Three-dimensional all-solid-state mini thin-film lithium battery with inverted pyramid array structure

An array structure and inverted pyramid technology, applied in the field of three-dimensional all-solid-state micro-thin film lithium batteries, can solve the problems of difficult integration of microelectronics process, low space utilization rate, high process requirements, etc., achieve good sealing and drainage, and improve electrochemical performance , Good effect of process continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

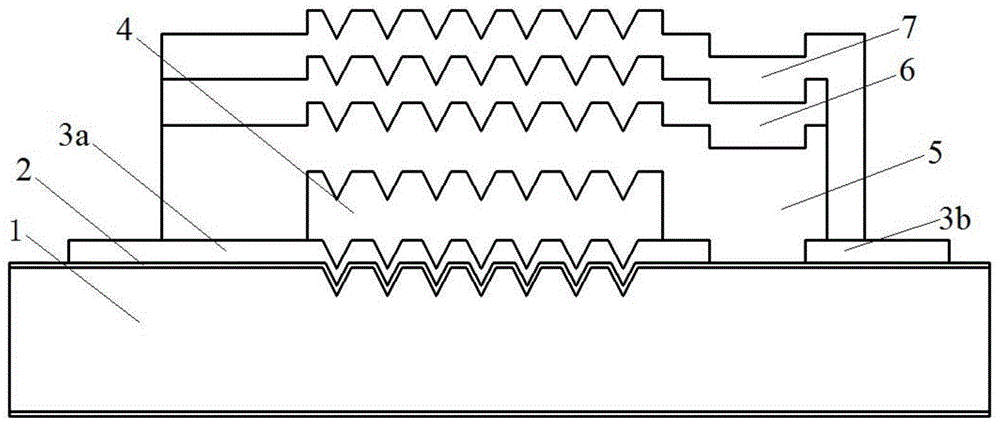

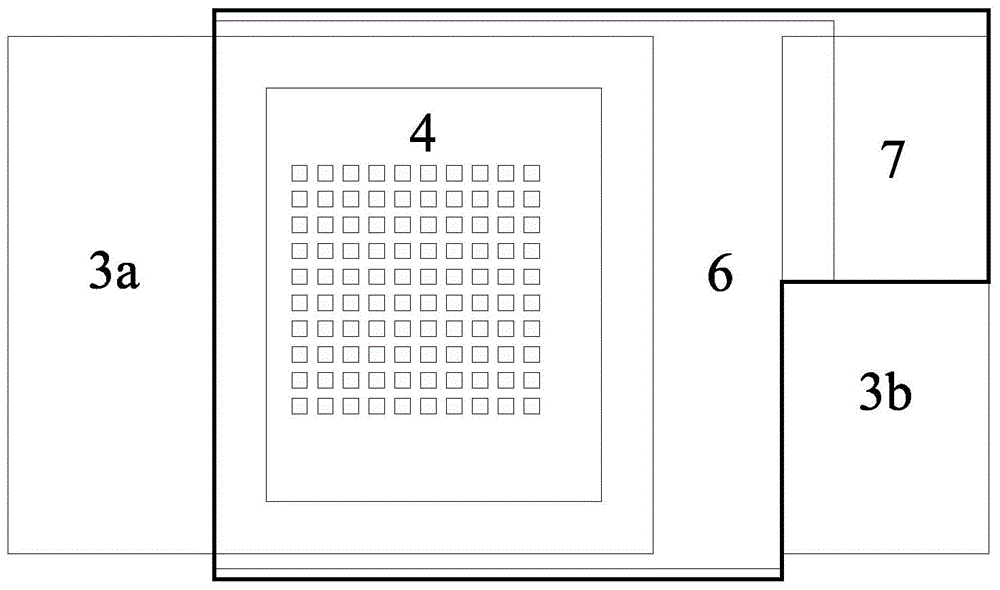

[0023] Such as Figure 1~4 As shown, the embodiment of the present invention has a substrate 1, an insulating film 2, a cathode current collector 3a, a lower anode current collector 3b, a cathode film 4, a solid electrolyte film 5, an anode film 6 and an upper anode current collector 7.

[0024] The insulating film 2 is set on the substrate 1, the cathode current collector 3a and the lower anode current collector 3b are set on the insulating film 2, the cathode film 4 is set on the cathode current collector 3a, and the solid electrolyte film 5 is covered on the cathode film 4 , the anode film 6 is provided on the solid electrolyte membrane 5, and the upper anode current collector 7 is provided on the anode film 6 and the lower anode current collector 3b.

[0025] The three-dimensional structure is made using SiO 2 As a mask layer, it is obtained by anisotropic etchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com