Polyester-based protective film for preventing oligomer preparation and manufacturing method thereof

A polyester-based protective film and a production method technology, applied in the direction of film/flake adhesive, coating, adhesive, etc., can solve the problems of fog, peeling, veneer bubbles, etc., and achieve good process durability, The effect of strong blocking ability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

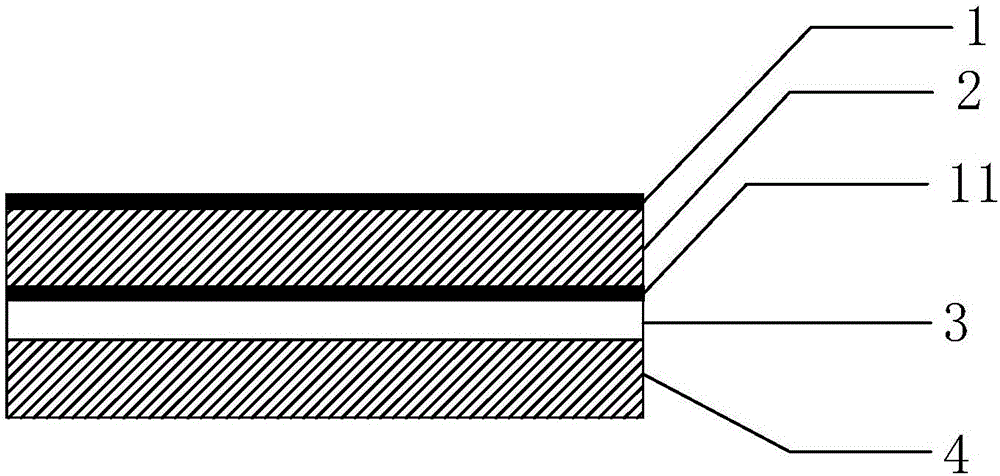

Image

Examples

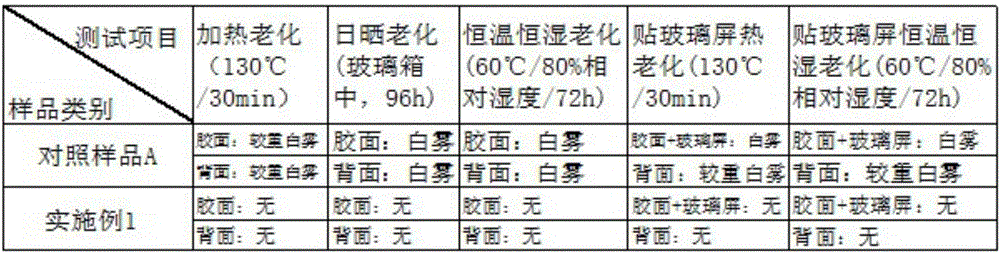

Embodiment 1

[0089] A kind of manufacture method that prevents the polyester-based protective film that oligomer produces, comprises the steps:

[0090] 1. Preparation of raw materials for sealing agent: 4.0Kg of acrylic acid, 3.0Kg of hydroxyethyl acrylate, 21.0Kg of methyl methacrylate, 12.0Kg of methyl acrylate, 57.0Kg of ethyl acetate, 3.0Kg of toluene, 160.0 g of BPO with 25% water;

[0091] 2. Refining and configuration of initiator:

[0092] A. 160.0g of BPO containing 25% moisture content is dissolved in 3.0Kg of toluene, and the resulting solution is left standing until the solution turns from light white to clear and transparent;

[0093] B. Carefully remove the water and a little other impurities in the lower layer of the solution;

[0094] C. Divide the obtained supernatant into three equal parts to obtain the addition solution 1, the addition solution 2 and the addition solution 3.

[0095] 3. Synthesis of sealing agent:

[0096] A. Add 4.0Kg of acrylic acid, 3.0Kg of hydr...

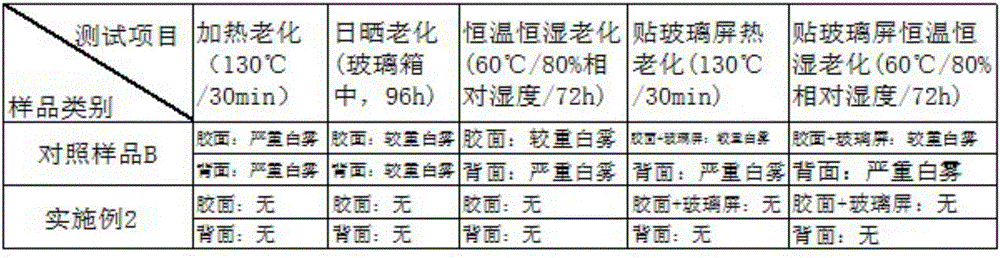

Embodiment 2

[0129] Embodiment 2. a kind of preparation method that prevents the polyester-based protective film that oligomer produces, comprises the steps:

[0130] 1. Preparation of raw materials for sealing agent: 3.5Kg of acrylic acid, 4.5Kg of hydroxyethyl acrylate, 19.0Kg of methyl methacrylate, 11.0Kg of methyl acrylate, 2.0Kg of acrylonitrile, 60.0Kg of butanone, 200.0 g of azobisisobutyronitrile, 2000ml of 95% ethanol;

[0131] 2. Refining and configuration of initiator:

[0132] A. Put 2000ml of 95% ethanol in a glass container, heat it in a water bath to about 70°C; quickly add 200.0g of azobisisobutylcyanide into the ethanol solution, stir quickly until it is completely dissolved, and quickly filter the hot solution , After cooling the glass container holding the filtrate with water, put it in the refrigerator for crystallization, and the crystallization obtained is the refined azobisisobutylcyanide initiator. Refined azobisisobutyrocyanide should be stored at low temperatur...

Embodiment 3

[0165] Embodiment 3. a kind of preparation method that prevents the polyester-based protective film that oligomer produces, comprises the steps:

[0166] 1. Preparation of raw materials for sealing agent: 3.5Kg of acrylic acid, 3.5Kg of hydroxypropyl acrylate, 25.0Kg of methyl methacrylate, 8.0Kg of methyl acrylate, 57.0Kg of ethyl acetate, 3.0Kg of toluene, 160.0 g of BPO containing 25% water;

[0167] 2. Refining and configuration of initiator:

[0168]A. 160.0g of BPO containing 25% moisture content is dissolved in 3.0Kg of toluene, and the resulting solution is left standing until the solution turns from light white to clear and transparent;

[0169] B. Carefully remove the water and a little other impurities in the lower layer of the solution;

[0170] C. Divide the obtained supernatant into three equal parts to obtain the addition solution 1, the addition solution 2 and the addition solution 3.

[0171] 3. Synthesis of sealing agent:

[0172] A. Add 3.5Kg of acrylic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com