Hydrotreating device and application thereof as well as residual oil hydrotreating method

A technology for hydrotreating and residual oil hydrogenation, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problem of wasting reactor space, etc., and achieves the advantages of less risk, simple switching procedure and less high-pressure valves. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

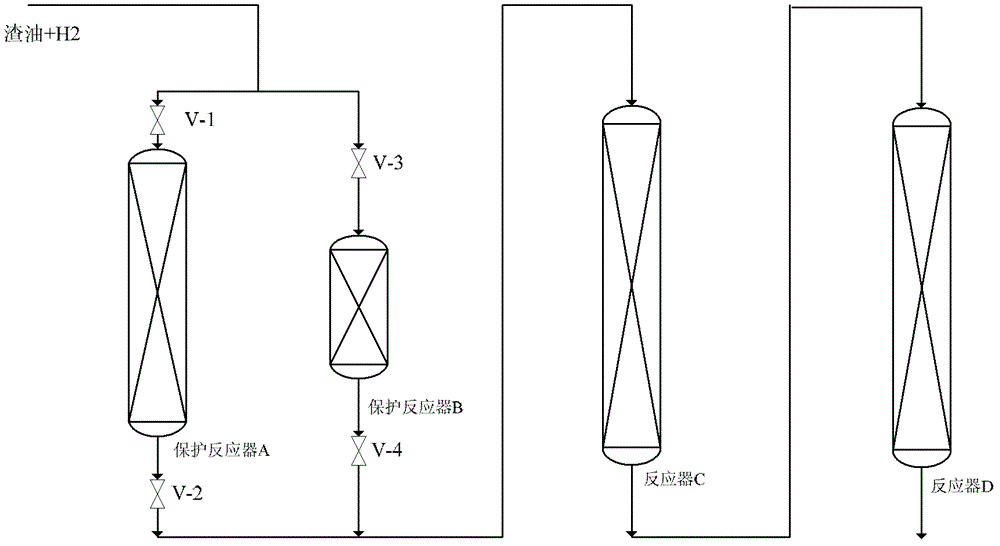

[0038] 60ml of hydrogenation protection catalyst RG-10B and 60ml of hydrogenation demetallization catalyst RDM-2B are sequentially filled in protection reactor A, and 30ml of hydrogenation protection catalyst RG-10B and 10ml of hydrogenation demetallation catalyst RDM-2B are sequentially filled in protection reactor B 2B, 200ml of hydrodemetallization catalyst RDM-2B is filled in reactor C, and 400ml of hydrodesulfurization catalyst RMS-1B is filled in reactor D.

[0039] The raw material residue M1 (see Table 1 for the composition) is mixed with hydrogen and enters the protection reactor A, and then enters the reactor C and the reactor D. The operating conditions include: the residual oil feed rate is 180g / h, the hydrogen flow rate at the reactor inlet is 126L / h, the pressure is 15.0MPa, the reaction temperature is adjusted in the range of 350-410°C according to the sulfur content of the hydrogenated oil, so The sulfur content of the hydrotreated oil was maintained at 0.30% b...

Embodiment 2

[0052] Fill protection reactor A with 40ml protection agent RG-10B and 100ml demetallization catalyst RDM-2B in turn, protection reactor B with 20ml protection agent RG-10B and 20ml demetallation catalyst RDM-2B, and reactor C with 300ml Demetallization catalyst RDM-2B, reactor D is filled with 300ml desulfurization catalyst RMS-1B.

[0053]The raw material residue M2 (the composition is shown in Table 1) is mixed with hydrogen and enters the protection reactor A, and then enters the reactor C and the reactor D. A sampling point is set after the protection reactor and before the reactor C to monitor the demetallization performance of the protection reactor. The operating conditions include: feed rate of residue oil is 140g / h, hydrogen flow rate at reactor inlet is 98L / h, pressure is 14.5MPa, reaction temperature of protection reactor A is based on the residue oil collected at the sampling point after protection reactor A The metal (Ni+V) content in the reactor is adjusted wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com