Synthetic supercharged methanol engine oil as well as preparation method and application thereof

A technology of methanol engine and synthetic base oil, applied in the petroleum industry, lubricating composition, base material, etc., can solve the problems of engine failure, strong water absorption, wear of synthetic supercharged engine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

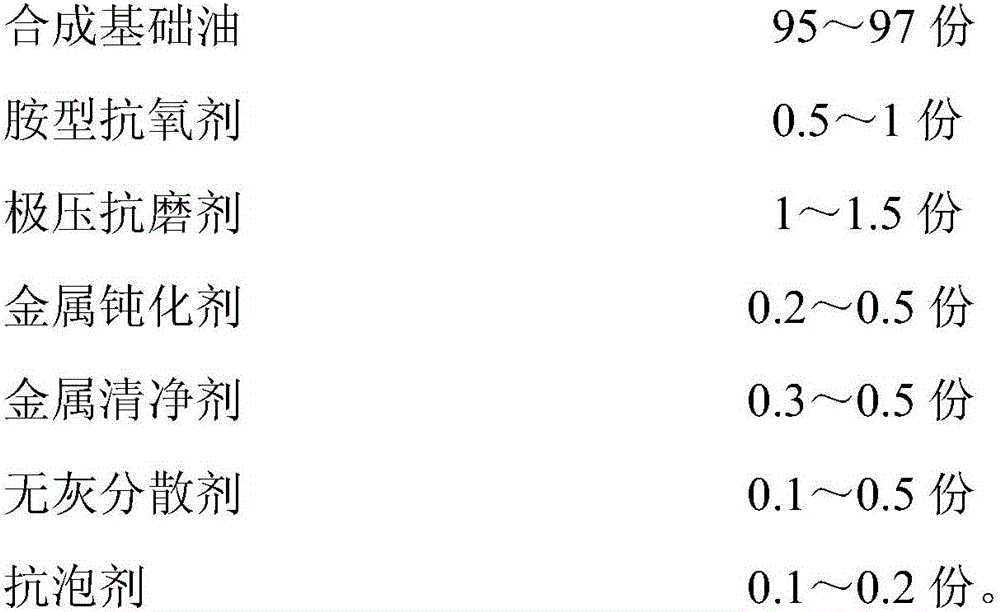

Method used

Image

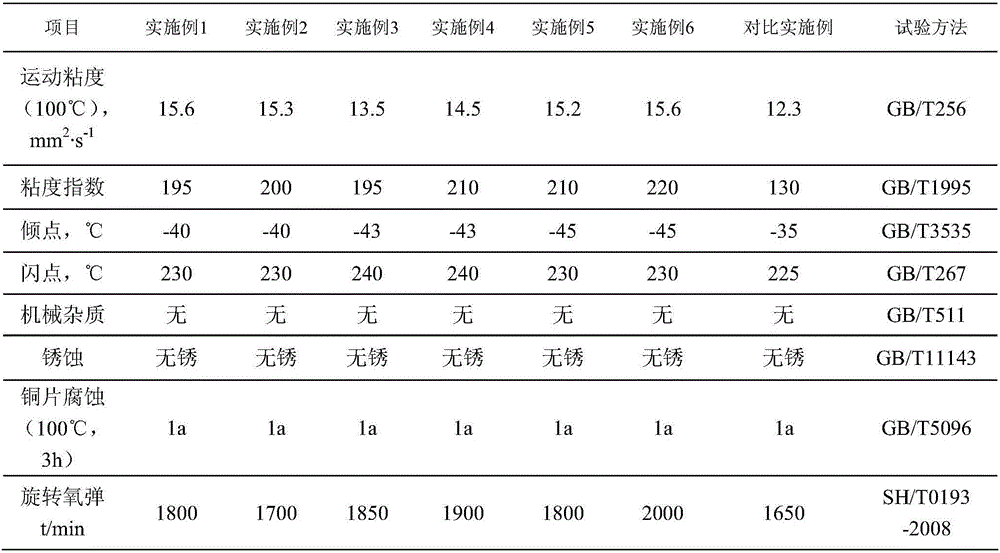

Examples

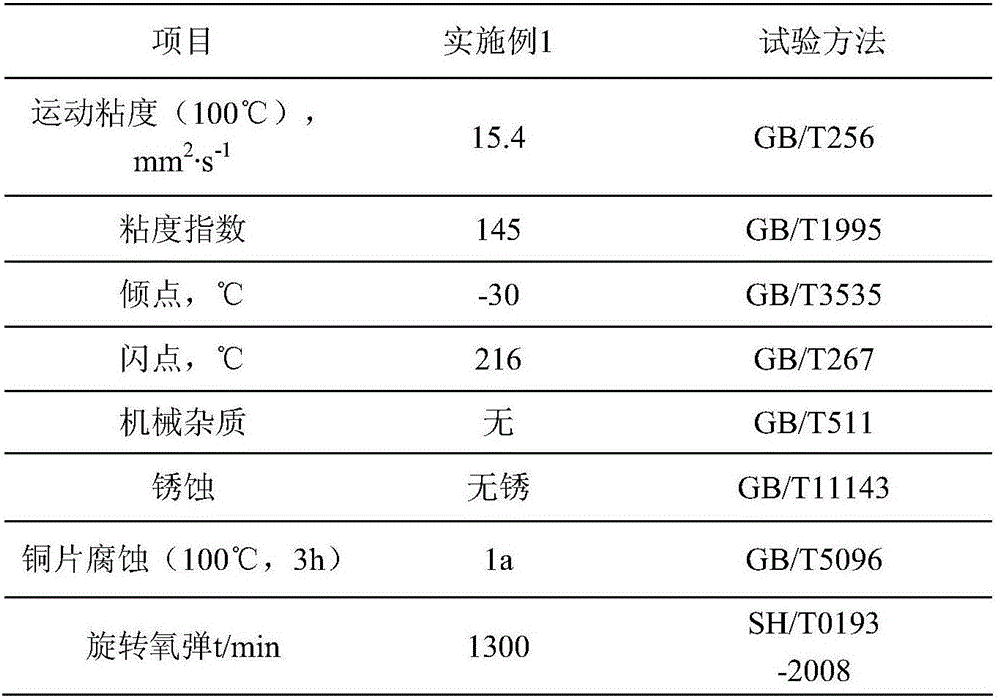

Embodiment 1

[0037] 97 parts by mass of synthetic base oil A (1-hexene, 1-octene and 1-dodecene in a molar ratio of 1:4:5 are placed in a high-pressure reactor with a vacuum, sample delivery and stirring device , feed nitrogen after vacuuming, add the catalyst triisobutyl aluminum and biscyclopentadienyl zirconium dichloride with a mass ratio of 3:1, the total mass of the catalyst is 1-hexene, 1-octene, 1-deca 1% of the total mass of diene, keep the reactor at 20°C for 2 hours, and remove the insoluble matter uniformly after the reaction. The obtained synthetic base oil A has a kinematic viscosity of 60.4mm at 100°C 2 / s) into a three-necked flask with a stirring device and a water bath device, the water bath is kept at a constant temperature of 60 ° C, and then 1 mass part of N-phenyl-2-naphthylamine, 1 mass part of primary alcohol dialkyl dithiophosphate zinc , 0.3 parts by mass of benzotriazole, 0.3 parts by mass of high base value calcium sulfonate, 0.3 parts by mass of polymerized suc...

Embodiment 2

[0039] 96.5 parts by mass of synthetic base oil A (1-hexene, 1-octene and 1-dodecene are placed in a high-pressure reactor with a vacuum, sample delivery and stirring device according to the molar ratio of 1.5:4:4.5 , pass into nitrogen after several times of vacuuming, adding mass ratio is 3:1 catalyst triisobutylaluminum and biscyclopentadienyl zirconium dichloride, the total mass of catalyst is 1-hexene, 1-octene, 1 - 1.5% of the total mass of dodecene, keep the reactor at 20°C for 2 hours, after the reaction removes the insoluble matter evenly, it is prepared, and the obtained synthetic base oil A has a kinematic viscosity of 82.7mm at 100°C 2 / s) was added to a three-necked flask with a stirring device and a water bath device, and the water bath was kept at a constant temperature of 60°C, and then 1 mass part of 4,4'-dioctyldiphenylamine, 1 mass part of phosphate disulfide, 0.5 mass part of primary Zinc alcohol dialkyldithiophosphate, 0.3 parts by mass of tolyltriazole, 0...

Embodiment 3

[0041] 97 parts by mass of synthetic base oil B (1-hexene, 1-octene and 1-dodecene in a molar ratio of 0.5:5.5:4 are placed in a high-pressure reactor with a vacuum, sample delivery and stirring device , pass into nitrogen after several times of vacuuming, adding mass ratio is 2:1 catalyst triisobutylaluminum and dicyclopentadienyl zirconium dichloride, the total mass of catalyst is 1-hexene, 1-octene, 1 - 1% of the total mass of dodecene, keep the reactor at 20°C for 2 hours, and remove the insoluble matter evenly after the reaction. The kinematic viscosity of the obtained synthetic base oil B at 100°C is 101.3mm 2 / s) was added to a three-necked flask equipped with a stirring device and a water bath device, and the water bath was kept at a constant temperature of 60°C, and then 1 mass part of diisooctyldiphenylamine, 1 mass part of primary alcohol dialkyl dithiophosphate zinc, 0.3 mass parts 1 part of thiadiazole derivatives, 0.3 parts by mass of high alkali value calcium su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com