Internal sealing specific pressure-regulable fixed-ball ball valve

An adjustable and fixed ball technology, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the problems of inability to adjust, valve jamming or leakage, spring fatigue and relaxation, etc., to improve the basic parameters and the scope of use, prolonging the service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

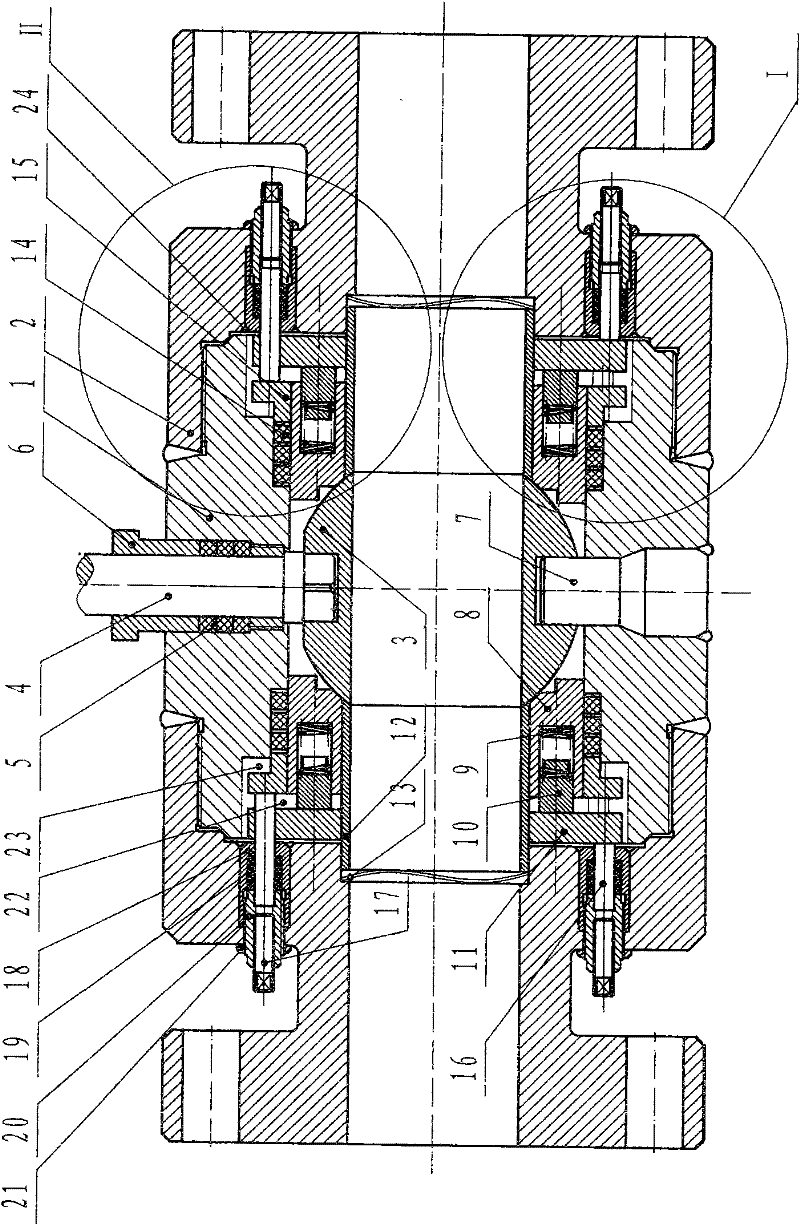

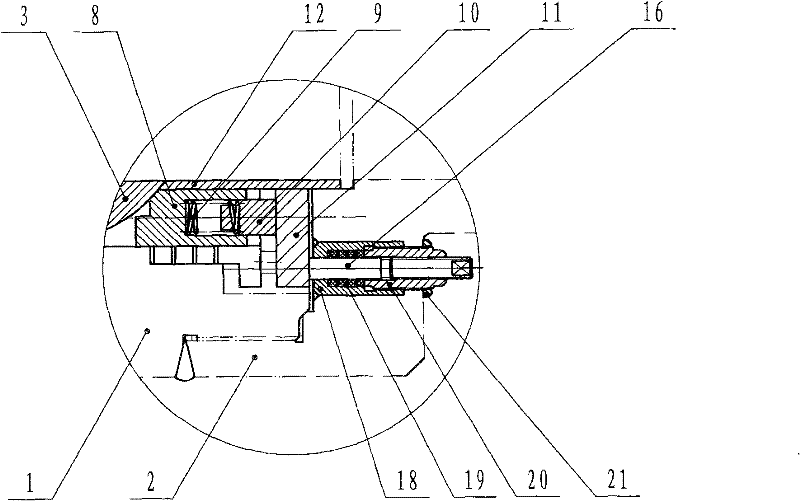

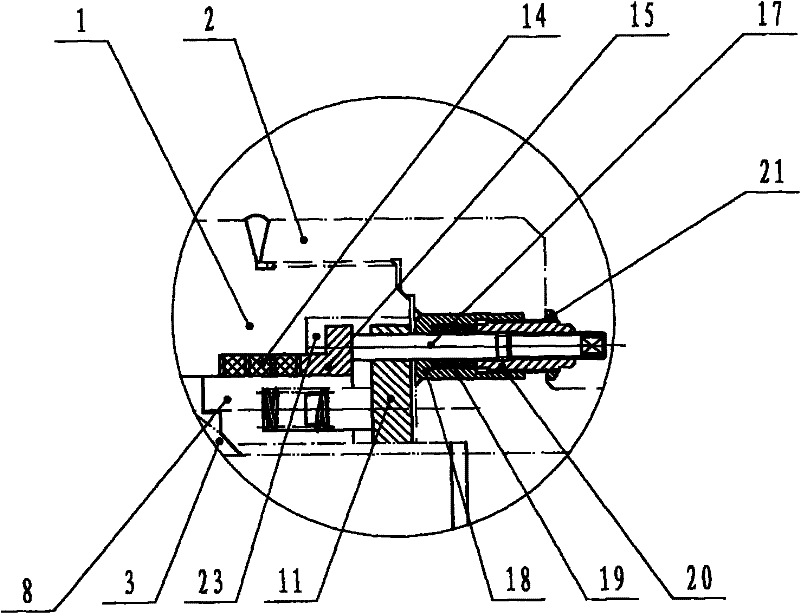

[0038] Such as figure 1 The shown internal seal specific pressure adjustable trunnion ball valve includes a valve body 1, a valve cover 2 is installed at both ends of the valve body 1, a ball 3 with a flow channel is placed in the inner cavity of the valve body 1, and the upper end of the ball 3 Connected to the valve stem 4, there is a valve stem packing 5 and a valve stem packing gland 6 between the valve stem 4 and the valve body 1, the upper end of the valve stem 4 is connected to the driving device, and the lower end of the ball 3 is provided with a round hole and a fixed The shaft 7 is matched, the two sides of the sphere 3 are equipped with floating valve seats 8, and the back of the floating valve seat 8 has several closed holes arranged in a circle, and a spring 9 is placed in the closed holes, and the outside of the spring 9 has a plunger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com