Composite catalyst, and preparation method of nonyldiphenylamine

A composite catalyst, nonyldiphenylamine technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, preparation of amino compounds from amines, etc., can solve the problems affecting the appearance and performance of nonyldiphenylamine, Diphenylamine residue and other problems, to achieve the effect of improved performance, high base value and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

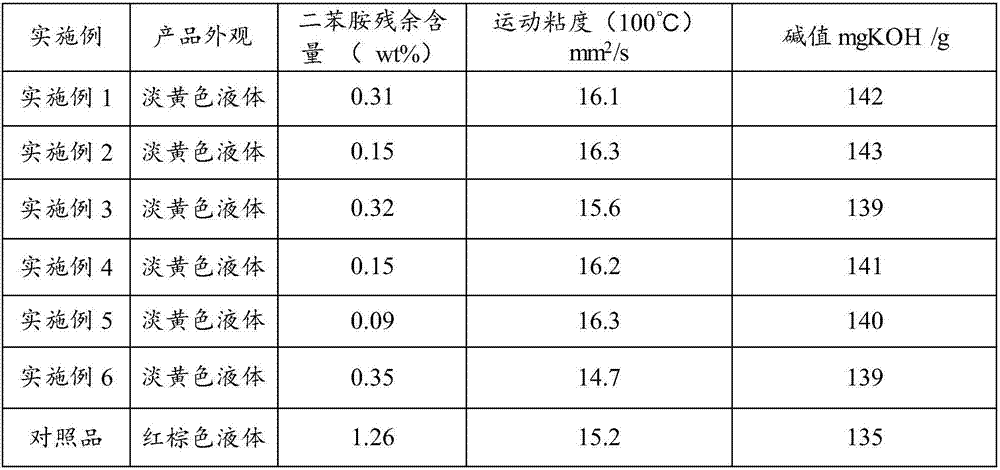

Examples

preparation example Construction

[0029] In the present invention, the preparation method of described composite catalyst preferably follows the steps:

[0030] The activated clay, p-toluenesulfonic acid and activated zinc oxide are evenly mixed to obtain a composite catalyst.

[0031] The preparation method of the composite catalyst is simple, and has high activity in catalyzing the alkylation reaction of diphenylamine and nonene; the aftertreatment is not complicated, and there is no generation of three wastes; and the composite catalyst can be recycled.

[0032] The invention provides a kind of preparation method of nonyl diphenylamine, comprises the following steps:

[0033] Under the action of a catalyst, diphenylamine and nonene are alkylated to obtain nonyldiphenylamine;

[0034] The catalyst is the composite catalyst described in the above technical scheme.

[0035] In the present invention, the alkylation reaction of diphenylamine and nonene specifically preferably includes:

[0036] Mix diphenylam...

Embodiment 1

[0050] Add 200g of activated clay, 5g of p-toluenesulfonic acid and 6g of active zinc oxide into the mixing device for compounding, start the mixing device for half an hour, and obtain a uniformly mixed activated clay composite catalyst for subsequent use.

[0051] Add 50g diphenylamine, 12.5g activated clay composite catalyst, 60ppm polymerization inhibitor hydroquinone in the stainless steel reaction kettle, feed nitrogen into the reaction kettle, fully replace the air in the kettle, and start heating. At the same time, the vacuum system is turned on, and the vacuum degree in the kettle is controlled at 0.08MPa to 0.095MPa; when the temperature reaches about 70°C, the stirring is started, and the stirring rate is 300 rpm, and the moisture in the reaction system is removed under vacuum conditions. Gradually raise the temperature to 100°C and keep it warm for half an hour, then stop the vacuum system and replace it with nitrogen to normal pressure; add 152.5g nonene, and start ...

Embodiment 2

[0057] Add 200g of activated clay, 1g of p-toluenesulfonic acid and 3g of active zinc oxide into the mixing device for compounding, start the mixing device for half an hour, and obtain a uniformly mixed activated clay composite catalyst, which is ready for use.

[0058] Add 50g diphenylamine, 16g activated clay composite catalyst, 65ppm polymerization inhibitor hydroquinone in the stainless steel reaction kettle, feed nitrogen into the reaction kettle, fully replace the air in the kettle, and start heating. At the same time, the vacuum system is turned on, and the vacuum degree in the kettle is controlled at 0.08MPa~0.095MPa. When the temperature reaches about 70°C, the stirring is started at a stirring rate of 300 rpm, and the moisture in the reaction system is removed under vacuum conditions. Gradually raise the temperature to 100°C and keep it warm for half an hour, then stop the vacuum system, and replace it with nitrogen to normal pressure; first add 55g of nonene, gradua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com