Laminate body

A laminated body and rubber layer technology, applied in the direction of layered products, rubber layered products, synthetic resin layered products, etc., can solve the problems of increasing the thickness of the barrier layer, usability (unfavorable assembly, unfavorable energy saving, etc.), and achieve softness Improved performance, low cost, and easy molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

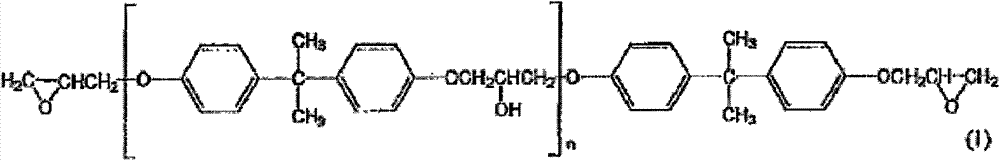

Image

Examples

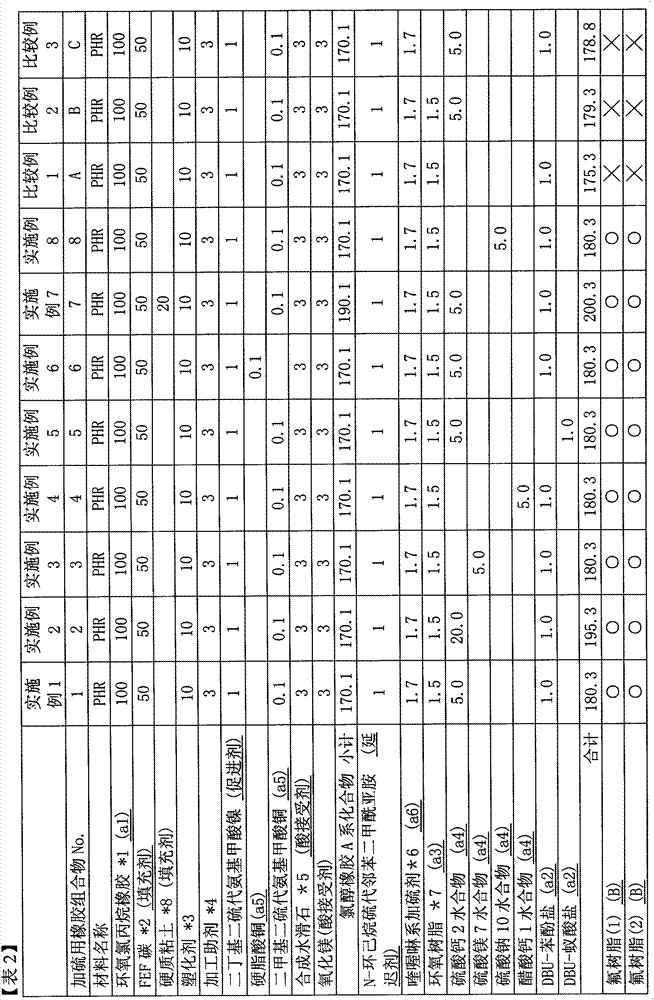

Embodiment 1~8、 comparative example 1~3

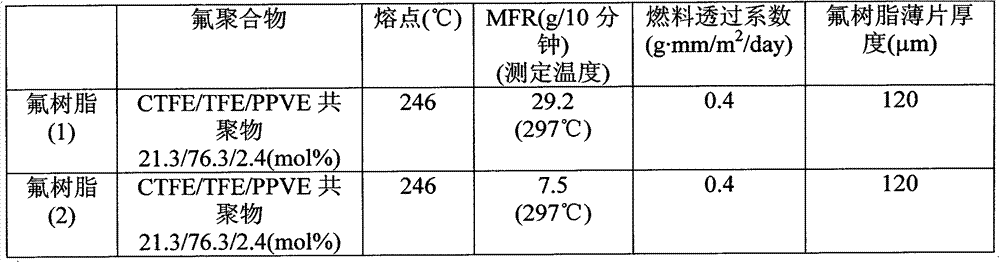

[0190] A sheet of the rubber composition for vulcanization shown in Table 2 with a thickness of about 3 mm is overlapped with a fluororesin sheet with a thickness shown in Table 1, and a resin with a width of about 10 to 15 mm is sandwiched between the two sheets at one end. The film (release film with a thickness of 10 μm) was inserted into a mold with a metal separator so that the thickness of the obtained sheet was 2 mm, and pressed at 170° C. for 15 minutes to obtain a sheet-shaped laminate. The obtained laminate was cut into strips of width 10 mm x length 40 mm x 3 sets, and the release film was peeled off to prepare a gripping test piece. Using Autograph (Shimadzu Corporation AGS-J 5kN), according to the method described in JIS-K-6256 (Adhesion test method for cross-linked rubber), at 25°C at a tensile speed of 50mm / min , the peeling test was performed on this test piece, the peeling pattern was observed, and it evaluated by the following reference|standard. The obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com