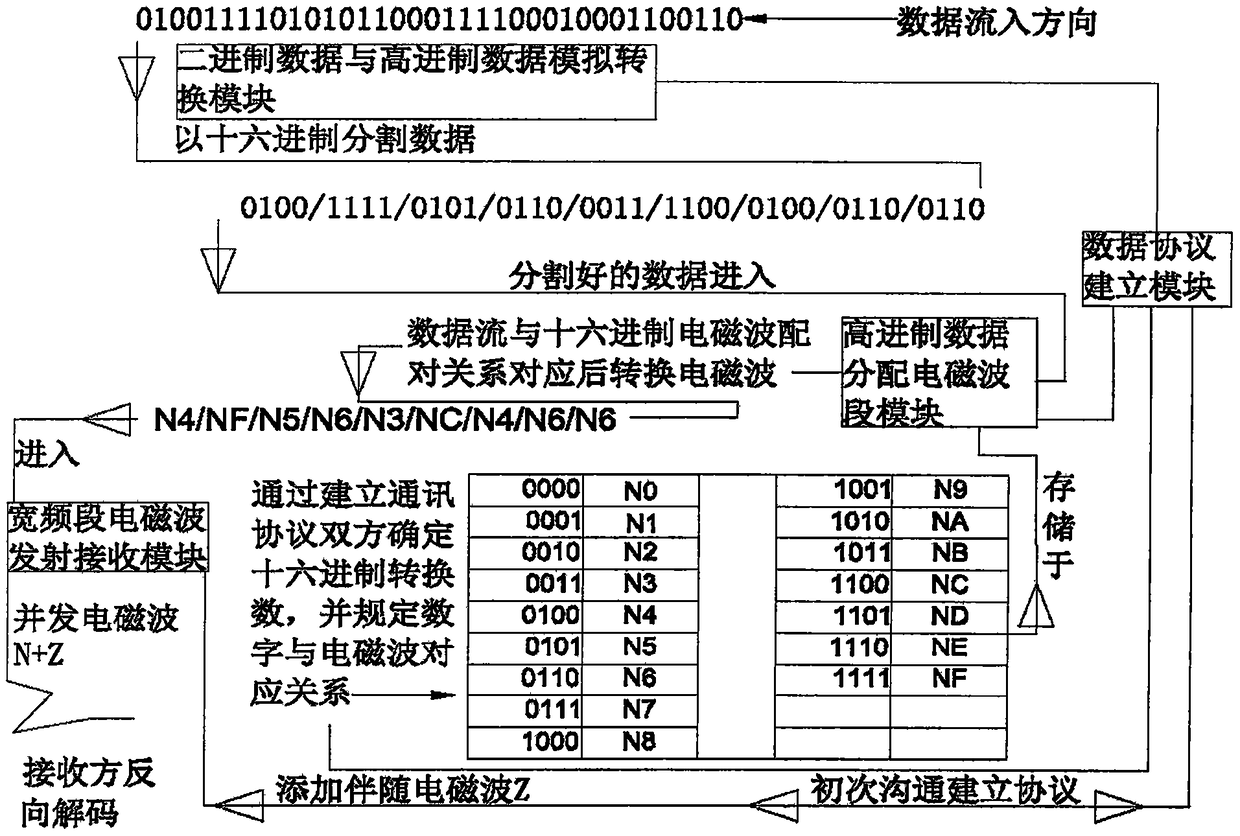

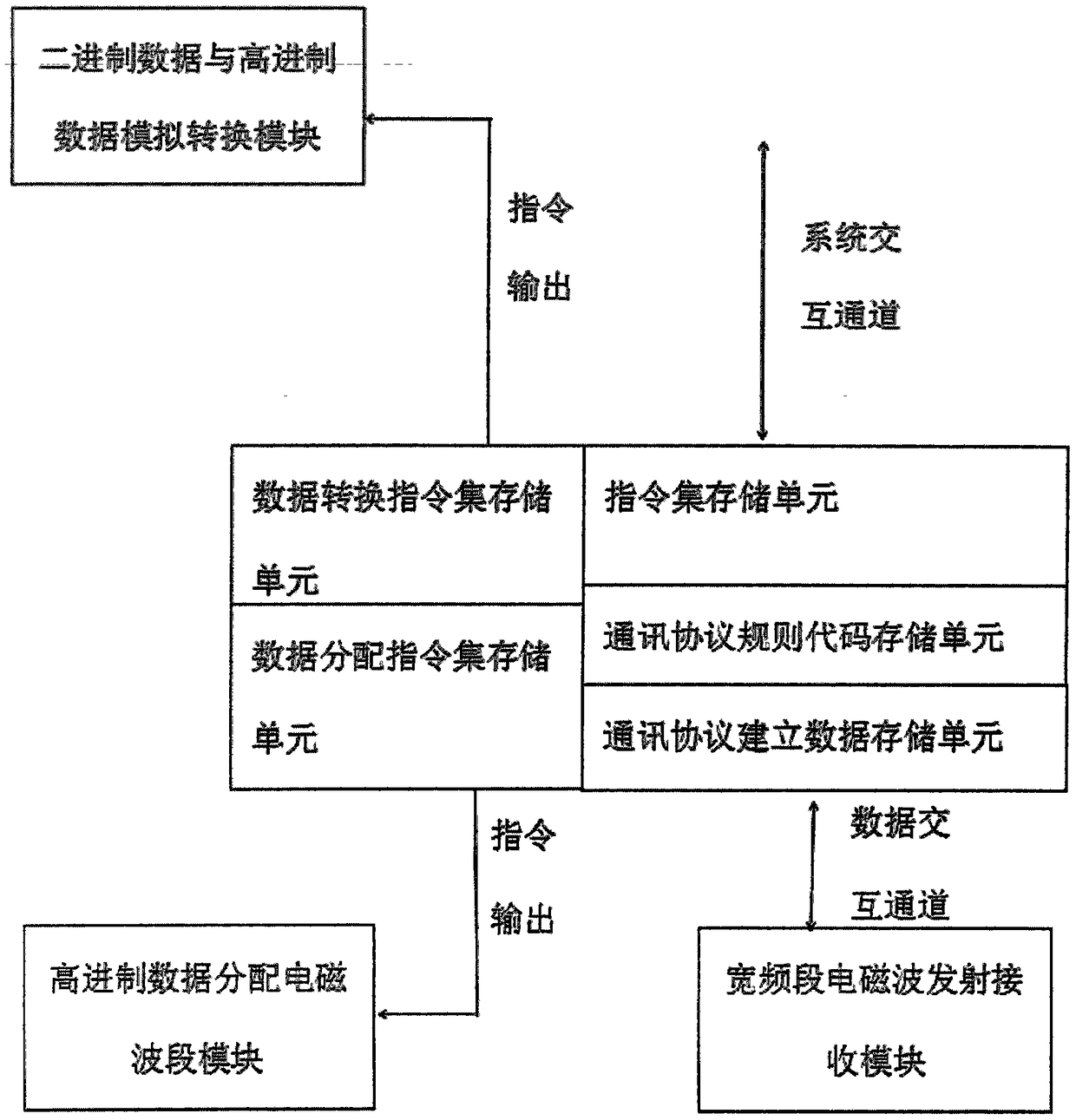

Electromagnetic wave analog digital high band transmission system and transmission method thereof

ActiveCN105634564AReduce signal interferenceReduce energy consumptionNear-field systems using receiversData simulationElectromagnetic electron wave

The invention discloses an electromagnetic wave analog digital high band transmission system and a transmission method thereof. The system is composed of a data protocol building module, a binary data and high band data analog conversion module, a high band data distribution electromagnetic wave band module and a wide band electromagnetic wave transmitting and receiving module. The binary data and high band data analog conversion module comprises a first instruction storage unit, a data analyzing unit and a data overweight and underweight output unit; the computer binary data are equally segmented and converted into ternary and above analog high band data; the data are transmitted by electromagnetic wave bands paired with the analog high band data in the shortest oscillation period; and reverse decoding is carried out to the data so as to reduce the data into binary data. According to the system and the method of the invention, the data signal interference is low; the energy consumption is low; the data transmission quantity is high; and the security is high.

Owner:XUZHOU SPACE TIME THOUGHT INTELLIGENT TECH CO LTD

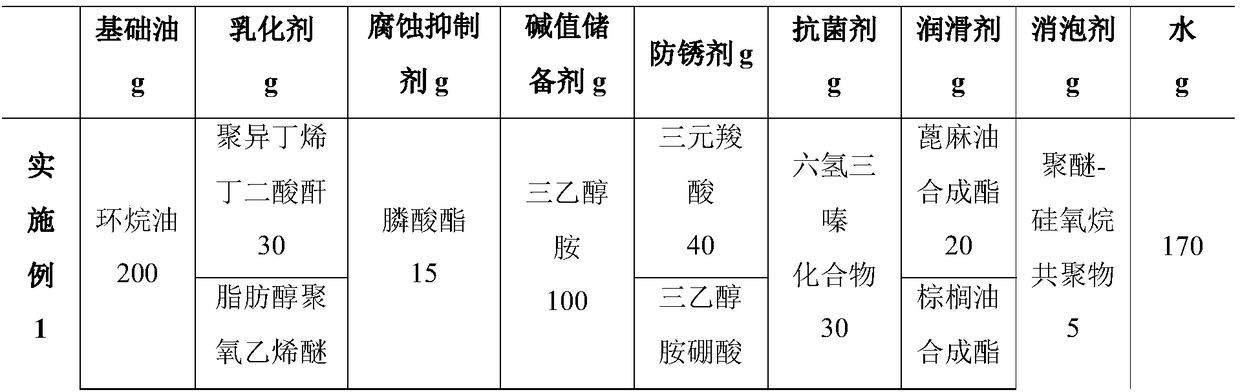

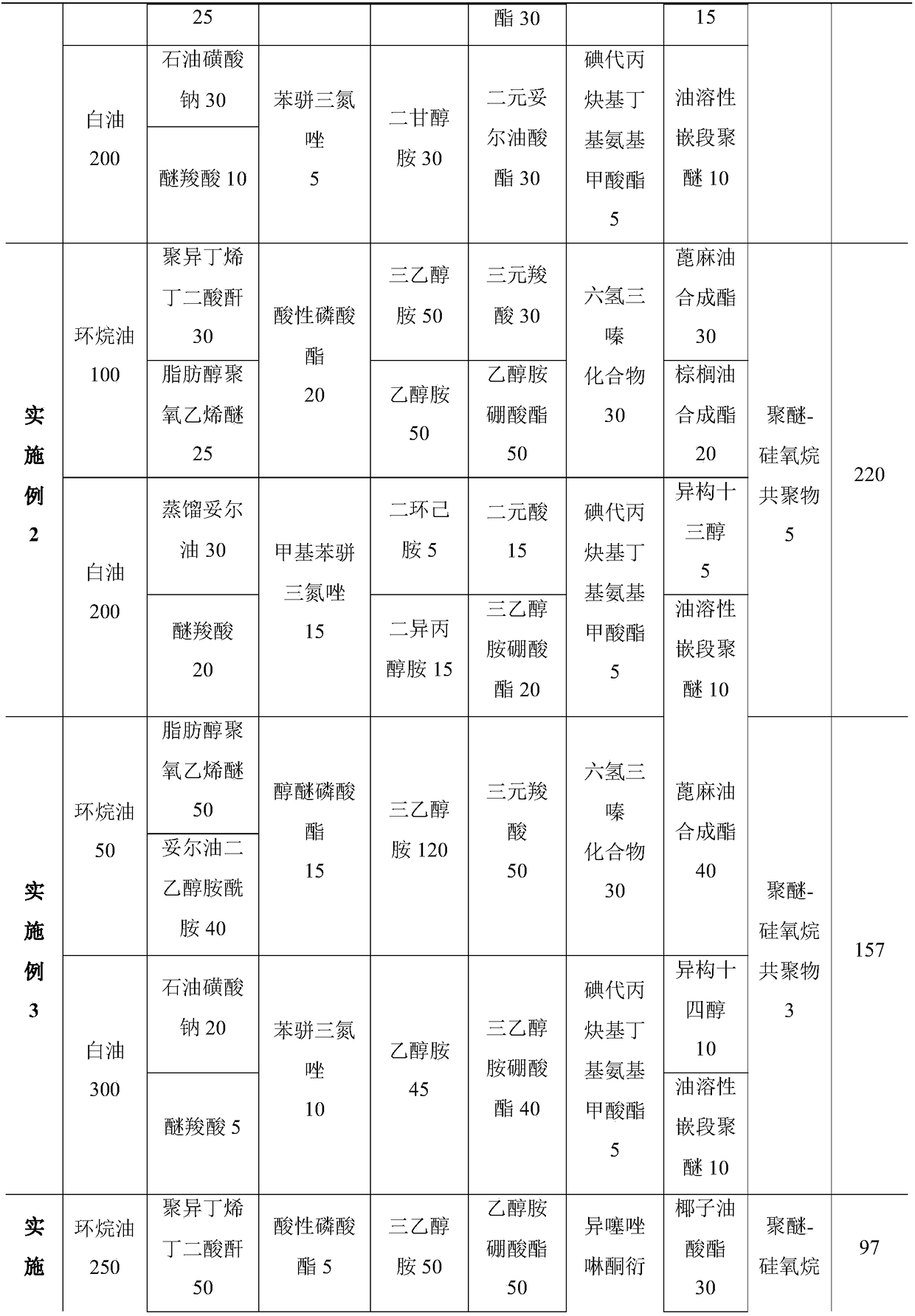

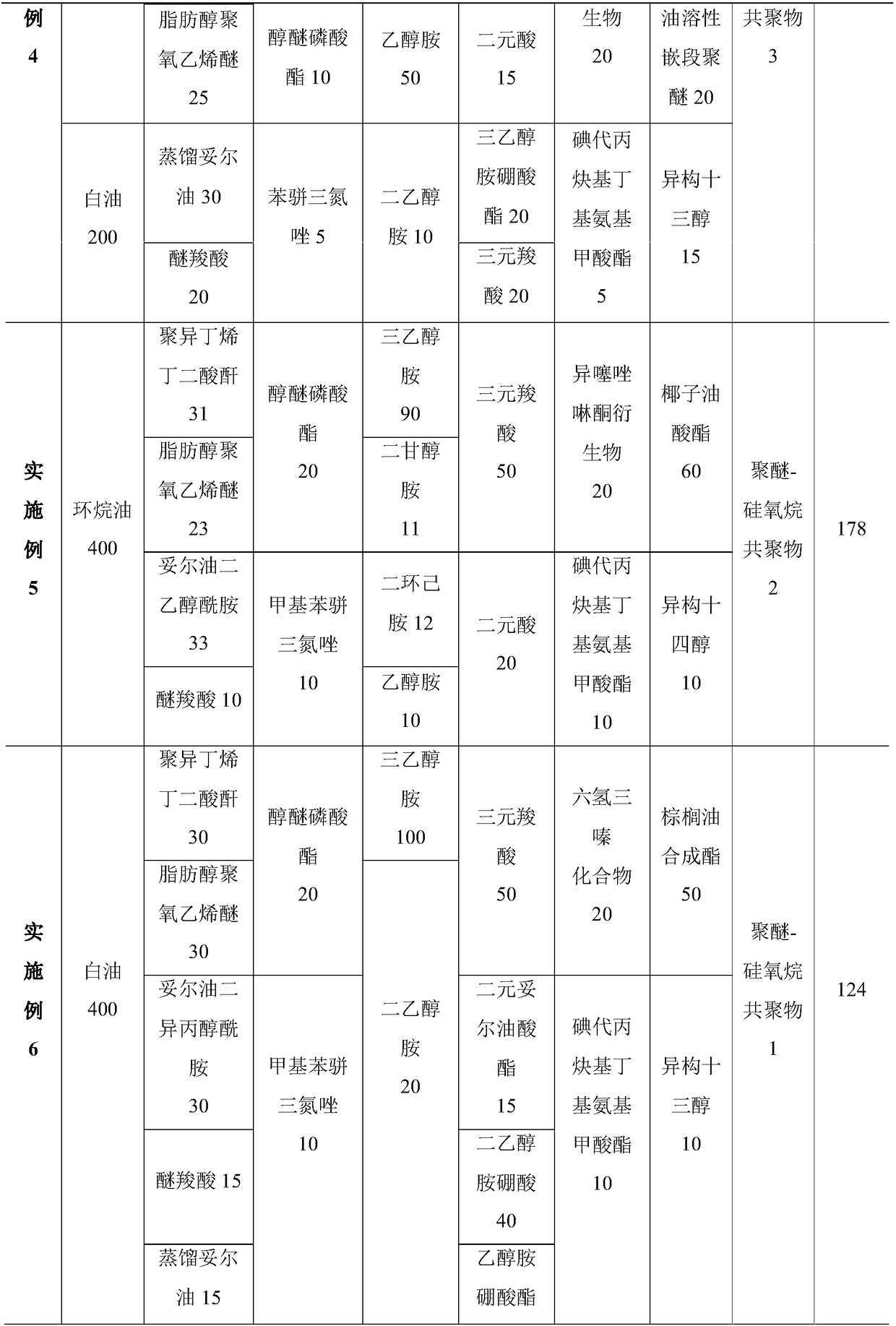

Hard-water-resisting semi-synthetic metal processing fluid and preparation method thereof

The invention provides hard-water-resisting semi-synthetic metal processing fluid and a preparation method thereof. The hard-water-resisting semi-synthetic metal processing fluid is prepared from thefollowing components in parts by weight: 25 to 60 parts of basic oil, 3 to 20 parts of emulsifier, 3 to 20 parts of antirust agent, 2 to 6 parts of corrosion inhibitor, 5 to 30 parts of alkali value storage agent and 8 to 40 parts of water. The hard-water-resisting semi-synthetic metal processing fluid provided by the invention has the advantages of good hard water stability and excellent antirustperformance, safe and odorless working environment and no irritation on human body skin and respiratory tracts.

Owner:超滑科技(佛山)有限责任公司

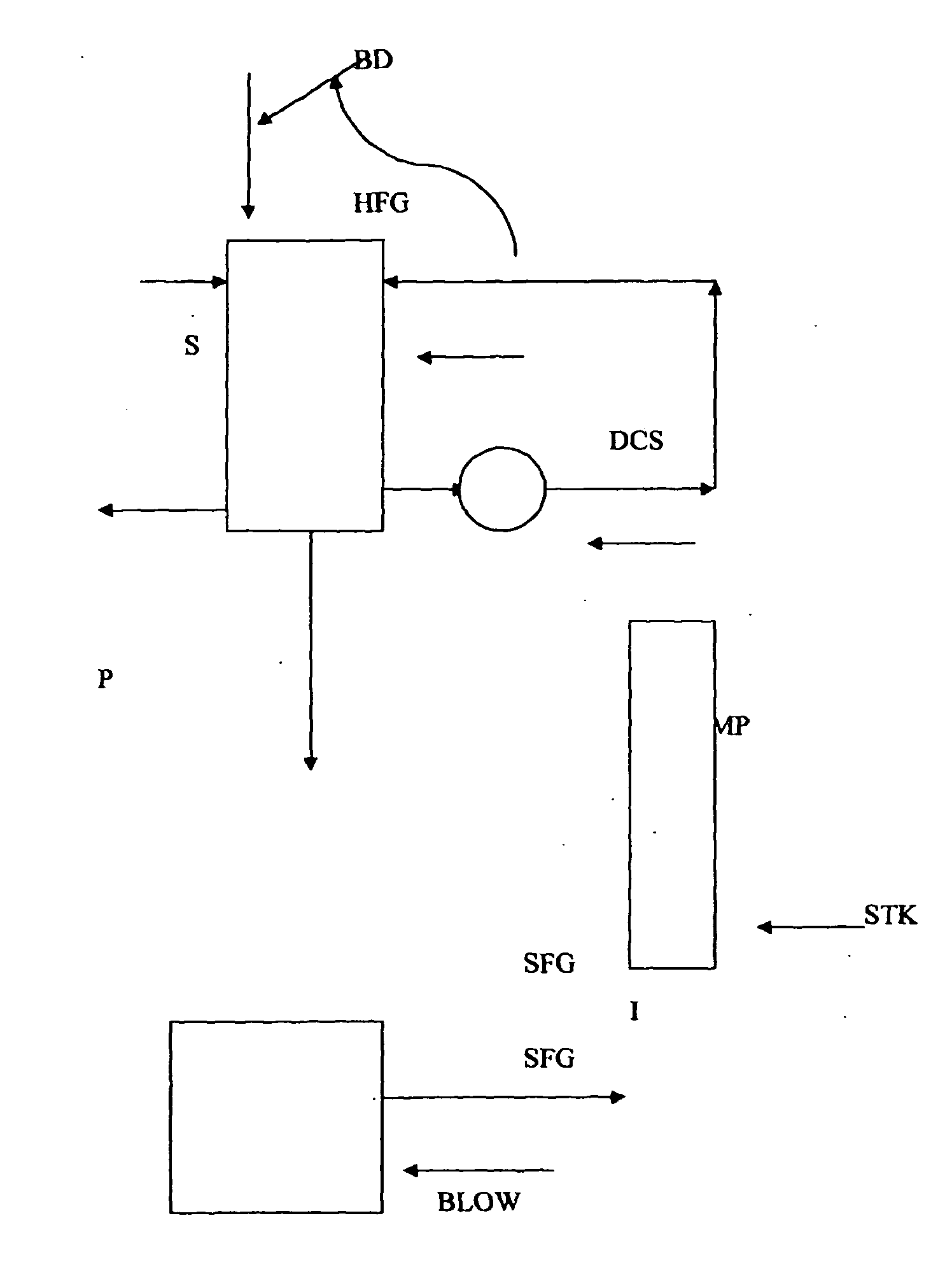

Process and system for quenching heat, scrubbing, cleaning and neutralizing acidic media present in the flue gas from the firing of fossil fuel

InactiveUS20120285353A1High base numberStrong alkalineUsing liquid separation agentSolid fuel combustionAlkalinityNuclear engineering

The present invention provides a novel process for quenching heat, scrubbing, cleaning and neutralizing the hot and dirty fossil fuel fired flue gas liberated by a fossil fuel fired boiler using the high temperature and high pressure present in fossil fuel fired boiler blow-down comprising the steps of quenching the fossil fuel fired flue gas by evaporating sufficient quantity of water from sea water / scrubbing liquid and mixing vapors thus generated with hot and dirty flue gas; using the high temperature and high pressure present in fossil fuel fired boiler blow-down (waste water) for atomizing / spraying high alkalinity sea water / scrubbing liquid on said flue gas to neutralize the acidic substances in said flue gas.

Owner:KUMAR SUBRAHMANYAM

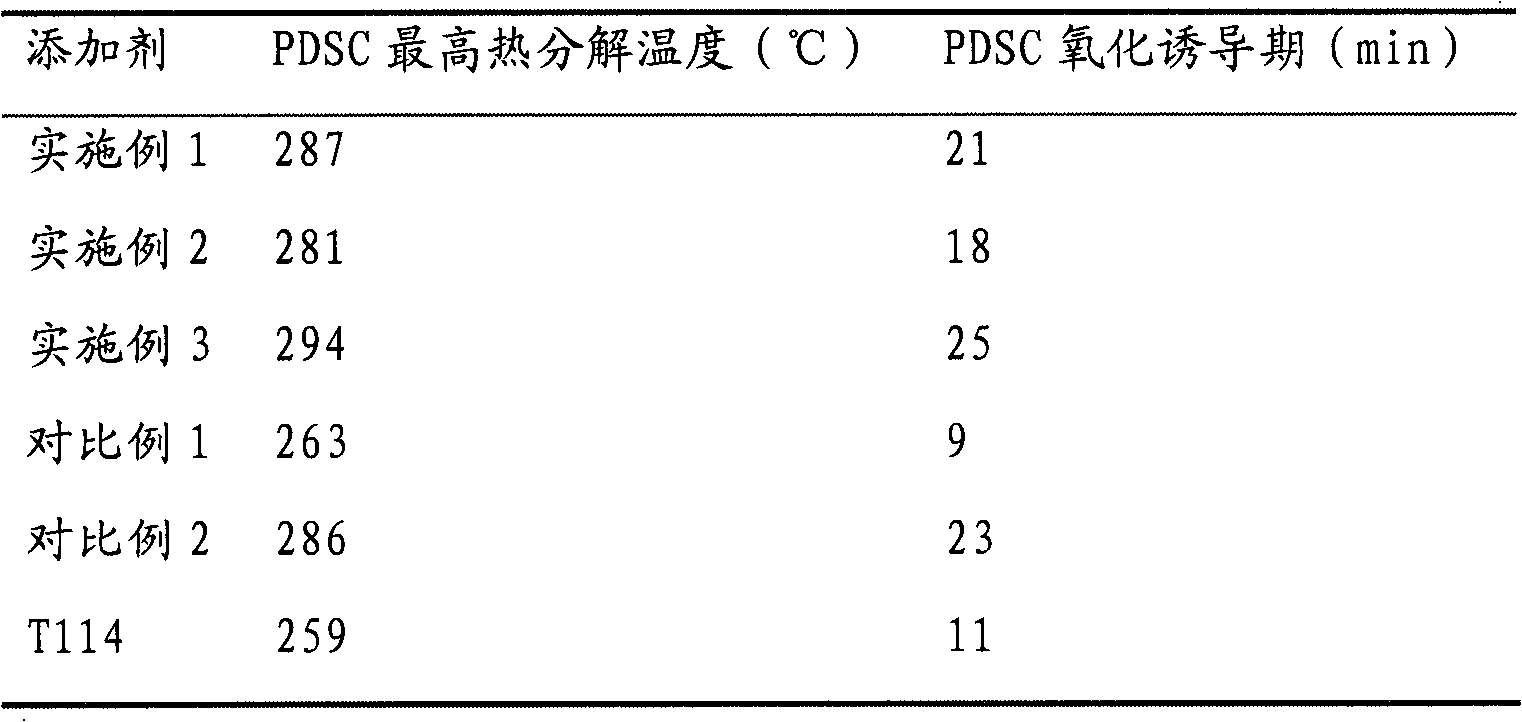

Polyolefinn succinimide ashless dispersing agent, preparation method and applications thereof

The present invention discloses a polyolefin succinimide ashless dispersing agent, a preparation method and applications thereof. The preparation method comprises: a) carrying out a reaction on maleic anhydride and alpha-olefin in the presence of a solid acid catalyst and an optionally added or optionally being not added solvent to produce polyolefin succinic anhydride; and b) carrying out an amidating reaction on the polyolefin succinic anhydride and polyethylenepolyamine until no water is separated so as to obtain the polyolefin succinimide ashless dispersing agent. According to the present invention, the reaction is catalyzed by using the solid acid catalyst, such that the reaction product is easily separated from the catalyst so as to substantially simplify the reaction post-treatment; the catalyst has characteristics of wide source, low cost, and easy obtaining; the operation of the production process is simple, and the safety of the process is high; and the obtained polyolefin succinimide ashless dispersing agent has the high base value, can be used in the lubricant compositions, and can effectively improve the dispersibility and the cleaning performance of the compositions.

Owner:江西福安路润滑材料有限公司

Isostearic acid composite metal salt clearing agent and preparation method thereof

The invention belongs to the field of chemical engineering, particularly relates to an isostearic acid composite metal salt clearing agent, and further discloses a preparation method of the isostearic acid composite metal salt clearing agent. The isostearic acid composite metal salt clearing agent is prepared from, by weight, 0.5-2 parts of isostearic acid, 1.5-3 parts of pentaerythrityl tetraethylhexanoate base oil, 0.5-3 parts of calcium oxide, 0.5-3 parts of magnesium oxide, 10-30 parts of solvent, 0.2-1 part of methyl alcohol, 1-8 parts of water and 0.5-4 parts of carbon dioxide. The composite calcium / magnesium salt clearing agent is obtained by fine screening the raw material and ratio of the product with calcium oxide and magnesium oxide as the alkali raw materials; compared with a simplex magnesium salt clearing agent in the prior art, the clearing agent has the advantages of a calcium salt clearing agent and a magnesium salt clearing agent at the same time; the alkali value of the product is further increased, the acid neutralization capacity is higher, and meanwhile the product is better in oil solubility.

Owner:济南佳进新材料有限公司

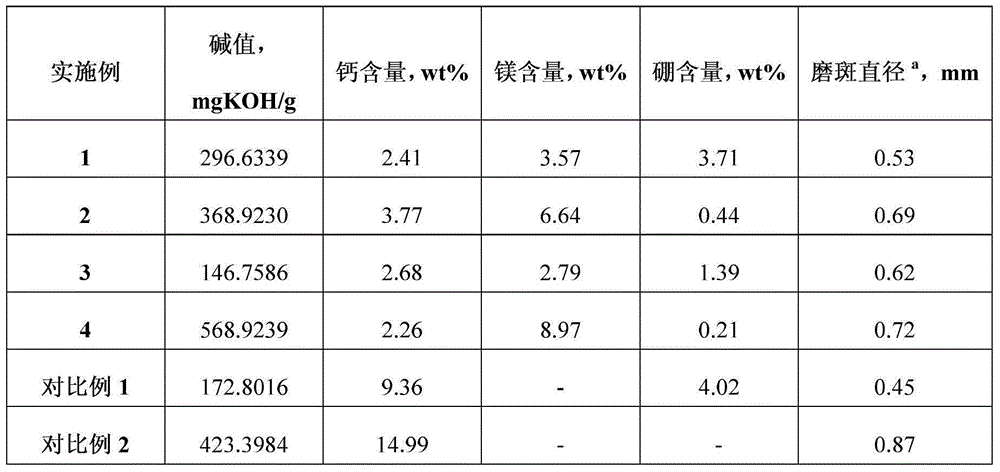

High-base-number naphthenic acid composite calcium-magnesium detergent, preparation method thereof and lubricating oil composition

The invention provides a high-base-number naphthenic acid composite calcium-magnesium detergent, a preparation method thereof and a lubricating oil composition comprising the detergent. The preparation method of the high-base-number naphthenic acid composite calcium-magnesium detergent comprises the steps of mixing naphthenic acid, calcium oxide and / or calcium hydroxide with a solvent to have neutralization reaction, then adding magnesium oxide and / or magnesium hydroxide, introducing the carbon dioxide to have the carbonation reaction, adding an accelerant in the neutralization reaction and / or carbonation reaction, and collecting products. Compared with the traditional metal detergent product of calcium salt and magnesium salt and the corresponding lubricating oil composition, the high-base-number naphthenic acid composition and the lubricating oil composition containing the detergent have lower ash content, higher base number and better acid neutralization capacity, different problems in the compounding of different metal salt detergents can be avoided, the detergent of different calcium / magnesium ratios can be obtained, and the requirement of the top-grade lubricating oil can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

Mono (terephthalate)octanol ester calcium salt clearing agent and synthetic method thereof

The invention discloses a lubricating oil clearing agent and a preparation method, the clearing agent and comprises the following raw materials by mass ratio: 1-4 parts of mono(terephthalate)alcohol ester-12, 1-3 parts of cutback oil, 7-15 parts of calcium hydrate, 0.15-0.5 parts of calcium chloride, 12-30 parts of solvent, 0.15-1.5 parts of methanol, 0.2-0.8 parts of water and 0.2-1 part of carbon dioxide. A preparation method comprises the steps of high alkalinity reaction and neutralization reaction. The lubricating oil clearing agent has good clean dispersibility and extremely strong corrosive acid neutralization capability, calcium carbonate particles in the lubricating oil clearing agent are uniformly distributed; in the whole reaction process, the preparation and treatment processes are simple, a high temperature processing technology is not required, the synthetic method is easily realized, most raw materials can be regenerated and have high biodegradability, and the clearing agent and synthetic method accord with green environmental protection requirement.

Owner:东营市广利临港产业园有限公司 +1

Multifunctional sulfonate detergent with controllable base number as well as preparation method and application thereof

The invention discloses a multifunctional sulfonate detergent with a controllable base number as well as a preparation method and application thereof. The preparation method comprises the following steps of: a) mixing alkyl sulfonic acid and / or alkyl sulfonate, a calcium-containing alkaline compound or magnesium-containing alkaline compound and a diluent and / or accelerant added or not, and enabling a neutralizing reaction; b) adding a magnesium-containing alkaline compound and a boron-containing compound, and introducing carbon dioxide for reacting; and c) separating to obtain the target product. The preparation method disclosed by the invention is simple and controllable while the cost is low; the obtained detergent has an excellent detergent-dispersant effect as well as perfect friction / wear resistance, rust resistance, corrosion resistance and extreme pressure property and can be widely applied to various lubricants as an additive such as engine lubricating oil, marine lubricating oil, antirust lubricating oil, industrial lubricating oil, automatic and manual transmission fluid, tractor fluid, hydraulic fluid, power steering gear fluid, gear lubricating oil and pump working oil.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

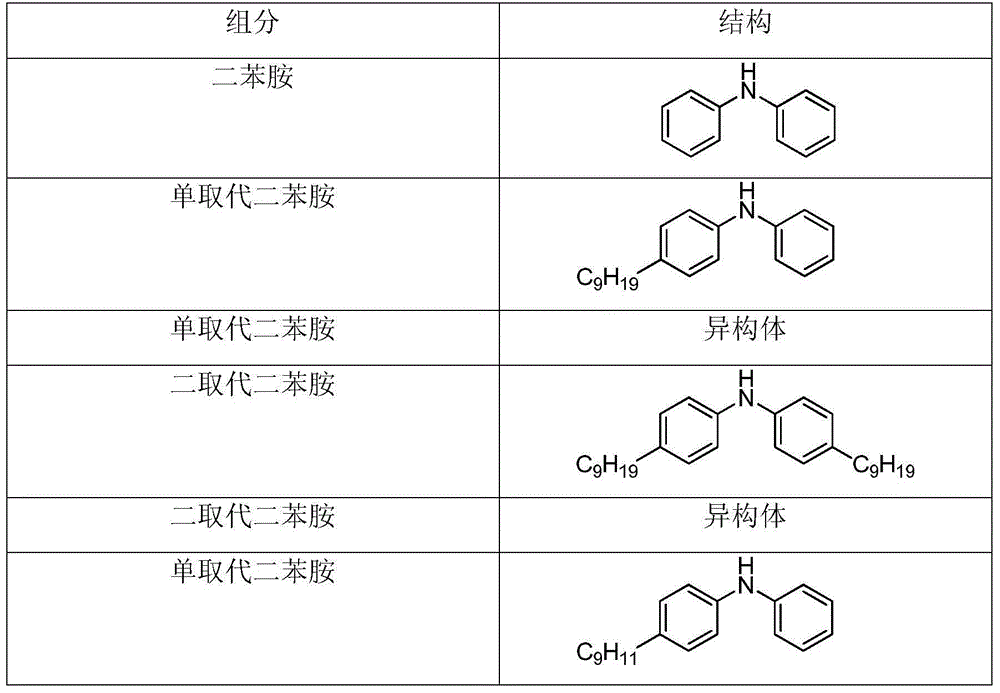

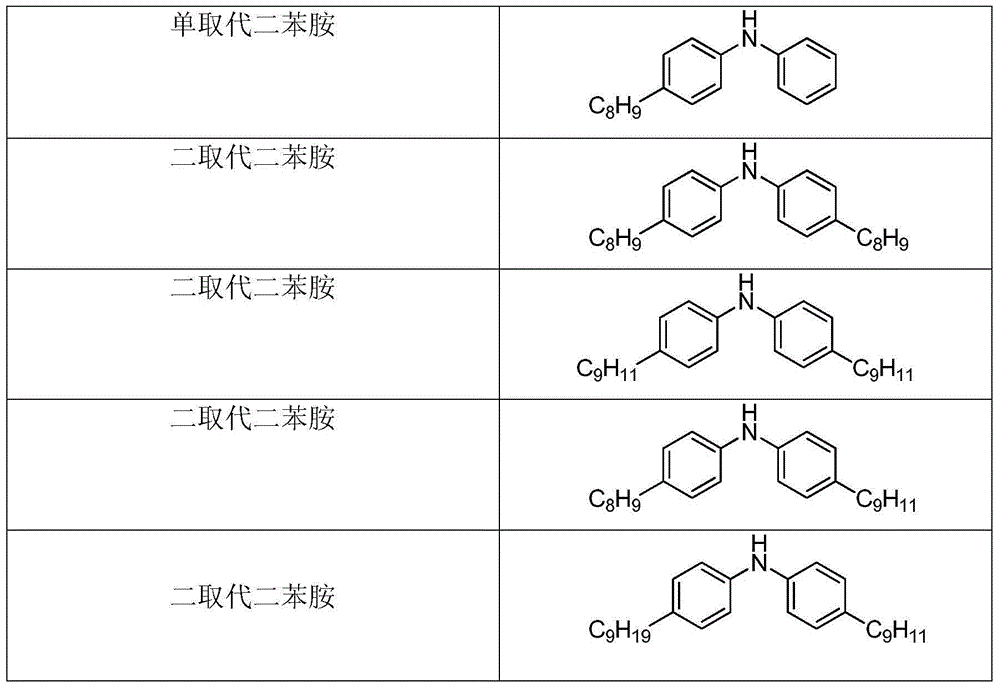

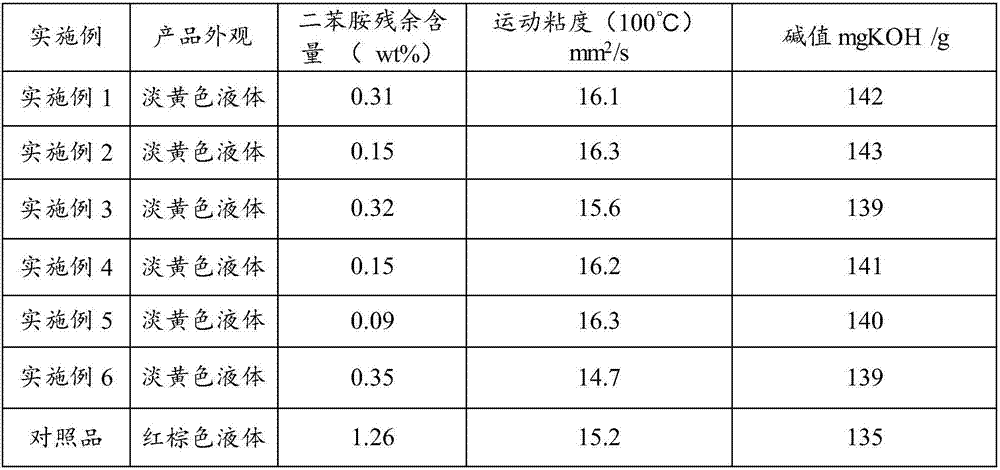

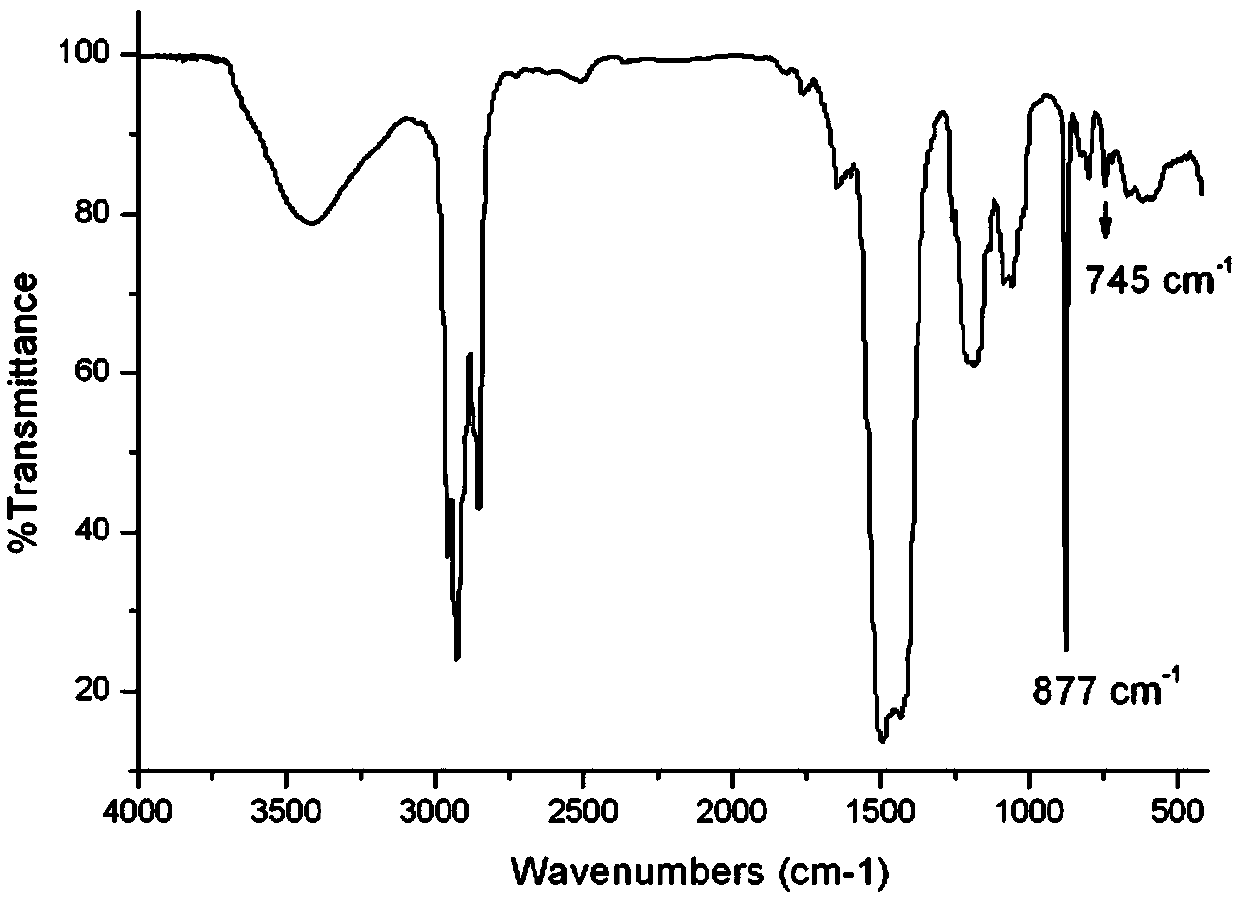

Mixed-alkene-participating preparation method of nonyl diphenylamine

ActiveCN104628580AImprove conversion rateReduce remaining amountPhysical/chemical process catalystsAmino preparation from aminesAlkyl transferDistillation

The invention relates to a mixed-alkene-participating preparation method of nonyl diphenylamine. The preparation method comprises the following steps: mixing diphenylamine with C9 alkene, adding a mixed catalyst of activated montmorillonite and active Al2O3 to carry out alkylation reactions at a temperature of 75 to 170 DEG C; then adding mixed alkenes and a polymerization inhibitor, filtering the reaction products, then subjecting the reactions products to reduced pressure distillation so as to obtain the nonyl diphenylamine, collecting the solid catalyst for cycle use, and collecting and recovering the alkenes for subsequence reactions. The provided preparation method can effectively improve the product appearance, increase the base number, and reduce the content of residual diphenylamine. The yield of the preparation method can reach 65-85%. The catalyst can be repeatedly used. Furthermore, no wastewater or waste gas is generated and the preparation method is environment-friendly therefore.

Owner:PETROCHINA CO LTD

Composite catalyst, and preparation method of nonyldiphenylamine

ActiveCN106944142AHigh viscosityHigh base numberAmino preparation from aminesOrganic-compounds/hydrides/coordination-complexes catalystsOxideZinc

The invention provides a composite catalyst and a preparation method of nonyldiphenylamine. The composite catalyst comprises active clay, p-toluenesulfonic acid and active zinc oxide according to a mass ratio of 100:(0.1-5):(0.1-5). The composite catalyst can catalyze the alkylation reaction of diphenylamine and nonene, so the obtained nonyldiphenylamine product has light color, high viscosity and high base value, the residual content of diphenylamine in the product is low, and the performances of the product are greatly improved.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

High-alkaline-value synthetic calcium alkyl benzene sulfonate nano detergent and preparation method thereof

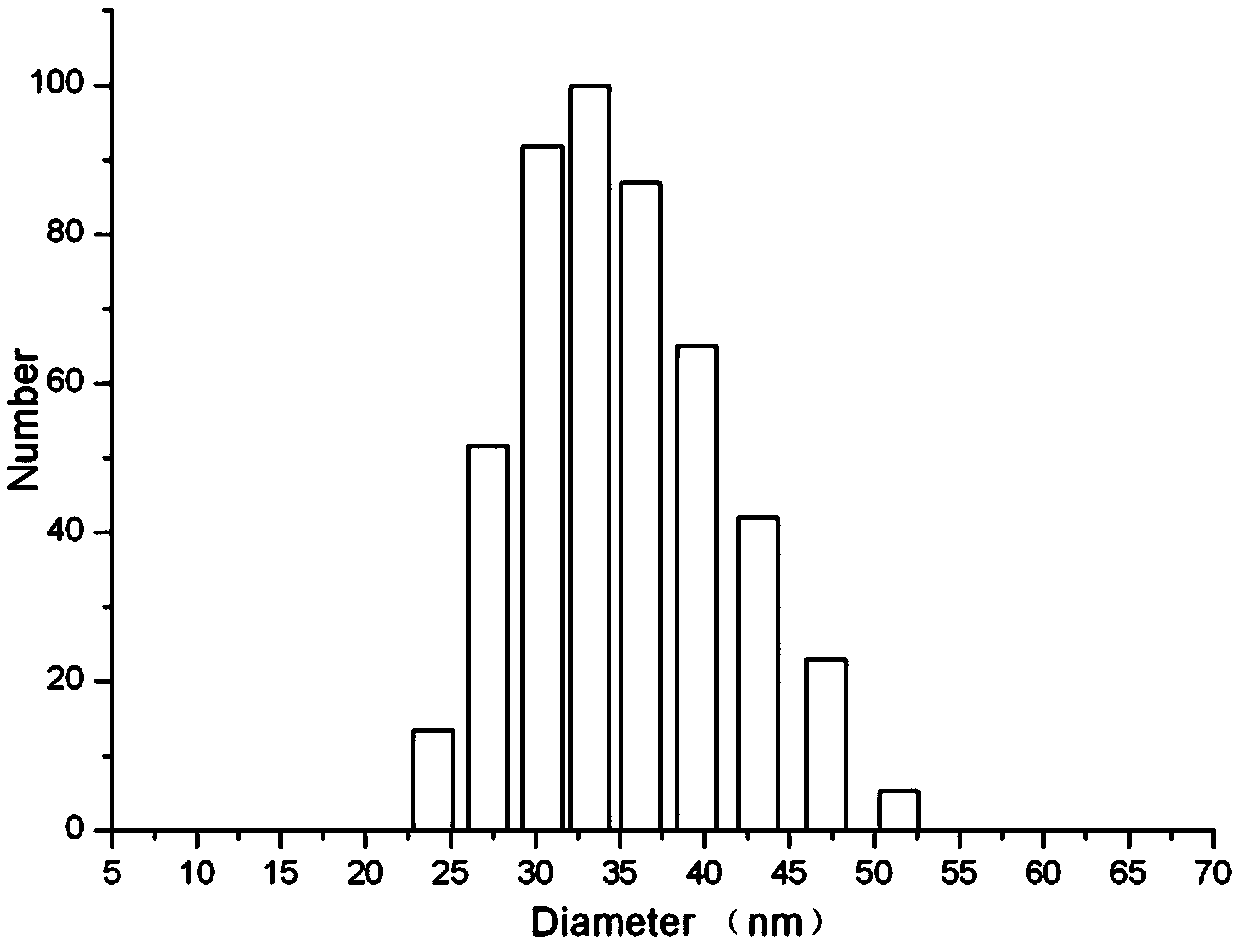

InactiveCN105503670AIncrease profitHigh base numberSulfonic acids salts preparationAdditivesBase oilViscosity

The invention discloses high-alkaline-value synthetic calcium alkyl benzene sulfonate nano detergent and a preparation method thereof and belongs to the field of lubricating composite preparation. The high-alkaline-value synthetic calcium alkyl benzene sulfonate nano detergent is formed by compounding synthetic calcium alkyl benzene sulfonate, ball graupel crystal type calcium carbonate and base oil; the preparation method includes the steps of (1), preparation of a synthetic calcium alkyl benzene sulfonate solution; (2), preparation of the synthetic calcium alkyl benzene sulfonate nano detergent, (3) posttreatment and the like; the alkali content of a prepared product is higher than 400 mg KOH / g, the movement viscosity at the temperature of 100 DEG C is lower than 100 mm<2> / s, the product particle size is controlled within the range of 10-100 nm according to different preparation conditions, the particle size distribution is narrow, and the high-alkaline-value synthetic calcium alkyl benzene sulfonate nano detergent has the advantages of being high in alkaline value, low in viscosity, clear, stable and the like.

Owner:ANHUI JINTONG FINE CHEM CO LTD

Engine lubricating oil composition

InactiveCN1181168CHigh base numberImproved high temperature detergencyAdditivesAntioxidantEngineering

The present invention relates to one kind of composite engine lubricating oil, and is especially one for diesel engine. It features its containing great amount of hydrogenated base oil. It also contains proper amount of modified salicylate, mixed matrix metal detergent, alkyl phenolate sulfide, ashless dibutyl diimide dispersant, dialkyl dithiophosphate zinc and phenol type co-antioxidant. The composite engine lubricating oil can meet the lubricant requirement of API CF diesel engine and has simple formula, low cost and easy compounding.

Owner:PETROCHINA CO LTD

Preparation method of lubricating oil detergent

InactiveCN106318543AGood compatibilityDoes not affect the colorAdditivesEthylenediamineSodium sulfate

The invention relates to a preparation method of a lubricating oil detergent, and belongs to the technical field of lubricating oil detergent preparation. The lauryl sodium sulfate preparation method comprises the steps that magnesium aluminum hydrotalcite is modified with lauryl sodium sulfate and then added into alkali liquor, modification is conducted with an ethylenediaminetetraacetic acid complexing agent, and then drying is conducted to obtain powder; rice and yeast powder are sealed to be fermented, and fermentation liquor is collected, concentrated and then mixed with xylene, calcium hydroxide powder and calcium oxide powder to obtain suspension liquor; the modified powder is mixed with the suspension liquor, and after the pH value is regulated with ammonia water, the lubricating oil detergent can be obtained. The lubricating oil detergent prepared through the method is high in compatibility with lipid lubricating oil, the lubricating oil detergent prepared from the modified magnesium aluminum hydrotalcite not only can achieve the good detergency and dispersibility, the extremely high capacity of neutralizing corrosive acid and the high antioxidant property, but also cannot influence the color, luster and properties of base oil of the lubricating oil and has the high base number advantage, wherein the base number is higher than 330 mgKOH / g.

Owner:梅庆波

Bacterial strain medium and preparation method thereof

The invention discloses a bacterial strain medium and a preparation method thereof. The bacterial strain medium solves the problems of soft and loose states of the traditional bacterial strain medium, improves base hardness and is convenient for transport and storage. Because of matrix change, physical vibration and temperature difference adaptability are improved. The traditional medium tissue structure is changed so that matrix permeability is improved and mycelia growth oxygen demands are greatly satisfied. The matrix components are changed so that a bacterial strain quality guarantee period is prolonged. The bacterial strain medium changes nutrition components of the traditional medium, has comprehensive and reasonable nutrition, improves medium base number and effectively inhibits infectious microbes. Through use of needlebush particles and sawdust, a raw material source and an application scope are widened. Inoculation efficiency is improved and a bacterial strain cost is about 1 / 5 that of the traditional PDA medium.

Owner:宫晶晶

Method for preparing liquidized butyl diphenylamine/octyl diphenylamine

ActiveCN104628579AImprove conversion rateHigh base numberAmino preparation from aminesAdditivesDistillationAniline

The invention relates to a method for preparing liquidized butyl diphenylamine / octyl diphenylamine. The method comprises the following steps: mixing diphenylamine with C8 alkene according to a mole ratio of 1:1.35-1:3.2, adding 5 to 25% of catalyst and polymerization inhibitor, carrying out alkylation reactions for 0.5 to 20 hours at a temperature of 80 to 165 DEG C under a reaction pressure of 0.25 to 0.5 MPa; wherein the addition amount of the polymerization inhibitor is 60 to 180 ppm; then adding ending alkene, wherein the adding amount of the ending alkene is 10 to 40% of the molar weight of the diphenylamine; heating the reaction product, filtering, then subjecting the filtrate to reduced pressure distillation, collecting the solid catalyst for cycle use, collecting and recovering the alkene, returning the collected alkene to the reaction system, and collecting the liquid namely the liquidized butyl diphenylamine / octyl diphenylamine. The color of obtained product is lightened, the product is clear and transparent, the base number reaches 140 to 180, the content of residual diphenylamine is less than 1%, the conversion of diphenylamine is increased, the performance of the product on controlling the viscosity increasing is excellent, the catalyst can be repeatedly used, and no wastewater is discharged.

Owner:PETROCHINA CO LTD

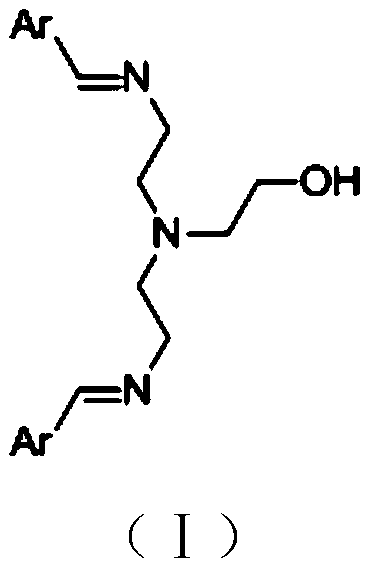

Catalyst, preparation method thereof, and application of catalyst in preparation of beta-isophorone

ActiveCN111215138AHigh selectivityHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceIsomerization

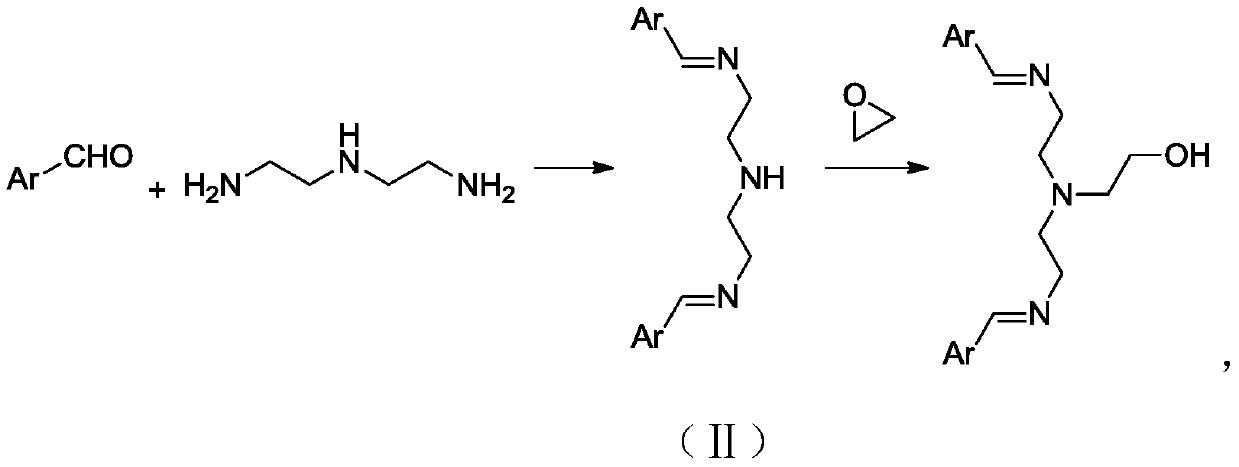

The invention provides an N-(2-hydroxyethyl)diethylenetriamine Schiff base catalyst, a preparation method thereof, and an application of the catalyst in the preparation of beta-isophorone. The preparation method of the catalyst comprises the following steps: 1) reacting diethylenetriamine with aromatic aldehyde to prepare a bis-Schiff base; and 2) reacting the bis-Schiff base compound with ethylene oxide to obtain the N-(2-hydroxyethyl)diethylenetriamine Schiff base. The invention also provides a method for preparing beta-isophorone from alpha-isophorone through an isomerization reaction underthe action of the Schiff base. The catalyst is simple to prepare and easy to industrialize. The prepared N-(2-hydroxyethyl)diethylenetriamine Schiff base has the advantages of high selectivity and high yield for the reaction of isomerizing alpha-isophorone to generate beta-isophorone, low generation possibility of byproducts, easiness in industrial production, and no corrosion to equipment.

Owner:WANHUA CHEM GRP CO LTD

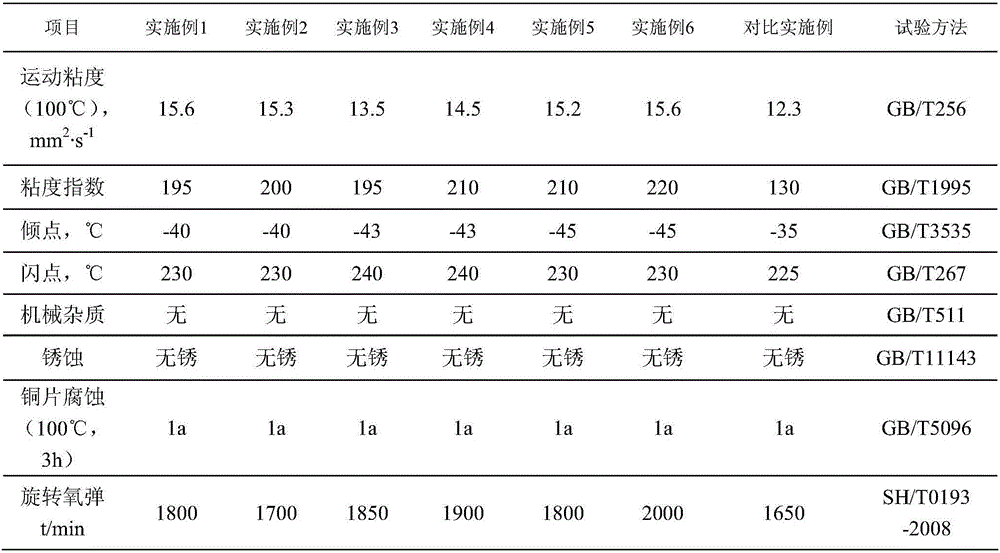

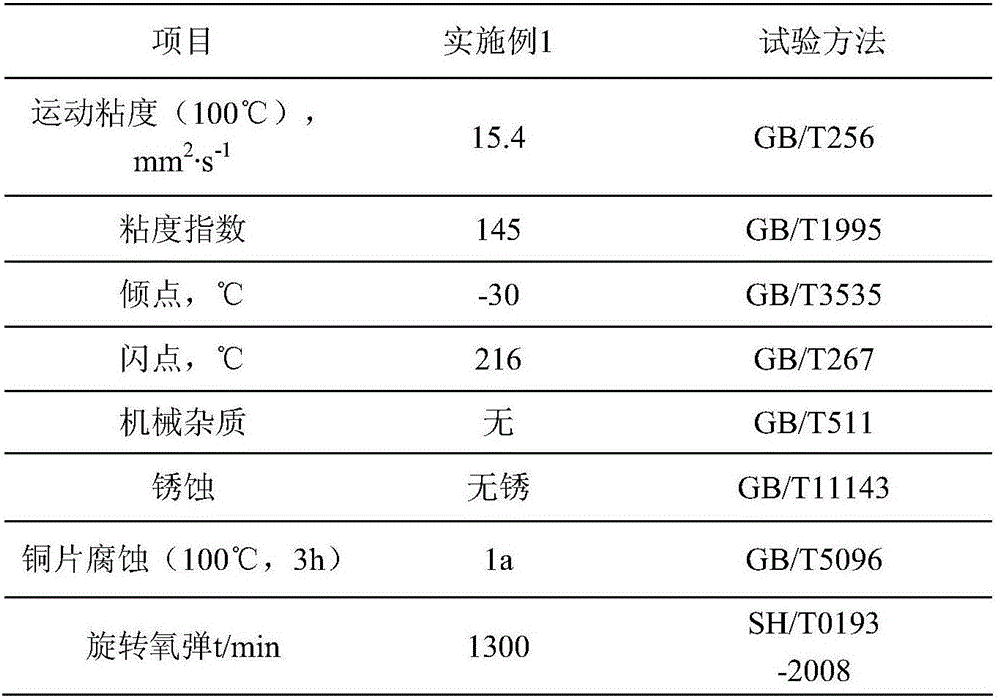

Synthetic supercharged methanol engine oil as well as preparation method and application thereof

ActiveCN106590853AHigh viscosity indexHigh base numberBase-materialsOxidation resistantViscosity index

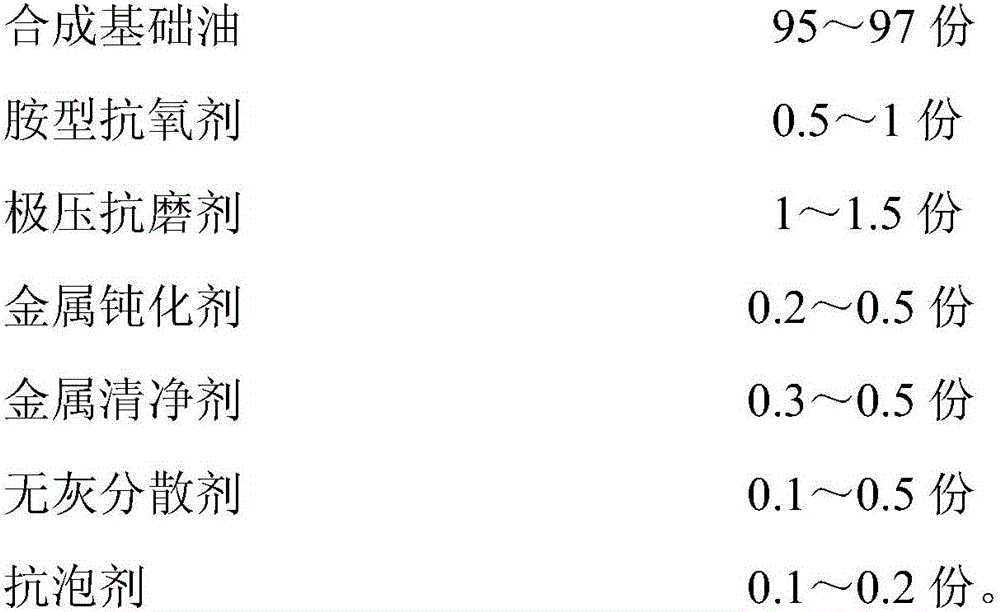

The invention belongs to the field of engine lubricating oil and discloses synthetic supercharged methanol engine oil as well as a preparation method and an application thereof. 95-97 parts of synthetic base oil is added to a three-mouth flask provided with a stirring device and a water bath device and subjected to a water bath at the constant temperature of 60 DEG C, then 0.5-1 part of an amine antioxidant, 1-1.5 parts of an extreme-pressure anti-wear agent, 0.2-0.5 parts of a metal passivator, 0.3-0.5 parts of a metal detergent, 0.1-0.5 parts of an ashless dispersant and 0.1-0.2 parts of an anti-foaming agent are added and stirred, and the synthetic supercharged methanol engine oil is obtained. The synthetic supercharged methanol engine oil has the advantages that the viscosity index is high, the shear performance is good, the low-temperature performance is good, the base number is large, the lubricity, the anti-oxidation and anti-corrosion performance and the cleaning and dispersing effect are good, a preparation process is simple, the cost is low, application range is wide, and the like.

Owner:广州国机润滑科技有限公司 +1

Preparation method of antifreezing solution

The invention discloses a preparation method of an antifreezing solution. The antifreezing solution is characterized by being prepared from the following components by weight percent: 0 to 35 percent of synthesized glycerinum, 0 to 20 percent of alpha, alpha, alpha minute-trimethyl trimethylene glycol, 0 to 45 percent of N-methyldiethanolamine, 0.1 to 1.5 percent of 2,4,6-tri(caproyl aminomethyl sulfo)-s-triazine, 0.1 to 3.0 percent of cyclohexanehexol phosphate, 0.01 to 0.05 percent of polyether, 0.01 to 1.5 percent of sodium lignosulphonate, 0 to 0.5 percent of red bean pigment, 0 to 0.5 percent of acorn shell brown and the balance of deionized water. The renewable environment-friendly glycerinum is compounded with 0 to 20 percent of alpha, alpha, alpha minute-trimethyl trimethylene glycol and N-methyldiethanolamine to be used as an antifreezing medium, and various additives with excellent performance are used as a corrosion inhibition medium to prepare the novel antifreezing solution with a low ice point and high corrosion inhibition capacity, a corrosion inhibition effect for multiple metals is realized, and the long-term normal operation of a cooling system can be guaranteed.

Owner:温州宝罗润滑材料有限公司

Heavy-loading CNG natural gas engine oil complexing agent and preparation method and application thereof

The invention relates to a heavy-loading CNG natural gas engine oil complexing agent and a preparation method and application thereof. The raw materials of the complexing agent comprise base zinc saltof dioctyl thiophosphate, super-alkali-value synthesis calcium sulfonate, alkylated diphenylamine, amidogen thioester, super-alkali-value synthesis magnesium sulfonate, high-molecular-weight ashlessdispersing agent and single alkenyl succinimide. The method comprises the steps that the raw materials are weighed, added to a blending kettle, heated to 60-70 DEG C, stirred for 2-3 hours at normal pressure and filtered, and the heavy-loading CNG natural gas engine oil complexing agent is obtained. The heavy-loading CNG natural gas engine oil complexing agent and the preparation method and application thereof have the advantages that the preparation method is easy to operate and the agent is easy to prepare. The complexing agent can distinctly meet the requirements in the second, third and fourth type of oil and is suitable for meeting the performance requirement of large-sized fixed and large-power mobile CNG natural gas engines.

Owner:锦州新兴石油添加剂有限责任公司

Lubricating oil composition for gas engines

This lubricating oil composition for gas engines contains (A) a base oil, (B1) overbased calcium salicylate, (B2) overbased sodium sulfonate, (C1) an amine-based antioxidant, and (C2) a phenol-based antioxidant, the total contained amount of the (C1) amine-based antioxidant and (C2) phenol-based antioxidant being 4 mass% or higher based on the total amount of the composition.

Owner:IDEMITSU KOSAN CO LTD

Mixed-substrate magnesium salt detergent of lubricating oil and preparation method of detergent

InactiveCN107118824AImprove high temperature detergencyGood dispersionAdditivesDispersityMagnesium salt

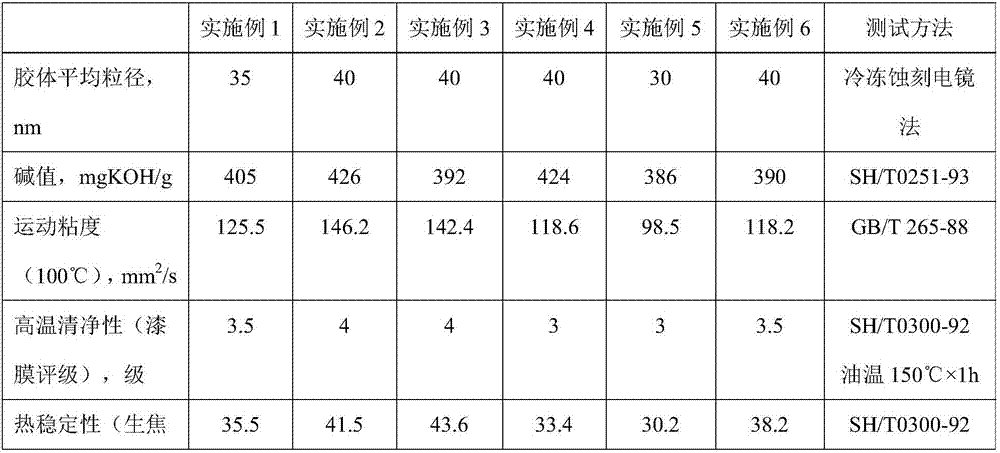

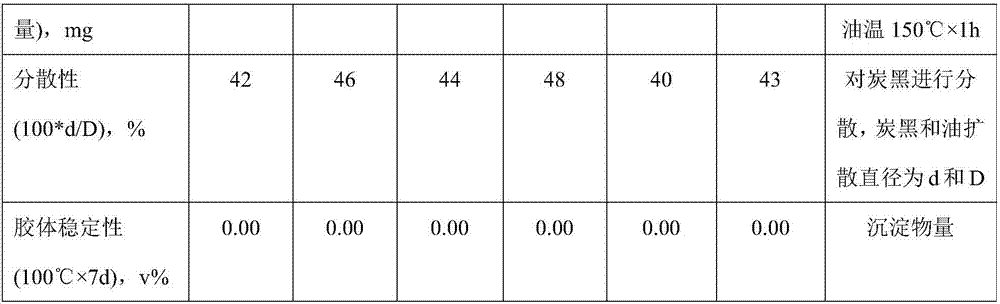

The invention discloses a mixed-substrate magnesium salt detergent of lubricating oil and a preparation method of the detergent. The preparation method takes active magnesium oxide and at least two different types of organic acids as raw materials, wherein the organic acids include mahogany acid or petroleum ammonium sulfonate, synthesized sulfonic acid, alkyl salicylic acid and naphthenic acid. The detergent and the method have the benefits that: (1) a super-high base number mixed-substrate magnesium salt detergent product of the lubricating oil, with a base number of greater than 380 mgKOH / g can be prepared; and some performance in high temperature detergency, dispersity, thermostability and the like of the detergent product can be improved specifically by changing proportions of different types of substrates; (2) a series of detergent products with the different base numbers can be prepared by changing proportions of other materials to meet different requirements; the maximum base number can reach above 420 mgKOH / g; and (3) a particle size of a colloid particle of the product is less than 80nm, so that the product has good colloid stability.

Owner:XI'AN PETROLEUM UNIVERSITY

A kind of light-duty diesel oil/gasoline car engine lubricating oil composition

ActiveCN104046418BExcellent anti-oxidation and anti-wear propertiesExcellent medium and low temperature dispersibilityLubricant compositionChemical compositionFoaming agent

The invention discloses an engine lubricating oil composition. The engine lubricating oil composition has quality satisfying ACEA-2010A3 / B4 and SAEJ300 specification requirements, is suitable for lubricating a light-duty diesel oil / gasoline car engine under harsh conditions and is especially suitable for lubricating a direct injection light-duty diesel oil / gasoline engine having turbocharging. The engine lubricating oil composition has excellent oxidation and wear resistance, middle / low temperature dispersibility and high temperature detergency, a high base number and strong alkali maintenance capability, can effectively inhibit high-temperature piston deposit generation, can prevent piston adhesion to a ring, has a long oil change period and can provide full lubricating protection on the engine. The engine lubricating oil composition comprises at least two metal detergents, two ashless dispersants, three antioxidant, anticorrosive and antiwear agents, a viscosity index improver, a pour point depressant, an anti-foaming agent and two base oil.

Owner:PETROCHINA CO LTD

An electromagnetic wave analog digital advanced transmission system and its transmission method

ActiveCN105634564BReduce signal interferenceReduce energy consumptionNear-field systems using receiversData simulationHigh density

The invention discloses an electromagnetic wave analog digital high-ary transmission system and a transmission method thereof. The system consists of a data protocol establishment module, a binary data and high-ary data analog conversion module, a high-ary data distribution electromagnetic band module and a wide-band electromagnetic wave Composed of transmitting and receiving modules. The binary data and high-ary data simulation conversion module includes a first instruction storage unit, a data analysis unit, and a data addition and subtraction output unit. The high-ary data distribution electromagnetic band module includes a second instruction storage unit, a high-ary code storage unit, an electromagnetic band data corresponding code storage unit, and a comparison data input and output unit. Divide the computer binary data into equal parts and convert it into ternary or higher simulated high-ary data, and use the electromagnetic band paired with the simulated high-ary data to emit with the shortest number of oscillation cycles; then reversely decode and restore it to binary data. The invention has small data signal interference, low energy consumption, large data transmission volume and strong security.

Owner:XUZHOU SPACE TIME THOUGHT INTELLIGENT TECH CO LTD

Polyester lubricating oil and process

The invention discloses polyester lubricating oil and a blending process thereof. The polyester lubricating oil comprises the following components in percentage by mass: 18-25 percent of PAO4 base oil, 38-44 percent of PAO6 base oil, 12-16 percent of polyol ester base oil, 10-12 percent of a tackifier, 0.2-0.5 percent of a pour point reducer, 0.7-1.2 percent of a friction modifier and 11.30001-12.70003 percent of a complexing agent, wherein the complexing agent comprises 8.0-8.5 mass percent of high-alkali number petroleum calcium sulfonate, 2.0-2.5 mass percent of zinc butyl octyl dithiophosphate, 1.3-1.7 mass percent of zinc dialkyl dithiophosphate and 0.0001-0.0003 percent of methyl silicone oil ester. The polyester lubricating oil disclosed by the invention can meet the performance of the traditional lubricating oil, is high in stability, can achieve the effects of reducing pollution emission and energy consumption and automatically repairing abrasion equipment and has an environment-friendly effect.

Owner:ZHUHAI SINOCU LUBRICATING TECH CO LTD

Preparation process of high-base value sulfurized alkyl salicylate

The invention discloses a preparation process of high-base value sulfurized alkyl salicylate. The preparation process comprising the following steps: firstly taking salicylic acids and long-chain alkenes as initiators, performing alkylation reaction under the action of a polar catalyst to prepare alkyl salicylate and preparing a high-base value (TBN) 350 mgKOH / g) sulfurized alkyl salicylate product through neutralization, vulcanization and high alkalization reactions of the alkyl salicylate. The preparation process disclosed by the invention has the benefits that a continuous synthesis processis adopted, reaction conditions are mild, the product has a higher base value, contains no free phenol and has excellent high temperature detergency, oxidation resistance and abrasion resistance, thereby being a comprehensive, environmentally-friendly and energy-saving product.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com