Waste alkali wet oxidation system and method

An oxidation system, wet technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of easy fouling of heat exchange tubes, poor oxidation effect, high energy consumption in operation, etc. , to achieve the effect of improving long-term stable operation time, large amount of waste lye, and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

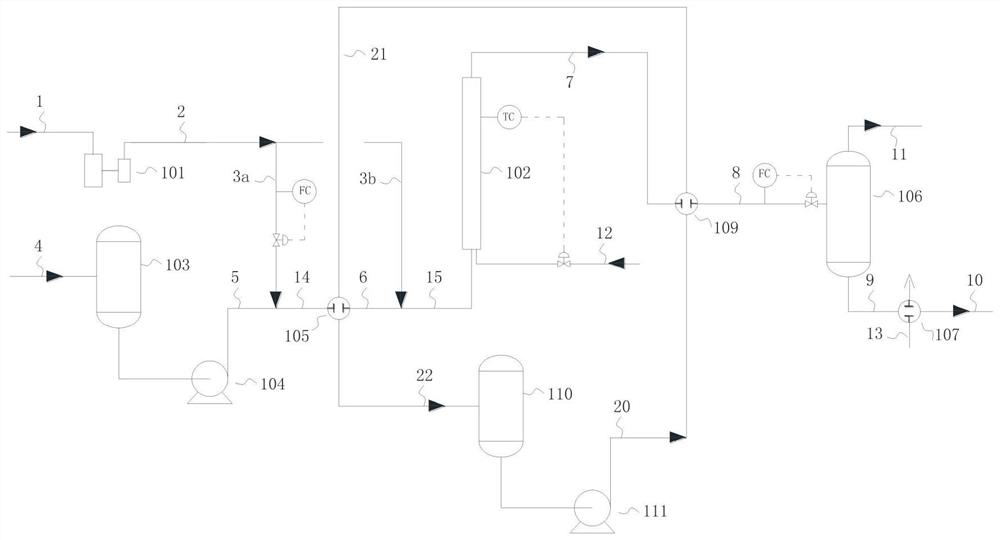

[0049] According to another specific embodiment of the present invention, there are three oxygen-containing gas inlets, two of which are respectively arranged upstream and downstream of the heat transfer medium / feed heat exchanger, and the other is arranged at the heat transfer medium / feed heat exchange There are multiple injection points on the heat transfer medium / feed heat exchanger.

[0050] Depending on the composition of the reaction raw materials, the oxygen-containing gas enters the waste lye delivery pipeline through different oxygen-containing gas inlets, for example: when the content of butter and olefins in the reaction raw materials is high, you can choose to use the heat transfer medium / feed heat exchanger Inject oxygen-containing gas into the oxygen-containing gas inlet on the front and / or the oxygen-containing gas inlet on the heat transfer medium / feed heat exchanger to avoid fouling of the heat exchanger.

[0051] According to a specific embodiment of the pres...

Embodiment 1

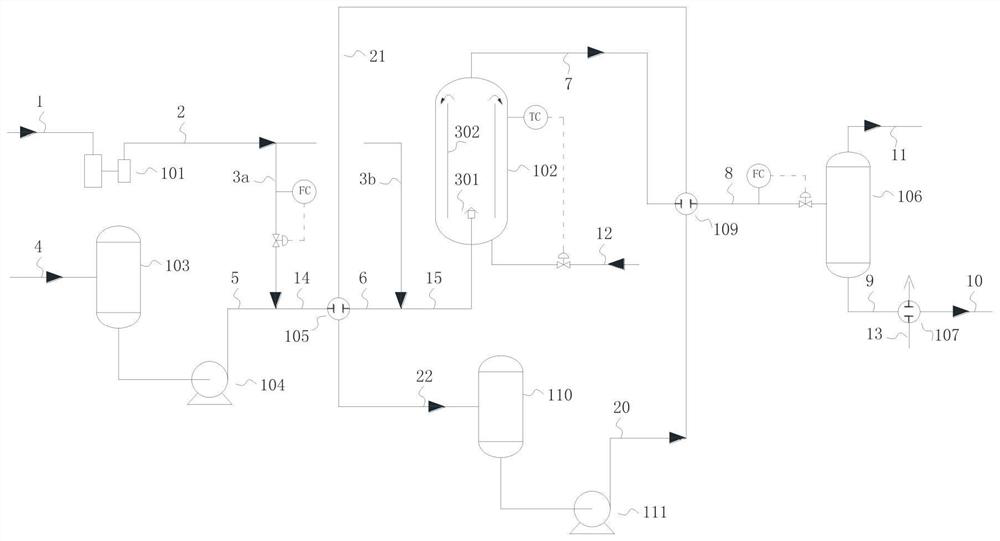

[0071] Such as figure 1 As shown, a waste alkali wet oxidation system includes a reaction raw material feed system, a reaction system, a heat transfer medium heat exchange system and a product separation system;

[0072] The reaction raw material feed system includes an oxygen-containing gas supply system and a waste lye supply system, the oxygen-containing gas supply system includes an oxygen-containing gas delivery pipeline, and the waste lye supply system includes a waste lye delivery pipeline, the Two oxygen-containing gas inlets are arranged on the waste lye delivery pipeline, and the oxygen-containing gas delivery pipeline is connected with the oxygen-containing gas inlet;

[0073]Described reaction system comprises reactor 102, and the discharge end of described waste lye delivery pipeline links to each other with the reaction raw material inlet of reactor 102 bottoms, and the top of described reactor 102 is provided with reaction product outlet pipeline, and the reacti...

Embodiment 2

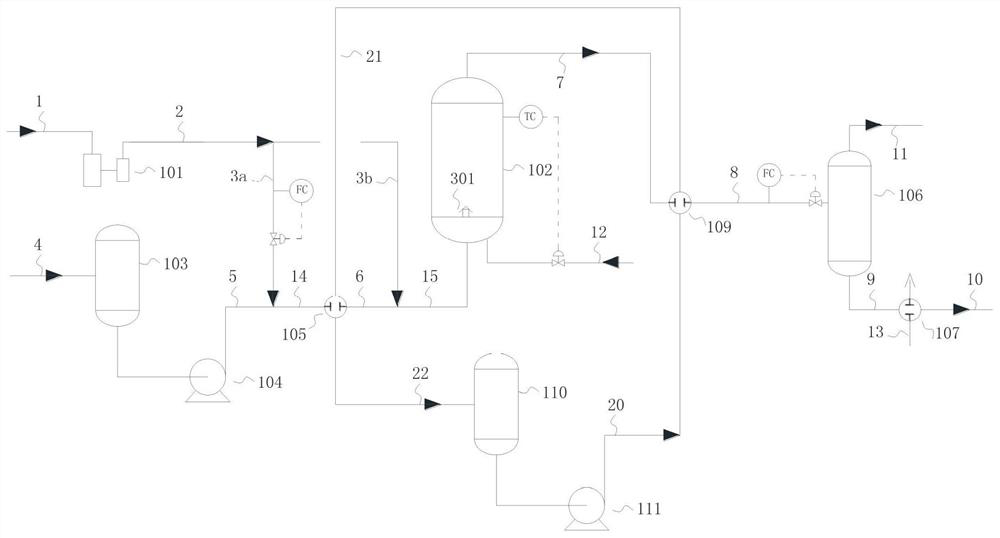

[0099] like figure 2 As shown, compared with Example 1, the spent alkali wet oxidation system of this example is the same as Example 1 except that the reactor 102 adopts the form of empty barrel + distributor 301 .

[0100] The spent lye of this embodiment is also ethylene spent lye, and the composition and flow rate of the spent lye are the same as in Example 1, the difference being that the reaction temperature of the reactor 102 is 190°C, the reaction pressure is 3.35MPaG, and the feed The outlet pressure of the pump 104 is 3.75MPaG; the outlet pressure of the gas compressor 101 is 3.9MPaG. All the other process parameters and equipment models are the same as in Example 1, and no additional steam is needed during normal reactions in this example.

[0101] In this embodiment, desalted water is used as the heat transfer medium, and the flow rate is 42t / h. The heat transfer medium circulation pump 111 is a centrifugal pump, the pump inlet pressure is 0.5MPa, and the pump out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com