Silicon wafer grinding disc correction device and correction process

A technology for grinding discs and silicon wafers, applied in grinding/polishing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low precision of grinding correction equipment, reduction of grinding fluid, heavy pollution, etc., to avoid energy consumption, reduce Use, solve the effect of low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

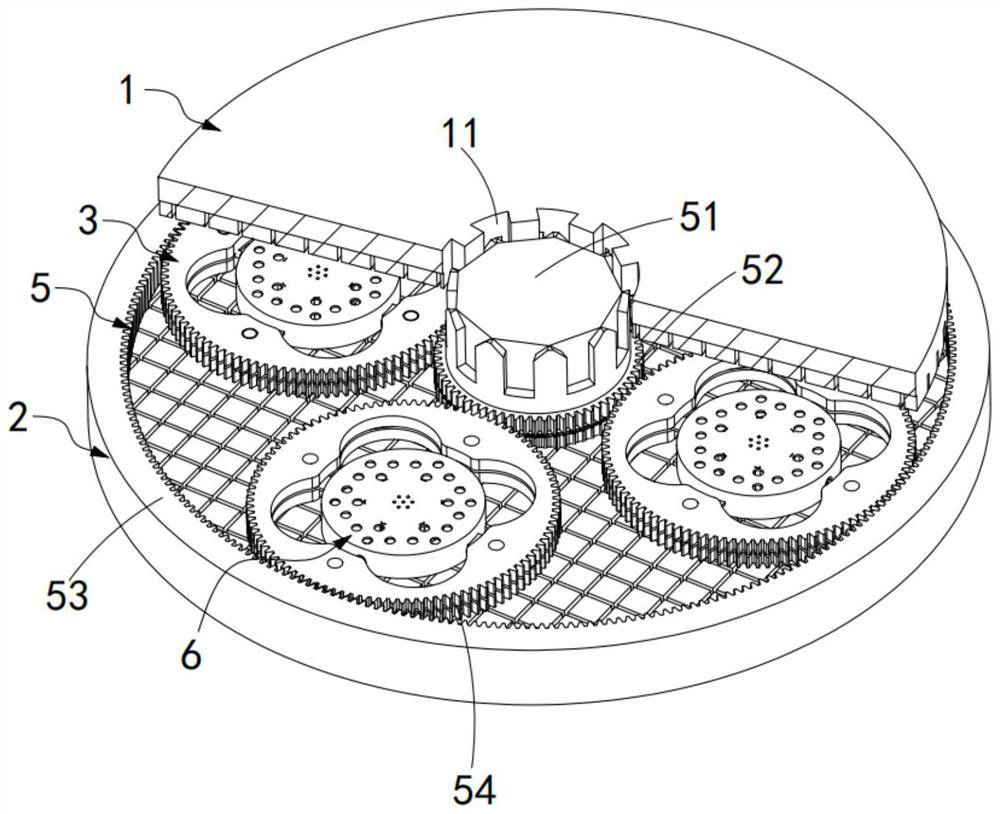

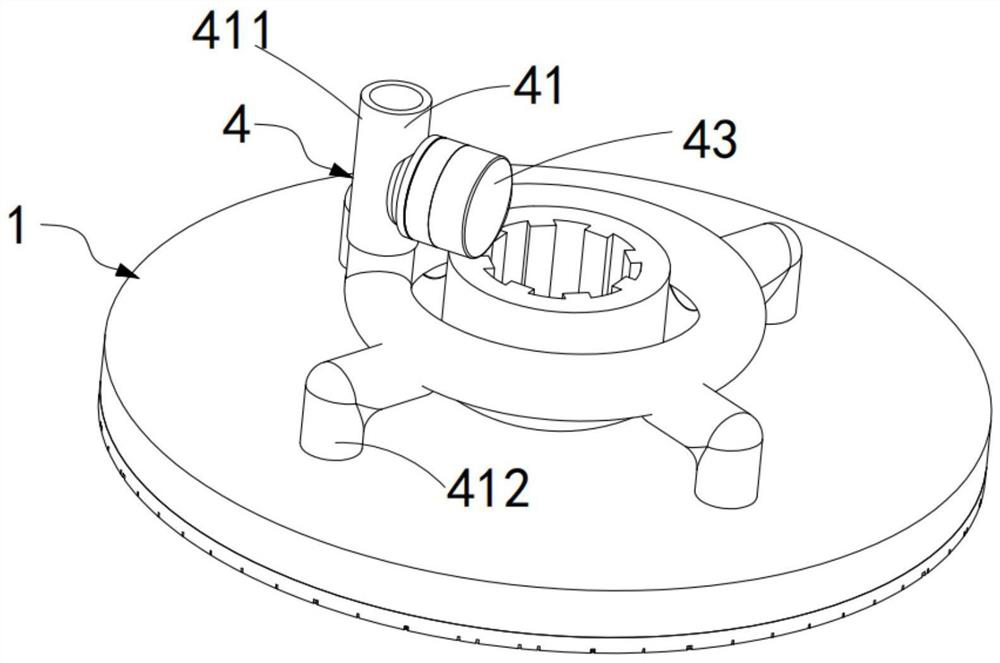

[0067] Such as Figure 1-7 and Figure 9 As shown, a silicon wafer grinding disc correction device includes an upper grinding disc system 1 coaxially arranged, a lower grinding disc system 2 and several dressing wheels arranged between the upper grinding disc system 1 and the lower grinding disc system 2 3. The upper grinding disc system 1 and the lower grinding disc system 2 rotate in opposite directions, the upper grinding disc system 1 is provided with a liquid supply system 4 for supplying grinding fluid, the lower grinding disc system 2 and the A planetary gear linkage system 5 is arranged between the dressing wheels 3. While the dressing wheel 3 revolves around the central axis of the lower grinding disc system 2 through the planetary gear linkage system 5, the dressing wheel 3 revolves around its own central axis. axis rotation;

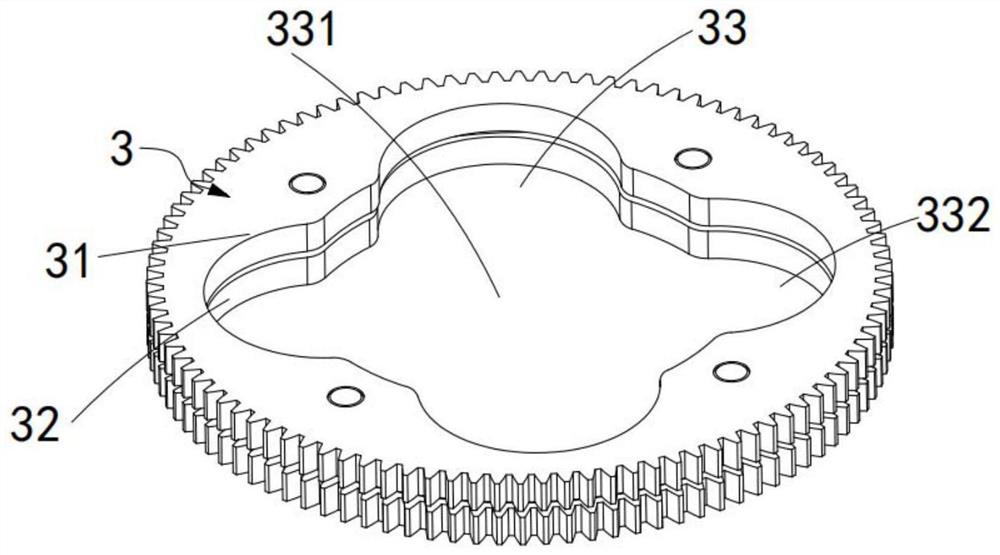

[0068] The dressing wheel 3 is composed of an upper dressing disc 31 and a lower dressing disc 32 stacked and overlapped. A gap 33 is arran...

Embodiment 2

[0104] Referring to the first embodiment of the present invention, a silicon wafer grinding disc correction process according to the second embodiment of the present invention will be described. :

[0105] Such as Figure 13 As shown, a silicon wafer grinding disc correction process includes the following steps:

[0106] Step 1, cleaning, spray cleaning liquid on the upper grinding disc system 1 and the lower grinding disc system 2 before trimming, to clean and moisten the working environment;

[0107] Step 2, dressing wheel top loading: take 4 sets of dressing wheels 3 with the same specifications and install them on the lower grinding disc system 2, so that the planetary gear 54 on the dressing wheel 3 is respectively connected to the sun gear 52 and the sun gear on the central spindle 51. The ring gear 53 on the outer circumference of the lower grinding disc system 2 is engaged;

[0108] Step 3, install the backspray system, synchronized with step 2, during the process o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com