Selective zinc oxide leaching and weak acidic zinc sulfide flotation smelting and selection combining process

A combined process, zinc oxide technology, applied in flotation, chemical instruments and methods, solid separation, etc., can solve the problems of low product consumption and energy consumption, less types of flotation reagents, increased coal combustion, and purification agent production and consumption. , to improve the grade rate and recovery rate, reduce the amount of flotation reagents, save energy and reduce consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

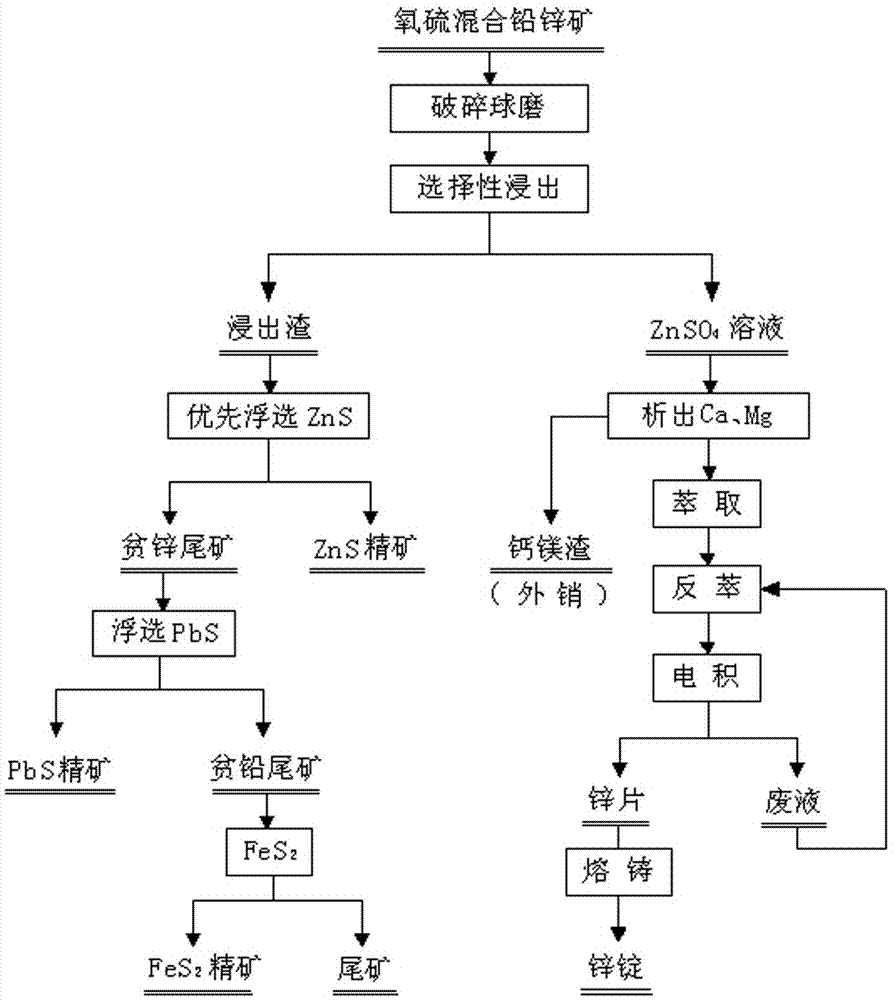

[0021] As shown in the figure, the combined smelting process of selective leaching of zinc oxide and weak acid flotation zinc sulfide of the present invention is aimed at oxygen-sulfur mixed lead-zinc ore, and combines the zinc hydrometallurgy process with the zinc flotation process. The hydrometallurgy process selectively leaches the zinc oxide part in the ore, and then uses the flotation process to float out the zinc sulfide part in the ore.

[0022] The zinc hydrometallurgy process of the present invention uses sulfuric acid as a solvent to process the oxides in the raw ore by the process technology of selective leaching. Specifically, sulfuric acid is added to the pulp of oxygen-sulfur mixed lead-zinc ore. Under the conditions of acidity, high temperature and stirring, the pulp completely dissolves zinc oxide, copper oxide, cadmium oxide and other oxides in the pulp into ZnSO 4 In the solution, leaching slag containing zinc sulfide and sulfide is produced at the same time....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com