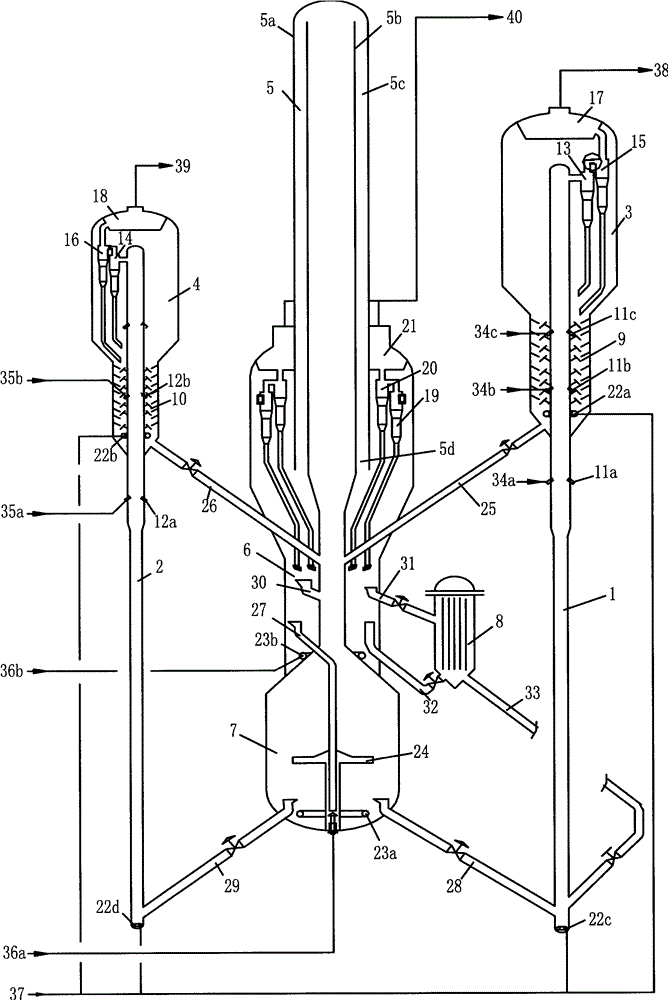

Double-lifted pipe catalytic cracking device and method thereof

A technology of double risers and risers, which is applied in the field of double riser catalytic cracking devices, can solve the problems of difficult realization of heavy oil risers, short oil contact time, narrow application range, etc., and achieves short heavy oil oil contact time, short Effect of contact time and property improvement of light hydrocarbon oil

- Summary

- Abstract

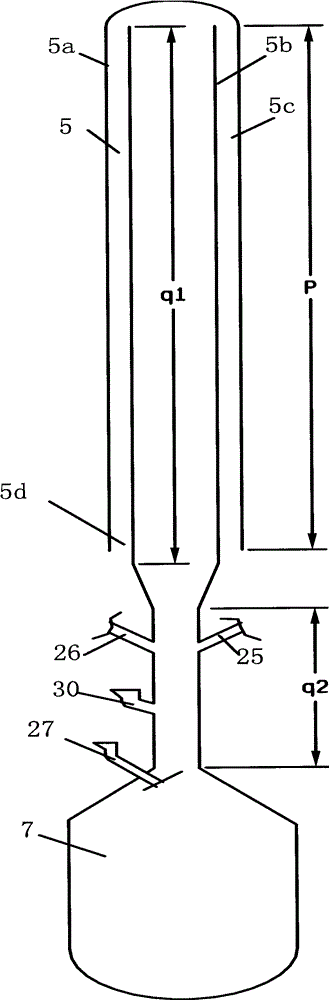

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

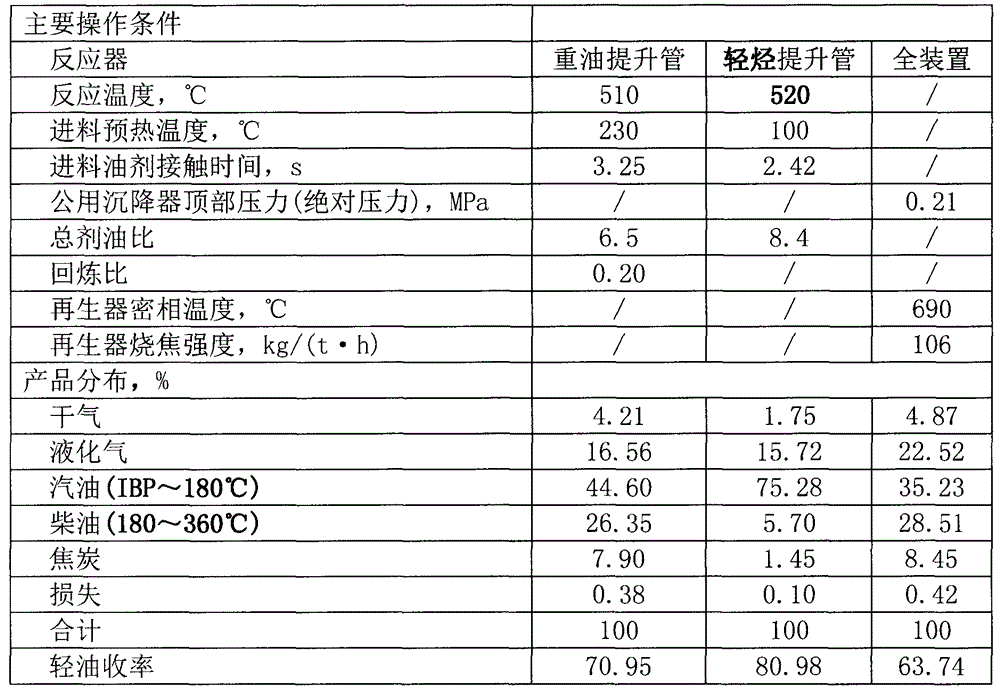

Embodiment 1

[0072] The main operating conditions and product distribution of embodiment 1 are shown in Table 4, and the main properties of the liquid product of embodiment 1 are shown in table 5; the main operating conditions and product distribution of embodiment 2 are shown in table 6, and the main properties of the liquid product of embodiment 2 are shown in table 7; the main operating conditions and product distribution of embodiment 3 are shown in Table 8, and the main properties of the liquid product of embodiment 3 are shown in Table 9; the main operating conditions and product distribution of embodiment 4 are shown in Table 10, and the main properties of the liquid product of embodiment 4 See Table 11; the main operating conditions and product distribution of Example 5 are shown in Table 12, and the main properties of the liquid product of Example 5 are shown in Table 13.

[0073] Table 1 Properties of heavy oil raw materials (comparative examples, examples 1-5)

[0074] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com