Pressure type oil-contaminated water air-float machine

A pressure-type, oil-polluted technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, liquid separation, etc., can solve the problems of easy fouling and high conductivity of the plate, and reduce the amount of dosing and occupy The effect of small floor area and flexible equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

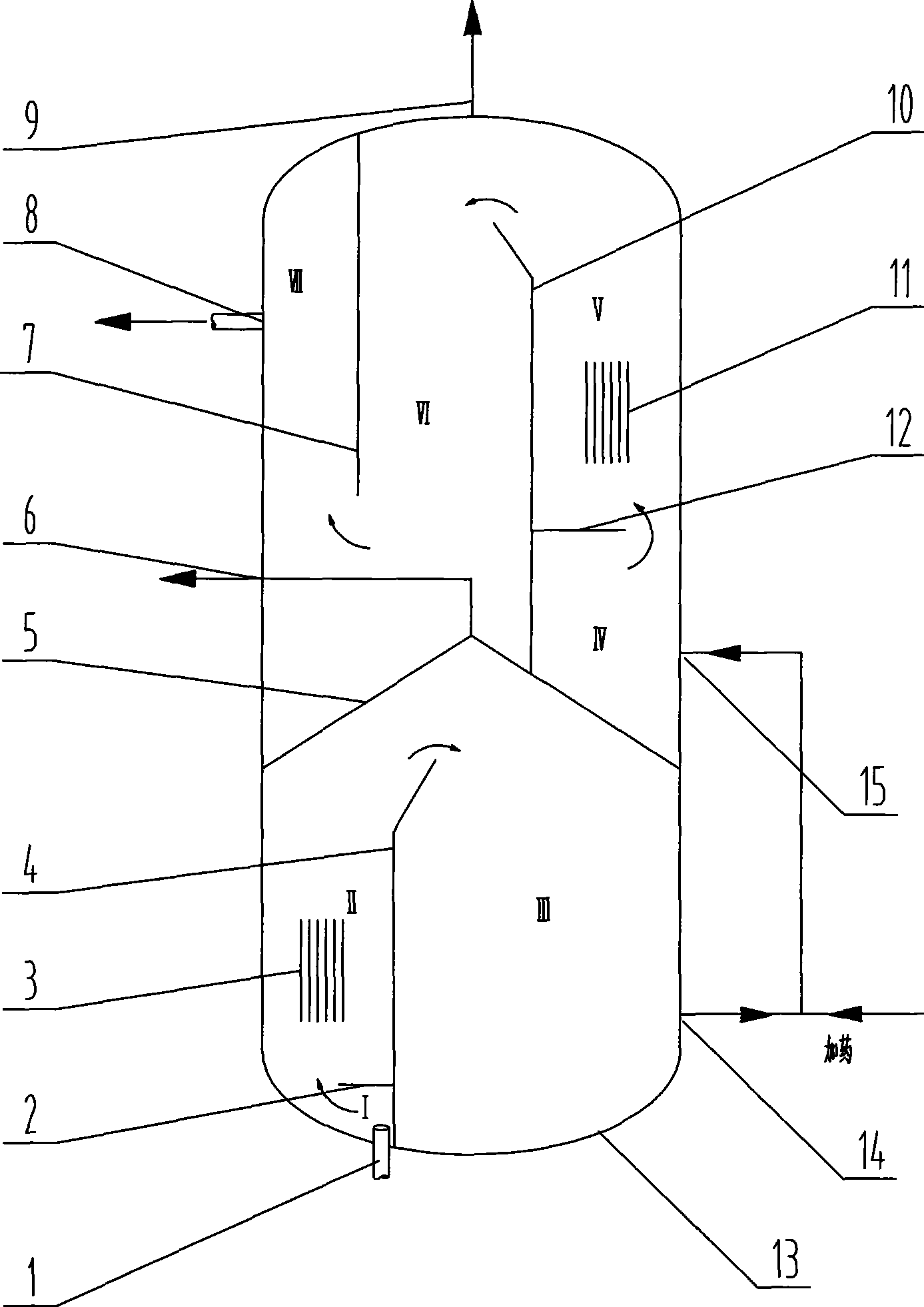

[0009] Such as figure 1 As shown, the water inlet 1 is set at the lower bottom of the casing 13, and the inner cavity of the casing 13 is divided into upper and lower chambers (the lower chamber is a first-level electric floating chamber, and the upper chamber is a second-level electrical floating chamber). The transverse partition 5 of the floating chamber), the transverse partition 5 is a cone whose middle part is higher than the periphery. An oil discharge port A 6 communicating with the outside of the casing 13 is provided at the top of the transverse partition 5 .

[0010] A vertical baffle A 4 is arranged below the transverse partition 5 of the inner cavity of the casing 13 , the lower end of the vertical baffle A 4 is connected to the lower bottom of the casing 13 , and a gap is set between the upper end and the transverse partition 5 . The electrode A3 is arranged on one side of the inner cavity of the casing 13 facing the baffle A4, and the water inlet 1 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com