Nonyl phenol refining process

A nonylphenol and process technology, which is applied in the field of industrial nonylphenol refining process, can solve the problems of dinonylphenol not being used as a product, poor purity of dinonylphenol, and high phenol content, and achieve the goal of improving color stability and increasing product yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

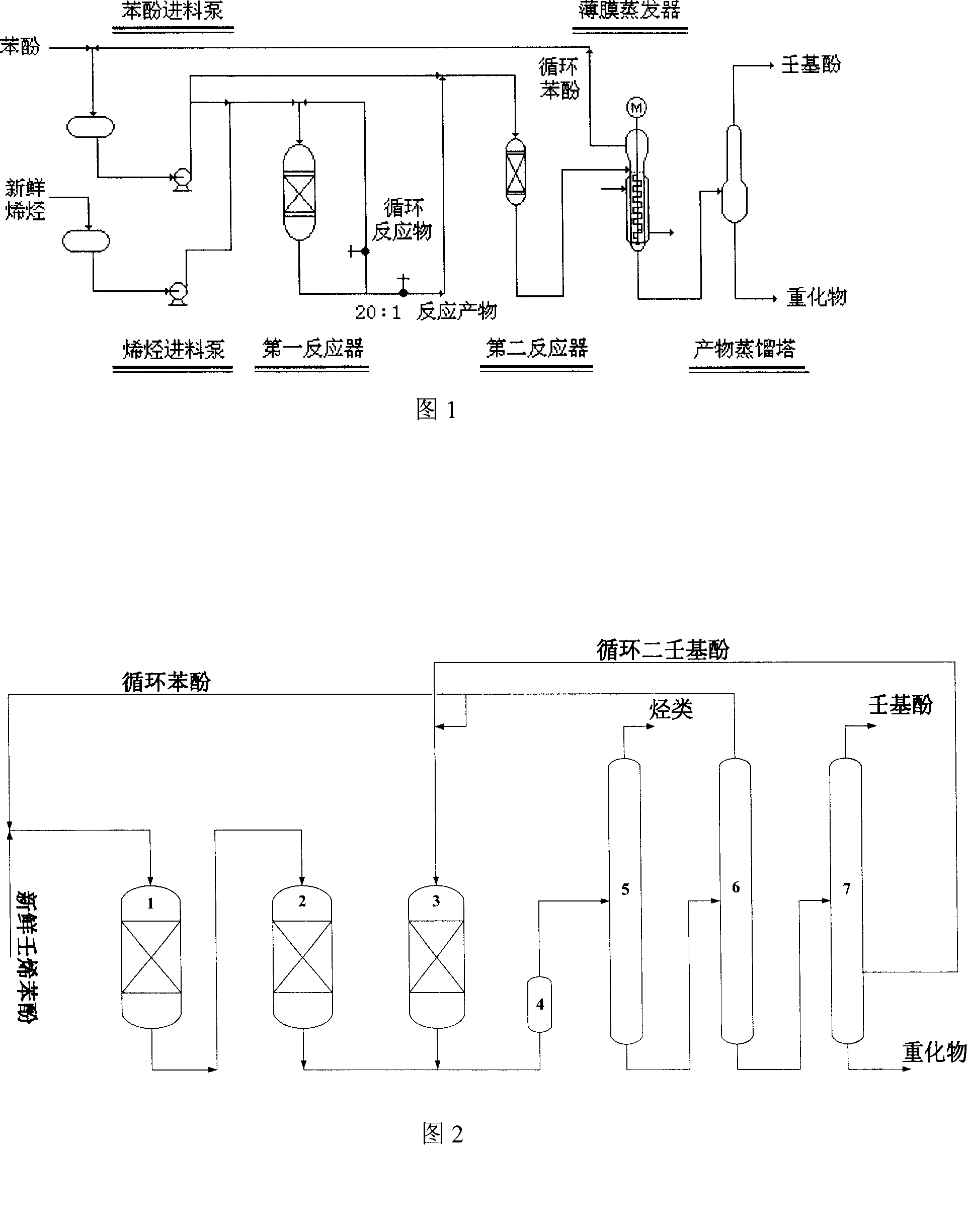

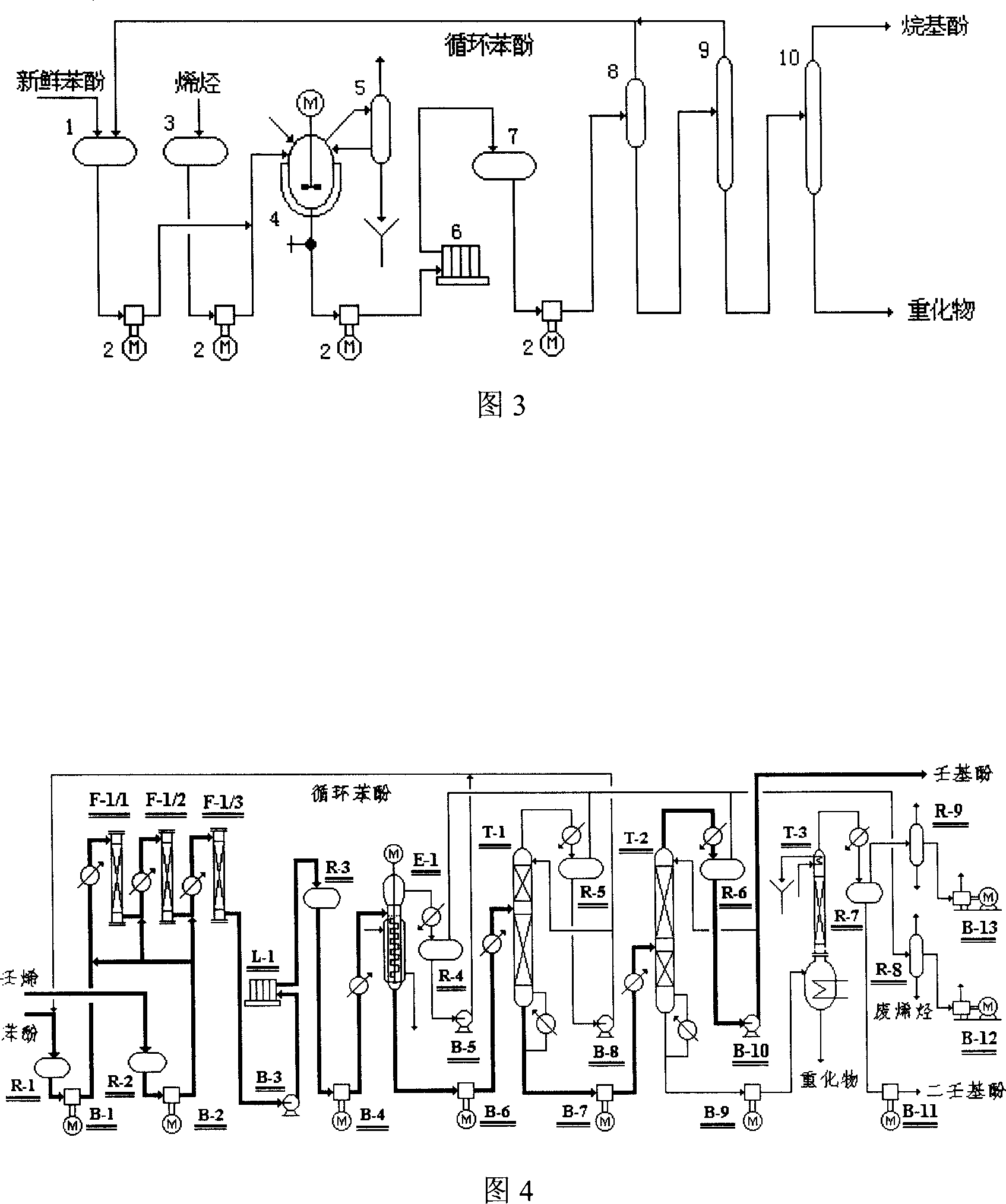

Method used

Image

Examples

Embodiment 1

[0031] 1 Evaporation: Dephenol

[0032] The thin film evaporator is used to remove most of the phenol in the reaction material, and the purpose is to remove most of the phenol in the material from the reactor through a high-efficiency evaporator, so as to reduce the load of the subsequent phenol removal tower. The feeding temperature is controlled at 70-150°C.

[0033] 2 Distillation: Removal of residual phenol

[0034] A: The mixture material from which most of the phenol has been removed from the thin film evaporator continuously enters the feed intermediate tank through the pipeline. The material is transported by the feed pump into the plate and frame filter, after filtering out the resin particles, it is in the feed preheater After heating, the temperature of the material rises and reaches the 70°C required by the process, and its outlet temperature is adjusted by the temperature control of the feed section of the phenol removal tower.

[0035] B: Establish a liquid level for ...

Embodiment 2

[0056] The operating conditions of each tower are shown in Table 3:

[0057] Table 3 Operating parameters of each tower

[0058] Phenol removal tower T-1

Nonylphenol distillation tower T-2

Recovery tower T-3

Theoretical plate number

Packing model and height

Tower top pressure KPa

Feed flow kg / h

10

6m wire mesh packing

1.333

1100

120

8

6m wire mesh packing

1.333

1000

130

10

6m wire mesh packing

1.333

900

130

[0059] Tower top temperature ℃

Tower kettle temperature℃

Total packing pressure drop KPa

Reflux ratio R

85

215

0.4

1.5

170

225

0.4

1.5

170

230

0.7

1.2

[0060] After adding the color stabilizer, the specific data of the composition before and after refining are shown in Table 4.

[0061] Table 4 Composition before and after refining

[0062] Nonylphenol

%

Dinonylphenol

%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com