Patents

Literature

192results about How to "Improve process continuity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

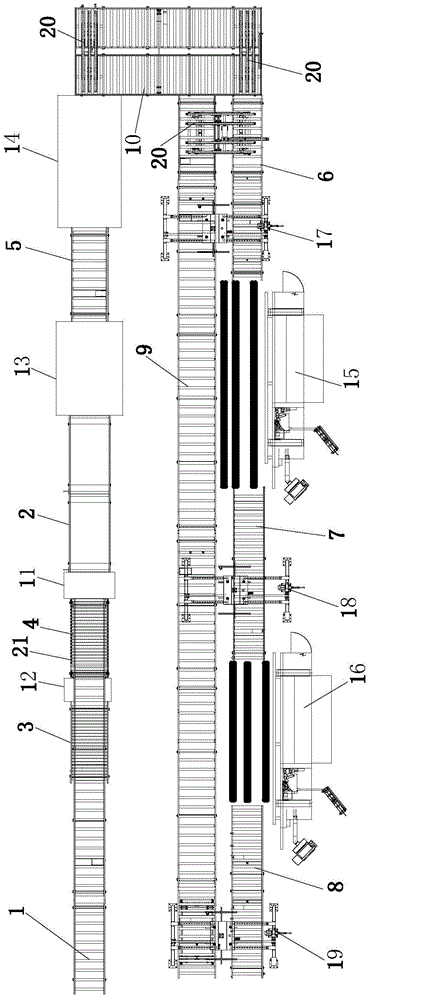

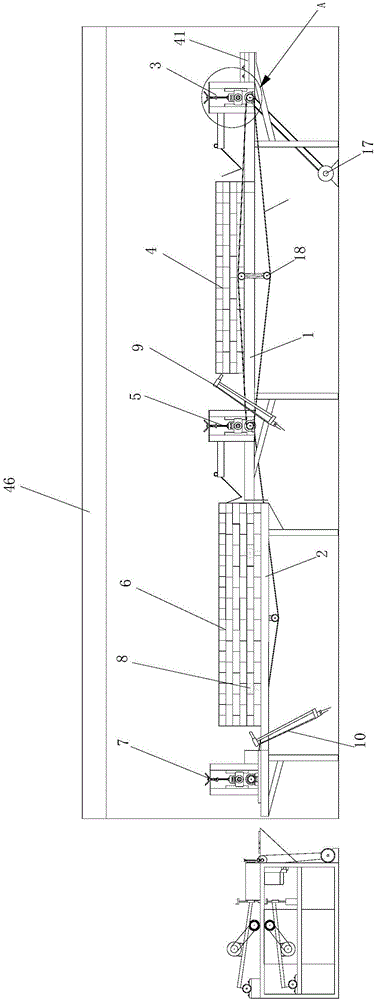

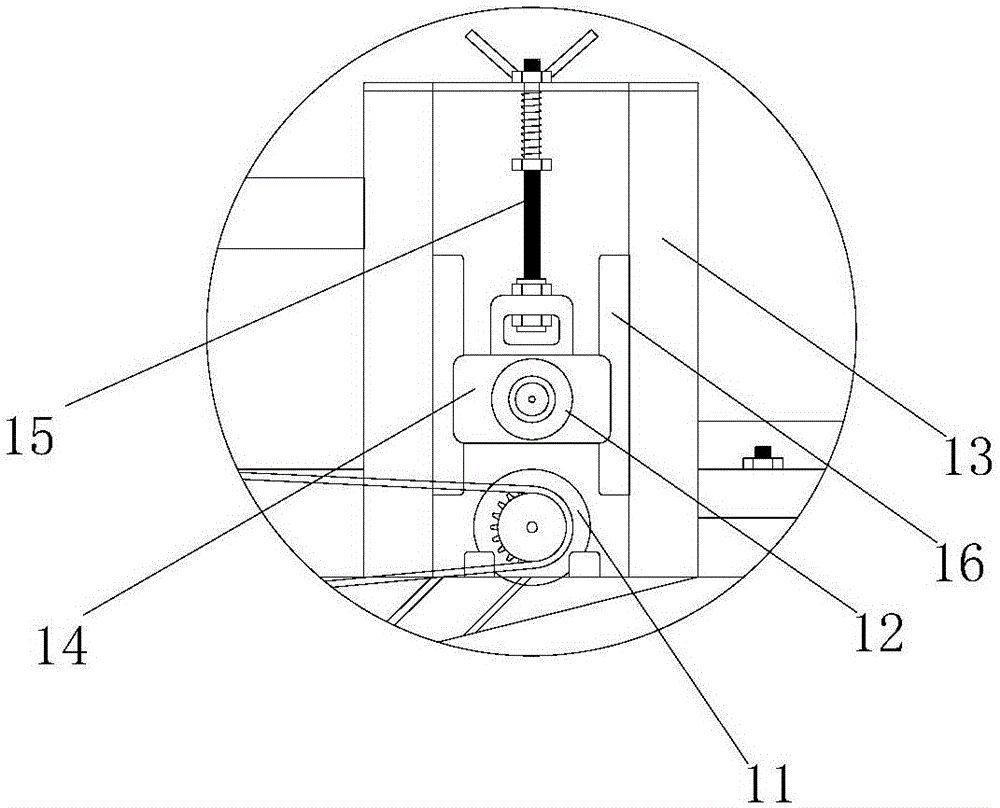

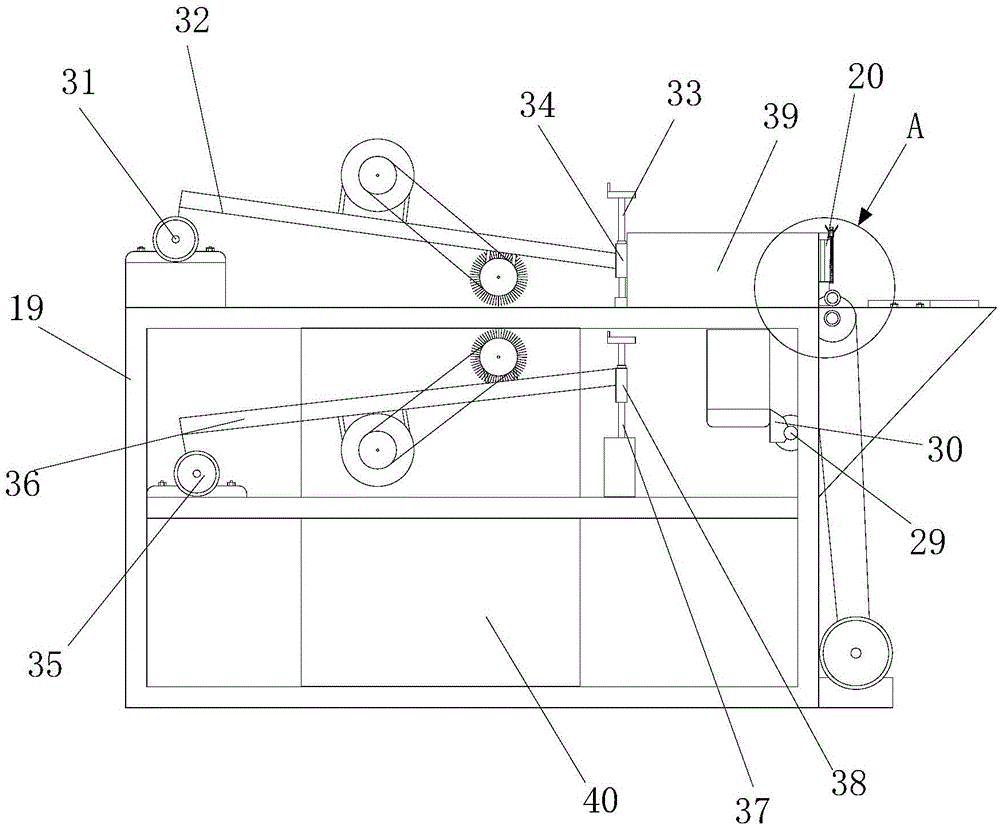

Wooden door production line

InactiveCN104960063AIncrease productivityGuaranteed normal operationWood veneer joiningGlue vesselsProduction lineUltimate tensile strength

The invention discloses a wooden door production line which saves time and labor and can greatly improve the production efficiency simultaneously. The wooden door production line comprises a first conveying line, a second conveying line, a third conveying line, a fourth conveying line, a fifth conveying line, a sixth conveying line, a seventh conveying line, an eighth conveying line, a ninth conveying line, a two-side gumming machine, a one-side gumming machine, a press, a quadrilateral saw, a first edge bonding machine, a first rotating mechanism, a second edge bonding machine, a second rotating mechanism and a third rotating mechanism. When the wooden door production line is utilized to produce wooden doors, normal running of the whole wooden door production line can be guaranteed only by arranging workers at the front end of the first conveying line, the two sides of the second conveying line, the two sides of the third conveying line and the tail end of the eighth conveying line, all processes are connected with each other through the conveying lines, manual carrying is not needed, the labor intensity of the workers is greatly reduced, the time and the labor are saved, the automation degree is high, the production efficiency of the wooden doors is greatly improved, and the wooden door production line is suitable for being applied and popularized in the field of wooden door processing.

Owner:SUZHOU NOELL IND EQUIP MFG CO LTD

Instant green tea powder processing method

The invention relates to an instant green tea powder processing method which comprises the following steps of: killing out fresh tea leaves by adopting a vacuum microwave method, carrying out superfine grinding after deep freezing, extracting and superfinely filtering by adopting secondary vacuum ultrasonic wave, and freezing and drying to obtain the instant green tea powder. The killing, extraction and drying steps are completed under a vacuum condition, and the action temperature is low, so that the oxidation of effective ingredients in fresh tea leaves can be effectively avoided; and vacuum ultrasonic extraction after freezing and superfine grinding ensures the full leaching of the effective ingredients. The product produced by the processing method has the advantages of high production efficiency, good product color, fresh taste, good dissolvability, incapability of generating tea cream and the like.

Owner:HEBEI STRONG FOOD

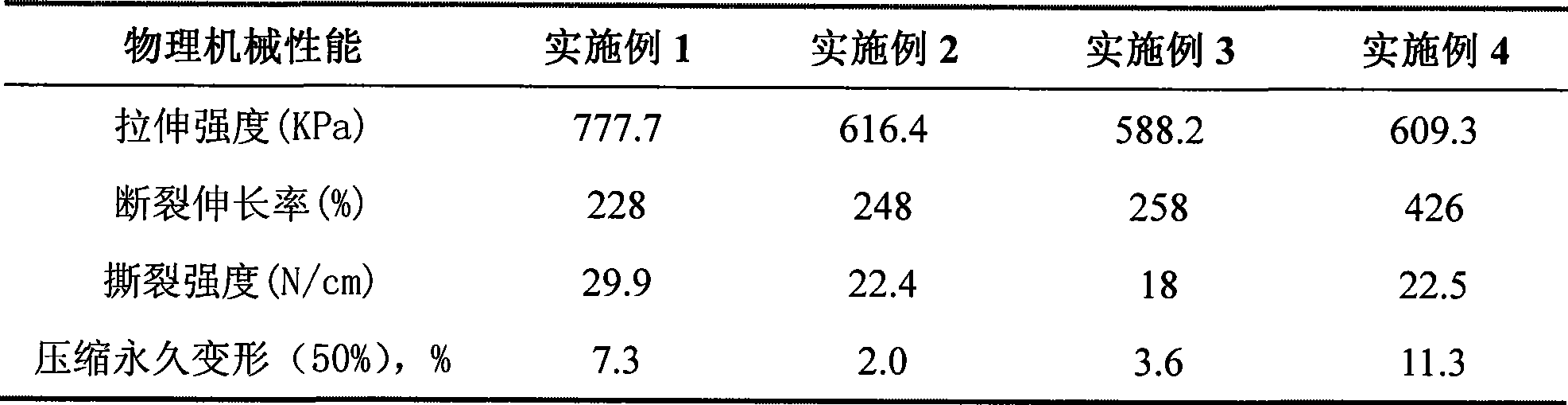

Duprene rubber foamed sheet and preparation method thereof

ActiveCN101392076AImprove flame retardant performanceHigh tensile strengthPolymer sciencePropanoic acid

The invention relates to a neoprene foaming board and a preparation method thereof. The neoprene foaming board is prepared by the following materials according to weight parts: 100 portions of neoprene, 15 portions to 200 portions of kaolin or calcium carbonate, 15 portions to 45 portions of carbon black, 10 portions to 20 portions of a vulcanizing agent, 0 portion to 2 portions of an accelerant, 5 portions to 15 portions of a vesicant, 0 portion to 5 portions of urea resin, 1 portion to 4 portions of olefin, 0 portion to 3 portions of dilauryl thiodipropionate, 0 portion to 2 portions of 2, 2'-methylene-bis(4-methyl-6- tert-butylphenol), 0 portion to 1 portion of nickel dibutyldithiocarbamate, 0 portion to 2 portions of stearic acid, 8 portions to 30 portions of black factice, 0 portion to 4 portions of vaseline, 10 portions to 20 portions of naphthenoid oil, 20 portions to 40 portions of perfume oil, and 1 portion to 4 portions of a dispersant. The preparation method thereof includes the steps of first-time mixing of a pressurizing milling machine, first-time mixing of a mixing mill, second-time mixing of the pressurizing milling machine, second-time mixing of the mixing mill, extrusion of an extruder, first-time foaming vulcanization, second-time foaming vulcanization, cooling and the like. The neoprene foaming board and the preparation method have the advantages of good flame resistance, high tensile strength, high extensibility, good performance of tear resistance, small compression set, good abrasion resistance and skidproof effect, good effect of shock absorption and the like.

Owner:常州美利晟高分子科技有限公司

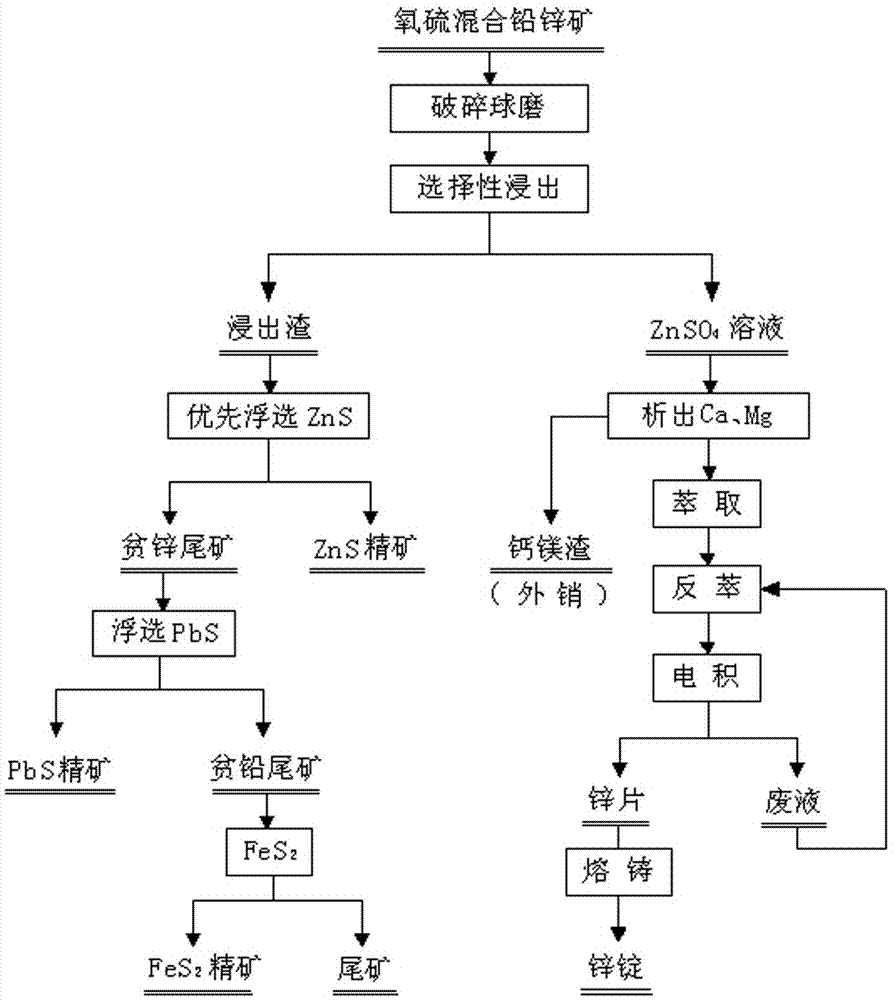

Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

ActiveCN103301929AReduce calcium concentrationHarm reductionFlotationWet separationOxygenTotal recovery

The invention discloses a selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process. For oxygen and sulfide mixed lead zinc ore, a zinc wet-method smelting process and a zinc flotation process are combined, zinc oxide in the ore is partially and selectively leached out by the first wet-method smelting process, and then zinc sulfide in the ore is floated out by the flotation process. In order to overcome the difficulty in treating the oxygen and sulfide mixed lead zinc ore, the invention provides the smelting and selection combining process which is short in process flow, reliable in technology, easy to operate and control, relatively low in material consumption and energy consumption for production, high in metal reclaiming efficiency, relatively good in economic benefit and high in practicability, the recovery of lead and zinc in the low-grade complex difficultly-selected oxygen and sulfide mixed lead zinc ore can be greatly improved, and the total recovery of lead and zinc can be up to over 90 percent.

Owner:云南金鼎锌业有限公司

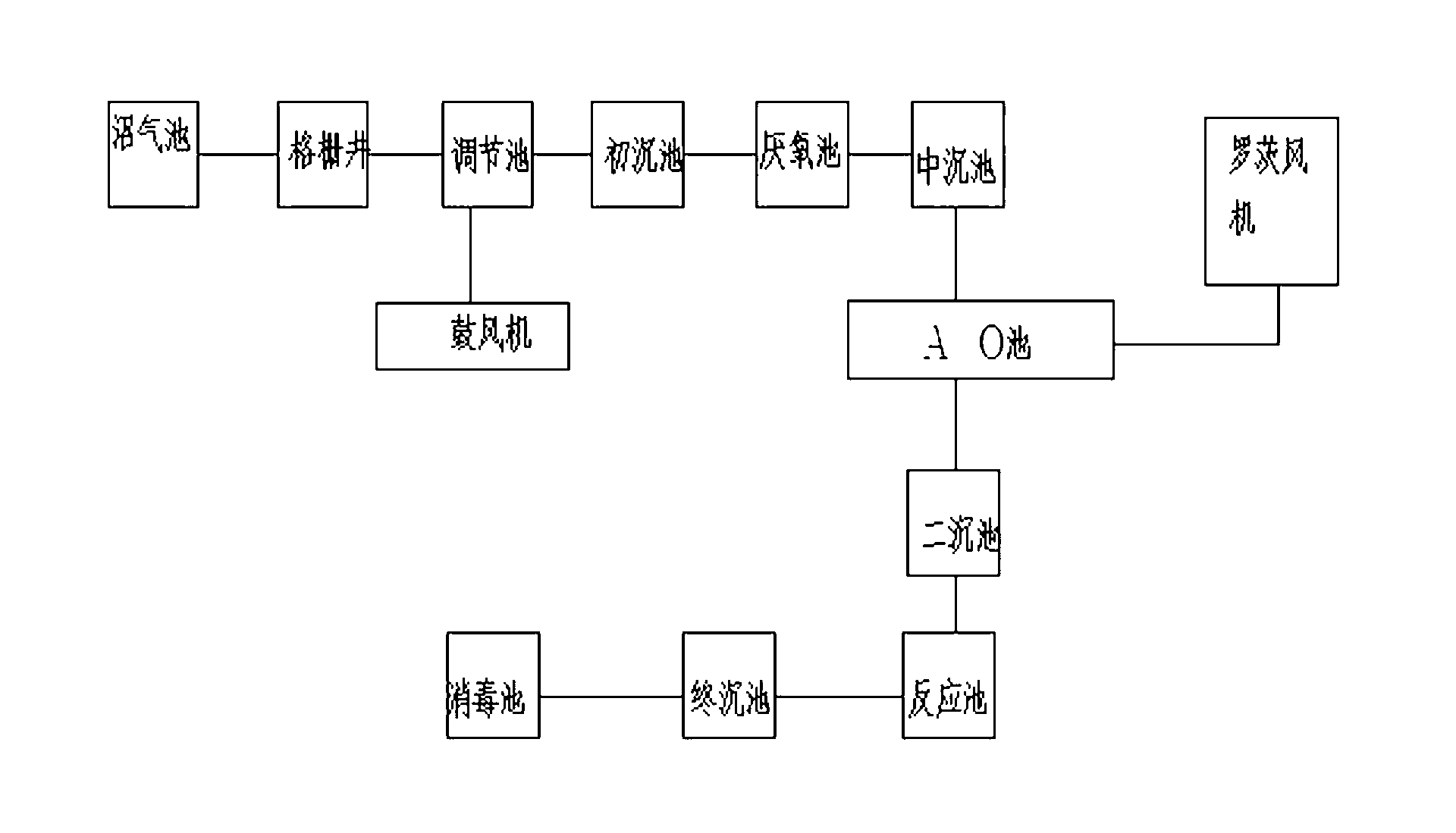

Large-scale pig farm wastewater treatment method

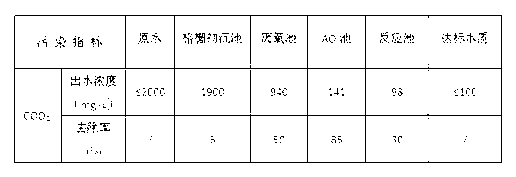

ActiveCN103241908AImprove biodegradabilityAvoid churnMultistage water/sewage treatmentPig farmsMedicine

The invention relates to a large-scale pig farm wastewater treatment method comprising anaerobic fermentation, filtering, regulating pool treatment, primary precipitation, anaerobic pool treatment, secondary precipitation, A / O pool treatment, precipitation of secondary sedimentation tank, flocculent precipitation treatment, final precipitation treatment and disinfecting tank treatment. The treatment method provided by the invention is simple in treatment procedures, low in treatment cost and strong in treatment ability, thereby being suitable for popularization and application of large-scale pig farm wastewater treatment.

Owner:巨星农牧有限公司

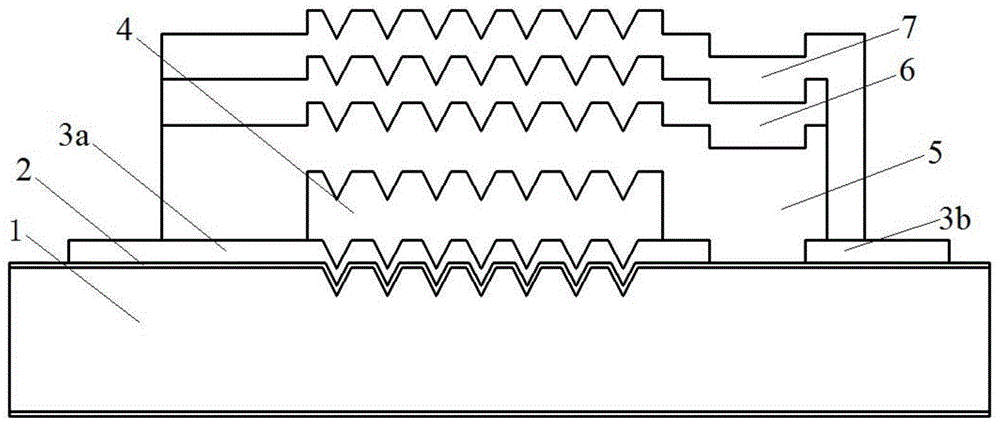

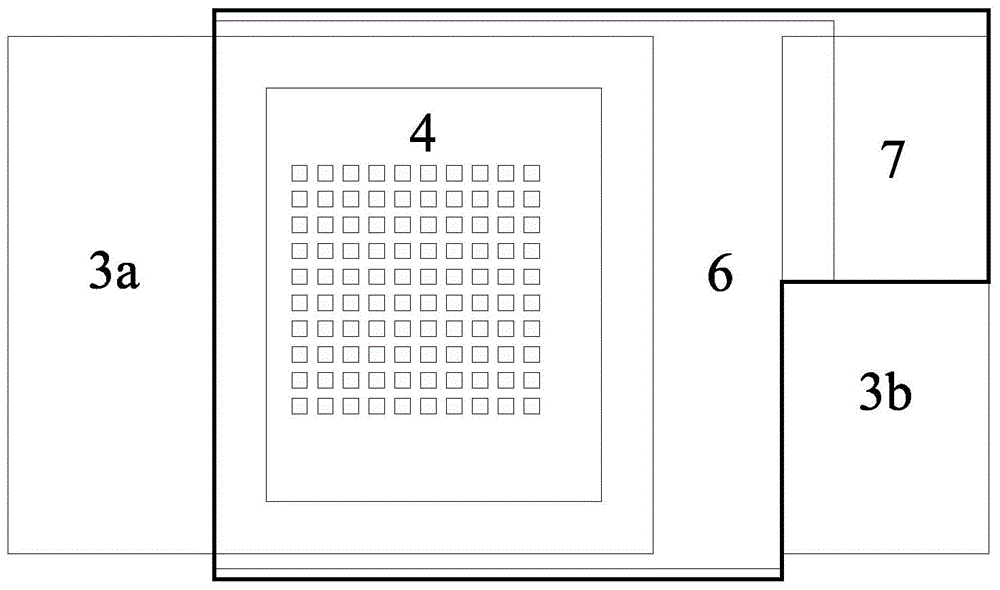

Three-dimensional all-solid-state mini thin-film lithium battery with inverted pyramid array structure

InactiveCN104134816AImprove space utilizationImprove structural stabilityFinal product manufactureLi-accumulatorsAll solid stateInverted pyramid

The invention discloses a three-dimensional all-solid-state mini thin-film lithium battery with an inverted pyramid array structure, and relates to lithium batteries. The three-dimensional all-solid-state mini thin-film lithium battery is provided with a substrate, an insulation film, a cathode current collector, a lower anode current collector, a cathode film, a solid electrolyte film, an anode film and an upper anode current collector, wherein the insulation film is arranged on the substrate; the cathode current collector and the lower anode current collector are arranged on the insulation film; the cathode film is arranged on the cathode current collector; the solid electrolyte film covers the cathode film; the anode film is arranged on the solid electrolyte film; the upper anode current collector is arranged on the anode film and the lower anode current collector. Based on the anisotropic etching of a silicon substrate, the inverted pyramid array structure is precisely manufactured and applied to the all-solid-state mini thin-film lithium battery, so that the capacity of active substances in unit standing area is improved and the contact between the thin films is tight. According to the unique design of a mask, the upper and lower circuits are guided to a same plane, so that the space utilization rate and the structure stability of the mini battery are effectively improved.

Owner:XIAMEN UNIV

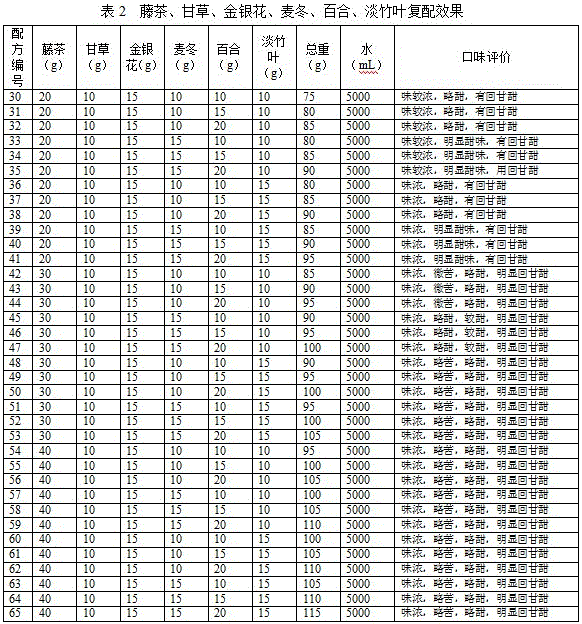

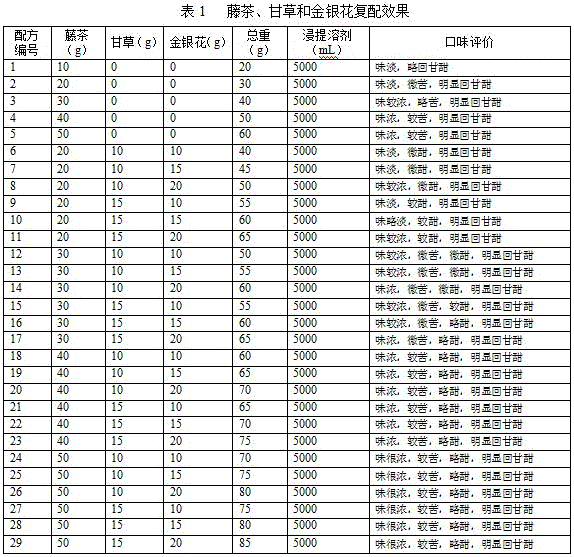

Ampelopsis grossedentata tea health-care compound beverage and preparation method thereof

InactiveCN106106942AHigh content of active ingredientsHas multiple health functionsTea substituesAlcoholAdditive ingredient

The invention provides an ampelopsis grossedentata tea health-care compound beverage and preparation method thereof. The method comprises the following steps: by taking ampelopsis grossedentata tea, radix glycyrrhizae, flos lonicerae, radix ophiopogonis, bulbus lilii, herba lophatheri, folium mori, fructus lycii, fructus momordicae and rhizoma imperatae as raw materials, crushing the raw materials, leaching the crushed raw materials by adopting water extraction, alcohol extraction or combination of alcohol extraction with water extraction, and filtering to obtain leaching solution, and collecting filtrate to obtain ampelopsis grossedentata tea health-care compound beverage. The active efficacy of active ingredients in the prepared ampelopsis grossedentata tea health-care compound beverage can be effective guaranteed not to lose, the beverage has multiple health-care efficacies through the synergistic compatibility of multiple raw materials, the overall attribute of the beverage is mild or warm, so that the beverage is more applicable to drinking of the majority of consumers, the contents of each active ingredient in the beverage is within the daily maximum usage amount range, so that the safety of the beverage can be further guaranteed, the side effect due to excessive drinking can be avoided, and the beverage is healthier.

Owner:YANGTZE NORMAL UNIVERSITY

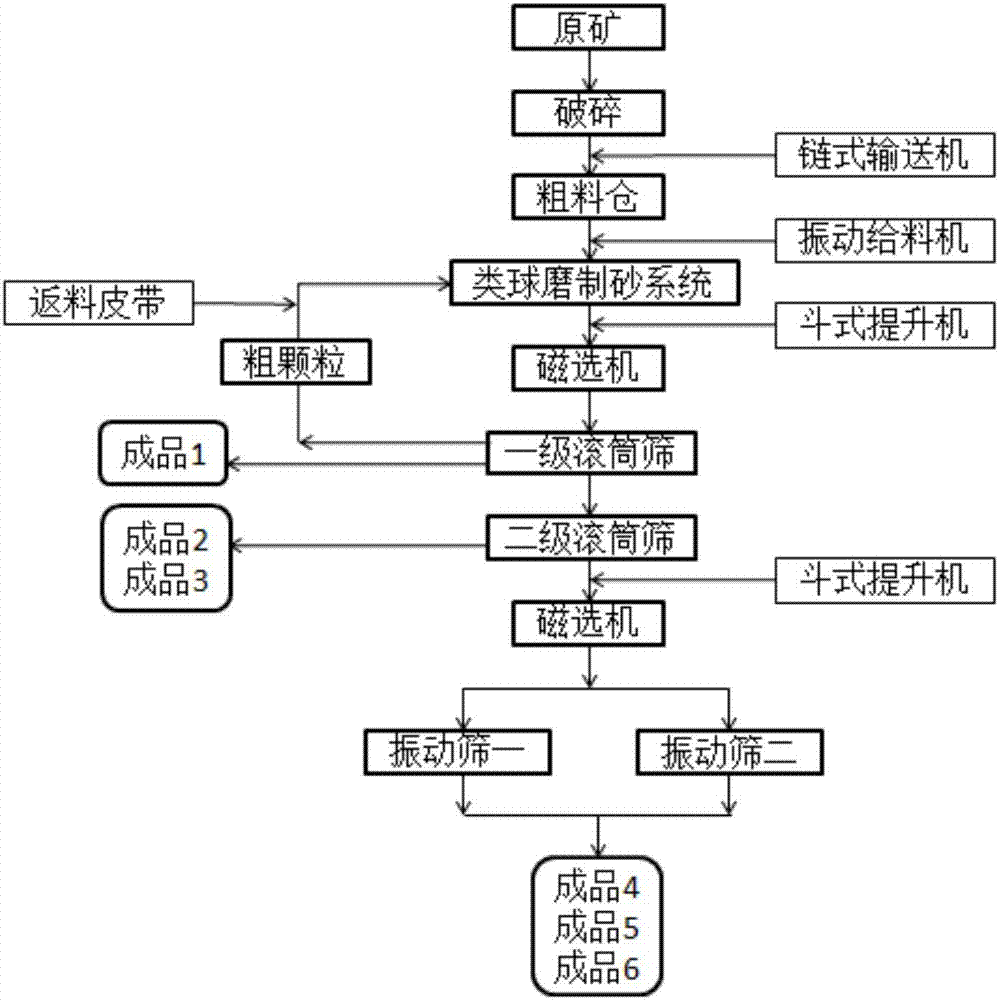

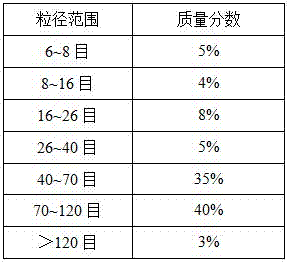

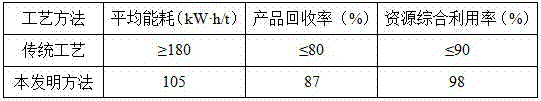

Processing technique of quartz sand

The invention belongs to the field of quartz sand production, and particularly relates to a processing technique of quartz sand. The invention aims to provide the processing technique of high-quality quartz sand, which has the advantages of low energy consumption and good product grain shape and particle size distribution. In order to solve the problem, the processing technique adopts the technical scheme that the processing technique comprises the steps of crushing, making sand, sieving and classifying. According to the processing technique, the operating principle that the crushing, grinding and classifying techniques are matched is fully used, continuous sieving and classifying is realized through process design, a series of 6 to 400-mesh products of more than 6 specifications can be stably produced, the average energy consumption is controlled to be 90 to 110 kW.h / t, the recovery rate of finished products is greater than or equal to 85%, and the comprehensive utilization rate of resources reaches more than 98%. The high-quality quartz sand obtained by adopting the processing technique can satisfy the production requirements of artificial quartz.

Owner:四川晶天地新材料科技有限公司

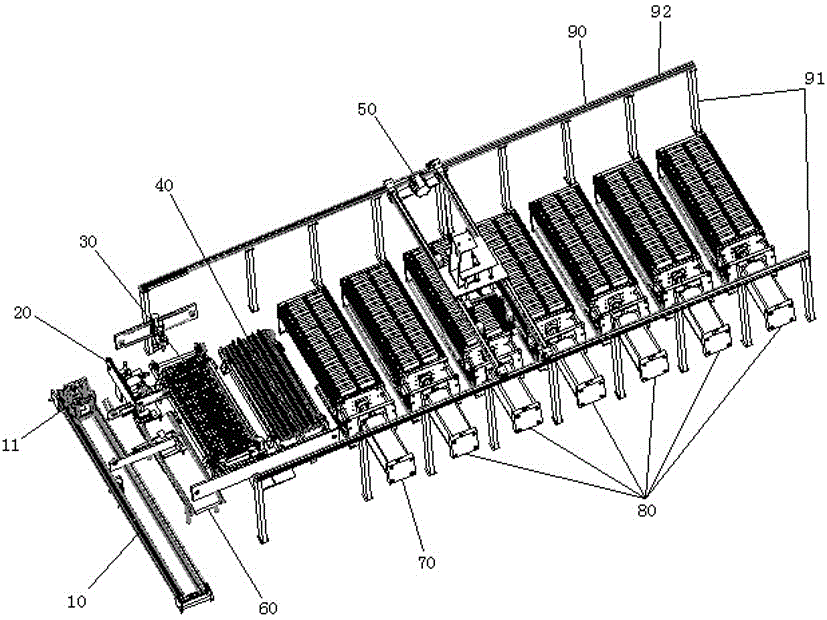

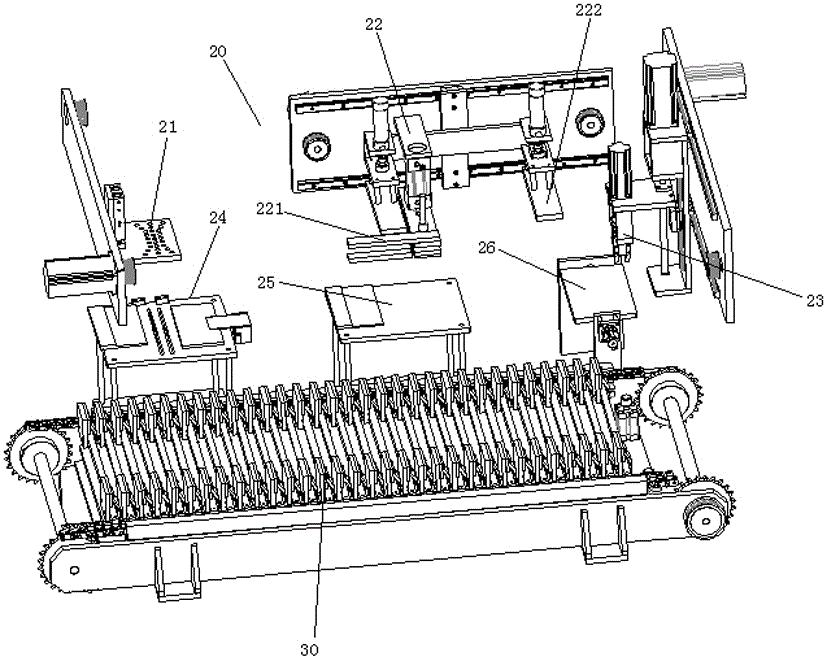

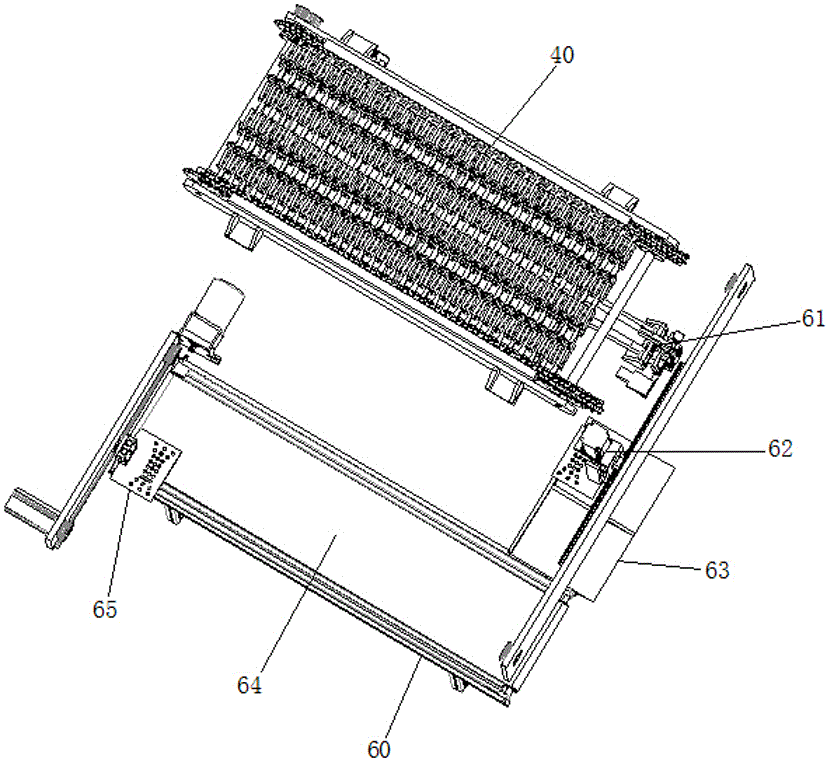

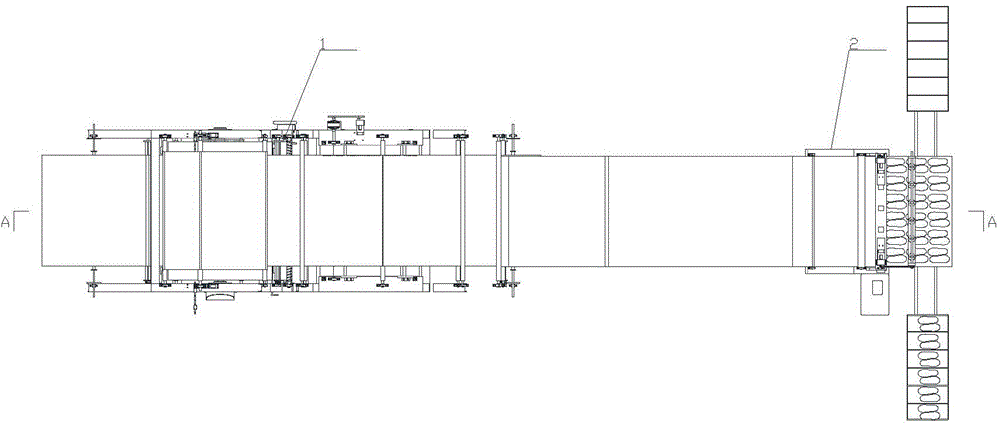

All-in-one machine for polymer lithium battery with functions of formation and capacity grading

PendingCN106129449AGood process continuityGood effectAssembling battery machinesFinal product manufactureCell assemblyManipulator

The invention discloses an all-in-one machine for a polymer lithium battery with functions of formation and capacity grading. The all-in-one machine comprises a cell assembly line, wherein a cell elastic clamp which is fully loaded with cells; a formation and capacity-grading apparatus is arranged on one side of the cell assembly line; the formation and capacity-grading apparatus comprises a material-feeding mechanical arm bracket and a material-discharging mechanical arm bracket; a material-feeding material-waiting frame, a material-discharging material-waiting frame, a group of formation clamps and multiple capacity-grading clamps are arranged in the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket; the material-feeding material-waiting frame, the material-discharging material-waiting frame, the group of formation clamps and the multiple capacity-grading clamps are arranged in sequence from one side to the other side; a material-feeding mechanism and a material-discharging mechanism are arranged between the material-feeding material-waiting frame and the cell assembly line; the material-feeding mechanism and the material-discharging mechanism are positioned on the front and back sides respectively; and material-moving mechanical arms are arranged on the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket. The all-in-one machine for the polymer lithium battery with the functions of formation and capacity grading has the advantages of high continuity of capacity-grading processes, high degree of automation, high efficiency, good formation effect, high product quality and the like.

Owner:东莞德方智能装备中心(有限合伙)

Processing method for high-quality, low-sugar content plum slice

The invention provides a processing method for a high-quality, low-sugar content plum slice. The flow of the method is as follows: semifinished fruit pickling, picking and washing, desalination, core removal, pulping, flavoring, shaping, drying, slicing and finished product packaging. Because the processing method adopts flowing hot water to carry out gradient desalination, the process of desalination is accelerated, and the loss of heat energy is reduced; since semifinished plums are pulped, the subsequent process of flavoring is facilitated, the pickling time spent in whole fruit processingis saved, the loss of nutrients is prevented in the process of pickling, overall drying is facilitated, and the uniformity of the color of the product is guaranteed; because xylitol is directly addedto replace the osmotic cane sugar adopted by the conventional process, the processing period is greatly shortened, and the sugar content in the product is decreased; after pulp is scraped into pieces, the pieces are dried under vacuum and constant temperature, and cut into the plum slices with uniform size and thickness, the plum slices are neat and attractive, the product keeps the original color and flavor, the original nutrient ingredients are prevented from being destroyed as well, and moreover, the plum slices are convenient to eat.

Owner:ZHEJIANG UNIV OF TECH

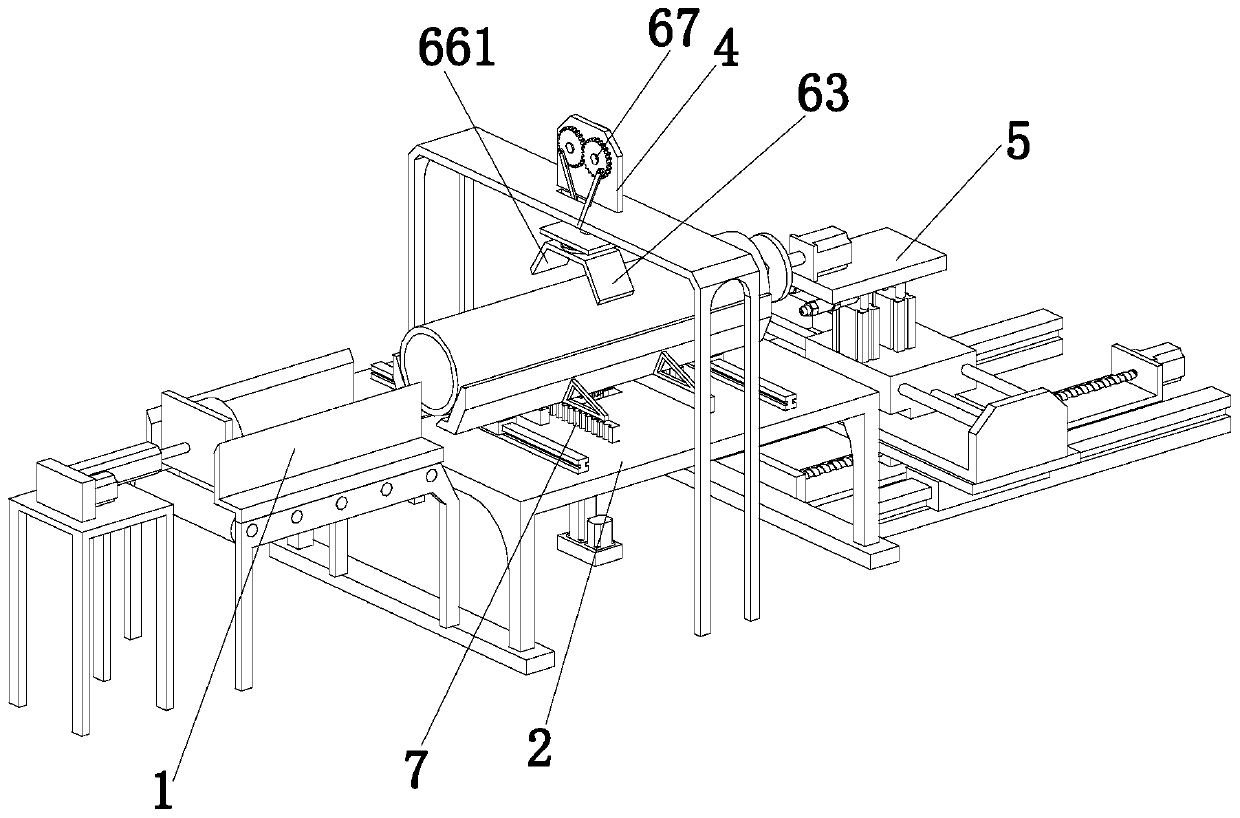

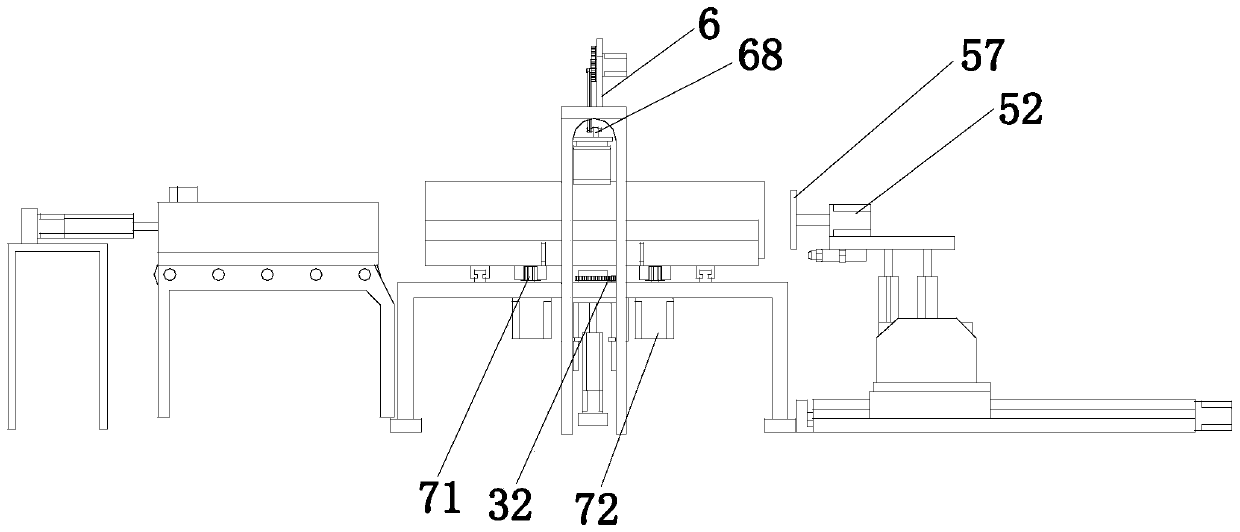

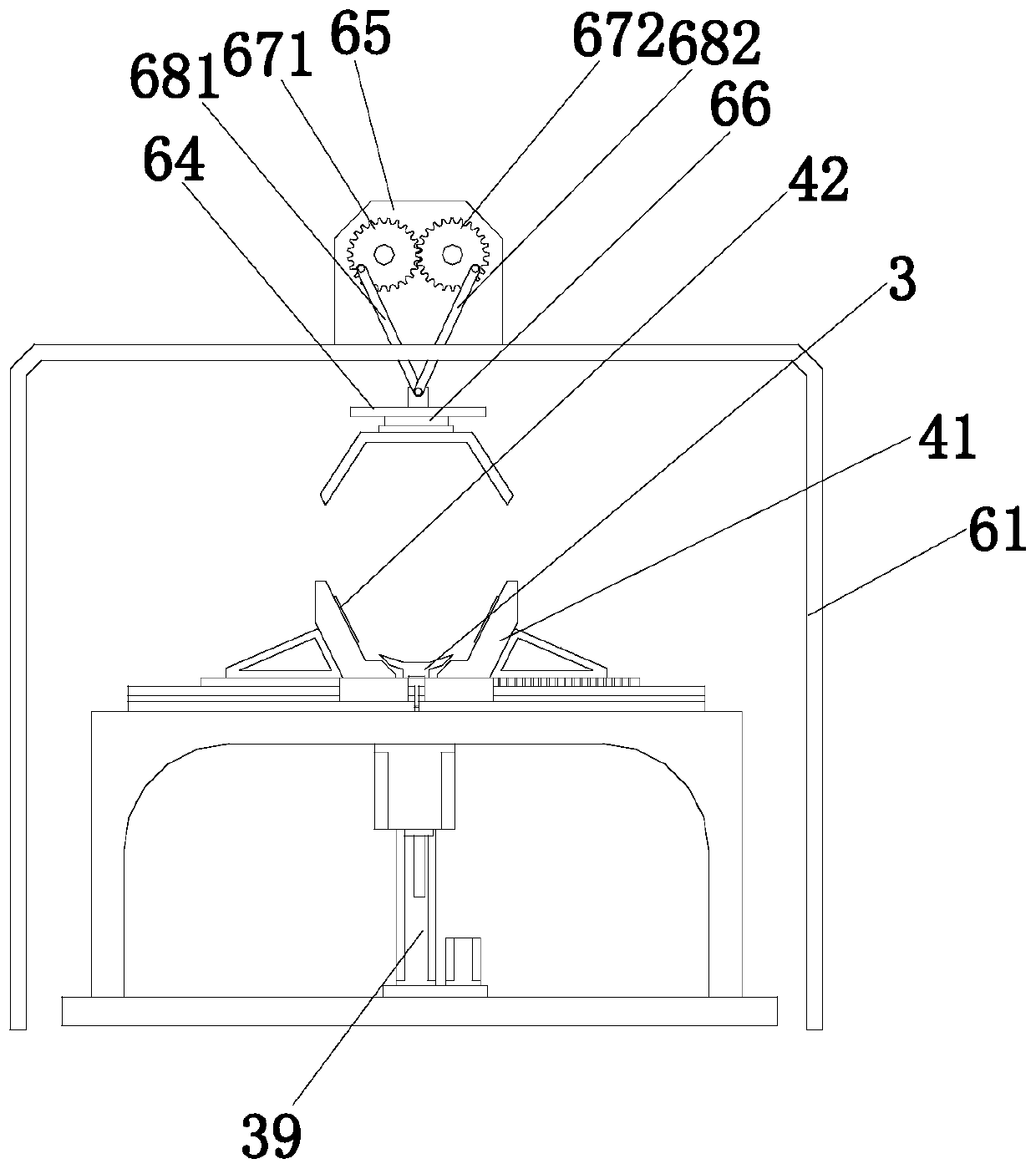

Port deburring device for reinforced concrete sewer pipe production

PendingCN111266957AImprove stabilityImprove process continuityEdge grinding machinesGrinding feedersRebarReinforced concrete

The invention discloses a port deburring device for reinforced concrete sewer pipe production, and belongs to the technical field of sewer pipe deburring equipment. The port deburring device for reinforced concrete sewer pipe production comprises a pipeline feeding mechanism, a working table, a rotary turn-around mechanism, a pipeline limiting mechanism and an automatic deburring mechanism, wherein the pipeline limiting mechanism is arranged on the top part of the working table; the rotary turn-around mechanism comprises a lifting table, a rotation assembly and two vertically arranged liftingelectric cylinders; a through slot for the lifting table to pass through is arranged on the working table; and the output ends of the two lifting electric cylinders are fixedly connected with the bottom part of the lifting table. According to the port deburring device for reinforced concrete sewer pipe production provided by the invention, a sewer pipe can be turned around through the rotary turn-around mechanism; a pressing seat can be matched with a limiting seat in the turn-around process, so that the sewer pipe is prevented from falling off; and in addition, the sewer pipe between two positioning tables can be pressed tightly through an upper limiting assembly so as to be tightly pressed between the two positioning tables.

Owner:广东鑫隆管业有限公司

Extraction and separation technology for reclaiming main impurity in indium in hydrochloric acid system

The invention relates to technology for extracting and separating main impurities from indium with hydrochloric acid system. The acidity of the said leachate is adjusted by adding material or concentrated hydrochloric acid and adjusting to hydrochloric acid of 4+-0.3 mol / L, then filtrating. The said Ferric, tin and antimony is extracted with mixed extractant of 30%TBP+60%sulfonate kerosene +10%octyl alcohol. The said ferric is extracted by washing the organic phase with 1N hydrochloric acid solution. The said tin and antimony is extracted by adding little citric acid into 0.1 hydrochloric acid solution. The invention has good continuity, no loss of indium, can recover chloride ferric, tin, and antimony, reduces production cost, and improves operation environment.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

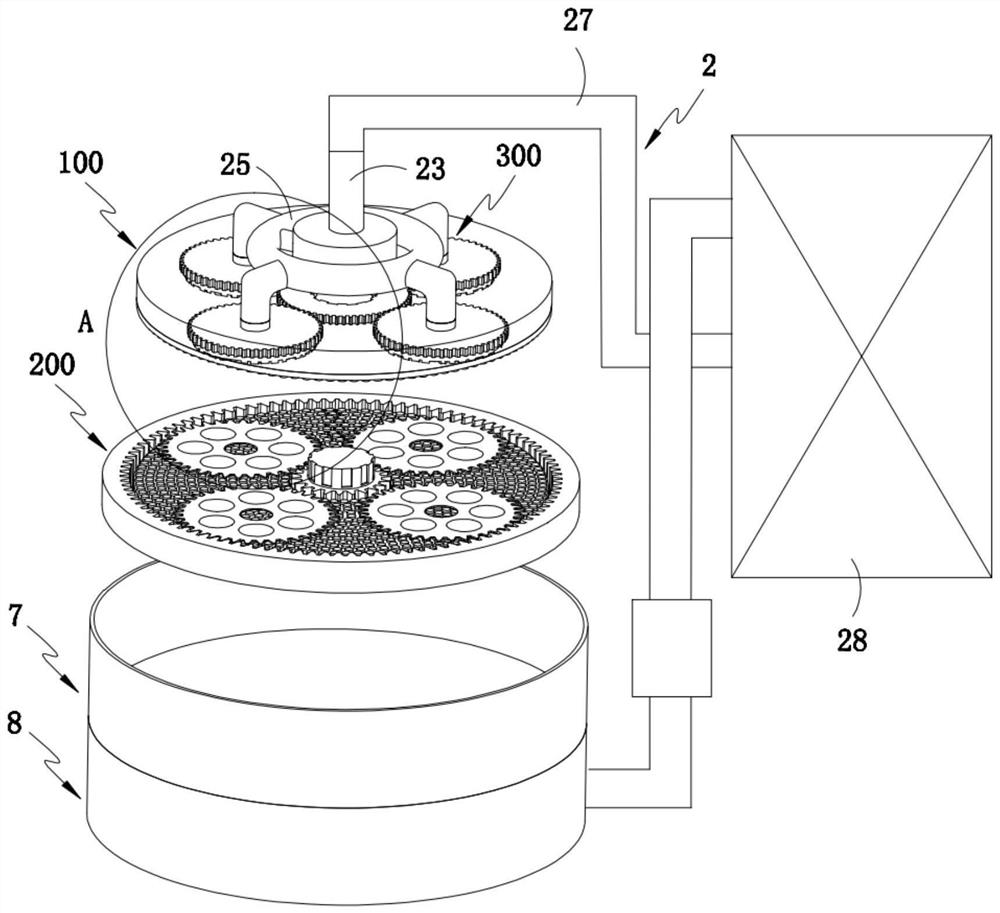

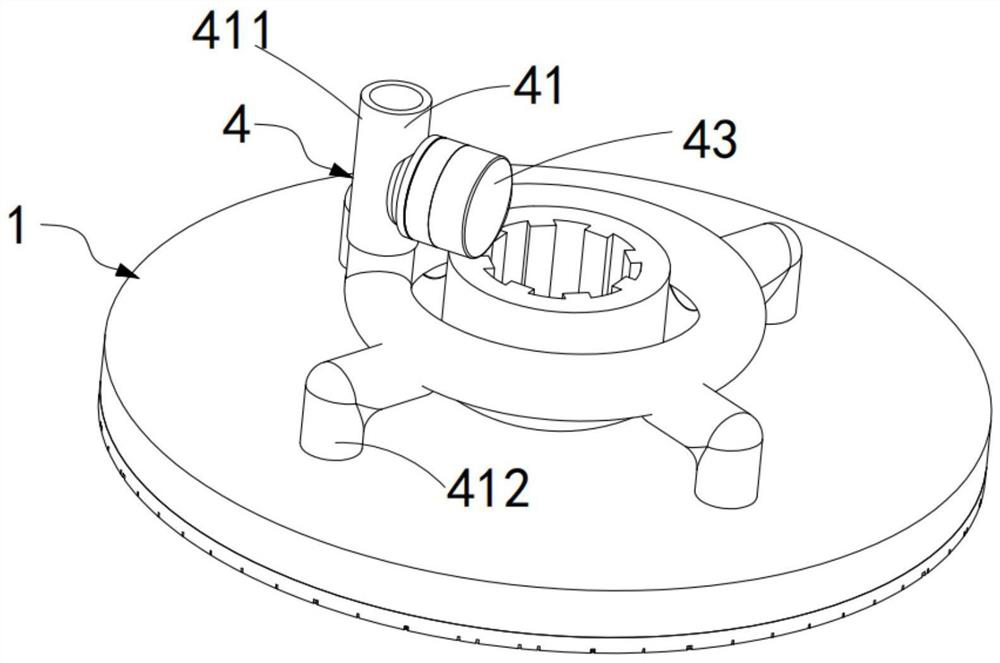

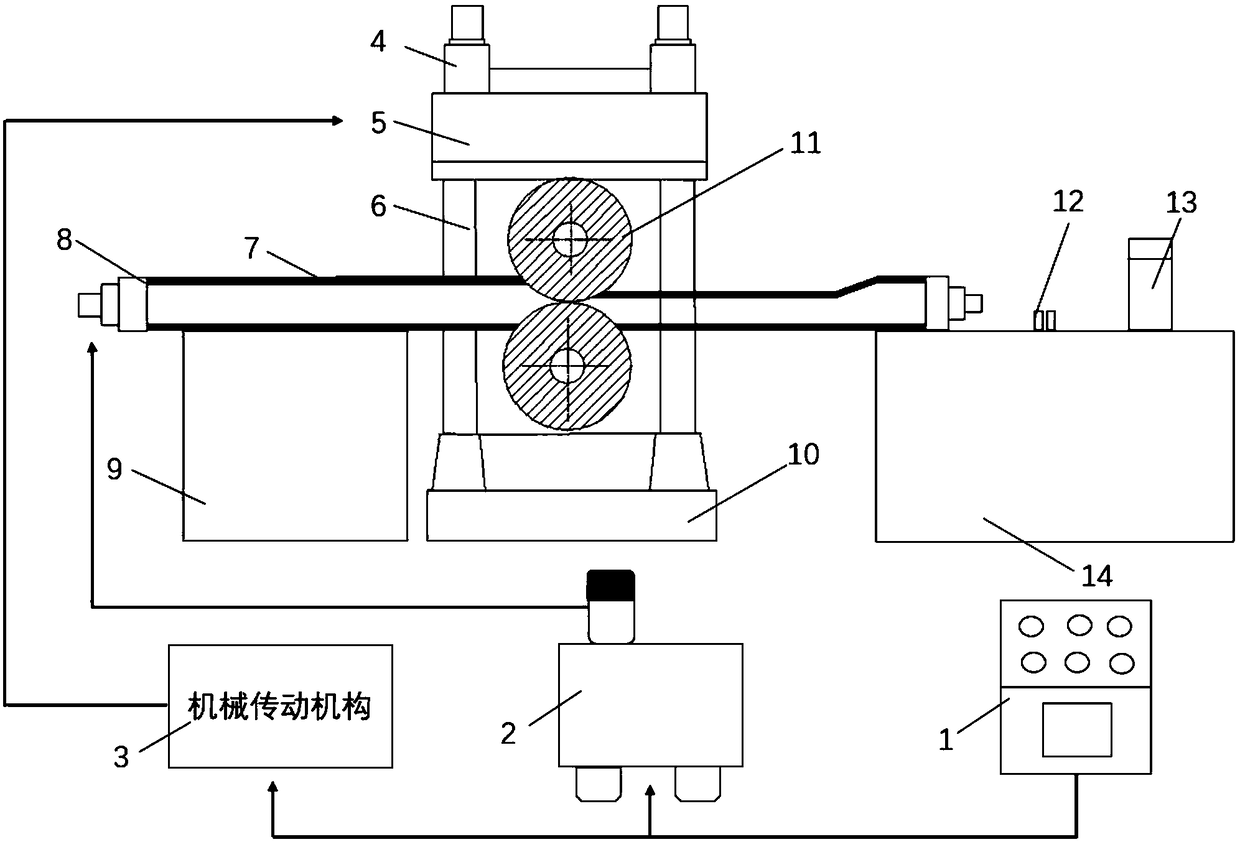

Silicon wafer dual-face grinding equipment and production process thereof

ActiveCN111761505AAffects high-quality grindingIngenious structural designLapping machinesWork carriersEngineeringSilicon chip

The invention provides silicon wafer dual-face grinding equipment and a production process thereof. The equipment comprises an up and down grinding disc system, a lower plane disc for loading a silicon wafer to be ground and a spraying sweeping chip removal system mounted on the upper grinding disc system, the spraying sweeping chip removal system comprises an upper plane disc mechanism corresponding to the lower plane disc, a liquid supply device communicating with the upper plane disc mechanism, and an upper transmission assembly for driving the upper plane disc mechanism to rotate, when theupper plane disc mechanism rotates to the position above the corresponding lower plane disc, trigger liquid outlet is achieved, cleaning liquid is sprayed out under the rotation centrifugal effect ina sprinkler manner, grinding impurities are removed in a spraying manner from the center of the lower plane disc to the center and are swept, in cooperation with a chip removal extrusion system mounted on the lower grinding disc system, impurity mixed liquid is extruded, transferred, filtered and recycled, the liquid outlet manner is ingeniously designed while the automatic liquid supply is achieved to synchronously remove the grinding impurities in time, and the technical problems that in the prior art, the grinding impurities cannot be removed in time, and a silicon wafer product is poor inquality and low in yield can be solved.

Owner:ZHEJIANG COWIN ELECTRONICS

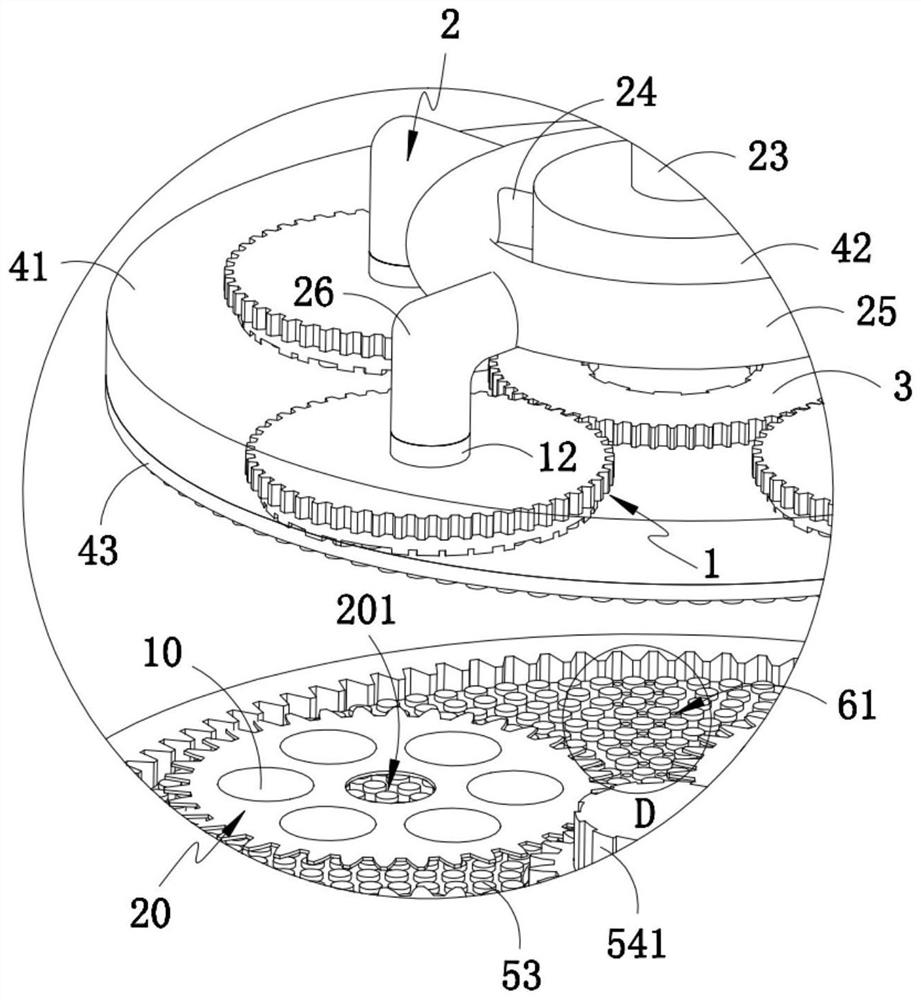

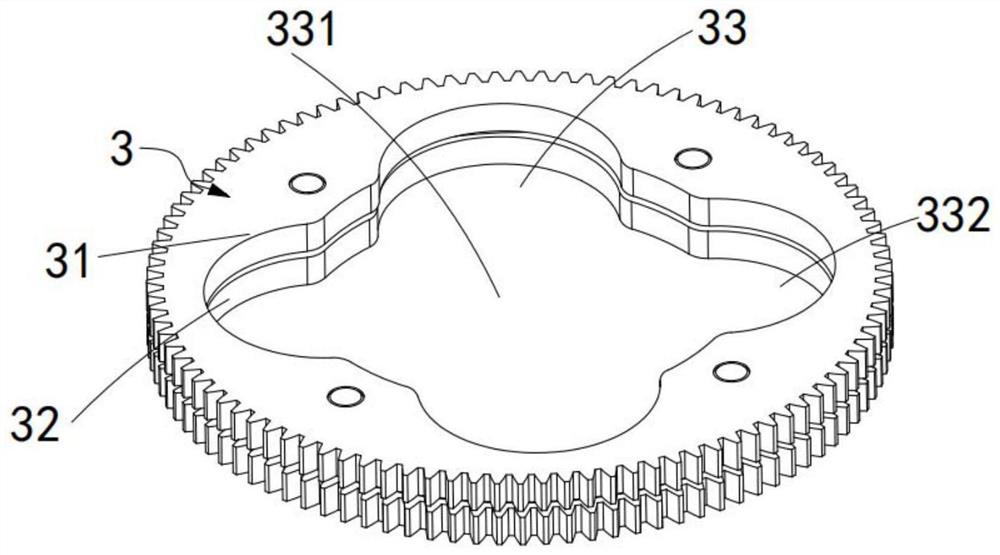

Silicon wafer grinding disc correction device and correction process

ActiveCN111761516AEvenly distributedReduce usageAbrasive surface conditioning devicesEngineeringSilicon chip

The invention relates to the field of silicon wafer grinding device correction machining, in particular to a silicon wafer grinding disc correction device and correction process. The device comprisesan upper grinding disc system, a lower grinding disc system and a plurality of correction wheels arranged between the upper grinding disc system and the lower grinding disc system, and recycling and spraying mechanisms are arranged on the central notches of the correction wheels. The recycling and spraying mechanisms are arranged on the correction wheels, a grinding liquid between the upper grinding disc system and the lower grinding disc system is recycled and then sprayed and utilized through the recycling and spraying mechanisms, grinding liquid distribution between the upper grinding discsystem and the lower grinding disc system is sufficiently guaranteed to be uniform, use of the grinding liquid is reduced while the grinding effect is improved, and the technical problems of low precision, poor efficiency and heavy pollution of an existing grinding correction device are solved.

Owner:ZHEJIANG COWIN ELECTRONICS

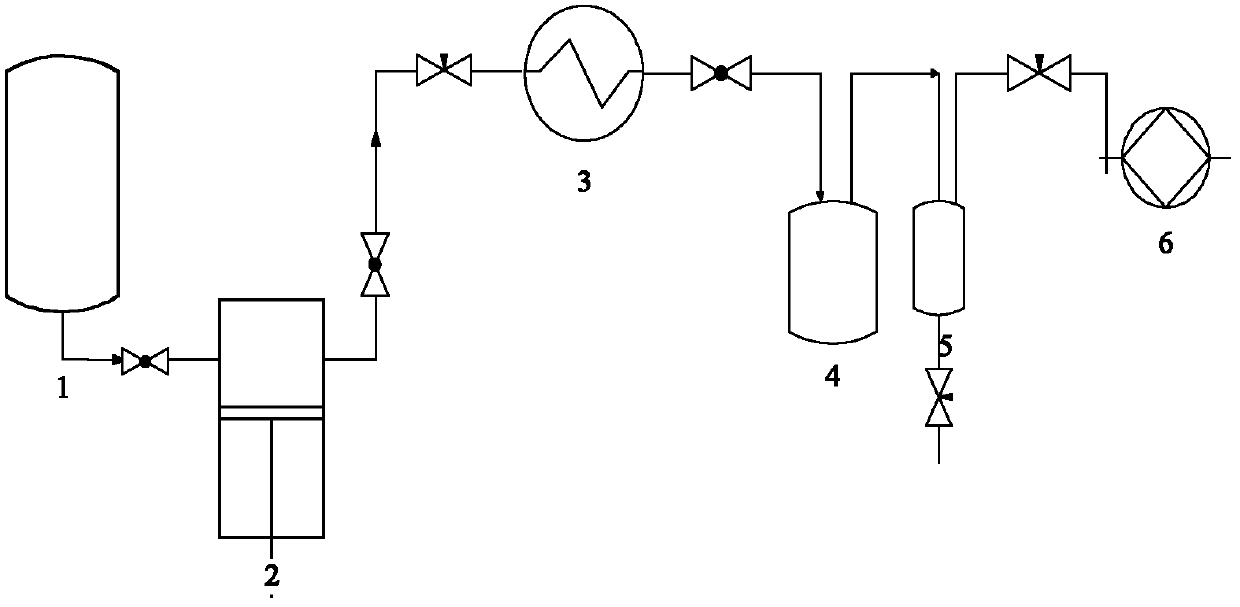

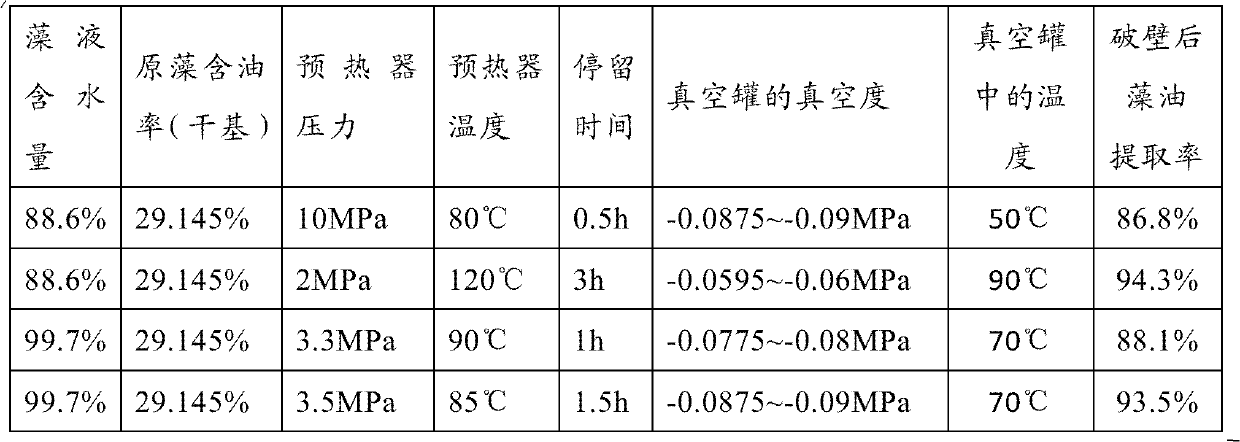

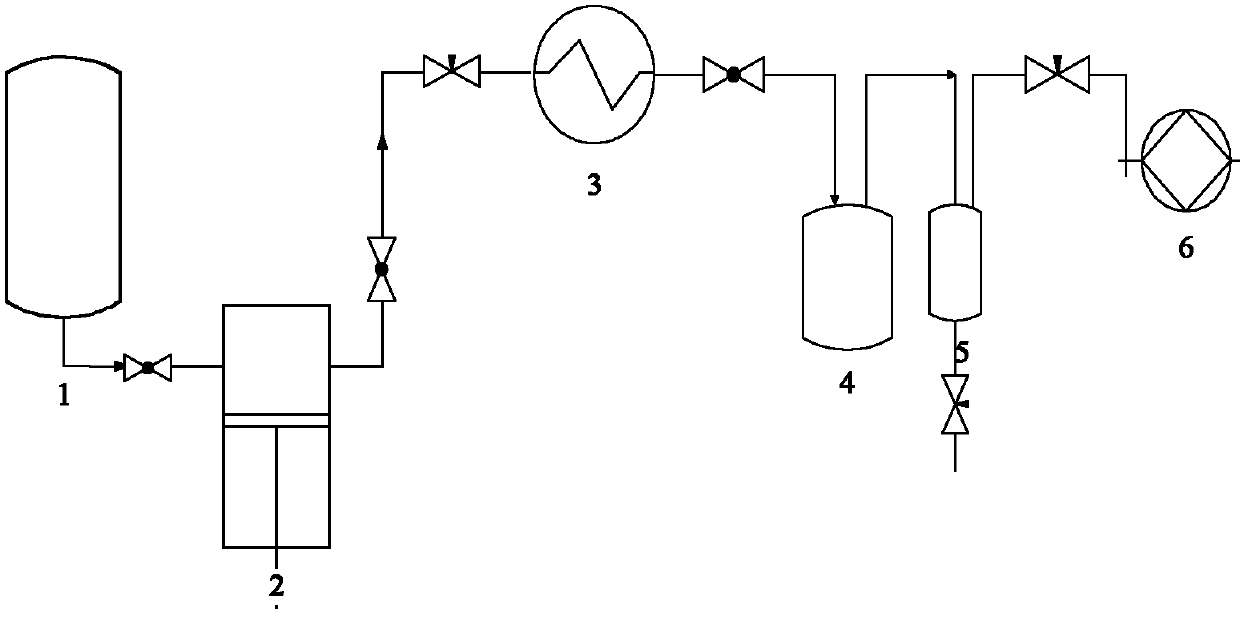

Method and device for processing microalgae

ActiveCN102559370ARealize the collectionAchieve dryingFatty-oils/fats productionWater dischargeBuffer tank

The invention provides a method for processing microalgae. The processing method includes placing microalgae liquid in an environment with a normal temperature and pressure, increasing the temperature and pressure of the environment of the microalgae liquid, continuously subjecting the microalgae liquid to the environment after the temperature and pressure are increased, and directly transferring the microalgae liquid to a vacuum environment from the environment. The invention further provides a device for preparing the microalgae, which includes a microalgae liquid storage tank used for storing the microalgae liquid at the normal temperature and under the normal pressure, a high-pressure pump used for pressurizing the microalgae liquid storage tank, a heater used for heating the microalgae liquid storage tank, a vacuum container with a vacuum pump, which is empty inside and used for containing the microalgae liquid obtained from the microalgae liquid storage tank, and a buffer tank used for containing water discharged from the vacuum container. According to the method and the device for processing microalgae, the collecting, wall-breaking and drying of the microalgae are achieved simultaneously or performed by one step and the extraction rate of microalgae oil after wall-breaking can be reached above 90%. The method and the device for processing microalgae have the advantages of simple process, high wall-breaking efficiency, low energy consumption, and the like.

Owner:ENN SCI & TECH DEV

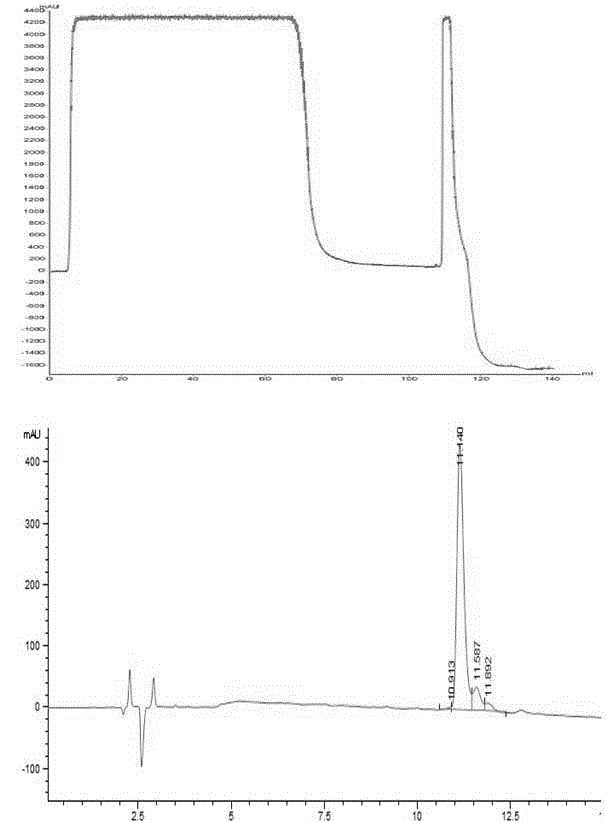

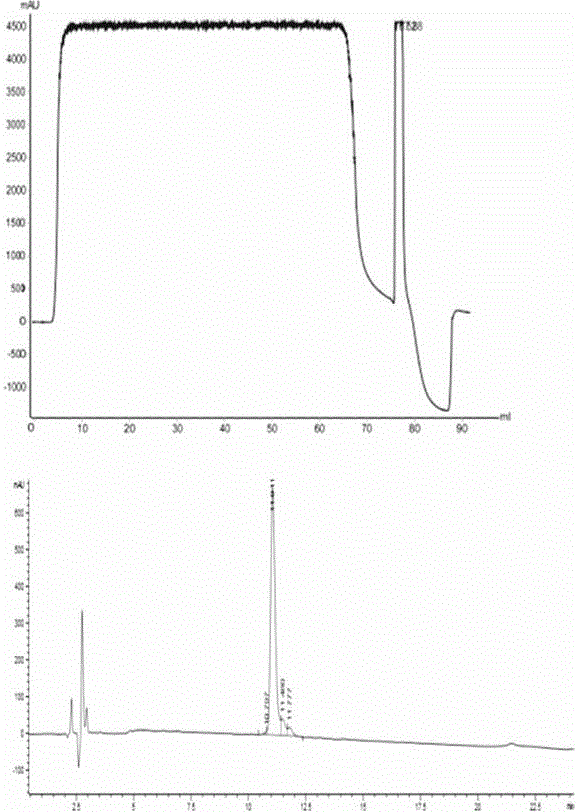

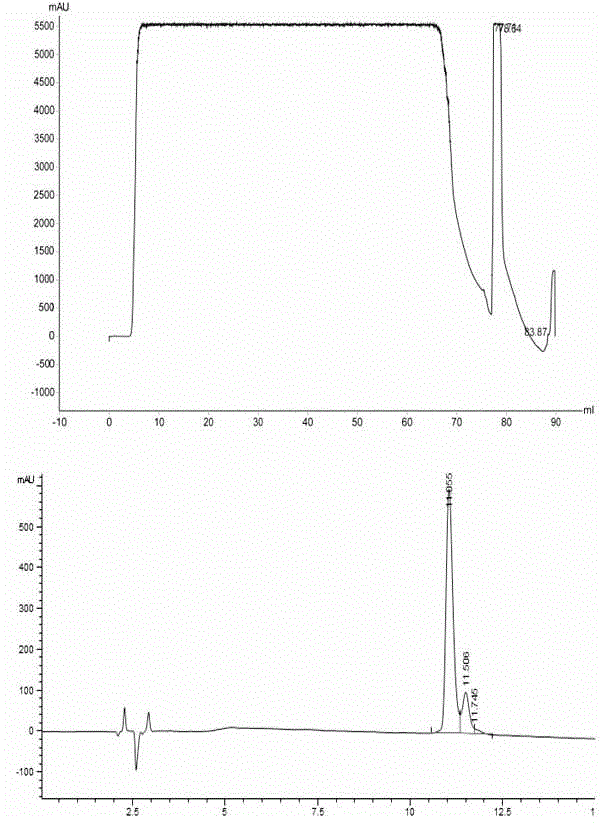

Recombinant insulin and insulin analogue precursor purification method

InactiveCN105153294AGood technical effectAvoid time costPeptide preparation methodsInsulinsPurification methodsCentrifugation

The invention relates to the field of insulin production methods and discloses a recombinant insulin and insulin analogue precursor purification method. The invention solves the problems that conventional chromatographic packing cannot tolerate high-salinity sample loading, the amount of used organic reagent is great, the cost is high and the product purity is not high in the purification process of recombinant expressed insulin precursors and insulin analogue precursors. The invention adopts the technical scheme that the method comprises the steps of performing pH regulation and centrifugation to centrifuged fermentation supernatant, then directly loading a sample and performing adsorption, separation, purification and elution through a chromatographic column prepared by using any packing of Capto S, Capto MMC, Uni PMM S and Uni MSP to finally obtain high-purity recombinant insulin and insulin analogue precursors. Compared with the existing purification method, the recombinant insulin and insulin analogue precursor purification method has the advantages that the operation is simple, the yield is high, the spent time is short, the environmental influence is small, and the product production cost of the existing insulin and insulin analogues can be greatly reduced.

Owner:JINAN KANGHE MEDICAL TECH

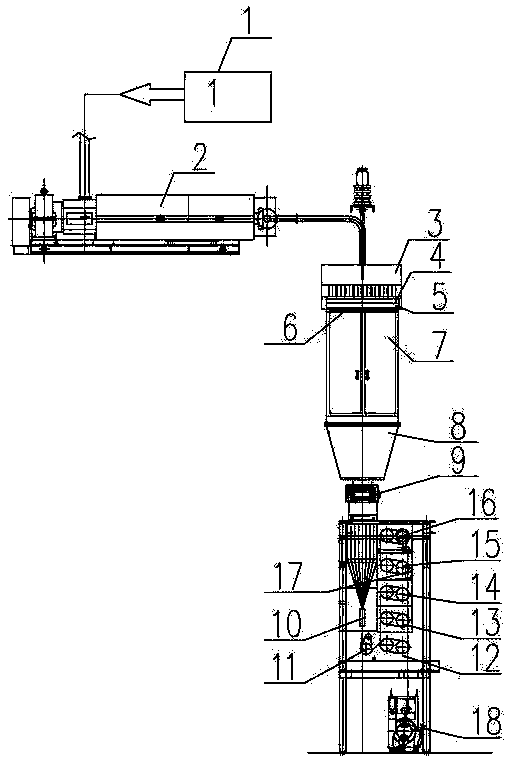

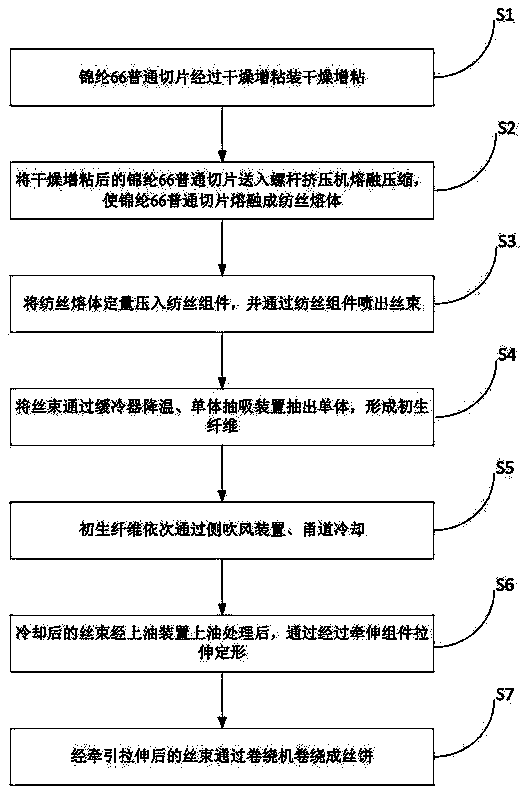

Production method of chinlon 66 high-strength fiber and chinlon 66 high-strength fiber

InactiveCN110067033AQuality improvementHigh degree of automationSpinnerette packsFilament forming substance formingState of artFiber

The invention belongs to the technical field of spinning chemical fiber production and particularly relates to a production method of a chinlon 66 high-strength fiber and the chinlon 66 high-strengthfiber. The production method comprises the following steps: drying and tackifying common chinlon 66 pieces by using a drying and tackifying device; melting and compressing the common chinlon 66 piecesafter drying and tackifying in a screw extruder, and melting the common chinlon 66 pieces into spinning melt; quantitatively compressing the spinning melt into a spinning component, and ejecting fiber beams from the spinning component; cooling the fiber beams by using a slow cooling device, drawing single parts by using a single part drawing device, and forming a primary fiber; cooling the primary fiber by using a side air blowing device and a channel in sequence; carrying out oiling treatment on the cooled fiber beams by using an oiling device, and carrying out tension and shaping by using atraction component; coiling the fiber beams after traction and shaping by using a coiling machine, so as to obtain fiber cakes. The production method is capable of making up technical schemes that inthe prior art a chinlon 66 high-strength fiber less than the specification of 150de is produced through one-step method spinning and traction shaping, and has very good popularization prospects.

Owner:BEIJING CHONGLEE MACHINERY ENG

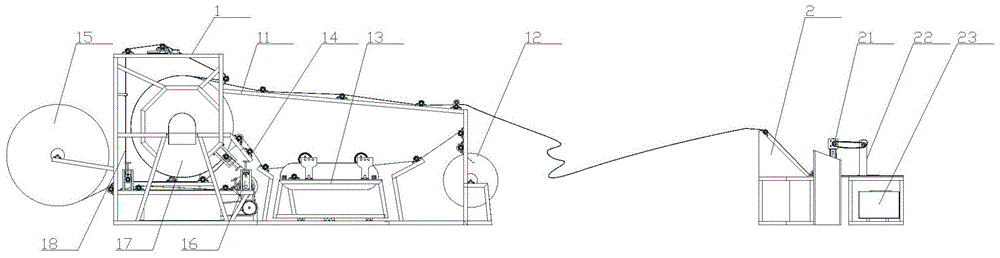

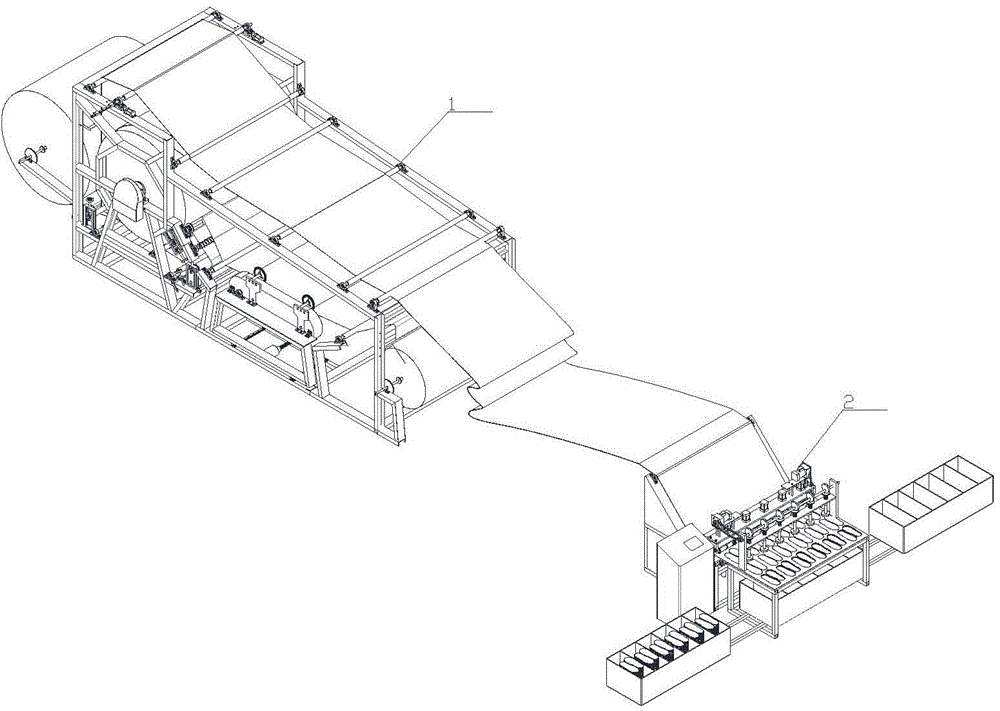

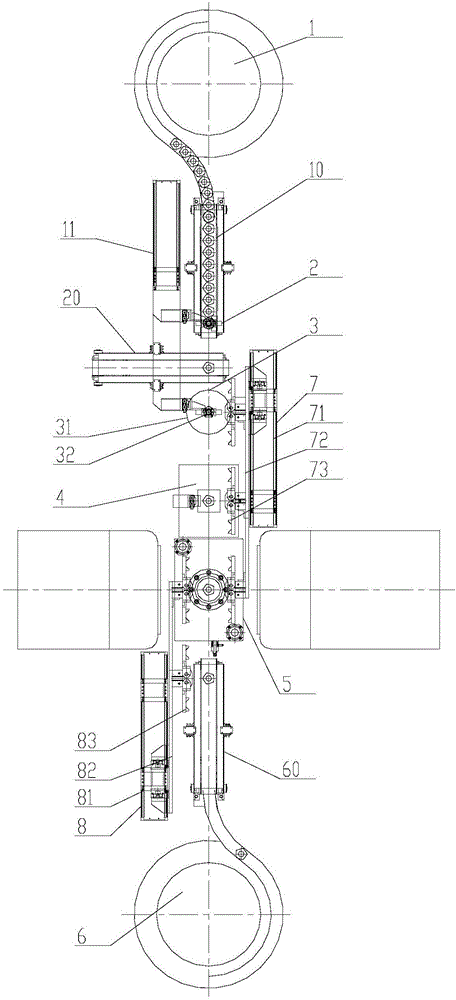

Production line and production method of composite material shoe soles

Provided are a production line and production method of composite material shoe soles. The production line comprises a compound machine and a roll-cutting machine which are arranged in an adjacent mode. The production method comprises the steps that 1, soft material feeding is conducted, and exporting, width sizing, gluing, error correcting and roller feeding are conducted; 2, hard material feeding is conducted; 3, hot pressing is conducted; 4, roll cutting is conducted; 5, unloading is conducted; 6 discharging is conducted, and the work is finished. The production line and production method of the composite material shoe soles have the advantages of high in processing efficiency, high in degree of adaptability of soft materials and hard materials, low in rejection rate and manual labor intensity and good in operational safety on the whole. The roll-cutting machine adopts a cutting mode of supersonic vibration and high temperature and continuous roll cutting, the evenness of the cut surface is effectively guaranteed, the processing speed is increased, the processing effect is greatly improved, and the rejection rate is reduced. The production line and production method of the composite material shoe soles have the advantages of high in processing efficiency, high in degree of automation, good in continuity of processing and good in processing effect on the whole.

Owner:JIANGSU ASK TECH

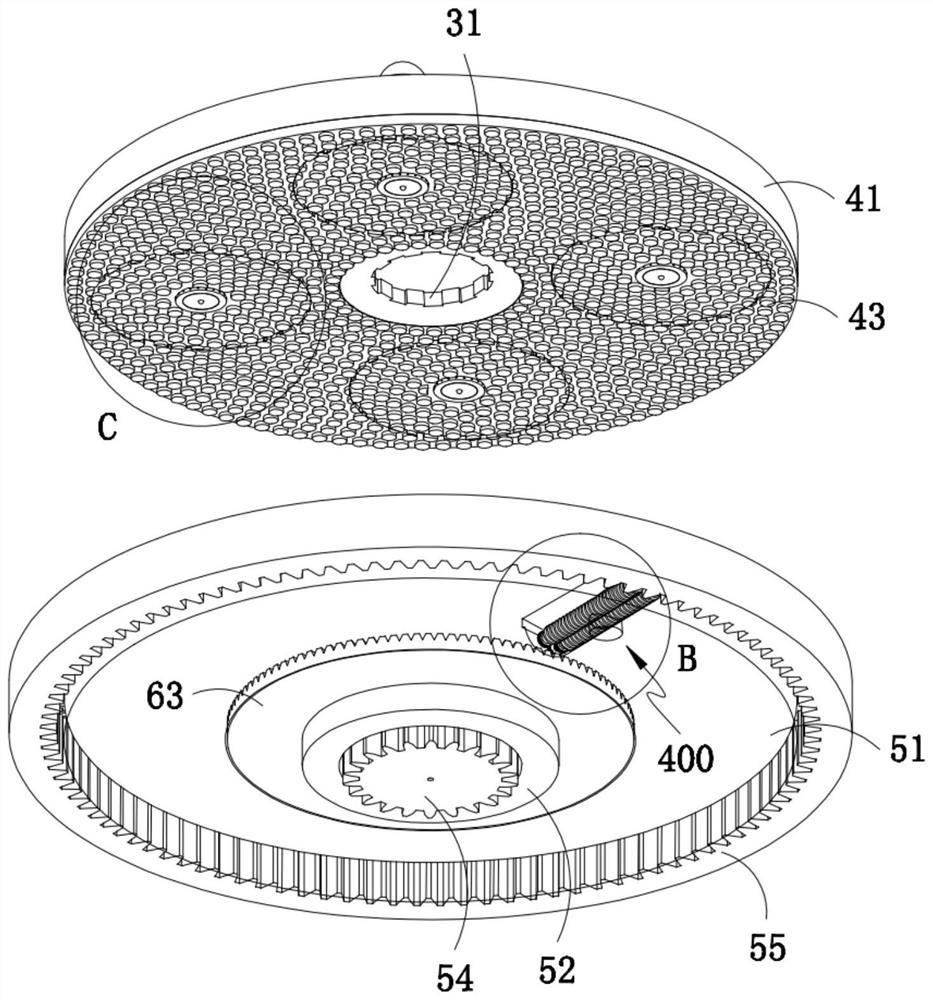

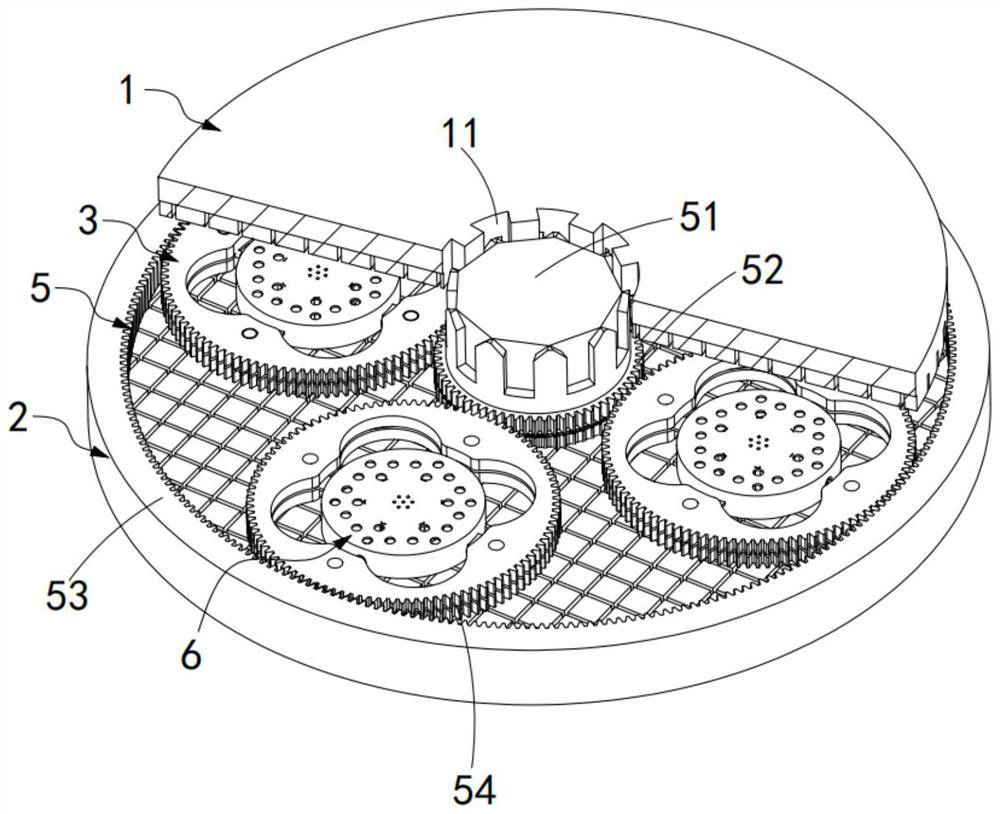

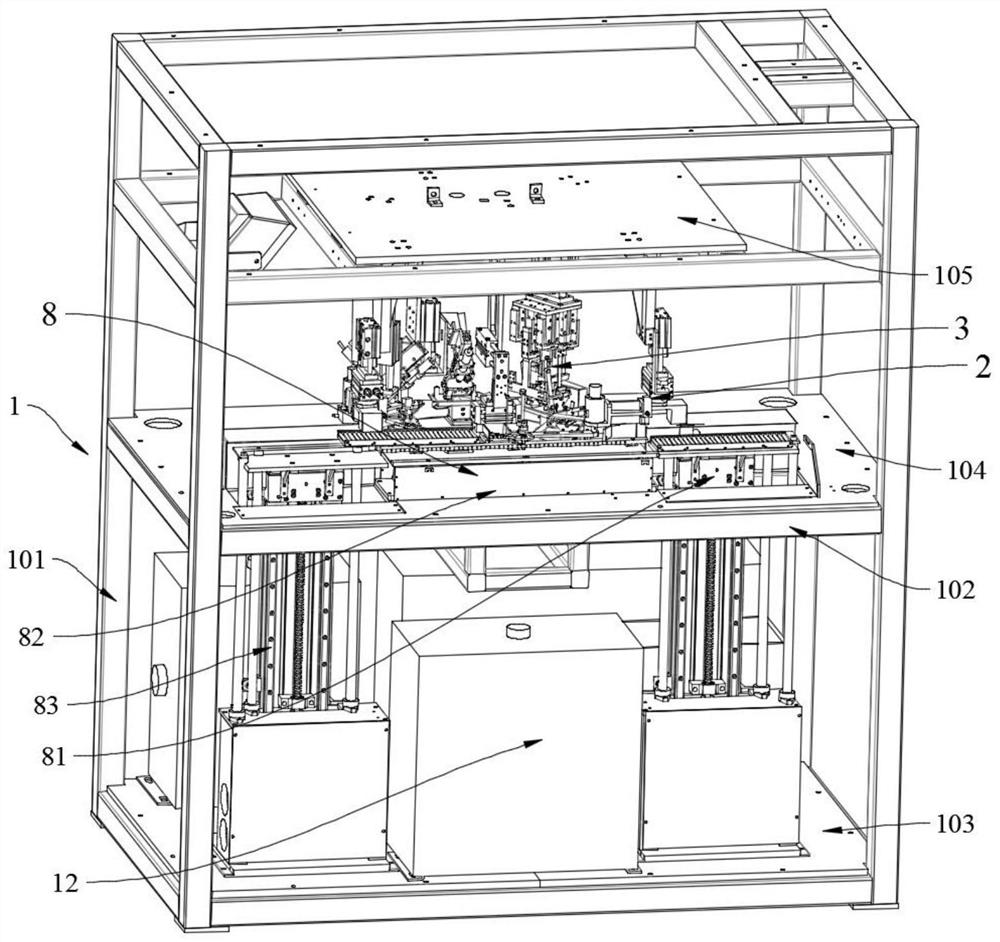

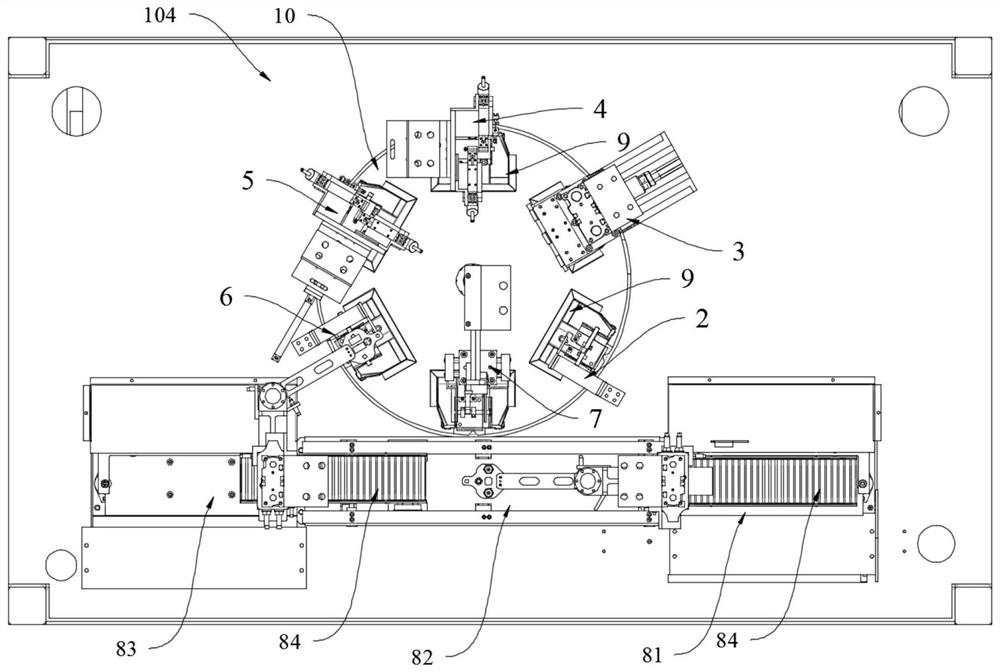

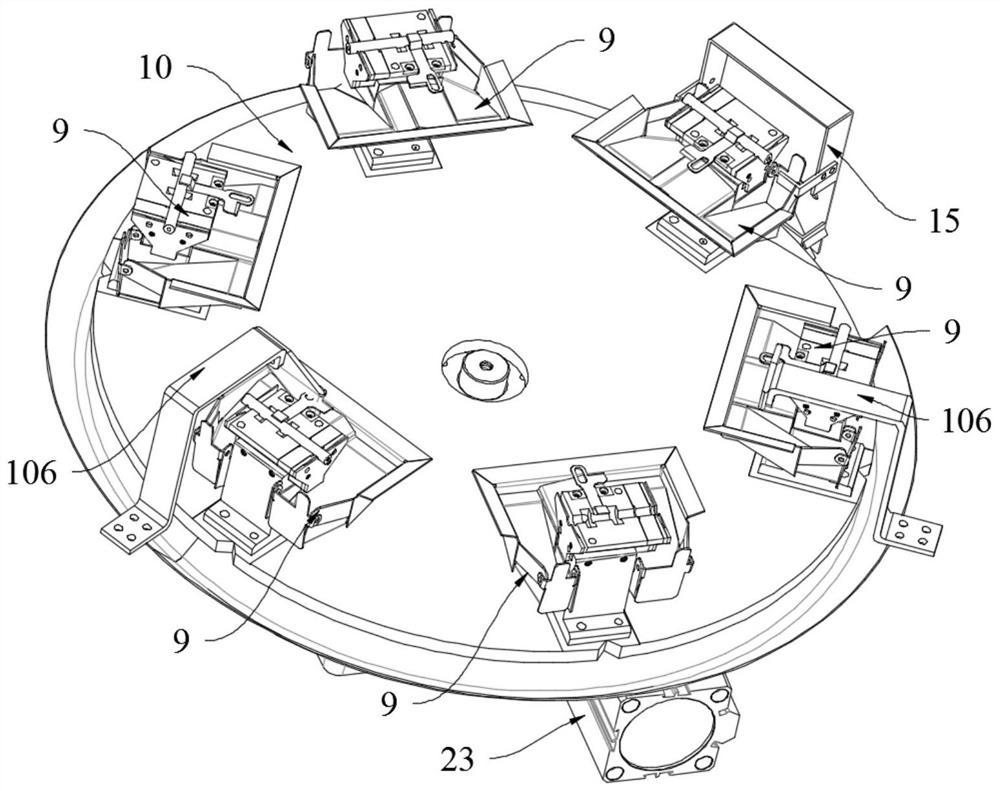

Automatic feeding and discharging viscoelastic bar machining device

ActiveCN112372313APrecise positioningHigh dimensional accuracyOther manufacturing equipments/toolsMaintainance and safety accessoriesPunchingEngineering

The invention discloses an automatic feeding and discharging viscoelastic bar machining device. The automatic feeding and discharging viscoelastic bar machining device comprises a machine frame and further comprises a feeding device, an end cutting device, a punching device, a hole cleaning device, a discharging device, a waste sweeping device, a material conveying device and a machining platformwhich are installed on the machine frame. The machining platform comprises a rotation disc and a work platform, the rotation disc is installed in a round hole in the middle of the work platform, the feeding device, the end cutting device, the punching device, the hole cleaning device, the discharging device and the waste sweeping device are sequentially installed on the periphery of the rotation disc at equal intervals to form six stations including the feeding station, the end cutting station, the punching station, the hole cleaning station, the discharging station and the sweeping station, and six viscoelastic bar clamping devices corresponding to the six stations are arranged on the rotation disc. The material conveying device is used for conveying material discs along a fixed path; andin the rotating process of the rotation disc, the six stations conduct corresponding action machining, and automatic machining of viscoelastic bar-shaped materials is achieved. The automatic feedingand discharging viscoelastic bar machining device is high in machining efficiency and precision and capable of achieving automatic operation.

Owner:HUBEI UNIV OF TECH

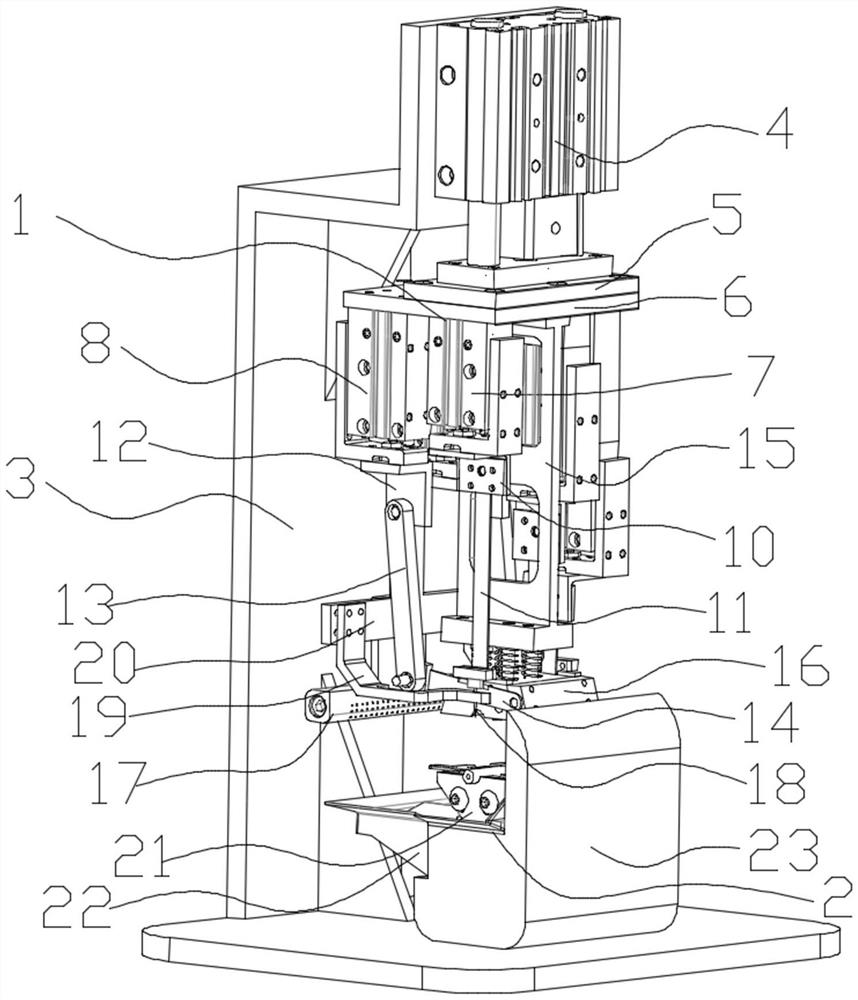

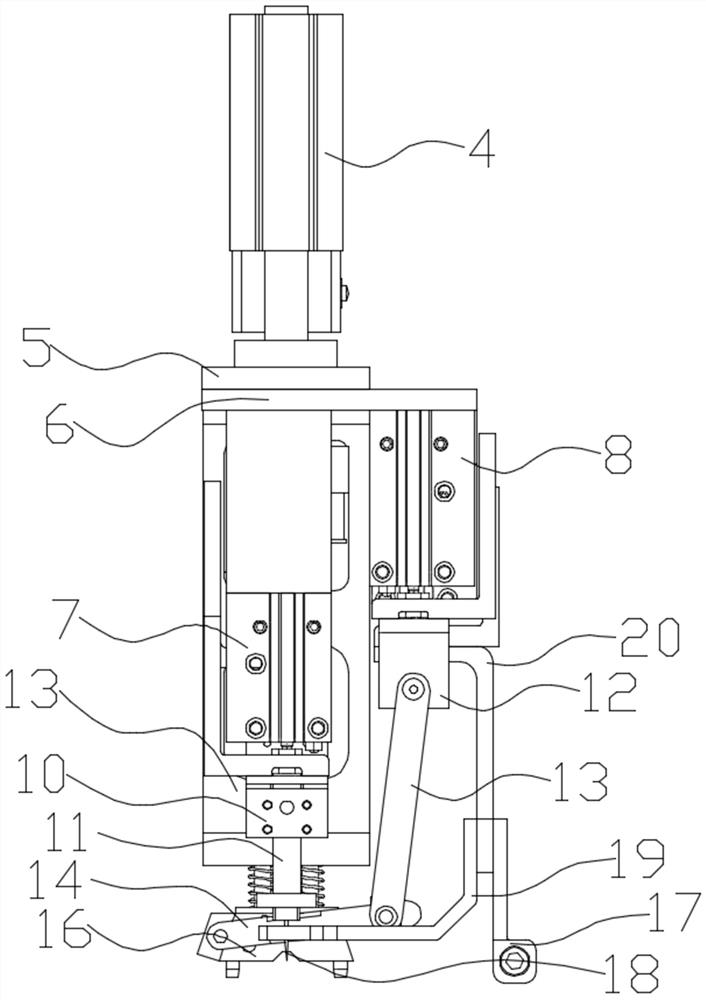

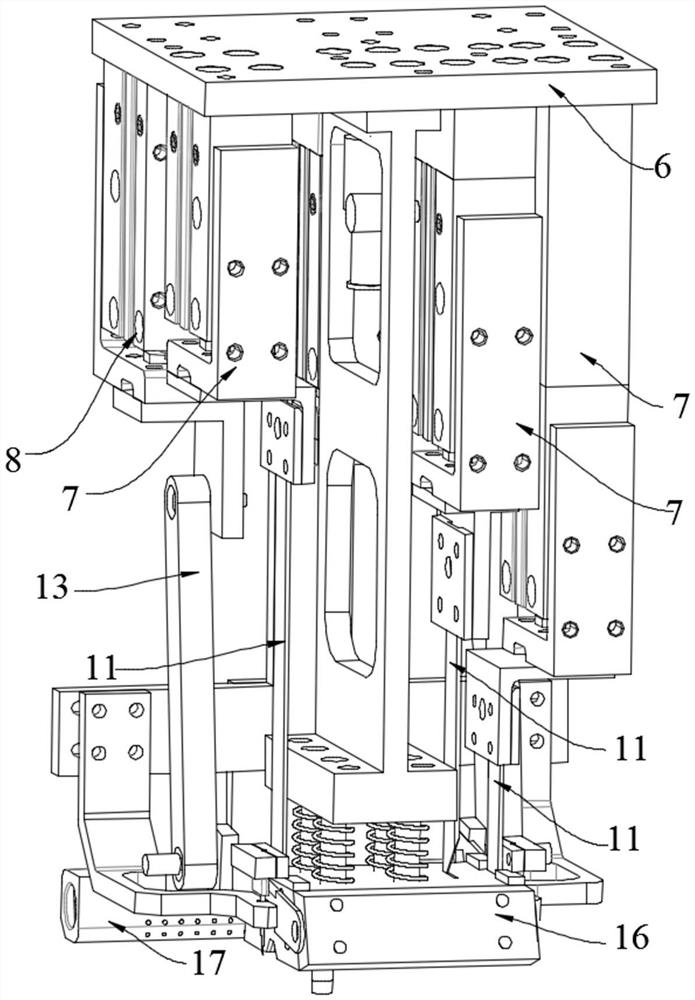

End cutting device for viscoelastic bar-shaped material

The invention discloses an end cutting device for a viscoelastic bar-shaped material. The end cutting device comprises a pressing and cutting device, a rack and a material carrying platform, wherein the material carrying platform is mounted at the bottom of the rack; a material carrying groove is formed in the material carrying platform; the pressing and cutting device is mounted on the rack abovethe material carrying platform and comprises a pressing plate cylinder, a pressing and cutting moving plate, an upper pressing table, a blowing nozzle bracket, a blowing nozzle cylinder, a discharging rod and a plurality of telescopic cutting devices; the pressing plate cylinder is vertically and fixedly mounted on the rack; the pressing and cutting moving plate is mounted on the pressing plate cylinder; the upper pressing table is mounted at the bottom of the pressing and cutting moving plate through a flexible device; a material taking needle is arranged at each of the two ends of the upperpressing table; the blowing nozzle cylinder is vertically and fixedly mounted on the pressing and cutting moving plate; the blowing nozzle is mounted at a moving telescopic end at the lower part of the blowing nozzle cylinder through the blowing nozzle bracket; and the discharging rod is fixed on the blowing nozzle bracket and moves up and down along with the stretching and retracting of the blowing nozzle cylinder. The end cutting device is high in notch quality and high in precision and can simultaneously finish end cutting of various bar materials with similar length requirements.

Owner:HUBEI UNIV OF TECH

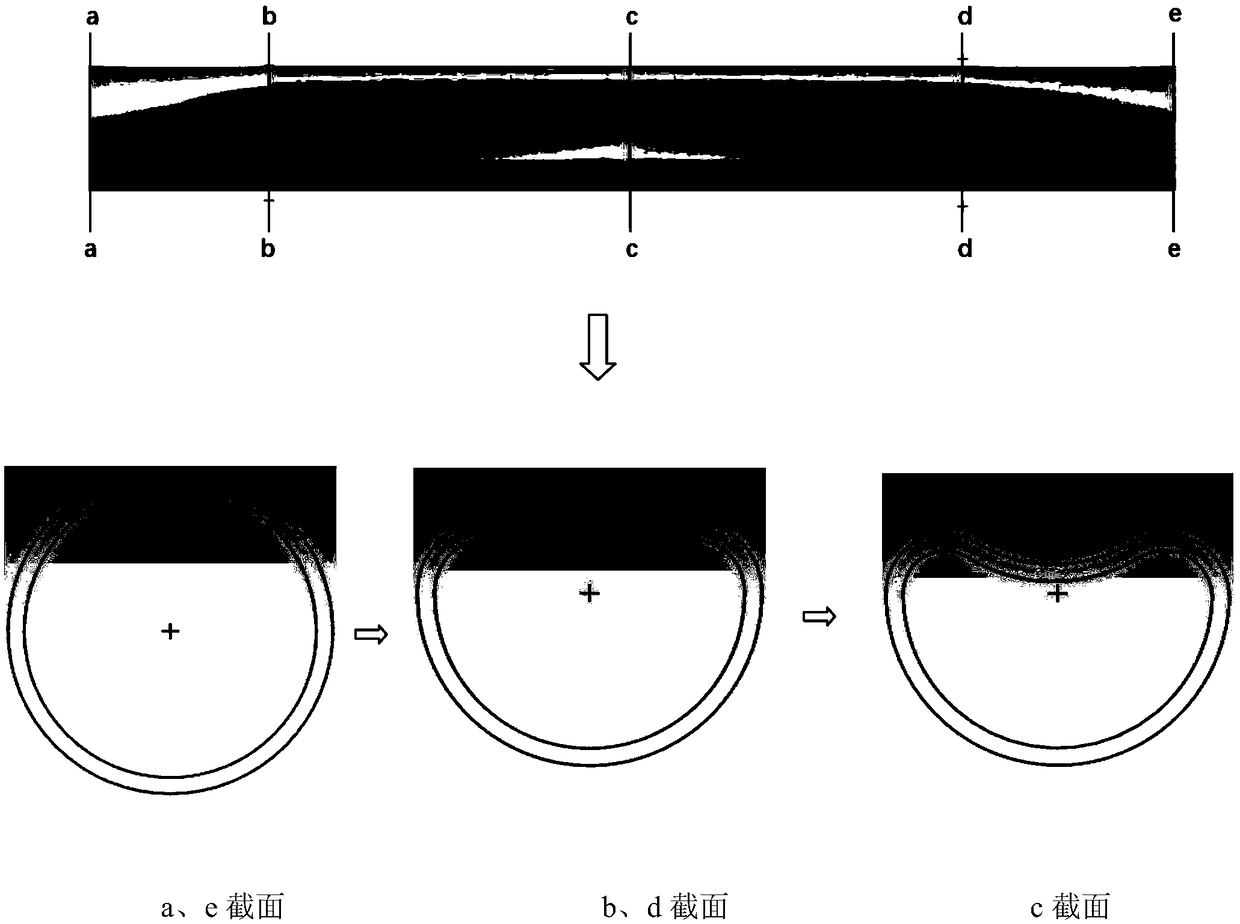

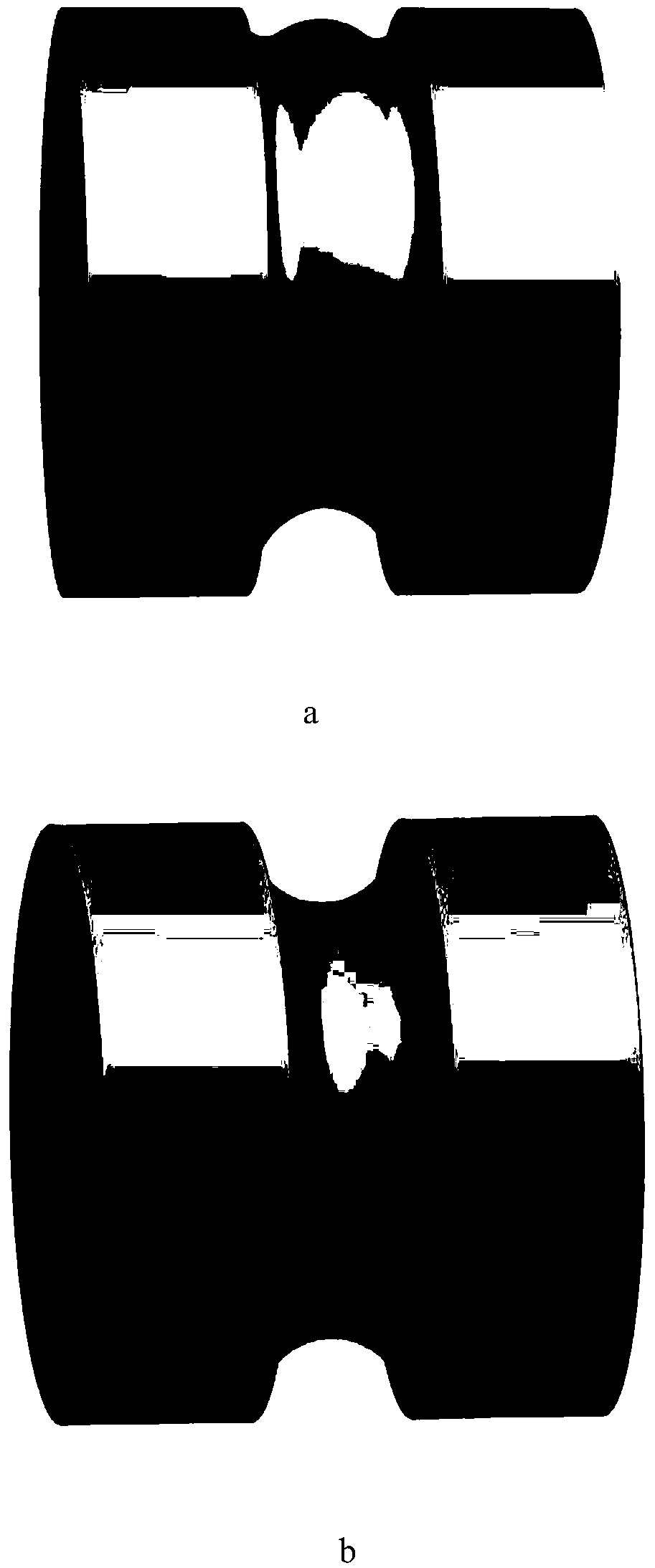

Rolling forming method and device for metal special-shaped variable-section pipe based on hydraulic forming

ActiveCN109174970ALow investment costLess investmentMetal rolling arrangementsFriction effectRolling resistance

The invention discloses a rolling forming method and device for a metal special-shaped variable-section pipe based on hydraulic forming, relates to a metal pipe part forming technology and aims at solving the problems that in an existing method, the investment cost is high, the production efficiency is low, and crumpling and cracking are likely to be generated due to the friction effect. Rollers are obtained, and forming technology parameters in the rolling forming process are determined; the two ends of a pipe blank are sealed and put into grooves of the upper roller and the lower roller; theupper roller is pressed down and is engaged with the lower roller, and certain die combining force is applied; and the pipe is filled with a liquid medium; the rollers rotate according to a preset angle to drive the pipe to move, and needed section characteristics are formed in the roller grooves. By means of the supporting effect of liquid pressure, a rolling technological method is adopted forforming the metal pipe, sliding friction of traditional inner high pressure forming is changed into rolling friction of the rolling technology, meanwhile, the friction direction is changed so that thecondition that friction impedes material flowing can be changed into the condition that friction facilitates material flowing, and the product forming quality is improved.

Owner:HARBIN INST OF TECH

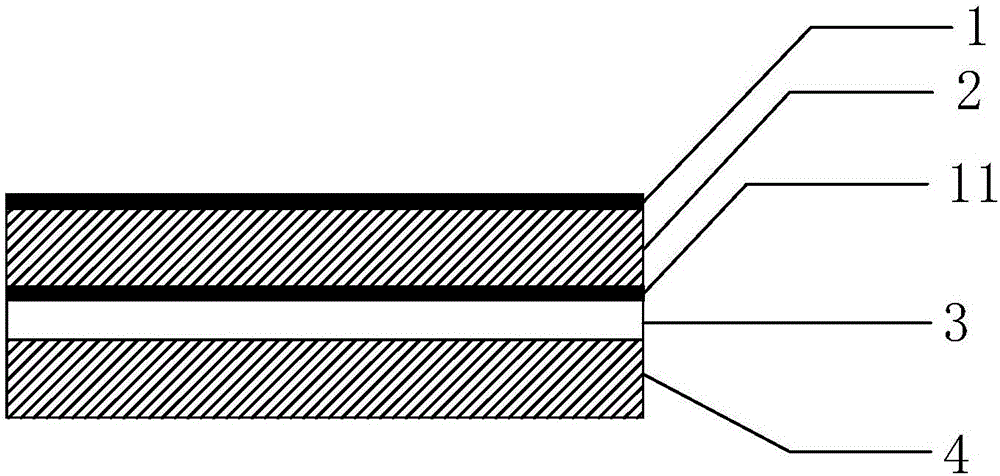

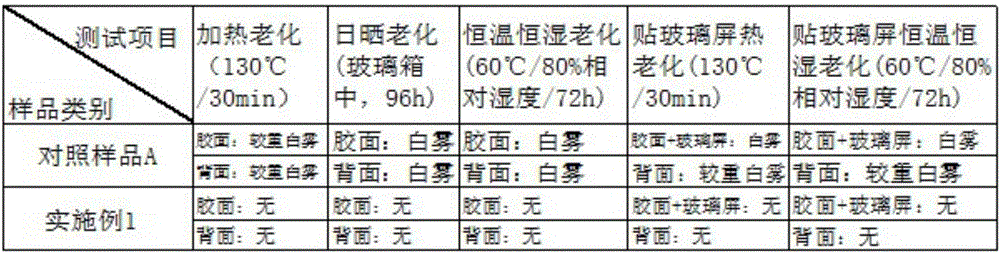

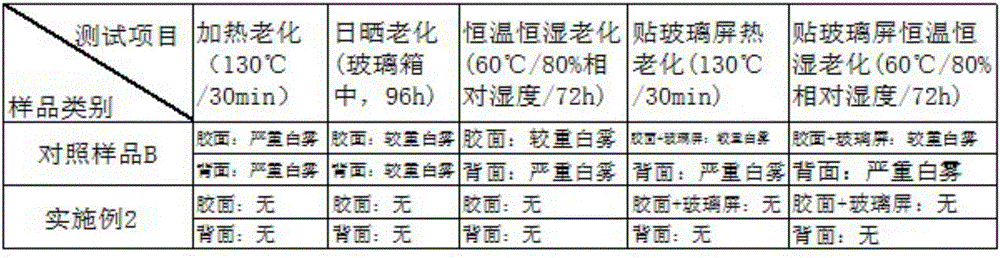

Polyester-based protective film for preventing oligomer preparation and manufacturing method thereof

InactiveCN106366962AImprove cleanlinessGuaranteed Optical PerformanceFilm/foil adhesivesCoatingsPolyesterOligomer

The invention relates to a polyester-based protective film for preventing oligomer preparation and a manufacturing method thereof. The polyester-based protective film comprises a multi-layer composite polyester-based base material and a pressure-sensitive adhesive coating coated on the surface of the composite base material; a crosslinking polyacrylate sealing agent upper surface layer and a crosslinking polyacrylate sealing agent lower surface layer are coated on the upper surface and the lower surface of the multi-layer composite polyester-based base material respectively. The manufacturing method includes the following steps that 1, a crosslinking polyacrylate sealing agent is synthesized; 2, the multi-layer composite polyester-based base material is prepared; 3, the polyester-based protective film for preventing oligomer preparation is prepared. The fogging problem caused by oligomer emigration in the polyester-based base material in the storage, processing and using processes of a conventional protective film is solved, when long-term exposure to sunlight, constant-temperature constant-humidity artificial aging and heating ageing are carried out on the polyester-based protective film for preventing oligomer preparation, the fogging phenomenon on the film face due to oligomer emigration is avoided, and use requirement of high-end glass films is ensured.

Owner:ANHUI MINGXUN NEW MATERIAL TECH

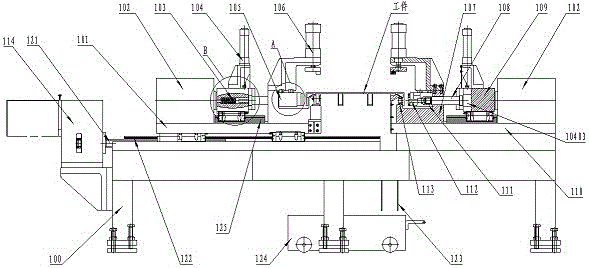

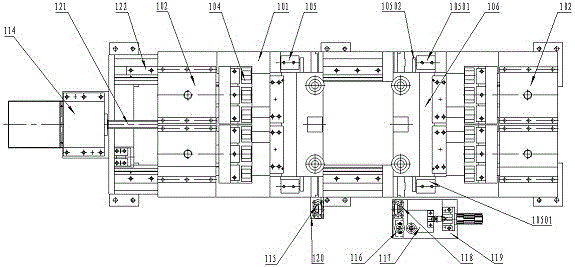

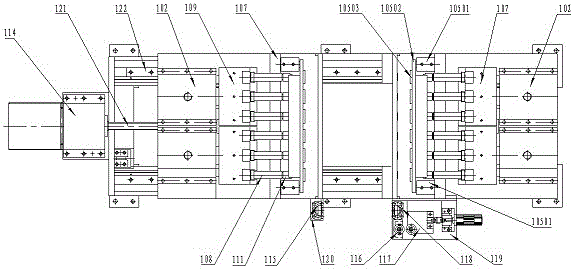

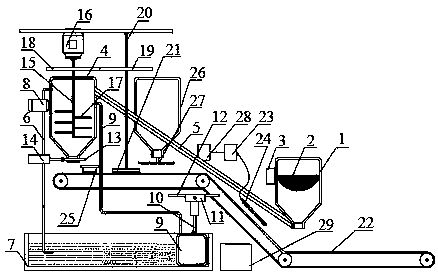

Powder product finishing production line

The invention provides a powder product finishing production line, and relates to improvement of a production line for finishing formed powder products. The powder product finishing production line is exquisite in structure, is easy to use, is low in reject rate, can accurately position products so as to achieve high efficient machining of the products such as special-shaped gears. The powder product finishing production line successively includes a loading device, a front and back recognition device, an image positioning device, an oil immersion device, a finishing machine, and a receiving device in the feeding direction of the products. High efficient overall adjustment is performed on a finishing production line for powder products in the prior art, and in this way, the machining continuity is high, the automatic level is high, accurate positioning can be performed on the products in a conveying process, and a position of each product in the finishing machine can keep constant, the machine efficiency can be effectively improved, the accuracy of machining positions of the products can be effectively ensured, and high efficient machining of the products such as the special-shaped gears can be achieved. The powder product finishing production line is high in machining efficiency and automatic level, is good in machining continuity, is high in machining accuracy, and is low in reject rate.

Owner:YANGZHOU FORGING MACHINE TOOL

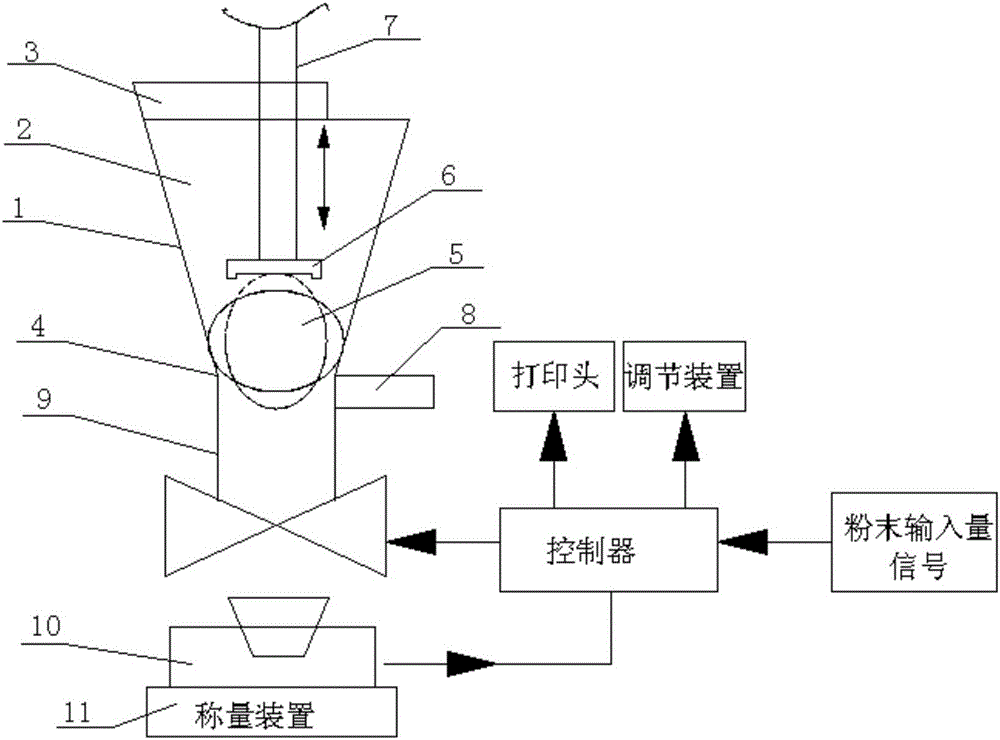

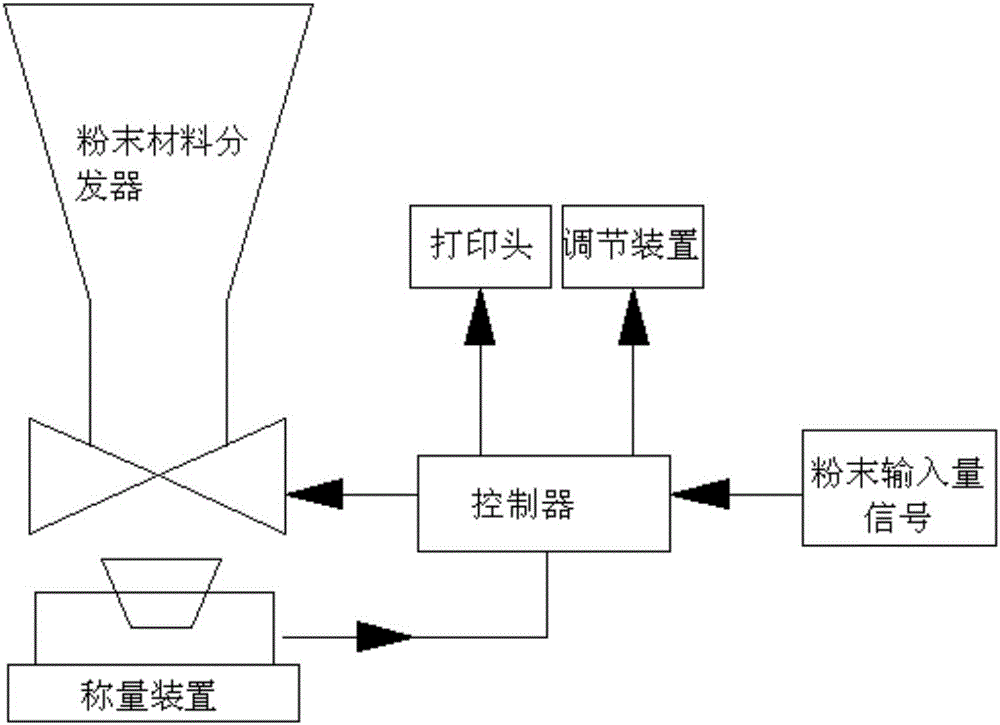

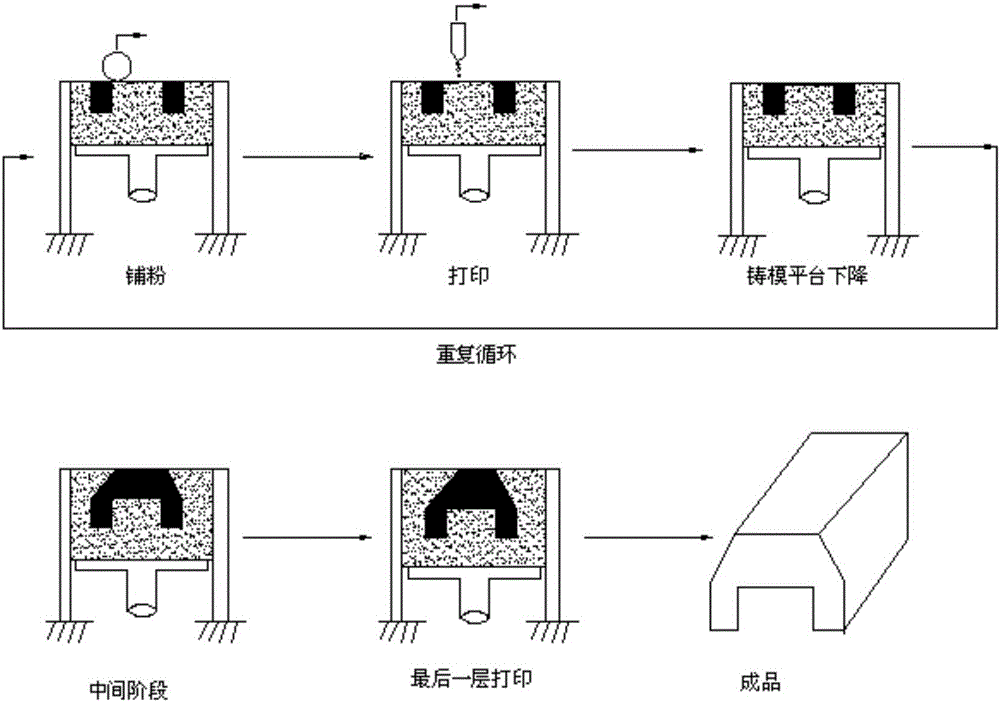

Automatic conveying device for 3D printer powder material

InactiveCN105881905ARealize quantitative automatic powder spreadingReasonable structureAdditive manufacturing apparatusMicroscopic scaleDistributor

The invention discloses an automatic conveying device and method for a 3D printer powder material. The automatic conveying device comprises a powder material distributor, an adjusting device, a flow guiding channel and a printing carrier; a material cavity of the powder material distributor is a distributing groove of a circular truncated cone structure; the diameter of the upper bottom face of the distributing groove and the diameter of the lower bottom face of the distributing groove tend to be progressively decreased; the adjusting device is arranged at the position of an inlet of the top end of the distributing groove; an adjustable sealing piece is arranged at the position of a hole opening of the bottom end of the distributing groove and connected with a stopping bolt; the upper portion of the stopping bolt is connected with an adjusting rod; a vibrator is installed on the side wall of the bottom end of the distributing groove; the hole opening of the distributing groove communicates with the flow guiding channel; the position of an outlet of the flow guiding channel right faces the printing carrier; and a weighing device is installed at the bottom of the printing carrier and connected with a controller. The automatic conveying device is reasonable in structure, the powder material weight is calculated in advance according to the exterior and a micro structure of a model, quantitative automatic powder laying of the powder raw material is achieved, the work efficiency is high, the powder laying is uniform, the requirement for the powder scraping process of a scraper is not high, and the cost investment is low.

Owner:SUZHOU ATAPE MACHINERY CO LTD

Punching production main machine

ActiveCN105964763AHigh degree of automationIncrease productivityPerforating toolsPunchingElectrical control

The invention discloses a punching production main machine. The punching production main machine comprises a base, a fixed machine base, a movable machine base, die changing devices, pressing devices, a positioning device, a floating supporting device, a servo power device, a hydraulic power device and an electrical control device. The fixed machine base is fixed to the base, and the movable machine base can move in the Y direction along a guide rail on the base. The servo power device is fixed to the base. The punching production main machine is characterized in that each of the fixed machine base and the movable machine base is provided with a hydraulic power cylinder, a pressing head and a die frame; each pressing head is provided with the corresponding die changing device and internally provided with a resilience device; and each die frame is provided with the corresponding upper side pressing device, the corresponding side face pressing device, a punch rod, a punch nut, a punch and a female die. According to the technical scheme, operation is convenient, the automation degree is high, and the machining precision is improved; and the work hour is reduced, the machining cost is reduced, and the production efficiency is improved.

Owner:济南天辰智能装备股份有限公司

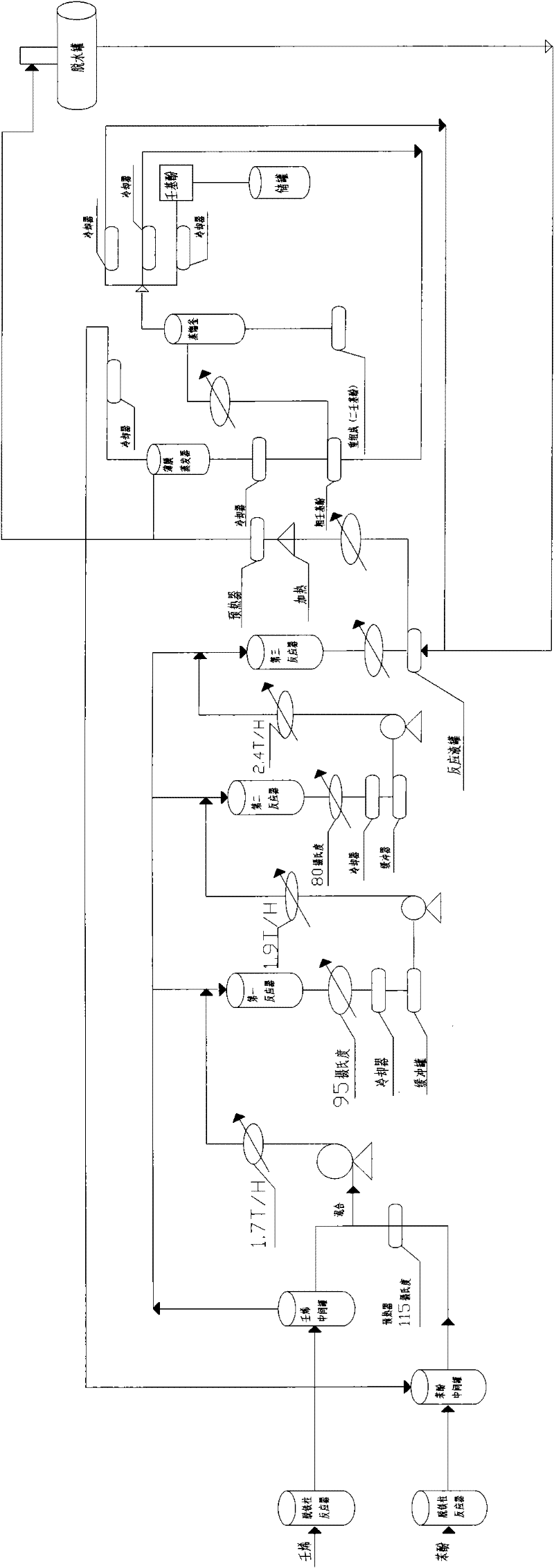

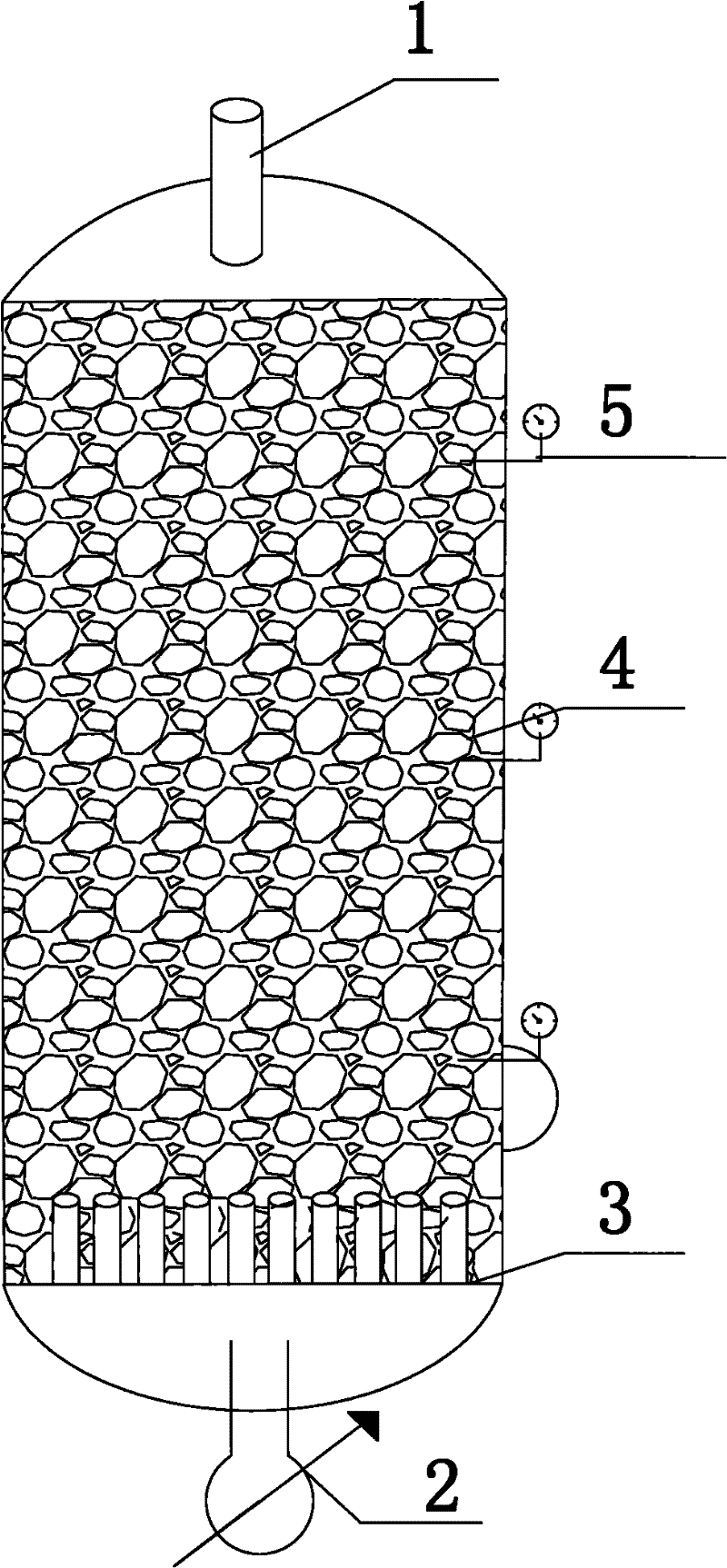

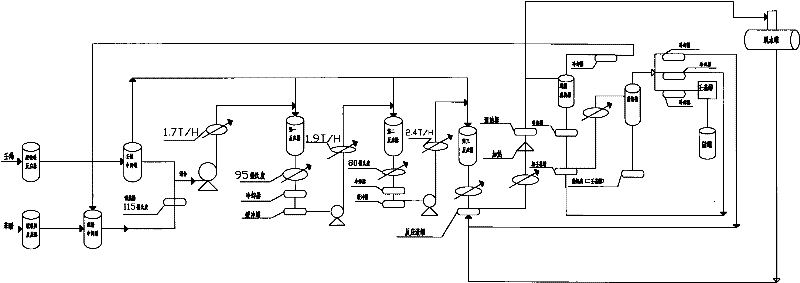

Method for producing nonyl phenol

ActiveCN101913994BHigh energy consumptionImprove process continuityOrganic chemistryOrganic compound preparationRetention timeThree stage

The invention discloses a method for producing nonyl phenol, which comprises the steps of: preheating phenol to a temperature between 115 DEG C and 125 DEG C, then fully mixing nonene at a room temperature with the preheated phenol, cooling to about 120 DEG C in a first-stage reactor, then putting in a second-stage reactor and dripping the nonene at the same time, cooling to the temperature of about 85 DEG C after the second-stage reaction, then reacting in a third-stage reactor and dripping the nonene at the same time, dephenolizing nonyl phenol reaction liquid obtained after three-stage reaction in a film evaporator, and distilling coarse nonyl phenol subjected to dephenolizing in a distilling still to obtain high-purity nonyl phenol. The method has the advantages of short reaction retention time, less by-products, small required power and low energy consumption, and the product produced has good quality. The whole production process is carried out continuously, has excellent stability, and improves production efficiency.

Owner:TAIXING LINGFEI CHEM TECH CO LTD

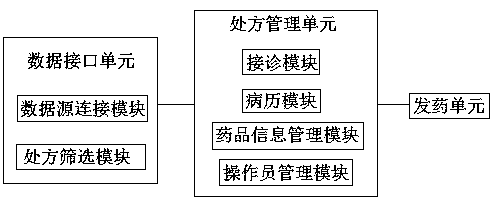

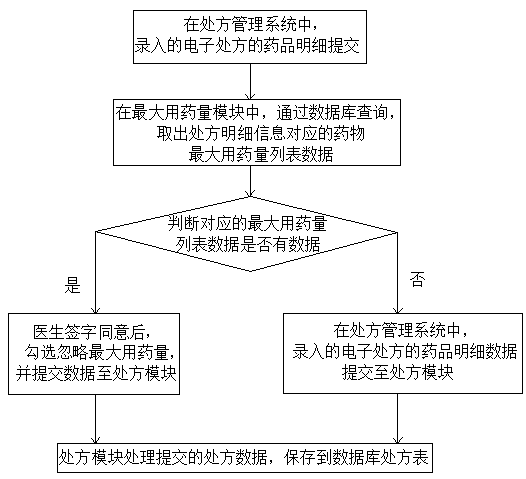

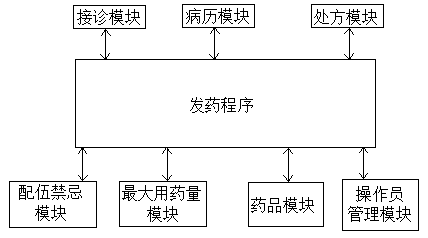

Intelligent traditional Chinese medicine pharmacy system

PendingCN108766523AStructural specificationCompact structureDrug and medicationsHealthcare resources and facilitiesContraindicationData interface

The invention discloses an intelligent traditional Chinese medicine pharmacy system, and belongs to the technical field of medicine. The intelligent traditional Chinese medicine pharmacy system is characterized by comprising a data interface unit, a prescription management unit and a medicine dispensing unit, which are connected electrically; the data interface unit sends a queried and obtained prescription data signal to the prescription management unit; the prescription management unit sends the reviewed prescription data signal to the medicine dispensing unit; and the medicine dispensing unit receives the prescription data signal and then sends medicines through an intelligent medicine dispensing machine. According to the invention, the safety of the medication is ensured by the arrangement of contraindication compatibility; detailed information of a prescription can be accurately checked before the medicines are dispensed, and subsequent inspection is not required; the entire electronic prescription is standardized in procedure and strong in effectiveness from the treatment to the completion of the medicine dispensing, thereby greatly improving the accuracy of medicine dispensing and the efficiency of medicine dispensing, and saving the time for taking medicines for patients; the medicine dispensing machine is compact in structure, small in space occupation and simple to operate; and the system is controlled by a mechanical automatic program, the prescription is simply written and the medicine packing speed is high.

Owner:CHENGDU YH INTELLIGENT EQUIP TECH CO LTD

Carbonizing device

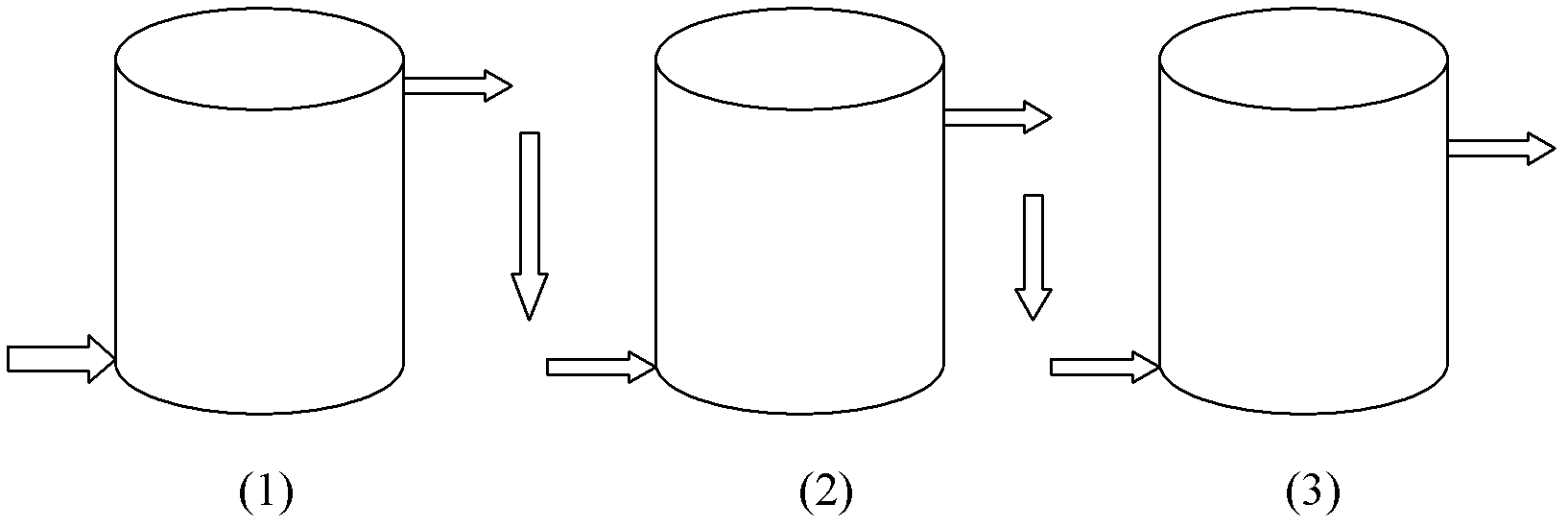

ActiveCN105773775AGood process continuityImprove work efficiencyBark-zones/chip/dust/waste removalWood charring/burningEngineeringMechanical engineering

The invention discloses a carbonizing device which comprises a carbonizing mechanism and a dust collection mechanism, wherein the carbonizing mechanism is composed of a first rack and a second rack; a first conveying device, a first carbonizing chamber and a second conveying device are sequentially arranged on the first rack in the conveying direction of a wood board; a second carbonizing chamber and a third conveying device are sequentially arranged on the second rack in the conveying direction of the wood board; the second conveying device is arranged corresponding to the inlet of the second carbonizing chamber; the dust collection mechanism is composed of a third rack; a fourth conveying device, a first group of brush rolls and a second group of brush rolls are sequentially arranged on the third rack in the conveying direction of the wood board; and the fourth conveying device is arranged corresponding to the third conveying device. The carbonizing device can finish two procedures of carbonizing of carbonized wood and dust collection and is good in procedure continuity and high in working efficiency.

Owner:杜丽红

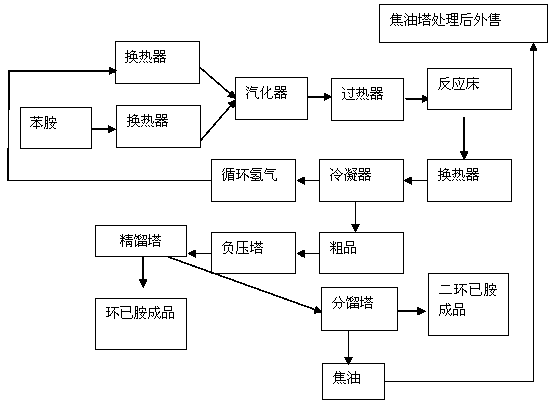

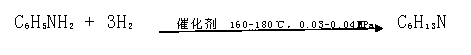

Production method for preparing cyclohexylamine from phenylamine

ActiveCN103351302AHigh yieldReduce the ratioOrganic compound preparationChemical industryBiotechnologyCyclohexylamines

The invention belongs to the technical field of the production and preparation of cyclohexylamine and particularly relates to a production method for preparing cyclohexylamine from phenylamine. Through controlling parameters, such as time, temperature, pressure and the like, of all steps, the yield of cyclohexylamine products is high and is over 98%, the quality is stable, the yield is high, the production capacity is large, the side reactions are few, a small amount of byproduct dicyclohexylamine produced during reaction can be recovered and purified, and the added value of the products is increased; and through engineering calculation and advanced DCS (Distributed Control System) control, the parameters are stable and are little in fluctuation, and qualified materials in a negative pressure tower are directly transferred to a rectification tower from the negative pressure tower through pressure difference between the negative pressure tower and the rectification tower, so that the working procedure is efficient and energy-saving, the continuous rectification procedure is completed, the continuity of the whole process is strong, the degree of automation is high, the staff ratio is low, the unit consumption is low, and the yield is high.

Owner:BINZHOU YUNENG CHEM

Agricultural seed screening and drying device

The invention relates to an agricultural seed screening and drying device. The processing continuity is high, the cooperation degree of a plurality of working procedures is high, the process transferring time is short, the labor intensity is low, the processing efficiency is high, and the treatment effect is good. A feed port of a washing cylinder is connected with a discharge port of a screeningcylinder through a charging elevator, and the washing cylinder is connected with a water tank. The water tank is internally provided with a waste frame, the waste frame is driven by a first power device to move up and down, and a sliding block is driven by a second power device to do horizontal movement along a sliding rail. A material baffle is driven by a third power device to do horizontal movement. An installation rod is driven a fourth power device to rotate, part of the installation rod is located in the washing cylinder, the periphery of the part, located in the washing cylinder, of theinstallation rod is sleeved with a plurality of stirring blades, the stirring blades are distributed in an up-down stagger manner, the periphery of the part, located outside the washing cylinder, ofthe installation rod is sleeved with a drive gear, the drive gear is engaged with a driven gear, the driven gear is arranged on the periphery of a material distribution rod in a sleeving manner, and the lower end of the material distribution rod is connected with material distribution blades. A discharging mechanism comprises a discharging conveyor belt.

Owner:MAANSHAN QUANRUN AGRI SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com