Monte carlo based method for simulating carbon/ carbon composite material texture

A technology of Monte Carlo simulation and carbon composite materials, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve problems such as high cost, long time consumption, and difficult waste gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

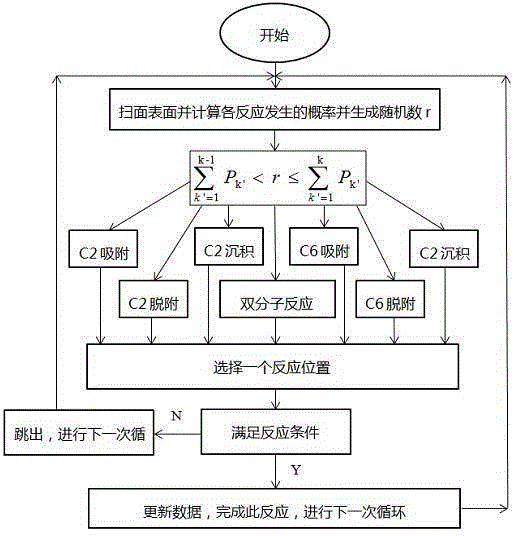

[0051] In this embodiment, the method for studying the texture of carbon / carbon composite materials based on Monte Carlo simulation can be implemented in the following five steps:

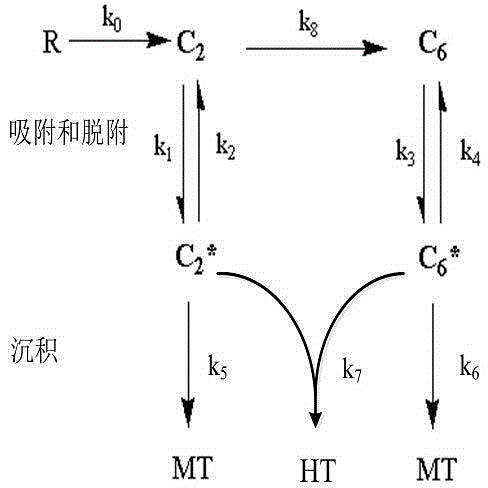

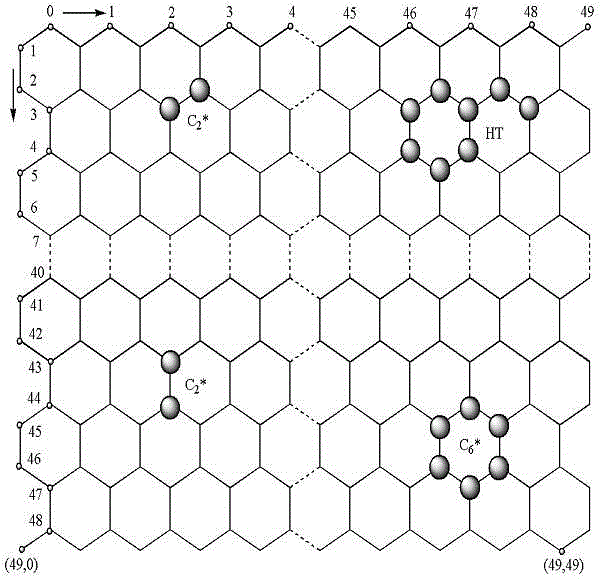

[0052] A. Chemical kinetic modeling of pyrolytic carbon deposition: The growth of pyrolytic carbon matrix in the CVI process is a growth process controlled by heterogeneous reactions, involving 7 components and 9 reactions, including small molecular aromatic hydrocarbons C 6 (denoted as P) and small molecular linear hydrocarbons C 2 (denoted as F) two main gas phase components, according to the L-H theory, the process of deposition into carbon is divided into three processes: component adsorption, surface component desorption and surface dehydrogenation reaction. Based on the P-F model, MT and HT pyrolytic carbon are regarded as two metastable phases of carbon, and the two main components in the gas phase are used as precursors for pyrolytic carbon deposition (linear small molecule hydrocarbon C 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com