Preparation method of super-hydrophobic aluminum surface with self-cleaning function

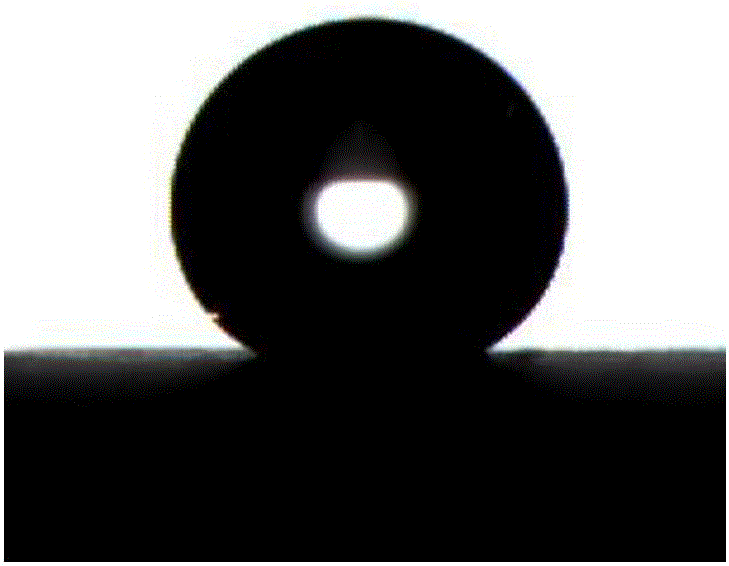

A super-hydrophobic, aluminum surface technology, applied in the direction of metal material coating process, can solve the problems of complex preparation process of super-hydrophobic aluminum surface, achieve excellent self-cleaning and hydrophobic effects, simple preparation process, and reduce corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of the superhydrophobic aluminum surface with self-cleaning function of the present embodiment, comprises the steps:

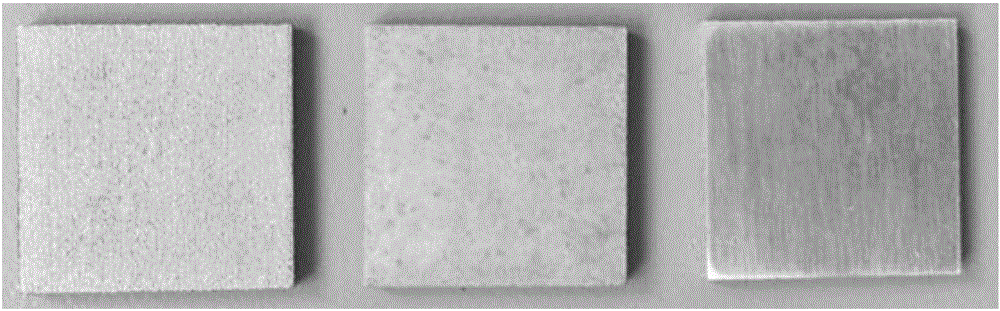

[0026] (1) Pretreatment: the 6061 aluminum alloy sheet is subjected to 400 # 、1000 # 、3000 # Grinding with sandpaper, the polished samples were ultrasonically cleaned with absolute ethanol and distilled water in sequence, the ultrasonic temperature was 50°C, the time was 20min, and then dried in a constant temperature oven at 80°C for 10min to obtain a clean sample;

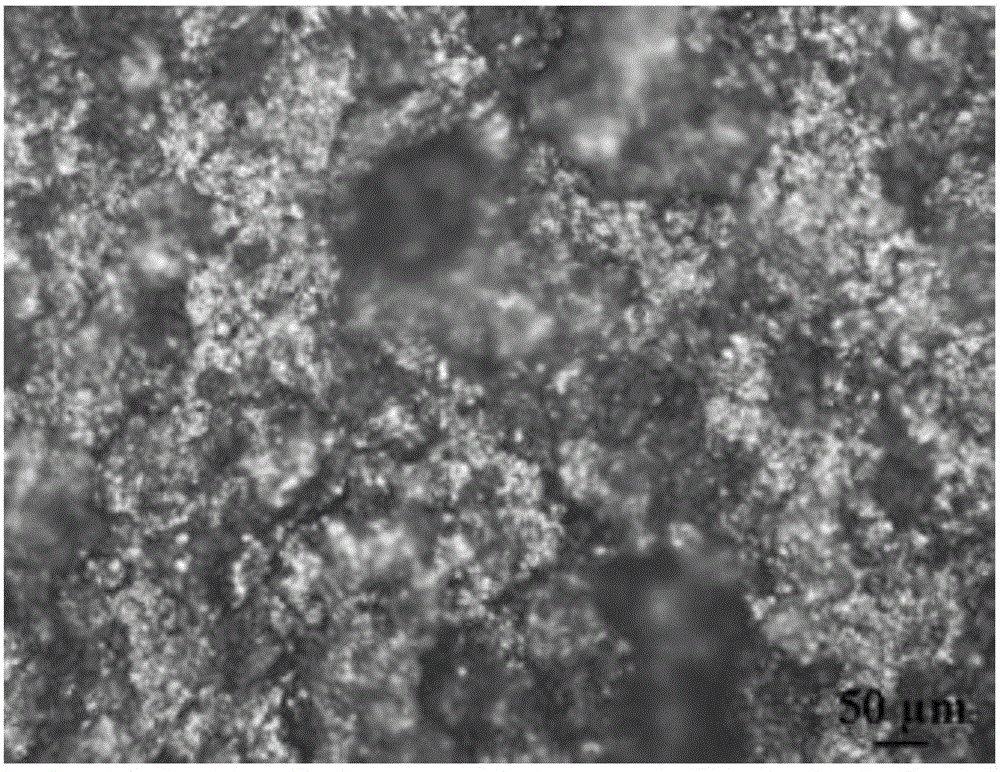

[0027] (2) Chemical etching: put the clean sample into 1.4 mol / L ferric chloride aqueous solution, and soak for 60 min at room temperature. Take it out and put it into an ultrasonic cleaning machine, then use absolute ethanol and distilled water to ultrasonically clean at a constant temperature of 60°C for 5 minutes to remove surface dirt, and air dry;

[0028] (3) Surface modification: soak the chemically treated sample in 2% ethanol solution of 1H,1H,2H,2H...

Embodiment 2

[0039] (1) Pretreatment: the 6061 aluminum alloy sheet is subjected to 400 # 、1000 # 、3000 # Grinding with sandpaper, the polished sample was ultrasonically cleaned with absolute ethanol and distilled water in sequence, the ultrasonic temperature was 40°C, the time was 30min, and then dried in a constant temperature oven at 50°C for 20min to obtain a clean sample;

[0040] (2) Chemical etching: put the clean sample into a 1.5 mol / L ferric chloride aqueous solution, and soak for 30 minutes at room temperature. Take it out and put it into an ultrasonic cleaning machine, then use absolute ethanol and distilled water to ultrasonically clean at a constant temperature of 40°C for 10 minutes to remove surface dirt, and air dry;

[0041] (3) Surface modification: soak the chemically treated sample in 1% ethanol solution of heptadecafluorodecyltrimethoxysilane for 2 hours at room temperature to form a hydrophobic film on the surface of the sample, then take it out and put it in 130 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com