A kind of preparation method of calcium-removing resin

A technology of resin and chelating resin, applied in the direction of aluminum halide, aluminum chloride, etc., can solve the problems of poor effect and difficulty in removing calcium ions, improve chelating ability, solve technical bottlenecks, and achieve great economic benefits and social value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

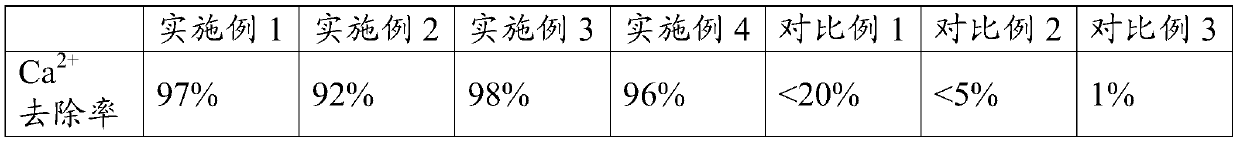

Embodiment 1

[0044] 1) Add 3L of water, 30g of gelatin, 9g of hydroxymethyl cellulose, and 150g of sodium chloride into a 5L three-necked bottle, stir to dissolve and clear, and obtain an aqueous phase; 230.79g of industrial divinylbenzene, 76.92g of industrial styrene, 426.05 Mix g toluene and 189.35 g 200# gasoline, add 9.23 g benzoyl peroxide, dissolve and clear it by ultrasonication for 20 minutes, and obtain an oil phase; heat the obtained water phase to 55 ° C, add the oil phase, and heat the reaction solution to React at 83°C for 10 hours, filter, extract, wash with water, and dry to obtain resin white balls;

[0045] 2) Mix 350g of resin dry white balls with 1050g of chloromethyl ether, stir and swell at room temperature for 10h, then add 35g of zinc chloride as a catalyst, stir evenly, heat to 45°C for 10h, filter, wash with water to obtain chloromethylated resin, It is the resin chlorine ball. The measured resin chlorine content is 19.2%;

[0046] 3) Mix 300 g of resin chlorine...

Embodiment 2

[0049] The aqueous solution of aminosugar in step 3 in "Example 1" is changed to the diethanolamine aqueous solution that mass concentration is 10%, under the situation that other conditions remain unchanged, obtain and contain amino group and hydroxyl resin (weak base exchange volume: 3.2mmol / g), dry the resin, take 200g of dry resin and mix with 1600g of methanol, swell at room temperature for 3h, then add 34g of sodium methoxide methanol solution with a mass concentration of 15%, and start to drop 62.93g of carbon disulfide after heating to 35°C for 30min. After the addition, react at 45°C for 6 hours, filter, extract, and wash with water to obtain a resin containing amino groups, hydroxyl groups, and mercaptocarboxyl groups. The measured sulfur content is above 1.5 mmol / g.

Embodiment 3

[0051] The aqueous solution of aminosugar in the step 3 of "Example 1" is changed to the o-hydroxyaniline aqueous solution of mass concentration 10%, under the situation that other conditions remain unchanged, obtain and contain amino group and hydroxyl resin (weak base exchange volume: 2.32mmol / g), dry the resin, mix 200g of dry resin with 1000g of dimethyl sulfoxide, swell at room temperature for 3h, then add 50g of dimethyl sulfoxide solution with a mass concentration of 10% tert-butyl sodium, and heat to 80 Begin to add dropwise an aqueous solution of sodium sulfite (containing 90 g of sodium sulfite) with a mass fraction of 24% at ℃, react at 80 ℃ for 10 h after 60 min of dropwise addition, filter, extract, and wash to obtain resins containing amino groups, hydroxyl groups, and mercapto groups, and the sulfur content is measured as 1.62 mmol / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com