High silicon-containing waste water in oil field reuse boiler pretreatment technology and apparatus

A pretreatment device and pretreatment technology, applied in mining wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of large amount of sludge, high treatment cost, and large investment in equipment , achieve the effect of high selectivity, simple regeneration method and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

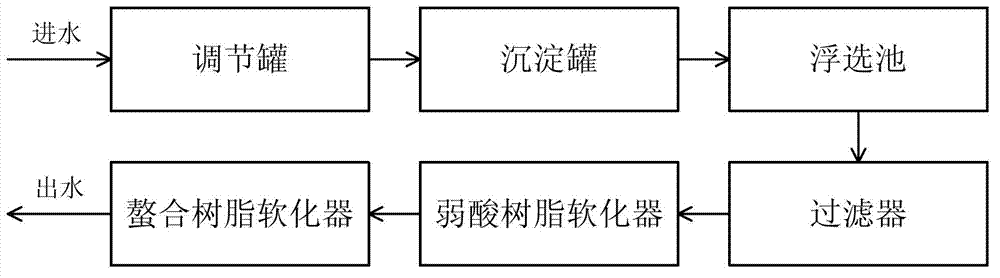

[0041] This embodiment provides a boiler pretreatment device for reuse of oilfield high-silicon-containing wastewater, the structure of which is as follows: figure 1 shown.

[0042] The oilfield high silicon-containing waste water reuse boiler pretreatment device includes sequentially connected: an adjustment tank, a sedimentation tank, a flotation tank, a filter, a weak acid resin softener and a chelating resin softener.

Embodiment 2

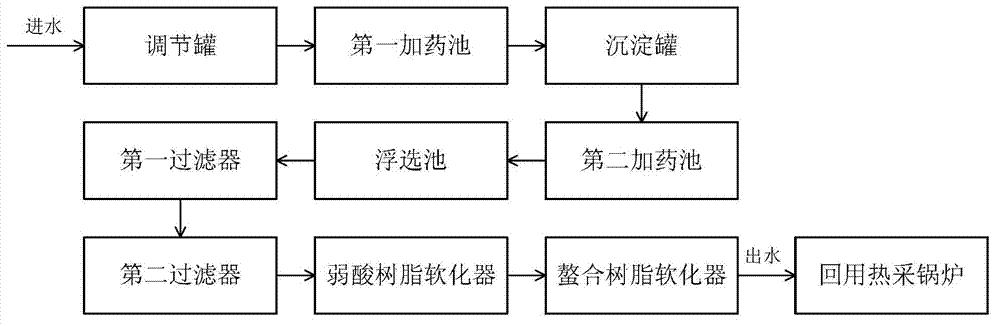

[0044] This embodiment provides a boiler pretreatment device for reuse of oilfield high-silicon-containing wastewater, the structure of which is as follows: figure 2 shown.

[0045] The pretreatment device includes sequentially connected: regulating tank, first dosing tank, sedimentation tank, second dosing tank, flotation tank, first filter, second filter, weak acid resin softener and chelating resin softener device;

[0046] Among them, the first filter is a double filter material filter: the tank diameter × height is Φ1200mm × 3572mm, the filtration rate is 11.1m / h, the filter material is anthracite and walnut core, the control mode is batch automatic, and the quantity is 1 set; In the container, the upper layer is anthracite, the lower layer is walnut core, and the layer heights of anthracite and walnut core are 0.2-1.0m and 0.4-2.0m respectively;

[0047] The second filter is a multi-media filter: the tank diameter × height is Φ1200mm × 3572mm, the filtering speed is 1...

Embodiment 3

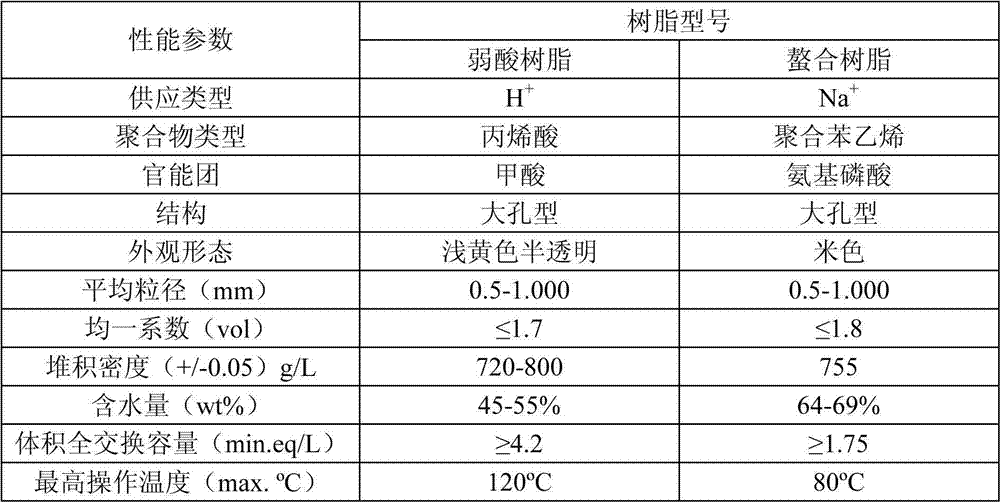

[0069] This embodiment also provides a boiler pretreatment process for oilfield high-silicon-containing wastewater reuse boiler, which is a process for pretreating heavy oil sewage using the device provided in Example 2, a weak acid resin softener and a chelating resin softener The specific parameters of the resin added in are shown in Table 5. The pretreatment process includes the following specific steps:

[0070] Introduce the heavy oil sewage into the adjustment tank for proper adjustment, and adjust the amount of water entering the follow-up treatment facilities to be 10-20% of the high silicon-containing wastewater in the oil field;

[0071] Make the heavy oil sewage from the adjustment tank enter the first dosing pool, and put 60mg / L PR106 reverse phase demulsifier into the sewage for demulsification treatment;

[0072] Let the heavy oil sewage from the first dosing tank enter the sedimentation tank for sedimentation, and settle for 30 minutes. The oil-water separation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com