Secondary battery and its manufacturing method

A secondary battery, non-aqueous secondary battery technology, applied in secondary battery manufacturing, secondary batteries, battery electrodes, etc., can solve the problems of insufficient high temperature performance, insufficient, waste of time and cost of secondary batteries, etc. Achieve the effect of improving high temperature cycle characteristics and excellent high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Next, examples (and comparative examples) of the steps for evaluating the separator according to the present invention will be described. In these embodiments, each secondary battery is in the shape of a coin. However, a secondary battery having other shapes such as a cylindrical shape can also have the same result.

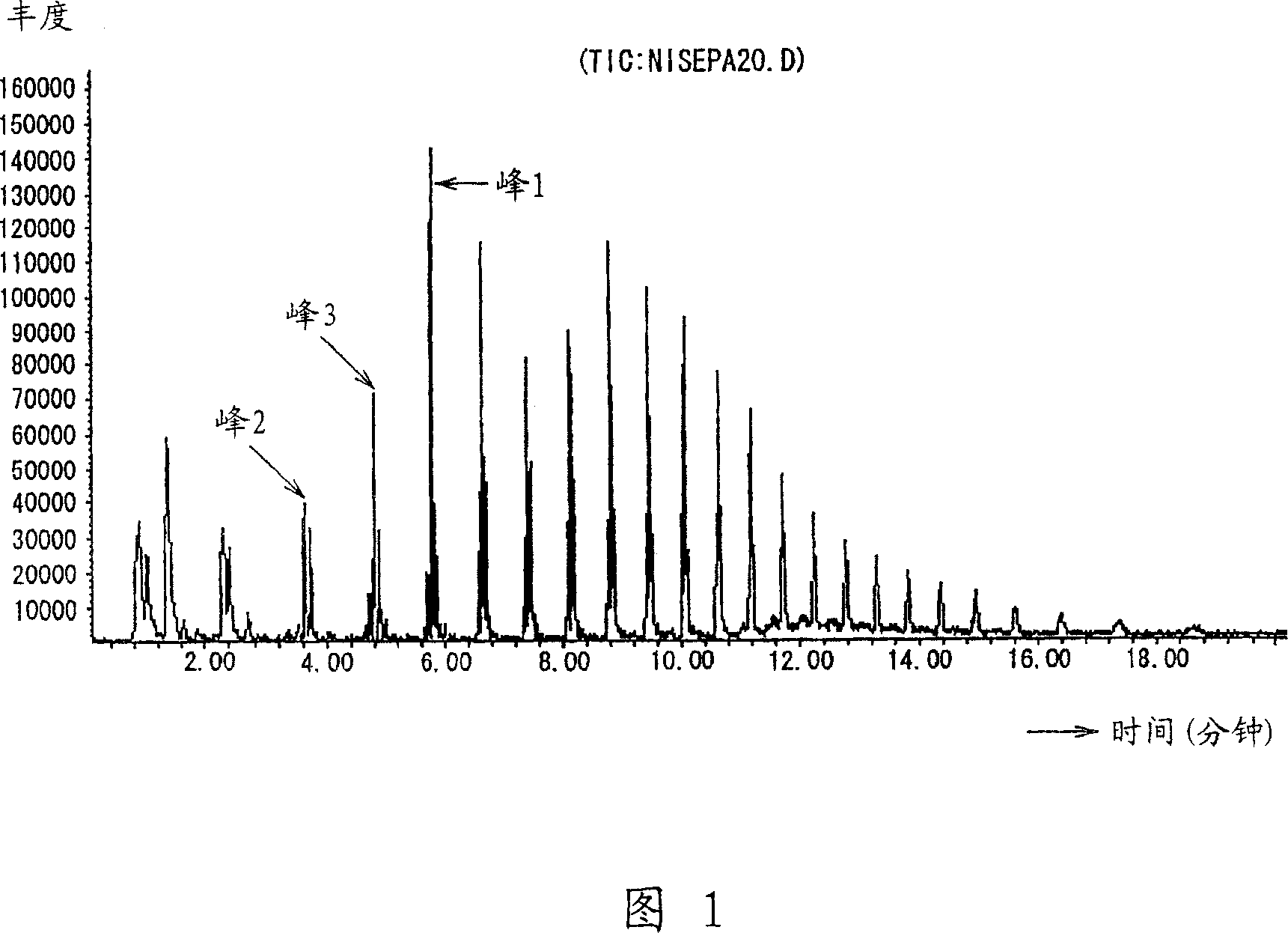

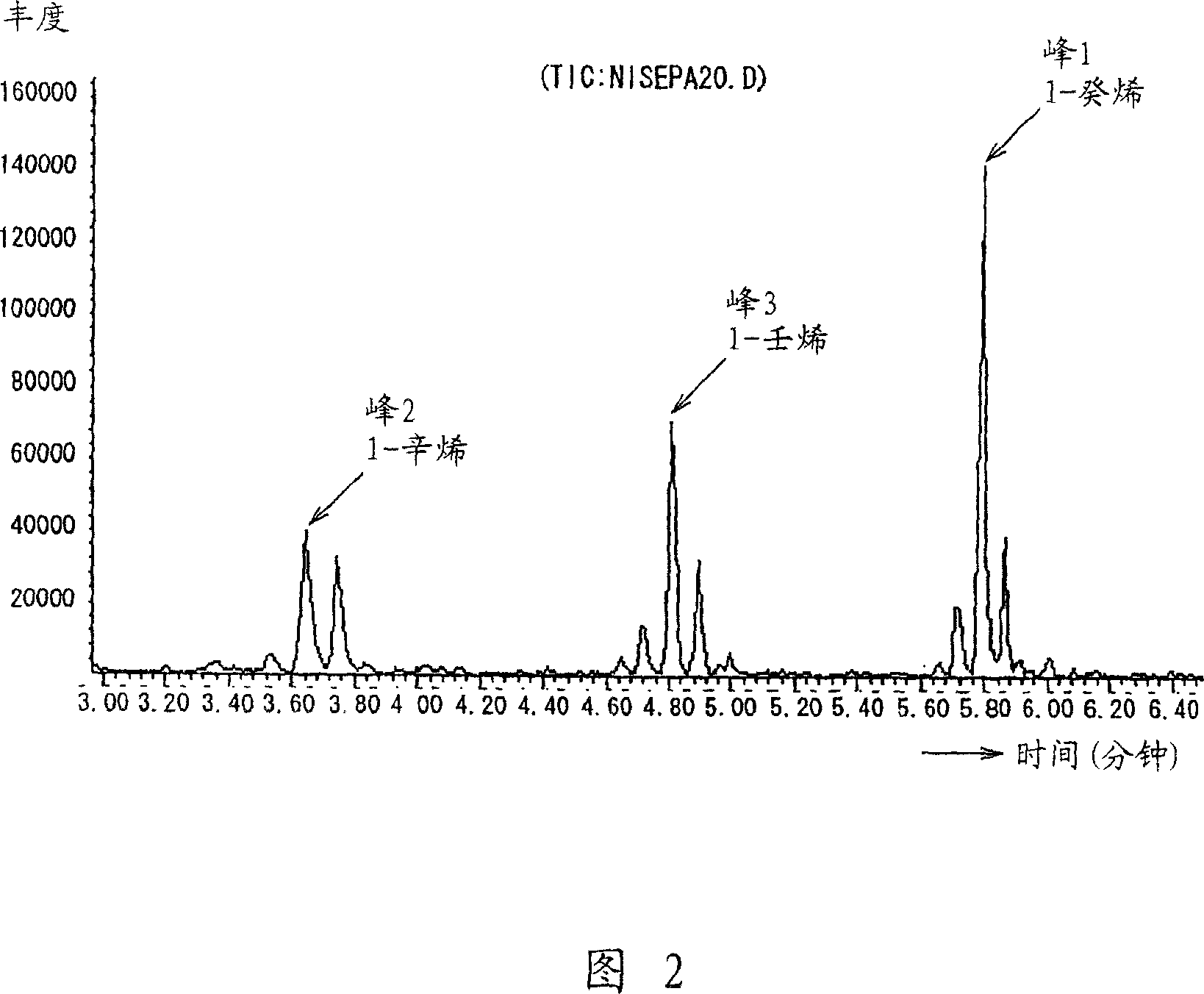

[0061] Various separator materials used in the examples were measured under the conditions described by Condition 1 represented by Pyrolysis+GC / MS. The main measurement procedure is (1) winding the separator on the high temperature foil, (2) placing the high temperature separator in a quartz tube, and placing the quartz tube in a thermal decomposer (produced by Japan Analytical Industry Co., Ltd.). Ltd), (3) thermally decompose the separator by high frequency at 590°C for 12 seconds; and (4) measure the pyrolysate by GC / MS.

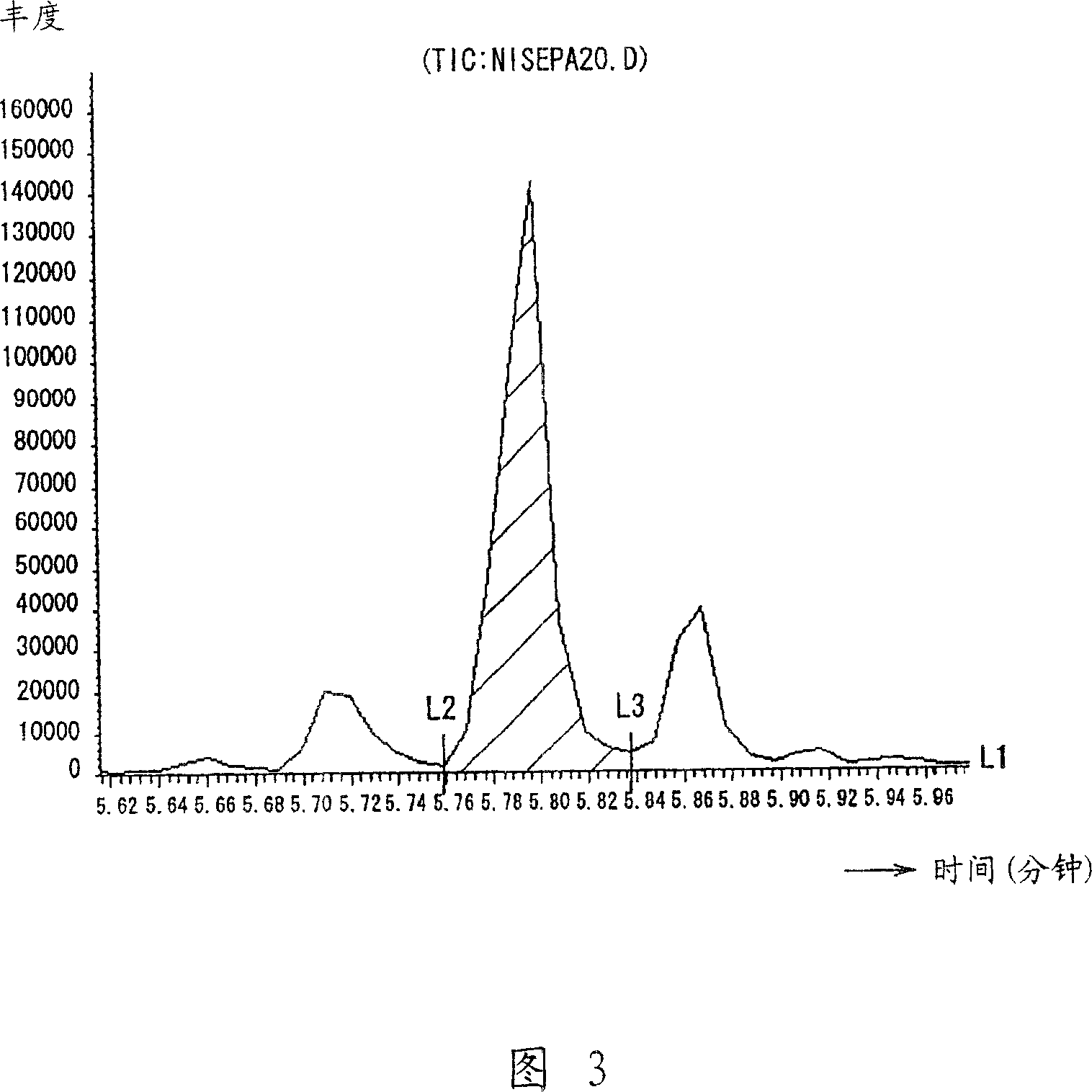

[0062] The MS spectrum obtained from the above measurements was analyzed. The relationship between the integrals (areas of the pe...

Embodiment 3

[0069] The cycle characteristics of the secondary batteries of Examples 1, 2 and 3 and Comparative Examples 1 and 2 were evaluated as follows. First, after charging the battery with a constant current of 1 mA at 45°C until the battery voltage reached 4.2 V, the battery was charged at a constant voltage of 4.2 V until the terminal current reached 0.05 mA, and then the battery was discharged at a constant current of 1 mA until the terminal The voltage reaches 2.5V. Under the same charge-discharge conditions, 100 charge-discharge cycles were performed, and in the case where the discharge capacity in the first cycle was 100, the discharge capacity retention ratio (%) in the 100th cycle was measured. The results are shown in FIG. 8 . As shown in FIG. 8 , it was confirmed that in the non-aqueous secondary batteries including the anode, the cathode separator and the non-aqueous electrolyte, in Examples 1, 2 and 3, a high-temperature cycle discharge capacity retention rate of 90% or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com