Patents

Literature

110 results about "Nonene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nonene is an alkene with the molecular formula C₉H₁₈. Many structural isomers are possible, depending on the location of the C=C double bond and the branching of the other parts of the molecule. Industrially, the most important nonenes are trimers of propene. This mixture of branched nonenes is used in the alkylation of phenol to produce nonylphenol, a precursor to detergents, which are also controversial pollutants.

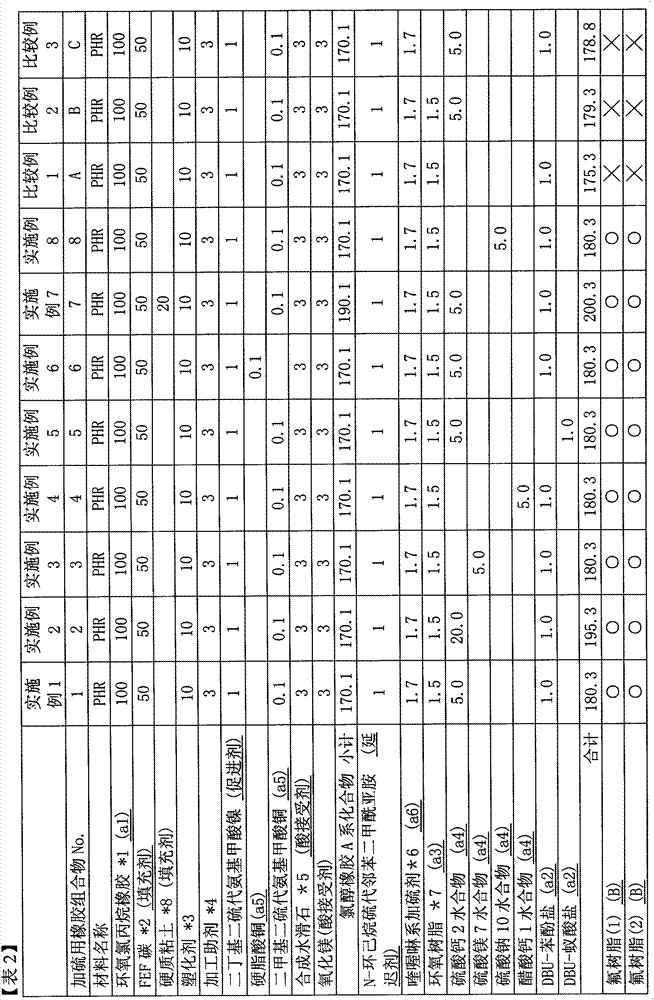

Vulcanized rubber laminate

The invention provides a vulcanized rubber laminate obtained by firmly bonding an unvulcanized epichlorohydrin rubber layer and an organic peroxide-containing fluororubber layer. The laminate is obtained by thermal adhesion a layer of an unvulcanized epichlorohydrin rubber composition to a layer of an unvulcanized fluororubber composition. The epichlorohydrin rubber composition comprises 1) an unvulcanized epichlorohydrin rubber containing 3 to 15 mol % of allyl glycidyl ether unit, 2) quinoxaline-based vulcanizing agents, mercaptotriazine-based vulcanizing agents or bisphenol-based vulcanizing agents, and 3) 1,8-diazabicyclo(5,4,0)undecene-7 salts, 1,5-diazabicyclo(4,3,0)nonene-5 salts, quaternary ammonium salts, quaternary phosphonium salts, basic white carbons or an alkaline metal salt of higher fatty acid the fluororubber composition comprises an fluororubber and an organic peroxide-based vulcanizing agent.

Owner:OSAKA SODA CO LTD

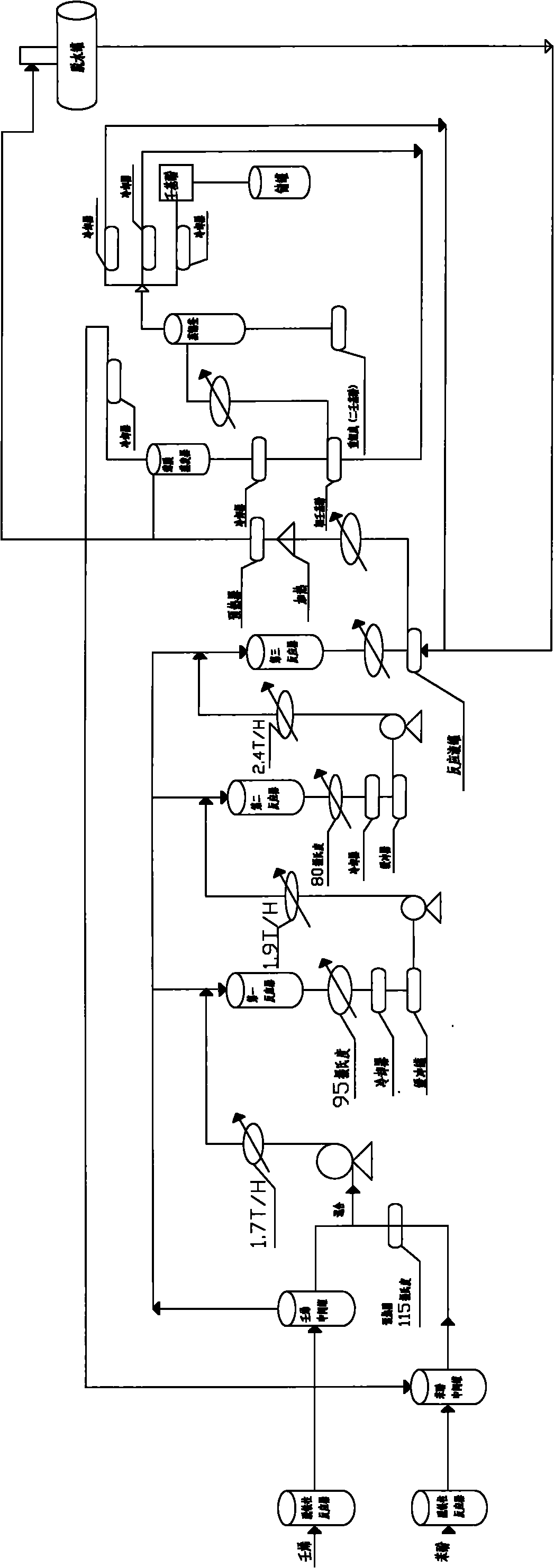

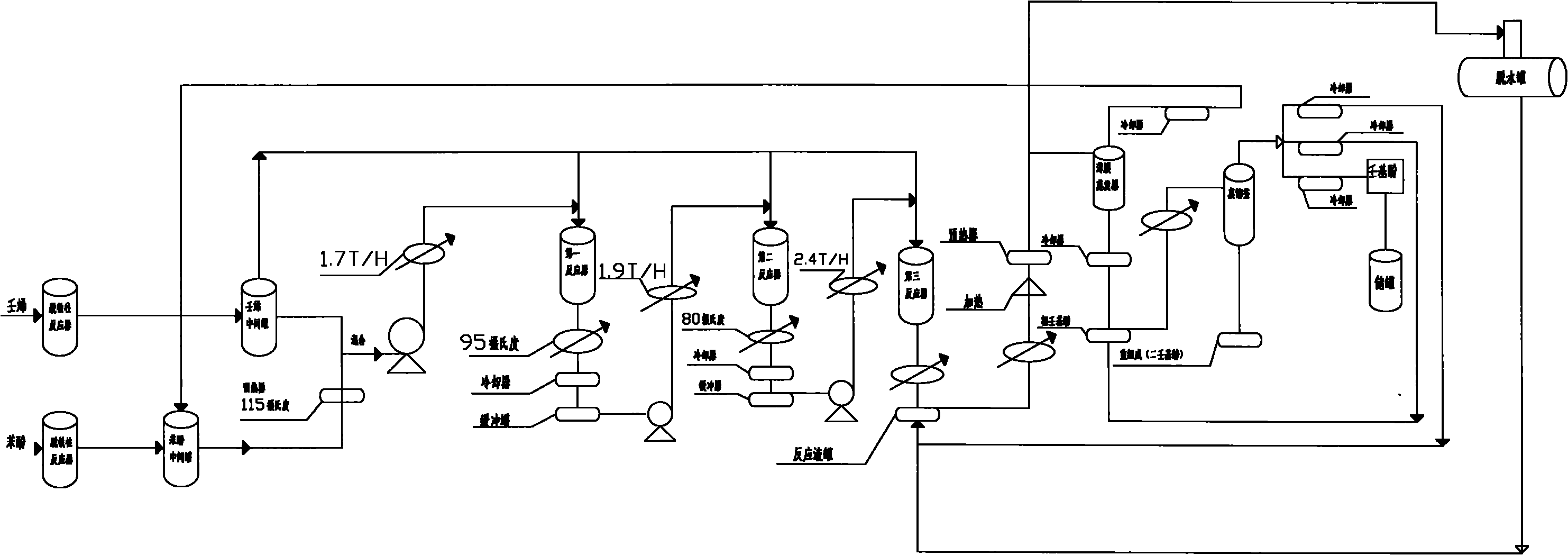

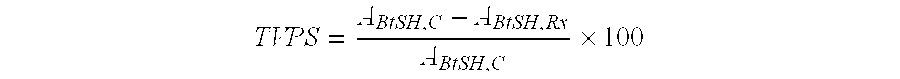

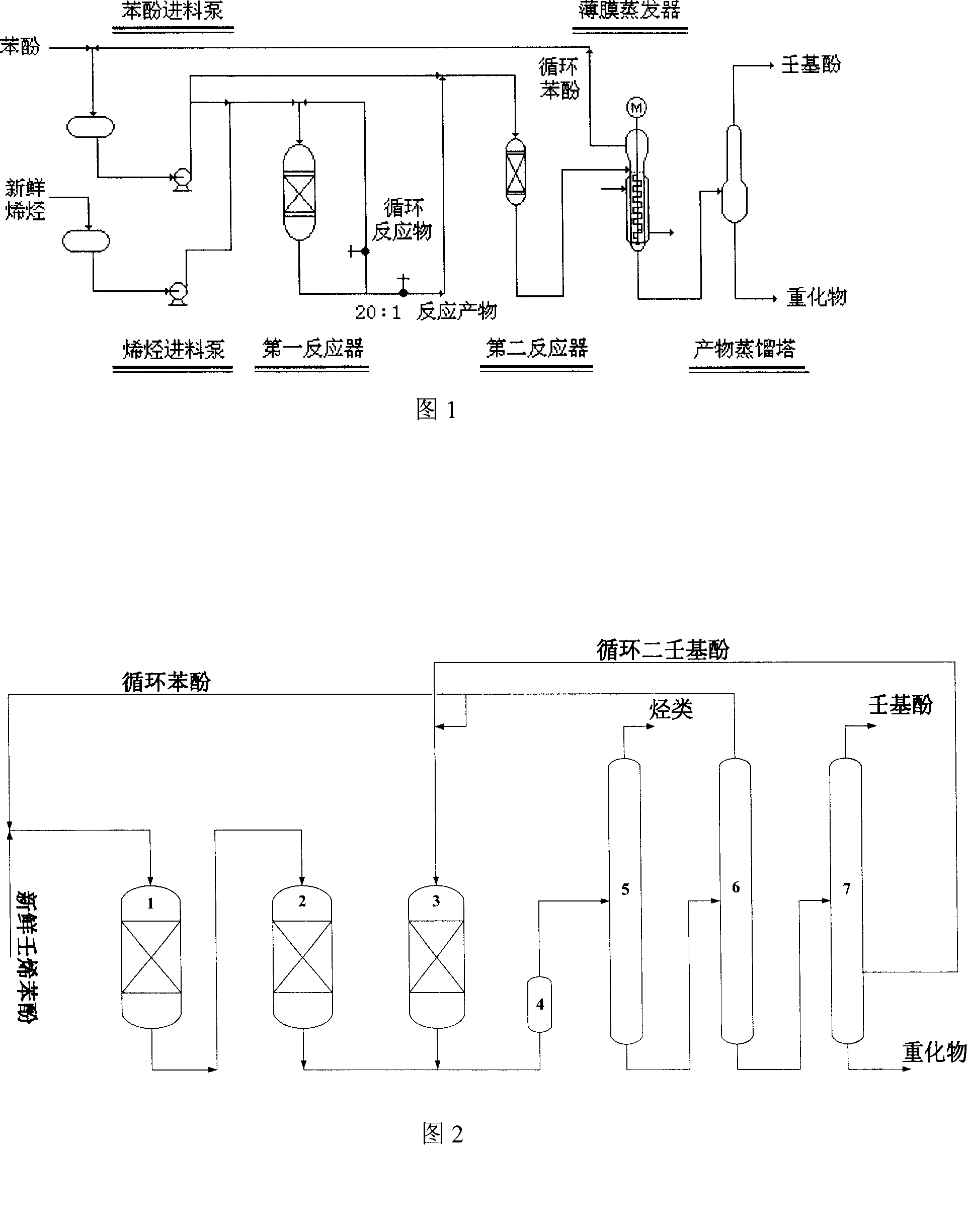

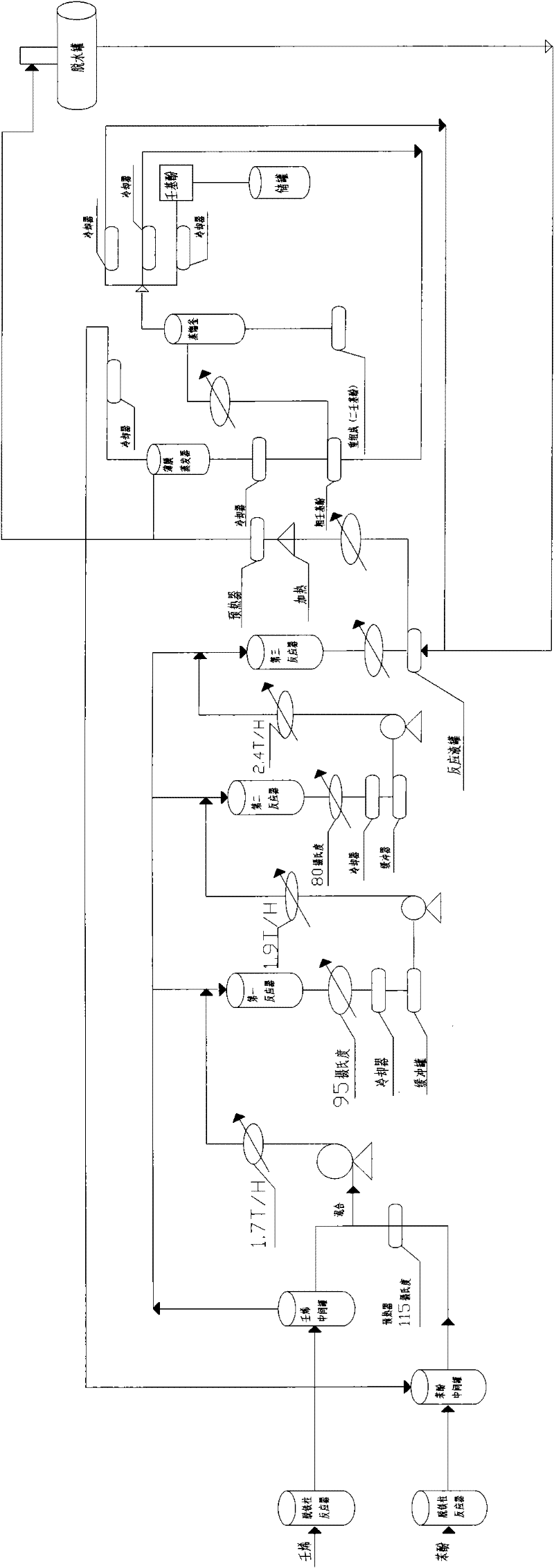

Method for producing nonyl phenol

ActiveCN101913994AHigh energy consumptionImprove process continuityOrganic chemistryOrganic compound preparationRetention timeThree stage

The invention discloses a method for producing nonyl phenol, which comprises the steps of: preheating phenol to a temperature between 115 DEG C and 125 DEG C, then fully mixing nonene at a room temperature with the preheated phenol, cooling to about 120 DEG C in a first-stage reactor, then putting in a second-stage reactor and dripping the nonene at the same time, cooling to the temperature of about 85 DEG C after the second-stage reaction, then reacting in a third-stage reactor and dripping the nonene at the same time, dephenolizing nonyl phenol reaction liquid obtained after three-stage reaction in a film evaporator, and distilling coarse nonyl phenol subjected to dephenolizing in a distilling still to obtain high-purity nonyl phenol. The method has the advantages of short reaction retention time, less by-products, small required power and low energy consumption, and the product produced has good quality. The whole production process is carried out continuously, has excellent stability, and improves production efficiency.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

Olefin compositions

A composition comprising: a) at least 76 mol % C10 monoolefins, the C10 monoolefins comprising i) at least 3 mol % 2-butyl-1-hexene, ii) at least 8 mol % 3-propyl-1-heptene, iii) at least 6 mol % 4-ethyl-1-octene, and iv) at least 20 mol % 5-methyl-1-nonene; and b) at least 1 mol % C14 monoolefins. A composition comprising at least 95 mol % C10 monoolefins, the C10 monoolefins comprising i) at least 3 mol % 2-butyl-1-hexene, ii) at least 10 mol % 3-propyl-1-heptene, iii) at least 7 mol % 4-ethyl-1-octene, and iv) at least 24 mol % 5-methyl-1-nonene. Processes to prepare a composition comprising at least 76 mol % C10 monoolefins and at least 1 mol % C14 monoolefins, or a composition comprising at least 95 mol % C10 monoolefins, where the C10 monoolefins comprise i) at least 3 mol % 2-butyl-1-hexene, ii) at least 10 mol % 3-propyl-1-heptene, iii) at least 7 mol % 4-ethyl-1-octene, and iv) at least 24 mol % 5-methyl-1-nonene.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

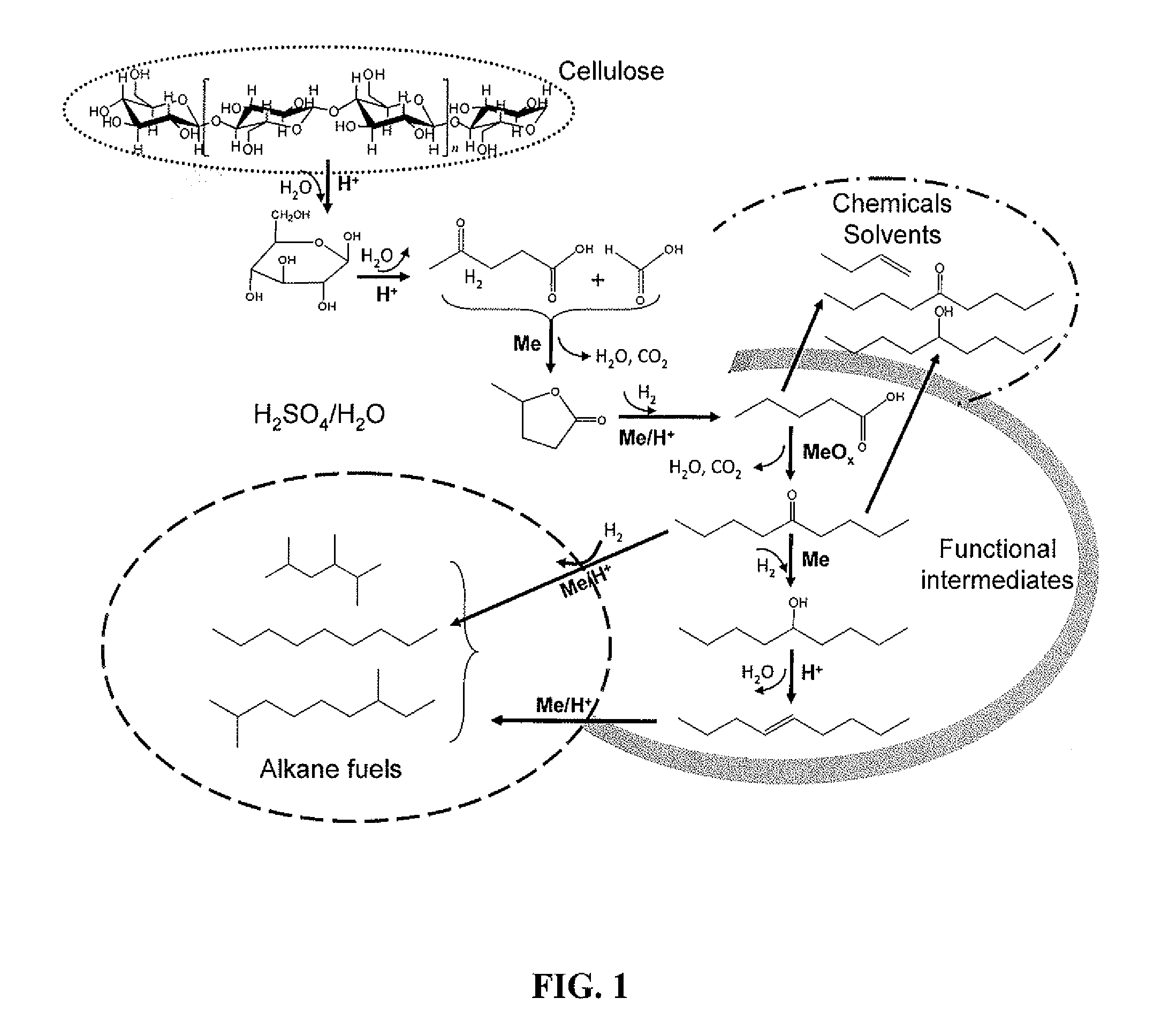

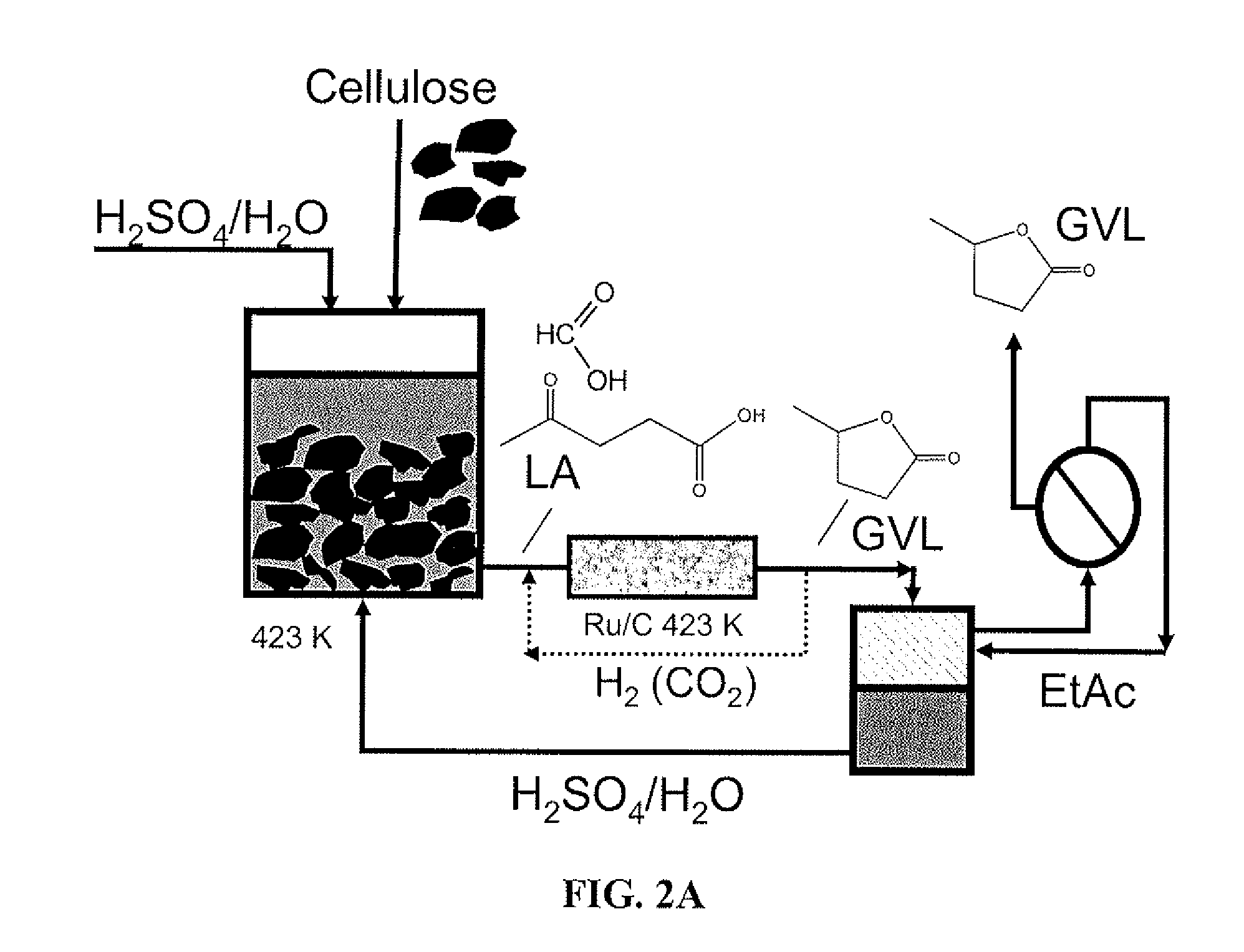

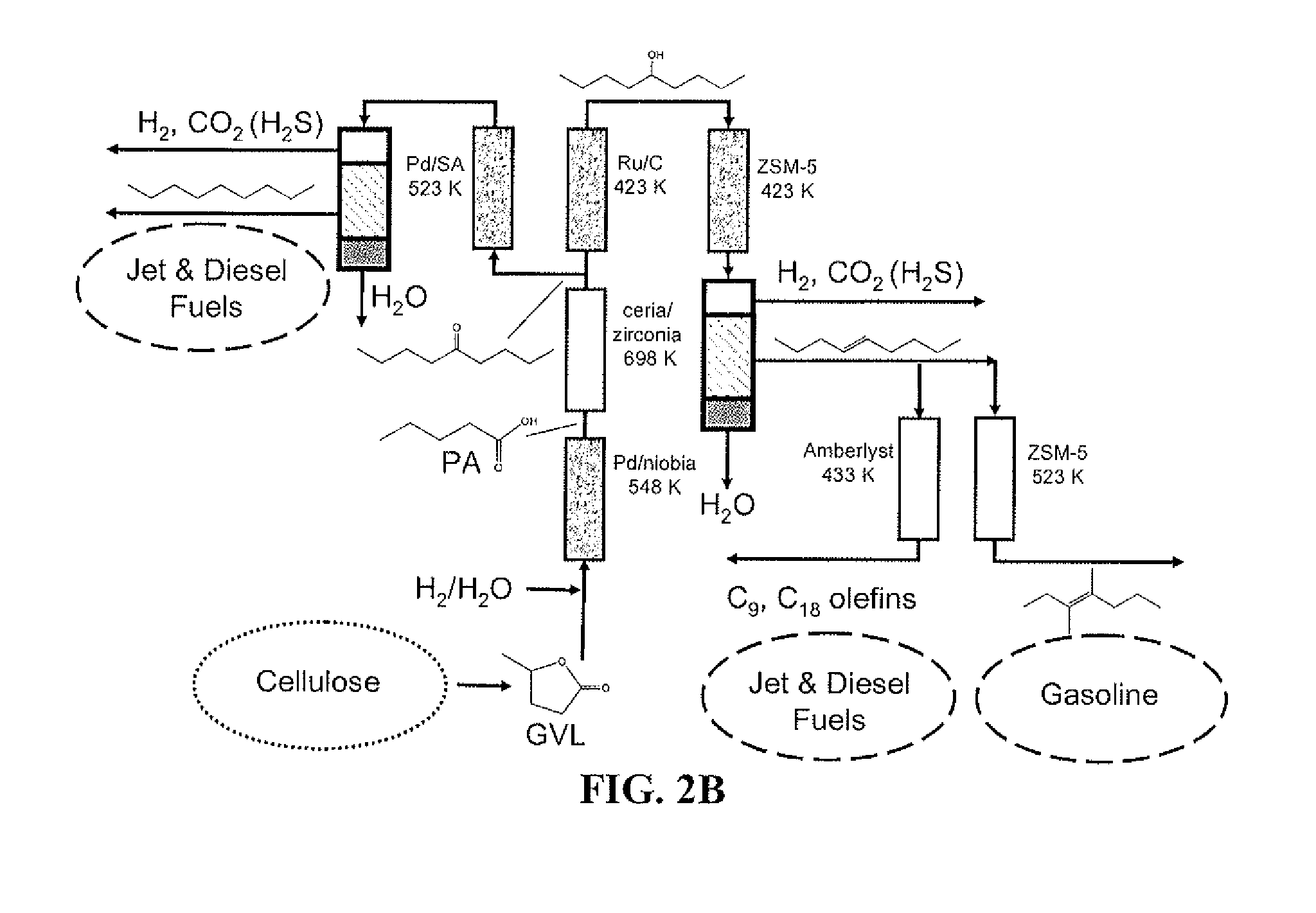

Catalytic conversion of cellulose to liquid hydrocarbon fuels by progressive removal of oxygen to facilitate separation processes and achieve high selectivities

Described is a method to make liquid chemicals, such as functional intermediates, solvents, and liquid fuels from biomass-derived cellulose. The method is cascading; the product stream from an upstream reaction can be used as the feedstock in the next downstream reaction. The method includes the steps of deconstructing cellulose to yield a product mixture comprising levulinic acid and formic acid, converting the levulinic acid to γ-valerolactone, and converting the γ-valerolactone to pentanoic acid. Alternatively, the γ-valerolactone can be converted to a mixture of n-butenes. The pentanoic acid so formed can be further reacted to yield a host of valuable products. For example, the pentanoic acid can be decarboxylated yield 1-butene or ketonized to yield 5-nonanone. The 5-nonanone can be hydrodeoxygenated to yield nonane, or 5-nonanone can be reduced to yield 5-nonanol. The 5-nonanol can be dehydrated to yield nonene, which can be dimerized to yield a mixture of C9 and C18 olefins, which can be hydrogenated to yield a mixture of alkanes. Alternatively, the nonene may be isomerized to yield a mixture of branched olefins, which can be hydrogenated to yield a mixture of branched alkanes. The mixture of n-butenes formed from γ-valerolactone can also be subjected to isomerization and oligomerization to yield olefins in the gasoline, jet and Diesel fuel ranges.

Owner:WISCONSIN ALUMNI RES FOUND

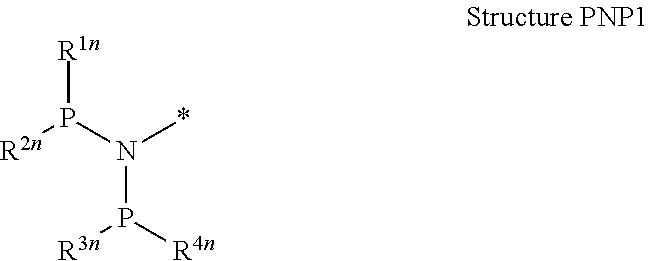

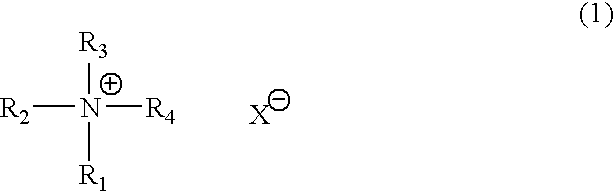

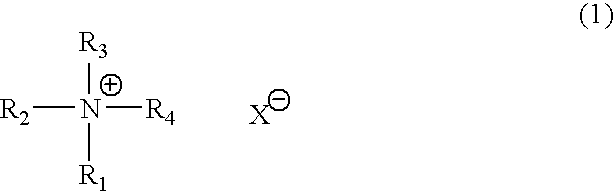

Catalyst composition for production of polyurethane resin and method for producing polyurethane resin (as amended)

ActiveUS20100130629A1Good molding effectIncrease production capacitySolesOrganic-compounds/hydrides/coordination-complexes catalystsAmmonium compoundsPolyisocyanurate

Disclosed is a catalyst composition for polyurethane resin production which contains (A) triethylenediamine, (B) a specific polyisocyanurating catalyst and / or (C) a specific highly temperature-sensitive catalyst. By using this catalyst composition, a polyurethane resin can be molded with good curability, while suppressing initial reactivity. Consequently, a polyurethane resin having excellent moldability and fluidity can be produced with high productivity by using the catalyst composition. The thus-obtained polyurethane resin is suitably applicable to shoe soles. The component (B) is selected from the group consisting of alkali metal salts of carboxylic acids, quaternary ammonium compounds expressed as R1R2R3R4N+,X−, N,N,N′-trimethylaminoethylethanolamine, and 2,4,6-tris(dimethylaminomethyl)phenol, while the component (C) is selected from the group consisting of triazole salts and benzotriazole salts of 1,8-diazabicyclo[5.4.0]undecene-7 or 1,5-diazabicyclo[4.3.0]nonene-5. The mixing ratio of the component (B) and / or the component (C) to the component (A) is from 2% by weight to 60% by weight.

Owner:TOSOH CORP

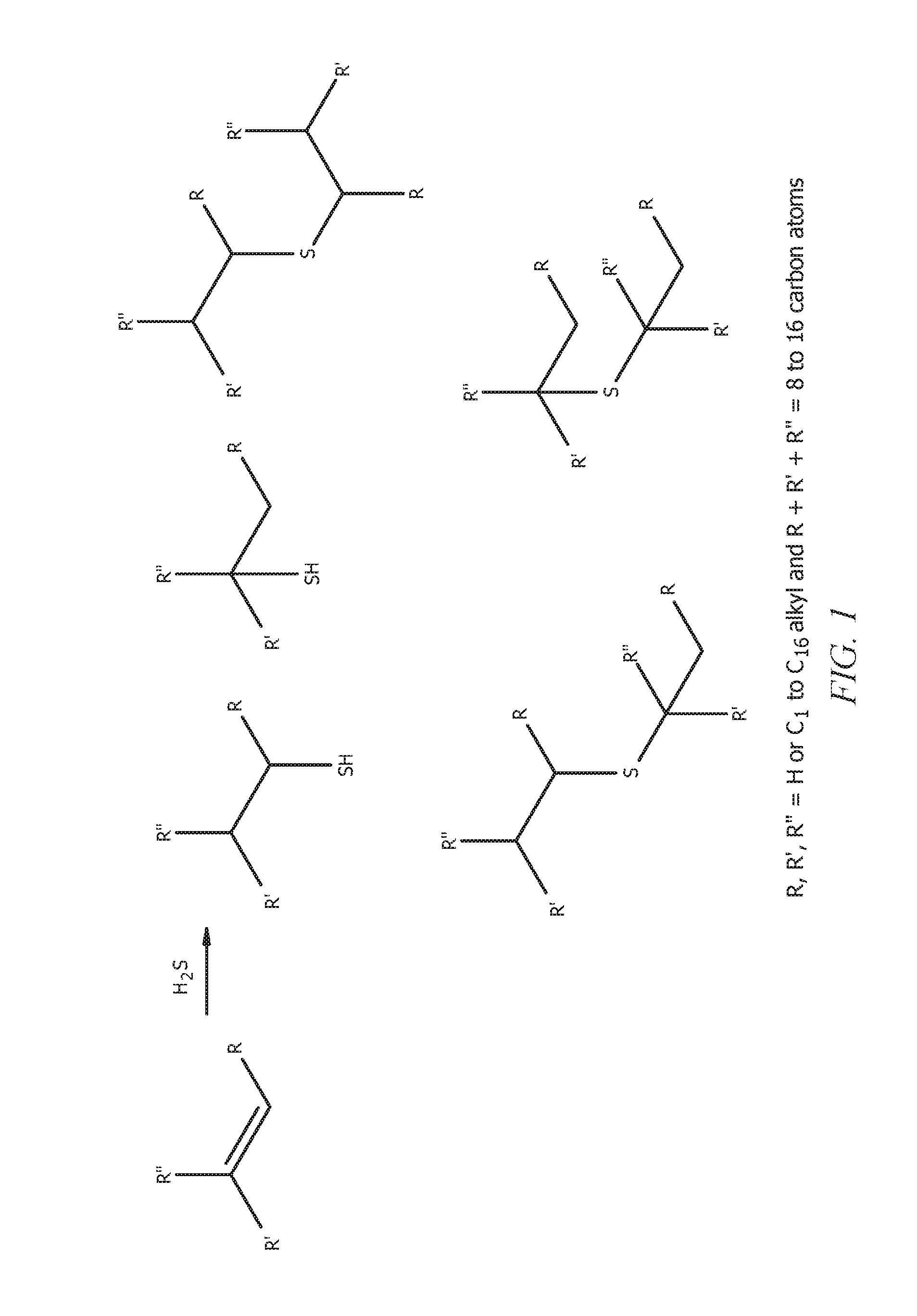

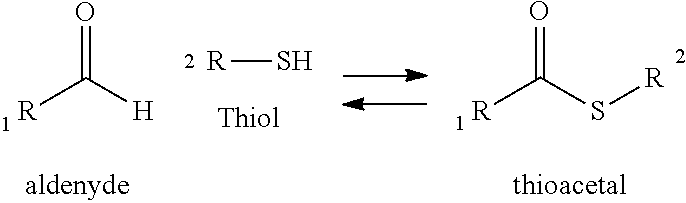

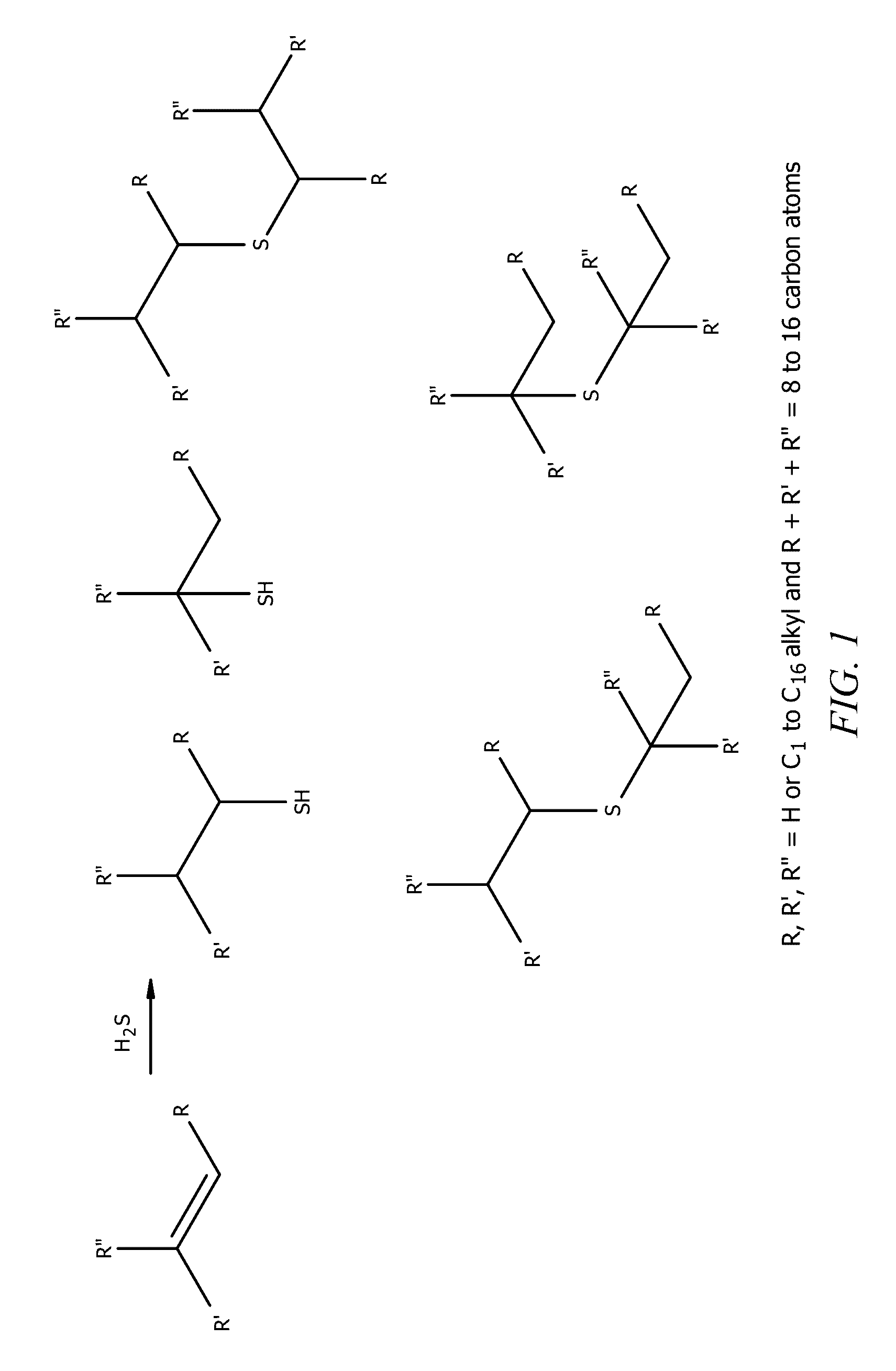

Mixed decyl mercaptans compositions and use thereof as mining chemical collectors

Disclosed herein is a process for the recovery of a metal from an ore using a collector composition. The process includes contacting the ore with the collector composition. The collector composition can include sulfur-containing compounds comprising (i) mercaptans comprising branched C10 mercaptans compounds selected from the group consisting of 5-methyl-1-mercapto-nonane, 3-propyl-1-mercapto-heptane, 4-ethyl-1-mercapto-octane, 2-butyl-1-mercapto-hexane, 5-methyl-2-mercapto-nonane, 3-propyl-2-mercapto-heptane, 4-ethyl-2-mercapto-octane, 5-methyl-5-mercapto-nonane, and combinations thereof; and (ii) sulfides comprising branched C20 sulfides represented by the structure R1—S—R2, wherein R1 and R2 are each independently a functional group derived from an olefin, wherein the olefin comprises 5-methyl-1-nonene, 3-propyl-1-heptene, 4-ethyl-1-octene, 2-butyl-1-hexene, or combinations thereof.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Absorbent article comprising complexed or encapsulated reactive compounds

ActiveUS20140377207A1Effective in counteracting malodourReduce odorCapsule deliveryMedical waste disposalAnimal fecesAcetaldehyde

Absorbent articles comprising one or more complexed or encapsulated compounds compounds selected from: melonal, adoxal, trans-2-hexenal, ligustral, Floral Super, Florhydral, 5-methyl-2-thiophene-carboxaldehyde, hydratropic aldehyde, undecenal, 9-undecenal, 10-undecenal, trans-4-decenal, cis-6-nonenal, isocyclocitral, precyclemone b, (E)-2,(z)-6-nonadienal, undecyl aldehyde, methyl-octyl-acetaldehyde, Lauric aldehyde, silvial, vanillin, floralozone; are particularly effective in reducing malodors coming from degradation of proteinaceous materials such as food, menses or feces.

Owner:THE PROCTER & GAMBLE COMPANY

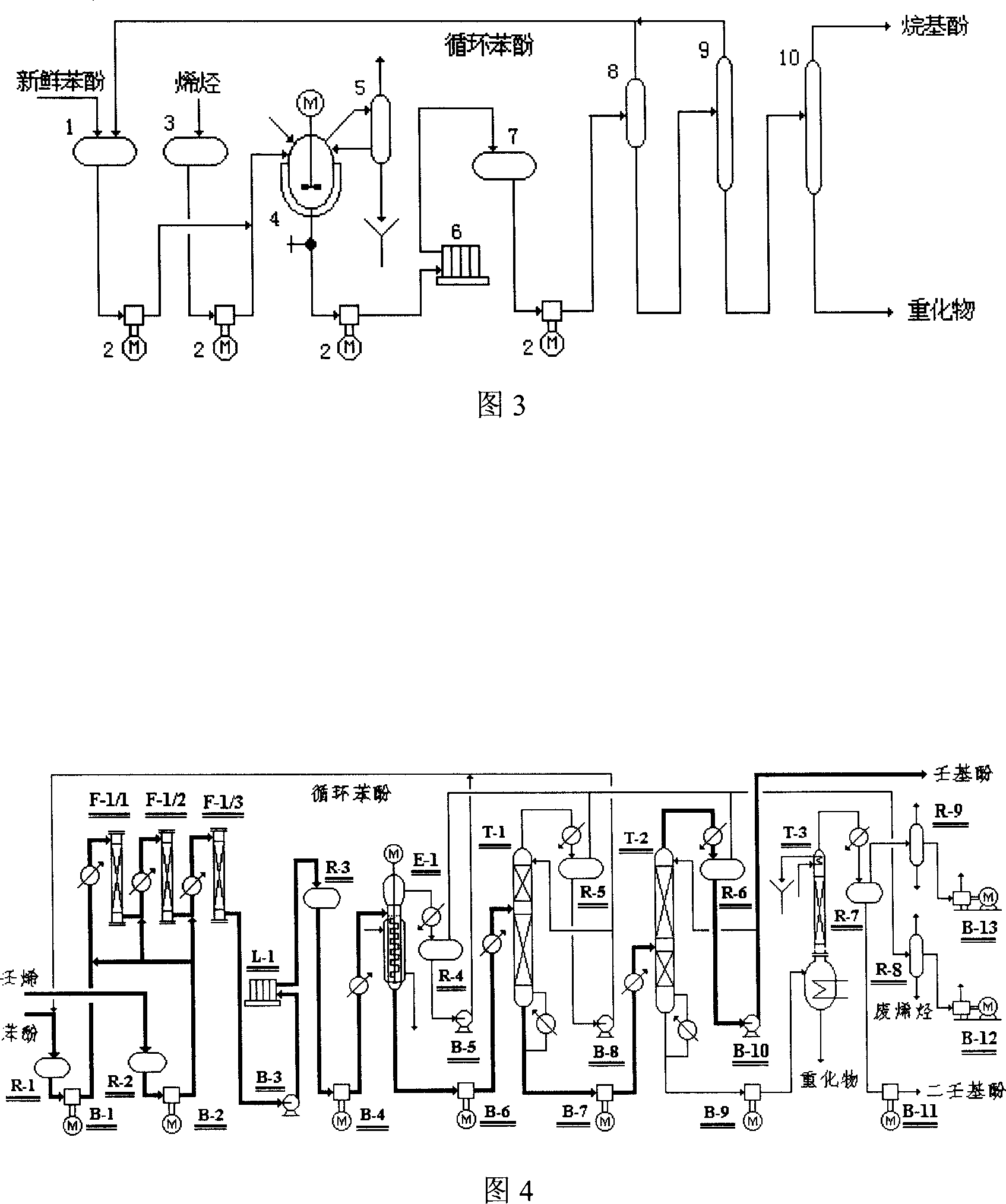

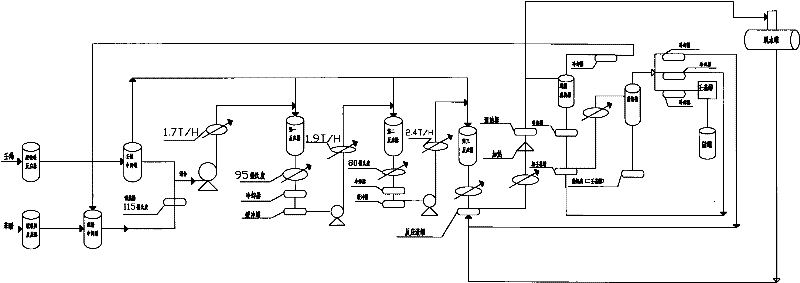

Nonyl phenol refining process

ActiveCN1970519AImproved color stabilityHigh yieldOrganic chemistryOrganic compound preparationTheoretical plateProcess engineering

The invention discloses a refining technique to synthesize industrial nonyl phenol, which comprises the following steps: a) evaporating to remove most of phenol in the industrial nonyl phenol; obtaining evaporator bottom material; b) distilling to remove phenol; obtaining rough nonyl phenol; setting the temperature of feed material into distill tower at 70-120 deg.c and tower top temperature at 40-85 deg.c and tower autoclave temperature at 170-215 deg.c; setting the total fill pressure at 0.4-1.0Kpa; controlling the reflux rate R between 0.5 and 2; obtaining the theoretical tower boards at 6-30 blocks; c) rectifying the rough nonyl phenol to obtain refined nonyl phenol and rough dinonyl phenol; setting the feed temperature of rectifying tower at 90-130 deg.c and tower top temperature at 80-170 deg.c and tower autoclave temperature at 180-260 deg.c; setting the total fill pressure at 0.4-1.0Kpa; controlling the reflux rate R between 0.4 and 2.5; obtaining the theoretical tower boards at 4-28 blocks.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

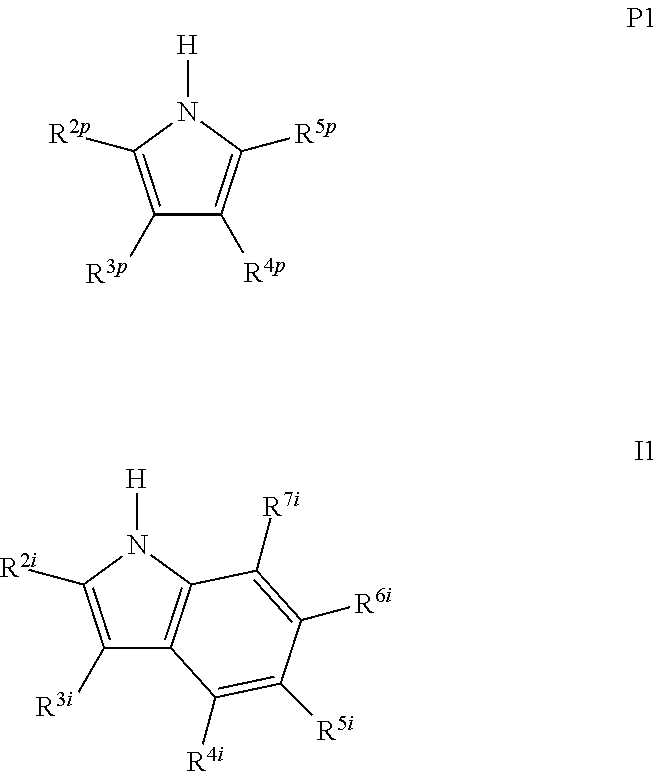

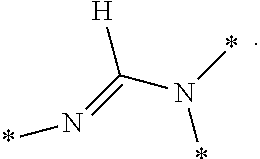

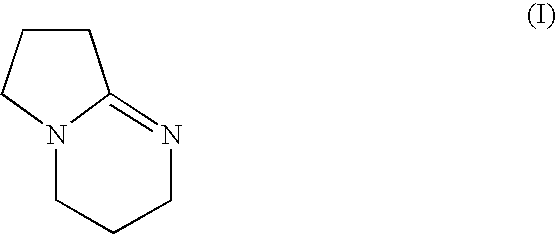

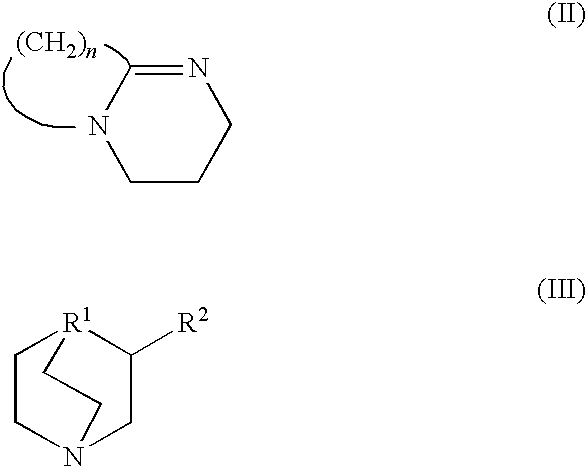

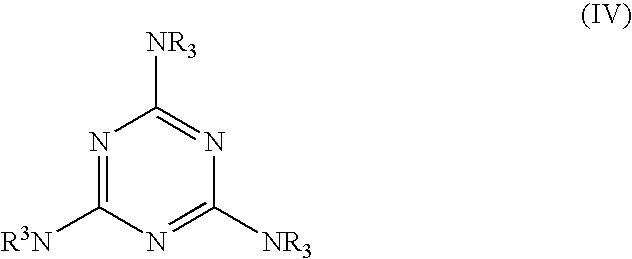

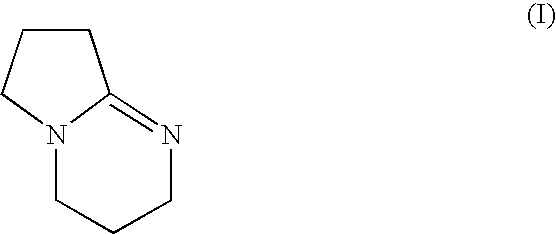

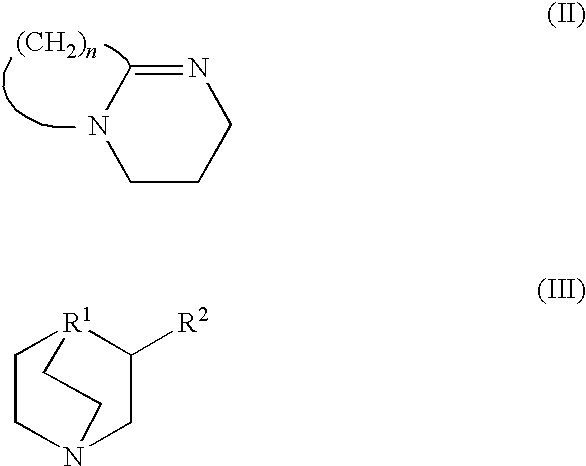

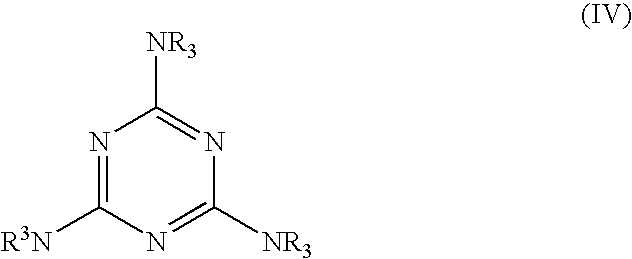

Rubber composition and pneumatic tire using the same

InactiveUS7795356B2Reduce dispersionShorten speedSpecial tyresOrganic dyesSilicon dioxideMethyl group

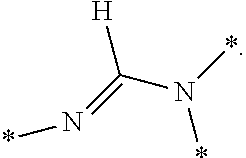

A rubber composition containing 100 parts by weight of a diene-based rubber, 20 to 120 parts by weight of silica, 3 to 15% by weight, based upon the weight of silica, of a sulfur-containing silane coupling agent and (A) 1,5-diazabicyclo[4,3,0]nonene-5 (DBN) having the formula (I):and / or a salt thereof or (B) 0.1 to 3.0 parts by weight of a compound having a piperidine skeleton having the formula (II) or a salt thereof and / or formula (III):wherein n indicates 3 or 5, R1 indicates CH or N and R2 indicates H or OH when R1 is CH, or H when R1 is N, and a melamine derivative of formula (IV):wherein R3 is a methoxymethyl group (—CH2OCH3) or methylol group (—CH2OH), the number of methoxymethyl groups is 3 to 6, and the number of methylol groups is 0 to 3, and / or polymer or copolymer resins of the same and a pneumatic tire using the same.

Owner:THE YOKOHAMA RUBBER CO LTD

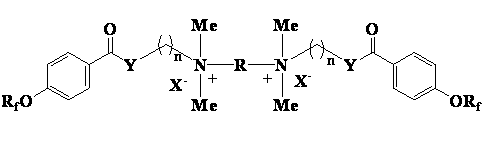

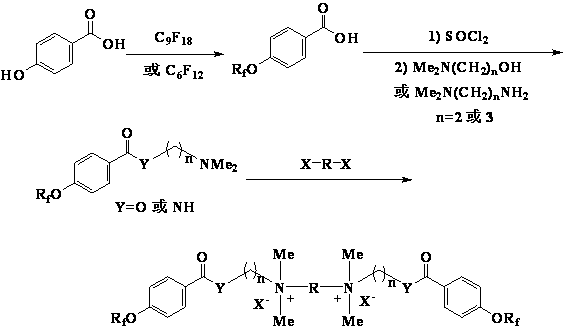

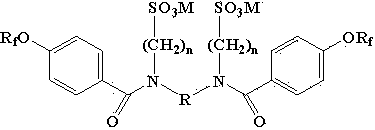

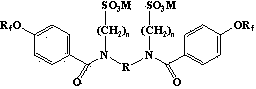

Cationic type gemini fluorinated surfactant based on perfluorinated nonene and perfluorinated hexene and preparation method of cationic type gemini fluorinated surfactant

ActiveCN102908937AHigh reactivityReactive and expensiveOrganic compound preparationTransportation and packagingBenzoic acidPolymer science

The invention discloses a cationic type gemini fluorinated surfactant based on perfluorinated nonene and perfluorinated hexene and a preparation method of the cationic type gemini fluorinated surfactant. The preparation method comprises the following steps of: with the perfluorinated nonene or perfluorinated hexene as a raw material, condensing the perfluorinated nonene or perfluorinated hexene with p-hydroxybenzoic acid, and carrying out chlorination on a matter obtained after condensation and thionyl chloride to prepare perfluorinated alkene oxyl benzoyl chloride; condensing the perfluorinated alkene oxyl benzoyl chloride without separation with 2-dimethylamino ethanol, 3-dimethylamino propanol, 2-dimethylamino ethylamine and 3-dimethylamino propylamine to obtain perfluorinated alkene oxyl benzoate or perfluorinated alkene oxyl benzamide with tertiary amine at an alkanol part or amine part; and finally, condensing the perfluorinated alkene oxyl benzoate or perfluorinated alkene oxyl benzamide with 1,2-dihaloethane, 1,3-dihalopropane, 1,4-dichlorobutane, 1,5-dichloropentane or 3-oxa-1,5-dichloropentane to prepare a quaternary ammonium gemini fluorinated surfactant. The synthesized compound is high in surface activity and is low in critical micelle concentration, has the characteristics of simpleness in synthesization, low cost and the like and has good application prospect.

Owner:江苏超至和新材料有限公司

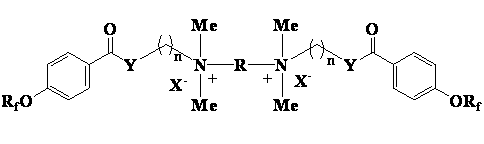

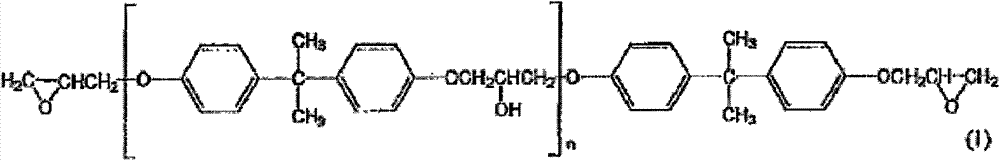

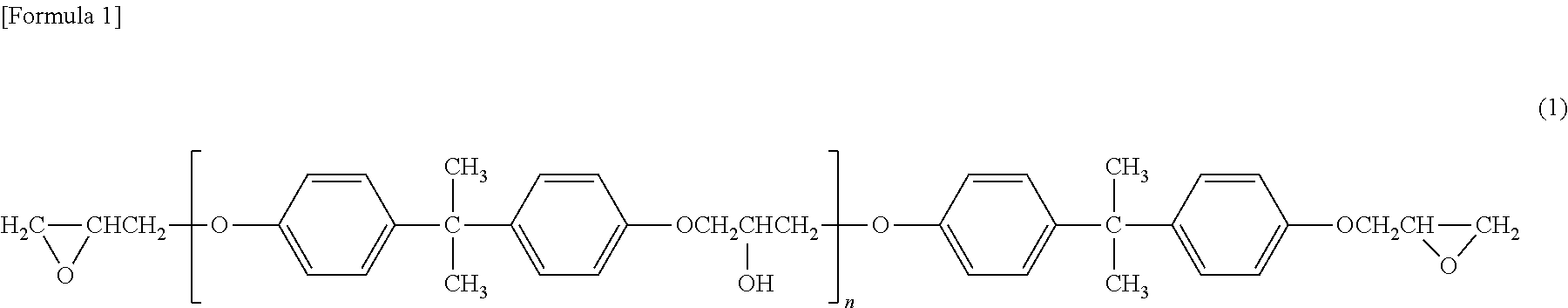

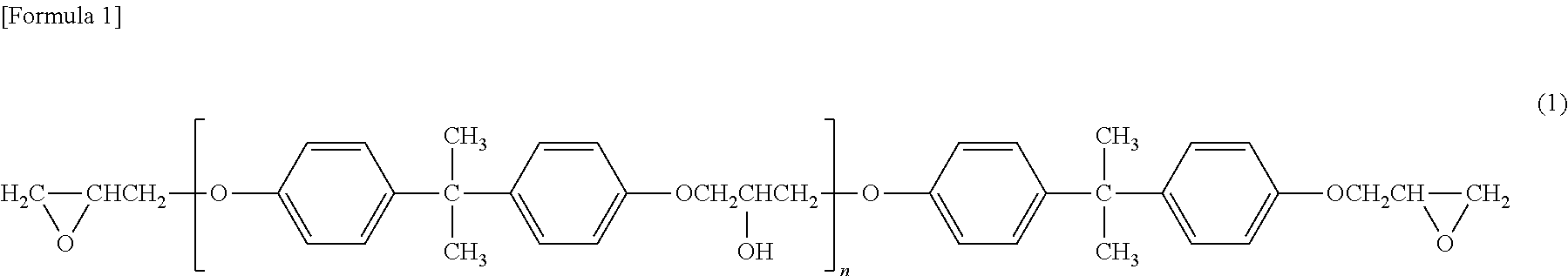

Laminate body

ActiveCN103249554AEasy to shapeGood flexibilityDomestic sealsSynthetic resin layered productsEpoxyVulcanization

Disclosed is a laminate body provided with a rubber layer (A) and a fluororesin layer (B) laminated on the rubber layer (A). The rubber layer (A) is formed from a rubber composition for vulcanization, and said rubber composition for vulcanization contains (a1) an epichlorohydrin rubber, (a2) at least one compound selected from a group consisting of 1,8-diazabicyclo(5.4.0)undecene-7 and salts thereof, and 1,5-diazabicyclo(4.3.0)-nonene-5 and salts thereof, (a3) an epoxy resin, and (a4) a water bearing substance. The fluororesin layer (B) is formed from a fluoropolymer composition, and said fluoropolymer composition contains (b1) a fluoropolymer having copolymer units derived from chlorotrifluoroethylene.

Owner:DAIKIN IND LTD +1

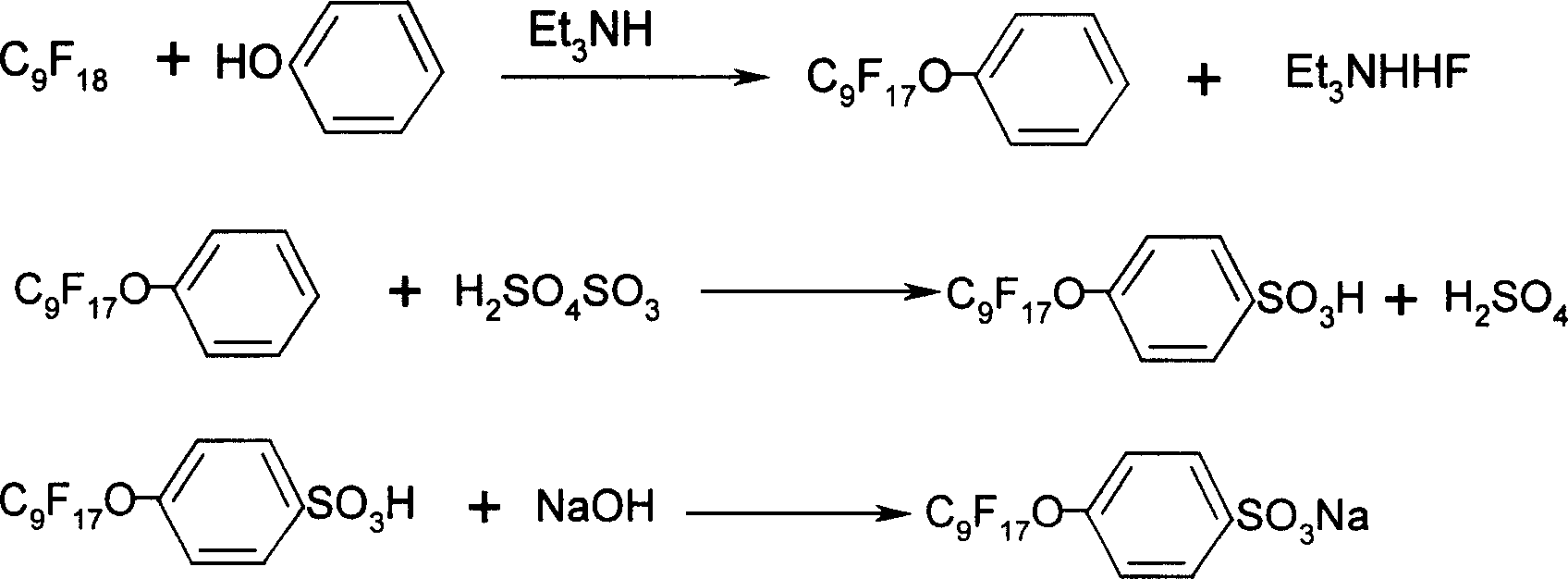

Method of synthesizing sodium p-perfluorous nonenoxybenzenesulfonate

InactiveCN101033205AShort process routeMild reaction conditionsOrganic chemistryHexafluoropropyleneReaction temperature

This invention discloses a method for synthesizing perfluorinated azelaic(en) sybthesis of benzene sodium sulfophenylate including: solving hexafluoropropylene trimer in a polarity solvent, adding p-hydroxybenzoic sodium sulfophenylate reacting the hexafluoropropylene trimer completely and adding a catalyst to control the reaction temperature to get a rough product of perfluorinated azelaic(en) sybthesis of benzene sodium sulfophenylate, which is separated from the solution.

Owner:JUHUA GROUP TECH CENT +1

Mixed decyl mercaptans compositions and use thereof as mining chemical collectors

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

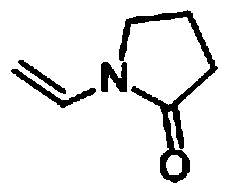

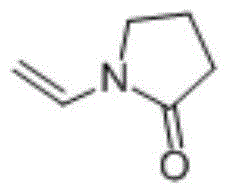

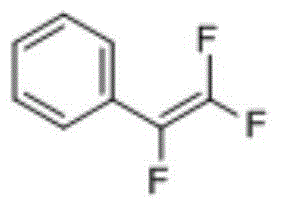

Low-carbon olefine oligomerization catalyst and preparation method thereof

ActiveCN103447089AHas a complexing effectHigh temperature resistantOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsLiquid productGasoline

The invention relates to a low-carbon olefine oligomerization catalyst and a preparation method thereof. A monomer N-vinyl pyrrolidone and trifluorostyrene are added to participate into polymerization in a polymerization process, and then sulfonated to generate the syrene cation exchange resin containing pyrrolidone in a skeleton. The catalyst disclosed by the invention has a high temperature resistant characteristic, is good in stability and yield of liquid products, and still can keep high catalytic activity after running for a long period of time. The resin catalyst disclosed by the invention is suitable for C3 and C4 olefine oligomerization reaction, so as to prepare C6-C16 olefins, and is especially suitable for a technology for producing nonene and laurylene by virtue of propylene oligomerization, a technology for producing a high-octane gasoline by C4 olefin oligomerization, a technology for producing isooctane by virtue of isobutene dimerization, and the like.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

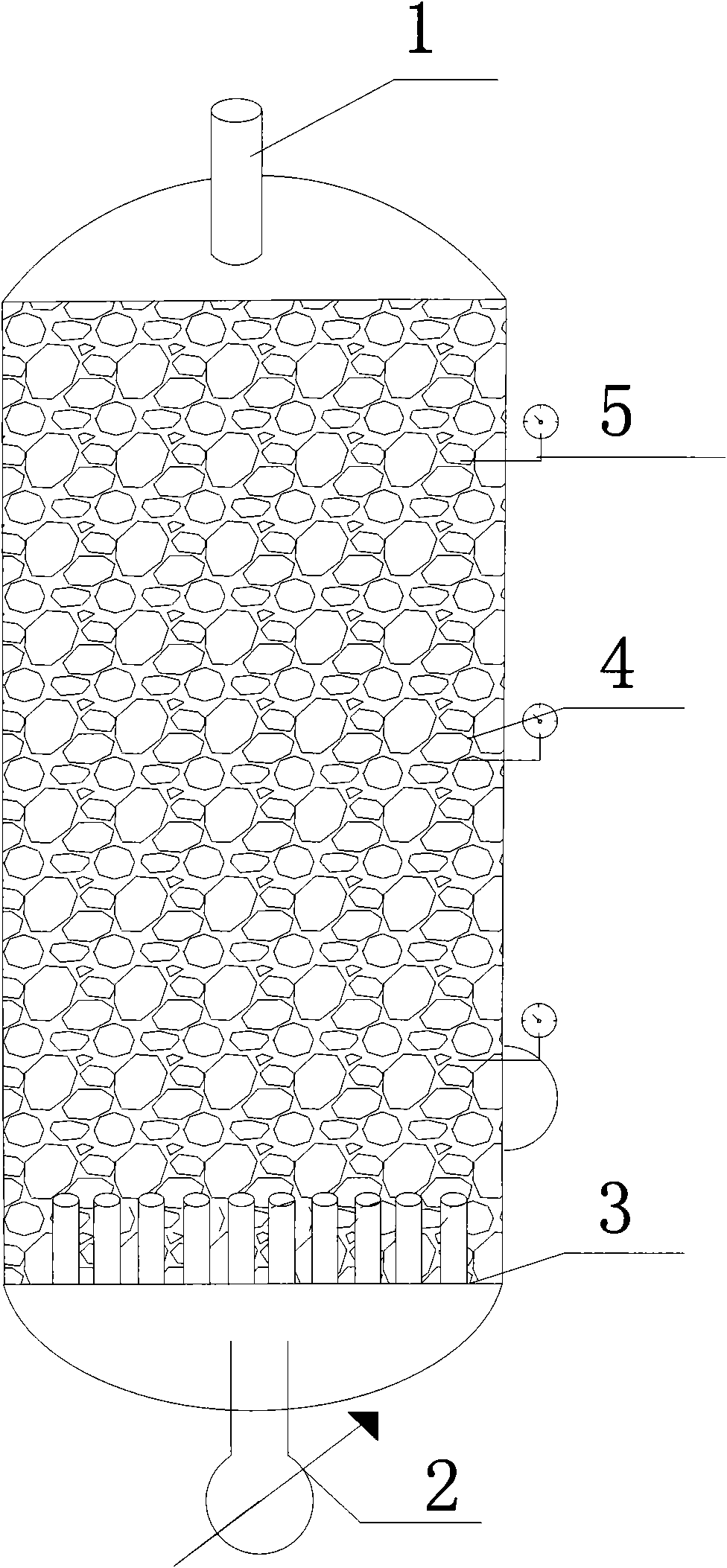

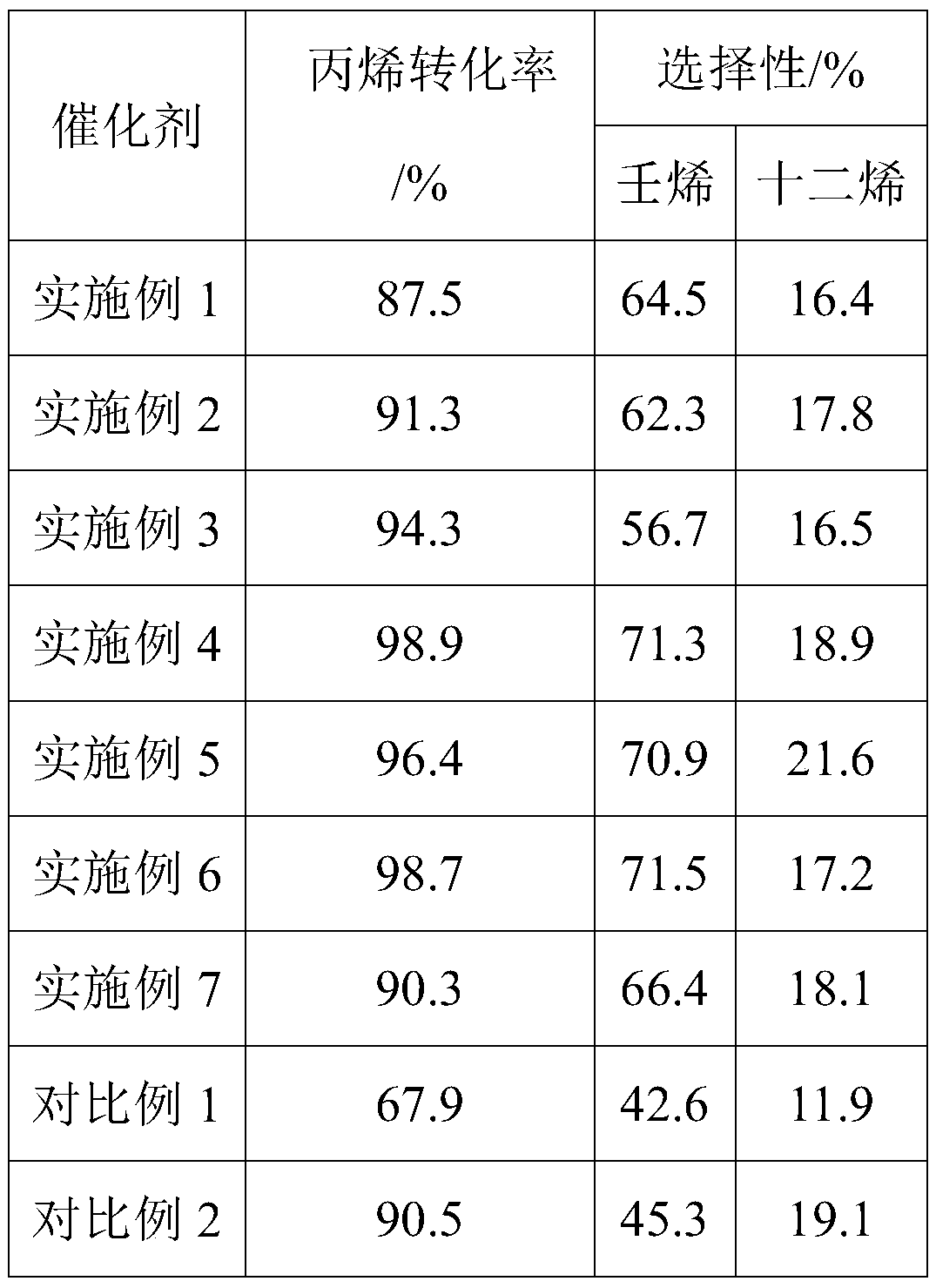

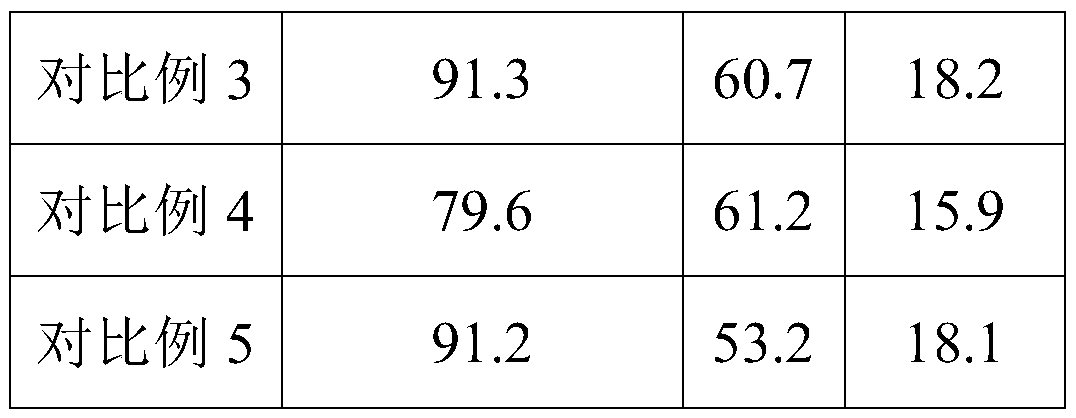

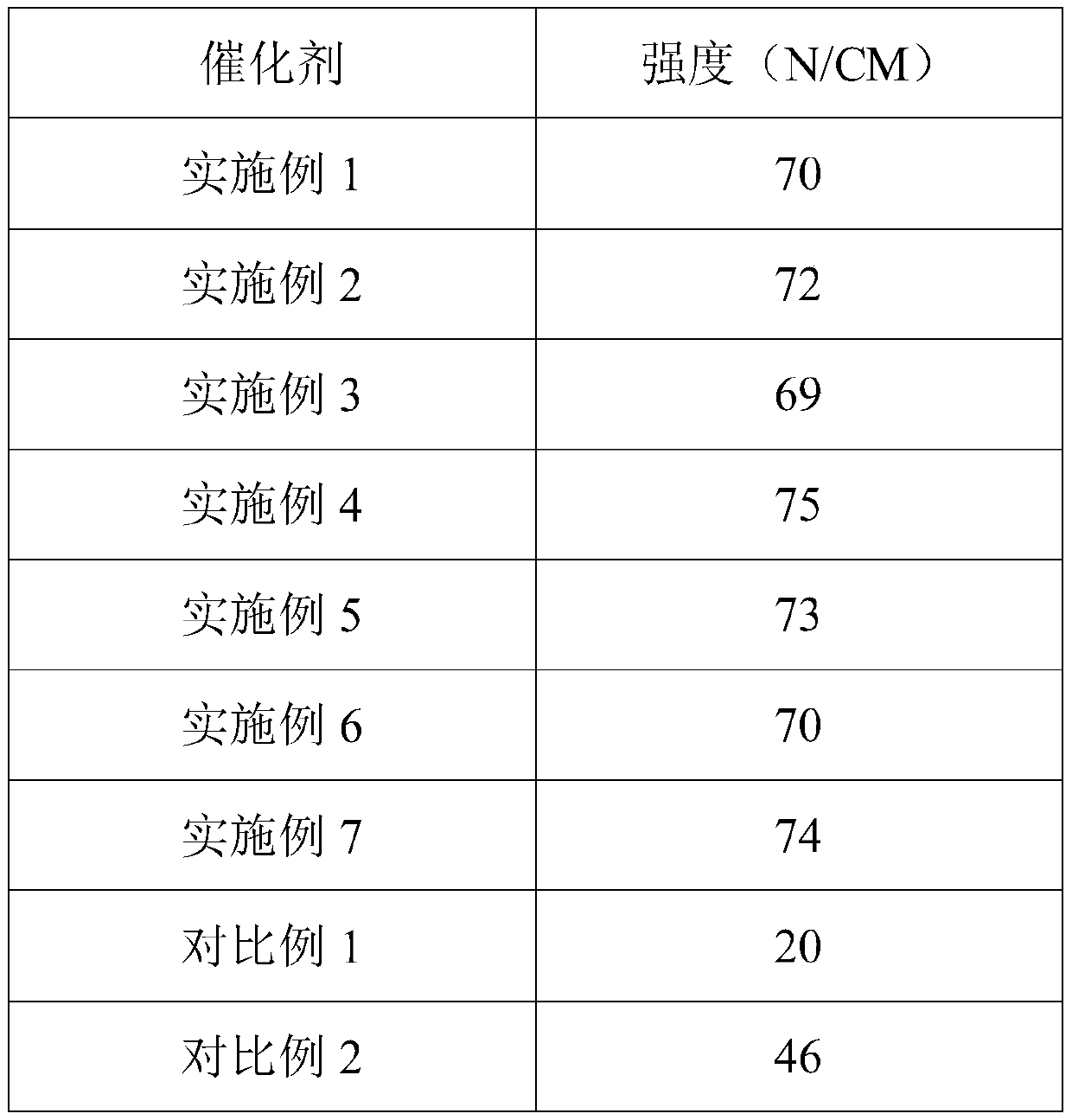

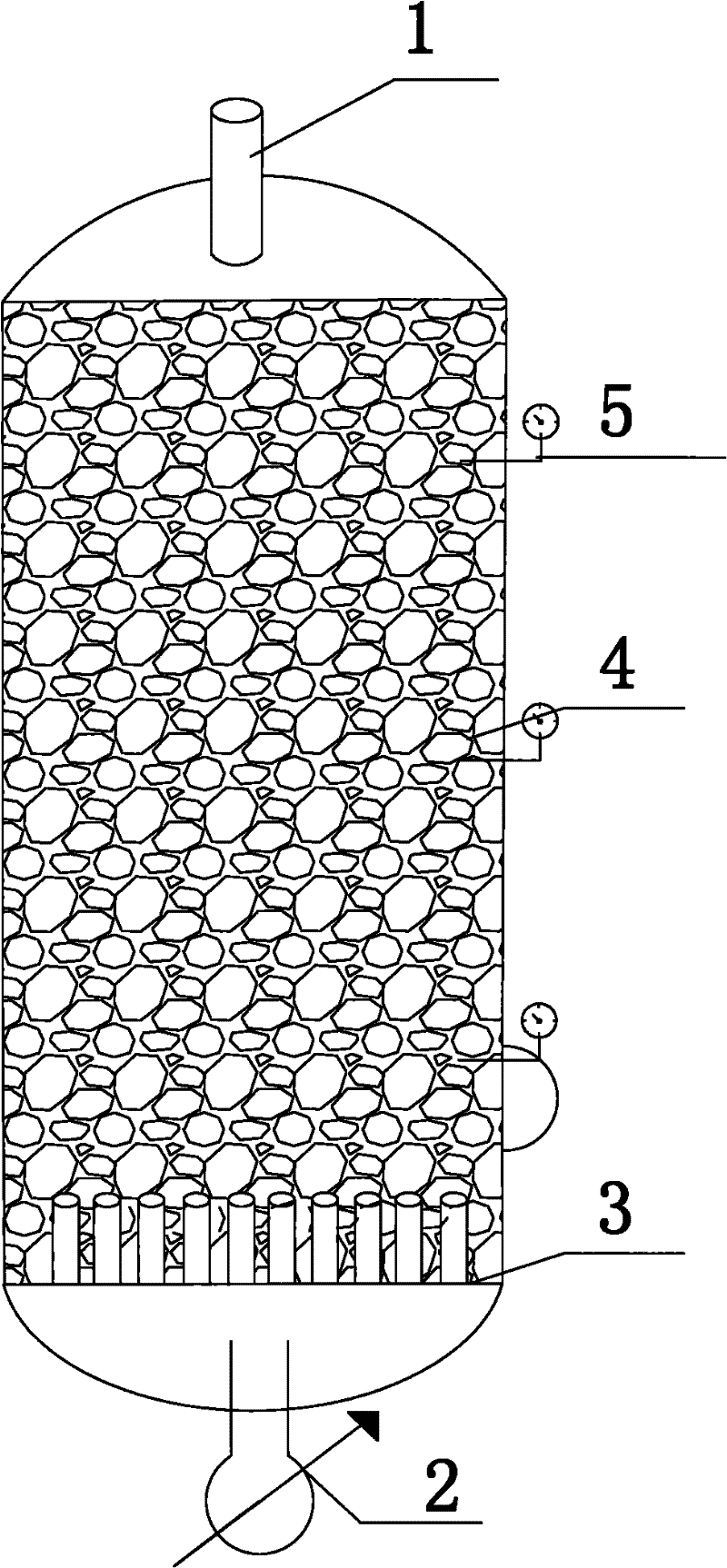

Catalyst for preparation of nonene and dodecene from sthylenediamine and preparation method thereof

ActiveCN109908944AIncrease carrier internal supportHigh strengthMolecular sieve catalystsHydrocarbonsMolecular sieveChemical industry

The invention belongs to the field of chemical industry, and specifically relates to a catalyst for preparation of nonene and dodecene from sthylenediamine and a preparation method thereof. Accordingto the catalyst for the preparation of the nonene and the dodecene by the sthylenediamine and the preparation method thereof, a core-shell structure with an aluminium oxide wrapped by molecular sievesis formed by loading the molecular sieves on the periphery of an aluminium oxide carrier after active ingredients are loaded on the aluminium oxide carrier. On the premise of fully playing the catalytic performance of the molecular sieves, the strength of the catalyst is effectively improved and the pulverization of simple molecular sieves is avoided by adding internal support of the aluminium oxide carrier; the active ingredients are positioned in the molecular sieves, so that the loss of the active ingredients is not caused easily, the stability of the catalyst is improved, and the servicelife of the catalyst is prolonged; the molecular sieves and aluminium oxide spheres form a core-shell shape, and both the molecular sieves and the aluminium oxide which is loaded with the active ingredients have catalytic activity, so that a stepped catalytic action is achieved; the raw materials which do not react on the peripheries of the molecular sieves enter aluminium oxide molecular sieves for further reaction; the catalytic actions of the molecular sieves and the aluminium oxide which is loaded with the active ingredients are added, so that the activity and the selectivity are further improved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

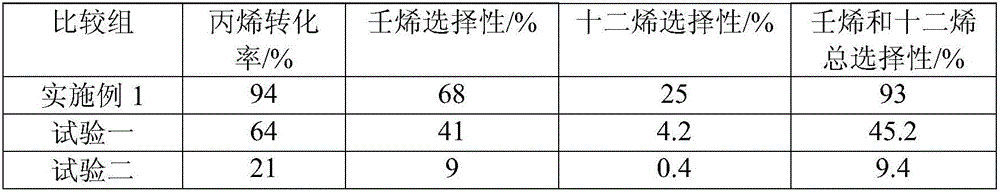

Catalyst for preparing nonene and dodecene through propylene oligomerization and purpose thereof

ActiveCN106732700AImprove conversion rateHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsReaction temperatureActive ingredient

The invention relates to a catalyst for preparing nonene and dodecene through propylene oligomerization and a purpose thereof. The catalyst is characterized in that phosphorus tungsten molybdenum oxide active ingredients are loaded on a TiO2 / SiO2 carrier by an in-situ sol-gel method. The catalyst is used for preparing the nonene and dodecene through propylene oligomerization. Under the conditions that the reaction temperature is 200 to 300 DEG C, the reaction pressure is 1.5 to 3.5MPa, the feeding air speed is 2000 to 5500 h<-1> and the activated water mass percentage is 0.8 percent to 1.2 percent, the conversion rate of propylene is greater than or equal to 90 percent; the selectivity of nonene is greater than or equal to 64 percent; the selectivity of the dodecene is greater than or equal to 23 percent. The catalyst provided by the invention is used for the propylene oligomerization, and has the advantages of high catalysis activity, low reaction temperature and low pressure. Experiments prove that the service life of the catalyst is more than three years; the requirements of long period operation of industry can be met; the total selectivity is high.

Owner:CHANGZHOU UNIV

Barium sulfate scale dissolving agent

PendingCN112745820ASolve solid phase cloggingSolve the problem of solid phase cloggingDrilling compositionActive agentEthyl group

The invention provides a barium sulfate scale dissolving agent which is composed of the following components: chelating agents: 8-12% of ethylenediamine tetraacetic acid, diethyl triamine pentaacetic acid and diethylene triamine penta (methylene phosphonic acid); solubilizers: sodium formate and sodium hydroxide with the content of 6-12%; the synergist comprises oxalic acid, salicylic acid, cinnamic acid and citric acid with the content of 0.4-1%; dispersing agents: polyethylene acid and polymethylacrylic acid with the content of 8-14%; corrosion inhibitor: hydroxyethylidene phosphonic acid with the content of 0.8-1.0%; surface active agent: alkylbenzene sulfonate, monoethanolamine and diethanolamine with the content of 3-5%; demulsifying agent: nonylphenol polyoxyethylene sodium sulfate with the content of 0.6-1.2%; a discharge aiding agent: perfluorononenyloxy sodium benzenesulfonate with the content of 1-2.4%; and clay stabilizer: epoxy chloropropane-dimethylamine condensation polymer with the content of 0.6-1.2%. The barium sulfate scale dissolving agent is suitable for dissolving barite solid-phase blockage in natural fractures, the scale dissolving rate reaches up to 97.19%, reservoir damage can be relieved, and the productivity of an oil and gas well can be recovered.

Owner:SOUTHWEST PETROLEUM UNIV

Composition for vulcanizing adhesion

ActiveUS20130236670A1Improve adhesionOrganic chemistryNon-macromolecular adhesive additivesNoneneChemistry

A composition for vulcanizing adhesion, comprises a rubber (a), at least one compound (b) selected from the group consisting of salts of 1,8-diazabicyclo(5.4.0) undecene-7, salts of 1,5-diazabicyclo(4.3.0)-nonene-5, 1,8-diazabicyclo(5.4.0) undecene-7, and 1,5-diazabicyclo(4.3.0)-nonene-5, and at least one water-carrying substance (c) selected from water-absorbed substances and hydrated substances.

Owner:OSAKA SODA CO LTD

Low-carbon olefine oligomerization catalyst and preparation method thereof

ActiveCN103447089BHas a complexing effectHigh temperature resistantOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsLiquid productGasoline

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

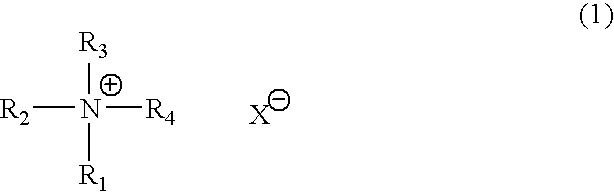

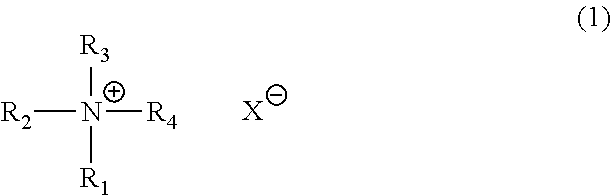

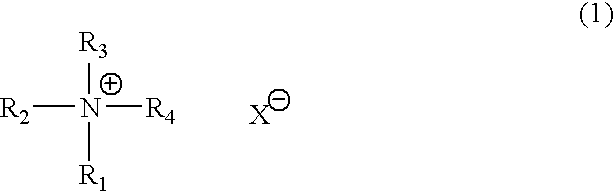

Catalyst composition for production of polyurethane resin and method for producing polyurethane resin

ActiveUS8877825B2Good molding effectIncrease production capacitySolesOrganic-compounds/hydrides/coordination-complexes catalystsPolyisocyanurateCarboxylic acid

To provide a catalyst composition which is a catalyst composition not impairing the physical properties of a polyurethane resin and the storage stability of the starting material blend liquid and which is capable of producing a polyurethane resin excellent in curability and also excellent in moldability by suppressing the initial reactivity, with good productivity.A catalyst composition for production of a polyurethane resin, which comprises (A) triethylenediamine, and (B) a polyisocyanurating catalyst and / or (C) a highly temperature sensitive catalyst, wherein the polyisocyanurating catalyst (B) is one or more compounds selected from the group consisting of an alkali metal salt of a carboxylic acid, a quaternary ammonium salt compound of the following formula (1):wherein each of R1 to R3 is a C1-12 linear or branched, saturated or unsaturated hydrocarbon group, provided that any two among R1 to R3 may form a hetero ring via an oxygen atom or a nitrogen atom, R4 is a C1-18 alkyl group or an aromatic hydrocarbon group, and X is an organic acid group having an acid dissociation constant (pKa) of at most 4.8, N,N,N′-trimethylaminoethylethanolamine and 2,4,6-tris(dimethylaminomethyl)phenol; the highly temperature sensitive catalyst (C) is one or more compounds selected from the group consisting of a triazole salt of 1,8-diazabicyclo[5.4.0]undecene-7, a benzotriazole salt of 1,8-diazabicyclo[5.4.0]undecene-7, a triazole salt of 1,5-diazabicyclo[4.3.0]nonene-5, a benzotriazole salt of 1,5-diazabicyclo[4.3.0]nonene-5, a triazole salt of 1,8-diazabicyclo[5.3.0]decene-7 and a benzotriazole salt of 1,8-diazabicyclo[5.3.0]decene-7; and the blend ratio of the polyisocyanurating catalyst (B) and / or the highly temperature sensitive catalyst (C) to the triethylenediamine (A) is from 2 wt % to 60 wt %.

Owner:TOSOH CORP

Method for producing nonyl phenol

ActiveCN101913994BHigh energy consumptionImprove process continuityOrganic chemistryOrganic compound preparationRetention timeThree stage

The invention discloses a method for producing nonyl phenol, which comprises the steps of: preheating phenol to a temperature between 115 DEG C and 125 DEG C, then fully mixing nonene at a room temperature with the preheated phenol, cooling to about 120 DEG C in a first-stage reactor, then putting in a second-stage reactor and dripping the nonene at the same time, cooling to the temperature of about 85 DEG C after the second-stage reaction, then reacting in a third-stage reactor and dripping the nonene at the same time, dephenolizing nonyl phenol reaction liquid obtained after three-stage reaction in a film evaporator, and distilling coarse nonyl phenol subjected to dephenolizing in a distilling still to obtain high-purity nonyl phenol. The method has the advantages of short reaction retention time, less by-products, small required power and low energy consumption, and the product produced has good quality. The whole production process is carried out continuously, has excellent stability, and improves production efficiency.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

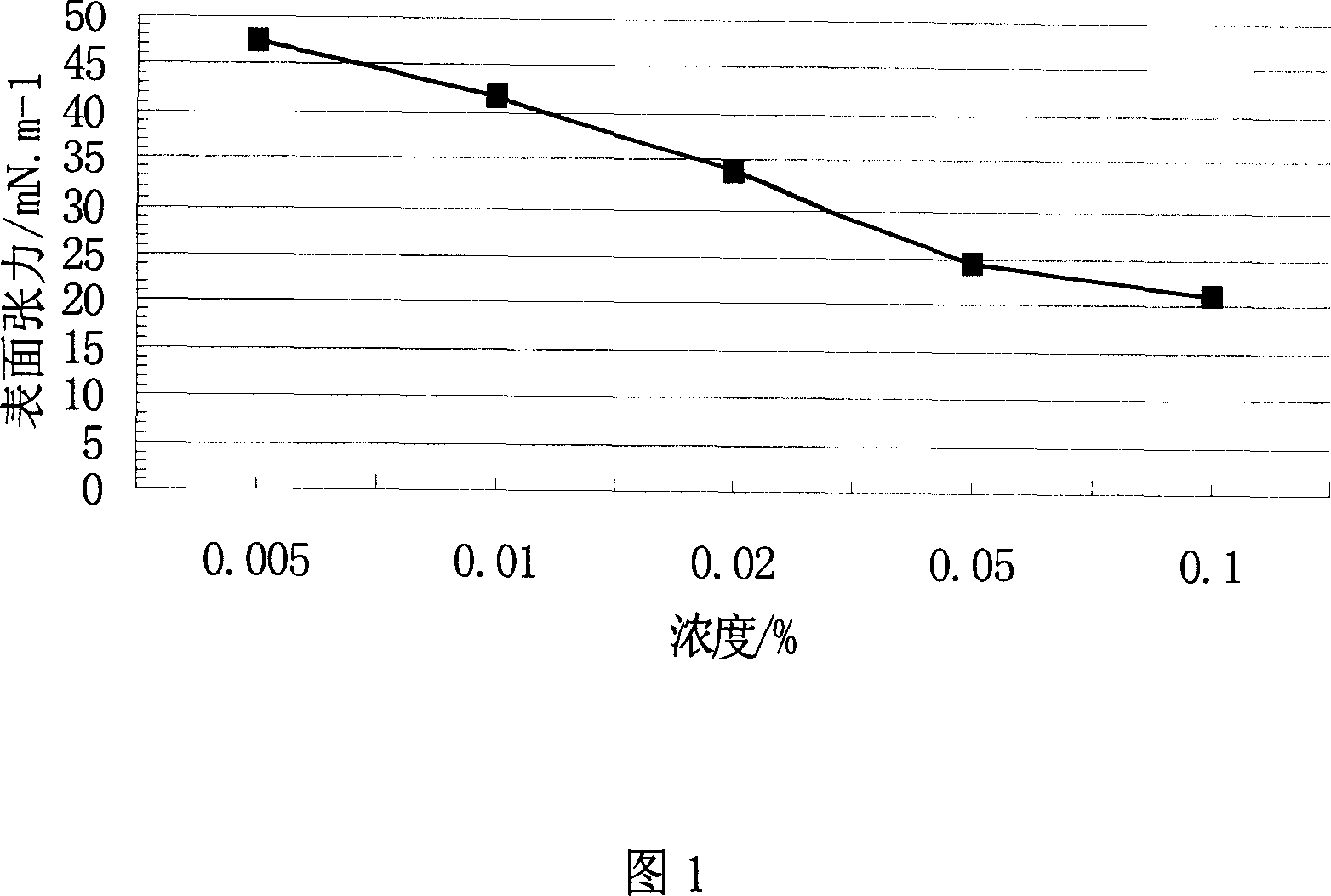

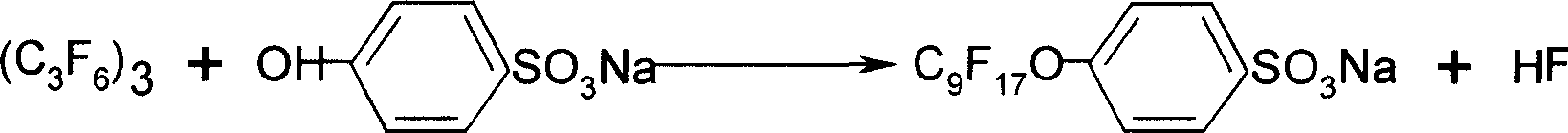

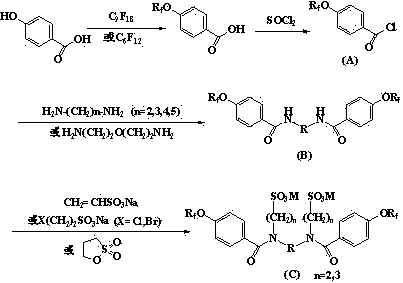

Perfluoroolefine type anionic gemini surfactant and preparation method thereof

InactiveCN103657512AImprove surface activityReduce surface tensionTransportation and packagingSulfonic acids salts preparationBenzoic acidPolymer science

The invention discloses a sulfonic acid type anionic gemini surfactant based on perfluorinated nonene and perfluorinated hexane, and a preparation method thereof. According to the preparation method, perfluorinated nonene or perfluorinated hexane is taken as a raw material; perfluorinated alkene oxyl benzoyl chloride is obtained via condensation of the raw material with p-hydroxybenzoic acid, and chlorination; perfluorinated alkene oxyl benzamide is obtained via direct condensation of perfluorinated alkene oxyl benzoyl chloride with diamine without separation; and at last the sulfonic acid type anionic gemini fluorinated surfactant is obtained via condensation of perfluorinated alkene oxyl benzamide with a sulfonated alkylation agent, wherein perfluorinated alkene oxyl phenyl groups are taken as lipophilic groups, amide bonds are taken as conjugation bridges, and sulfonates are taken as hydrophilic groups. The anionic gemini surfactant based on hexafluoropropene trimer or perfluoro(4-methylpent-2-ene) is high in surface activity, simple in synthesis, and low in cost, and possesses a promising application prospect.

Owner:QUZHOU UNIV

Catalyst for preparing polyurethane

A catalyst for preparing a polyurethane, containing triethylenediamine (component A), and at least one or more members selected from the group consisting of 1,8-diazabicyclo[5.4.0]undecene-7,1,5-diazabicyclo[4.3.0]nonene-5 and salts thereof (component B); a process for preparing a polyurethane, having the step of reacting a polyisocyanate component with a polyol component in the presence of the above-mentioned catalyst for preparing a polyurethane; and a polyurethane prepared by reacting a polyisocyanate component with a polyol component in the presence of the above-mentioned catalyst for preparing a polyurethane. The polyurethane of the present invention is suitably used, for example, for shoe soles for business shoes, sports shoes and the like, particularly for its outer soles.

Owner:KAO CORP

Rubber laminate

InactiveUS20110105668A1Satisfies interlayer adhesivenessOil resistance is impairedSynthetic resin layered productsVehicle componentsTetrafluoroethyleneVulcanization

Disclosed is a rubber laminate containing an unvulcanized fluororubber composition comprising: (A) fluororubber comprising a terpolymer containing 50 to 60 mol % of a constitutional unit derived from vinylidene fluoride, 20 to 30 mol % of a constitutional unit derived from tetrafluoroethylene, and 10 to 30 mol % of a constitutional unit derived from hexafluoropropene; (B) an oxide and / or hydroxide of a divalent metal; (C) a polyhydroxy aromatic compound; (D) a 2-substituted-4,6-dithiol-s-triazine derivative; (E1) a quaternary phosphonium salt or a tetraalkyl ammonium salt; (E2) 1,8-diazabicyclo[5.4.0]undecene-7 (salt); and (E3) a 5-substituted-1,5-diazabicyclo[4.3.0]-5-nonene (salt). In this rubber laminate, the fluororubber layer and the NBR layer are firmly vulcanization-bonded to each other without impairing various excellent characteristics of the fluororubber constituting the rubber layer.

Owner:UNIMATEC CO LTD

Laminated body

A laminated body comprises a rubber layer (A) and a fluororesin layer (B) laminated over the rubber layer (A) The rubber layer (A) is a layer comprising a rubber composition for vulcanization. The rubber composition for vulcanization comprises an epichlorohydrin rubber (a1), at least one compound (a2) selected from the group consisting of salts of 1,8-diazabicyclo(5.4.0)undecene-7, salts of 1,5-diazabicyclo(4.3.0)-nonene-5, 1,8-diazabicyclo(5.4.0) undecene-7, and 1,5-diazabicyclo(4.3.0)-nonene-5, an epoxy resin (a3), and at least one water-carrying substance (a4) selected from water-absorbed substances and hydrated substances. The fluororesin layer (B) is a layer comprising a fluorine-contained polymer composition and the fluorine-contained polymer composition comprises a fluorine-contained polymer (b1) having a copolymerization unit originating from chlorotrifluoroethylene.

Owner:DAIKIN IND LTD +1

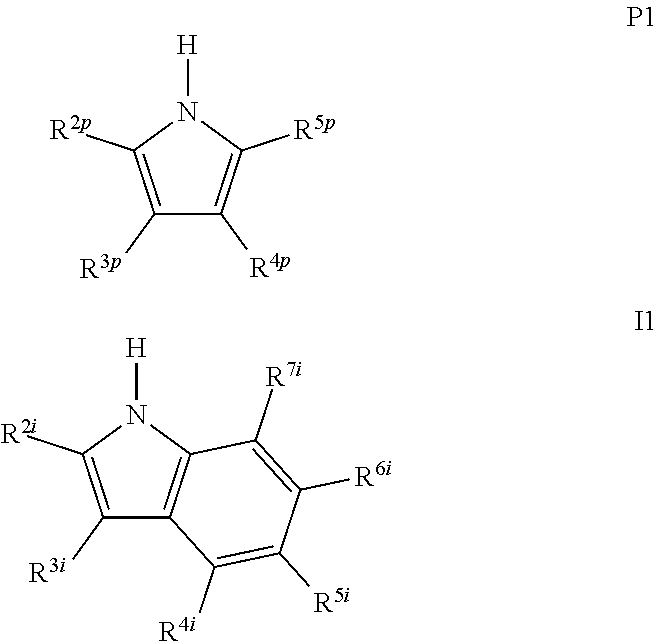

Rubber composition and pneumatic tire using the same

A rubber composition containing 100 parts by weight of a diene-based rubber, 20 to 120 parts by weight of silica, 3 to 15% by weight, based upon the weight of silica, of a sulfur-containing silane coupling agent and (A) 1,5-diazabicyclo[4,3,0]nonene-5 (DBN) having the formula (I):and / or a salt thereof or (B) 0.1 to 3.0 parts by weight of a compound having a ppiperidine skeleton having the formula (II) or a salt thereof and / or formula (III):wherein n indicates 3 or 5, R1 indicates CH or N and R2 indicates H or OH when R1 is CH, or H when R1 is N, and a melamine derivative of formula (IV):wherein R3 is a methoxymethyl group (—CH2OCH3) or methylol group (—CH2OH), the number of methoxymethyl groups is 3 to 6, and the number of methylol groups is 0 to 3, and / or polymer or copolymer resins of the same and a pneumatic tire using the same.

Owner:THE YOKOHAMA RUBBER CO LTD

Vulcanized rubber laminate

The invention provides a vulcanized rubber laminate obtained by firmly bonding an unvulcanized epichlorohydrin rubber layer and an organic peroxide-containing fluororubber layer. The laminate is obtained by thermal adhesion a layer of an unvulcanized epichlorohydrin rubber composition to a layer of an unvulcanized fluororubber composition. The epichlorohydrin rubber composition comprises 1) an unvulcanized epichlorohydrin rubber containing 3 to 15 mol % of allyl glycidyl ether unit, 2) quinoxaline-based vulcanizing agents, mercaptotriazine-based vulcanizing agents or bisphenol-based vulcanizing agents, and 3) 1,8-diazabicyclo(5,4,0)undecene-7 salts, 1,5-diazabicyclo(4,3,0)nonene-5 salts, quaternary ammonium salts, quaternary phosphonium salts, basic white carbons or an alkaline metal salt of higher fatty acid the fluororubber composition comprises an fluororubber and an organic peroxide-based vulcanizing agent.

Owner:OSAKA SODA CO LTD

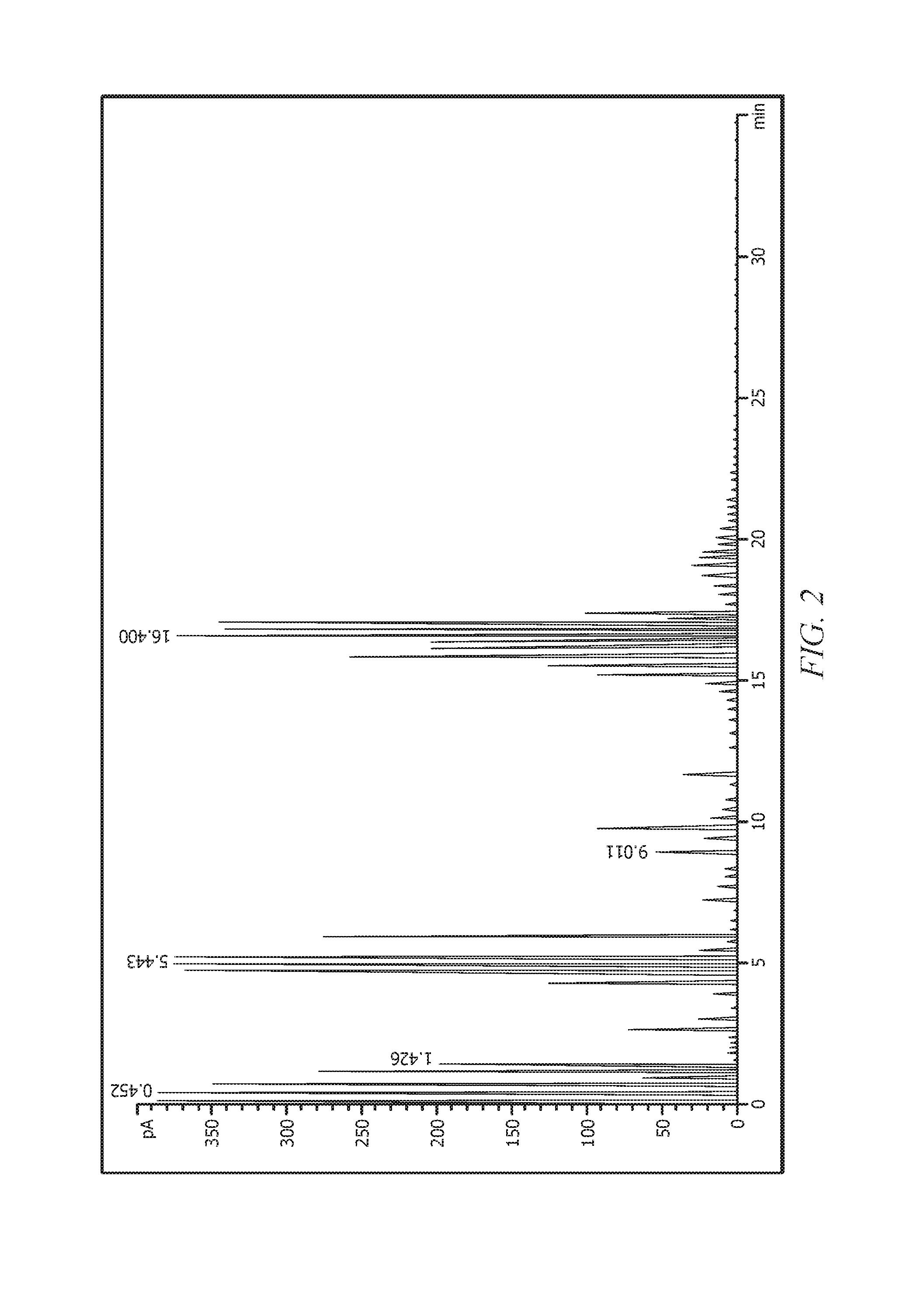

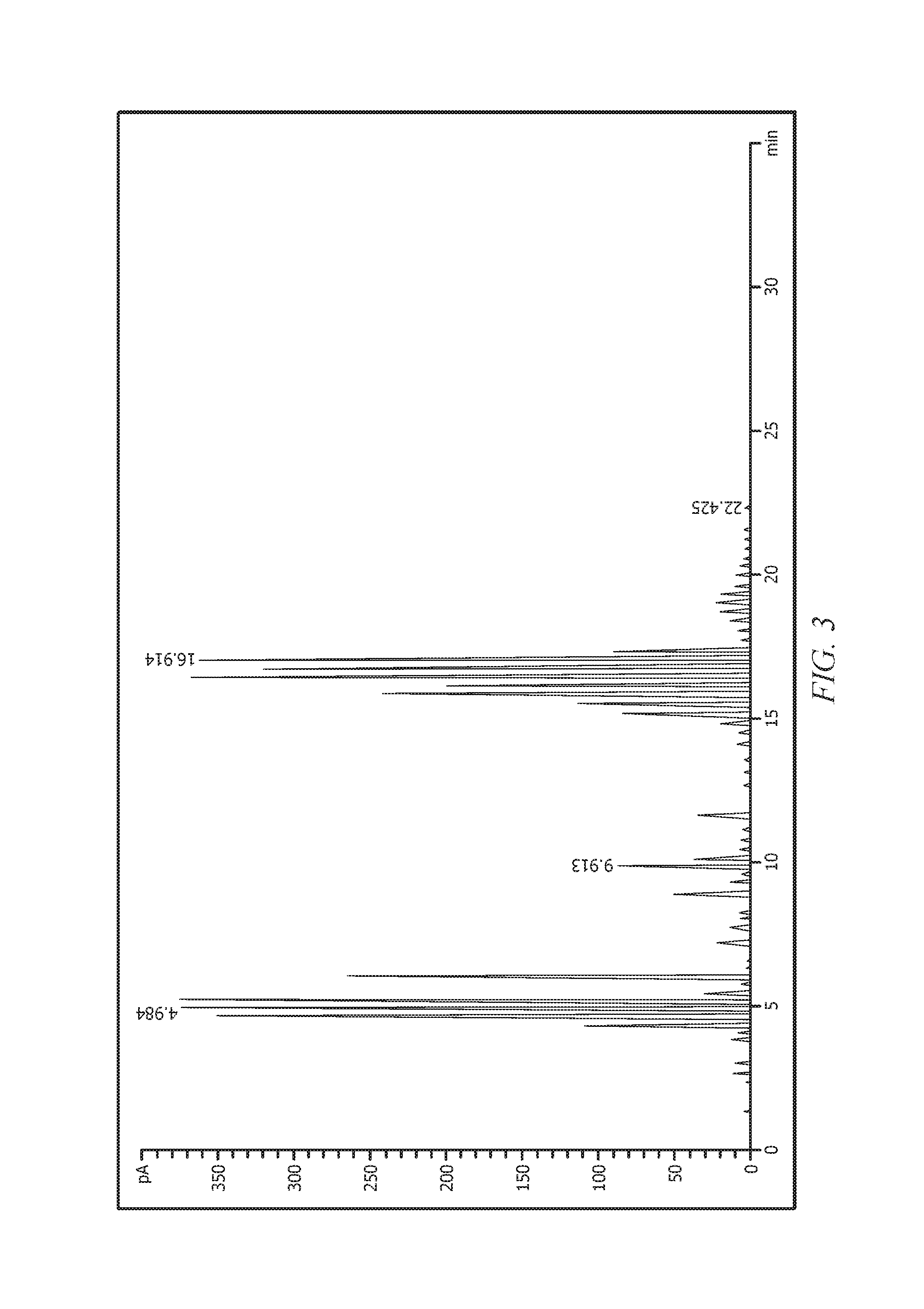

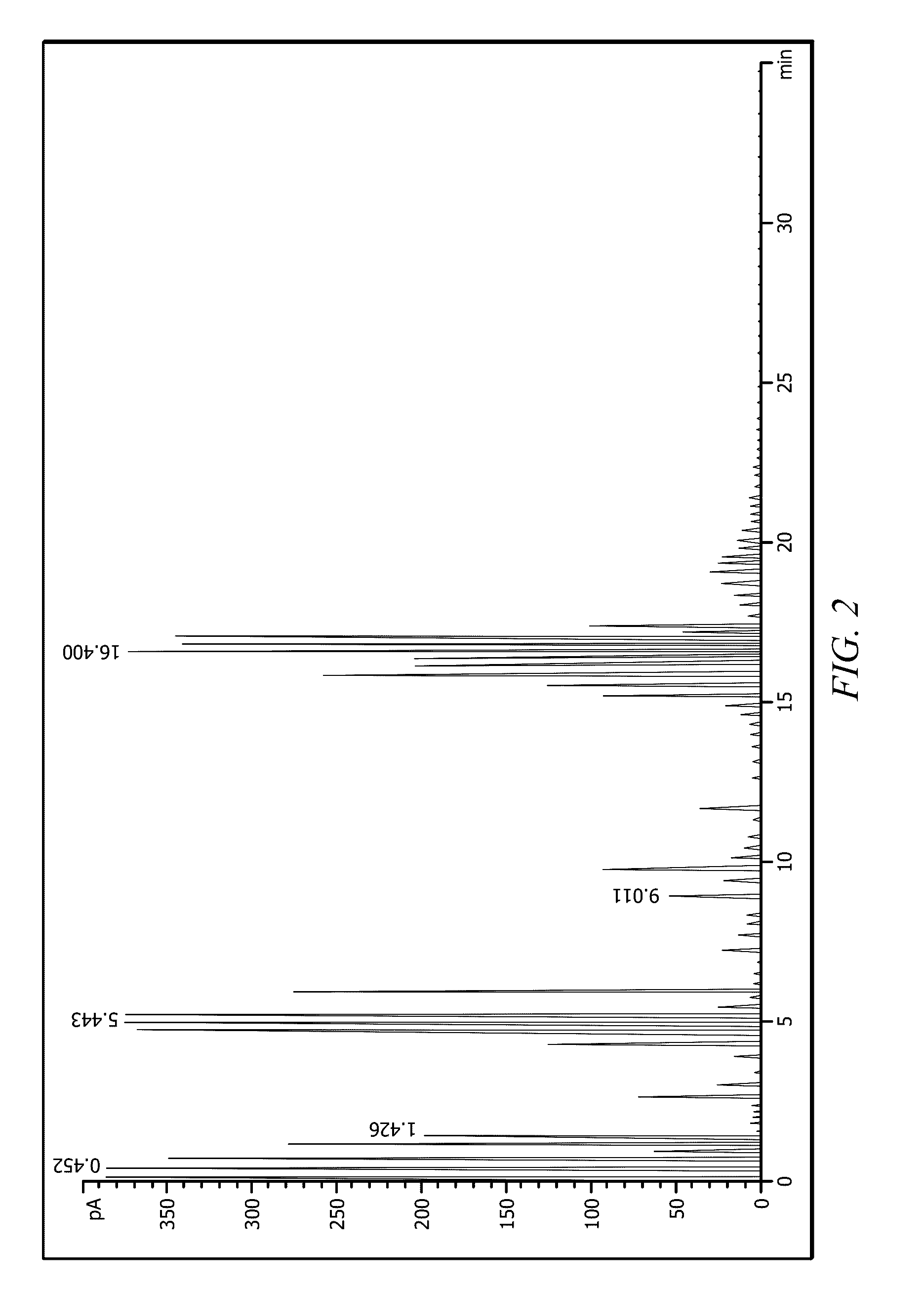

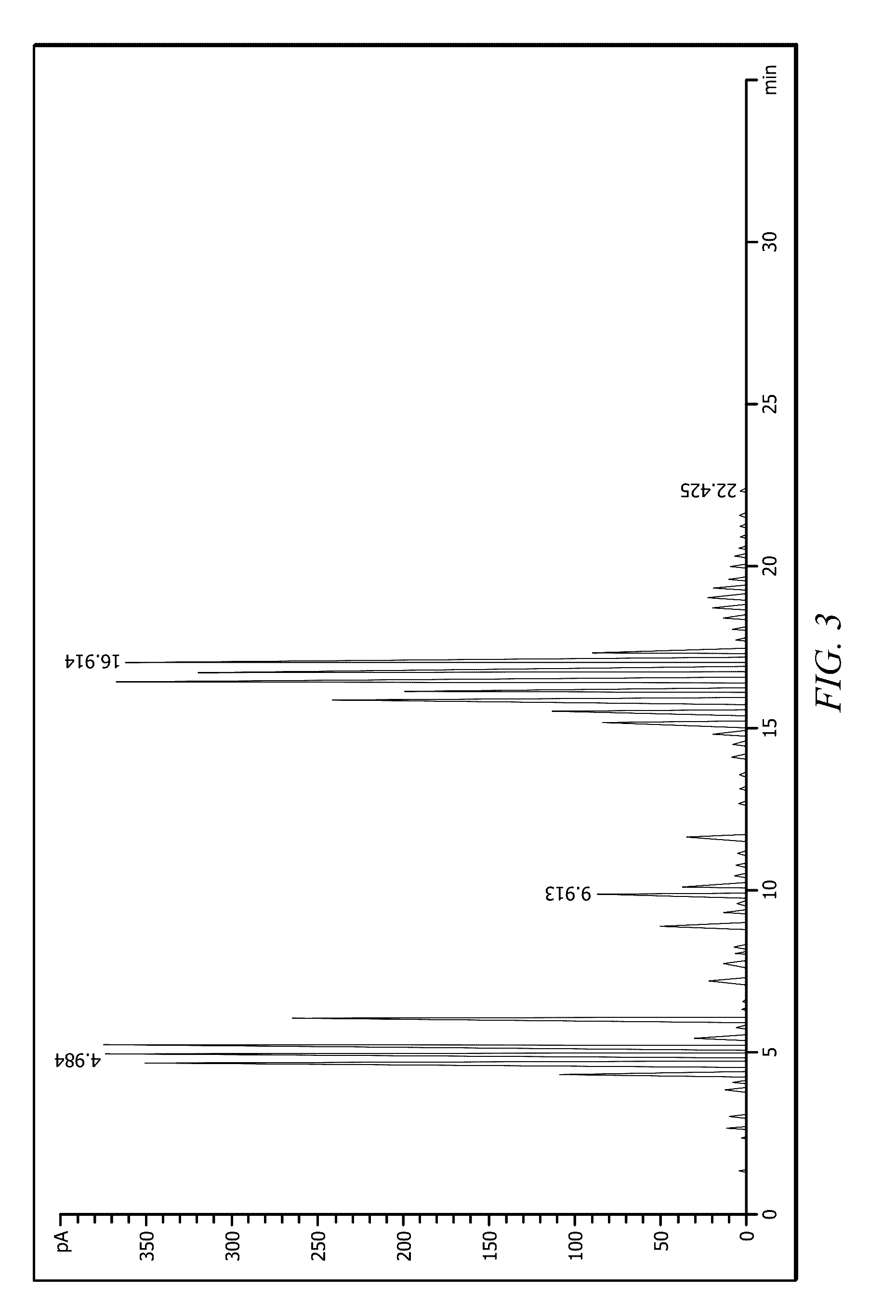

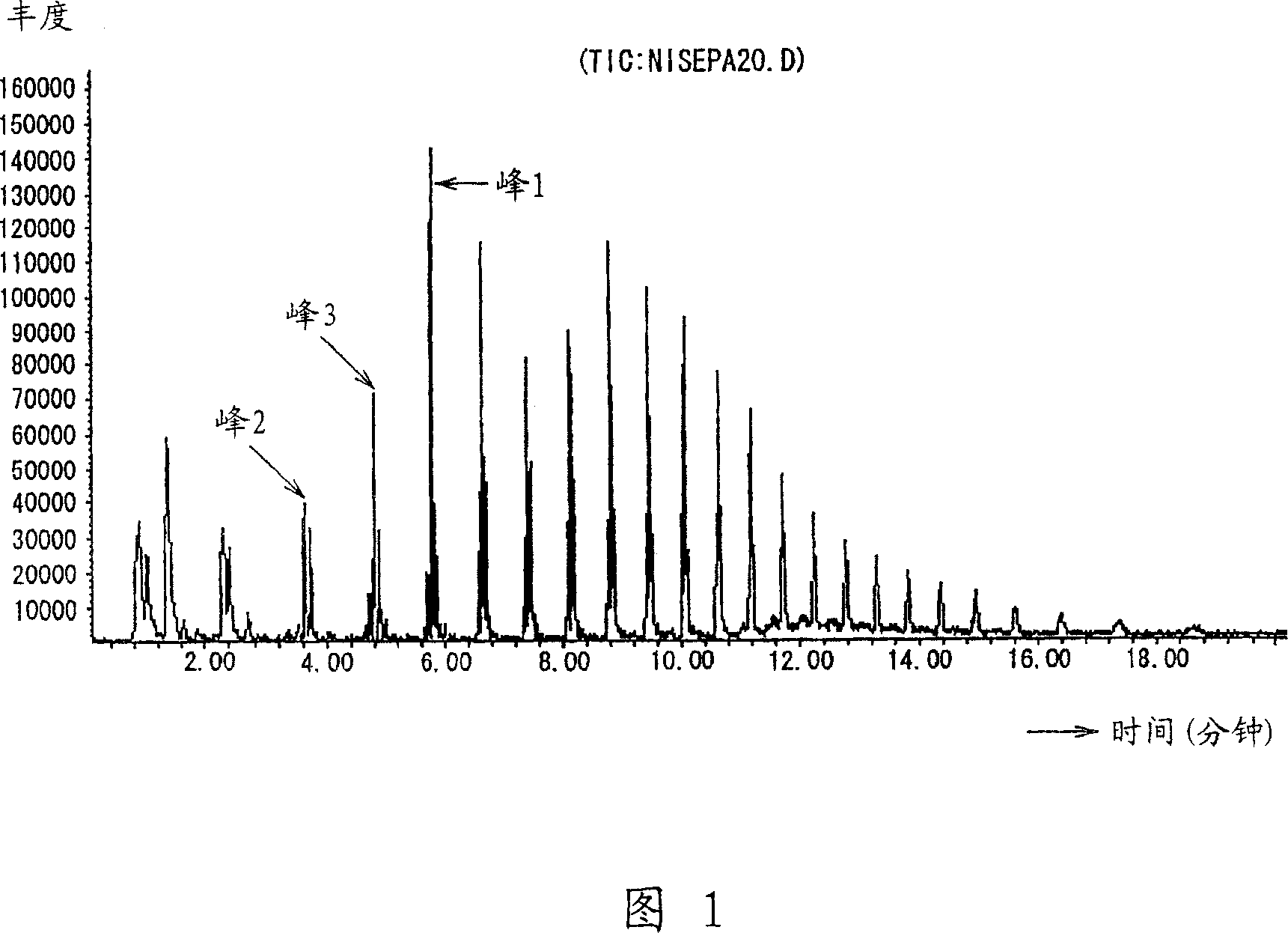

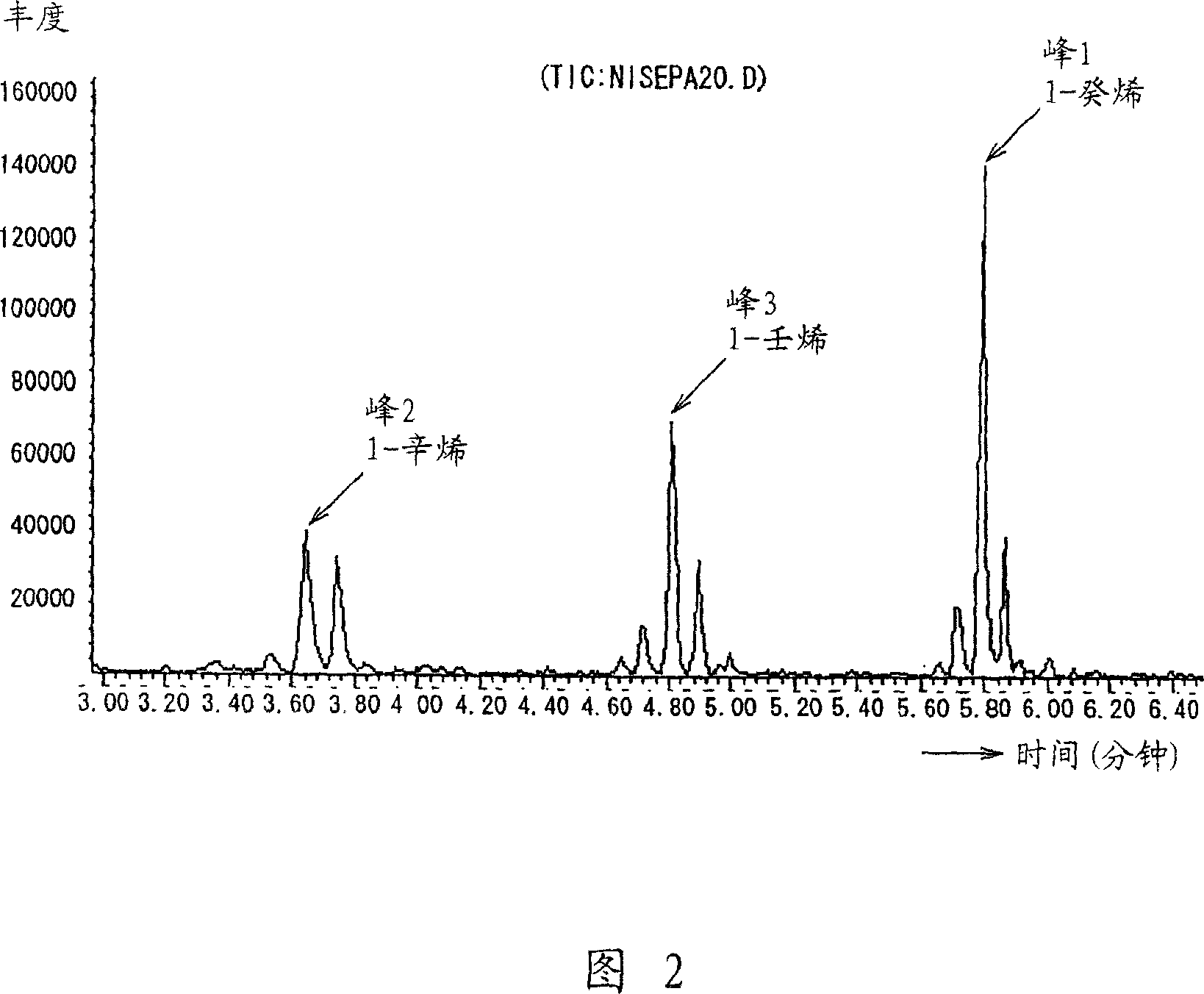

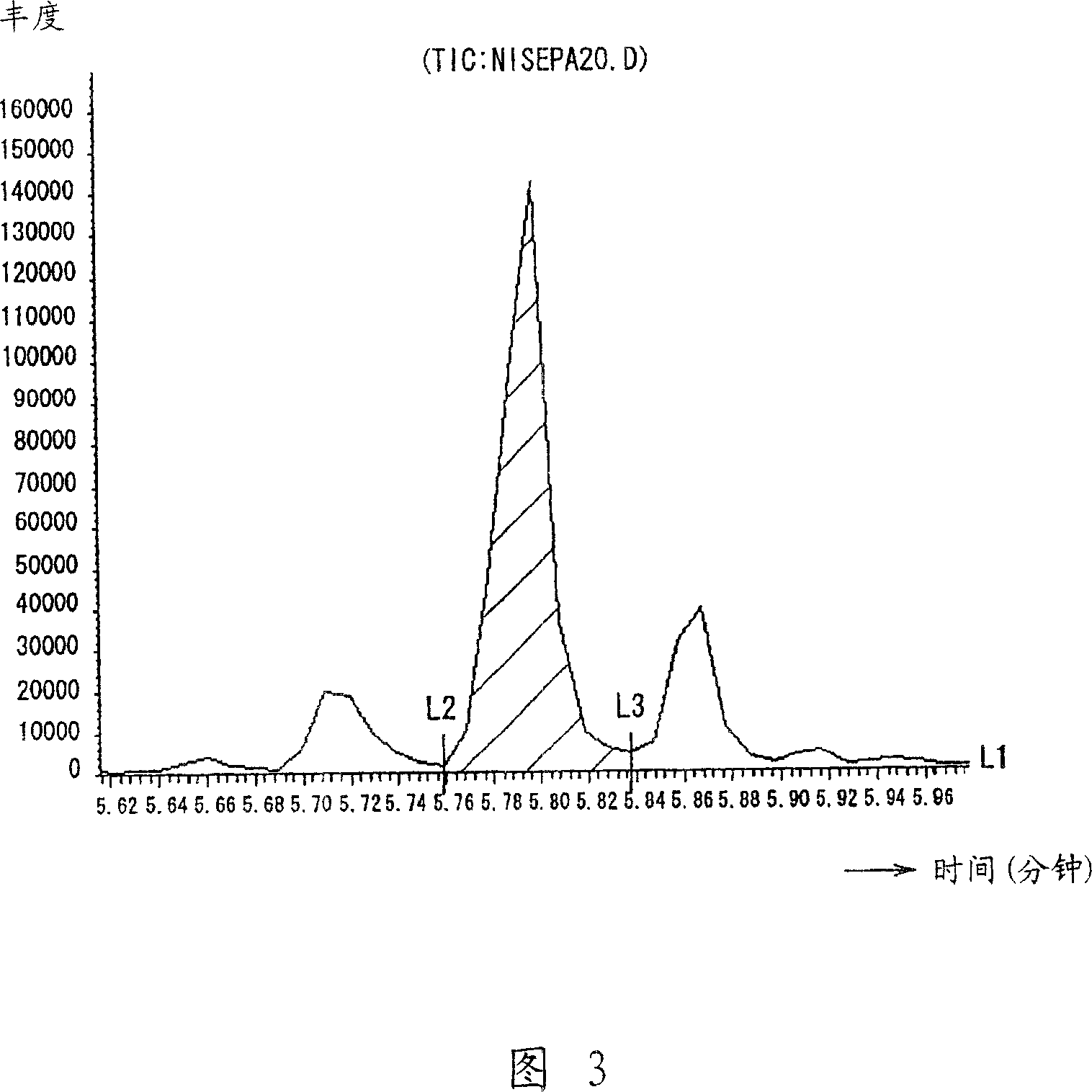

Secondary battery and its manufacturing method

InactiveCN1327547CImprove high temperature performanceFinal product manufactureCell electrodes1-OcteneHigh energy

Provided are a secondary battery comprising a separator material capable of achieving a secondary battery with superior high temperature cycle characteristics and a higher energy density, and a method of manufacturing a secondary battery. A separator is evaluated and selected by thermal decomposition gas chromatography (thermal decomposition+GC / MS). In a suitable separator, the value of (the area of Peak 1 exhibiting 1-Decene) / (the area of Peak 2 exhibiting 1-Octene) in a total ion chromatogram (TIC) of the pyrolysate of the separator is 2.05 or less. More preferably, a material in which the value of (the area of Peak 1) / (the area of Peak 2) is 2.00 or less, the value of (the area of Peak 1) / (the area of Peak 3 exhibiting 1-Nonene) is 1.87 or less, and the value of (the area of Peak 3) / (the area of Peak 2) is 1.05 or less is selected, and is used as a separator.

Owner:SONY CORP

Olefin Compositions

A composition comprising: a) at least 76 mol % C10 monoolefins, the C10 monoolefins comprising i) at least 3 mol % 2-butyl-1-hexene, ii) at least 8 mol % 3-propyl-1-heptene, iii) at least 6 mol % 4-ethyl-1-octene, and iv) at least 20 mol % 5-methyl-1-nonene; and b) at least 1 mol % C14 monoolefins. A composition comprising at least 95 mol % C10 monoolefins, the C10 monoolefins comprising i) at least 3 mol % 2-butyl-1-hexene, ii) at least 10 mol % 3-propyl-1-heptene, iii) at least 7 mol % 4-ethyl-1-octene, and iv) at least 24 mol % 5-methyl-1-nonene. Processes to prepare a composition comprising at least 76 mol % C10 monoolefins and at least 1 mol % C14 monoolefins, or a composition comprising at least 95 mol % C10 monoolefins, where the C10 monoolefins comprise i) at least 3 mol % 2-butyl-1-hexene, ii) at least 10 mol % 3-propyl-1-heptene, iii) at least 7 mol % 4-ethyl-1-octene, and iv) at least 24 mol % 5-methyl-1-nonene.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

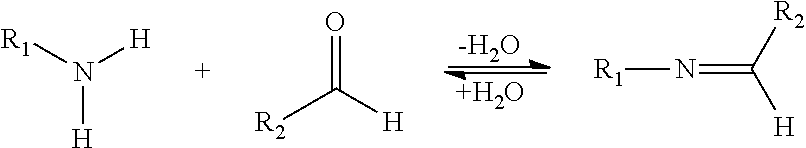

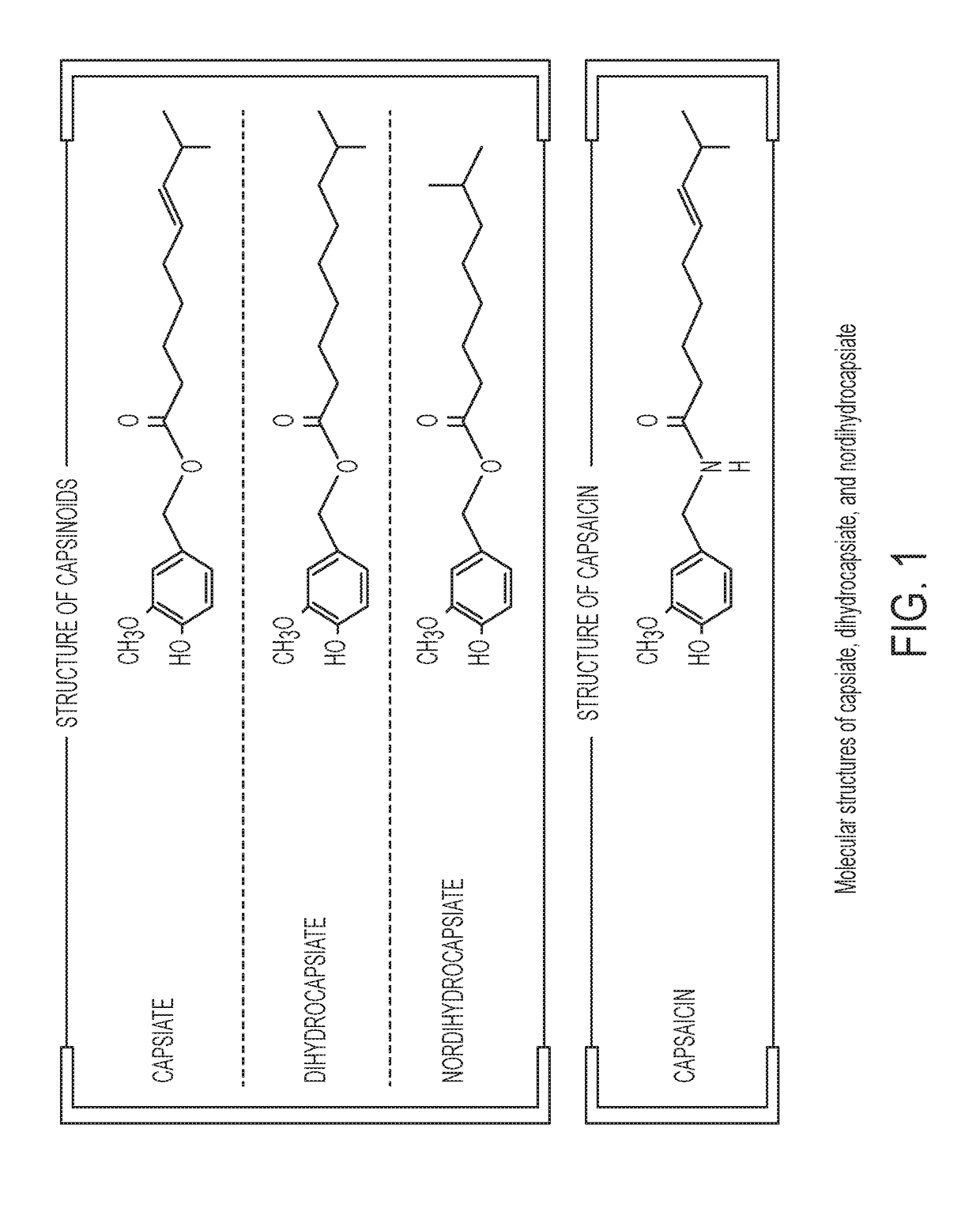

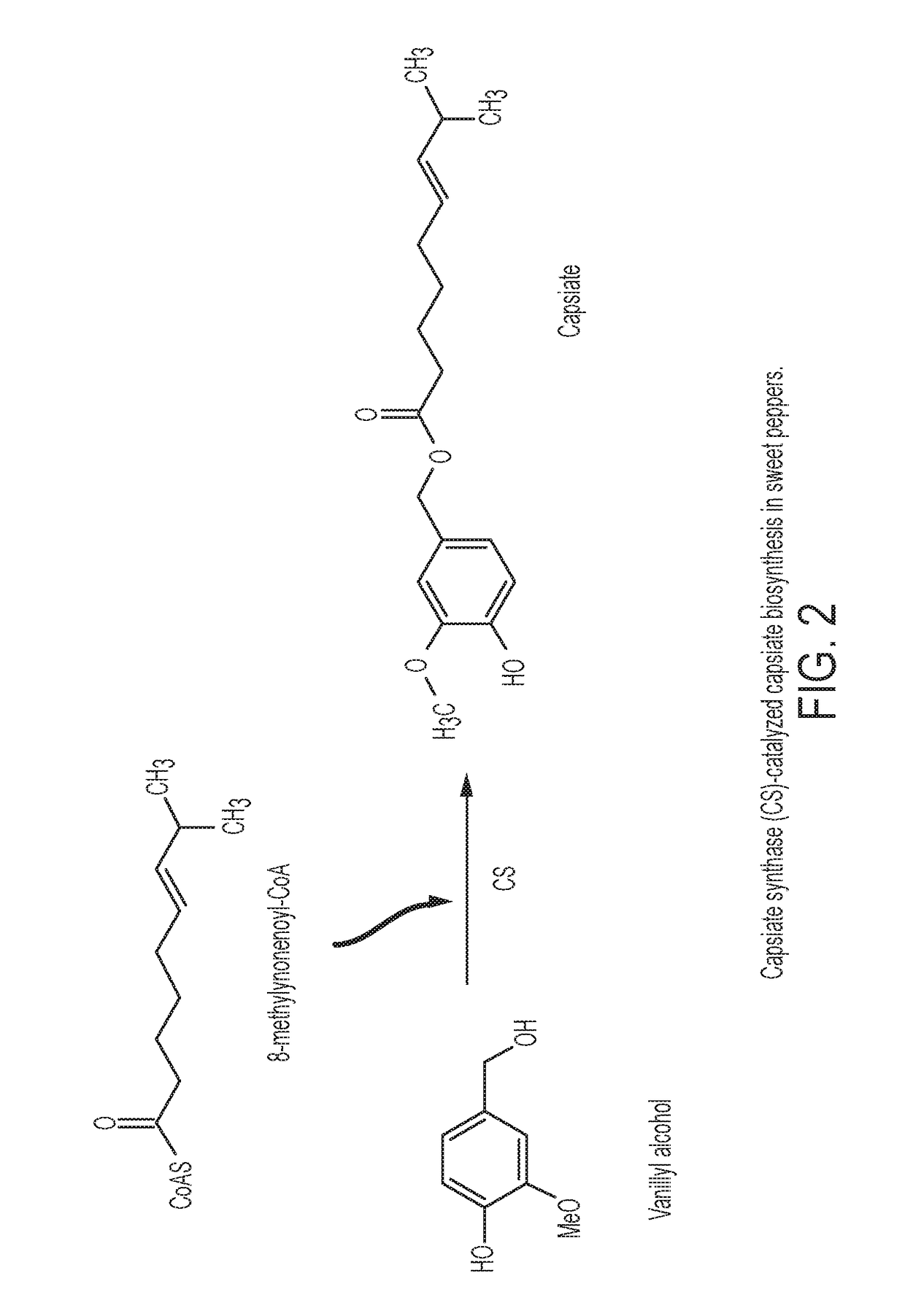

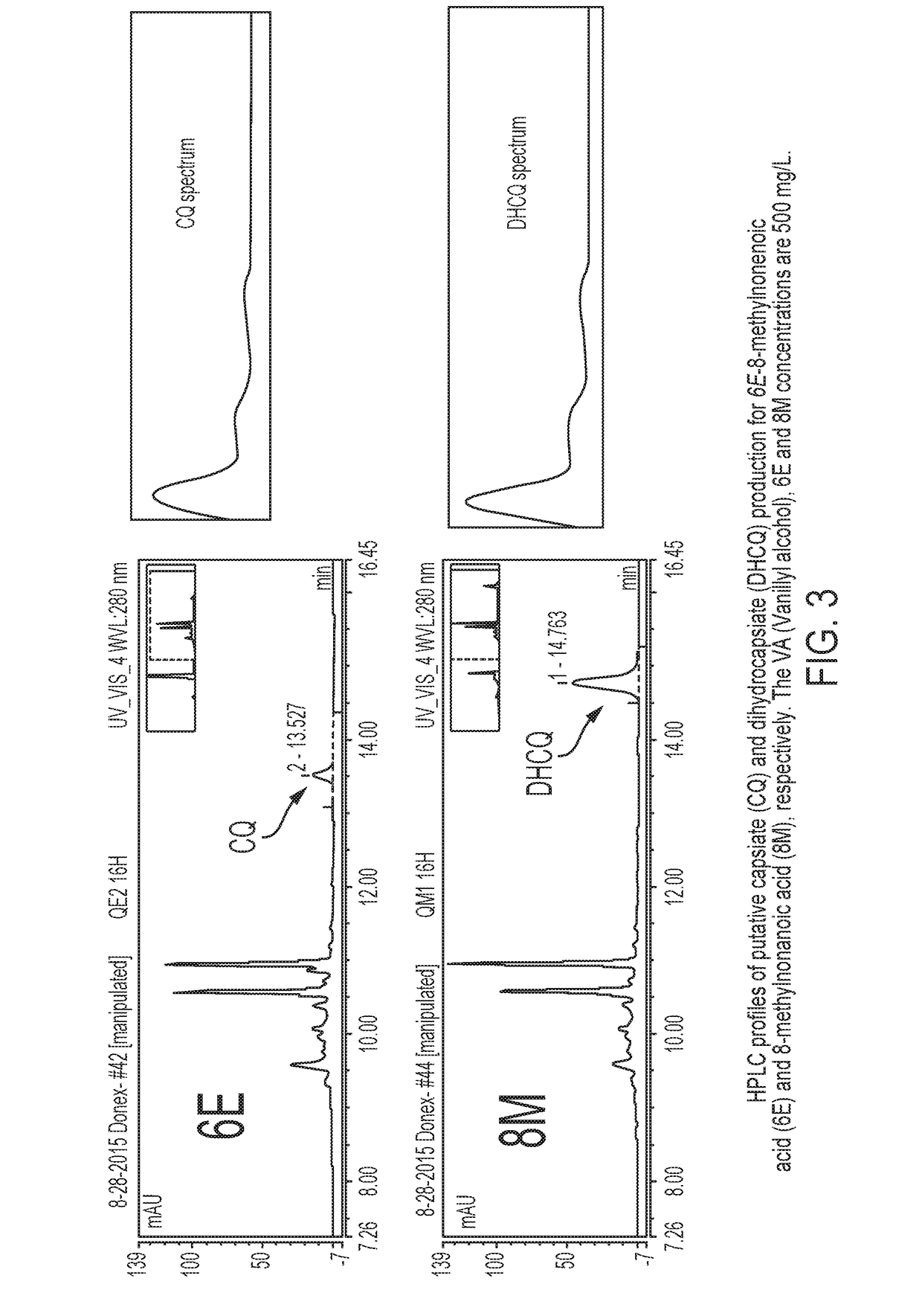

Methods of making capsinoids by biosynthetic processes

ActiveUS20190010522A1Organic compound preparationCarboxylic acid esters preparationCellulose biosynthetic processCapsaicin

Provided herein are methods of making capsinoids including providing a capsiate synthase in a mixture or cellular system, feeding 8-methyl-6-nonenoyl-CoA, 6E-8-methylnonenoic acid or 8-methylnonanoic acid into the mixture or cellular system, feeding vanillyl alcohol into the mixture or cellular system, and collecting capsinoids from the mixture or cellular system.

Owner:CONAGEN INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com