Catalyst for preparation of nonene and dodecene from sthylenediamine and preparation method thereof

A catalyst, dodecene technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that the strength and activity cannot meet the requirements of industrial applications at the same time, and can not meet the high-load, large-scale industrial applications requirements and other issues to achieve the effect of improving strength, increasing internal support, improving stability and life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

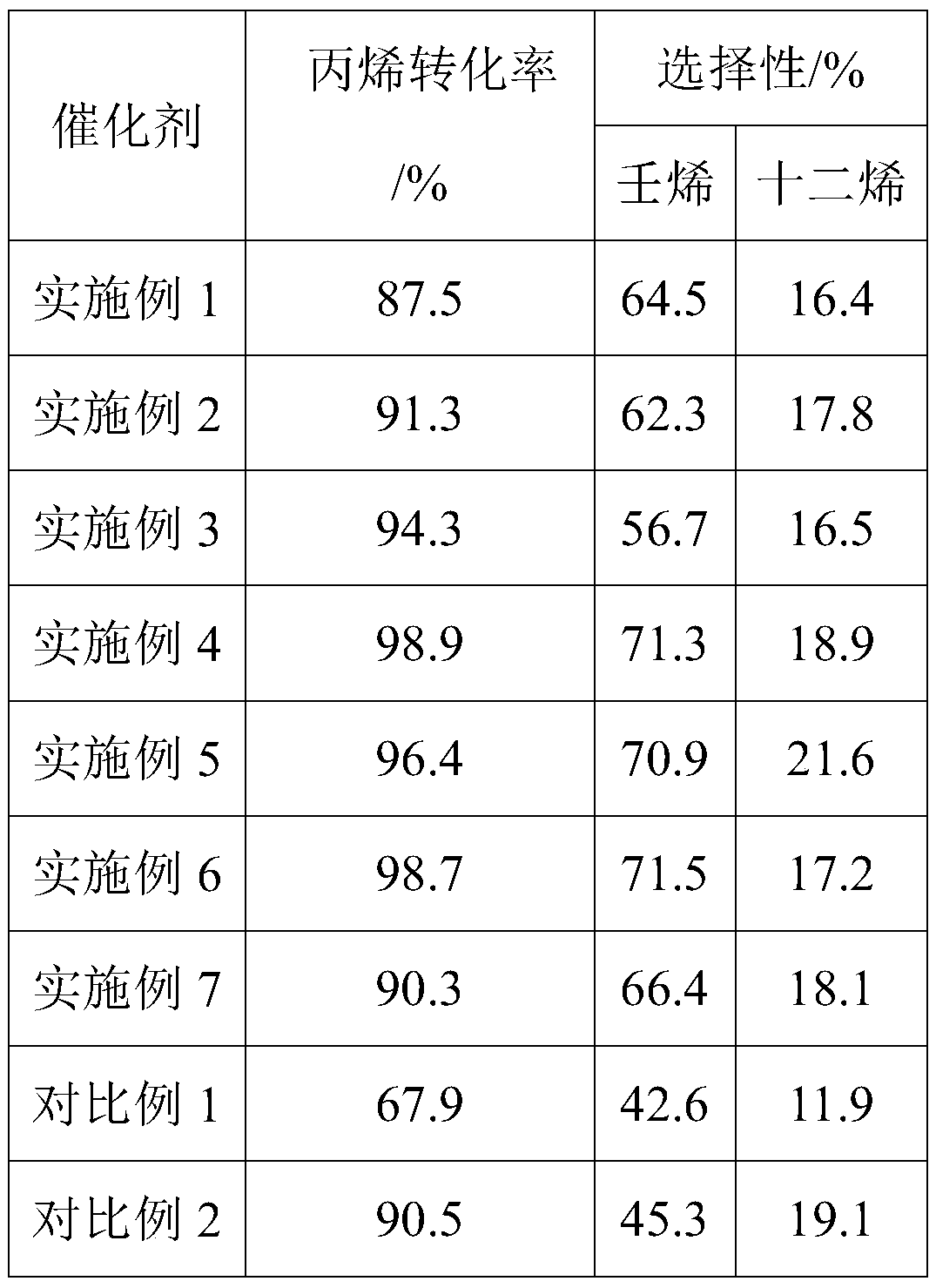

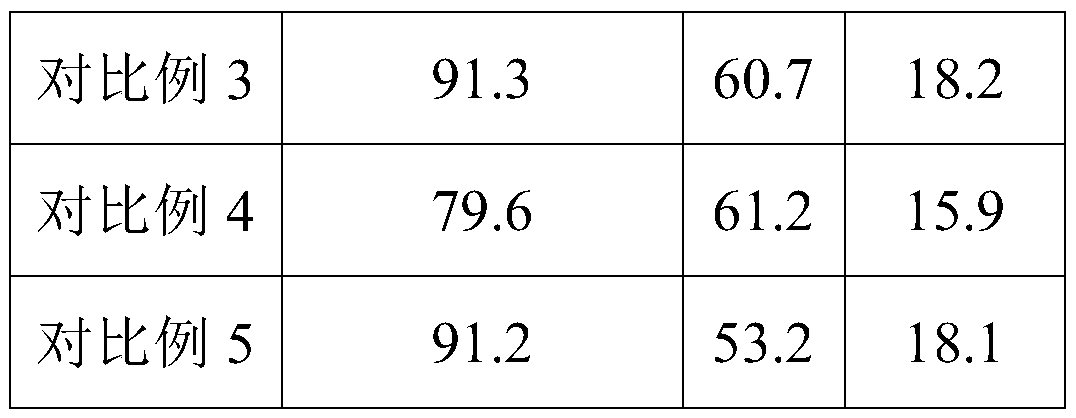

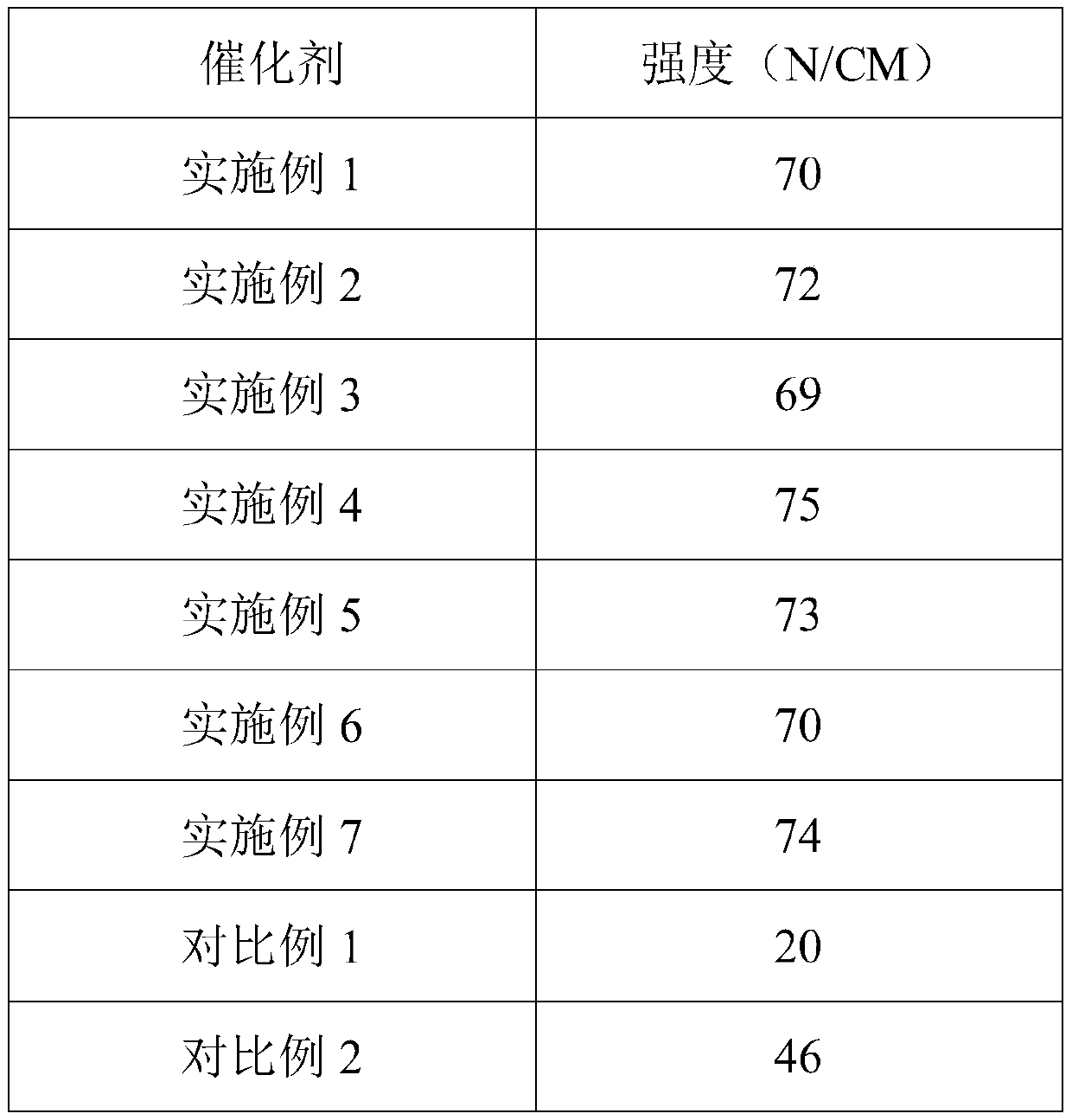

Examples

Embodiment 1

[0023] 1. In parts by mass, dissolve 0.1 part of nickel nitrate in 1 part of deionized water, add 1 part of γ-Al 2 o 3 After the sphere was stirred and impregnated, it was dried at 120°C and calcined at 500°C for 4 hours to obtain the precursor of the modified catalyst;

[0024] 2. Stir and mix 10 parts of ammonia water, 5 parts of tetrabutylammonium bromide, and 200 parts of deionized water to obtain solution A;

[0025] 3. Stir and mix 1 part of aluminum sulfate and 200 parts of deionized water evenly, and add the catalyst precursor obtained in the above 1 at the same time, and obtain solution B after stirring for a period of time;

[0026] 4. Stir and mix solution A and solution B to obtain solution C;

[0027] 5. Slowly add 50 parts of silica sol (25%) solution to solution C to obtain sol-gel. At the same time, add dilute nitric acid solution or ammonia solution to the sol-gel to adjust the pH value to 9.0-11.0 to obtain solution D;

[0028] 6. Transfer the solution D t...

Embodiment 2

[0030] 1. In parts by mass, dissolve 0.05 part of lead chloride in 1 part of deionized water, add 1 part of γ-Al 2 o 3 The sphere was stirred and impregnated, dried at 120°C, and calcined at 500°C for 4 hours to obtain the precursor of the modified catalyst;

[0031] 2. Stir and mix 10 parts of ammonia water, 5 parts of tetrabutylammonium hydroxide, and 200 parts of deionized water to obtain solution A;

[0032] 3. Stir and mix 1 part of aluminum nitrate and 200 parts of deionized water evenly, and add the catalyst precursor obtained in the above 1 at the same time, and obtain solution B after stirring for a period of time;

[0033] 4. Stir and mix solution A and solution B to obtain solution C;

[0034] 5. Slowly add 100% tetraethyl orthosilicate solution to solution C to obtain sol-gel, and at the same time add dilute nitric acid solution or ammonia solution to the sol-gel to adjust the pH value to 9.0-11.0 to obtain solution D;

[0035] 6. Transfer the solution D to a hi...

Embodiment 3

[0037] 1. In parts by mass, dissolve 0.2 part of nickel nitrate in 1 part of deionized water, add 1 part of γ-Al 2 o 3 After the sphere was stirred and impregnated, it was dried at 120°C and calcined at 500°C for 4 hours to obtain the precursor of the modified catalyst;

[0038] 2. Stir and mix 10 parts of ammonia water, 5 parts of tetraethylammonium bromide, and 200 parts of deionized water to obtain solution A;

[0039] 3. Stir and mix 1 part of aluminum sulfate and 200 parts of deionized water evenly, and add the catalyst precursor obtained in the above 1 at the same time, and obtain solution B after stirring for a period of time;

[0040] 4. Stir and mix solution A and solution B to obtain solution C;

[0041]5. Slowly add 150 parts of silica sol (25%) solution to solution C to obtain sol-gel, and at the same time add dilute nitric acid solution or ammonia solution to the sol-gel to adjust the pH value to 9.0-11.0 to obtain solution D;

[0042] 6. Transfer the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com