Sodium-calcium wet desulphurization, circulation, regeneration and precipitation integral treatment device

A wet desulfurization and treatment device technology, applied in the field of circulation, sodium-calcium wet desulfurization, precipitation overall treatment device, and regeneration, can solve the problems of low sulfur dioxide removal rate, water in the flue gas, low desulfurization efficiency, etc. The effect of equipment operation and maintenance, avoiding blockage and wear, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

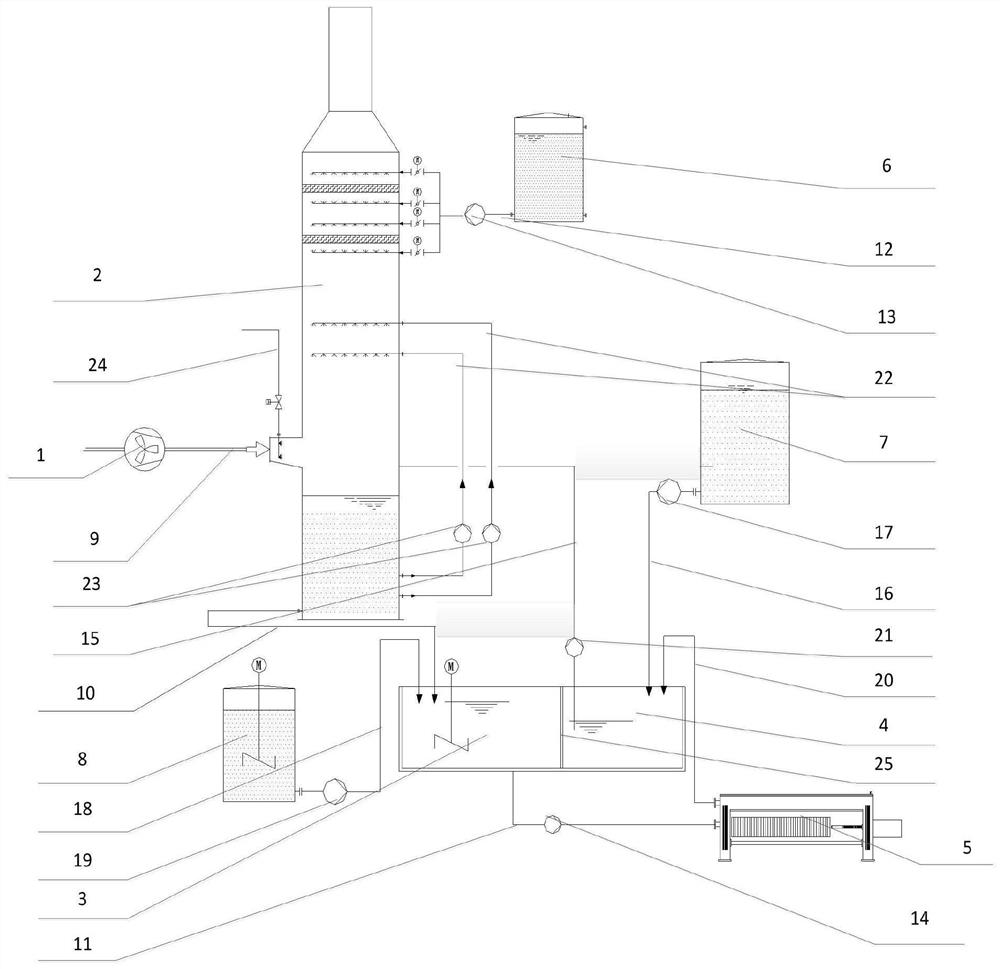

[0028] Such as figure 1 As shown, a sodium-calcium wet desulfurization, circulation, regeneration, precipitation overall treatment device, including induced draft fan 1, desulfurization tower 2, precipitation regeneration pool 3, circulation pool 4, plate and frame filter press 5, process water tank 6, sodium Alkali tank 7, lime slurry tank 8, the induced draft fan 1 is arranged on the flue gas pipeline 9, the induced draft fan 1 is connected with the desulfurization tower 2 by the flue gas pipeline 9, the bottom of the desulfurization tower 2 is connected with the sedimentation regeneration tank 3 They are connected by the circulating liquid discharge pipeline 10 provided, a partition 25 is arranged between the sedimentation regeneration tank 3 and the circulation tank 4, and a mud pipe 11 is arranged at the bottom of the sedimentation regeneration tank 3, and the mud pipe 11 is connected to the The plate and frame filter press 5 is connected, the mud pipe 11 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com