Catalyst for preparing nonene and dodecene through propylene oligomerization and purpose thereof

A technology of catalyst and dodecene, applied in catalysts, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of low propylene conversion rate, short catalyst life, low selectivity, etc., and achieve high propylene conversion rate and active group The effect of uniform distribution and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

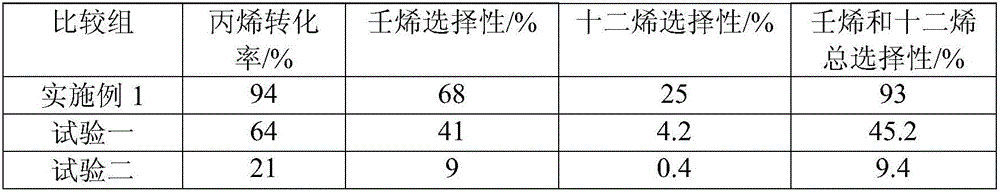

Examples

Embodiment 1

[0028] According to the molar ratio of ethyl orthosilicate to water and ethanol as 1:1:1, take 3.6g of water and 9.2g of ethanol into the beaker, add 41.7g of ethyl orthosilicate dropwise at room temperature, and stir for 2 hours; The atomic ratio is 1:8. Take 8.5g of butyl titanate and put it into the above beaker, stir for 20min, and let it stand for 2 days after the end. The prepared Ti-Si glue was stirred at 60° C. for 2 h. by SiO 2 : Water: Ethanol: The molar ratio of ethylene glycol is 1:5:2:0.4, take 18g water, 18.4g ethanol, 5g ethylene glycol, 3.0g phosphotungstomolybdenum heteropoly acid H 3 PW 6 Mo 6 o 40 , after stirring for 2 hours, add it into the Ti-Si glue, continue stirring for 1 hour, pour it into a shallow dish, dry it, and bake it at 550°C for 4 hours. Grinding into powder, adding molding aids, drying at 105°C for 12 hours, and then calcining at 550°C for 4 hours to obtain the desired catalyst. Put the catalyst into the tubular reactor, at a reaction ...

Embodiment 2

[0030] According to the molar ratio of ethyl orthosilicate to water and ethanol as 1:2:2, take 7.2g of water and 18.4g of ethanol into the beaker, add 41.7g of ethyl orthosilicate dropwise at room temperature, and stir for 3h; The atomic ratio is 1:4. Take 17g of butyl titanate and put it into the above beaker, stir for 30min, and let it stand for 1 day after the end. The prepared Ti-Si glue was stirred at 50° C. for 2 h. by SiO 2 : Water: Ethanol: The molar ratio of ethylene glycol is 1:5:2:0.6, take 18g water, 18.4g ethanol, 7.44g ethylene glycol, 2.5g phosphotungstomolybdenum heteropoly acid H 3 PW 6 Mo 6 o 40 , after stirring for 2 hours, add it into the Ti-Si glue, continue stirring for 1 hour, pour it into a shallow dish, dry it, and bake it at 500°C for 3 hours. Grind into powder, add molding aids to shape, dry at 95°C for 12 hours, and then bake at 550°C for 3.5 hours to obtain the desired catalyst. Put the catalyst into the tubular reactor, at a reaction tempera...

Embodiment 3

[0032] According to the molar ratio of ethyl orthosilicate to water and ethanol as 1:2:1, take 7.2g of water and 9.2g of ethanol into the beaker, add 41.7g of ethyl orthosilicate dropwise at room temperature, and stir for 2h; The atomic ratio is 1:6. Take 11.3g of butyl titanate and put it into the above beaker, stir for 1 hour, and let it stand for 2 days after the end. The prepared Ti-Si glue was stirred at 60° C. for 2 h. by SiO 2 : Water: Ethanol: The molar ratio of ethylene glycol is 1:6:3:0.6, take 21.6g water, 27.6g ethanol, 7.44g ethylene glycol, 2.0g phosphotungstomolybdenum heteropoly acid H 6 P 2 W 9 Mo 9 o 62 and 1.5g phosphotungstomolybdenum heteropolyacid H 3 PW 6 Mo 6 o 40 After stirring for 2 hours, add it into Ti-Si glue, continue to stir for 50 minutes, pour it into a shallow dish, dry it, and bake it at 550°C for 4 hours. Grinding into powder, adding molding aids to shape, drying at a constant temperature of 105°C for 8 hours, and then calcining at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com