Patents

Literature

613 results about "Chelating resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chelating resins are a class of ion exchange resins. They are almost always used to bind cations. They utilize chelating agents covalently attached to a polymer matrix. Chelating resins have the same bead form and polymer matrix as usual ion exchangers. Their main use is for preconcentration of metal ions in a dilute solution.

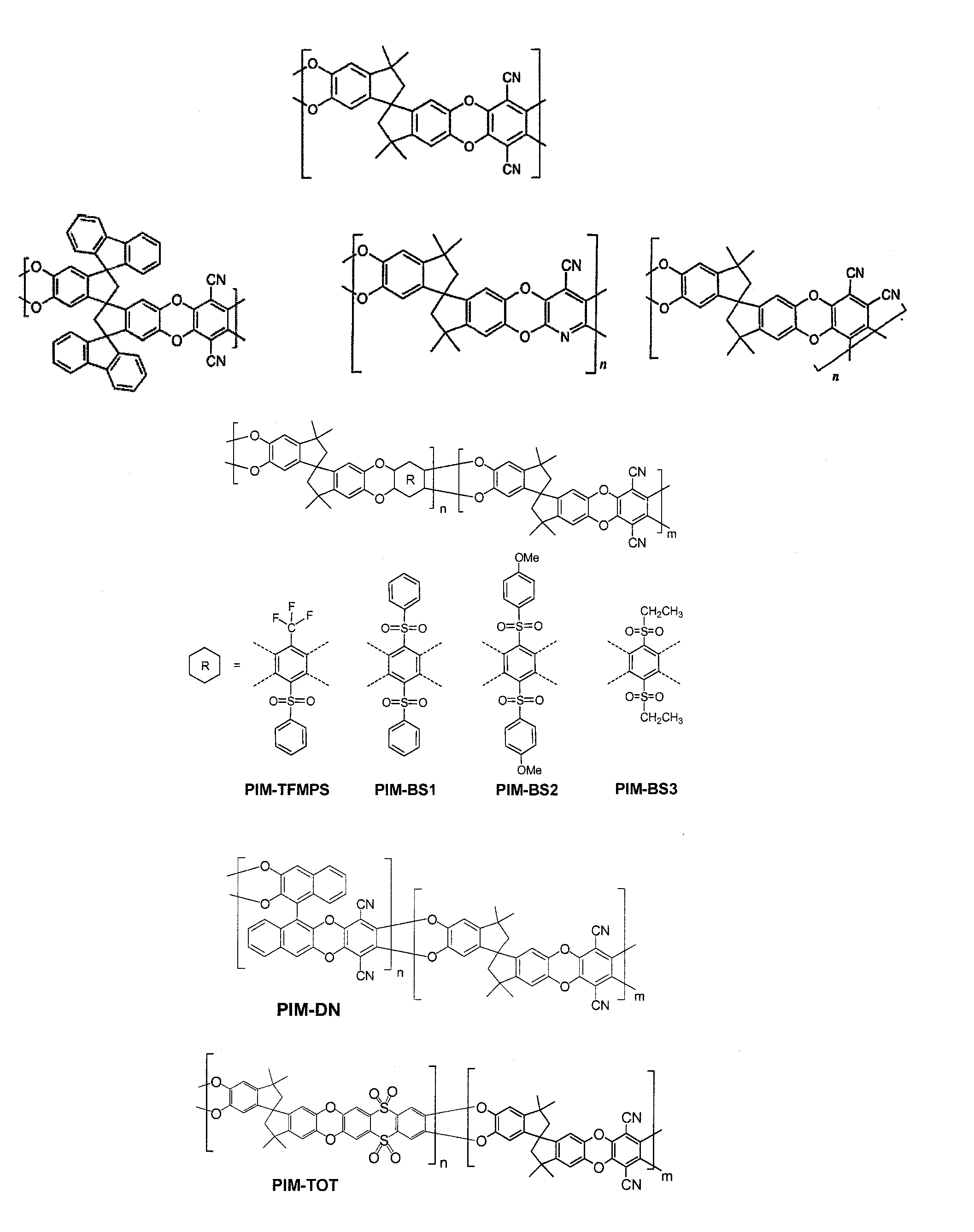

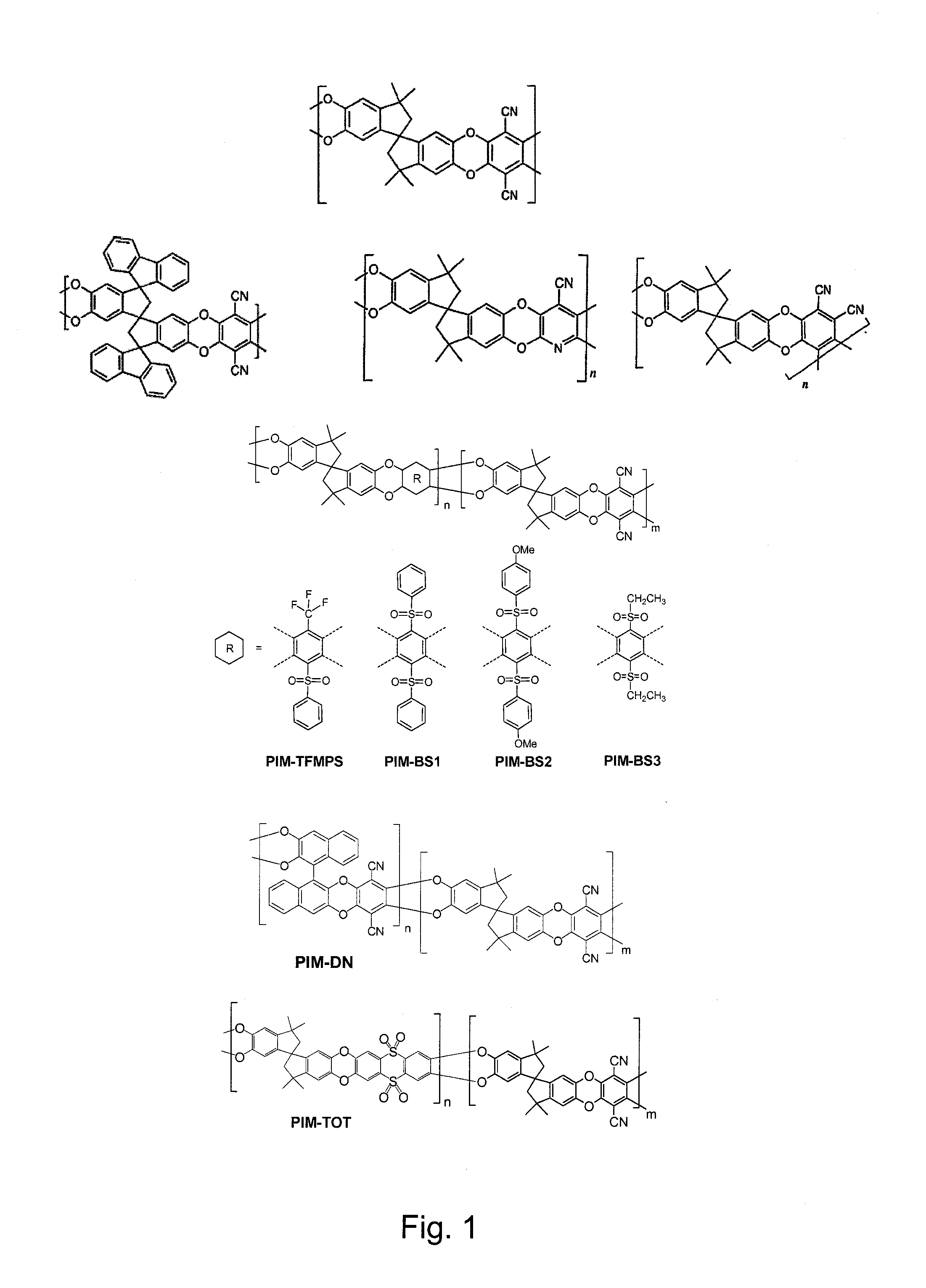

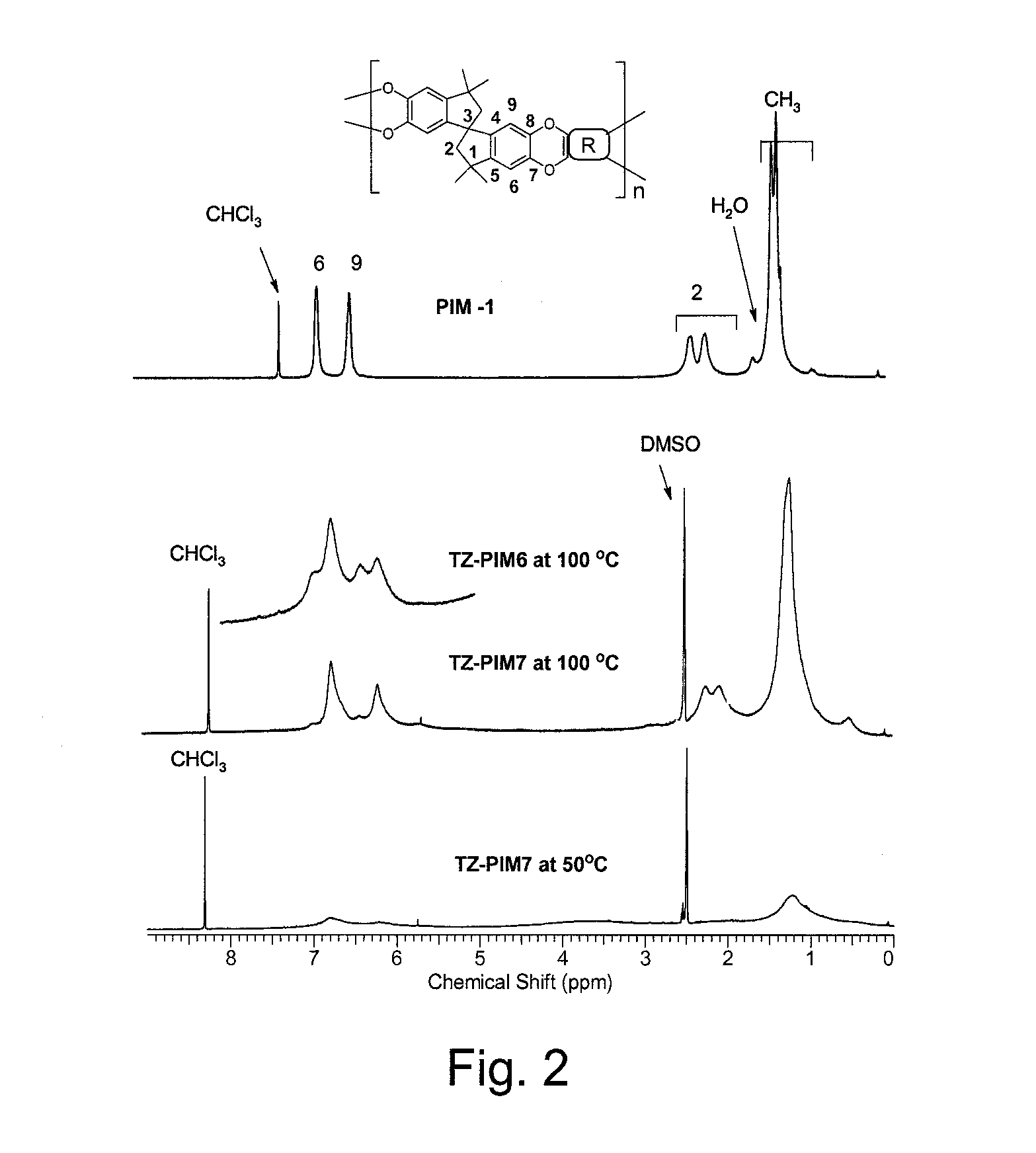

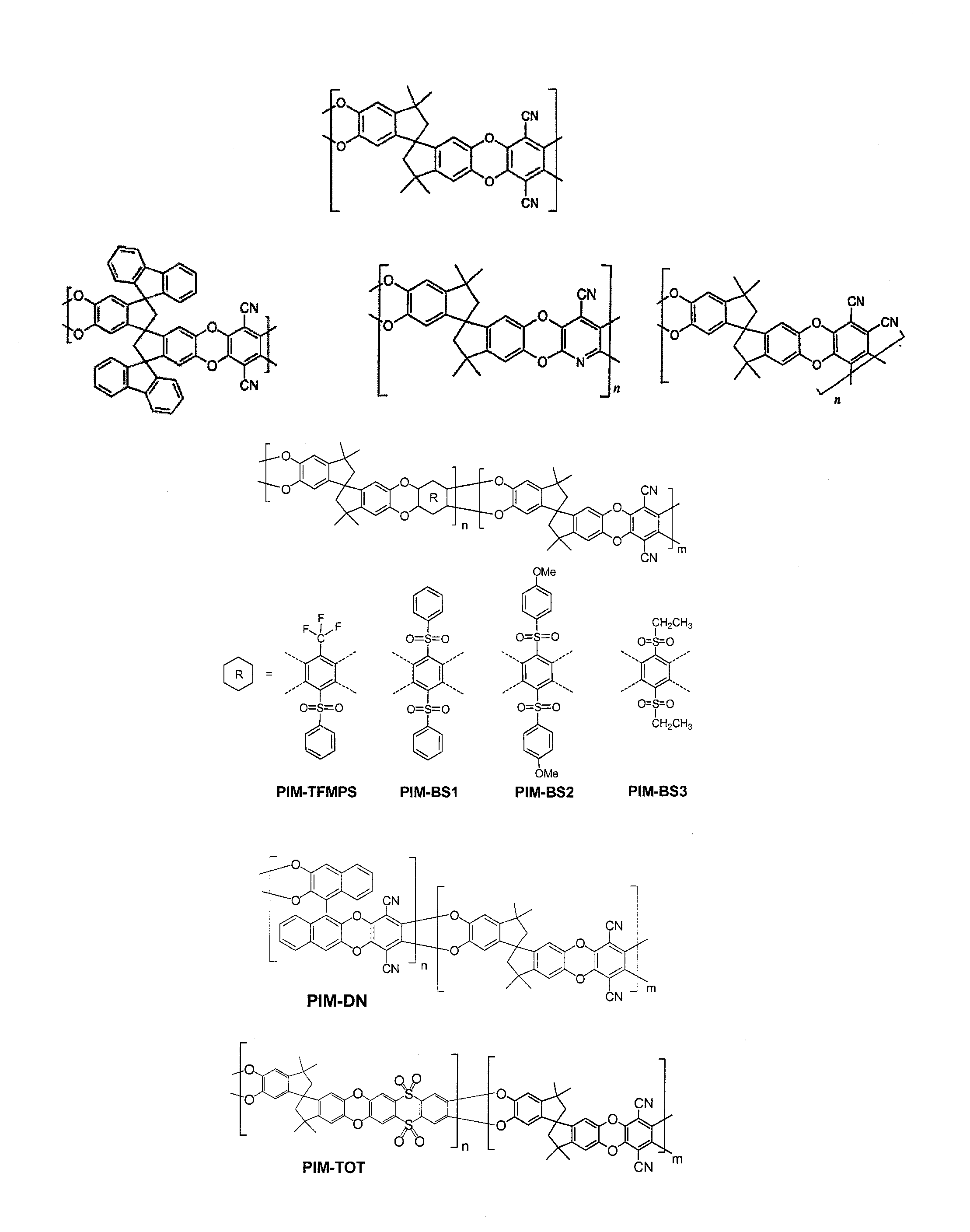

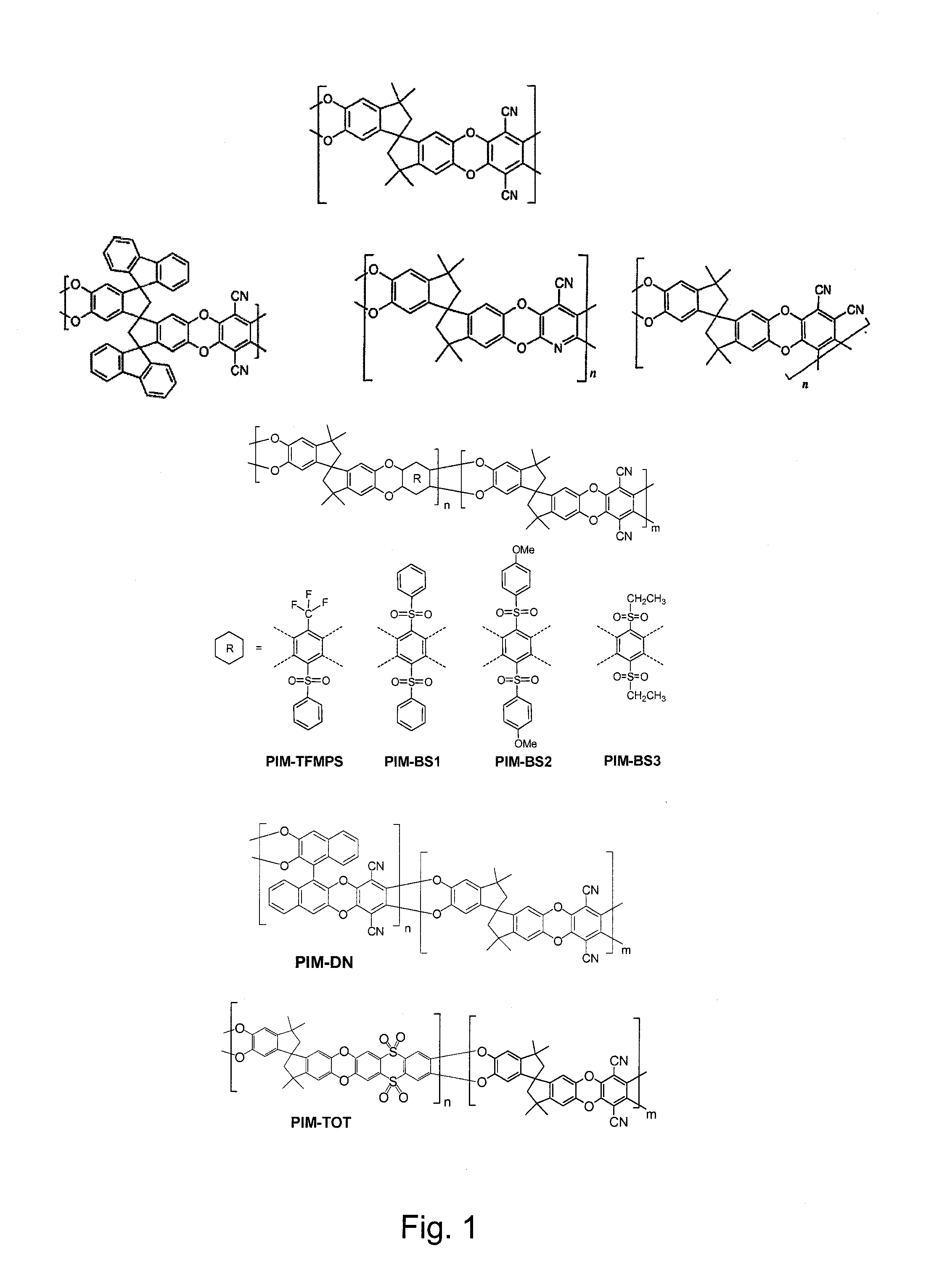

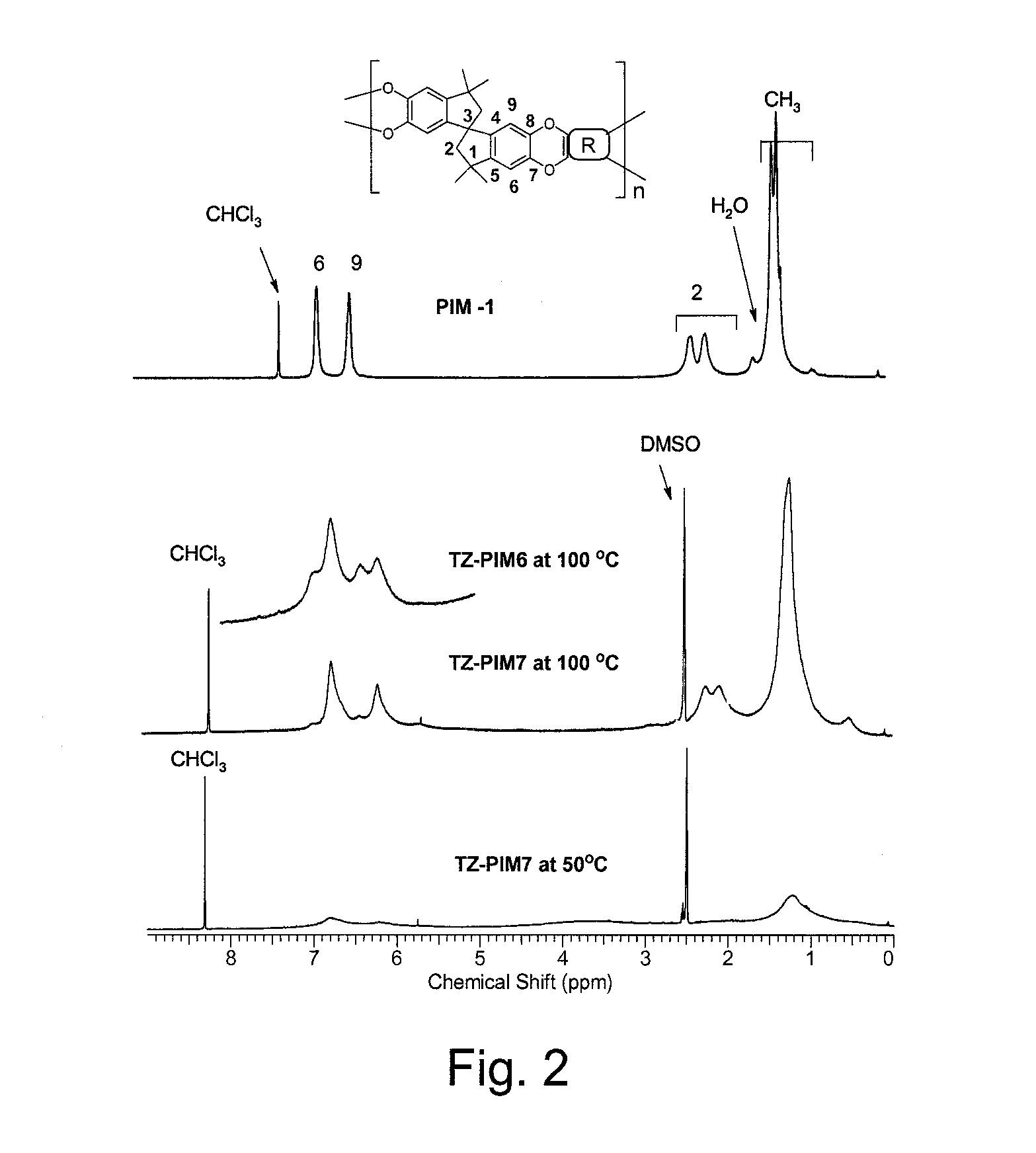

Polymers of intrinsic microporosity containing tetrazole groups

InactiveUS8623928B2Extending possible structureIncrease rangeOrganic chemistryOther chemical processesTetrazoleClick chemistry

The invention provides a tetrazole-containing polymer of intrinsic microporosity comprising (10) or more subunits, wherein one or more of the subunits comprise one or more tetrazolyl moieties. In one embodiment, a polymer of intrinsic microporosity (PIM-1) was modified using a “click chemistry” [2+3] cycloaddition reaction with sodium azide and zinc chloride to yield new PIMs containing tetrazole units. Polymers of the present invention are useful as high-performance materials for membrane-based gas separation, materials for ion exchange resins, materials for chelating resins, materials for superabsorbents, materials for ion conductive matrixes, materials for catalyst supports or materials for nanoparticle stabilizers.

Owner:NAT RES COUNCIL OF CANADA

Method for harmless and recycling treatment of stainless steel acid washing waste water neutralization sludge

ActiveCN101982433ASolve the problem of sediment lossImprove water qualitySludge treatmentMultistage water/sewage treatmentSludgeAcid washing

The invention discloses a method for harmless and recycling treatment of stainless steel acid washing waste water neutralization sludge, belonging to the field of harmful and valuable heavy metal resource recovery. The stainless steel acid washing waste water neutralization sludge is leached out by sulphuric acid, harmful and poisonous metals manganese, nickel and chromium enter into the leachate, and harmless treatment is carried out on the sludge. Separation, enrichment and recovery of metal resources of iron, manganese, chromium and nickel in the leachate are realized by adopting goethite method, potassium permanganate oxidation method, anion resin exchange method and chelate resin absorption method respectively, and effluent up to the standard is discharged after treatment or is returned to water consuming link in technologic process. The method of the invention has short technological flow, simple operation, management convenience, high recovery rate of valuable metal resources of manganese, nickel and chromium, recycling of multiple valuable metals is realized while the sludge is subject to harmless treatment, and unification of economic benefit, environmental benefit and social benefit is realized.

Owner:NANJING UNIV

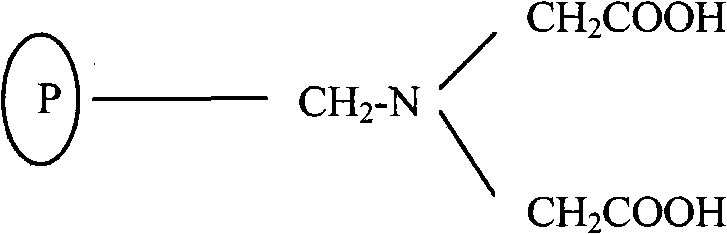

Novel chelate resin and production method and application thereof

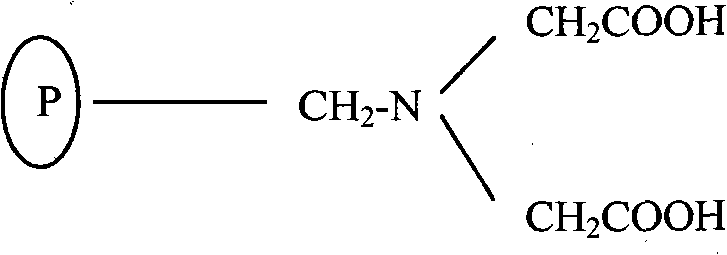

ActiveCN101735372AHigh removal rateSimple process controlOther chemical processesMetal impuritiesChloroacetic acids

The invention provides a chelate resin and a production method and the application thereof, and the novel chelate resin can effectively remove impurities in trichlorosilane; the preparation method provided by the invention comprises the following steps: (1) zinc chloride is used as catalyzer, a white ball and chloromethyl ether are reacted to obtain chloromethylate white ball; (2) the chloromethylate white ball and hexamine are reacted, and then concentrated hydrochloric acid-ethanol mixing solution is used for decomposing, so as to obtain primary amine resin; (3) the primary amine resin is added in the chloroacetic acid aqueous solution, and the reaction is carried out for 10-30 hours at 55-70 DEG C to obtain the chelate resin; the chelate resin can effectively remove the metal impurities such as boron, phosphorus, calcium, magnesium, copper, ferrum and other impurities in trichlorosilane, the removal rate can reach more than 99 percent; the chelate resin has high processing capacity with 200t per cube and is the optimal choice for improving the product quality.

Owner:SUNRESIN NEW METERIALS CO LTD XIAN

Deep purification process for thallium-containing waste water

The invention relates to a deep purification process for thallium-containing waste water, which belongs to the technical field of sewage treatment. The deep purification process for the thallium-containing waste water comprises the following steps: (1) adding excess oxidizing agent into the thallium-containing waste water so as to oxidize Tl<+> into Tl<3+>; (2) adjusting the pH value of the thallium-containing waste water to 7 to 13 so as to produce thallium hydroxide precipitate; (3) carrying out solid-liquid separation to remove the thallium hydroxide precipitate in the thallium-containing waste water so as to obtain preliminarily purified water; (4) adding a reducing agent into the preliminarily purified water so as to allow redox potential of the preliminarily purified water to be less than 200 mV; and (5) introducing the preliminarily purified water treated in the step (4) into an ion exchange column equipped with an adsorption resin for purification so as to obtain deeply purified water, wherein the adsorption resin is a macroporous chelate resin containing a mercapto group. The deep purification process enables the thallium-containing waste water to be deeply purified; and the obtained deeply-purified water has total thallium content of less than 0.1 [mu]g / L.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST

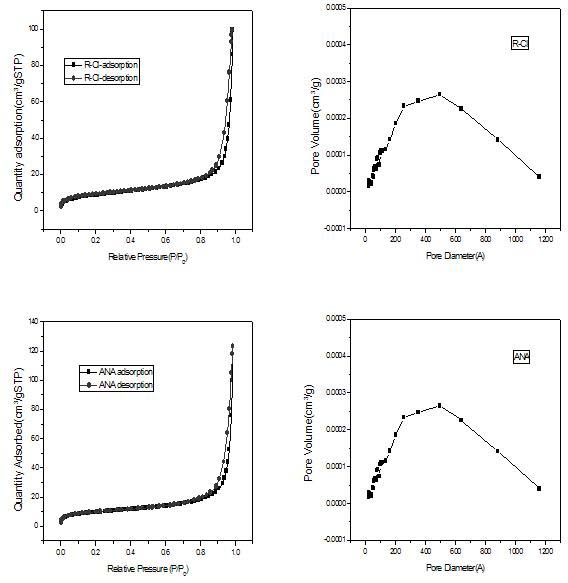

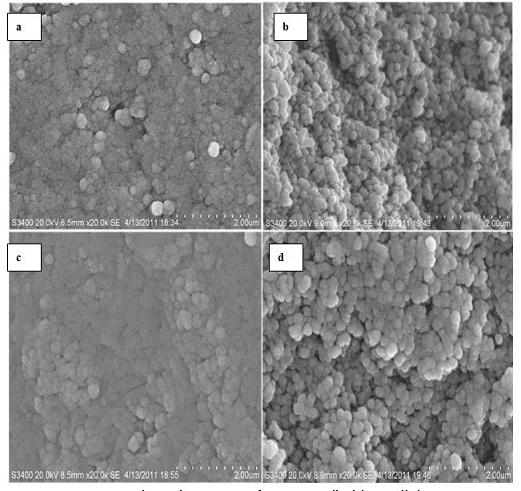

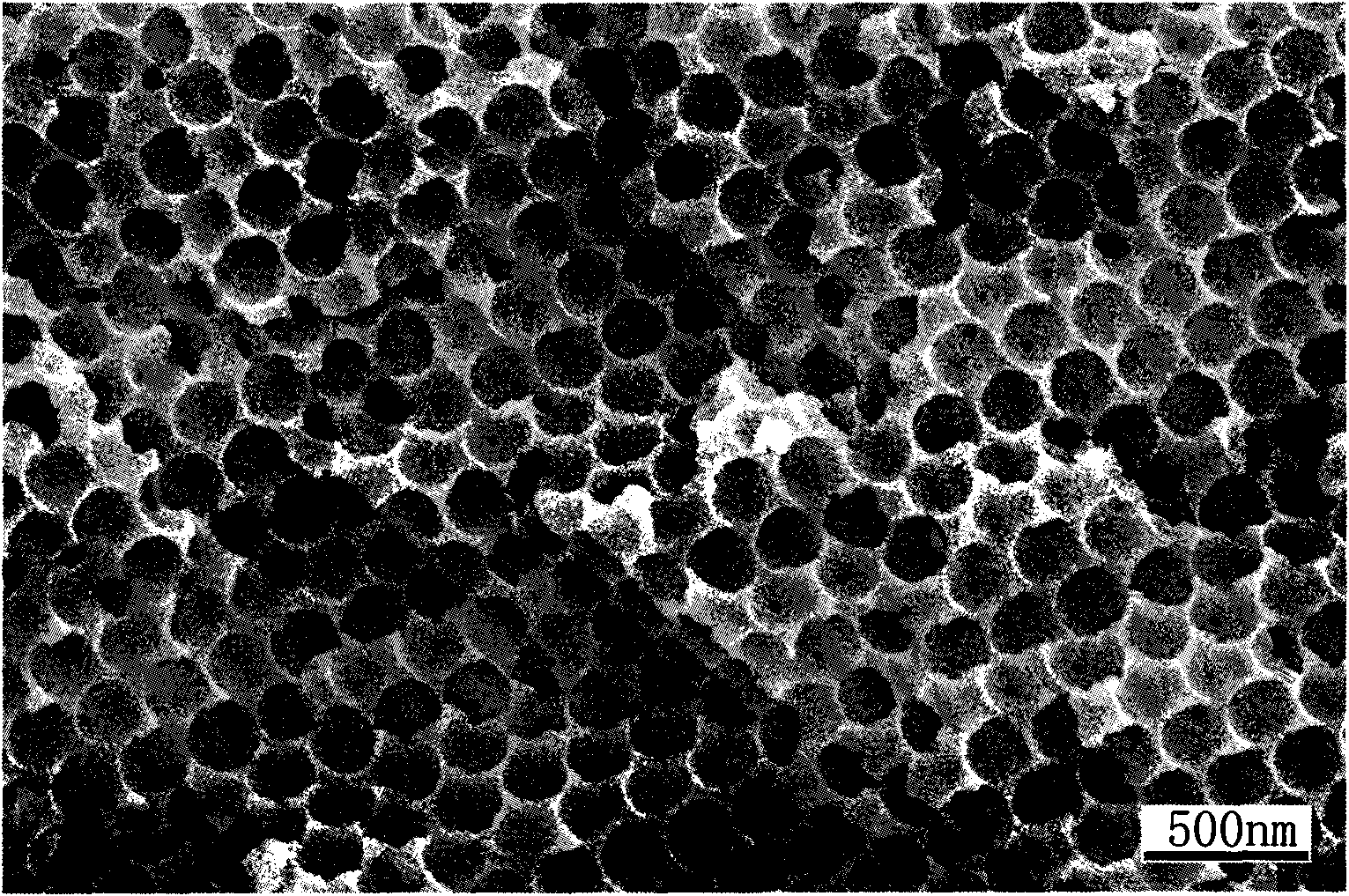

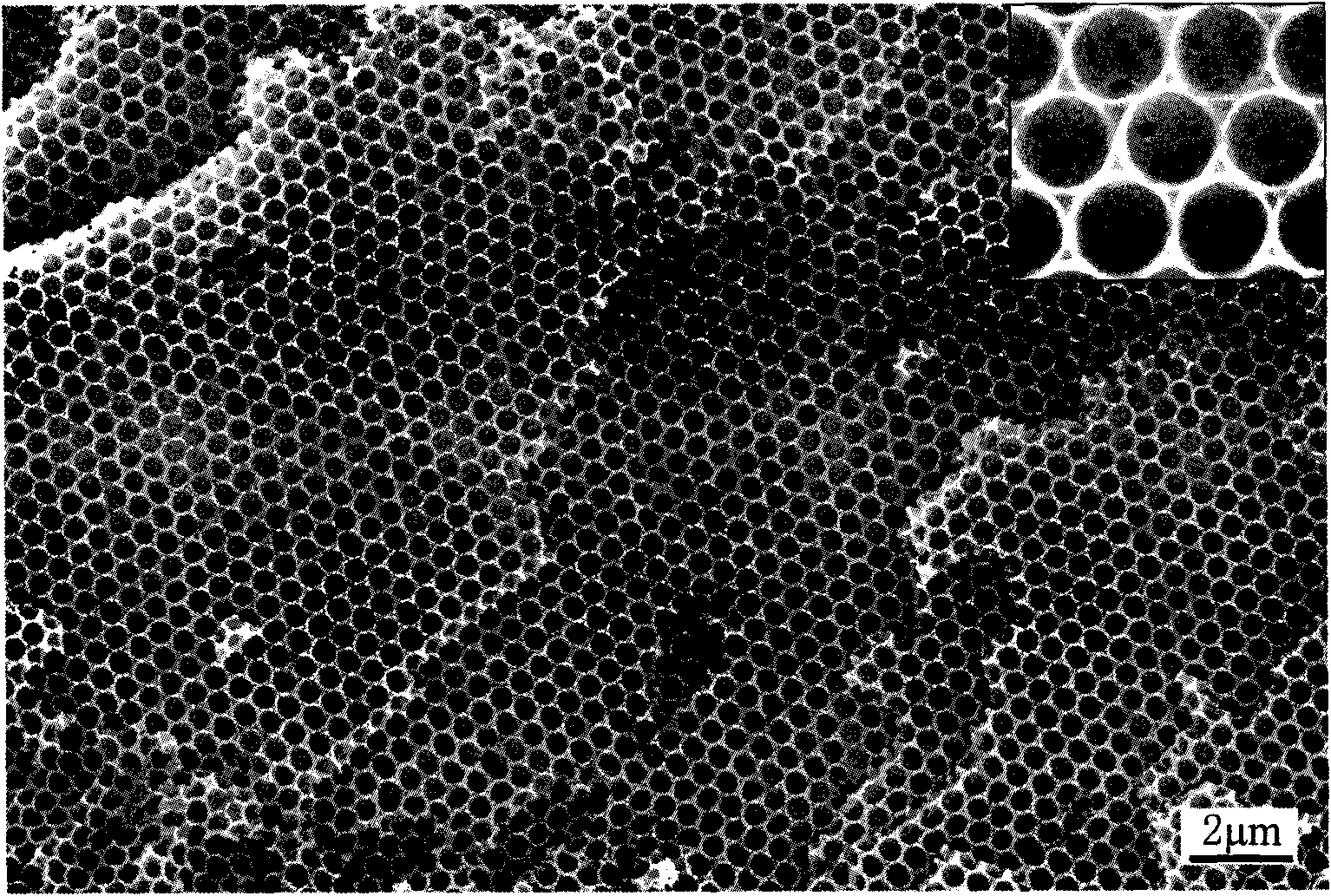

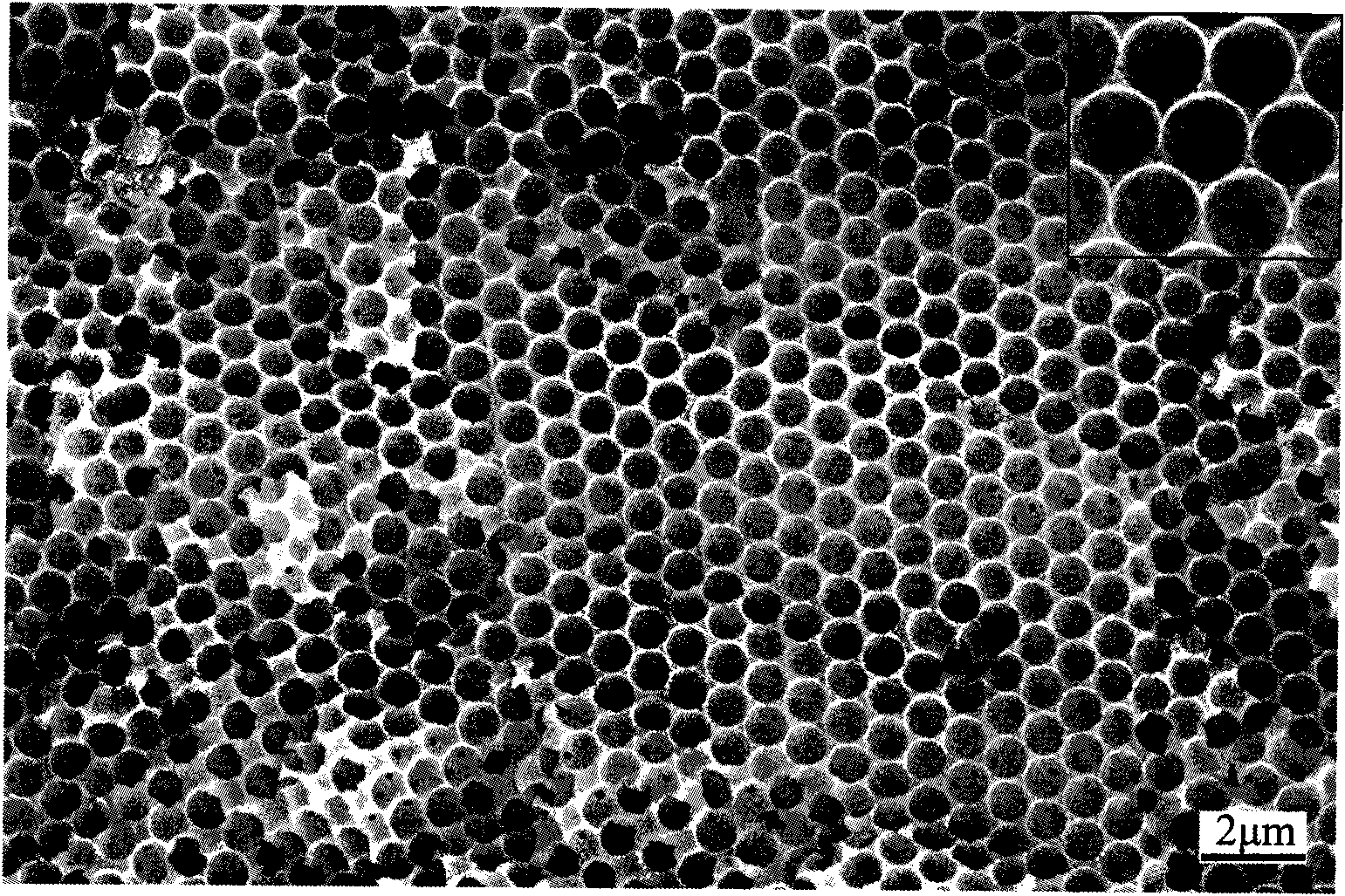

Method of preparing three-dimensionally ordered macroporous chelate resin with hydrophilic-structure framework

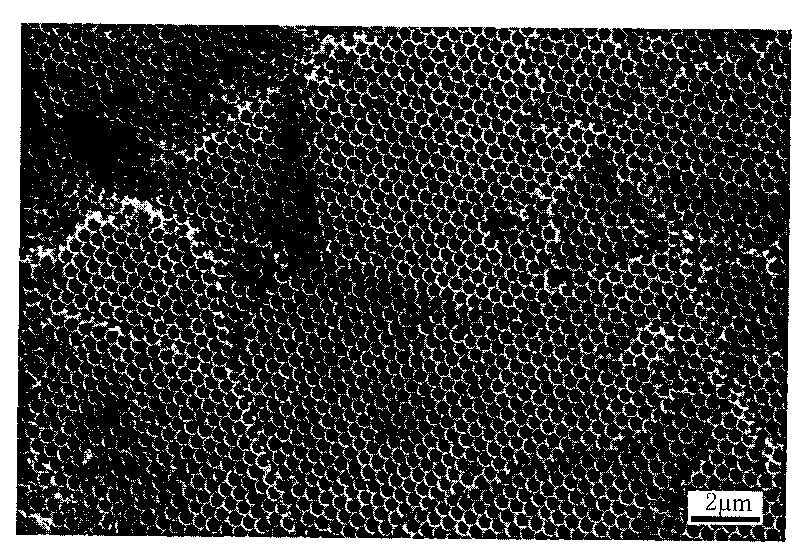

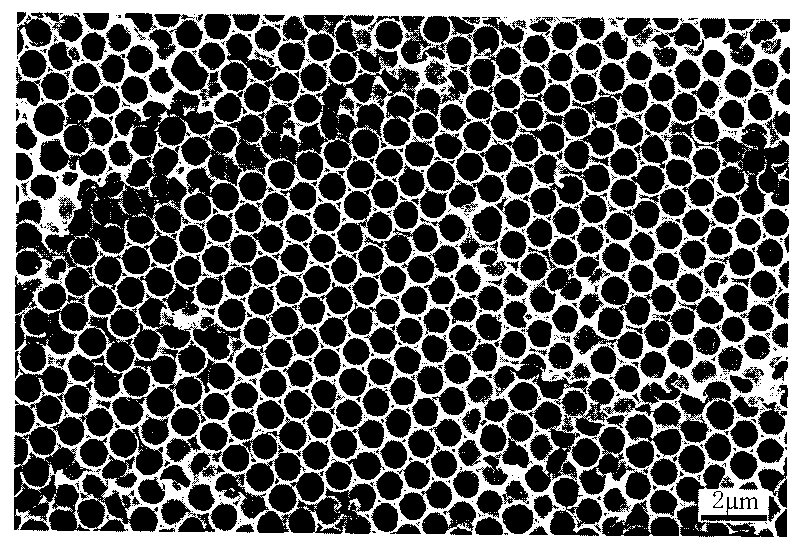

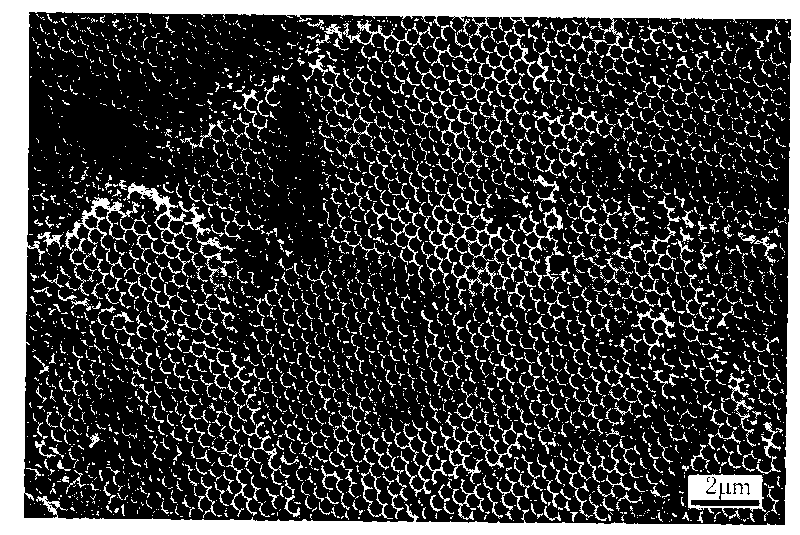

InactiveCN101691426AReduce resistanceEasy accessOther chemical processesDiffusion resistancePorous channel

The invention relates to a method of preparing three-dimensionally ordered macroporous chelate resin which has a hydrophilic-structure framework and can absorb precious metal irons in aqueous solution, belonging to the field of the chelate resin. The method of preparing the three-dimensionally ordered macroporous chelate resin comprises the following steps: (1) preparing 80-1000nm silica colloidal crystal template; (2) preparing three-dimensionally ordered Poly(N-vinylformamide) or poly(n-vinylacetamide) macroporous material; and (3) preparing hydrophilic three-dimensionally ordered macroporous chelate resin. Compared with the traditional macroporous or gel-type polyvinylamine resin, the novel three-dimensionally ordered macroporous chelate resin prepared with the method has the advantages that the regularly-arranged porous channel system has small diffusion resistance, which is good for the metal irons enter the absorption center from all directions. In addition, the novel three-dimensionally ordered macroporous chelate resin is easy to synthesize, has stable performance, good hydrophilic performance and high selectivity, contains many functional groups, can absorb a large number of metal irons and has better development and utilization values in the aspect of avoiding heavy metal pollution and protecting the environmental water.

Owner:HEBEI UNIV OF TECH

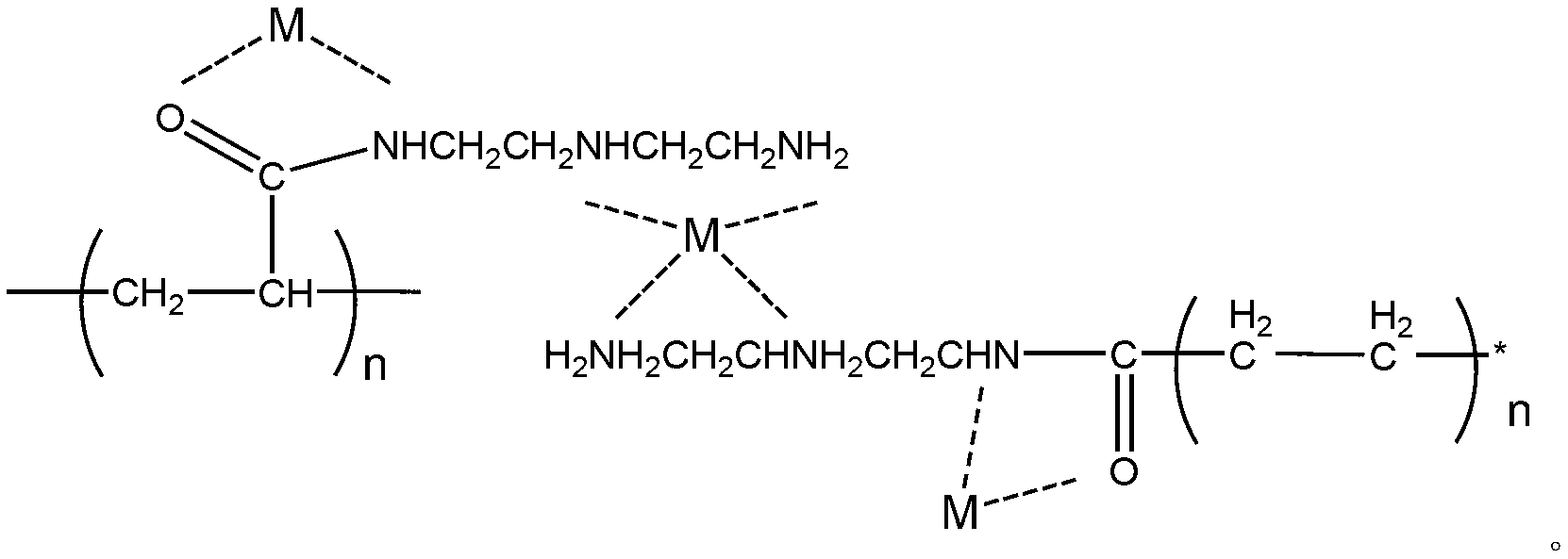

Acrylic-acid high-capacity primary-amino chelate resin for trapping copper ions and preparation method thereof

ActiveCN103159888ALarge adsorption capacityImprove adsorption capacityOther chemical processesWater contaminantsWastewaterAminolysis

The invention discloses an acrylic-acid high-capacity primary-amino chelate resin for trapping copper ions and a preparation method thereof, belonging to the field of polyamine resin wastewater treatment. The structural unit of the primary-amino chelate resin disclosed by the invention is disclosed in the specification, wherein x represents a repetitive structure unit of different aminolysis reagents. The preparation method disclosed by the invention has the advantages of wide material sources, low cost, simple operation steps and controllable synthesis conditions; and the synthesized resin has superhigh adsorption capacity for copper ions.

Owner:NANJING UNIV

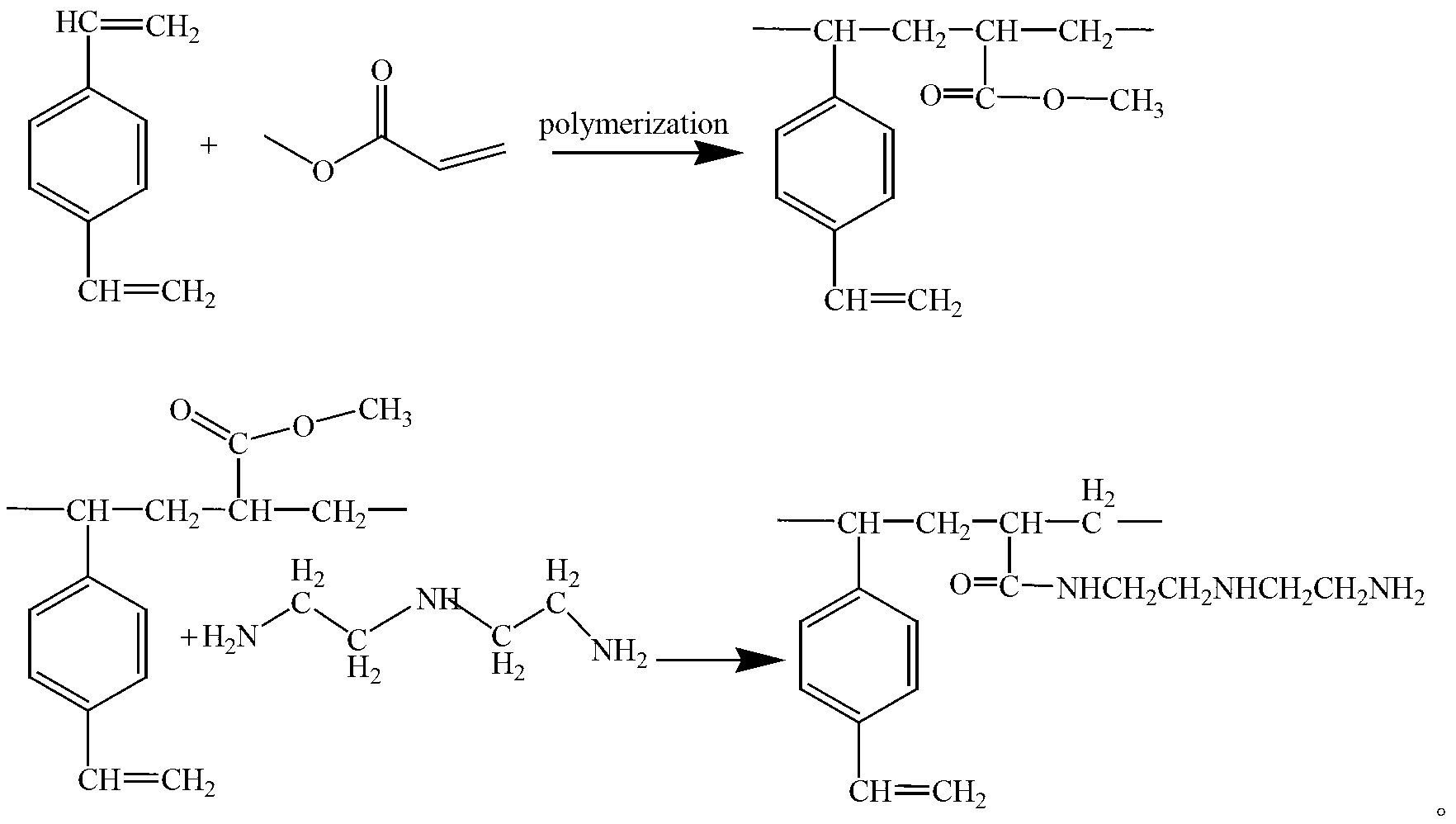

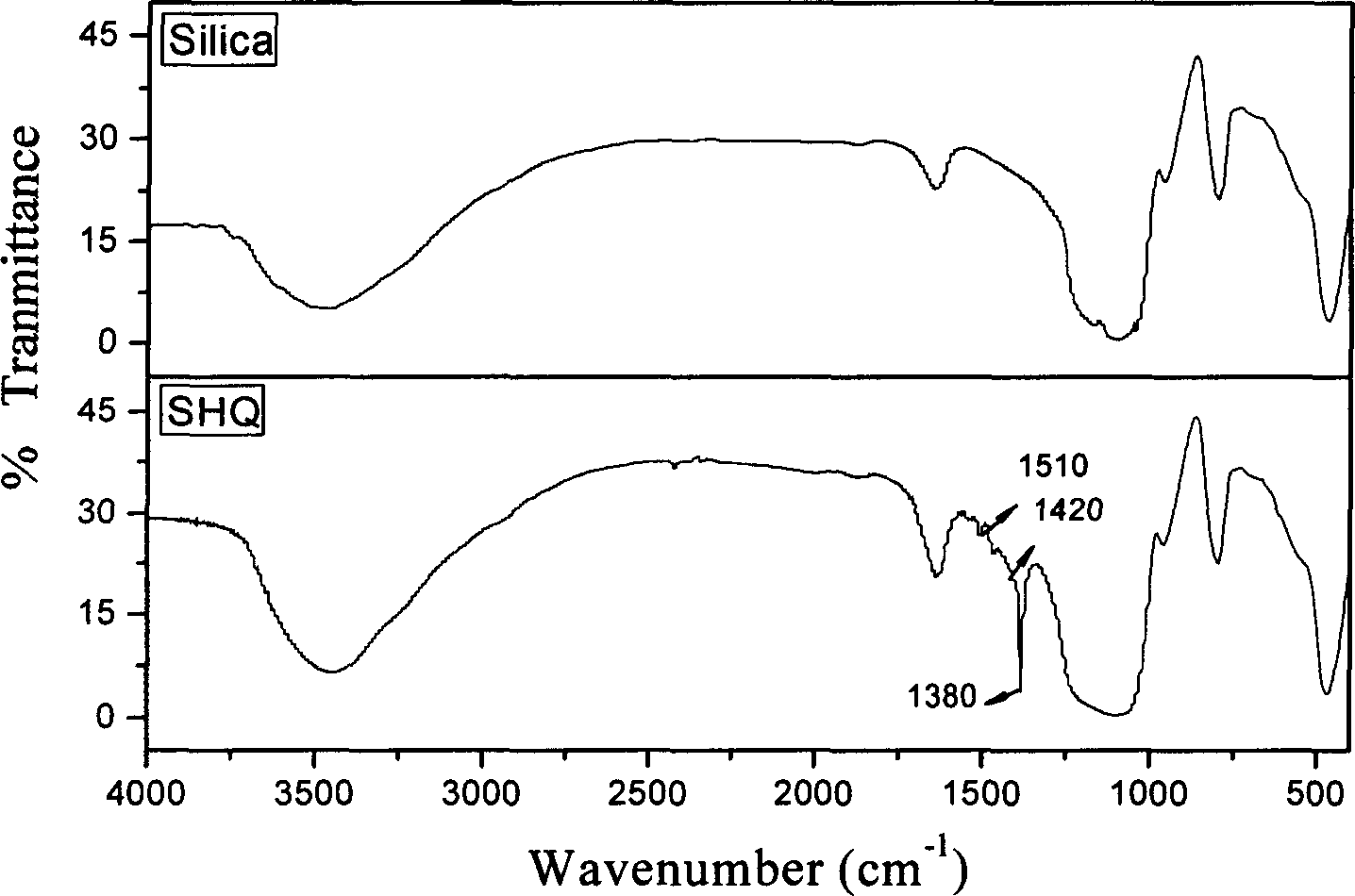

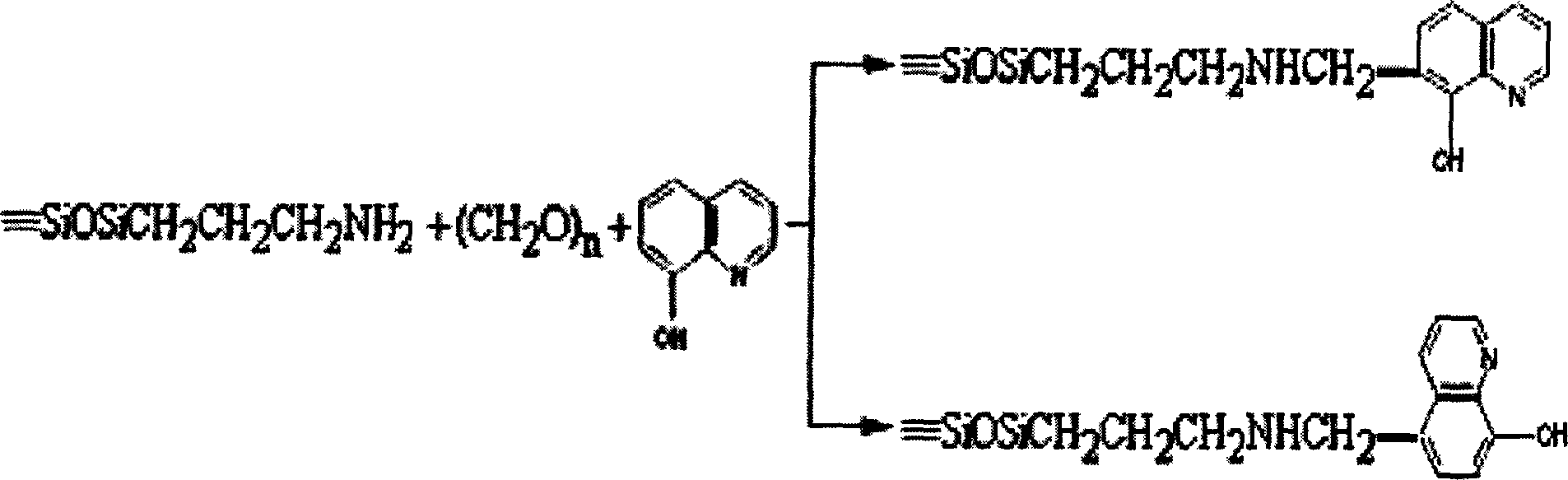

8-hydroxy quinoline type chelated resin and its synthesis

InactiveCN1772386AImprove rigidityImprove the coordination effectComplex ion-exchangersIndustrial waste waterQuinoline

The 8-hydroxy quinoline type chelated resin has 8-hydroxy quinoline fixed onto macroporous silica gel through silanizing reagent and paraformaldehyde as spacer arm and bonding amount of 120-542 umol / g. Its synthesis process includes the steps of: pre-treating macroporous silica gel; introducing spacer arm; fixing ligand and acid washing to set via drying intermediate product II, washing with alcohol and drying for several times, washing with hydrochloric acid, and washing with deionized water to neutral so as to obtain yellow chelated resin. The resin has simple synthesis process, mild reaction condition, short synthesis time, easy control, high synthesis efficiency, low cost, high rigidity and high metal ion complexing capacity, and may be used in on-line enriching analysis of trace metal, enriching recovery of noble metals, purifying industrial waste water, etc.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

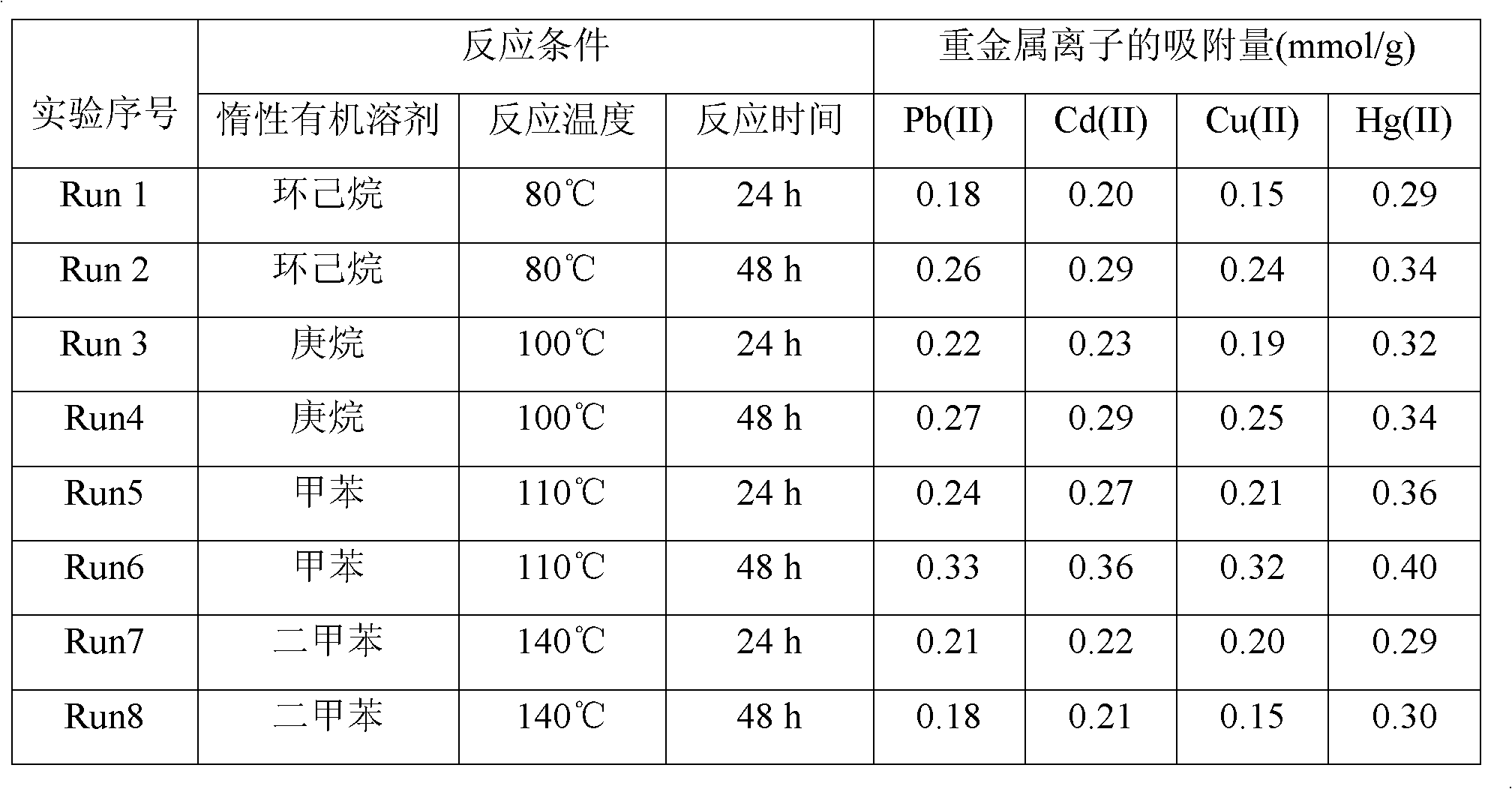

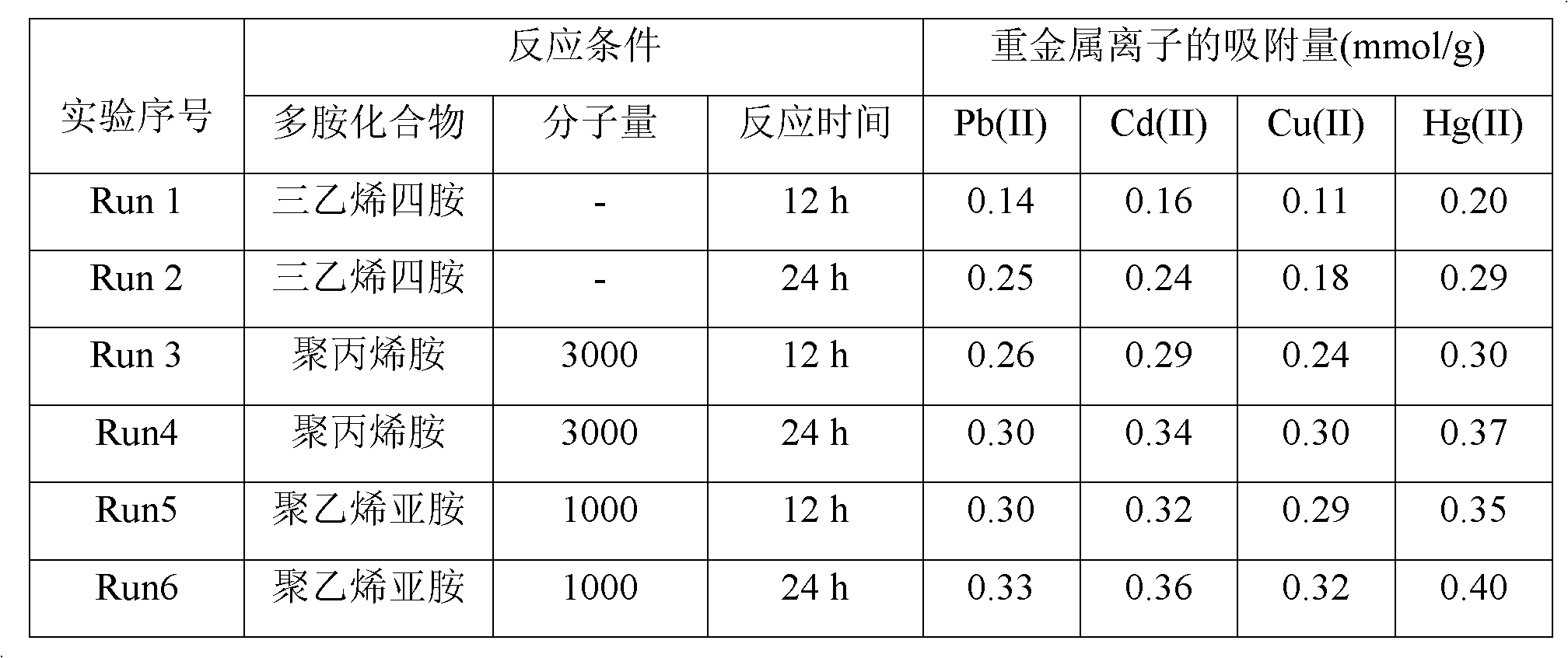

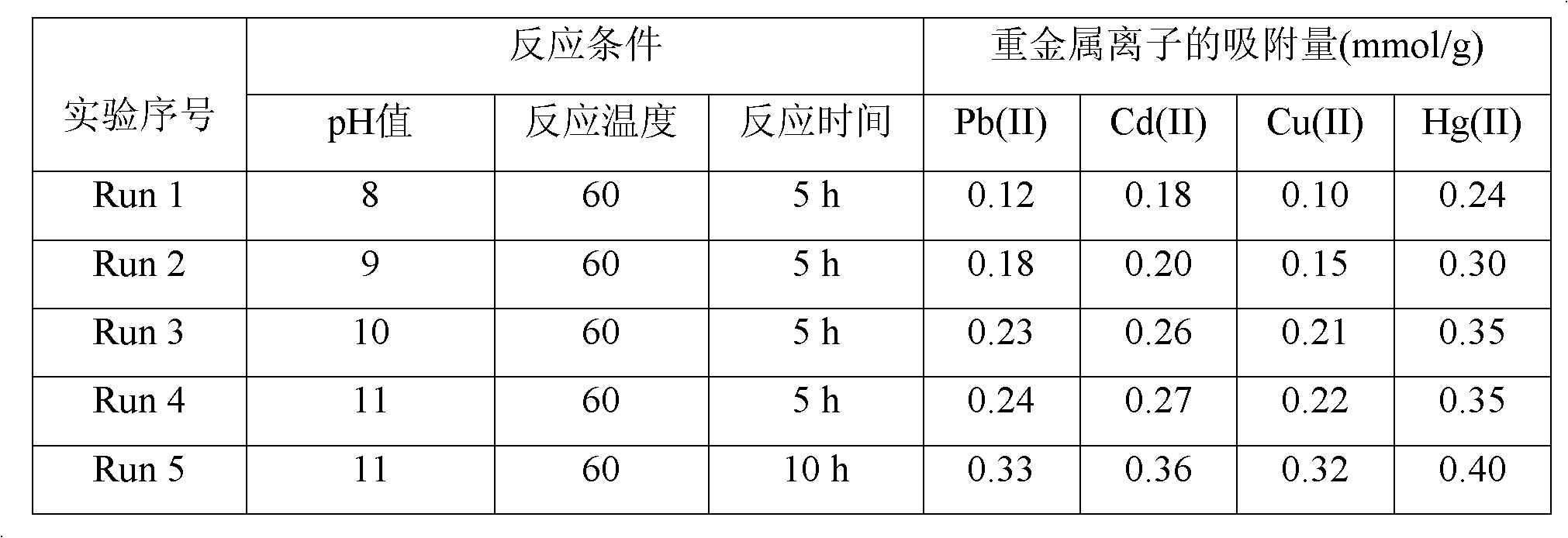

Method for preparing silica gel supported dithiocarbamate heavy metal chelating resin

InactiveCN102060995ALarge adsorption capacityImprove adsorption capacityOther chemical processesHeavy metal chelationSilica gel

The invention relates to a method for preparing heavy metal chelating resin, in particular to a method for preparing silica gel supported dithiocarbamate heavy metal chelating resin and adsorption of heavy metals such as lead, cadmium, copper, mercury and the like by the resin. The method comprises the following steps of: reacting carbon disulfide with a polyamine compound to generate a dithiocarbamate compound; and grafting the dithiocarbamate compound onto the surface of silicon dioxide, wherein a halogen group is modified on the surface of the silicon dioxide. By the method, the adsorption capacity of dithiocarbamate chelating resin is effectively improved; and the problem that silica gel is dissolved due to too high alkalinity of a reaction system (pH value is more than 11), or the dithiocarbamate compound cannot be generated through reaction due to too low alkalinity (the pH value is less than 10) when a dithiocarbamate functional group is prepared by reacting the silica gel with the carbon disulfide in the conventional synthetic route is solved, wherein an amino group is modified on the surface of the silica gel.

Owner:CENT SOUTH UNIV

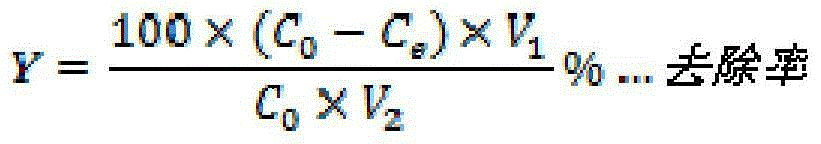

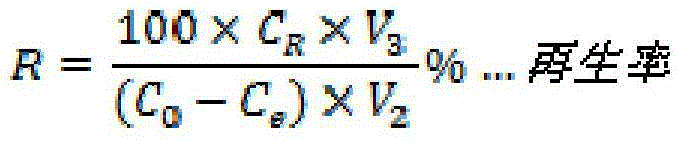

Method for simultaneous removal and recovery of heavy metal ions and organic acid by using chelating resin

ActiveCN104129831ACut heavy metalReduce concentrationWater/sewage treatment by ion-exchangeHigh concentrationOrganic acid

The invention discloses a method for simultaneous removal and recovery of heavy metal ions and organic acid by using s chelating resin, belonging to the field of resource treatment of heavy metal and organic acid composite wastewater. The invention comprises the following steps: (1) regulating the pH value of composite wastewater containing heavy metal ions and organic acid, pumping the wastewater into an adsorption columns packed with chelating resin, wherein metal removal rate is greater than 56%, the removal rate of organic acid is more than 58%, and the chelating resin is chelating resin containing primary amine groups; (2) conducting desorption on the chelating resin from the step (1) by a conventional inorganic acid desorption agent, and recovering a mixed solution of high concentration heavy metals and organic acid; stopping the desorption when no heavy metal or organic acid is detected in outlet water; and washing the resin after desorption to a neutral state for reuse. The invention is applicable to the simultaneous great reduction of concentrations of heavy metals and organic acid pollution and recovery of high concentration heavy metal ion and organic acid resources, so as to realize harmless treatment and resource recycling of the composite pollutants.

Owner:南京华创环境技术研究院有限公司

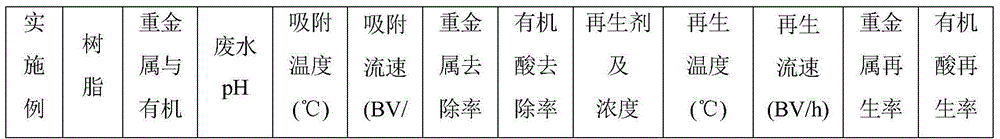

Method for producing battery-grade lithium hydroxide by utilizing battery-grade lithium carbonate lithium-depositing mother liquid

InactiveCN107986301ASimple processReduce manufacturing costLithium oxides/hydroxidesLithium hydroxideEvaporation

The invention discloses a method for producing battery-grade lithium hydroxide by utilizing battery-grade lithium carbonate lithium-depositing mother liquid. The method comprises the following steps:(1) accurately filtering the lithium-depositing mother liquid to remove undissolved substances; (2) adding sulfuric acid into the solution and removing carbonate radical through a stripping tower; (3)enabling the solution to flow through a chelate resin system to remove calcium and magnesium; (4) adding NaOH into the solution and transforming Li2SO4 into LiOH; (5) performing evaporation and concentration on the solution until the crystal slurry is 10 to 40 percent and performing centrifugal separation to obtain LiOH concentrated liquid; (6) cooling the LiOH concentrated liquid to 10 to 5 DEGC and separating out sodium to obtain LiOH purified liquid; (7) performing evaporation and concentration on the LiOH purified liquid and performing centrifugal separation to obtain a LiOH crystal; (8)recrystallizing the LiOH crystal to obtain the battery-grade lithium hydroxide. By the method, the battery-grade lithium hydroxide can be produced by circularly recovering the lithium-depositing mother liquid, the recovery rate of the lithium is increased and the production cost is reduced.

Owner:GANFENG LITHIUM CO LTD

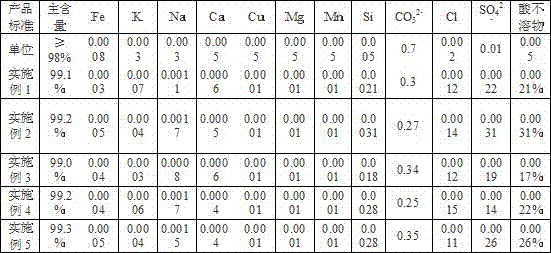

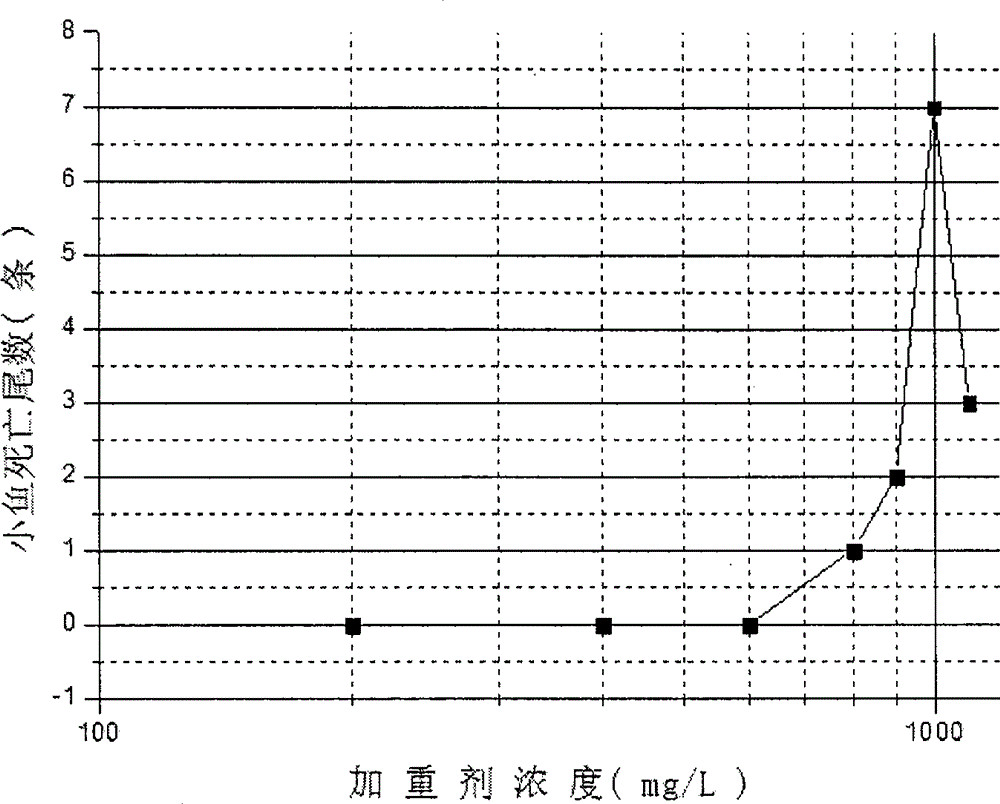

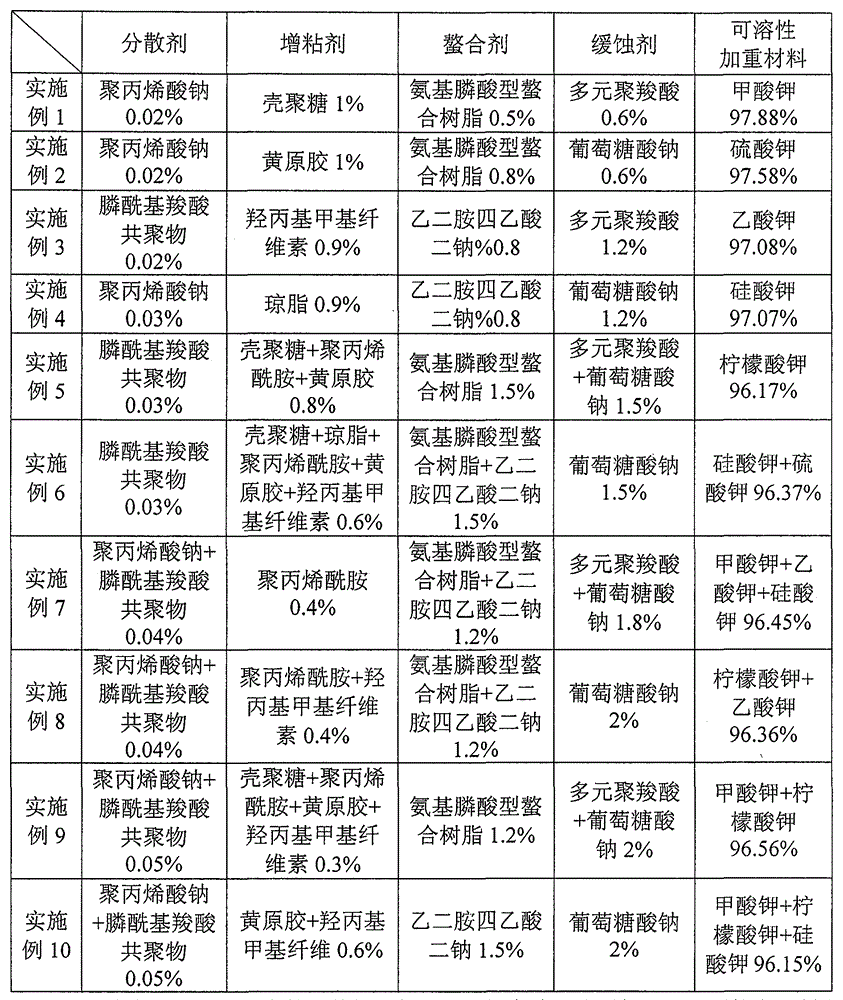

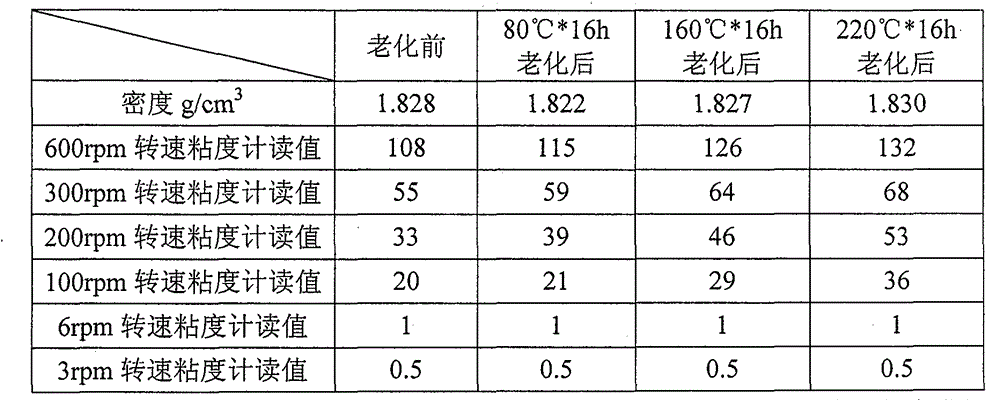

Environment-friendly high-density solid-free weighting agent and preparation method

ActiveCN104610937AWide range of densitiesReduce pollutionDrilling compositionCarboxylic acidPotassium formate

An environment-friendly high-density solid-free weighting agent comprises components in parts by weight as follows: 0.02-0.05 parts of a dispersant, 0.3-1 part of a tackifier, 0.5-1.2 parts of chelating agent, 0.6-2 parts of a corrosion inhibitor and the balance of soluble weighting materials, wherein the dispersant is one or two of sodium polyacrylate and copolymer of phosphono and carboxylic acid; the tackifier is one or more of chitosan, agar, polyacrylamide, xanthan gum and hydroxypropyl methyl cellulose; the chelating agent is one or two of aminophosphonic acid chelate resin and ethylenediamine tetraacetic acid disodium; the corrosion inhibitor is one or two of multiple polycarboxylate and sodium gluconate; the soluble weighting materials are one or more of potassium formate, potassium citrate, potassium acetate, potassium silicate and potassium sulfate. The process steps are as follows: the raw materials are taken in weight proportion, mixed and uniformly stirred; the raw materials are added to water and dissolved at the high temperature of 70-80 DEG C; a product is evaporated to dryness, and solid is obtained; the obtained solid is ground into powder, and the solid weighting agent is obtained.

Owner:成都西油华巍科技有限公司

Preparation method of ion imprinted hydroxamic acid chelate resin

ActiveCN103012677ALarge adsorption capacityHigh adsorption selectivityOther chemical processesHigh absorptionHydroxamic acid

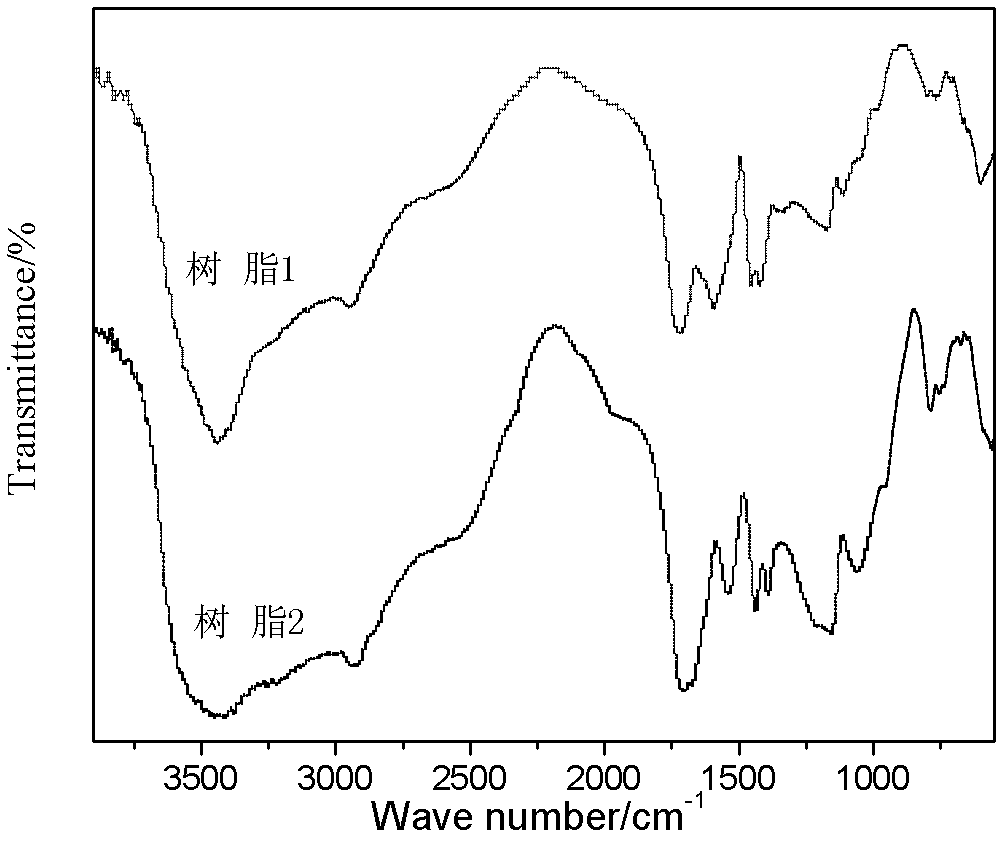

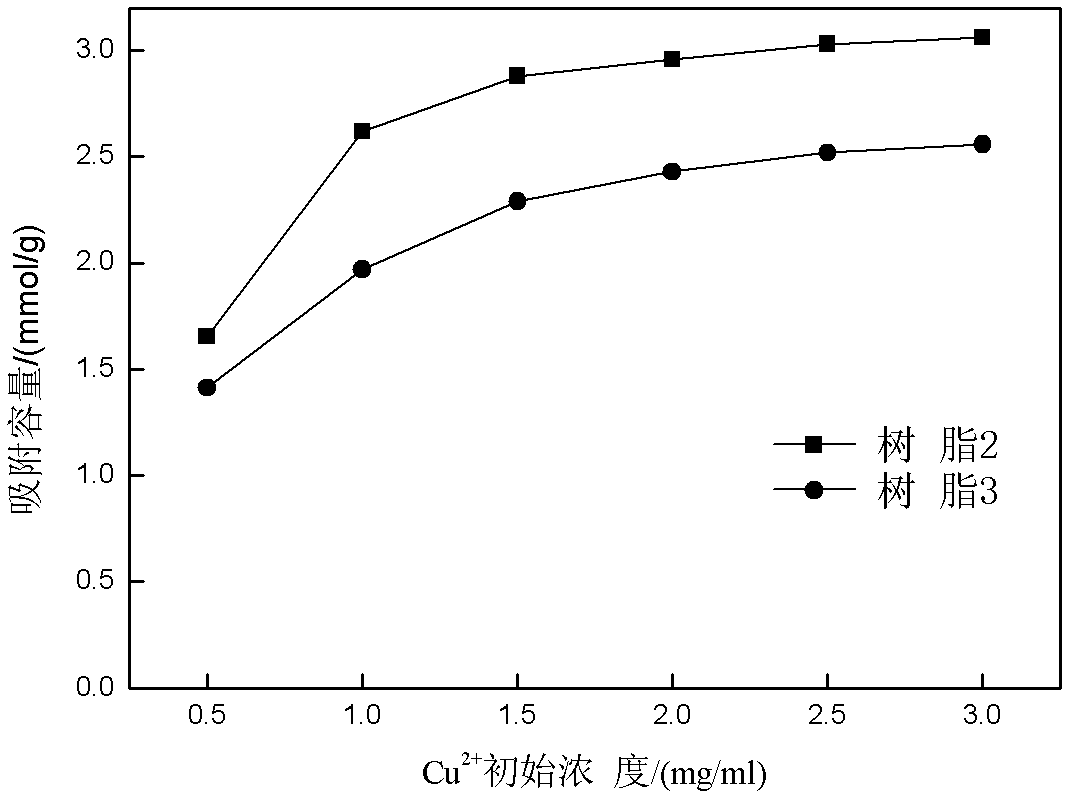

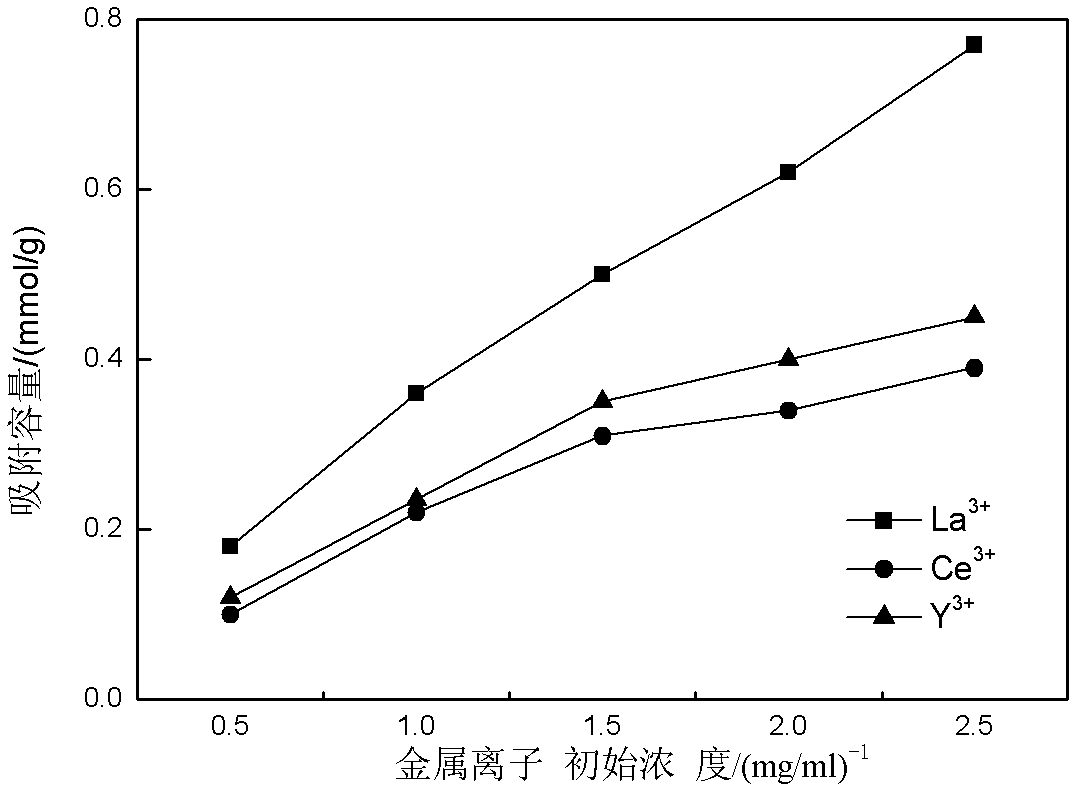

The invention discloses a preparation method of ion imprinted hydroxamic acid chelate resin. According to the invention, propenyl hydroxamic acid is subjected to coordination with imprinting metal ions such as manganese, copper, cobalt, nickel, lanthanum, cerium, yttrium, praseodymium, neodymium, and the like; under the effects of a crosslinking agent and an initiating agent, a propenyl hydroxamic acid-metal ion chelate is polymerized; and the imprinting metal ion is eluted, such that the ion imprinted hydroxamic acid chelate resin is obtained. The method provided by the invention has the advantages of mild reaction condition and high reaction efficiency. The prepared resin has the advantages such as high absorption capacity, high absorption selectivity, and the like.

Owner:CENT SOUTH UNIV

A kind of 6-aminopyridine-3-carboxylic acid chelating resin and preparation method thereof

ActiveCN102295723AHigh stability constantGood choiceOther chemical processesPolymer scienceChloromethyl Ether

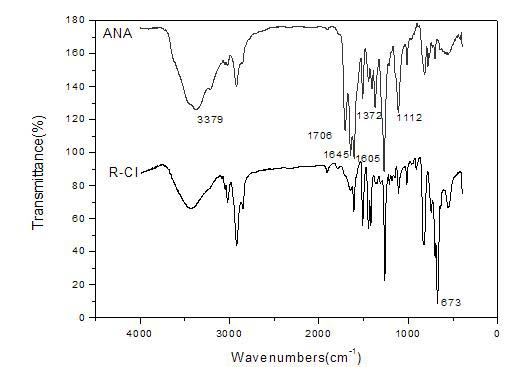

The invention discloses a 6-aminopyridine-3-carboxylic acid chelating resin and its preparation method, which belongs to the field of chelating resin. The resin has a following structural unit: a functional group is 6-aminopyridine-3-carboxylic acid, wherein the color is yellowish, the particle size is 0.45-0.6 mm, the content of the functional group is 1.37-2.38 mmol / g. The preparation method comprises the following steps: using styrene as a monomer, employing a suspension polymerization method to prepare a low crosslinking degree macroporous styrene-divinylbenzens copolymer, air-flow dryingto obtain low crosslinking macroporous polystyrene-divinylbenzens resin (white ball for short); immersing the white ball in chloromethyl ether, adding zinc chloride as a catalyst, carrying out a chloromethylation reaction to obtain chloromethylated low crosslinking polystyrene-divinylbenzens resin (chlorine ball for short); taking N,N-dimethyl formamide as a swelling agent, taking DMF as a swelling agent to swell the chlorine ball, dissolving 6-aminopyridine-3-carboxylic acid and sodium carbonate in N, N-dimethyl formamide for reaction, then adding the above swelled chlorine ball, stirring for reacting to prepare 6-aminopyridine-3-carboxylic acid chelating resin. The resin prepared by the invention is suitable for selectively absorbing and separating heavy metal ions of copper and the like.

Owner:NANJING UNIV

Purifying method of waste brine in glyphosate production

ActiveCN104163519ASolve problems such as difficulty in utilization as by-productsMultistage water/sewage treatmentNature of treatment waterChemical treatmentChlorine dioxide

The invention discloses a chemical treatment method, and concretely relates to a purifying method of waste brine in a glyphosate production process. The method comprises the following steps: adjusting the total phosphorus content and TOC and total nitrogen L in the waste brine, adjusting the pH value of the waste brine to 6-10, and carrying out nanofiltration membrane separation to obtain a penetrating fluid; processing the penetrating fluid by adopting a catalytic oxidation technology to obtain a first stage salt solution, wherein the catalytic oxidation is one or a combination of more of a Fenton oxidation processes, a hydrogen peroxide active carbon oxidation process, a sodium hypochlorite active carbon oxidation process, an ozone active carbon oxidation process and a chlorine dioxide oxidation process; and adsorbing by adopting an adsorbent to obtain a second stage salt solution, wherein the adsorbent can be one or a combination of more of macro-porous adsorption resin, chelating resin, molecular sieve, silica gel and activated alumina. The method can effectively solve the problems of difficult treatment, difficult us of waste salt as a byproduct and the like, and has very high economic and social benefits.

Owner:浙江海禹环保科技有限公司

Preparation method for novel three-dimensional ordered macroporous chelating resin

InactiveCN101670274AExcellent physical and chemical propertiesStrong chemical resistanceOther chemical processesMolecular materialsChelating resin

The invention relates to a high molecular material, in particular to a preparation method for a novel three-dimensional ordered macroporous chelating resin. The technological process comprises the following steps: (1) preparation of a silica colloidal crystal template; (2) preparation of a three-dimensional ordered macroporous material (3DOM); (3) chloromethylation of the 3DOM; (4) controlled grafting of a hydrophilic chain segment by using the 3DOM; (5) esterification of phenylsulfonyl for a PHEMA grafted chain; and (6) accessing chelation groups on the PHEMA grafted chain. The prepared three-dimensional ordered macroporous material is a polymer material, the pores are uniform and ordered, and more than one chelation group is accessed on each chain segment, therefore, the adsorptive capacity of the three-dimensional ordered macroporous chelating resin is far higher than that of other types of resin, and the adsorptive capacity to Hg<2+> is up to 1.96 mmol / g.

Owner:HEBEI UNIV OF TECH

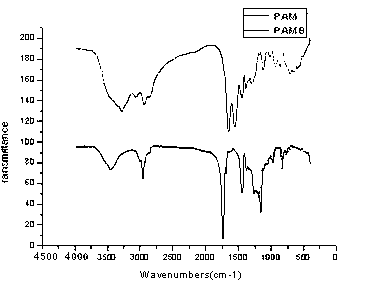

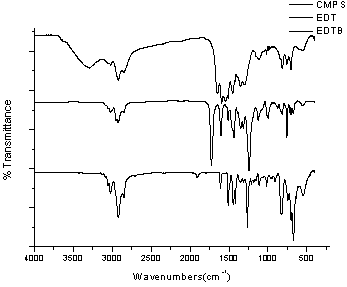

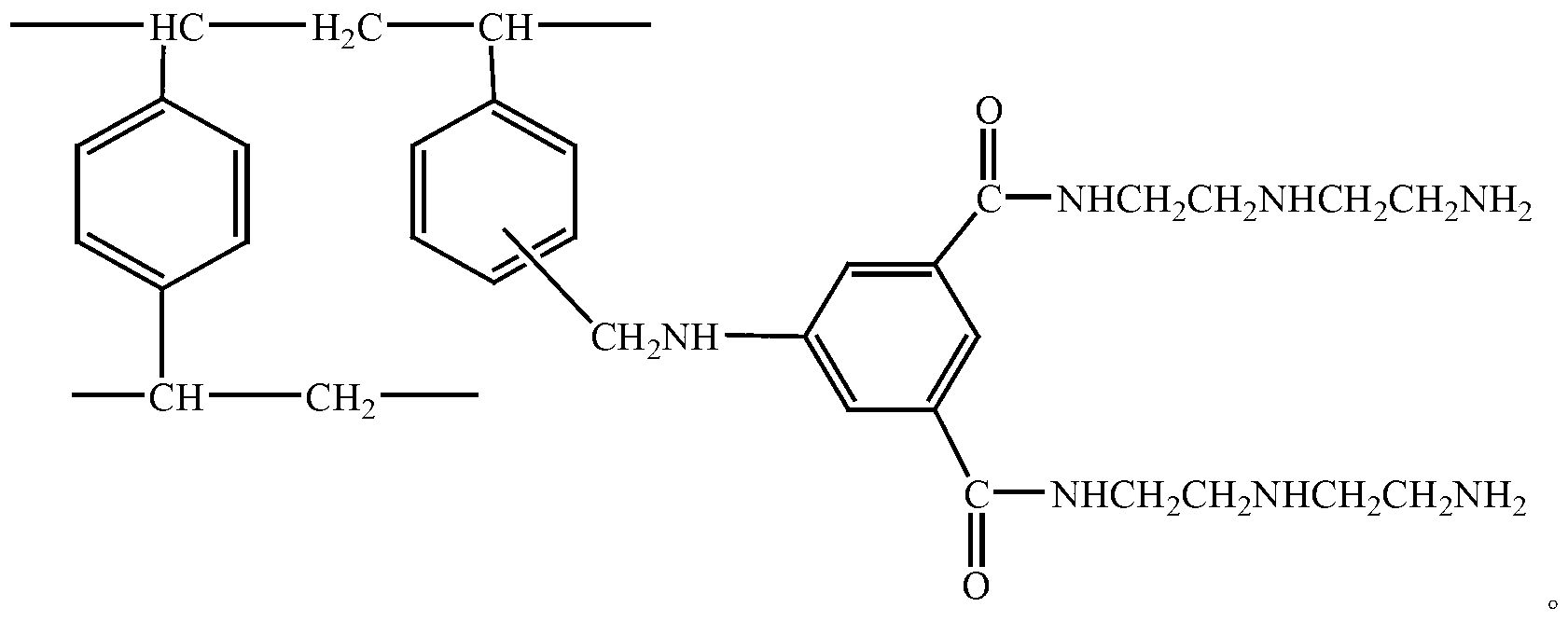

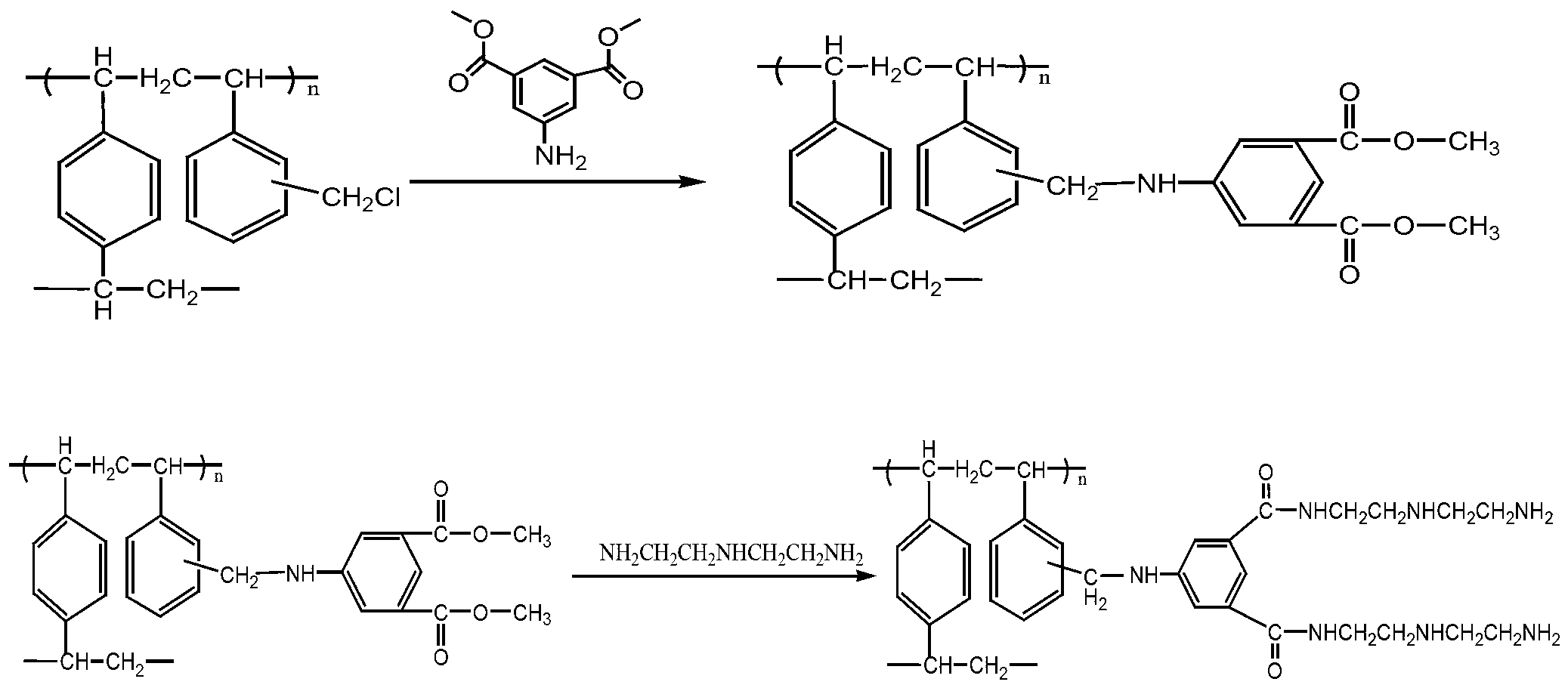

Primary diamido chelating resin and preparation method thereof

ActiveCN103073667AHigh adsorption selectivityWide range of usesOther chemical processesWater/sewage treatment by sorptionWastewaterCopper

The invention discloses primary diamido chelating resin and a preparation method thereof and belongs to the field of chelating resin waste water treatment. A constitutional unit of the primary diamido chelating resin is as follows as shown in the specification. The chelating resin has a certain space structure, and primary diamido groups of the resin has special adsorptive selectivity to copper ions.

Owner:NANJING UNIV

Polymers of intrinsic microporosity containing tetrazole groups

InactiveUS20120264589A1Extending possible structureIncreasing gas pair selectivityOther chemical processesIon-exchanger regenerationTetrazoleClick chemistry

The invention provides a tetrazole-containing polymer of intrinsic microporosity comprising (10) or more subunits, wherein one or more of the subunits comprise one or more tetrazolyl moieties. In one embodiment, a polymer of intrinsic microporosity (PIM-1) was modified using a “click chemistry” [2+3] cycloaddition reaction with sodium azide and zinc chloride to yield new PIMs containing tetrazole units. Polymers of the present invention are useful as high-performance materials for membrane-based gas separation, materials for ion exchange resins, materials for chelating resins, materials for superabsorbents, materials for ion conductive matrixes, materials for catalyst supports or materials for nanoparticle stabilizers.

Owner:NAT RES COUNCIL OF CANADA

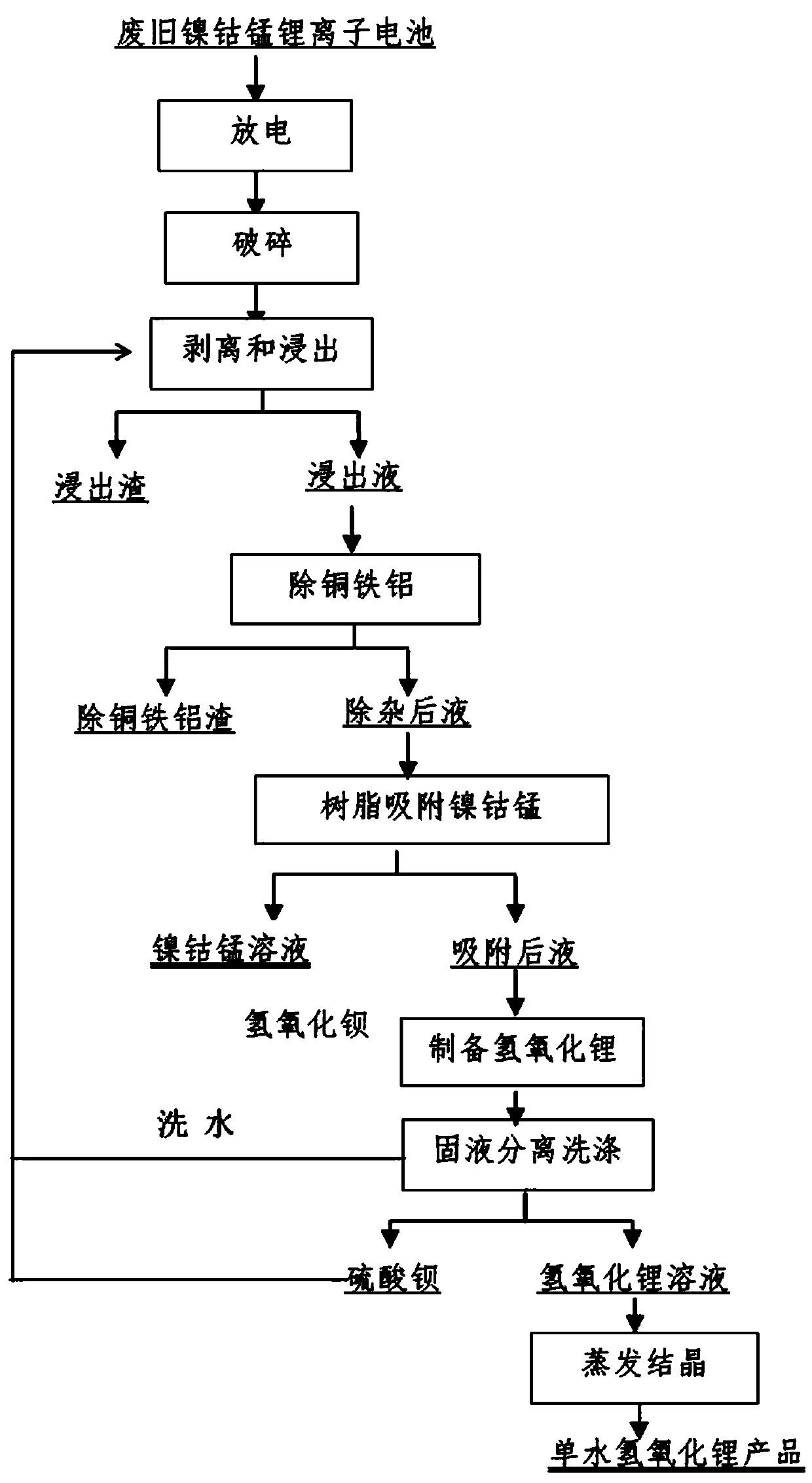

Method for recovering valuable metals in waste nickel-cobalt-manganese lithium ion battery by ion exchange method

InactiveCN110527836AAvoid introducingEliminate the evaporation crystallization processIon-exchange process apparatusIon-exchanger regenerationHigh sodiumIon content

The invention relates to a method for recovering the valuable metals in a waste nickel-cobalt-manganese-lithium ion battery by an ion exchange method, which comprises the following steps of disassembling, discharging and crushing the waste nickel-cobalt-manganese-lithium ion battery, leaching, replacing the leachate with nickel powder or cobalt powder to remove the copper, and hydrolyzing with a valuable metal alkali solution as a neutralizer to remove the iron and aluminum; regenerating the chelating resin with a lithium hydroxide solution, adsorbing the nickel, cobalt and manganese in the impurity-removed solution, and backwashing with sulfuric acid to obtain a nickel-cobalt-manganese mixed solution; and recovering the lithium in the liquid after resin adsorption in the form of lithium hydroxide. According to the method, the stripping and leaching of the waste nickel cobalt lithium manganate ion battery are completed in one step, the impurity elements are not introduced during the leachate impurity removal and valuable metal separation and extraction process, the lithium hydroxide used for ion exchange resin is regenerated via the lithium hydroxide, at the same time, the nickel-cobalt-manganese is absorbed, so that the lithium is prevented from being adsorbed and entering a nickel, cobalt and manganese solution to be lost, and the lithium recovery is prevented from being influenced due to the high sodium ion content in the solution with the sodium hydroxide. According to the present invention, the recovery rate of nickel, cobalt and manganese reaches 98% or above, the recovery rate of lithium reaches 90% or above, the technological process is short, the equipment is few, and the cost is low.

Owner:JINCHUAN GROUP LIMITED +1

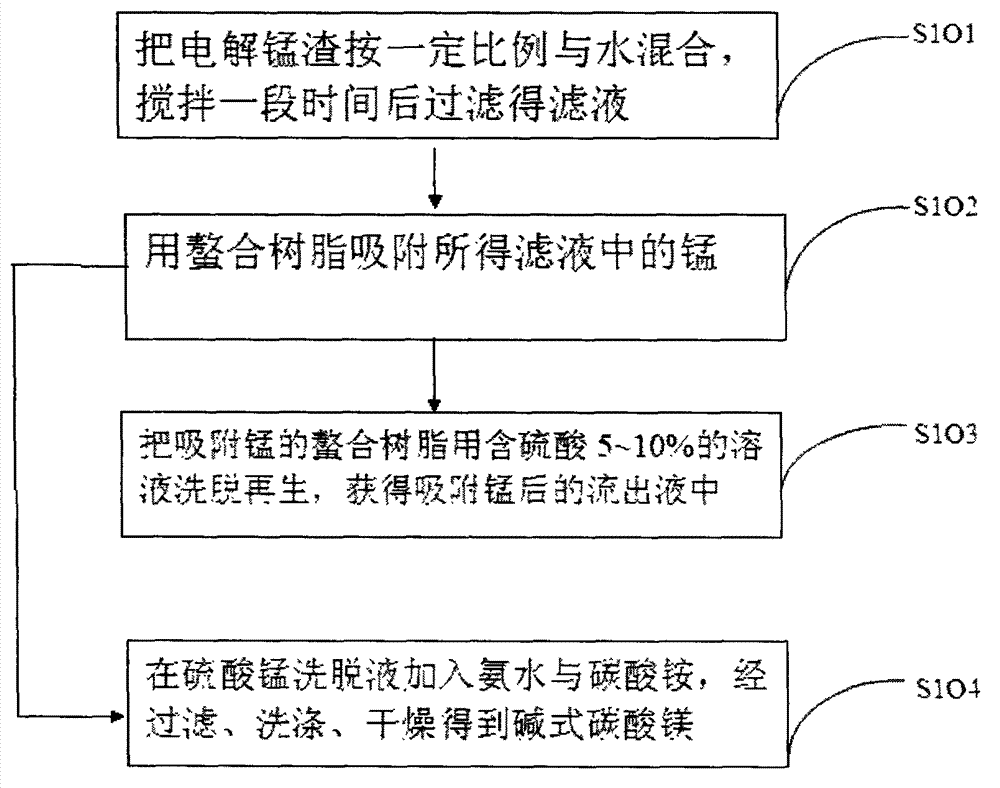

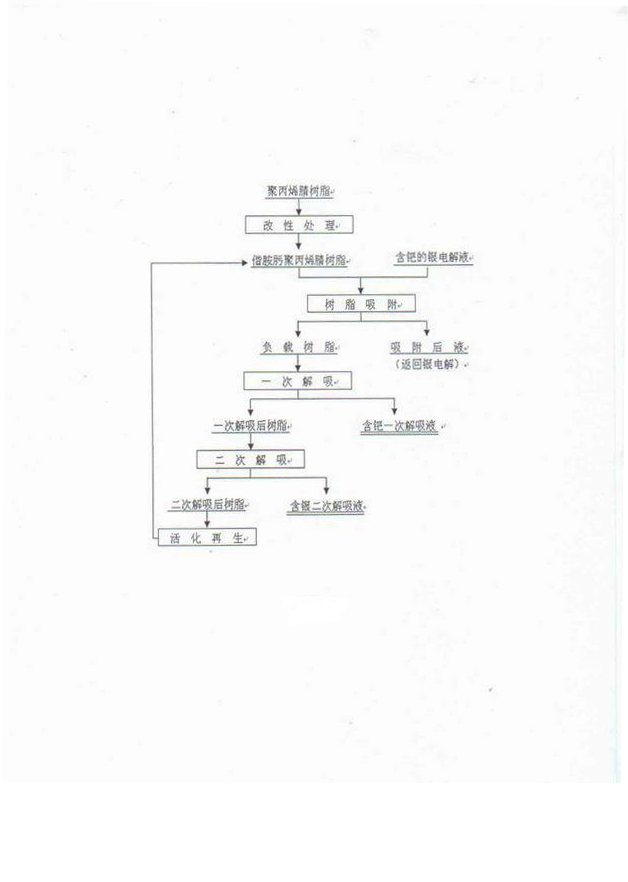

Method for recovering water soluble manganese and magnesium from electrolytic manganese residue

The invention discloses a method for recovering water soluble manganese and magnesium from electrolytic manganese residue. The method comprises the following steps: firstly, soluble salt in the electrolytic manganese residue is dissolved with water; secondly, by utilizing the manganese combining capability of chelating resin , which is far stronger than the magnesium combining capability of the chelating resin, a liquid is allowed to flow through a chelating resin column, manganese is absorbed and then flows out along with an outgoing liquid; and after absorbing the manganese, a resin-used sulfuric acid liquid is eluted to recover, thus the manganese is changed into a manganous sulfate liquid and enters into the liquid preparation procedures for an electrolytic manganese production system, and also can be used to prepare manganese salt. Liquid ammonia and ammonium carbonate are added into the outgoing liquid absorbing the manganese to enable the magnesium to deposit; alkali magnesium carbonate is obtained via filtering, washing and drying; and the deposited and filtered liquid is an ammonium sulfate liquid, which can be used to produce chemical fertilizers and electrolyte manganese production, and solves the problems that the electrolyte manganese residue contains a large amount of soluble manganese salt and magnesium salt and can enter into a soil environment, an underground water environment and a surface water to cause resource waste and environmental pollution.

Owner:JISHOU UNIVERSITY

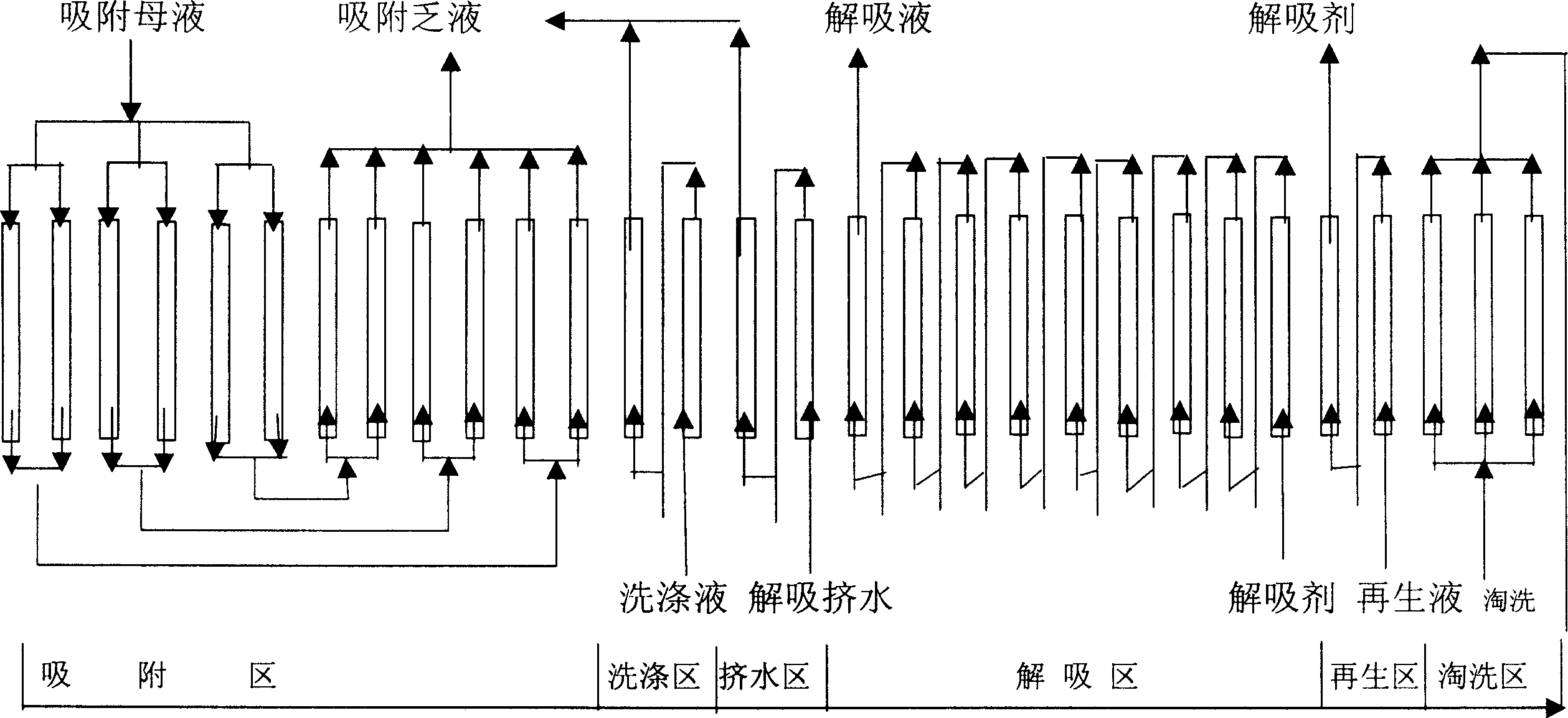

Method for extracting metallic gallium from aluminium oxide production procedure

ActiveCN1912153AMeet the requirements for extractionIncrease concentrationProcess efficiency improvementSeparation technologyAqueous sodium hydroxide

The invention relates to a method for extracting gallium from alumina production flow. It adopts ISEP ion separation technique and adsorption gallium chelating resin. Its technology conditions are as follows: back flow adsorbing that liquor in Bayer process is processed by two stage series connection to make gallium concentration difference be 50-60 mg / L; back flow washing by 0.5-1N sodium hydroxide solution for the resin; back flow desorbing by 2-3N sodium hydroxide and 0.6-1.0N sodium sulfide solution; back flow rebirthing by 0.5-1N sodium hydroxide solution for the resin. It has the advantages of short flow, simple operation, little resin abrasion, high automation etc.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Treatment method of chemical nickel-plating wastewater

ActiveCN104891632ARemove completelyLow costWaste water treatment from metallurgical processWater/sewage treatmentChelating resinPrecipitation

The invention discloses a treatment method of chemical nickel-plating wastewater. By the aid of hydrogen peroxide, hypophosphite remover can directly react with sodium hypophosphite to generate dissoluble hypophosphite precipitation under the acid condition, and total phosphorus can be more thoroughly removed; the hypophosphite remover contains trace ferrous ions, capable of catalyzing the hydrogen peroxide to generate hydroxyl free radicals of high oxidability, thus organic acid and organic amine complexing agents in the wastewater are completely destroyed. Therefore, after adjusting to alkalinity, the nickel in the wastewater can be directly removed by precipitating, and high-cost chemicals such as chelate resin and recapture agent are needed. The treatment method has no special requirements on equipment, thus investment cost is low, the cost of the chemicals used is low, and running cost is greatly lowered.

Owner:SUZHOU ZHANQING ENVIRONMENT PROTECTION TECHCO LTD

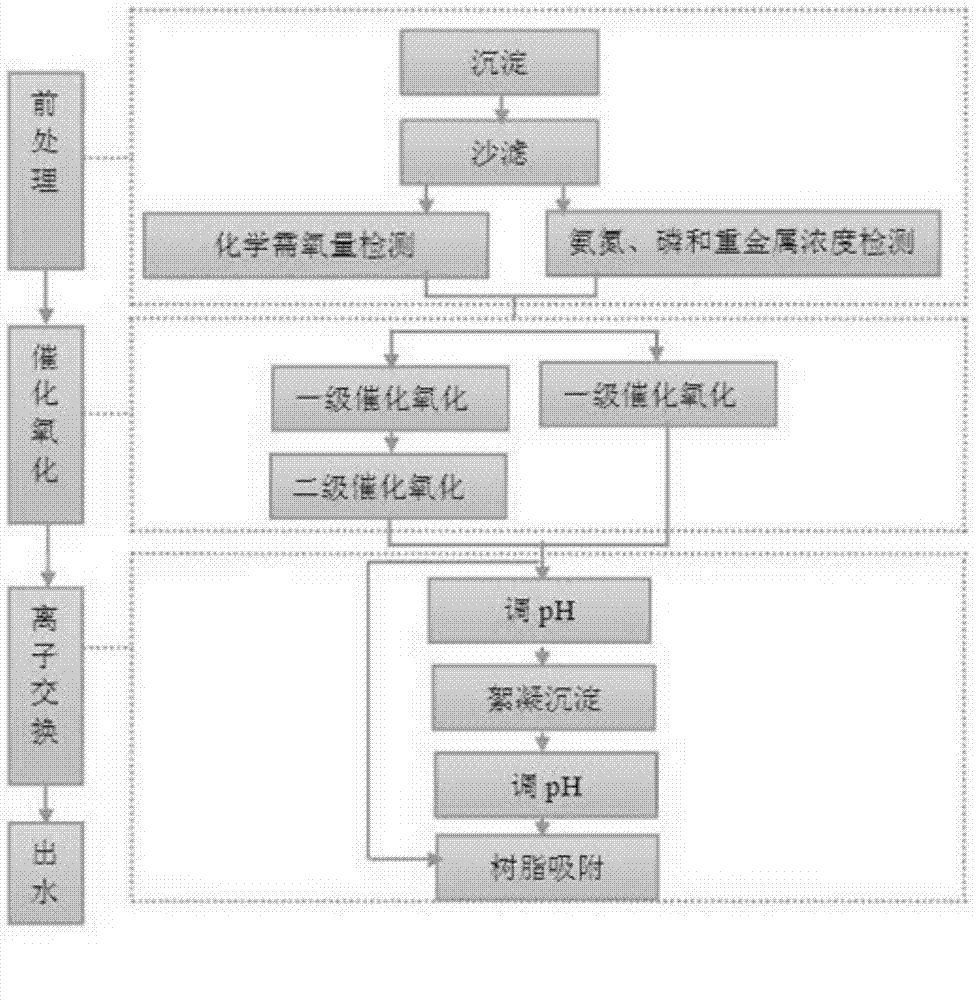

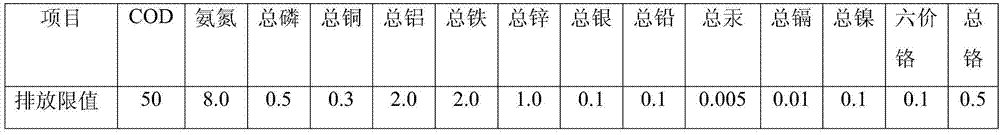

Electroplating comprehensive wastewater treatment process

InactiveCN104512975AExtended service lifeImprove pH requirementsWater treatment compoundsWater contaminantsActivated carbonChemical oxygen demand

The invention discloses an electroplating comprehensive wastewater treatment process, and relates to the technical field of electroplating wastewater treatment. The electroplating comprehensive wastewater treatment process comprises the following steps: step 1, pretreatment of electroplating comprehensive wastewater, comprising (1) precipitating and sand filtering; (2) wastewater composition detection; step 2, classified catalytic oxidation of the electroplating comprehensive wastewater, comprising (1) for the electroplating comprehensive wastewater with a chemical oxygen demand less than 950 mg / L, adopting one-stage heterogeneous Fenton-like reaction as catalytic oxidation; (2) for the electroplating comprehensive wastewater with a chemical oxygen demand more than or equal to 950 mg / L, adopting two-stage heterogeneous Fenton-like reaction as catalytic oxidation; step 3, ion exchange of the electroplating comprehensive wastewater: adopting chelate resin to adsorb corresponding heavy metal ions. The electroplating comprehensive wastewater treatment process disclosed by the invention improves the requirement of the Fenton technology on pH value, enhances the catalytic oxidation effect, prolongs the service life of activated carbon, prolongs the resin supersaturation time, ensures that the effluent meets the standard, reduces the cost, is convenient to operate, and facilitates implementation of large-scale automatic wastewater treatment.

Owner:SHENZHEN LVQIN ENVIRONMENTAL PROTECTION TECH CO LTD

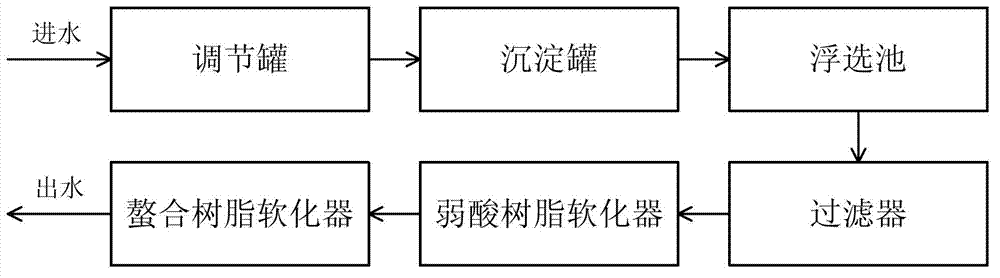

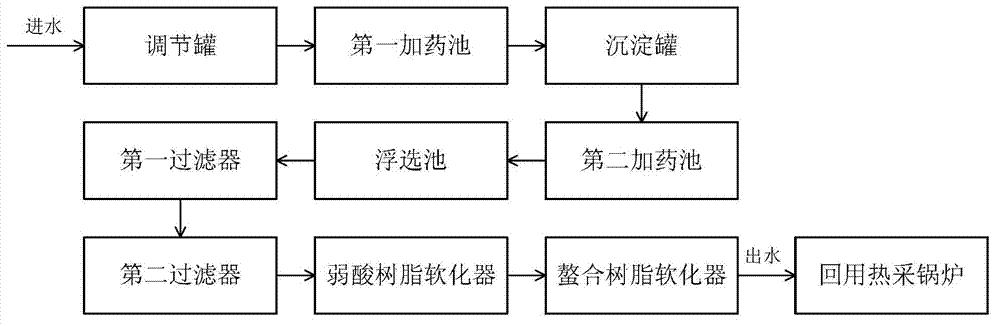

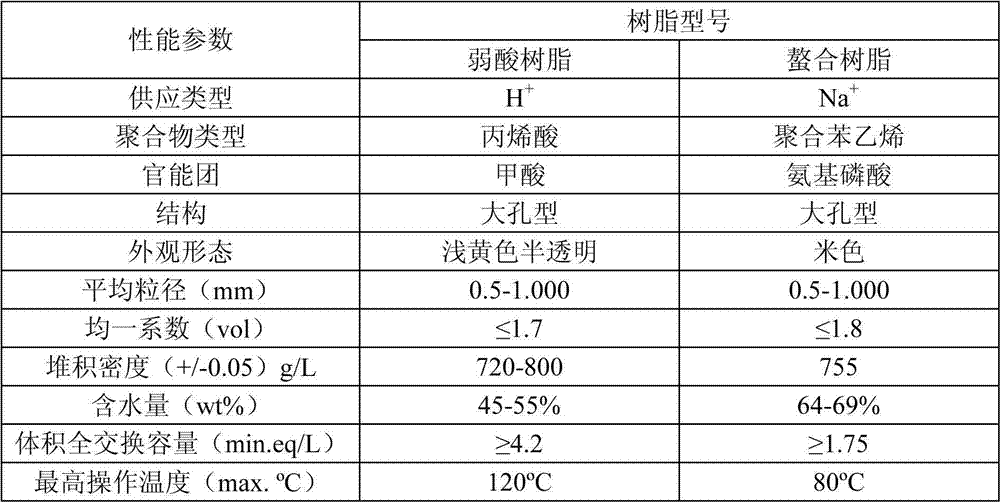

High silicon-containing waste water in oil field reuse boiler pretreatment technology and apparatus

ActiveCN102826680AReduced metal cation contentAdvantages of pretreatment processWaste water treatment from quariesMultistage water/sewage treatmentSolubilityChelating resin

The invention relates to a high silicon-containing waste water in an oil field reuse boiler pretreatment technology and an apparatus. The pretreatment technology comprises the following steps: adjusting the high silicon-containing waste water in the oil field and adding a reverse demulsifier; depositing the adjusted waste water, separating oil and water and removing the impurity in the waste water; adding a salt substance in the waste water after deposition treatment and performing air floatation treatment, removing an dissolved organic matter and oil, filtering the waste water after the air floatation treatment and removing suspended matters; using filtering weak acid resin for preliminarily softening the filtered waste water, reducing the concentration of high valent cationic to ppm grade, using chelate resin for deeply softening the waste water after preliminary softening, and reducing the concentration of high valent cationic to ppb grade to obtain the high silicon-containing waste water after pretreatment in the oil field. The invention also provides the high silicon-containing waste water in oil field reuse boiler pretreatment apparatus.

Owner:PETROCHINA CO LTD

Immobilized transaminase and application of immobilized transaminase in synthesis of sitagliptin intermediate

The invention provides immobilized transaminase. The immobilized transaminase is obtained by fixing transaminase, with histidine tag, derived from Mycobacterium vanbaalenii PYR-1 onto an enzyme immobilization carrier; the enzyme immobilization carrier is obtained by derivatization of epoxy resin through IDA (imino diethyl acetic acid) and cobalt chloride or derivatization of ionic chelate resin through cobalt chloride. The immobilized transaminase has the advantages of firmness in combination, low enzyme activity loss, simplicity in separation and high reusability; low cost of an asymmetric conversion process, mild reaction conditions, environment friendliness, simplicity and convenience in operation, easiness in industrial expanding and promising industrial application prospect are realized.

Owner:ABIOCHEM BIOTECH CO LTD

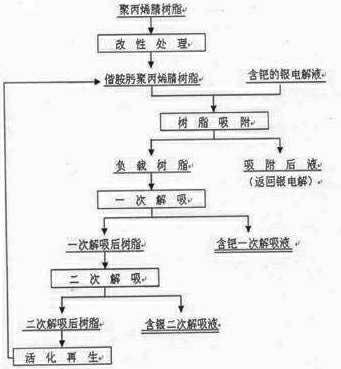

Separation method of palladium from silver electrolyte

InactiveCN102329959AAchieve separationHigh recovery ratePhotography auxillary processesProcess efficiency improvementChelating resinElectrolysis operation

The invention relates to a wet metallurgic method for effectively separating palladium from silver electrolyte by adopting modified polyacrylonitrile resin, and the process is free from pollution. The method adopts a technical scheme that: polyacrylonitrile resin is modified by adopting a hydroxyl amine hydrochloride solution to obtain a novel chelating resin namely amidoxime polyacrylonitrile resin; silver electrolyte which is roughly purified to remove heavy metal impurities is adsorbed by adopting the amidoxime polyacrylonitrile resin, so that palladium in the solution is loaded onto the resin, and the resin is subjected to primary desorption by adopting an acidic thiourea solution to obtain a palladium-containing desorption liquid; the resin is subjected to secondary desorption by adopting a high-concentration hydrochloric acid solution to obtain a silver-containing desorption liquid; and the resin which is subjected to twice desorption is regenerated by adopting a hydroxyl amine hydrochloride solution, and is returned to adsorb the palladium-containing silver electrolyte. According to the method, palladium and silver can be effectively separated, the adsorbed solution can be directly returned to silver electrolysis, the operation is simple, the purification time is short, the recovery rate of noble metals is high, and the practicality is strong.

Owner:CENT SOUTH UNIV

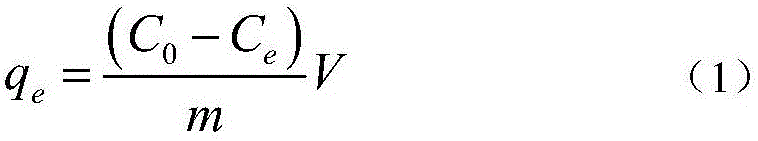

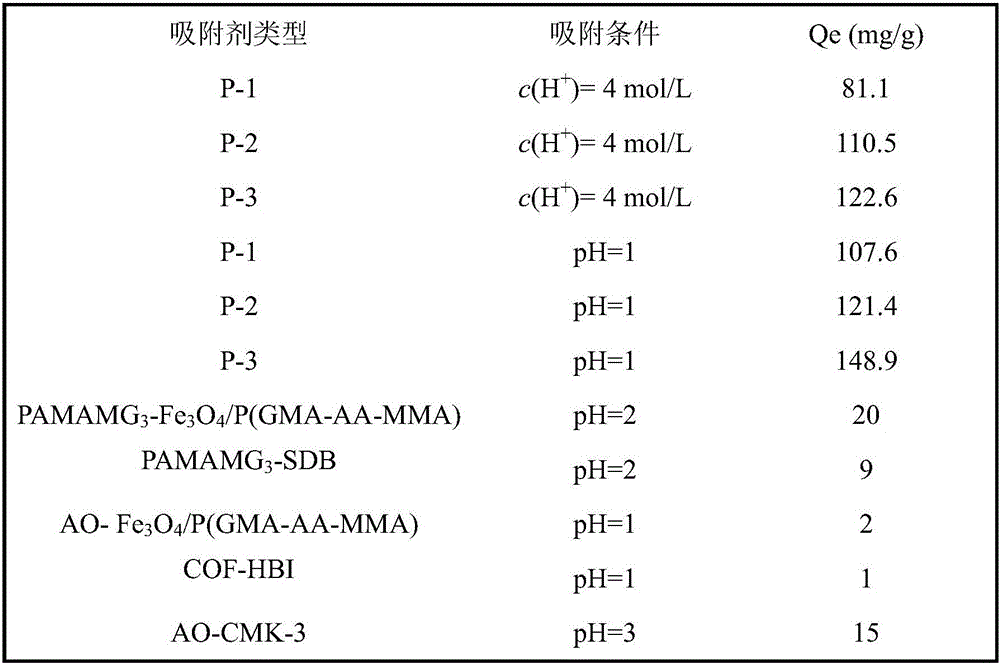

Mesoporous chelate resin containing phosphorus-oxygen functional groups and method for separating and enriching uranium

InactiveCN105688844AEasy to prepareLow costOther chemical processesWater contaminantsOrganic solventSorbent

The invention relates to mesoporous chelate resin containing phosphorus-oxygen functional groups and a method for separating and enriching uranium. A preparation method of the mesoporous chelate resin includes: adding 1-5g of organic crosslinking agent, 1-5g of unsaturated compound containing the phosphorus-oxygen functional groups and 0.02-0.08g of azodiisobutyronitrile into 1-10mL of organic solvent, stirring under 25 DEG C for 1-3 hours, adding the solution into a hydrothermal reaction kettle, reacting under 100 DEG C for 24 hours, taking out, opening the reaction kettle, performing rotation evaporation to remove the organic solvent, and performing vacuum drying under 45 DEG C for 12-24 hours to obtain the mesoporous chelate resin containing the phosphorus-oxygen functional groups, wherein mass number and volume number are proportionally adjusted. The preparation method is simple in synthesizing path and easy to operate. When the mesoporous chelate resin serving as an absorbent is used to separate and enrich the uranium under high acidity, the mesoporous chelate resin is high in absorption ability, large in absorption quantity, fast in absorption, and the like, and the mesoporous chelate resin can be easily separated from an aqueous solution and can effectively absorb and recycle the uranyl ions in the aqueous solution.

Owner:EAST CHINA UNIV OF TECH

Preparation method of novel silica gel-based hyperbranched PAMAM (polyamidoamine) chelating resin

InactiveCN102161758AWide variety of sourcesLow priceOther chemical processesWater/sewage treatment by sorptionPolymer scienceChelating resin

The invention discloses a novel silica gel-based PAMAM (polyamidoamine) hyperbranched macro-molecule chelating resin which is prepared by using aminated silica gel modified by a silane coupling agent as the core, directly adding an ABx type monomer (x>=2, and A and B are reactive groups) and carrying out one-step synthesis. The chelator prepared by the method can well adsorb heavy metal ions, can be repeatedly used, and has the advantages of simple synthesis process and low cost, thereby laying a foundation for large-scale production.

Owner:DALIAN UNIV OF TECH

Method for producing reagent grade sodium sulfate by using white carbon black mother solution

InactiveCN102320629ALow impurity contentImprove qualityAlkali metal sulfite/sulfate purificationCelluloseEvaporation

The invention discloses a method for producing reagent grade sodium sulfate by using a white carbon black mother solution. The method comprises the following steps of: 1) removing a little amount of solid residue such as white carbon black and the like in the white carbon black mother solution by using a mixed cellulose micropore filtration membrane with thickness phi of less than or equal to 0.15 micron, and preliminarily purifying the white carbon black mother solution into a sodium sulfate solution; 2) treating the sodium sulfate solution obtained in the step 1) by using chelating resin toobtain a 5 to 6 percent pure sodium sulfate solution; 3) performing electrodialytic concentration on the 5 to 6 percent pure sodium sulfate solution obtained in the step 2) to obtain a 15 to 25 percent pure sodium sulfate solution; and 4) performing multi-effect evaporation on the 15 to 25 percent pure sodium sulfate solution obtained in the step 3) to obtain crystal, separating the crystal by using a centrifuge, drying the separated crystal at the temperature of 120 DEG C, and thus obtaining a finished product. The sodium sulfate product prepared by the method has the characteristics of low impurity content, high quality, low moisture content and the like, and is a high reagent grade sodium sulfate product.

Owner:福建海能新材料有限公司

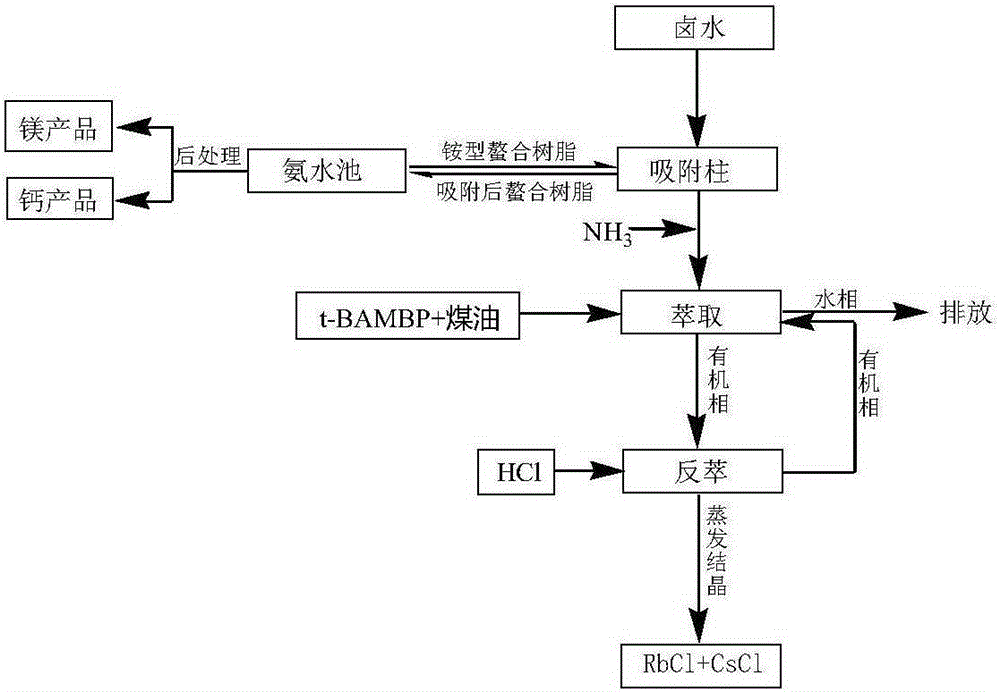

Method for extracting rubdium and cesium from acid brine

The invention discloses a method for extracting rubdium and cesium from acid brine. The method includes the steps that brine is pumped into an ammonium type chelate resin adsorption column, calcium ions and magnesium ions are adsorbed through the ammonium type chelate resin adsorption column, and effluent is brine without the calcium ions and the magnesium ions; the effluent is mixed with t-BAMBP or kerosene or sulfonated kerosene to be shaken, and a mixture stands still for layering and separation of a water phase and an organic phase; and reextraction is conducted on the organic phase, and the water phase containing rubidium chloride and cesium chloride is obtained. The method is simple in process, low in production cost, capable of achieving separate extraction for removing rubdium and cesium ions in radioactive water and free of secondary pollution.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

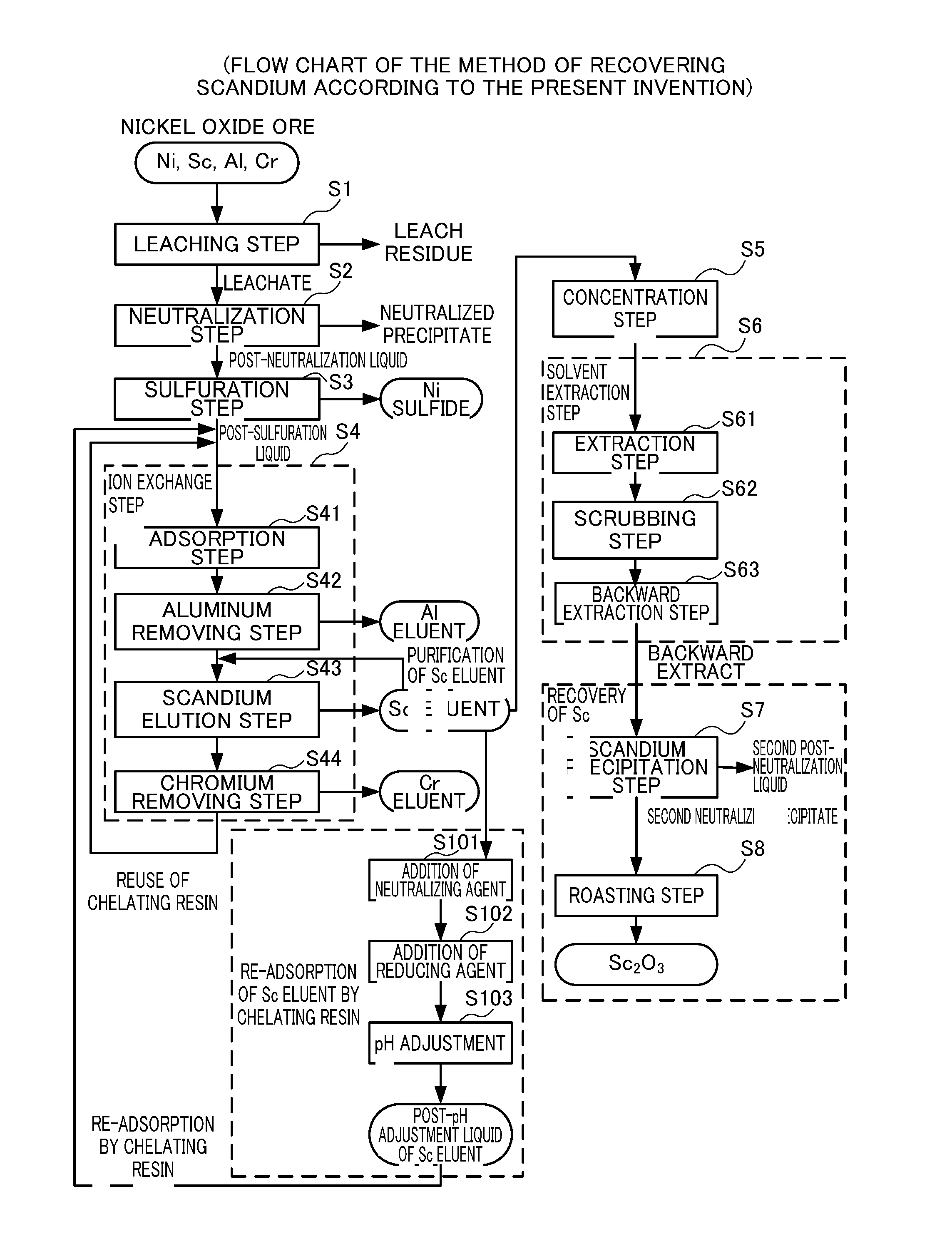

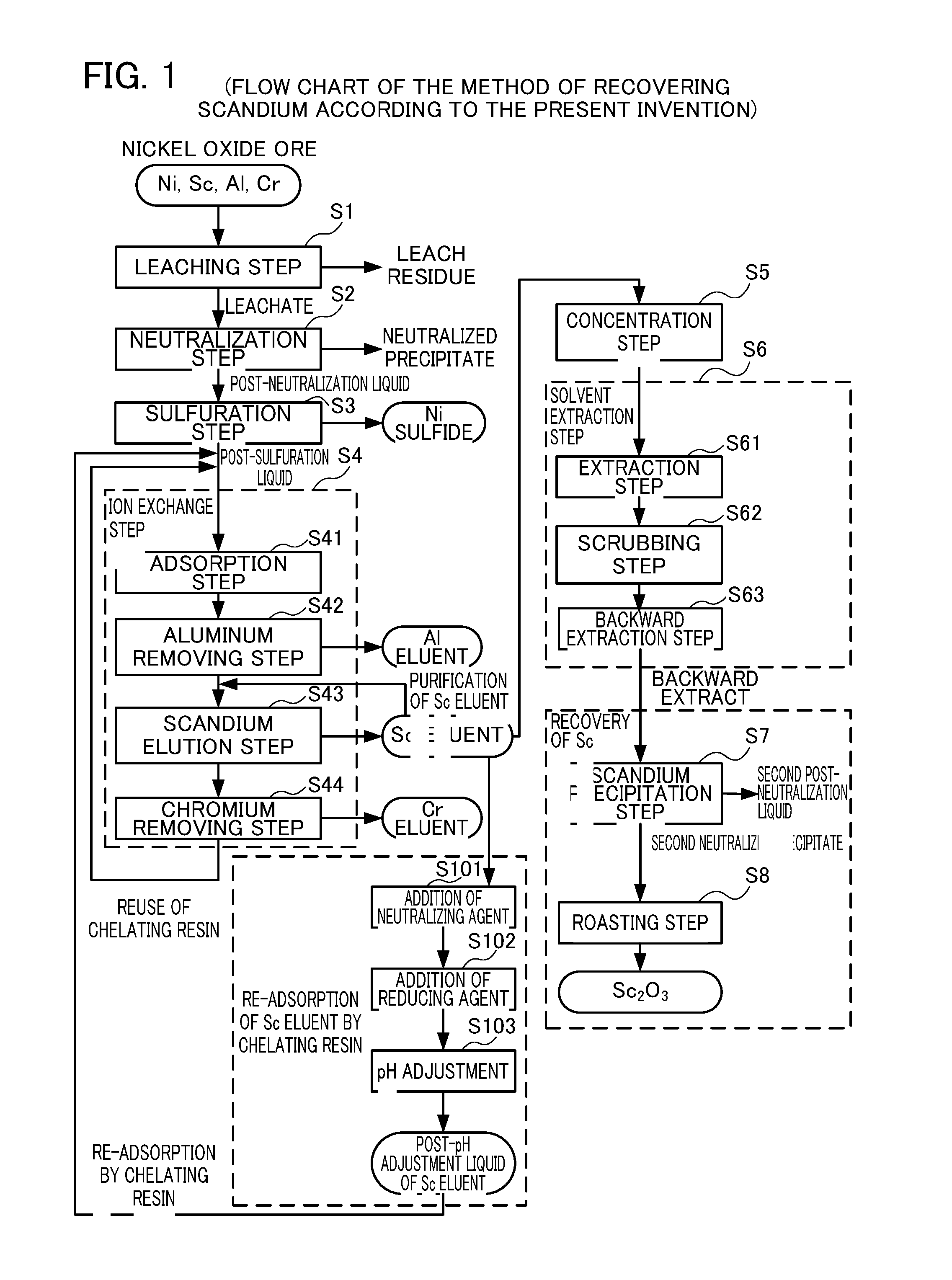

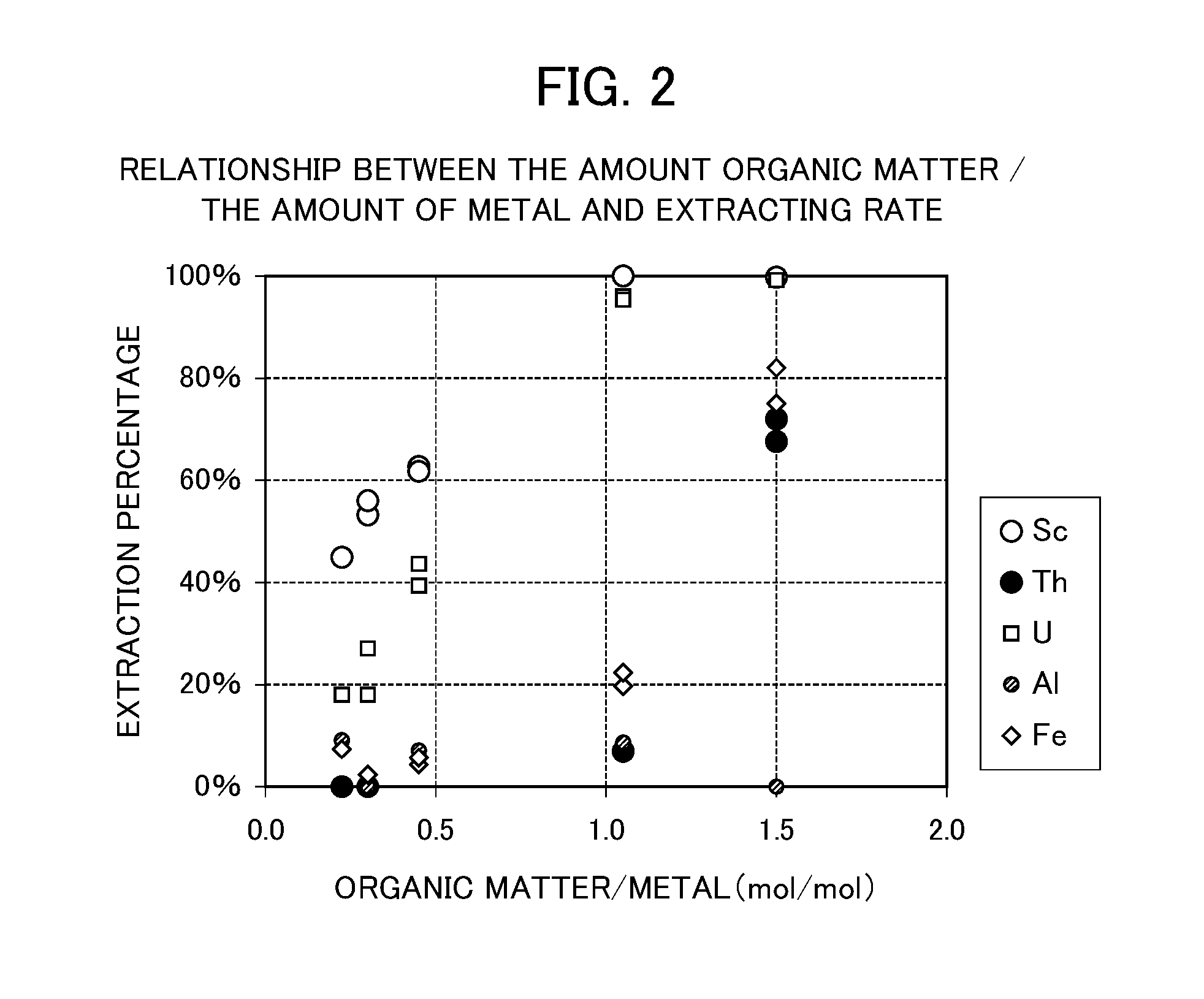

Scandium recovery method

InactiveUS20160340757A1Effective recoveryProcess efficiency improvementRecovery methodNickel sulfide

In order to recover high-quality scandium from nickel oxide ores efficiently, this method comprises: a step (S1) for feeding Ni oxide ores and sulfuric acid into a pressure vessel, and subjecting the mixture to solid-liquid separation to form a leachate and a leach residue; a step (S2) for adding a neutralizing agent to the leachate, and thus forming a neutralization sediment and a post-neutralization fluid; a step (S3) for adding a sulfurizing agent to the post-neutralization fluid, and separating the obtained mixture into Ni sulfide and a post-sulfurization fluid; a step (S4) for bringing the post-sulfurization fluid into contact with a chelating resin, making Sc adsorbed on the chelating resin, and forming an Sc eluent; a step (S6) for bringing the Sc eluent into contact with an extracting agent, adding a back-extraction agent to the extract, and forming back-extracted matter; and a step (S8) for roasting the back-extracted matter, and forming Sc oxide.

Owner:SUMITOMO METAL MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com