Patents

Literature

53results about How to "Solve easy fouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

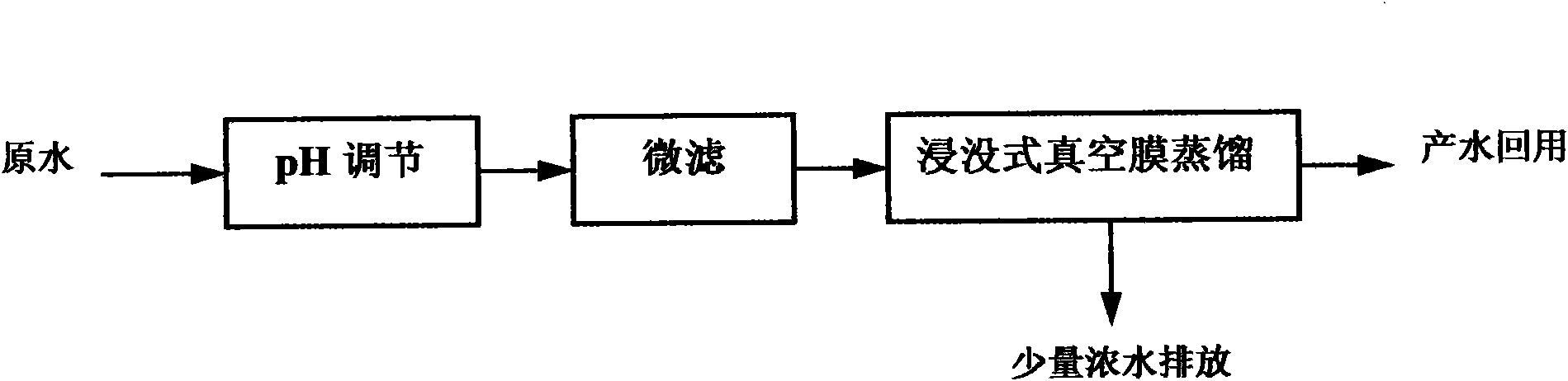

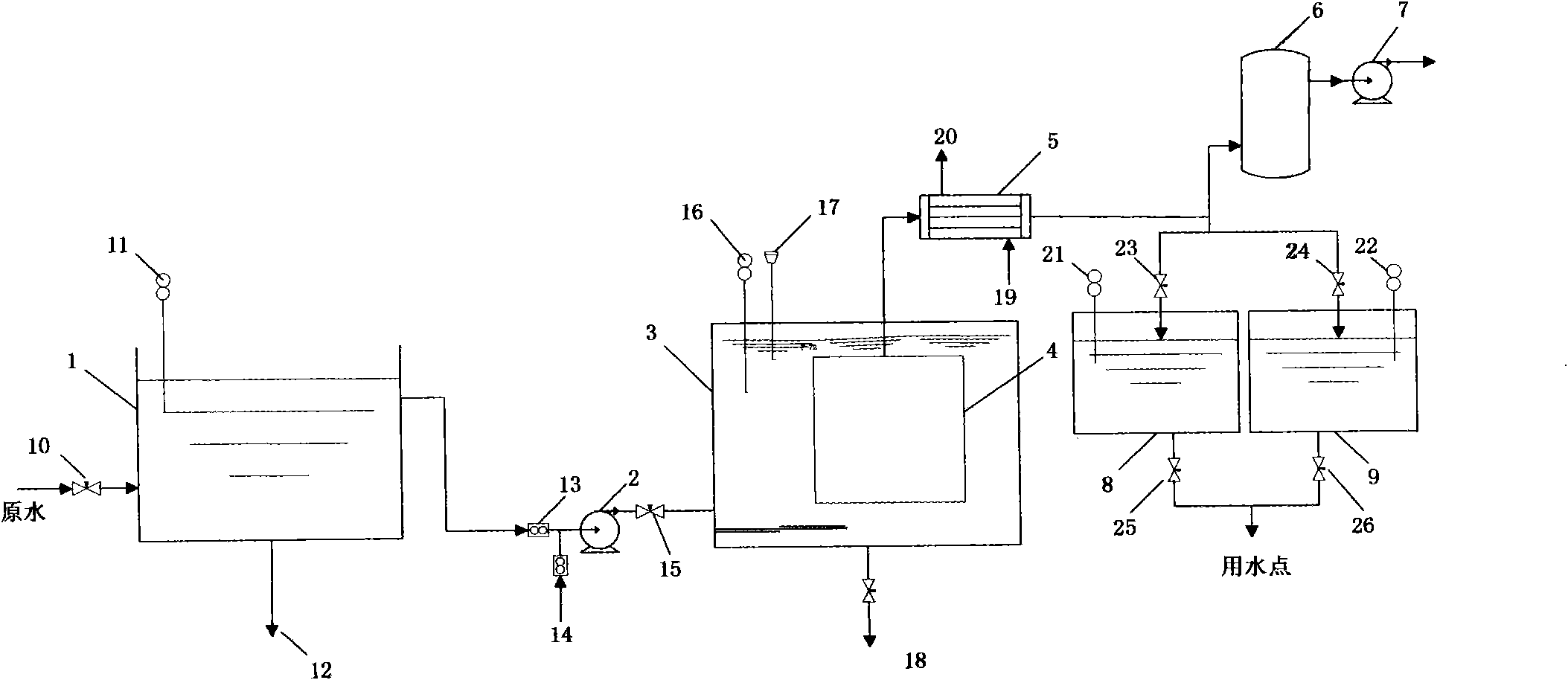

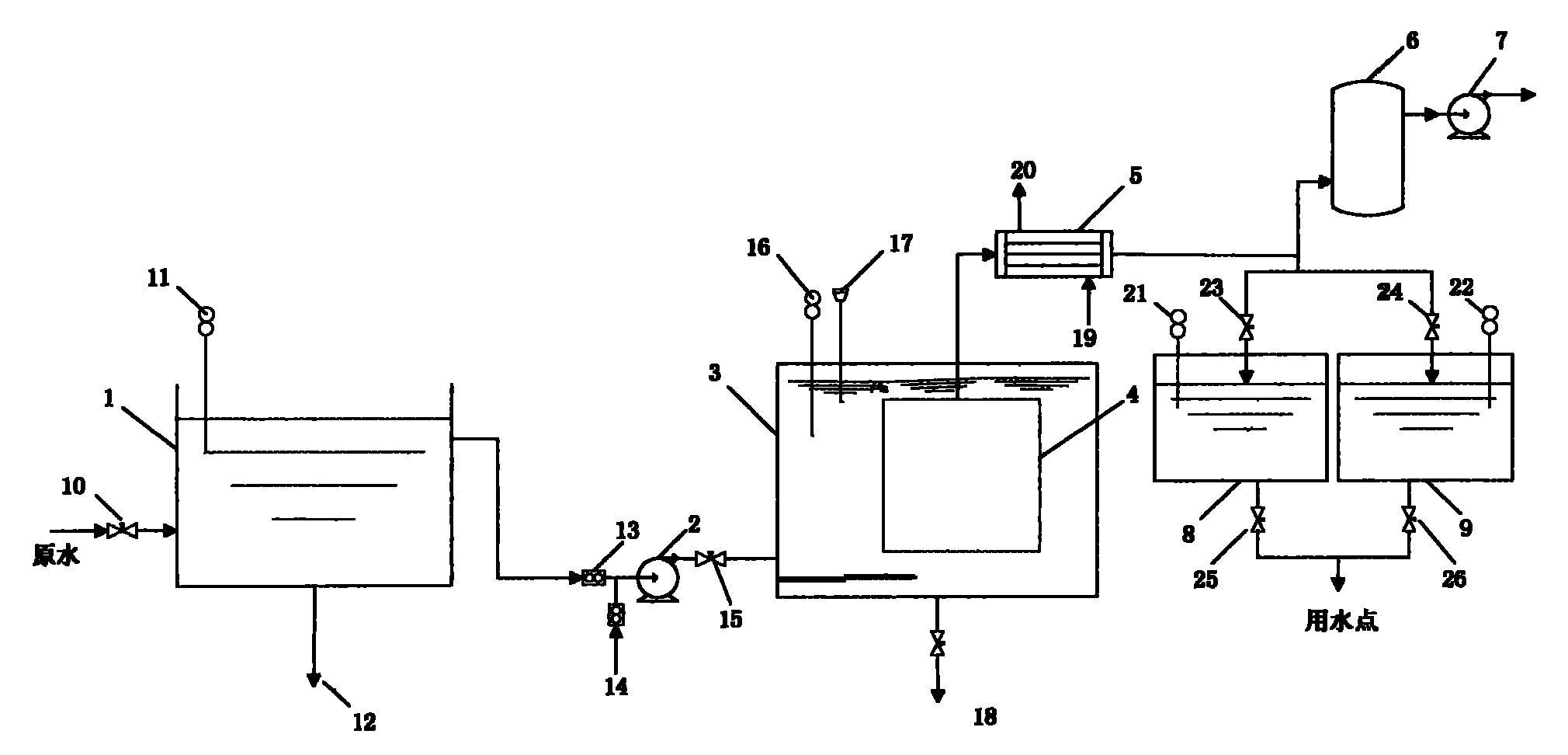

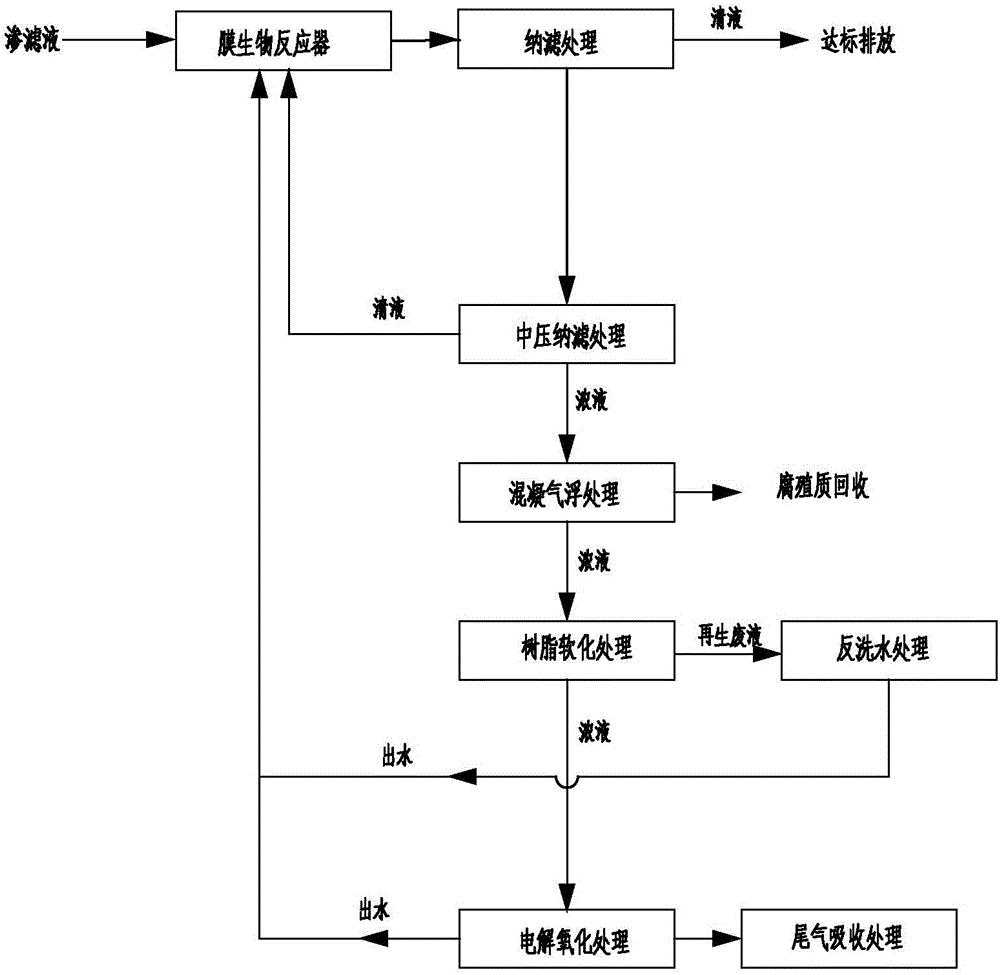

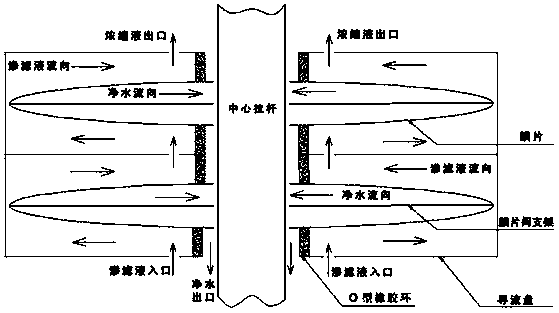

Immersed vacuum membrane distillation plant and sewage treatment technology using the same

ActiveCN102417210AIncreased distillation throughputReduce pollutionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentConcentration polarizationMeasuring instrument

The invention relates to an immersed vacuum membrane distillation plant and a sewage treatment technology using the same. The immersed vacuum membrane distillation plant comprises a raw water storage tank, a gas dissolving pump, a raw water heating water tank, a membrane distillation hydrophobic membrane module, a condenser, a vacuum buffer tank, a vacuum pump, a water producing tank, a valve, a measuring instrument, and an automatic controller. The sewage treatment technology is characterized in that: raw water is subject to pH regulation, microfiltration and other pretreatment, then the pretreated raw water enters into the raw water storage tank, the sewage in the raw water storage tank is subject to gas-water mixing through the gas dissolving pump, and then the gas-water mixture enters into the raw water storage tank for heating to a specific temperature, membrane distillation is carried out at the specific temperature, the produced water after membrane distillation is directly reused, and a little thick water is treated concentrately. According to the invention, the use of the plant in sewage treatment reduces the effect of concentration polarization and temperature difference polarization in the sewage, reduces membrane pollution, increases the membrane distillation flux, prolongs the operation period of the membrane module, reduces the heat loss of the pipeline, and increases the heat utilization rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

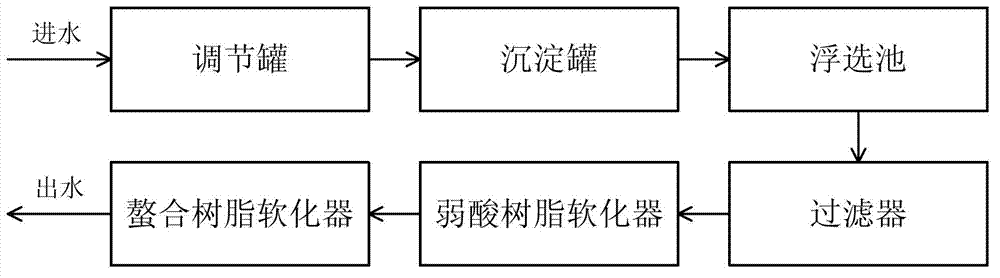

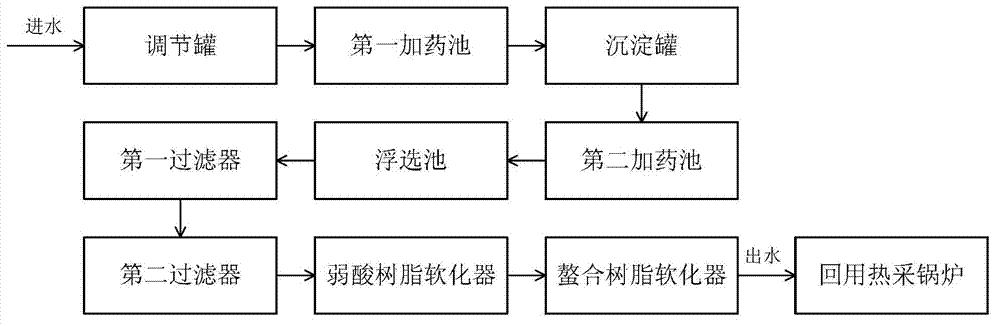

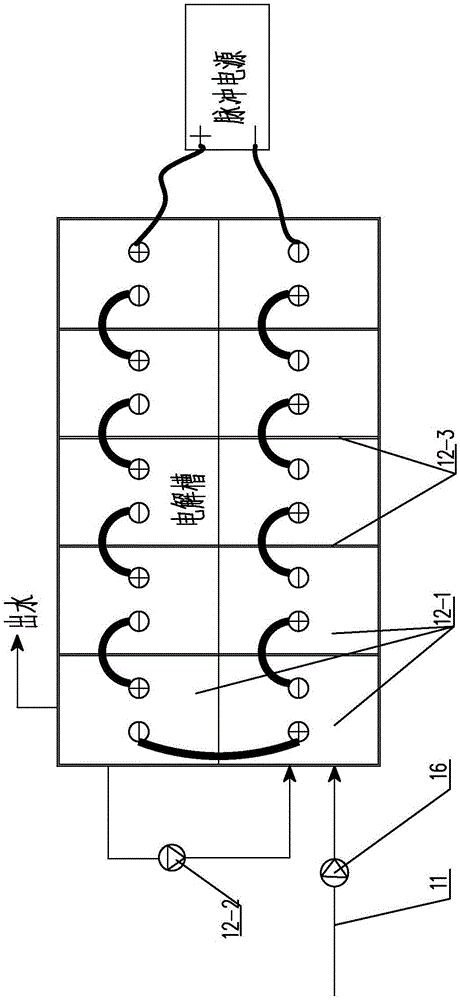

High silicon-containing waste water in oil field reuse boiler pretreatment technology and apparatus

ActiveCN102826680AReduced metal cation contentAdvantages of pretreatment processWaste water treatment from quariesMultistage water/sewage treatmentSolubilityChelating resin

The invention relates to a high silicon-containing waste water in an oil field reuse boiler pretreatment technology and an apparatus. The pretreatment technology comprises the following steps: adjusting the high silicon-containing waste water in the oil field and adding a reverse demulsifier; depositing the adjusted waste water, separating oil and water and removing the impurity in the waste water; adding a salt substance in the waste water after deposition treatment and performing air floatation treatment, removing an dissolved organic matter and oil, filtering the waste water after the air floatation treatment and removing suspended matters; using filtering weak acid resin for preliminarily softening the filtered waste water, reducing the concentration of high valent cationic to ppm grade, using chelate resin for deeply softening the waste water after preliminary softening, and reducing the concentration of high valent cationic to ppb grade to obtain the high silicon-containing waste water after pretreatment in the oil field. The invention also provides the high silicon-containing waste water in oil field reuse boiler pretreatment apparatus.

Owner:PETROCHINA CO LTD

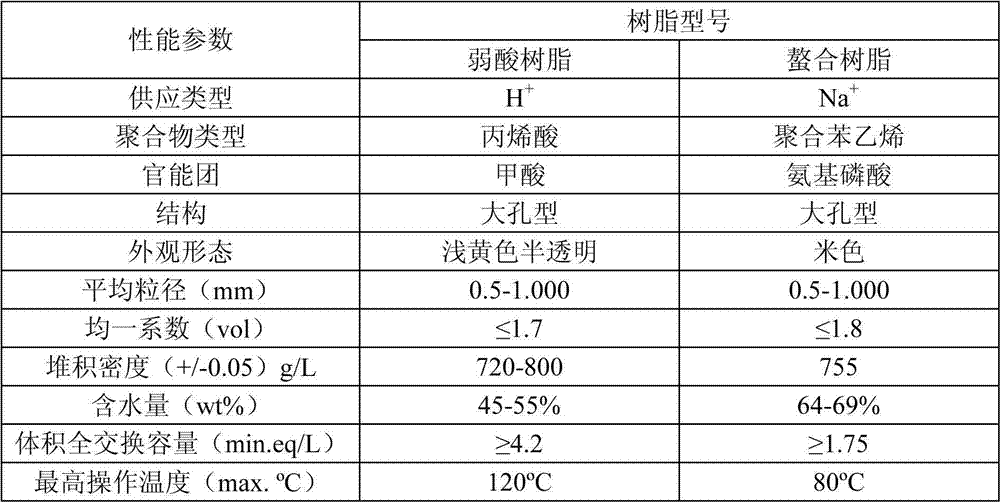

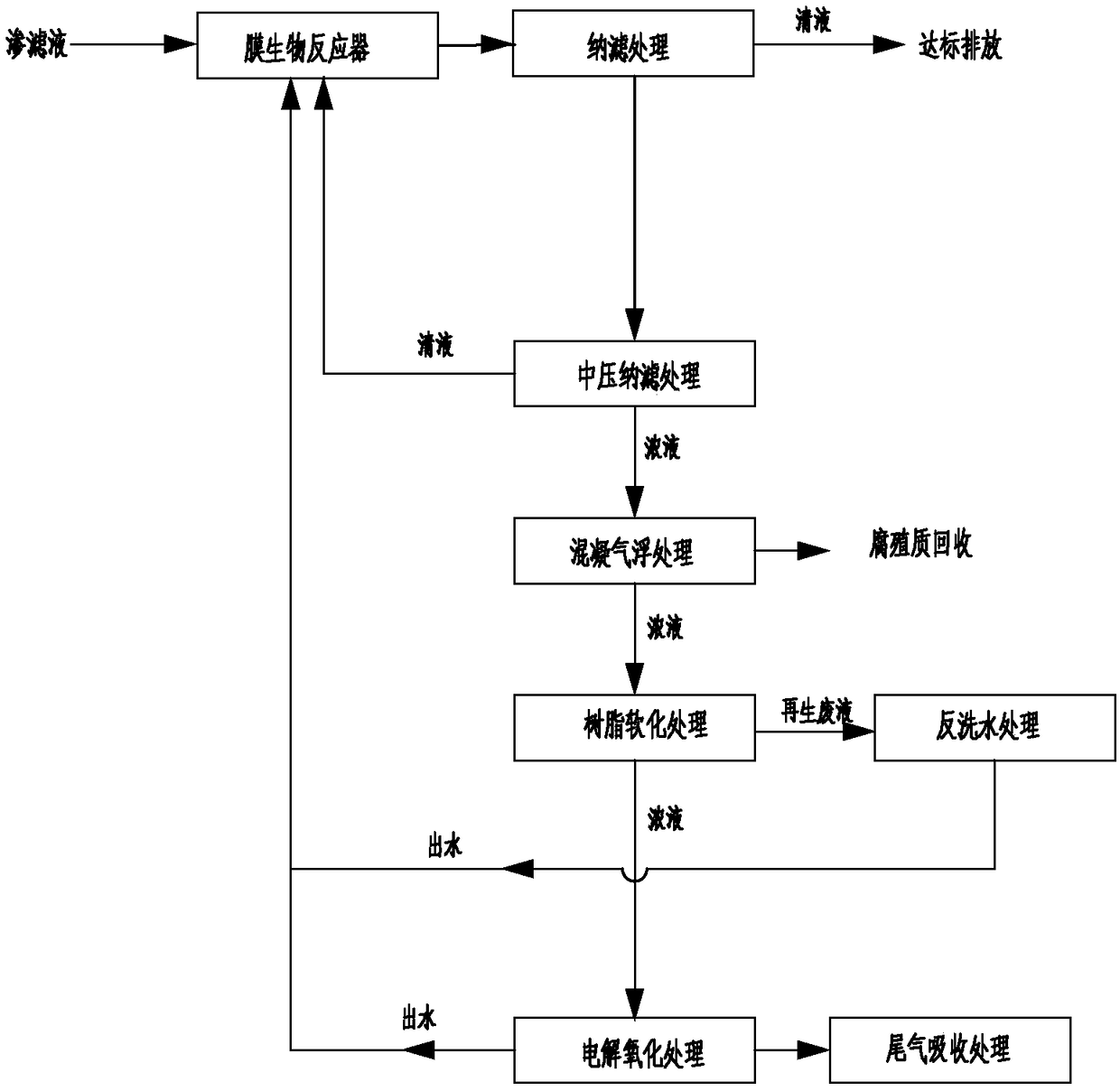

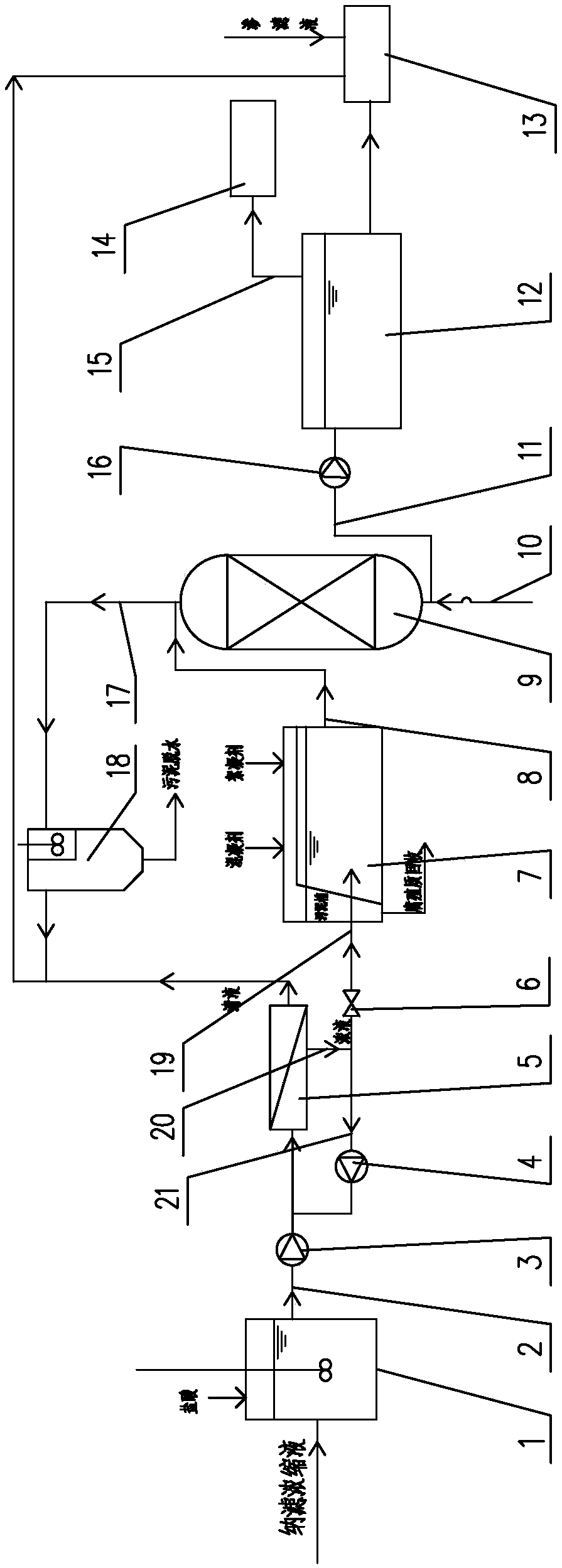

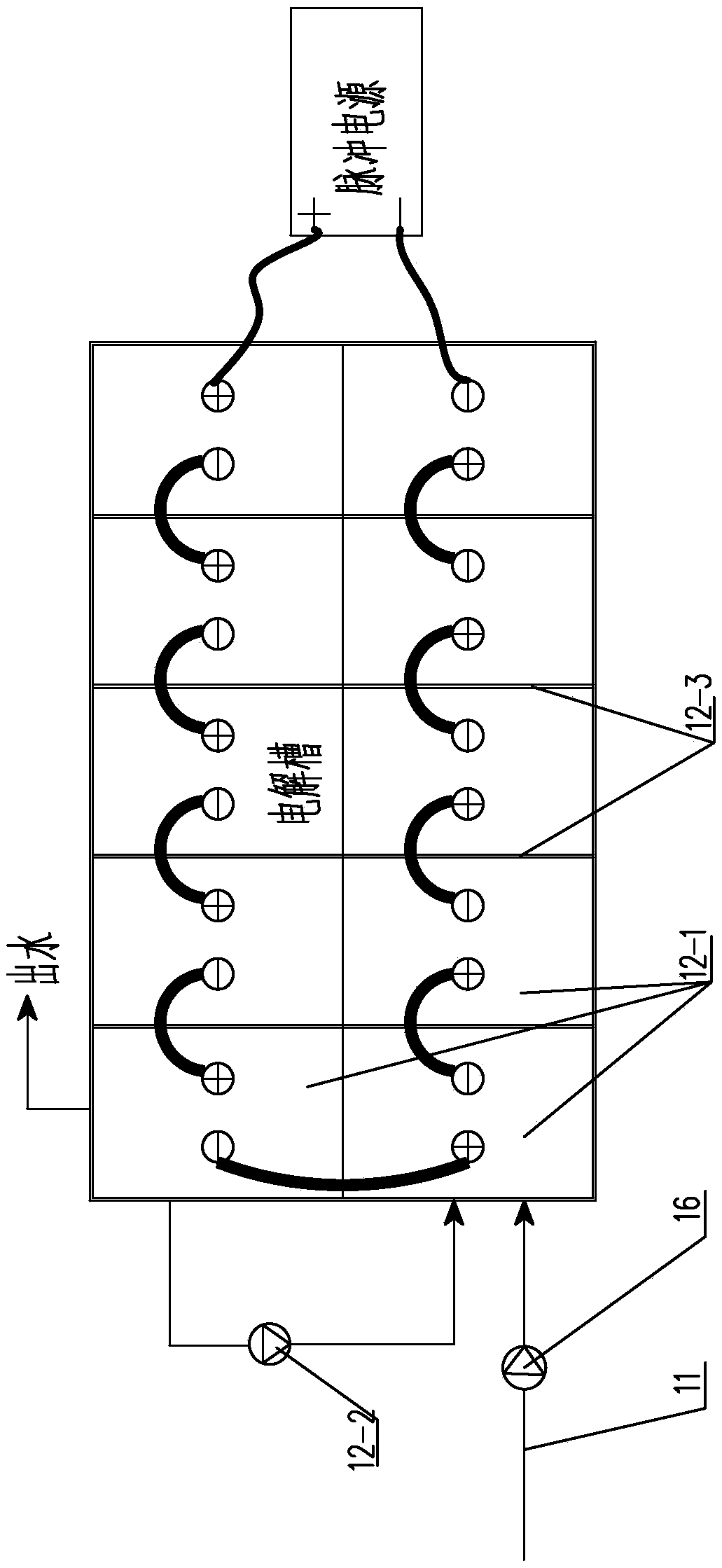

Treatment method for nanofiltration concentrated liquor of landfill leachate

ActiveCN106277591AGuaranteed uptimeIncrease flow rateWater contaminantsMultistage water/sewage treatmentElectrolysisResource utilization

The invention relates to a treatment method for nanofiltration concentrated liquor of landfill leachate, which comprises the following steps: carrying out medium-pressure nanofiltration treatment first for minimization, carrying out coagulation air floatation treatment for the concentrated liquor after the medium-pressure nanofiltration treatment to recycle humous larger molecular organics for resource utilization, carrying out resin-based softening treatment to reduce the hardness of the concentrated liquor after the coagulation air floatation treatment, performing electrolytic oxidation treatment on the concentrated liquor after the resin-based softening treatment and treating back washing water, feeding the clear liquid from the medium-pressure nanofiltration, yielding water from the regenerated waste liquor and yielding water after the electrolytic oxidation to membrane bioreaction treatment, performing tail gas absorption treatment on gases generated from the electrolytic oxidation, and absorbing chlorine gas in tail gases before up-to-standard emission. The treatment method for nanofiltration concentrated liquor of landfill leachate is reasonable in treatment process with a good treatment effect, and relatively low in investment and operation costs; the problem of accumulation of humic acids and hardness ions in the biochemical system is avoided, and the difficulty in treating the nanofiltration concentrated liquor of the landfill leachate is solved; and the treatment method is applicable to treating the nanofiltration concentrated liquor generated in the 'MBR+nanofiltration' treatment process for the landfill leachate.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

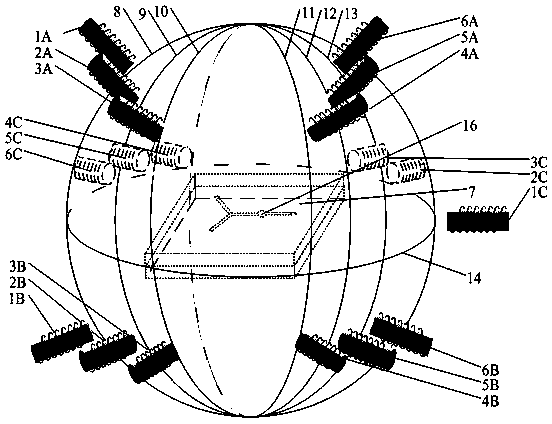

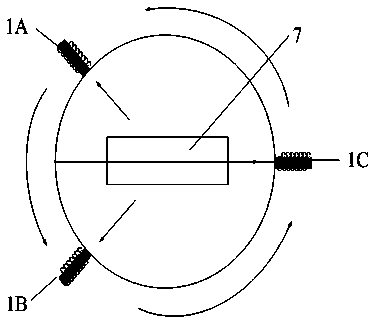

Micro-fluidic chip magnetic-bead chaotic mixing method and apparatus

Owner:JIANGSU UNIV

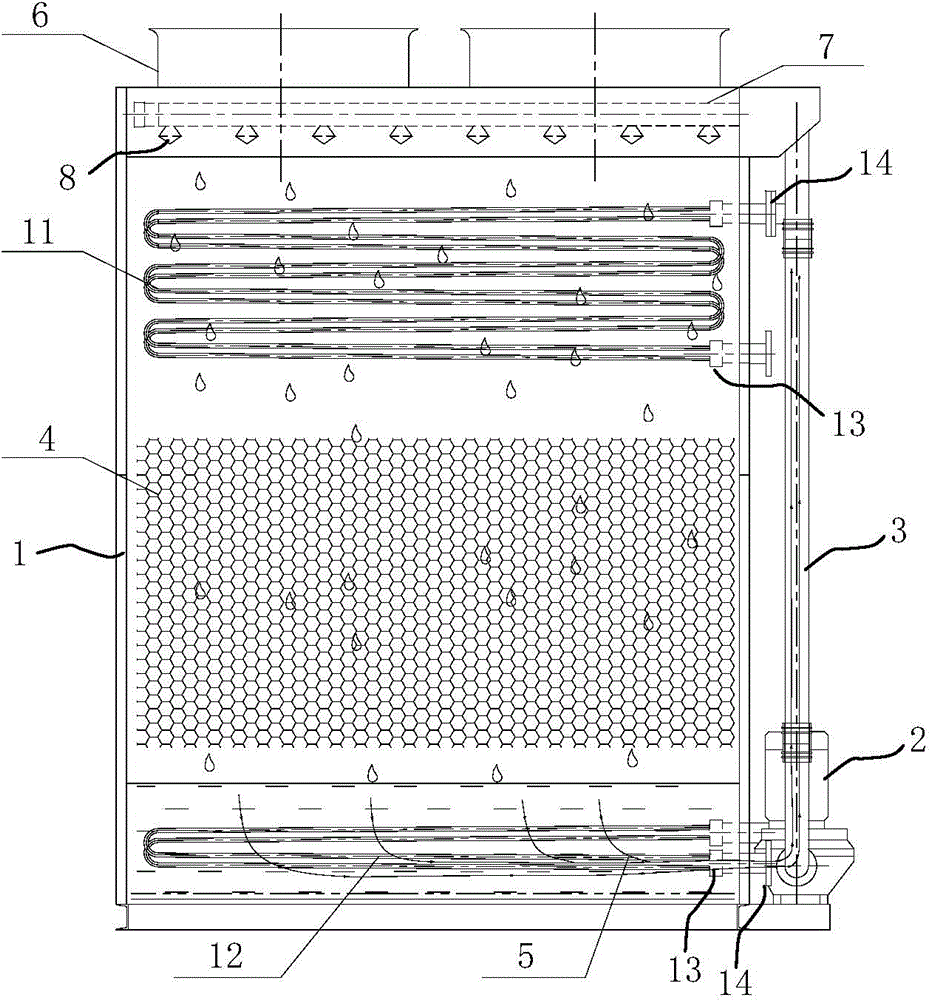

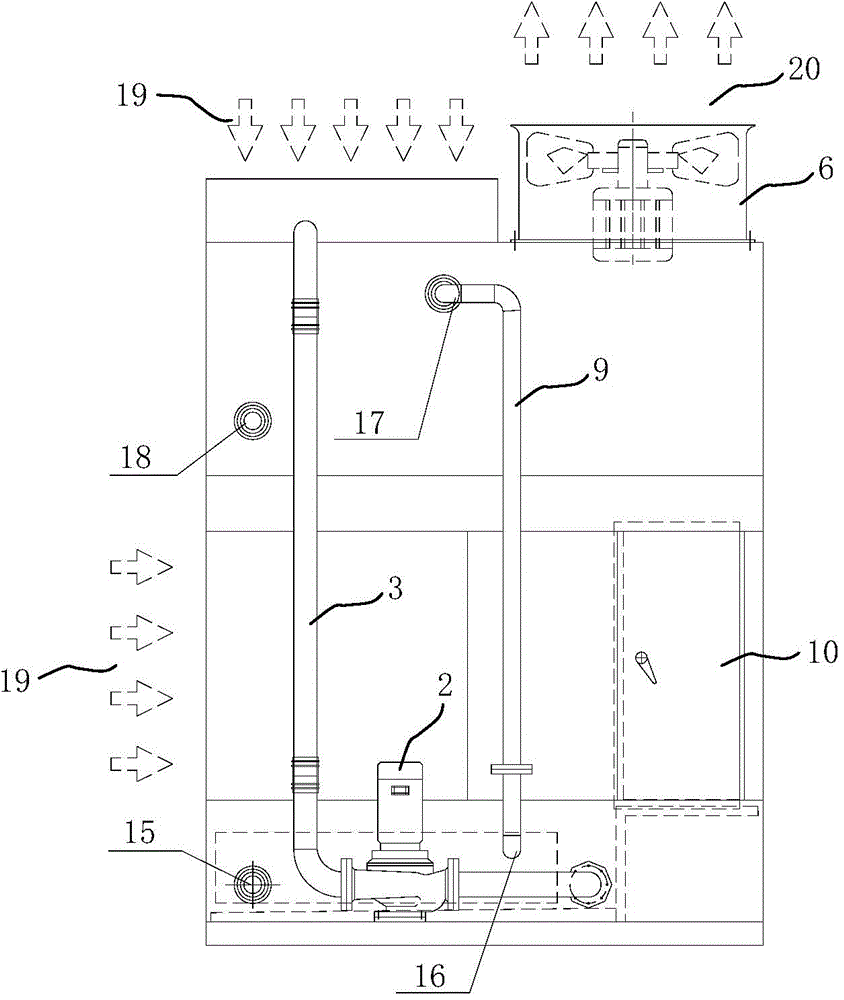

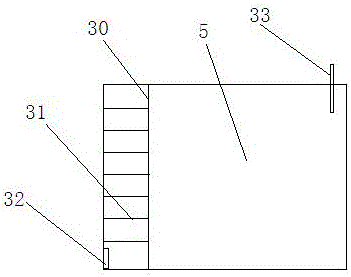

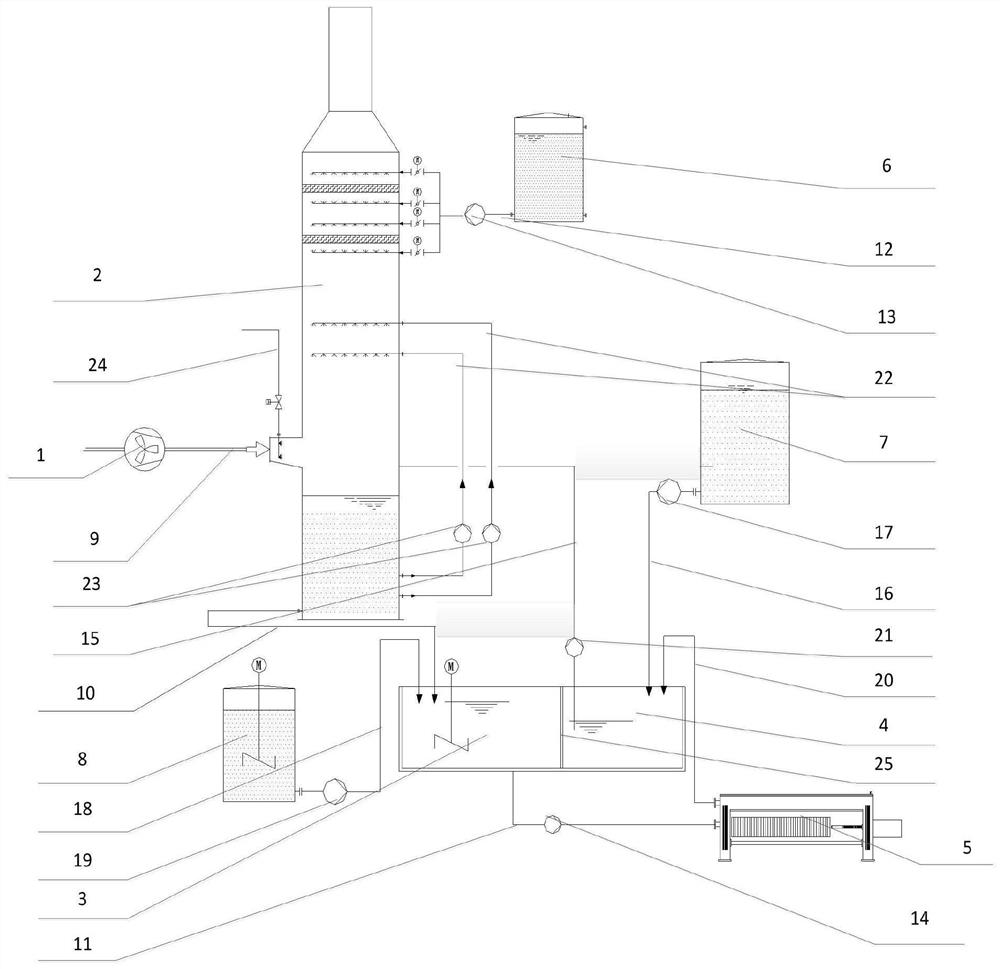

High-temperature closed cooling tower with pre-cooling device

InactiveCN105987620APrevent evaporationSolve easy foulingTrickle coolersCooling towerWater immersion

The invention discloses a high-temperature closed-type cooling tower with a precooling device, which includes a cooling tower body, and a spray branch pipe is arranged in the cooling tower body, and the spray branch pipe is connected with a spray water pump through a first main pipe. A first group of serpentine coils and heat dissipation filler filter screens are provided below the spraying branch pipes. The bottom of the cooling tower body is a water tank, and a second group of serpentine coils is arranged in the water tank. The second group of serpentine coils is connected with the first group of serpentine coils through the second main pipe. In the present invention, by setting the first group of serpentine coils and the second group of serpentine coils, the second group of serpentine coils is located in the water storage tank for water immersion heat exchange, and the high-temperature closed cooling tower is well Realize pre-cooling, so that the high-temperature fluid enters the first set of serpentine coils after pre-cooling, thereby avoiding the overheated high-temperature water from causing the spray water to evaporate instantly on the surface of the first set of serpentine coils, and solving the problem of high-temperature fluid in the closed cooling tower. The problem that the outer surface of the coil is easy to scale and cannot be cooled.

Owner:SHANGHAI WANXIANG COOLING EQUIP

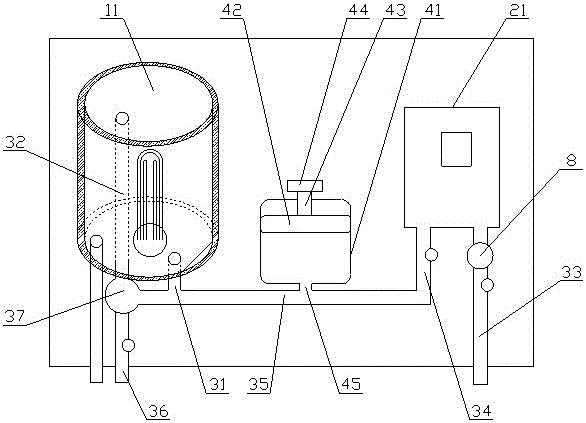

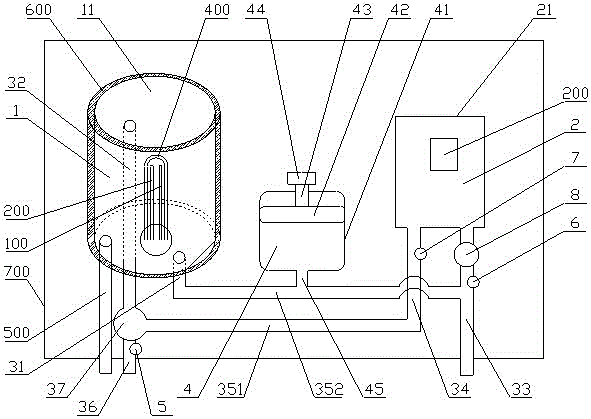

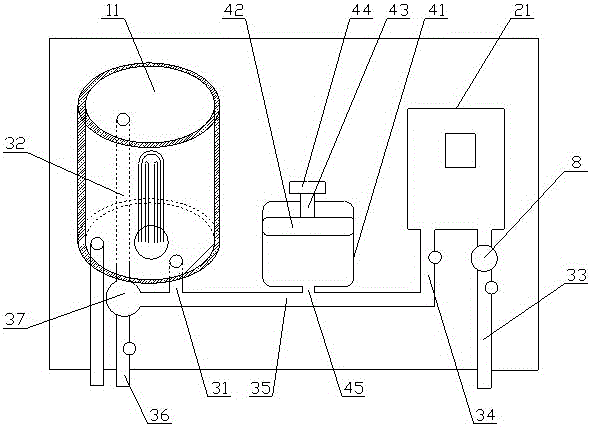

Preheating and instant heating dual-mode water heater

The invention discloses a preheating and instant heating dual-mode water heater and belongs to the field of water heaters. The preheating and instant heating dual-mode water heater comprises a storage type hot water device, an instant heating type hot water device, a pipe valve assembly and a pressure regulating cylinder, wherein the pressure regulating cylinder is used for storing pressure and reducing the overall pressure borne by the whole preheating and instant heating dual-mode water heater. The storage type hot water device is connected with the instant heating type hot water device through the pipe valve assembly. The storage type hot water device comprises a liner communicating with the pipe valve assembly. The pressure regulating cylinder directly communicates with the liner or communicates with the liner through a water inlet / outlet pipe, or the pressure regulating cylinder directly communicates with the pipe valve assembly or communicates with the pipe valve assembly through the water inlet / outlet pipe. According to the preheating and instant heating dual-mode water heater provided by the invention, the water storage liner is in the low-pressure state for a long time, hot water backflow is avoided, and the problems that a dual-mode electric water heater is prone to scaling and short in service life can be effectively solved.

Owner:中山市秦为电子科技有限公司

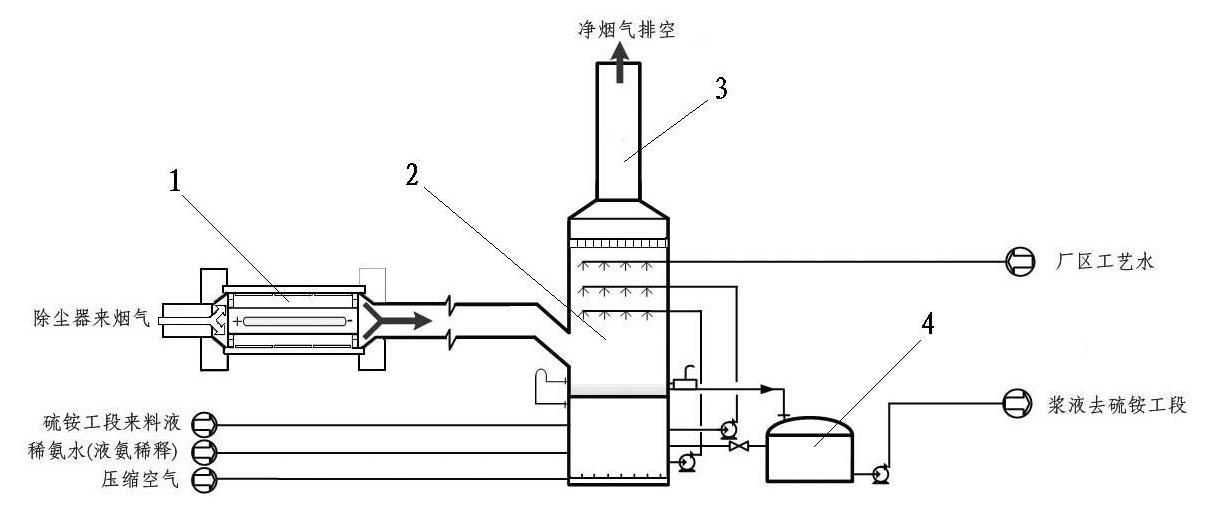

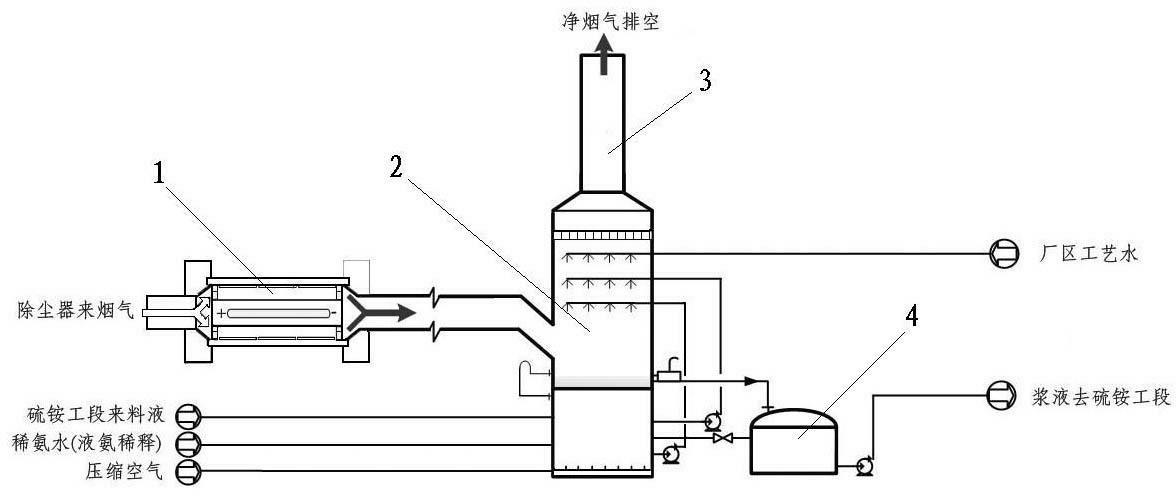

Simultaneous desulfuration and denitration method for smoke by combining photocatalytic oxidation with ammonia method

InactiveCN102350192ABig investmentSolve easy foulingDispersed particle separationAir quality improvementPhotocatalytic reactionPtru catalyst

The invention discloses a simultaneous desulfuration and denitration method for smoke by combining photocatalytic oxidation with an ammonia method, which is characterized in that boiler smoke firstly enters a photocatalytic reactor; NOx in the smoke is oxidized to generate NO2; smoke subsequently enters an ammonia method desulfurizing tower for inverse contact with desulfurizing agent solution; and SO2 and NO2 are further deeply removed. The photocatalytic reactor mainly comprises a reaction chamber and a light source system positioned in the middle comprises a high-voltage mercury lamp of which the power is above 125W and a quartz glass sleeve. Compared with the traditional SCR (Selective Catalyctic Reduction) denitration method, the simultaneous desulfuration and denitration method is characterized in that the problems of large land occupation, big investment, high operation cost, big possibility of scaling, blocking and positioning for cellular catalyst and the like in the SCR denitration method can be solved, the denitration problem can be solved, desulfuration and denitration are simultaneously carried out, desulfuration efficiency is above 95%, and denitration efficiency is above 70%. Denitration equipment can be constructed without large investment. Cost is low, operation cost is greatly lowered, and economic benefit is improved.

Owner:湖南湘达环保工程有限公司

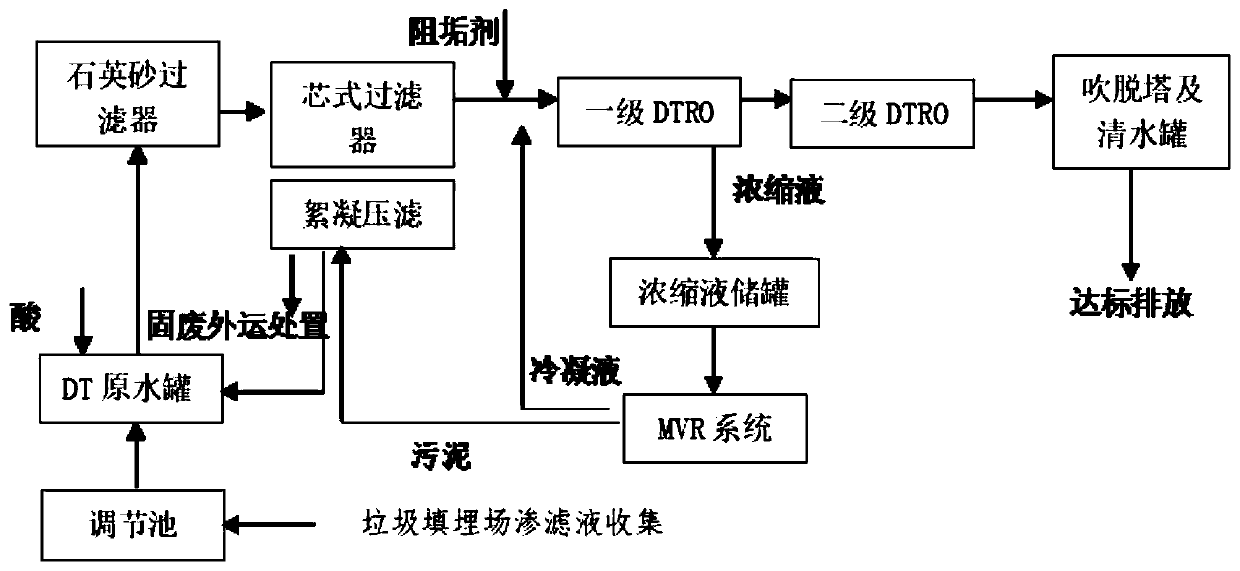

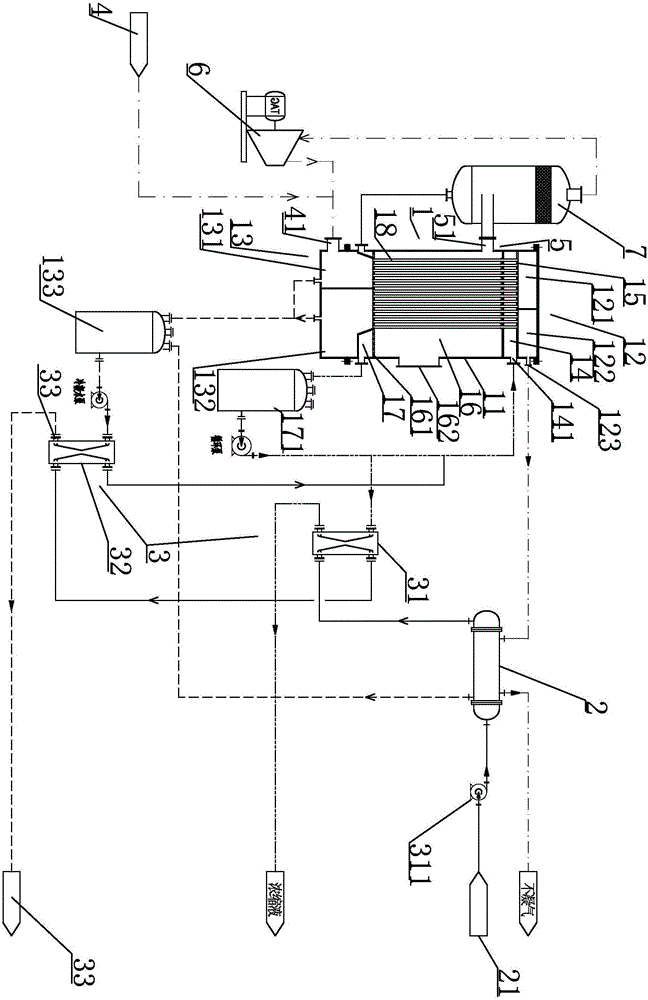

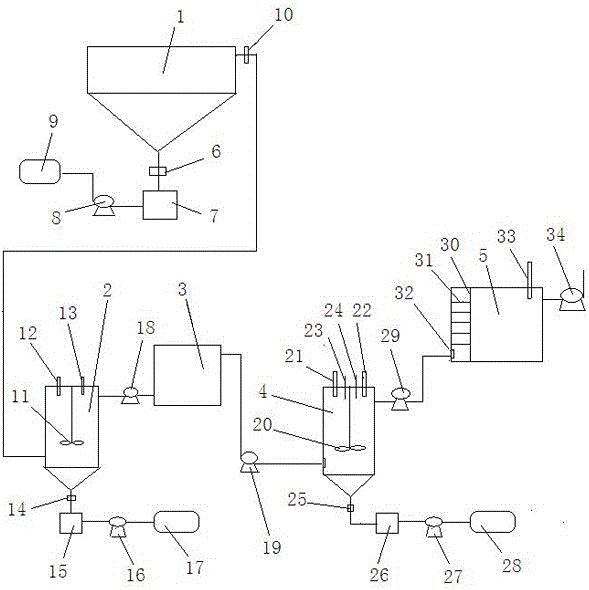

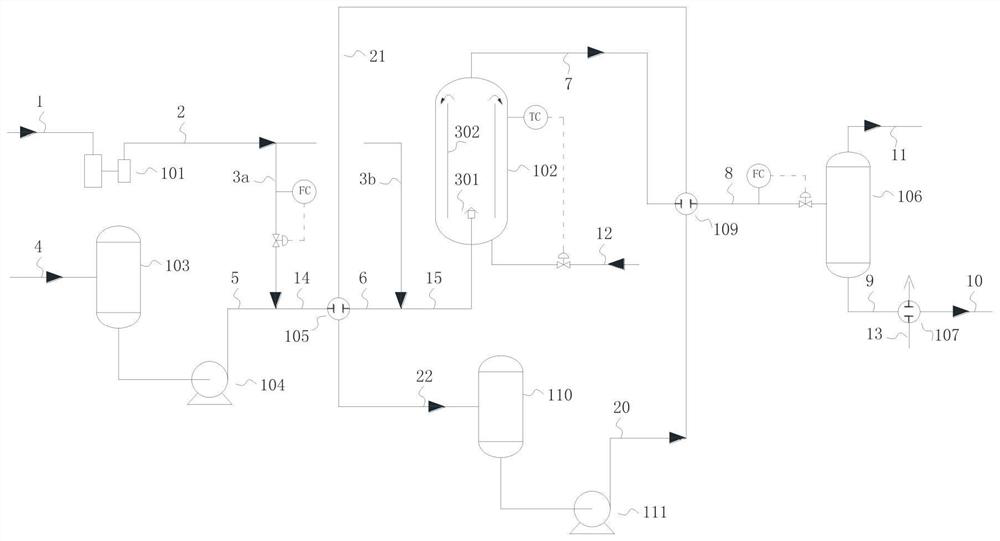

Two-stage treatment process for landfill leachate based on DTRO and MVR

InactiveCN111499062AStrong anti-pollutionSolution to short lifeWater treatment parameter controlTreatment involving filtrationReverse osmosisSand filter

The invention discloses a two-stage treatment process for landfill leachate based on DTRO and MVR. The two-stage treatment process comprises the following steps: acid regulation treatment of raw water: collecting raw percolate A generated by a refuse landfill by using a pipe network, adjusting water quality and quantity by using an adjusting tank, lifting the raw percolate A to a DT raw water tankby using a floating pump, adding acid into the DT raw water tank, and adjusting the pH value of the raw percolate A to obtain percolate B; sand filtration treatment: pressurizing the percolate B by using a raw water pump B, allowing the pressurized percolate B to enter a quartz sand filter, arranging pressure gauges at a water inlet end and a water outlet end of the quartz sand filter, and when apressure difference exceeds a set value, allowing the quartz sand filter to execute a backwashing procedure to obtain leachate C; and core filtration treatment: allowing the leachate C to enter a core type filter for treatment to obtain leachate D. A disc tube type reverse osmosis membrane column used in the invention is strong in pollution resistance and more durable to use; through usage of highly-integrated DTRO and MVR systems, the advantages of small size, compact layout and high efficiency are obtained; and due to the application of the MVR system, landfill leachate treatment is stableand up-to-standard in discharge, and no concentrated solution is recharged or transported outwards.

Owner:昆明金泽实业有限公司

Multi-functional heating furnace

InactiveCN104566975ASolve easy foulingSolve overheatingSolar heat devicesStorage heatersHeat conductingSolar water

The invention relates to a multi-functional heating furnace. The heating furnace comprises a heating furnace casing, a heat exchange barrel, a heating pipe, water circulating pipes and an external power source, wherein the heating furnace casing is used for storing oil well output liquid; the heat exchange barrel is directly inserted into the heating furnace casing and immersed into the output liquid, the heat exchange barrel consists of a main barrel and two wing barrels, and the main barrel and the two wing barrels are filled with heat-conducting media; the heating pipe is inserted into the main barrel and immersed into the heat-conducting media so as to heat the heat-conducting media; the output liquid is indirectly heated through the heat exchange barrel. According to the multi-functional heating furnace, the problems that the heating pipe is corroded and scaled and easy to burn out and the service life is short are effectively prevented, in addition, the heat exchange barrel and the heating pipe are respectively sunken in the output liquid and the heat-conducting media, so that heat loss is not generated, and the heating efficiency is improved. The heat exchange barrel is connected with a circulating water inlet pipeline and a circulating water outlet pipeline and can be connected with a solar water heater, and heat media preliminarily heated by the solar water heater are transported to the heating pipe to be reheated, so that solar energy resources are effectively utilized, and electric energy is saved. A power source of the heating pipe can be connected with a wind-energy generating battery and a solar battery, so that the comprehensive utilization of wind, light and electricity is realized, the energy is saved, and the emission is reduced. The heat exchange barrel comprises the two wing barrels, the diameter and the length of each wing barrel can be regulated so as to meet requirements of the heat exchange area, the same ends of the main barrel and the wing barrels are communicated through connecting pipes, after being inserted into the main barrel through the connecting pipes, the other ends of the wing barrels penetrate through sealing flanges of the main barrel and the casing, and penetrate out of the main barrel to be connected with a solar heat source, and the other end of the main barrel is connected with the solar heat source through a connecting pipeline, so that the closed cycle is realized.

Owner:史晨

Gas water heater

ActiveCN105588323AGood energy saving effectReduce generationWater heatersCombustion chamberWater storage tank

The invention discloses a gas water heater which comprises an air heater, a heat exchanger and a smoke exhaust fan. The air heater comprises a combustion chamber and a combustor arranged in the combustion chamber. The combustion chamber is provided with a cold air inlet, a hot air outlet and a gas inlet. The combustor is configured to enable the concentration of nitrogen oxide in generated hot air to be smaller than or equal to 30 mg / m<3> and the concentration of carbon monoxide in the generated hot air to be smaller than or equal to 50 mg / m<3>. The heat exchanger comprises a water storage tank and a heat exchange part. The heat exchange part is provided with a water inlet, a water outlet, an air inlet and an air exhaust opening. The water outlet communicates with the water storage tank. The air inlet communicates with the hot air outlet. The heat exchange part is configured to enable water entering from the water inlet to exchange heat with air entering from the air inlet. The smoke exhaust fan is used for sucking hot air generated by the combustor into the heat exchange part. By means of the gas water heater, generation of harmful gas of CO, nitrogen oxide and the like can better reduced, clean exhausting can be achieved, and the heat exchange efficiency between hot air and water can be improved.

Owner:BEIJING ORIENT DELTA SCI & TECH CO LTD

Harmless treatment system and method for waste incineration flue gas

PendingCN112844017ASolve the blockageGuaranteed filtering effectGas treatmentDispersed particle filtrationDust controlProcess engineering

The invention discloses a harmless treatment system and method for waste incineration flue gas. The harmless treatment system comprises a dust removal mechanism and a purification mechanism, and the interior of the dust removal mechanism communicates with the interior of the purification mechanism through a gas guide pipe. According to the harmless treatment system for the waste incineration flue gas, impurities on the surfaces of a coarse filter screen and a fine filter screen are cleaned through a cleaning brush, so that the problem that meshes in the coarse filter screen and the fine filter screen are blocked by the impurities can be effectively avoided, and the filtering effect of the filtering assembly on solid particle impurities in the flue gas is ensured, and the treatment effect on dust and solid particle impurities in the flue gas is improved. Sulfides in the flue gas is purified through flue gas purification treatment liquid in a purification box, sodium alkali serves as a desulfurizing agent, lime serves as a regenerant, and calcium sulfite and sodium alkali and calcium sulfite precipitates are generated by adding lime into a circulating water system; the calcium sulfite is precipitated, the sodium alkali is recycled along with the desulfurization circulating water, so that the problem of easy scaling of a lime method is effectively solved, and meanwhile, the advantage of high desulfurization efficiency of a sodium alkali method is achieved.

Owner:利晟(杭州)科技有限公司

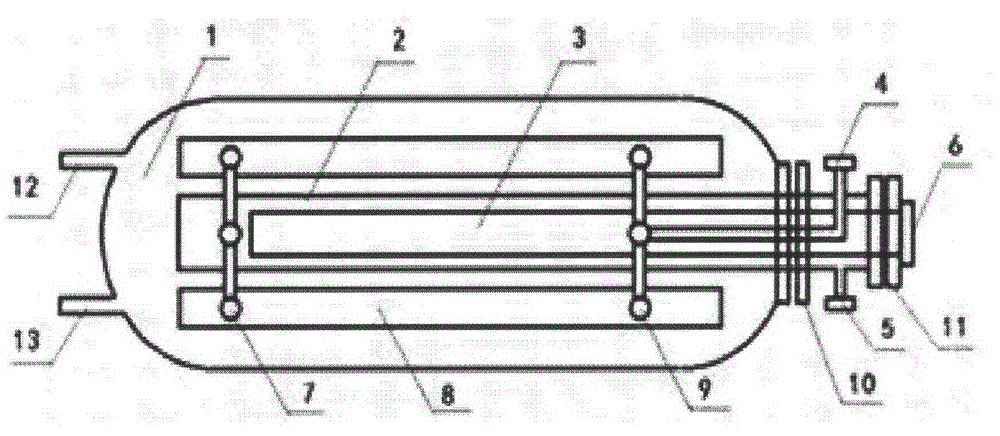

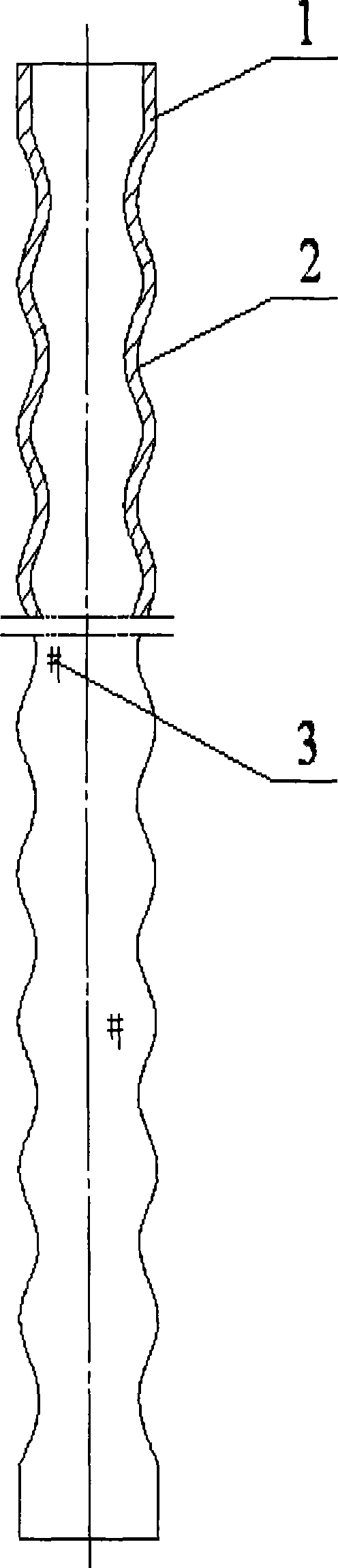

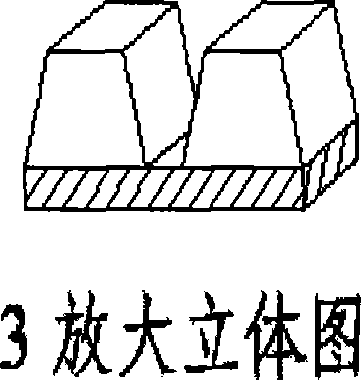

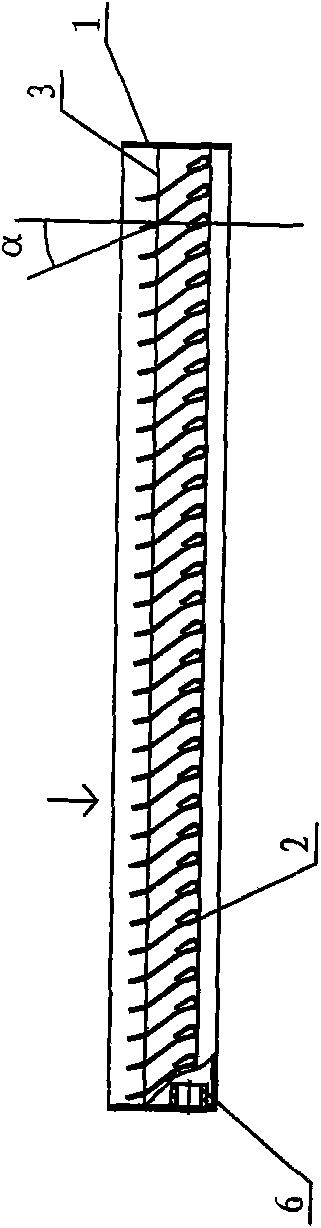

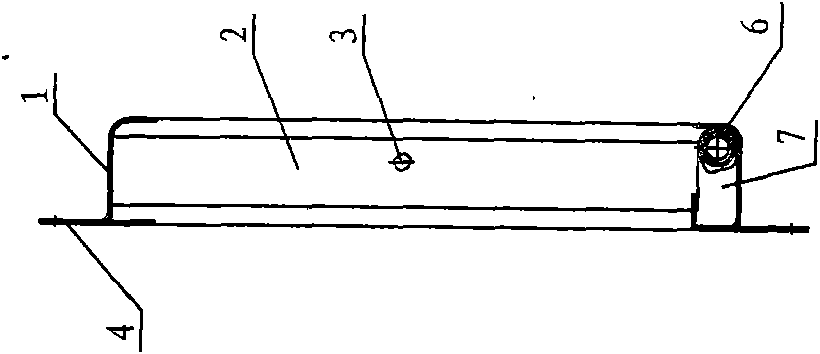

Efficient anti-scaling condensation pipe

InactiveCN101520285ASolve easy foulingImprove heat transfer coefficientEvaporators/condensersHeat transfer modificationVapor liquidEconomic benefits

The invention relates to an efficient anti-scaling condensation pipe. A thin-wall circular pipe is made of stainless steel, straight pipes with equal diameter are at two ends, a corrugated pipe is on the middle part, and the outer surface of the corrugated pipe is evenly distributed with raised pyramid lug bosses. The condensation pipe has the following advantages that: because fluid in the corrugated pipe disturbs intensively at low flow rate to generate turbulent flow which has complete flushing function on the pipe wall, the easy-scaling problem of the condensation pipe is well solved; simultaneously, due to surface curvature change and axial extension change of the corrugated pipe caused by temperature and larger linear expansibility difference of the stainless steel pipe wall and the scale, the scale is easy to fall off, self cleaning of the pipe is achieved, and the scale removing problem of the condensation pipe is well solved; moreover, the pyramid lug bosses on the outer surface of the corrugated pipe increase the heat exchange area and puncture condensate membranes, so drops are easy to form and drop quickly along a wave crest, and the vapor-liquid conversion time is quickened. The pipe has light weight, high strength and quick heat transfer, and is superior to the prior structural copper pipe in economic benefit, service life and the like.

Owner:吕美琪

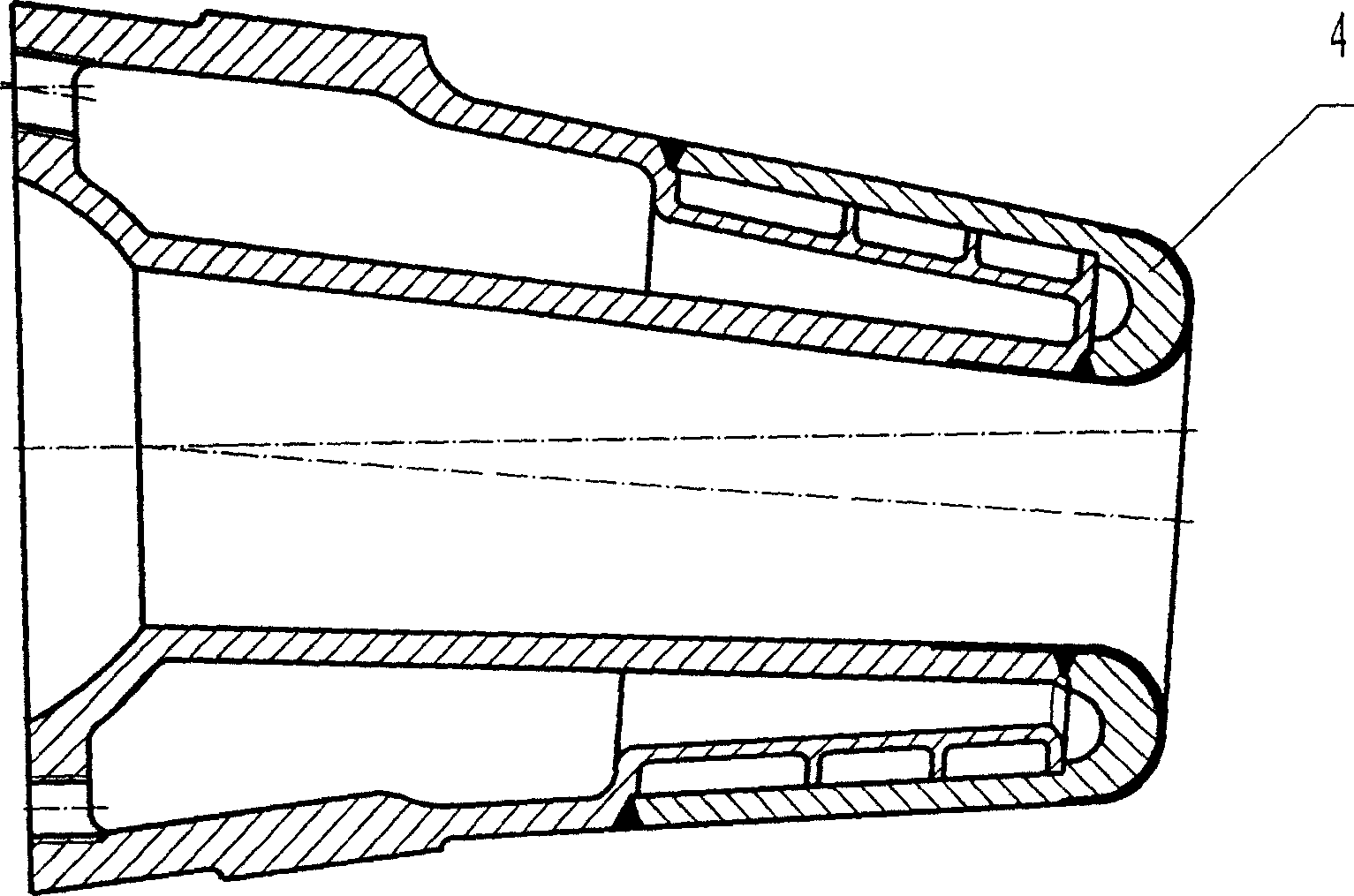

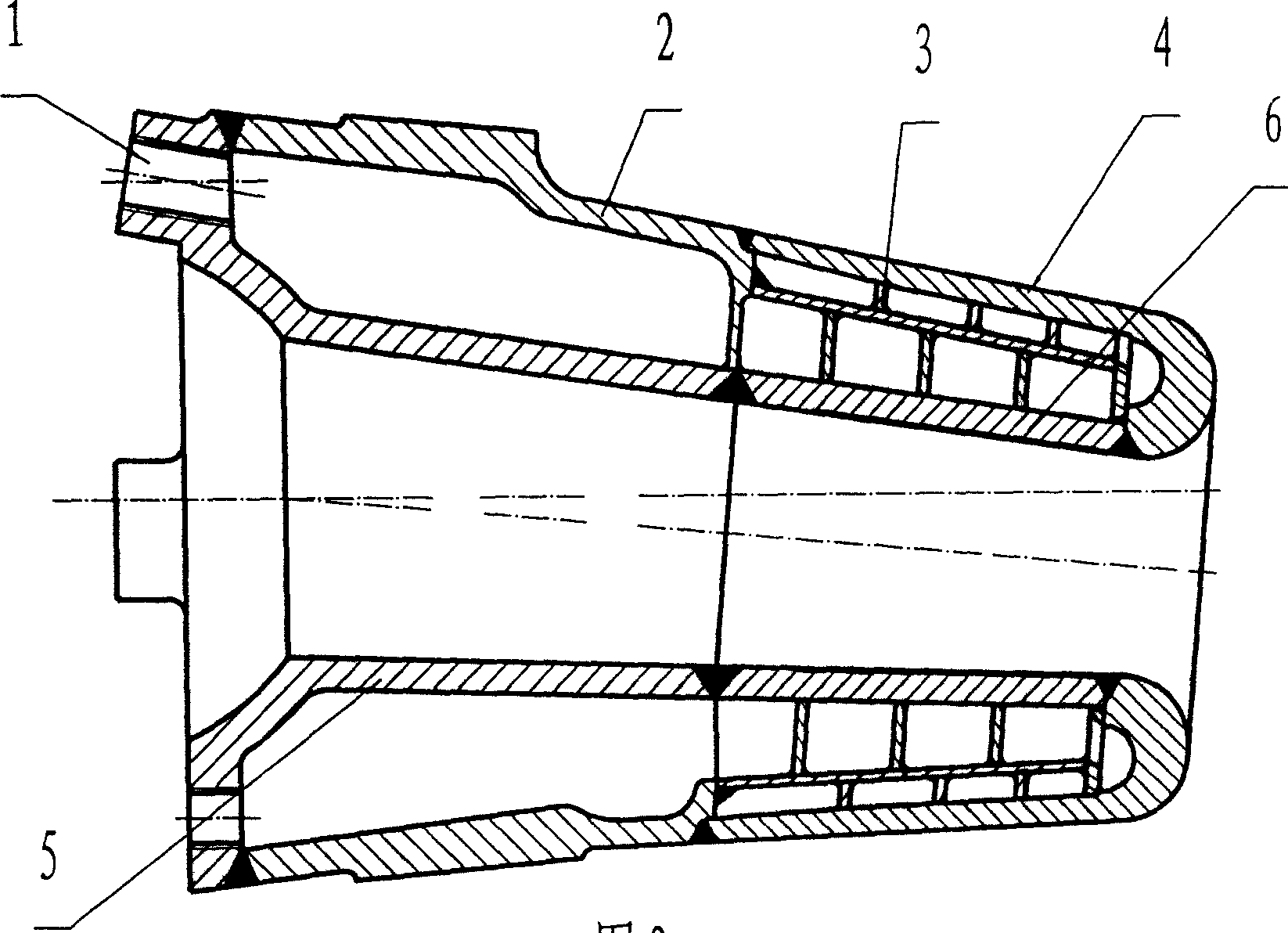

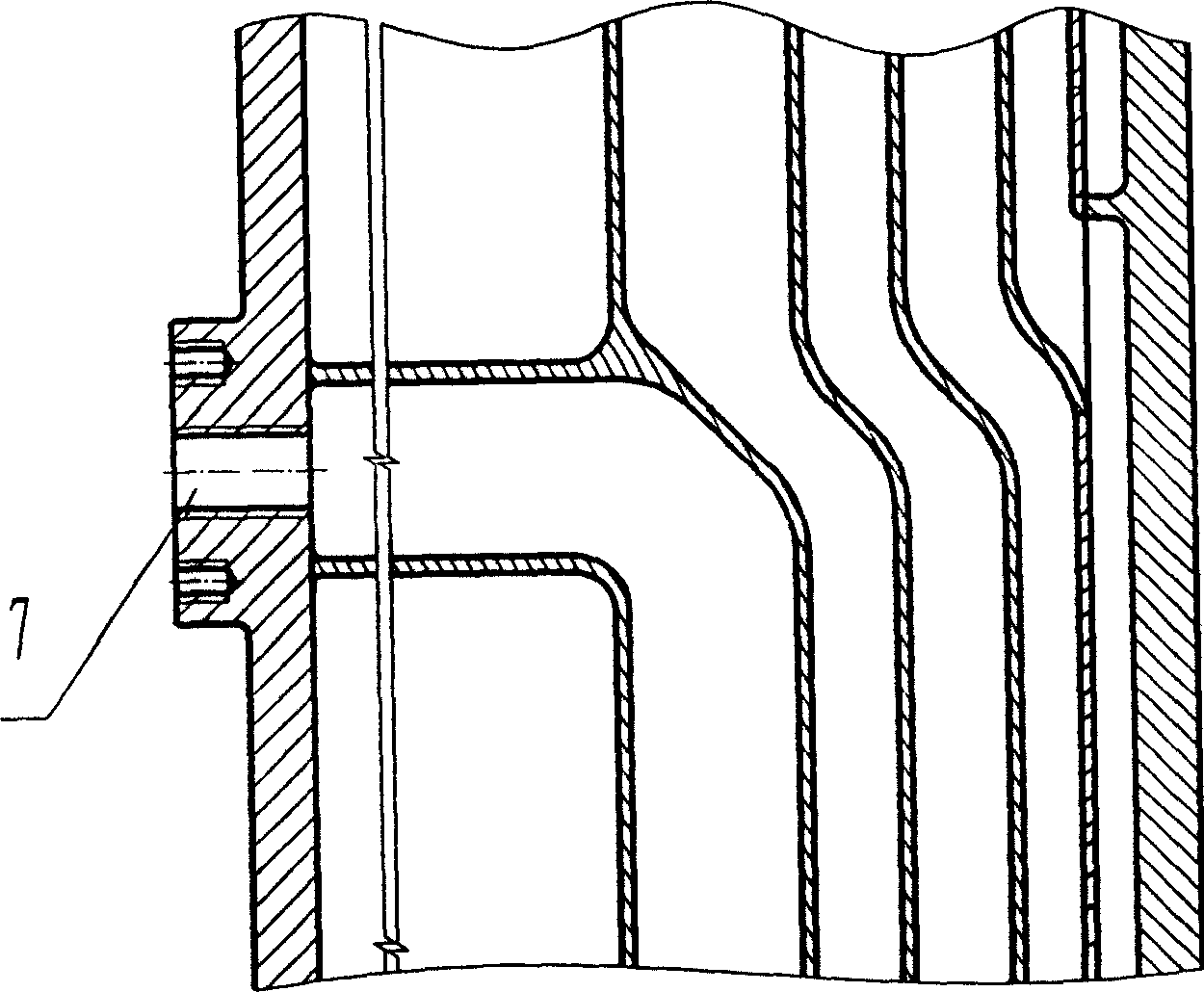

Tuyere cover of blast furnace

InactiveCN1810995AReduce manufacturing costImprove machining accuracyTuyeresCooling effectSteel frame

The present invention relates to blast furnace part, and is one kind of tuyere cover. Unlike available tuyere cover, which is made of copper and has high copper consumption and poor inner wall cooling effect, the tuyere cover of the present invention consists of a front body, a back body, a steel frame, a front cap and a back cap. The front body and the front cap are made of copper through extrusion and casting, the back body and the back cap is cast with boiler steel, and the steel frame is welded with common steel plate and provided with several inner and outer water passage partition layers. The tuyere cover of the present invention has lower copper consumption, low cost, raised machining precision, double circulating water passage and long service life.

Owner:万全县丰华有色金属加工有限公司

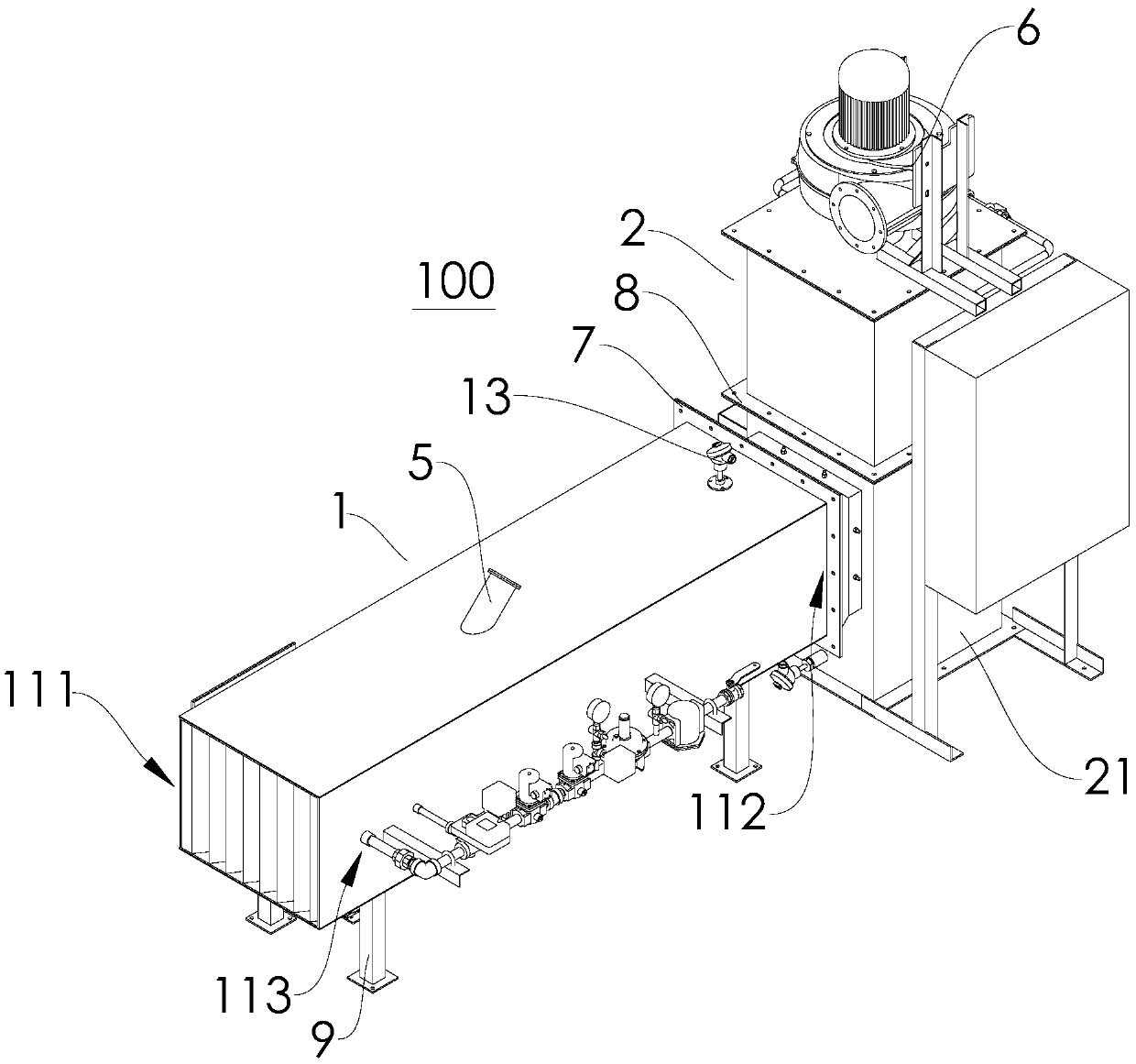

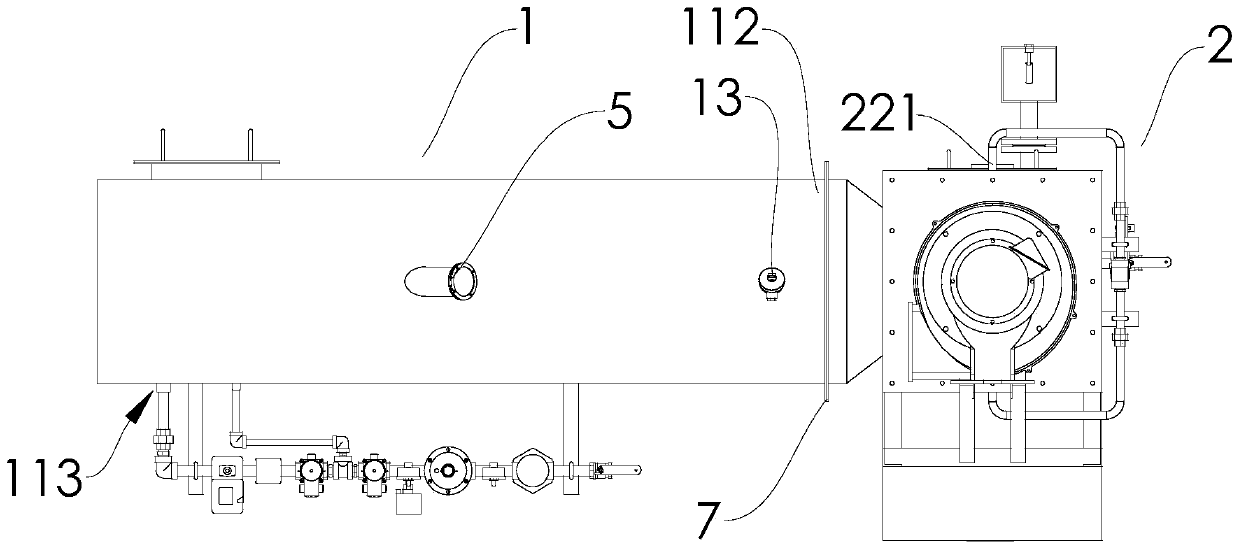

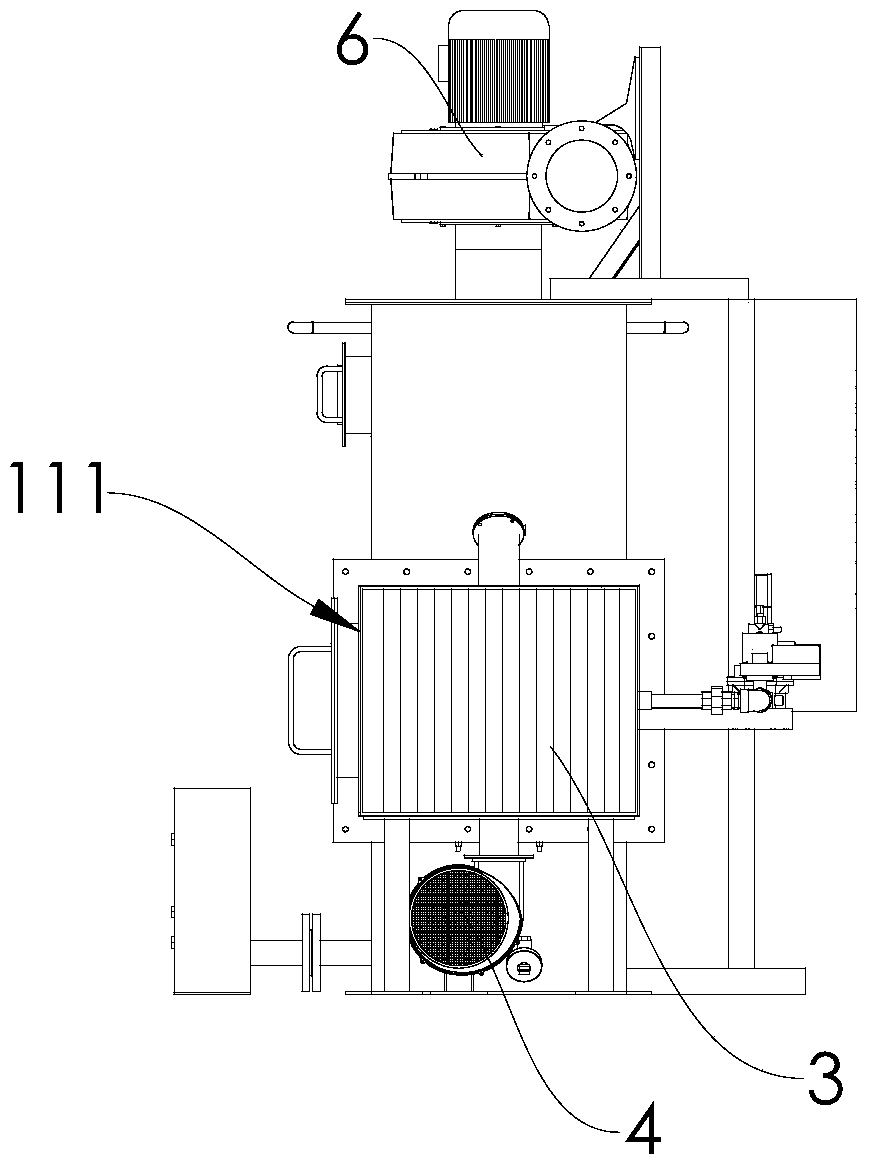

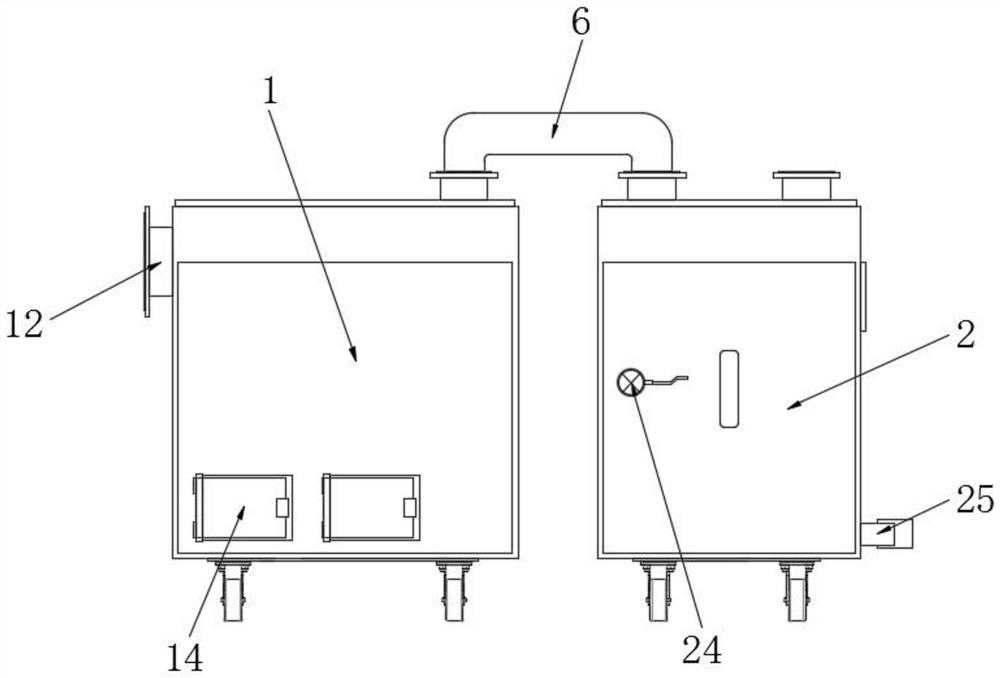

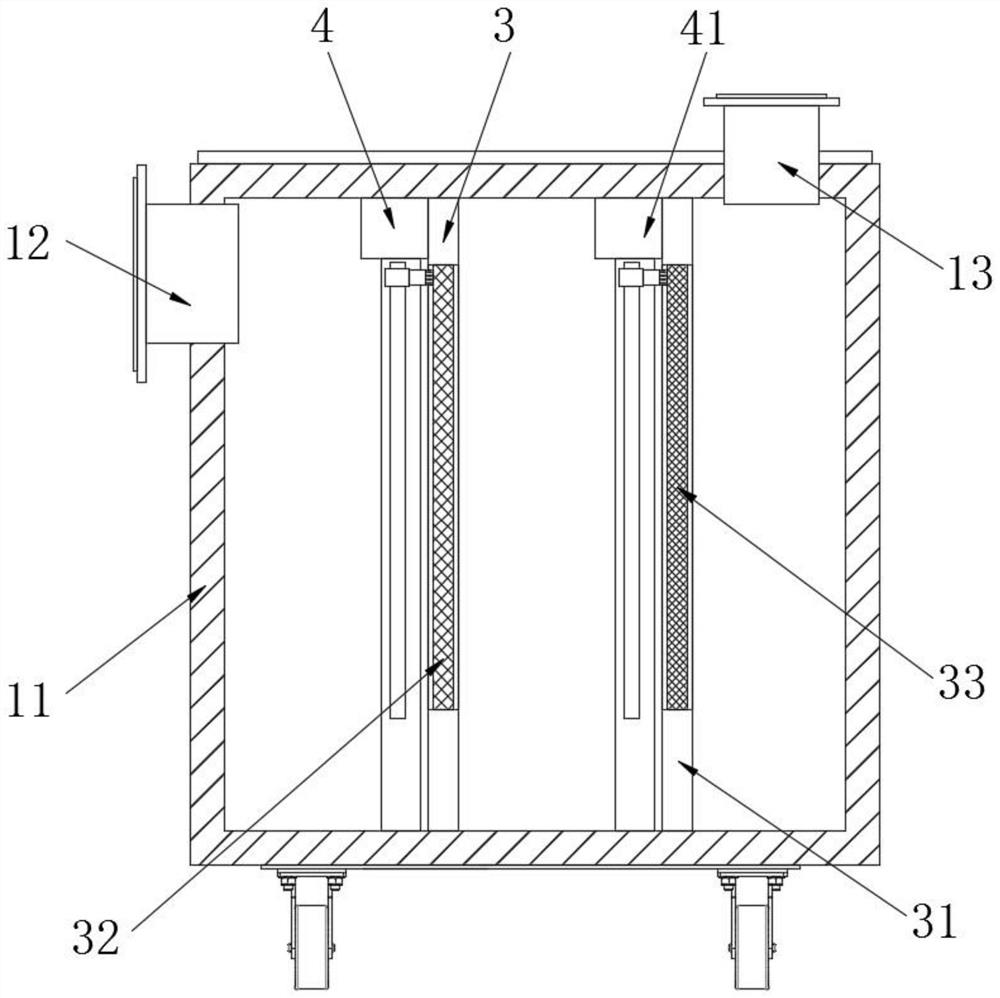

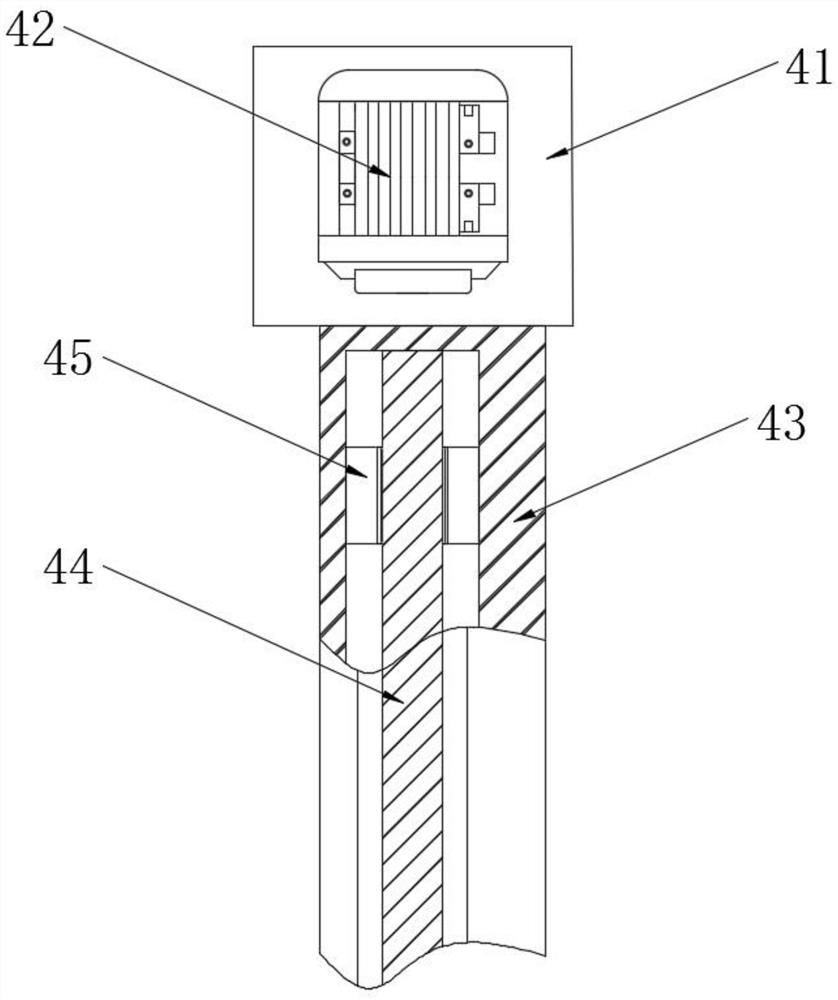

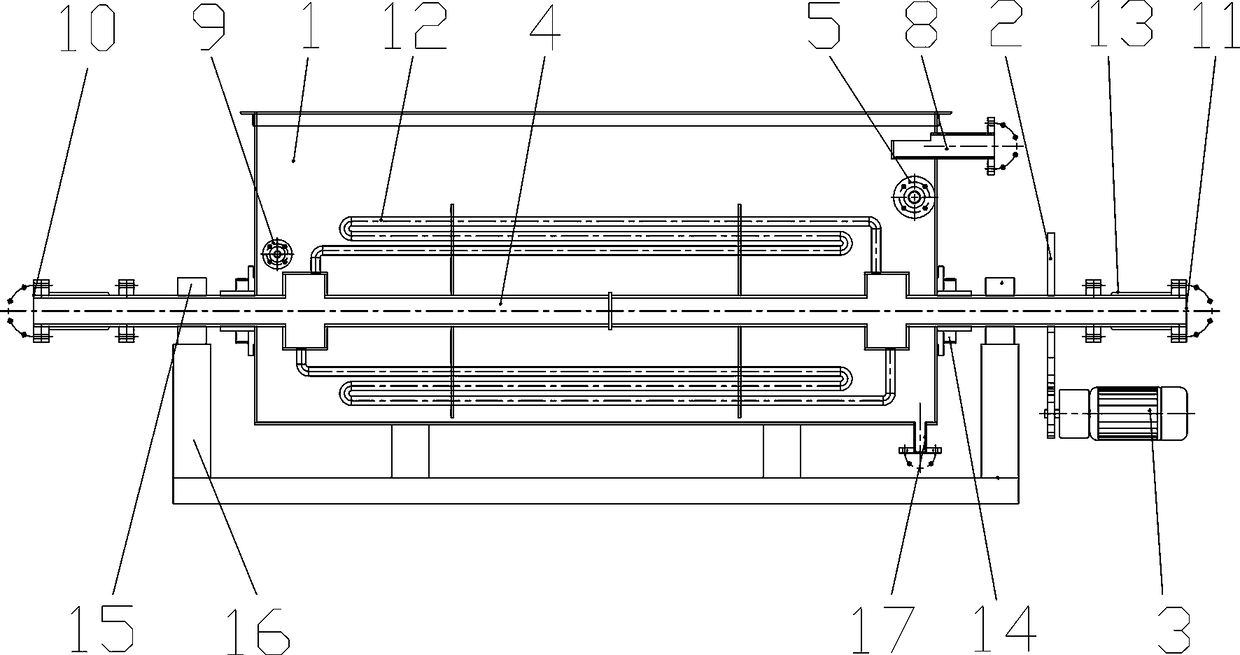

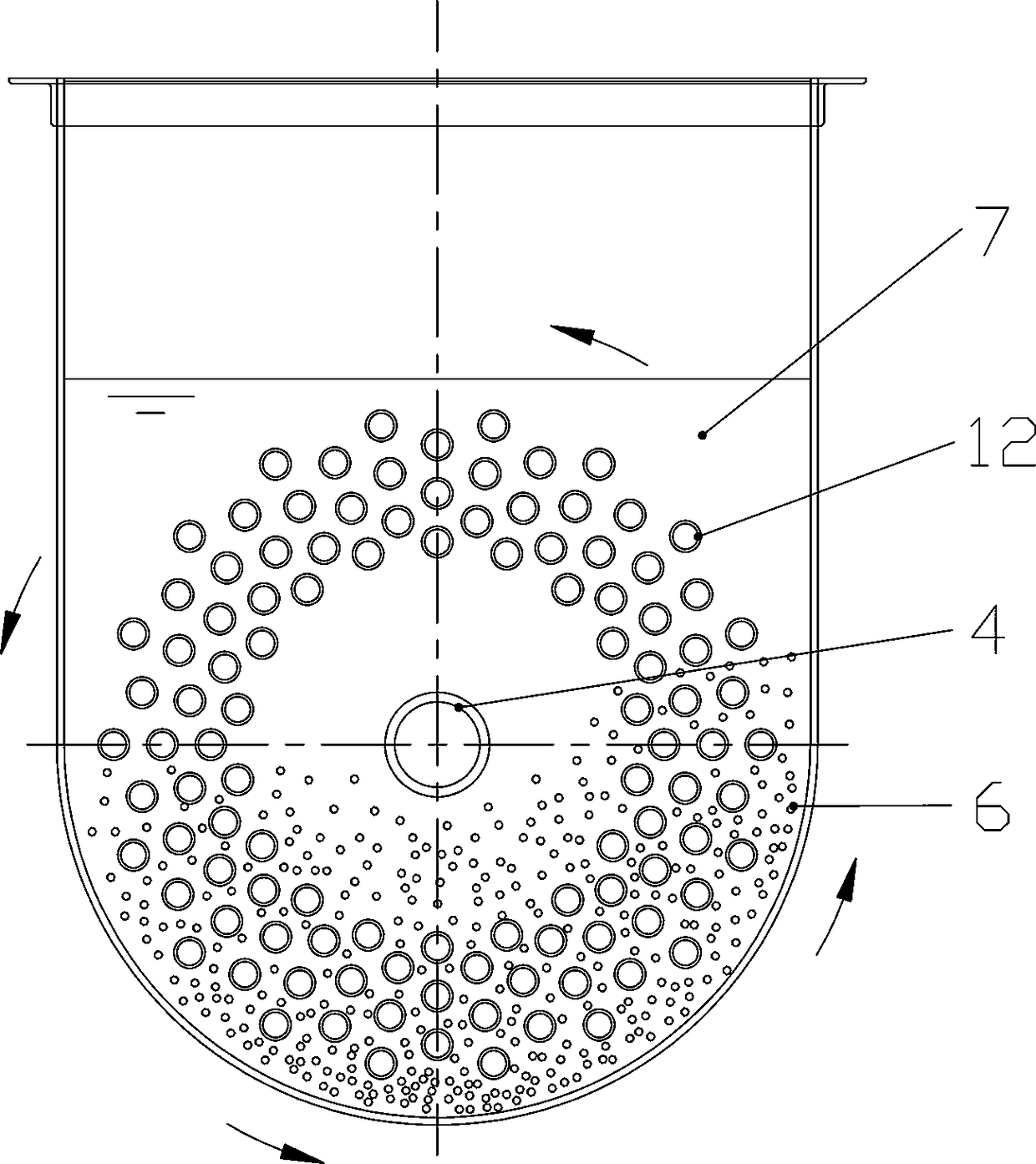

Self-descaling evaporator and running method thereof

PendingCN109399745ASolve easy foulingSolve the blockageWater/sewage treatment by heatingEngineeringDrive motor

The invention discloses a self-descaling evaporator. The self-descaling evaporator comprises an evaporator shell, a transmission device and a driving motor, wherein the evaporator shell is internallyprovided with a rotating inner tube, the rotating inner tube divides the evaporator shell into an inner part of the tube and an outer part of the tube, the outer side of the tube of the evaporator shell is provided with a working medium inlet, a working medium containing descaling particles is added into the evaporator shell from the working medium inlet, the outer side of the tube of the evaporator shell is further provided with a steam outlet and a working medium outlet, one end of the rotating inner tube is provided with a rotating inlet, the other end of the rotating inner tube is providedwith a rotating outlet, the steam in the evaporator shell enters the rotating inner tube from the rotating inlet via a pipeline through the steam outlet and is discharged from the rotating outlet after heat transfer, and a concentrated solution is discharged from the working medium outlet. The self-descaling evaporator has the advantages that the descaling particles are added, so that a heating tube rubs with the descaling particles, the problems of easy scale formation, blockage and sealing off of a heat exchanger are solved, and the effect of descaling is achieved; the driving motor can perform forward and backward switching, thereby capable of preventing scale formation on the reverse side of the heating tube during single-side rotation.

Owner:GUANGDONG CODE OF ENVIRONMENTAL PROTECTION ENG CO LTD

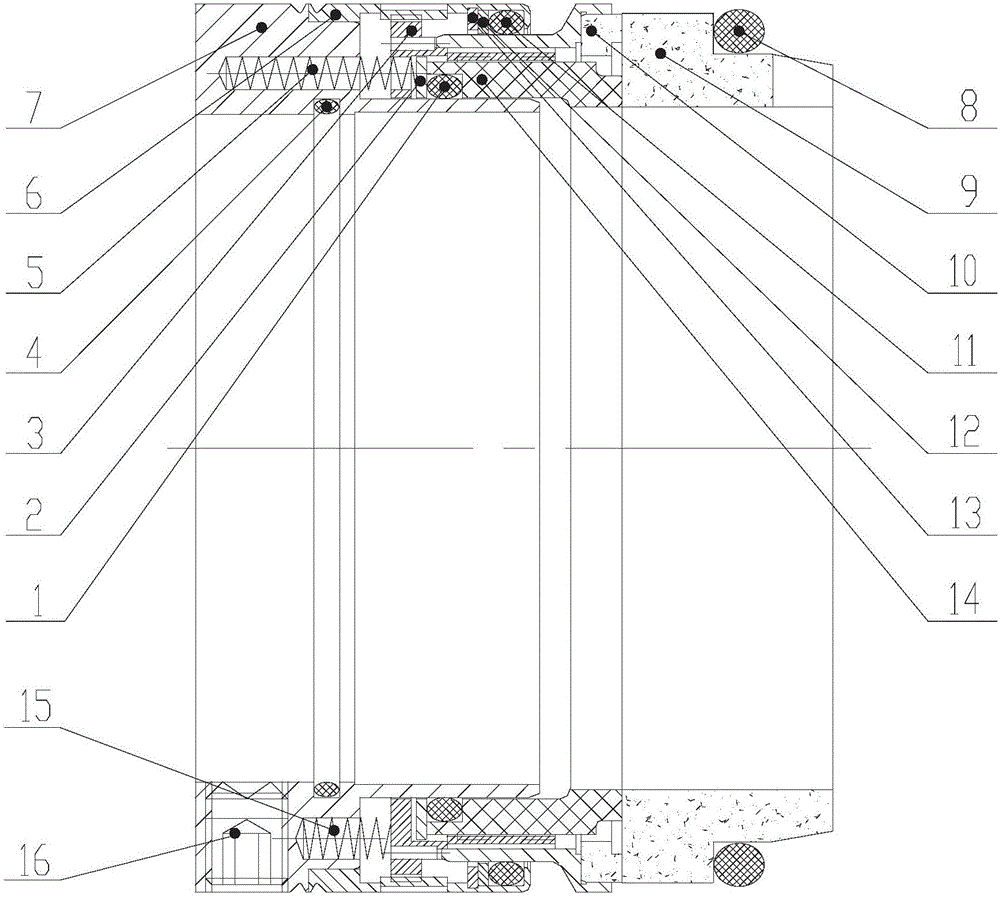

Integrated double mechanical seal

ActiveCN104696517ASealing is achieved independentlyImprove sealingEngine sealsEnd face mechanical seal

Owner:DANDONG BELLOWS SEALINGS

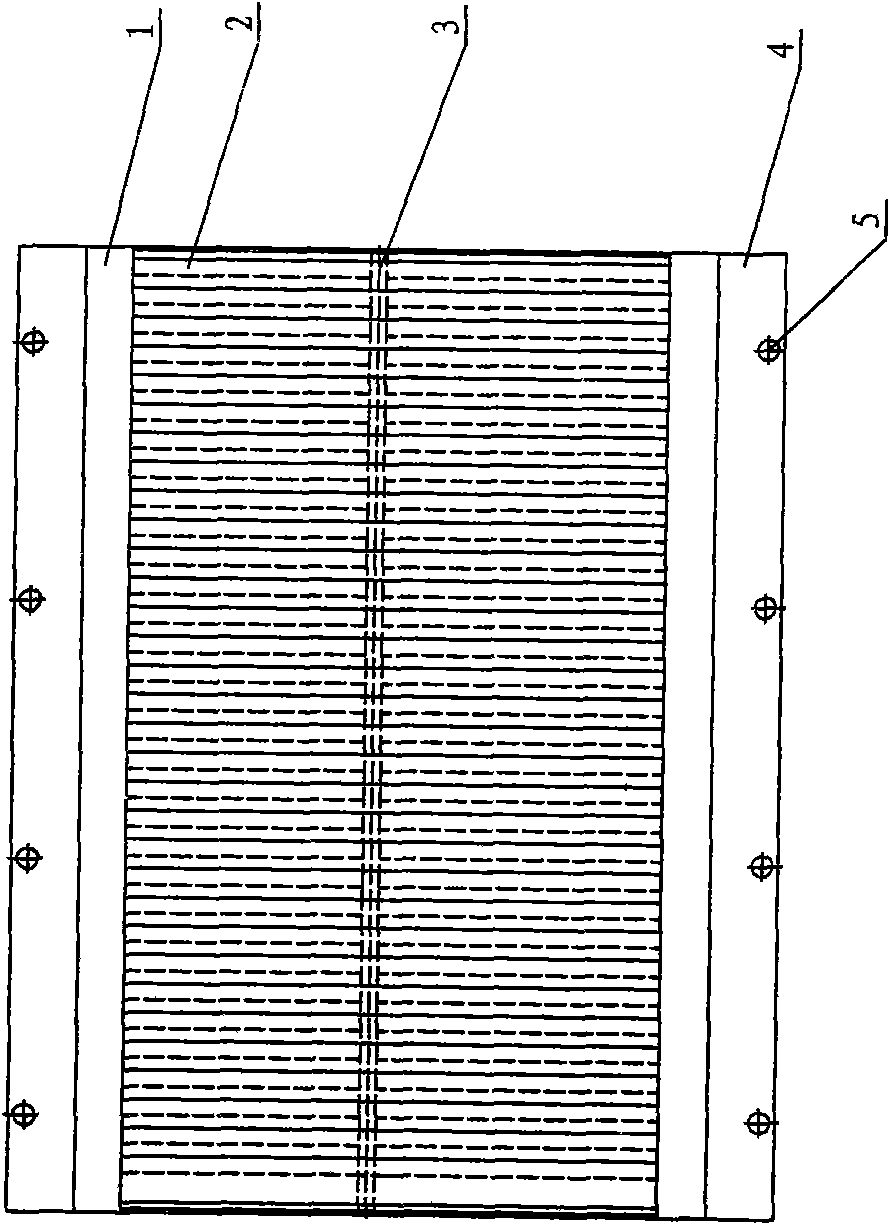

Efficient vortex blade-type gas-liquid separator core

InactiveCN101612501AEasy to cleanAchieve separationDispersed particle separationProduct gasSolid particle

The invention relates to an efficient vortex blade-type gas-liquid separator core for separating gas and liquid or solid. The core is provided with a frame, wherein a drainage groove and a water outlet are arranged on a lower frame of the framework. The core is characterized in that a plurality of hooked vortex separation blades are vertically arranged in the framework side by side, and 20 to 30 mm of clearance is reserved between the blades. The core overcomes the problems that the prior screen-structure and bag-structure separators are easy to block, resulting in the rupture and failure of screens and bags and short lifespan, and overcomes the defect that screen structure and bag structure cannot separate solid particles, and is mainly applied to the high-requirement separation of gas and liquid or solid in petrochemical, shipbuilding, metallurgy, medicine, electric power and other industries.

Owner:张平

Low-phosphorus scale and corrosion inhibitor, and preparation method thereof

InactiveCN109179700AWell mixedGood scale and corrosion inhibitionSpecific water treatment objectivesScale removal and water softeningPolyaspartic acidItaconic acid

The invention belongs to the technical field of scale and corrosion inhibition, and discloses a low-phosphorus scale and corrosion inhibitor, and a preparation method thereof. The low-phosphorus scaleand corrosion inhibitor comprises, by weight, 10-20 parts of 2-phosphonobutane-1,2,4-tricarboxylic acid, 5-12 parts of polyaminopolyether methylene phosphonate, 8-15 parts of polyaspartic acid, 5-12parts of phosphonocarboxylic acid, 8-15 parts of an itaconic acid copolymer, 5-12 parts of a water-soluble zinc salt and 3-7 parts of an acid. The preparation method comprises the following steps: A,slowly adding the acid to water, and then adding the water-soluble zinc salt to obtain an acid solution of the zinc salt; and B, adding the 2-phosphonobutane-1,2,4-tricarboxylic acid, polyaminopolyether methylene phosphonate, polyaspartic acid, phosphonocarboxylic acid and itaconic acid copolymer to the acid solution of the zinc salt at a constant temperature, performing uniform stirring, and cooling the obtained mixture to room temperature in order to obtain the low-phosphorus scale and corrosion inhibitor. The low-phosphorus scale and corrosion inhibitor has the characteristics of good stability, low phosphorus, environmental protection and low cost.

Owner:昆明明净科技有限责任公司

Pressure type oil-contaminated water air-float machine

InactiveCN101385910ASolve easy foulingFlexible structureWater/sewage treatmentLiquid separationSmall footprintEngineering

The invention discloses a pressure type oily water floatation machine, and more particularly relates to the technical field of an oily water treating floating device. A water inlet is installed at the lower bottom of a shell, a horizontal clapboard is installed inside the shell, and an oil and air outlet A is installed at the top end of the horizontal clapboard; a vertical baffle A is installed under the horizontal clapboard in the inner cavity of the shell, an electrode A is arranged at one side of the vertical baffle A, a first-grade liquid outlet is arranged at the other side, and a horizontal baffle A is connected with the vertical baffle A; a vertical baffle B is arranged above the horizontal clapboard, a horizontal baffle B is connected with the vertical baffle B, a second-grade liquid inlet is arranged under the horizontal baffle B, and an electrode B is arranged above the horizontal baffle B; a vertical baffle C is arranged at the other side of the vertical baffle B, a water outlet is arranged at one side of the vertical baffle C, and an oil and air outlet B is arranged at the top part of the shell at the other side. The pressure type oily water floatation machine has the advantages of being capable of operating under normal pressure as well as increased pressure, being flexible in equipment structure (placing in either a standing mode or a lying mode), reducing drug amount, being low in operation cost and small in floor space.

Owner:JIANGDU COUNTY ENVIRONMNT PROTECTION EQUIPS FACTORY

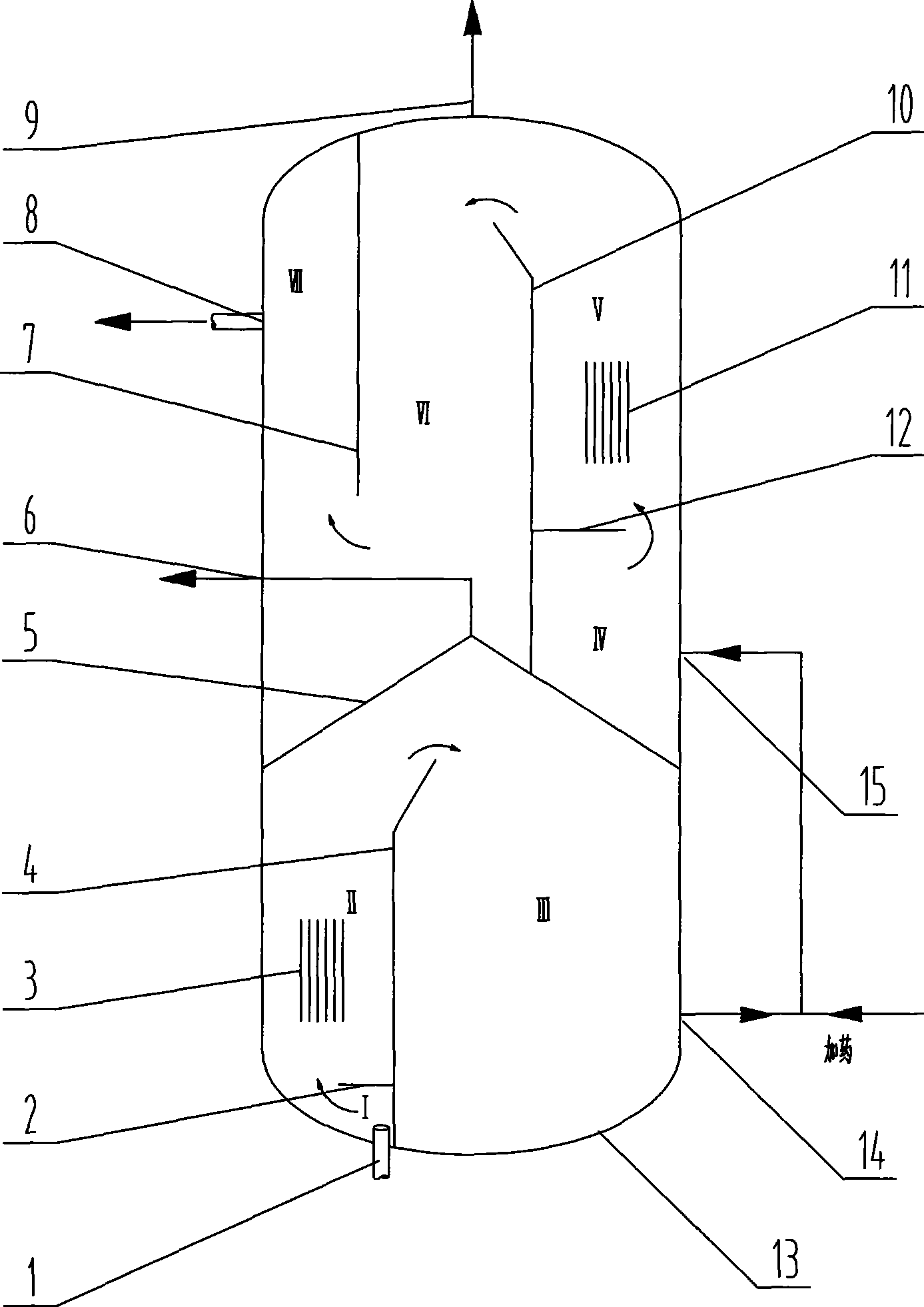

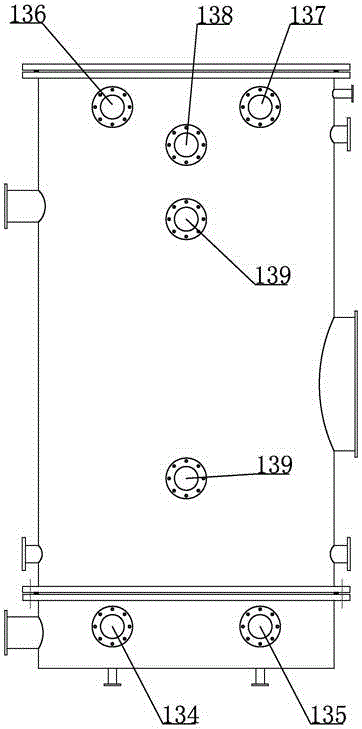

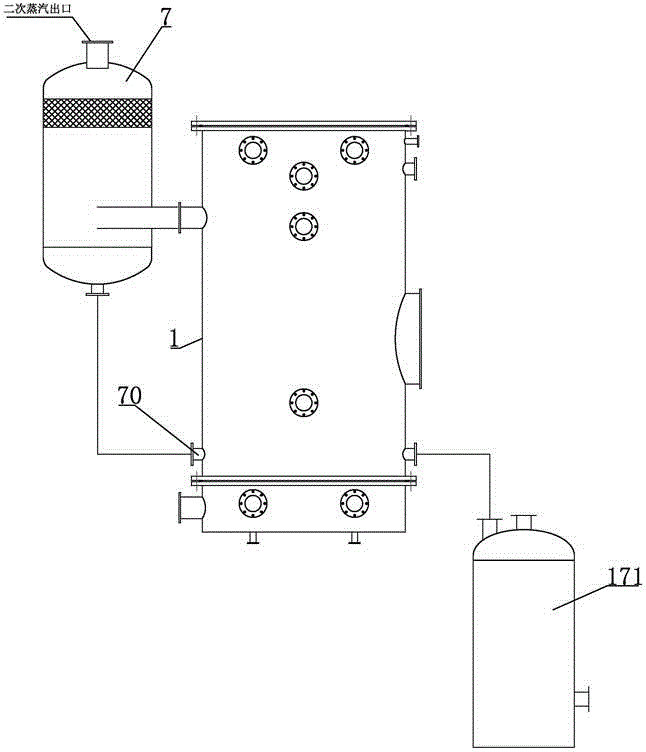

Vertical-type stock-solution outside tube falling-film evaporator

InactiveCN106039747AImprove evaporation efficiencyIncrease the scope of applicationEvaporator accessoriesEngineeringDrainage tubes

The invention discloses a vertical-type stock-solution outside tube falling-film evaporator. The falling-film evaporator comprises a vertical-type evaporator, a condenser, a heat exchanger, a steam input tube, a steam output tube and a compressor arranged on the steam output tube; the condenser is communicated with a stock solution tube, and the vertical-type evaporator comprises a vertical-type tube, a first steam box, a second steam box, a solution distribution box, a solution distributor, an evaporation chamber, a solution collection box and tube harnesses; the solution distributor comprises a plate and honeycomb holes, and gaps exist between the honeycomb holes and the outer surfaces of the tube harnesses; the second steam box comprises a first cavity and a second cavity, the first steam box comprises a third cavity and a fourth cavity, the condenser is communicated with a condensation water tank, the heat exchanger comprises a first plate-type heat exchanger and a second plate-type heat exchanger which is provided with a condensed water drainage tube communicated with the second plate-type heat exchanger, steam exhausted to a defoamer is secondary steam, and an external steam heat source can be boiler steam or compressor warming secondary steam or industrial waste steam. The vertical-type stock-solution outside tube falling-film evaporator has the advantages of being wide in application range, not prone to scaling and convenient to clean and achieving condition monitoring conveniently.

Owner:范亚平

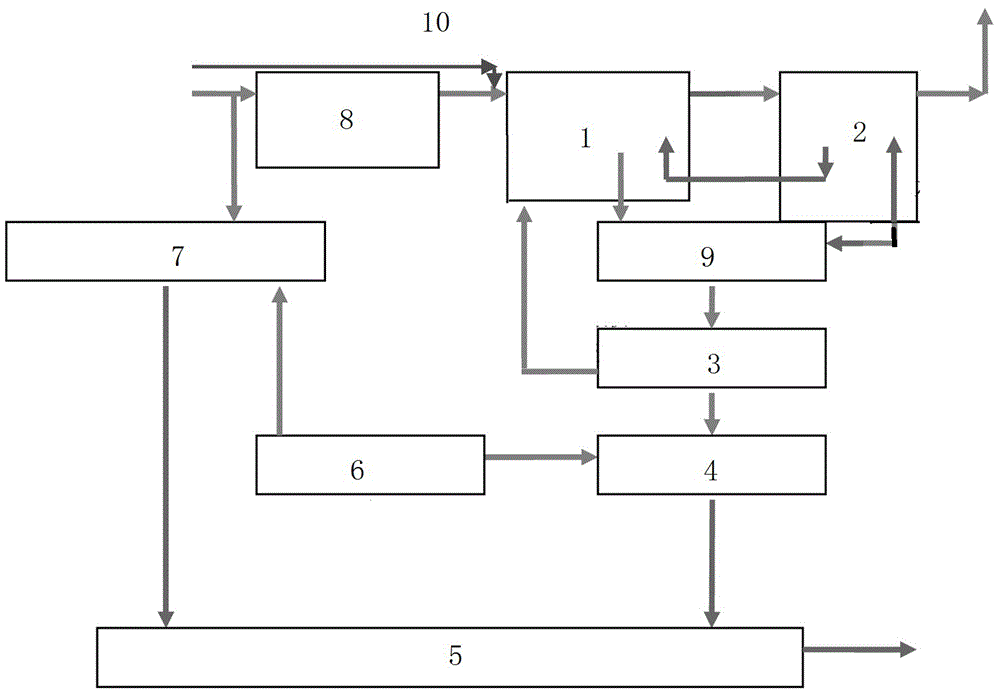

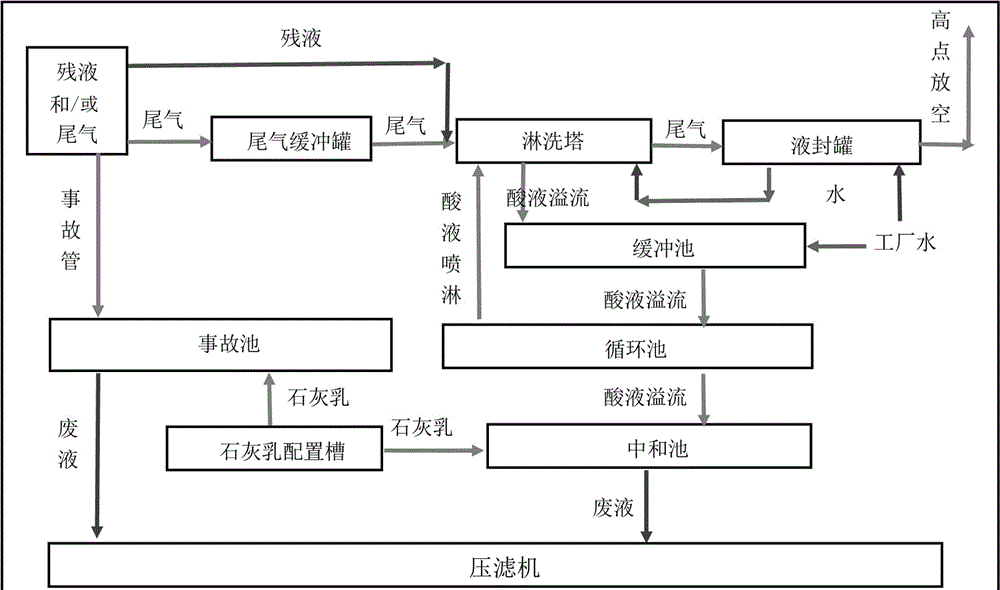

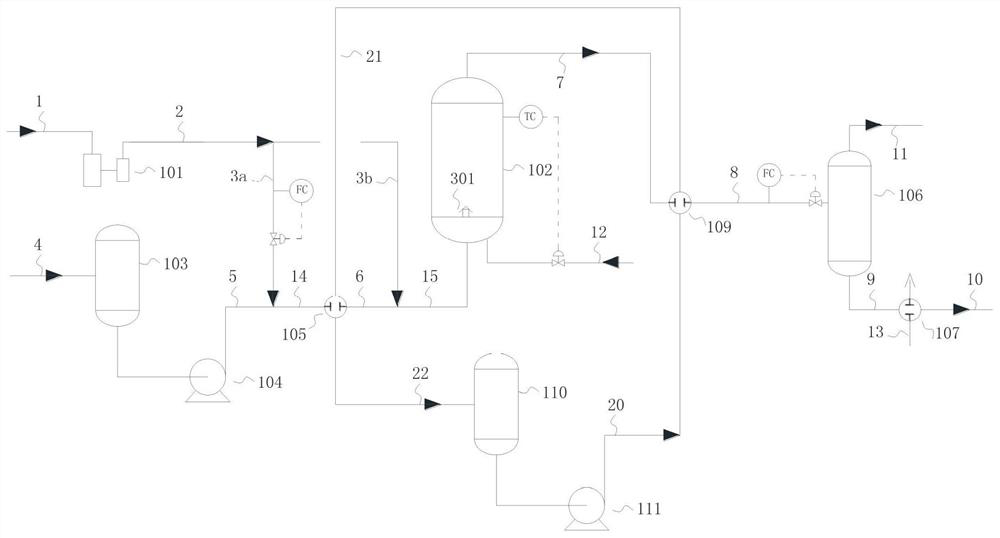

Process and device for treating tail gas and/or residual liquid in polycrystalline silicon production

InactiveCN105920986AReduce consumptionIncrease consumptionDispersed particle separationTreatment involving filtrationWater circulationChemistry

The invention discloses a process and device for treating tail gas and / or residual liquid in polycrystalline silicon production. According to the process, firstly, the tail gas and / or the residual liquid are fed into an elution column, weak-acid water with the mass concentration being 2-5% is used for carrying out spraying and washing at a countercurrent state, washed gas enters a liquid sealing tank to be purified through clean water, the finally released gas is discharged into air, and washed liquid serves as weak-acid water to carry out circular spraying; after the weak-acid water for circular spraying in the first step exceeds the limited concentration, part of waste acid water is drained, water is added to dilute the weak-acid water until the needed concentration is achieved, then, the weak-acid water continues to be used, lime emulsion is added into the exhausted waste acid water to neutralize the exhaust waste acid water, then, a pressure filter is used for carrying out filtering, part of filtrate is reused, and other filtrate and filter residues are discharged. The process and the device ensure that the treated tail gas reaches the standard and then is discharged; blockage of a spray head, a pipeline and equipment is avoided, and operation is safe and easy; part of the filtrate is reused, the chemical engineering waste acetylene sludge emulsion is recovered and used, the water consumption is reduced, and the treating cost for tail and / or residual liquid is saved.

Owner:YICHANG CSG POLYSILICON CO LTD

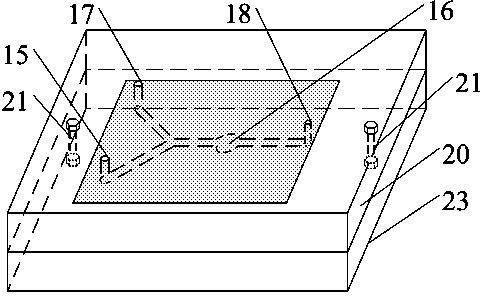

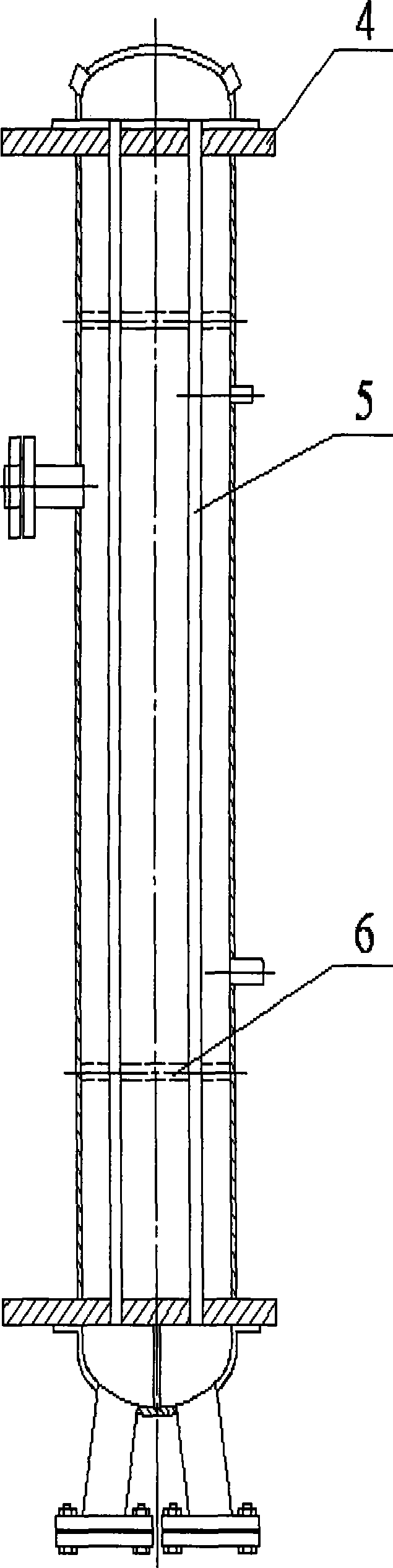

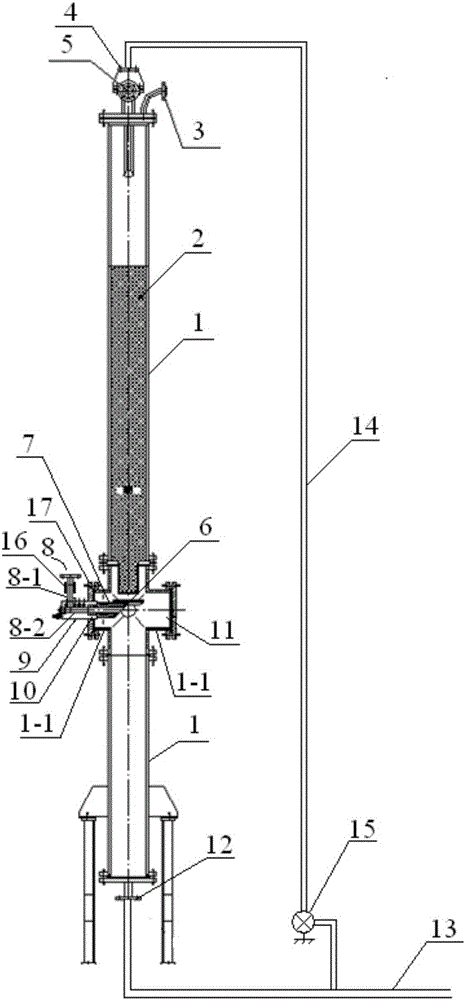

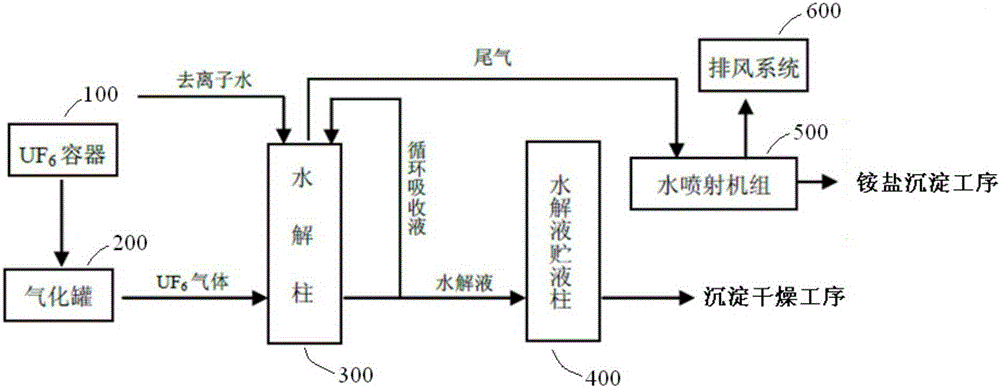

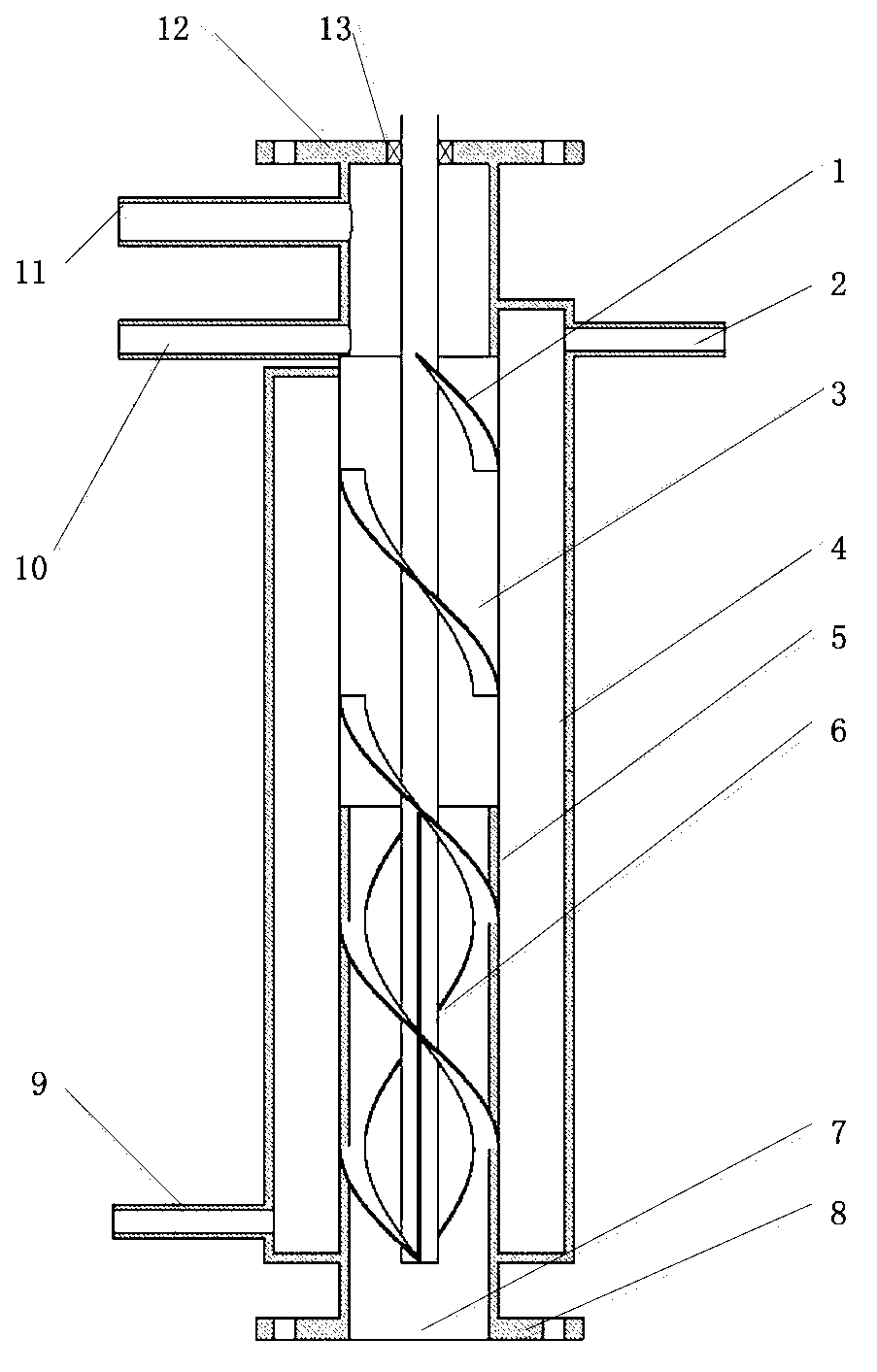

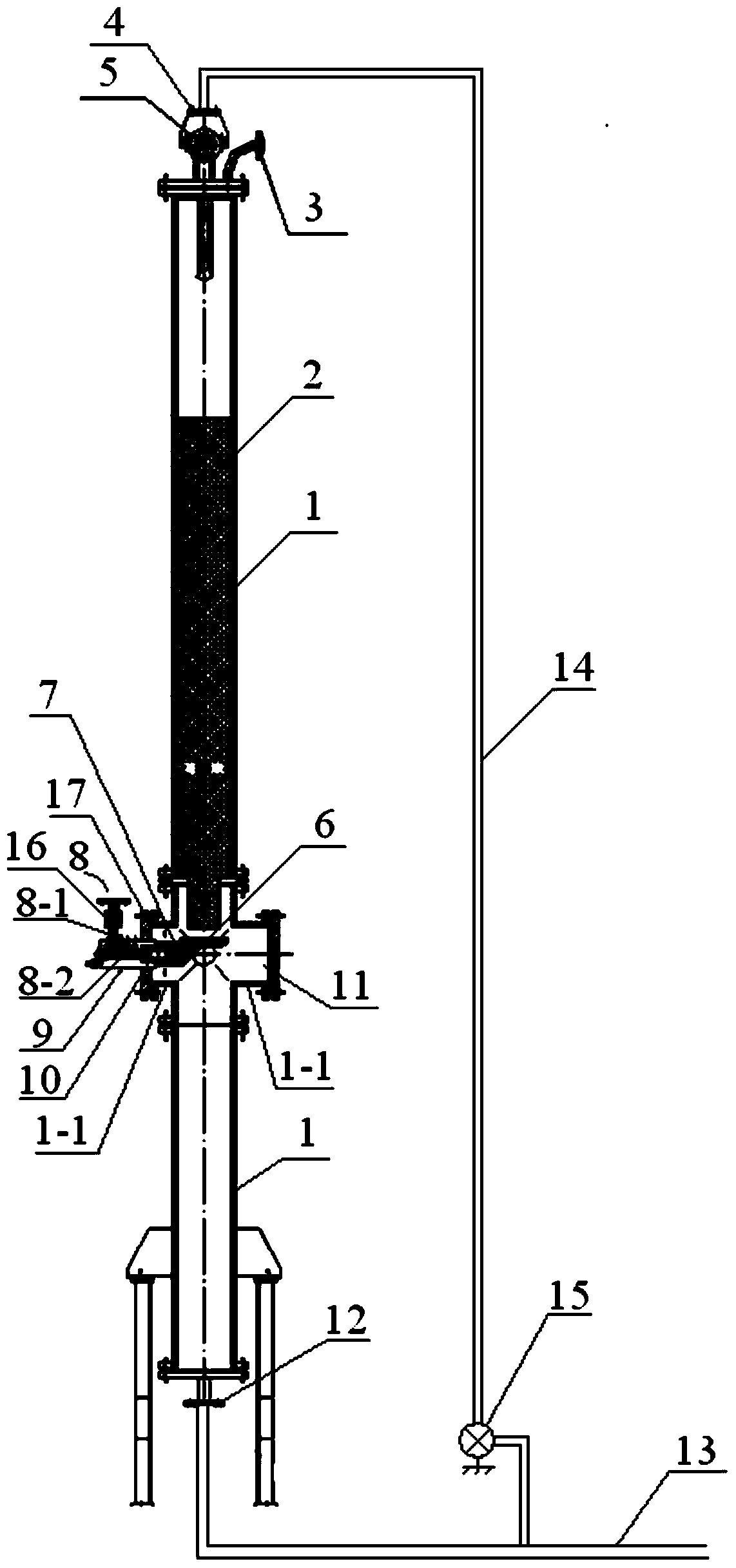

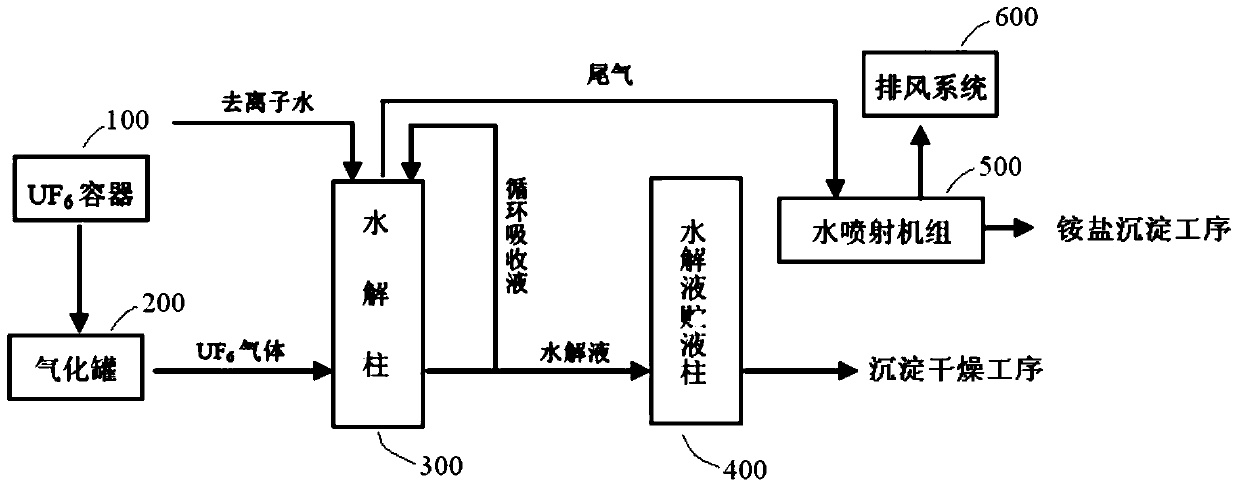

UF6 hydrolysis column, hydrolysis system and hydrolysis process

ActiveCN105174312AUniform temperature and concentrationEnsuring Nuclear Criticality SafetyUranium dioxideSpray nozzleCrystal

The invention relates to a UF6 hydrolysis column, a hydrolysis system and hydrolysis process. According to the invention, the top part of the UF6 hydrolysis column is provided with a water inlet (3), an air outlet (5) and a cyclic hydrolysate inlet (4); the bottom part of the UF6 hydrolysis column is provided with a hydrolysate outlet (12); the middle part of the UF6 hydrolysis column is provided with an air inlet pipe (8) which extends into the interior of a hydrolysis column shell (1); the air inlet pipe (8) is provided with an electric heat tracing mechanism (16); the end part of the air inlet pipe (8) extending into the hydrolysis column shell (1) is connected with a spray nozzle (7) which is equipped with a heat-preservation mechanism; and a hydrolysate outlet pipeline (13) connected with the hydrolysate outlet (12) is connected with a hydrolysate cyclic bypass (14) which is connected with the cyclic hydrolysate inlet (4). The UF6 hydrolysis column provided by the invention can guarantee the concentration of the hydrolysate therein, has uniform temperature; meanwhile, UO2F2 crystals located at the spray nozzle can be prevented from occurrence, and stability and safety are high; and the hydrolysis system and the hydrolysis process can realize continuous hydrolysis of UF6, and complete hydrolysis is guaranteed.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Treatment method of landfill leachate nanofiltration concentrate

ActiveCN106277591BGuaranteed uptimeIncrease flow rateWater contaminantsMultistage water/sewage treatmentLiquid wasteElectrolysis

The invention relates to a treatment method for nanofiltration concentrated liquor of landfill leachate, which comprises the following steps: carrying out medium-pressure nanofiltration treatment first for minimization, carrying out coagulation air floatation treatment for the concentrated liquor after the medium-pressure nanofiltration treatment to recycle humous larger molecular organics for resource utilization, carrying out resin-based softening treatment to reduce the hardness of the concentrated liquor after the coagulation air floatation treatment, performing electrolytic oxidation treatment on the concentrated liquor after the resin-based softening treatment and treating back washing water, feeding the clear liquid from the medium-pressure nanofiltration, yielding water from the regenerated waste liquor and yielding water after the electrolytic oxidation to membrane bioreaction treatment, performing tail gas absorption treatment on gases generated from the electrolytic oxidation, and absorbing chlorine gas in tail gases before up-to-standard emission. The treatment method for nanofiltration concentrated liquor of landfill leachate is reasonable in treatment process with a good treatment effect, and relatively low in investment and operation costs; the problem of accumulation of humic acids and hardness ions in the biochemical system is avoided, and the difficulty in treating the nanofiltration concentrated liquor of the landfill leachate is solved; and the treatment method is applicable to treating the nanofiltration concentrated liquor generated in the 'MBR+nanofiltration' treatment process for the landfill leachate.

Owner:WELLE ENVIRONMENTAL GRP CO LTD

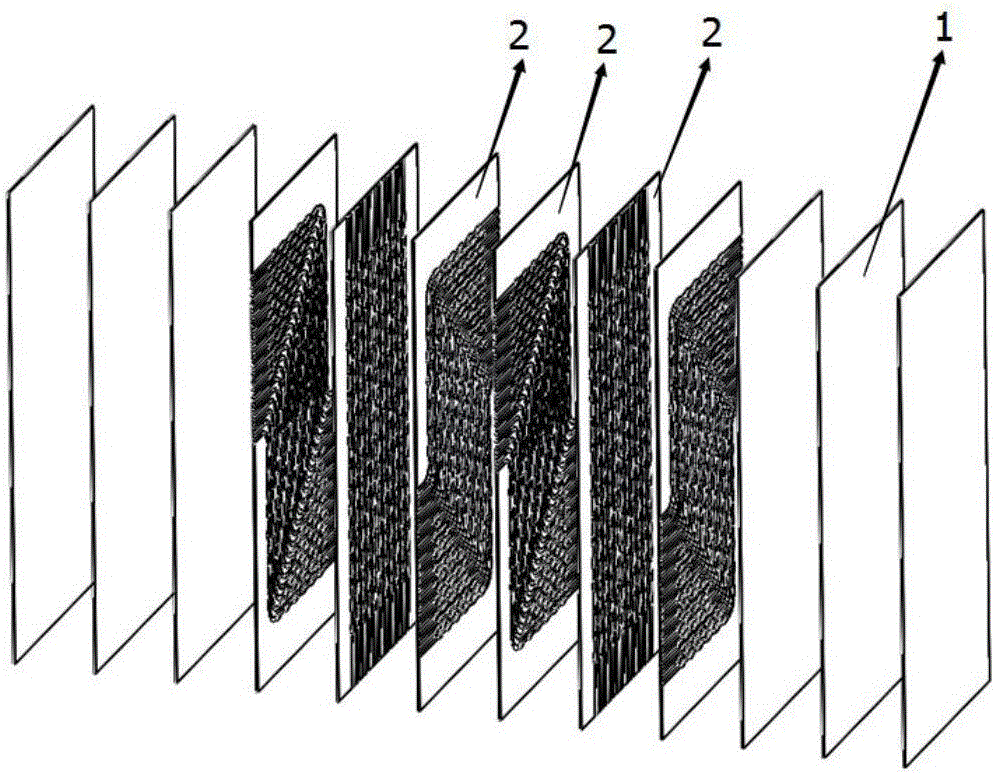

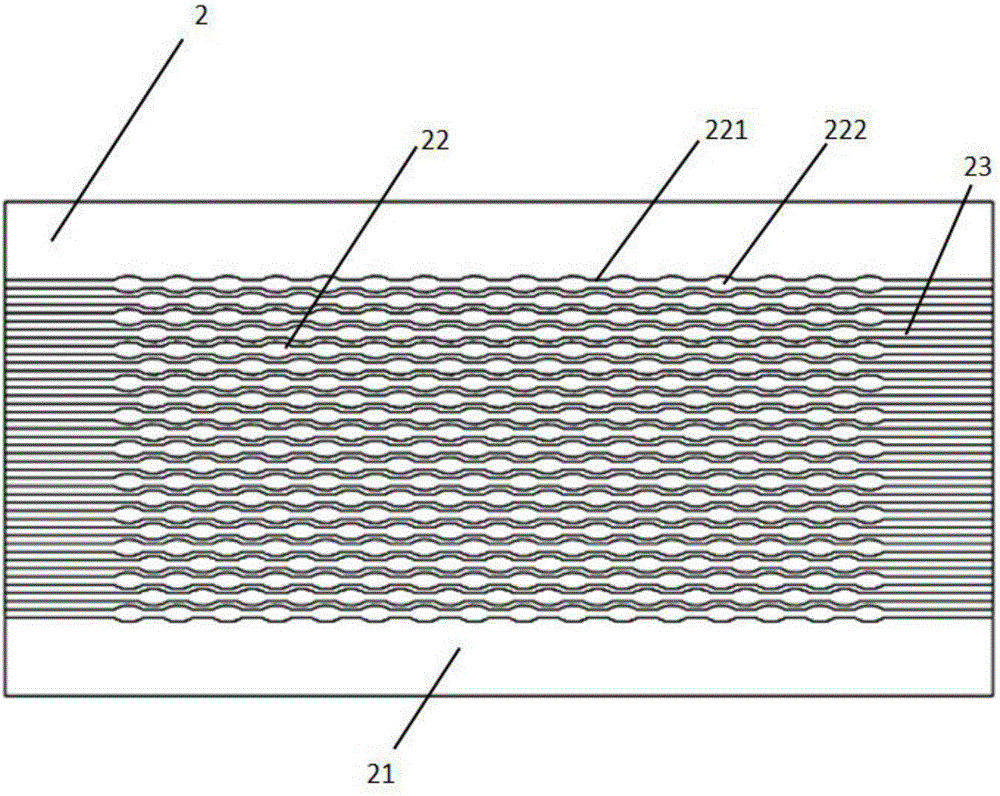

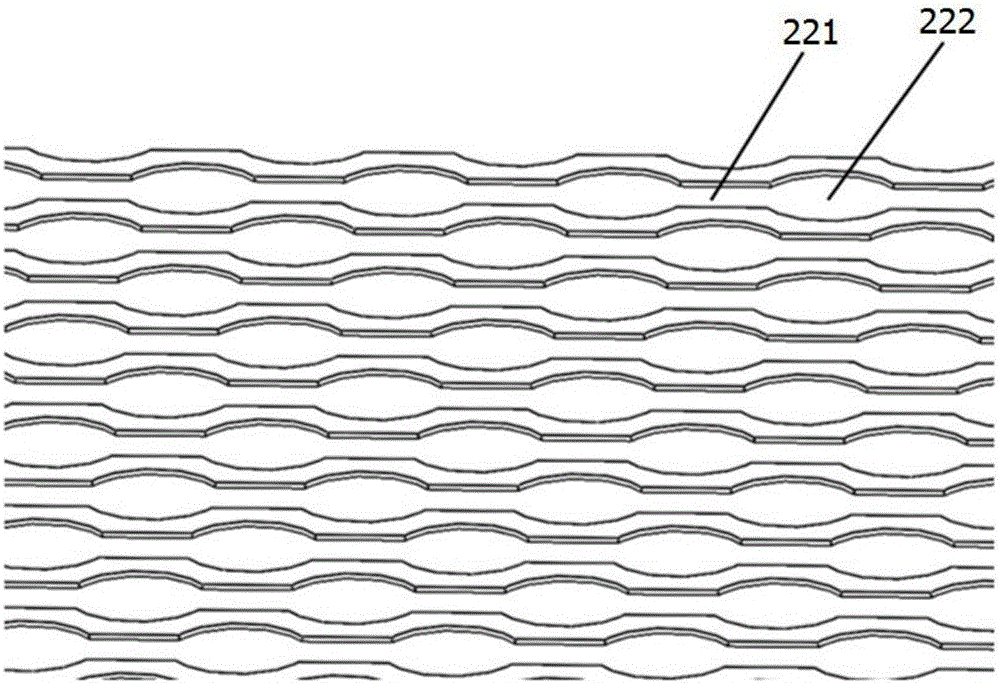

Novel heat exchanger core

ActiveCN106440913AAvoid easy cloggingLarge transmission capacityCorrosion preventionLaminated elementsLong axisEngineering

The invention provides a novel heat exchanger core. The novel heat exchanger core comprises a cover plate, a first heat exchange plate set, a second heat exchange plate set, ..., and a nth heat exchange plate set. The heat exchange plate sets are stacked, the cover plate is stacked on the outer side of the heat exchange plate sets, and each heat exchange plate set comprises more than one same heat exchange plate; each heat exchange plate is composed of a base body and a heat exchange flow passage processed in the base body in a chemical-etching mode, and the projection of flow inlets and flow outlets of different heat exchange plate sets in the direction perpendicular to the heat exchange plates is not overlapped with each other; each heat exchange flow passage is composed of straight flow passage bodies and oval flow passage bodies which are alternately arranged; the straight flow passage bodies are communicated with the oval flow passage bodies; the long axes of the oval flow passage bodies and the center axes of the straight flow passage bodies in the liquid flowing direction are located on the same straight lines; n is a positive integer larger than or equal to three. According to the novel heat exchanger core, the narrowing and widening flow passages are adopted, the flow passages are prevented from being blocked, and the novel heat exchanger core is particularly suitable for the working procedure of cooling natural gas on a sea working platform.

Owner:AEROSPACE HIWING HARBIN TITANIUM IND

Texaco gasifier grey water treatment and recovery system

PendingCN106379985AImprove water qualityThe water quality is clear and transparentCalcium/strontium/barium carbonatesWater treatment parameter controlWater treatment systemSlag

The invention discloses a Texaco gasifier grey water treatment and recovery system which comprises a Ca<2+> / Mg<2+> precipitation tank connected with a black water settling tank water outlet, a filtering machine feeding tank connected with a black water settling tank, a crude slag filtering machine connected with the filtering machine feeding tank, a first drainage pump, a first precipitate collecting tank and a grey water tank which are connected with the Ca<2+> / Mg<2+> precipitation tank, a precipitate filtering machine connected with the first precipitate collecting tank, a MAP reaction precipitation tank connected with the grey water tank, a second precipitate collecting tank and a clear water tank which are connected with the MAP reaction precipitation tank, a MAP recovery device connected with the second precipitate collecting tank, and a shock cooling water inlet pump connected with a clear water tank overflow weir water outlet. The system is simple in process and easy to operate, is a novel grey water treatment system capable of quickly and efficiently removing Ca<2+>, Mg<2+> and NH4<+>-N in grey water, and prolongs the equipment overhaul cycle and production cycle by more than 6 months.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

Oil well pipe body screw thread bonderite processing technology

InactiveCN101353791AShorten drying timeNot easy to scaleLiquid surface applicatorsMetallic material coating processesLiquid stateSpray coating

The invention discloses a phosphating technology for pipe body screw threads of an oil well pipe, which comprises the following steps: a liquid bonderite is put in a vessel; spray coating is conducted by adopting compressed air and simultaneously, the pipe body screw threads of the oil well pipe are turned; after the surfaces of the pipe body screw threads of the oil well pipe are all covered by phosphating liquid, even sweeping is carried out on the phosphating surfaces, thus leading the phosphating liquid on the phosphating surfaces to be further evenly distributed and the surplus phosphating liquid to be blown down; and after the phosphating-treated pipe body screw threads of the oil well pipe are laid aside for 15 seconds to 30 seconds, the surfaces of phosphating films thereof are dried. The phosphating technology of the invention atomizes and imposes the bonderite on the surfaces of steel component materials to be treated and leads the bonderite distributed on the surfaces to be treated to be even; the phosphating is simple and easy to be conducted, with short dry time; the bonderite does not scale easily and the phosphating film is uniform in thickness, compact and stable.

Owner:BAOSHAN IRON & STEEL CO LTD

Sodium-calcium wet desulphurization, circulation, regeneration and precipitation integral treatment device

PendingCN112263898AOvercoming easy foulingOvercome the costGas treatmentDispersed particle separationPhysical chemistryProcess engineering

The invention discloses a sodium-calcium wet desulfurization, circulation, regeneration and precipitation integral treatment device, which comprises an induced draft fan, a desulfurization tower, a precipitation regeneration tank, a circulation tank, a plate-and-frame filter press, a process water tank, a sodium alkali tank and a lime slurry tank, wherein a partition plate is arranged between theprecipitation regeneration tank and the circulation tank; a slurry pipe is arranged at the bottom of the precipitation regeneration tank; the slurry pipe is connected with the plate-and-frame filter press, the plate-and-frame filter press is provided with a filtrate return pipeline, the filtrate return pipeline is connected with the circulation tank, the circulation tank is provided with a returnliquid pipeline, the return liquid pipeline is connected with the desulfurization tower, a lime slurry pipeline is arranged between the precipitation regeneration pool and the lime slurry tank, and asodium alkali pipeline is arranged between the circulation tank and the sodium alkali tank. In actual use, the defects of a limestone method are overcome, SO2 is absorbed by sodium alkali in the absorption tower, and the absorbed desulfurization liquid is regenerated by cheap lime in the regeneration tank, so that the problem of easy scaling in the tower of the lime method is solved, and the method has the advantage of high absorption efficiency of the sodium alkali method.

Owner:宁夏和兴碳基材料有限公司

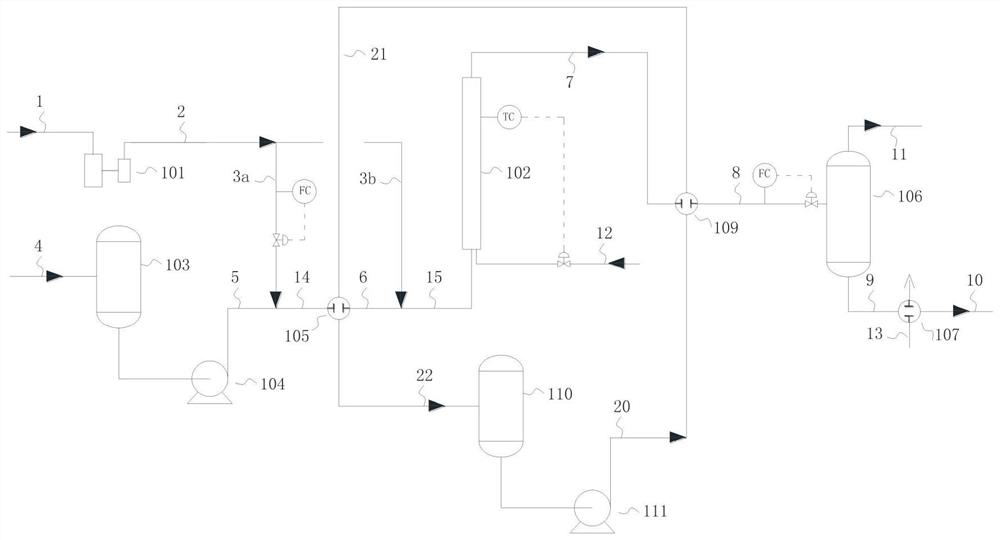

Waste alkali wet oxidation system and method

PendingCN114057277AFlexible temperature adjustmentSolve easy foulingWater treatment parameter controlMultistage water/sewage treatmentProcess engineeringGas supply

The invention relates to the technical field of waste alkali wet oxidation, and discloses a waste alkali wet oxidation system and method. The system is characterized in that an oxygen-containing gas supply system comprises at least one oxygen-containing gas conveying pipeline, wherein at least two oxygen-containing gas inlets are formed in a waste alkali liquid conveying pipeline of a waste alkali liquid supply system; the oxygen-containing gas conveying pipeline is connected with the oxygen-containing gas inlet; the waste alkali liquor conveying pipeline is connected with a reactor of the reaction system, and a reaction product outlet pipeline of the reactor is connected with the product separation system; a heat-conducting medium circulating pipeline of the heat-conducting medium heat exchange system is connected with a reaction product outlet pipeline through a heat-conducting medium / reaction product heat exchanger, and is connected with a waste alkali liquid conveying pipeline through a heat-conducting medium / feeding heat exchanger; the oxygen-containing gas inlets are formed in the upstream and downstream of the heat-conducting medium / feeding heat exchanger and the optional heat-conducting medium / feeding heat exchanger. The system and the method are low in energy consumption, can prevent blockage of the pipelines and equipment, and can work stably.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polluted waste liquid treatment device

InactiveCN103011316ALarge surface heat fluxHigh surface heat fluxWater/sewage treatment by heatingLiquid wasteHigh concentration

The invention discloses a polluted waste liquid treatment device comprising a spiral scraper, a first inlet, a planar scraper, a jacket, a vertical scraping barrel, a rotary shaft, a cavity, a first outlet, a second outlet, a second inlet, a third outlet, a flange and a shaft seal. The polluted waste liquid treatment device is high in operable flexibility, solves the problems that the inner contact wall surface of other film scrapers is easy to scale and high-concentration liquid is insufficiently evaporated, is high in evaporation performance due to the fact that a heating surface has high surface heat flux by the aid of characteristics of the film scrapers, is heat-sensitive in treatment due to short stop time and low evaporation temperature therein, capable of completely separating severely polluted liquid into distilled water, solid-state and semi-solid state residues discharged up to standard, and thoroughly effectively treating the high-concentration liquid. Besides, the polluted waste liquid treatment device is simple in structure and convenient to operate, over-concentrated liquid in sewage is efficiently treated, sewage treatment effect is improved, and the environment is protected.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A uf6 hydrolysis column, hydrolysis system and hydrolysis process

The invention relates to a UF6 hydrolysis column, a hydrolysis system and hydrolysis process. According to the invention, the top part of the UF6 hydrolysis column is provided with a water inlet (3), an air outlet (5) and a cyclic hydrolysate inlet (4); the bottom part of the UF6 hydrolysis column is provided with a hydrolysate outlet (12); the middle part of the UF6 hydrolysis column is provided with an air inlet pipe (8) which extends into the interior of a hydrolysis column shell (1); the air inlet pipe (8) is provided with an electric heat tracing mechanism (16); the end part of the air inlet pipe (8) extending into the hydrolysis column shell (1) is connected with a spray nozzle (7) which is equipped with a heat-preservation mechanism; and a hydrolysate outlet pipeline (13) connected with the hydrolysate outlet (12) is connected with a hydrolysate cyclic bypass (14) which is connected with the cyclic hydrolysate inlet (4). The UF6 hydrolysis column provided by the invention can guarantee the concentration of the hydrolysate therein, has uniform temperature; meanwhile, UO2F2 crystals located at the spray nozzle can be prevented from occurrence, and stability and safety are high; and the hydrolysis system and the hydrolysis process can realize continuous hydrolysis of UF6, and complete hydrolysis is guaranteed.

Owner:CHINA NUCLEAR POWER ENG CO LTD

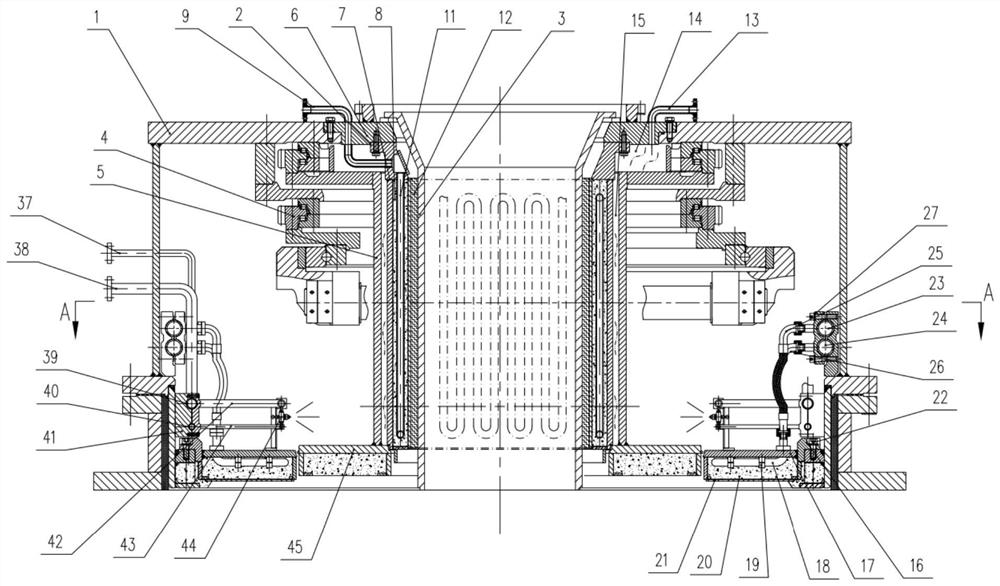

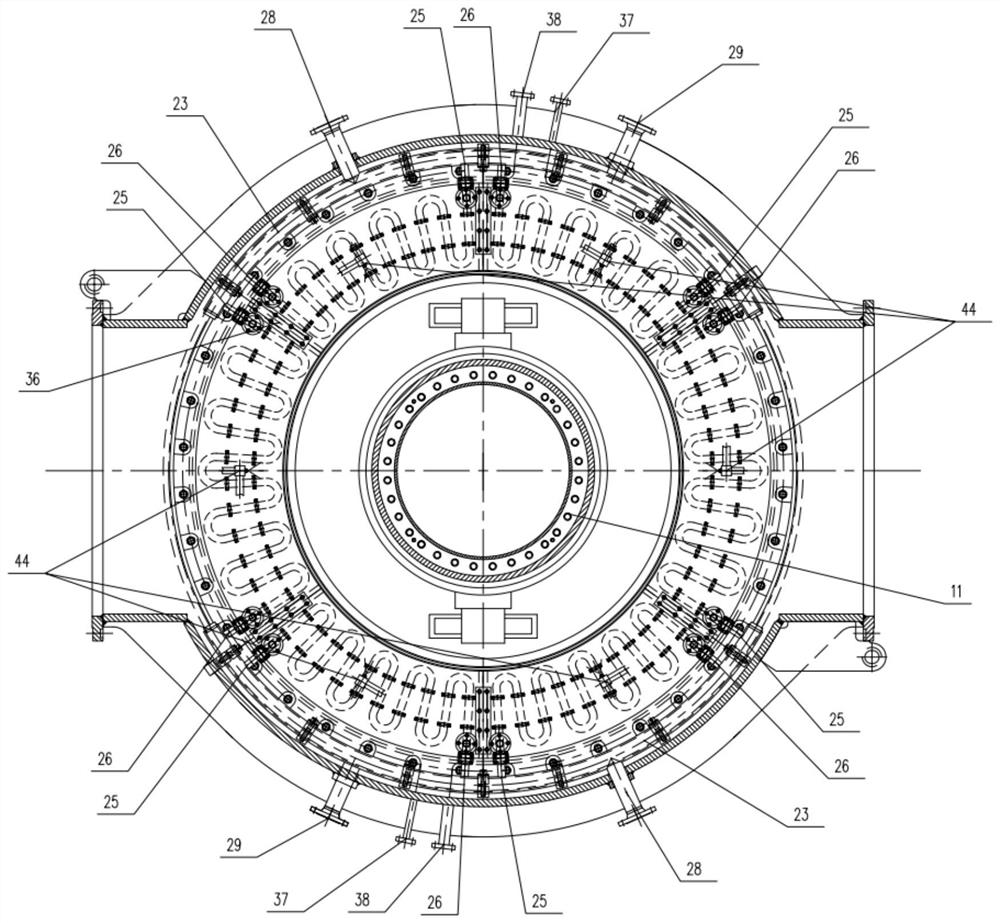

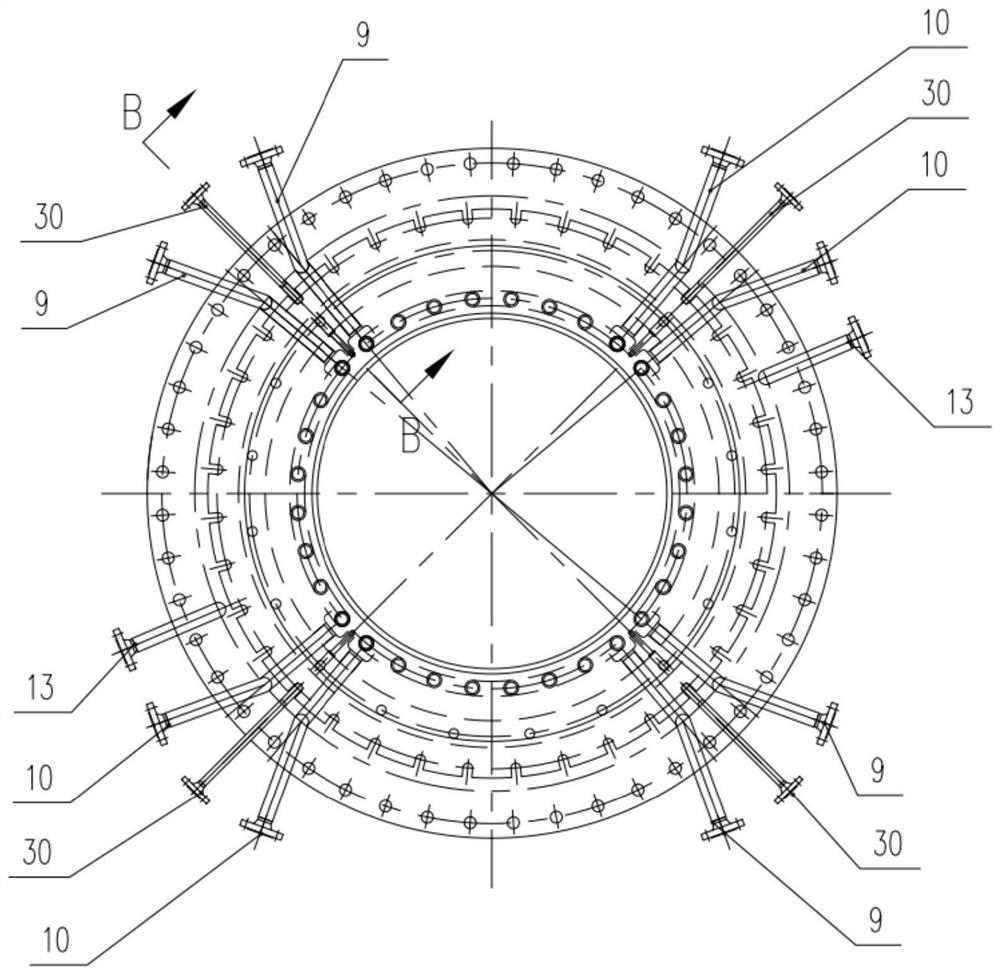

Mixed cooling type distributing device

ActiveCN113930567AAchieve coolingSolve the problem of rotation jammingBell-and-hopper arrangementCooling devicesAerosol MistWater leak

The invention belongs to the technical field of blast furnace distributing device cooling, and relates to a mixed cooling type distributing device. The device comprises a distributing device box body and a rotating cylinder body rotationally connected with the distributing device box body, a central throat pipe is arranged in the rotating cylinder body, and the central throat pipe is fixedly connected with the distributing device box body; the central throat pipe is sleeved with an intermediate cooling device for cooling the central throat pipe and the rotating cylinder body; the intermediate cooling device is fixedly connected with the distributing device box body and is arranged between the central throat pipe and the rotating cylinder body; and an aerial fog cooling device for cooling the bottom area of the rotating cylinder body is arranged at the bottom of the distributing device box body. By adopting a mixed cooling mode, high-pressure water cooling can be realized, the cooling efficiency is high, the problems of water leakage, easiness in scaling, low cooling efficiency and the like of open water cooling of an existing distributing device are solved, a traditional closed cooling mode which can be implemented only by rotating a joint is replaced, and no cooling dead zone exists.

Owner:CISDI ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com