Method and device for processing microalgae

A technology of microalgae and microalgae liquid, which is applied in the direction of fat production, fat oil/fat production, etc. It can solve the problems that the microalgae wall breaking, drying and collection process cannot be completed at the same time, the water content of the algae liquid is increased, and the separated water is high. Achieve the effects of saving post-processing steps, good drying effect and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

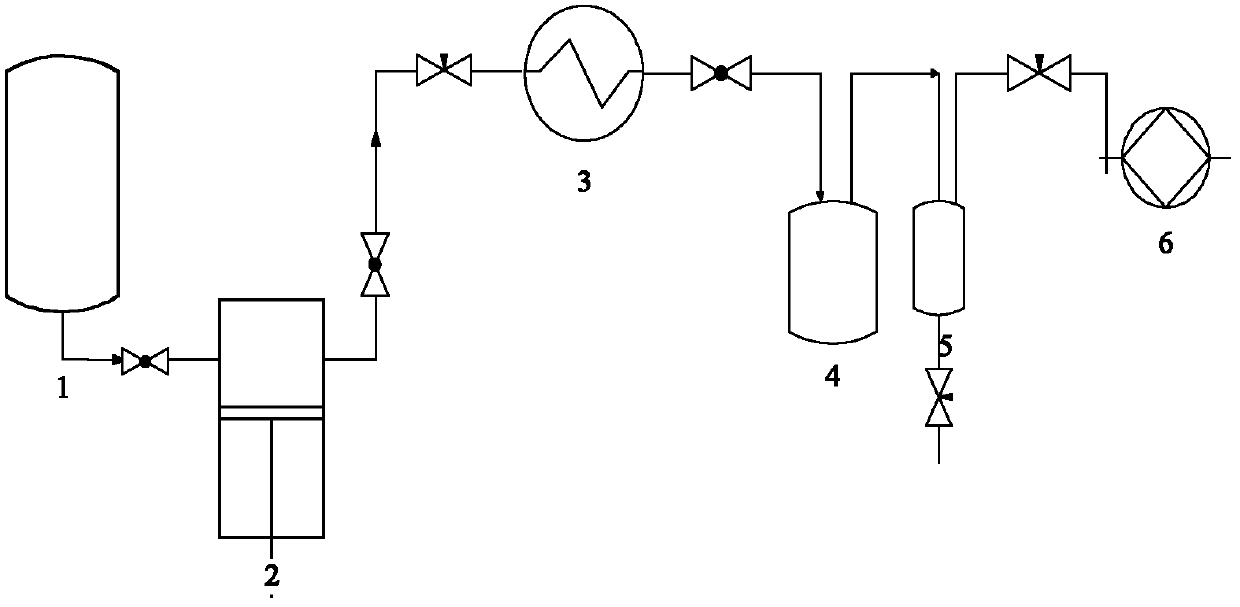

Method used

Image

Examples

Embodiment 1

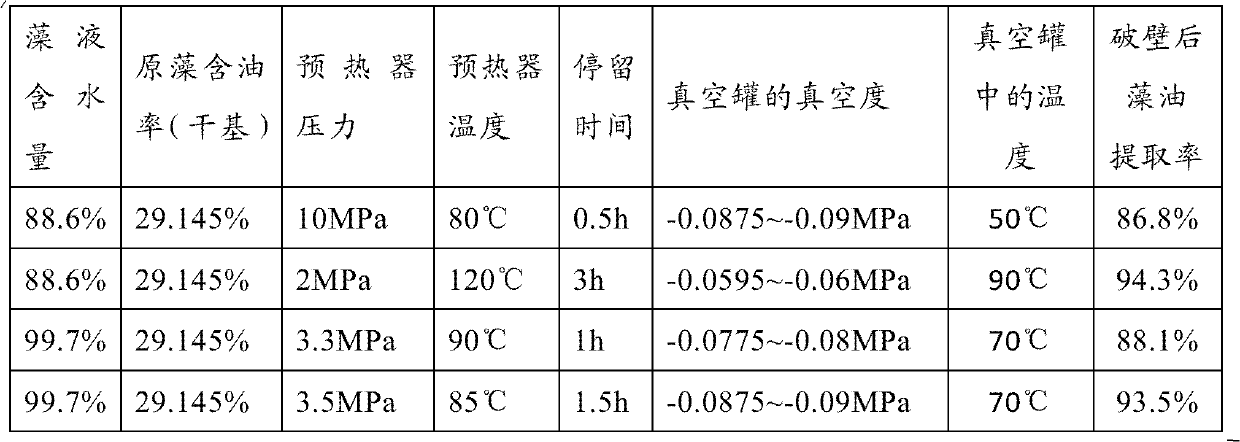

[0034] The water content in the algae liquid storage tank is 88.6% chlorella (chlorella) (Prototheca oil content rate is 29.145% (dry basis)) algae liquid, algae mud are added in the piston tank, and the addition is 500ml (supplementary adding volume), pressurize the piston tank with a nitrogen cylinder, and the pressurized algae liquor enters the preheater, the temperature of the preheater is maintained at 80°C, pressurized to 10MPa, and stays in the preheater for 0.5h. Then the material is discharged into the vacuum tank, the vacuum degree in the vacuum tank is maintained at -0.0875 ~ -0.09Mpa, and the temperature of the vacuum tank is maintained at 50°C to ensure that water exists in gaseous form under this condition. Water enters the buffer tank behind the vacuum tank in gaseous form, and the temperature of the buffer tank is room temperature to ensure that the water is liquefied. The broken microalgae and algae oil remain in the vacuum tank to achieve the effect of microa...

Embodiment 2

[0036] Add chlorella vulga (chlorella vulga) (the oil content of Prototheca 29.145% (dry basis)) with a water content of 88.6% in the algae liquid storage tank to the piston tank, and the amount of addition is 500ml , using a nitrogen cylinder to pressurize the piston tank, the pressurized algae liquid enters the preheater, the temperature of the preheater is maintained at 120 ° C, pressurized to 2 MPa, and stays in the preheater for 3 hours. Then the material is released into the vacuum tank, the vacuum degree in the vacuum tank is maintained at -0.0595 ~ -0.06Mpa, and the temperature of the vacuum tank is maintained at 90°C to ensure that water exists in gaseous form under this condition. Water enters the buffer tank behind the vacuum tank in gaseous form, and the temperature of the buffer tank is room temperature to ensure that the water is liquefied. The broken microalgae and algae oil remain in the vacuum tank to achieve the effect of microalgae drying. Then, the algae o...

Embodiment 3

[0038]The water content in the algae liquid storage tank is 99.7% Phaeodactylum tricornutum Bohlin (Phaeodactylum tricornutum Bohlin) (Prototheca oil content rate is 29.145% (dry basis)) algae liquid and algae mud are added in the piston tank, the addition is 500ml, utilizes The nitrogen cylinder pressurizes the piston tank, and the pressurized algae liquor enters the preheater, the temperature of the preheater is maintained at 90°C, pressurized to 3.3MPa, and stays in the preheater for 1h. Then discharge the material into the vacuum tank, the vacuum degree in the vacuum tank is maintained at -0.0775~-0.08Mpa, and the temperature of the vacuum tank is maintained at 70°C to ensure that water exists in gaseous form under this condition. Water enters the buffer tank behind the vacuum tank in gaseous form, and the temperature of the buffer tank is room temperature to ensure that the water is liquefied. The broken microalgae and algae oil remain in the vacuum tank to achieve the ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com