Production line and production method of composite material shoe soles

A composite material and production line technology, which is applied in the direction of shoe soles, footwear, applications, etc., can solve the problems of reduced production and processing speed, low work efficiency, and cumbersome operation steps, so as to improve processing speed, high processing efficiency, and good operation safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

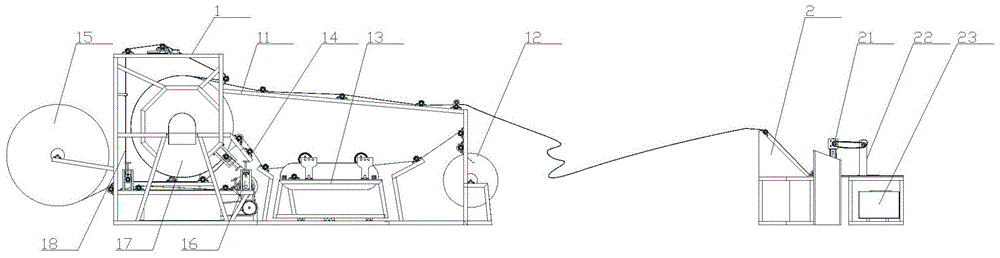

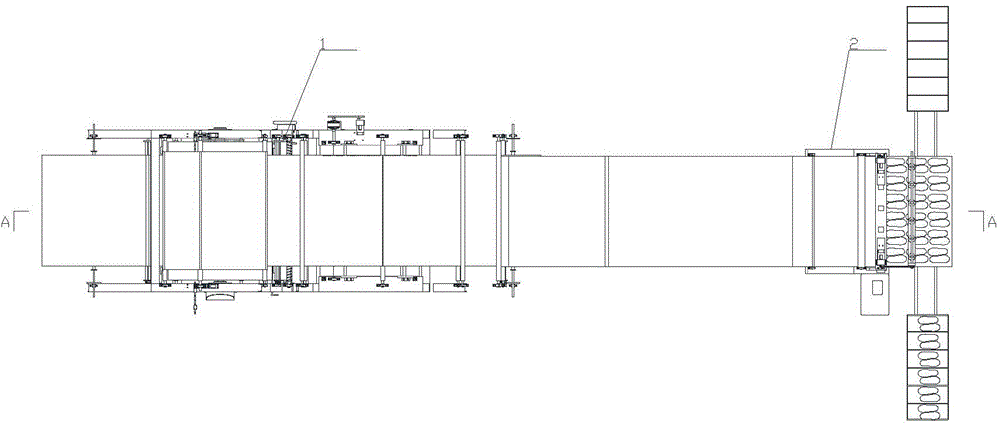

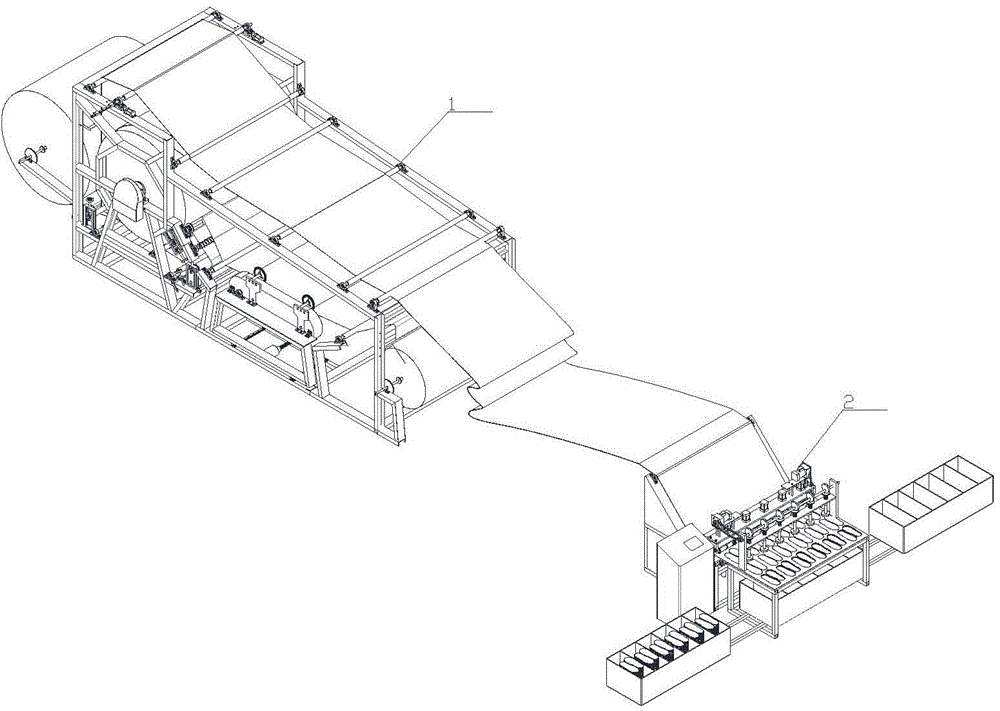

[0069] The present invention as Figure 1-23 As shown, it includes the composite machine 1 and the roller cutting machine 2 arranged adjacently; it avoids the problems of large floor area and low space utilization rate caused by excessive accumulation of composite materials;

[0070] The compound machine 1 comprises a frame 11, a soft material accommodation roller 12, a soft material adjustment assembly 13, a soft material guide roller set 14, a hard material accommodation roller 15, a hard material guide roller set 16 and a heating roller 17, the The soft material accommodation roller 12, the hard material accommodation roller 15 and the heating roller 17 are parallel to each other and are all hinged in the frame 11. The hard material guide rollers 16 groups are connected in the frame 11 and are located in the hard material accommodation Between the roller 15 and the heating roller 17; thereby making the hard material keep a tight state during the transmission process, the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com