Patents

Literature

60results about How to "Safe and smooth construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

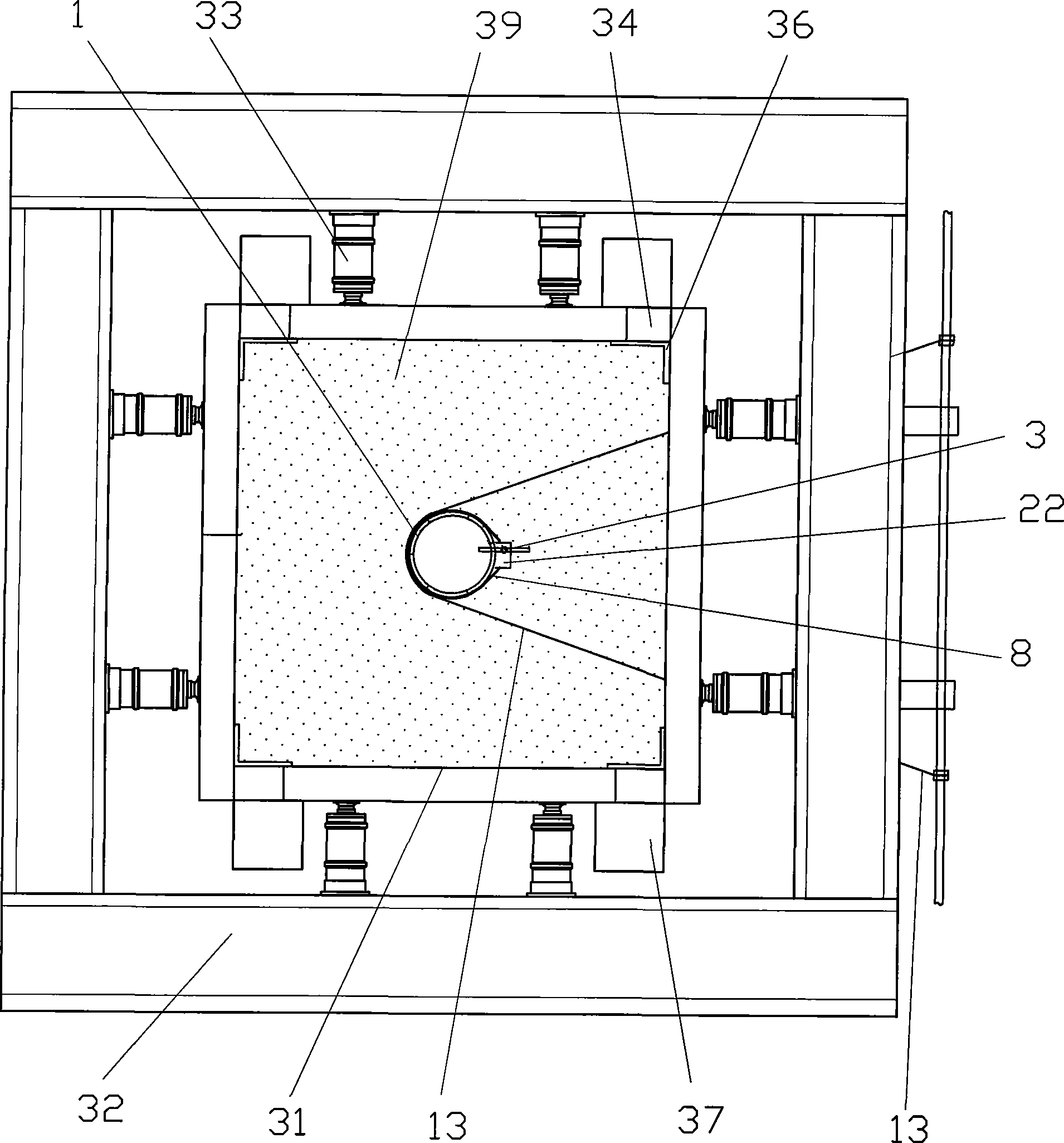

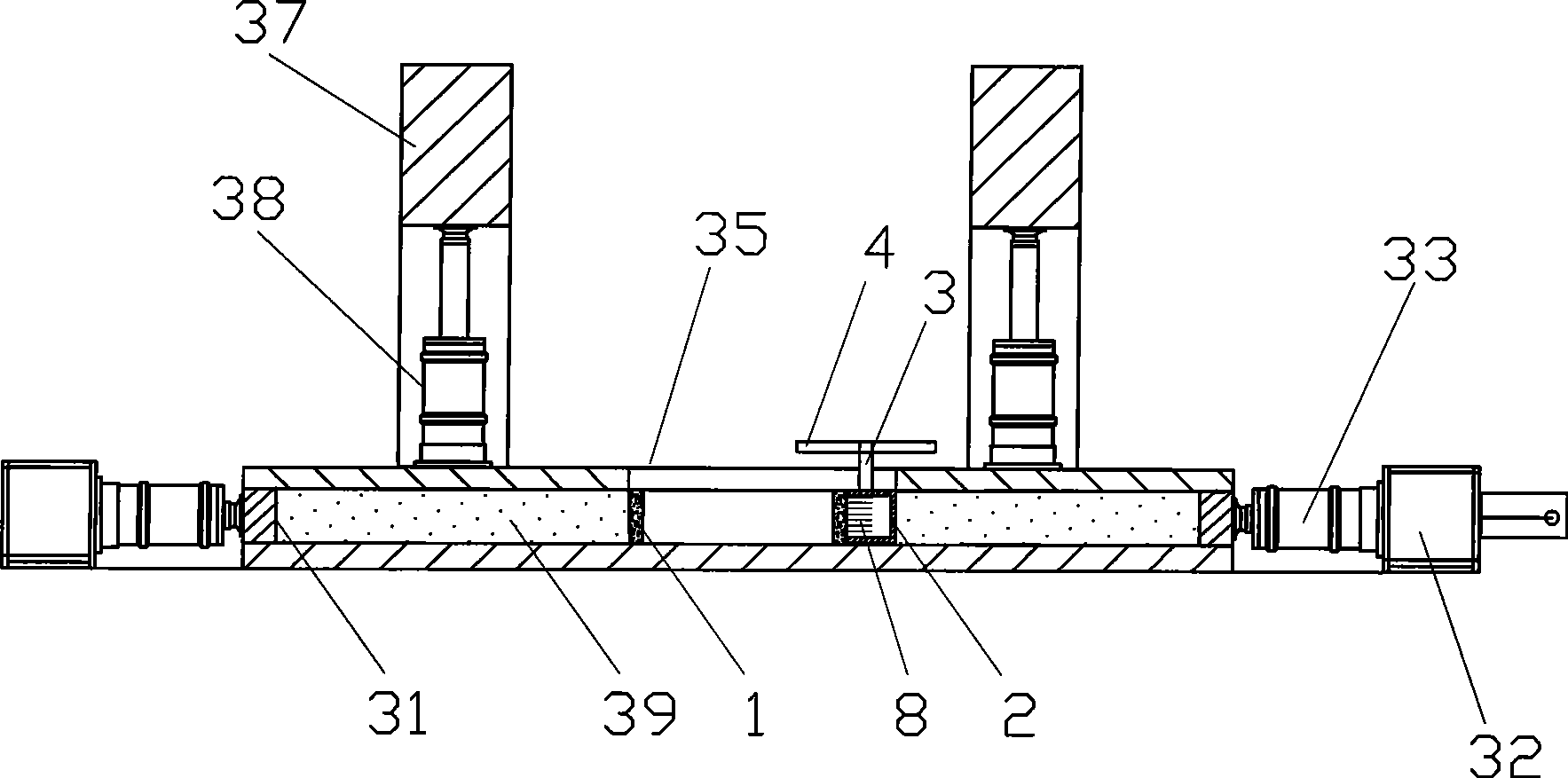

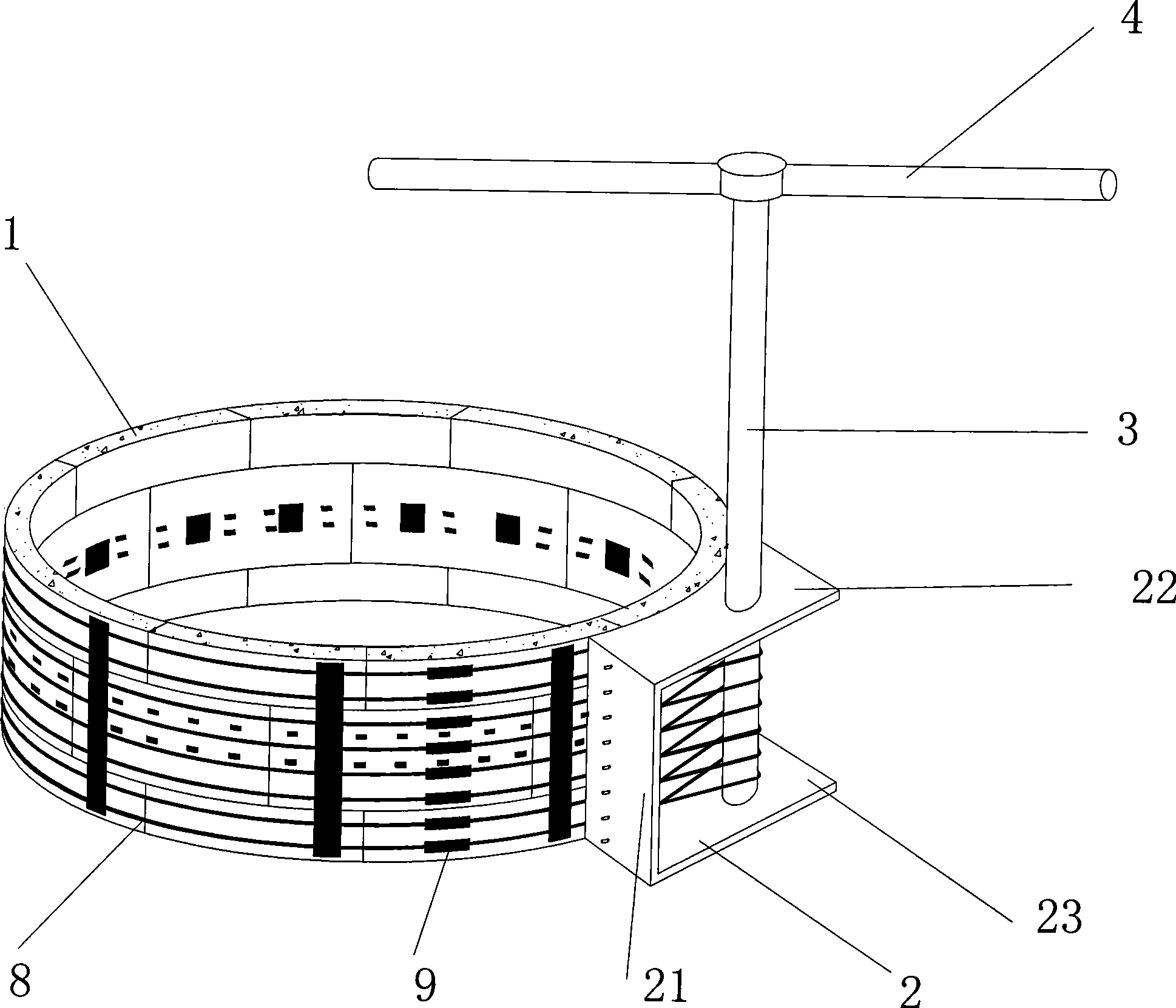

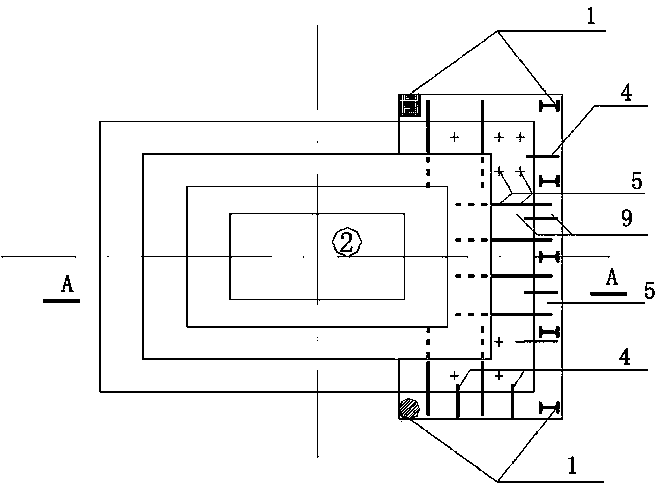

Comprehensive test system of shield tunnel construction model

InactiveCN101435746ARealistic simulation of formation pressureThe test data is accurateForce measurementStructural/machines measurementEngineeringShield tunnelling

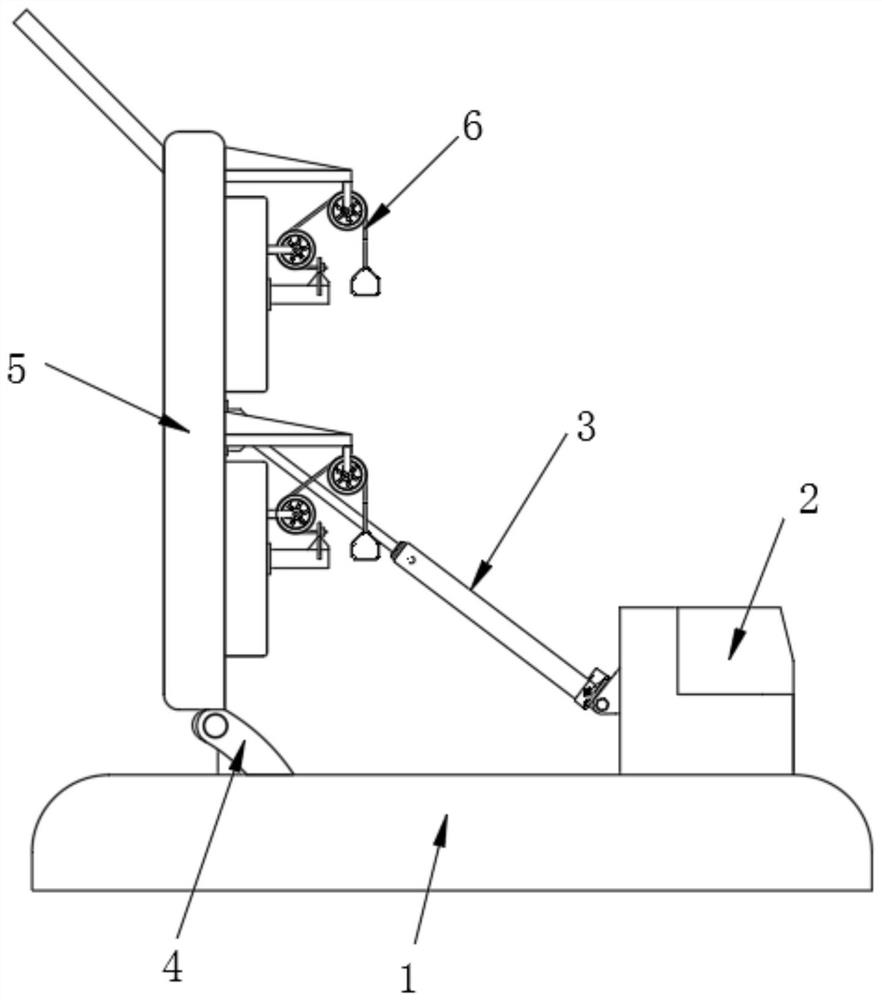

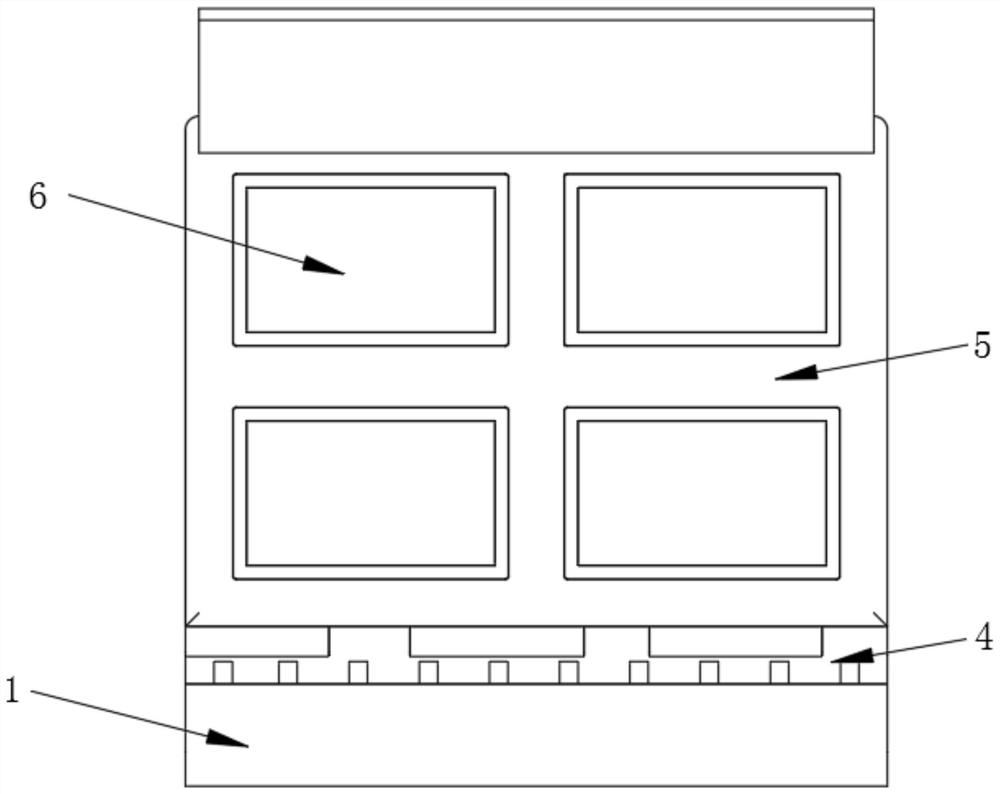

The invention provides a comprehensive testing system for a shield tunnel structural model, which comprises a soil horizon simulating and soil pressure loading device and a tunnel structural model; the soil horizon simulating and soil pressure loading device is a simulated soil body cavity enclosed by steel plates; a horizontal reaction frame is arranged outside the soil body cavity; a horizontal soil pressure jack is connected between each edge of the reaction frame and the soil body cavity; the tunnel structural model is attached with a uniform water pressure loading device and a non-uniform water pressure loading device, and is axially and vertically arranged in the center of the soil body cavity; simulation testing soil is filled between the tunnel structural model and the soil body cavity; the upper part of the soil body cavity is covered by a steel cover board; a vertical reaction portal frame is arranged above the soil body cavity; and a vertical soil pressure jack is connected between the lower part of a girder of the vertical reaction portal frame and the steel cover board. The system can simulate interactions between tunnel structures in different forms of fractures with the stratum under different stratigraphic and hydrologic conditions, and more truly simulate the environment conditions of the tunnel structures with more accurate and reliable test data, thereby providing more reliable safeguard for shield tunnel constructions.

Owner:SOUTHWEST JIAOTONG UNIV

Waste soil improving method of soil pressure balance shield of high water pressure and high permeability sandy stratum

A waste soil improving method of soil pressure balance shield of a high water pressure and high permeability sandy stratum comprises the steps that A, 0.8-1.2 parts by weight of sodium bentonite, 0.04-0.06 part by weight of carboxymethyl cellulose and 10 parts by weight of water are mixed, stirred continuously for 10-15 min and then placed in a container to stand for 20-24 h, and improved slurry is obtained; and B, before driving, the water containing state of rock soil of an excavation face is measured, in the soil pressure balance shield driving process, the improved slurry is injected into a soil bin of a shield machine, if the measured water containing state of the rock soil is a supersaturated state, the ratio of the injection volume of the improved slurry to the waste soil entering volume of the soil bin is 1:2-3.4, and otherwise, the ratio of the injection volume of the improved slurry to the waste soil entering volume is 1:3.5-4.5. By improving waste soil through the waste soil improving method, gushing can be better avoided and relieved during soil pressure balance shield construction, and the influence on the engineering progress is less; and the cost of subway construction is reduced.

Owner:SOUTHWEST JIAOTONG UNIV

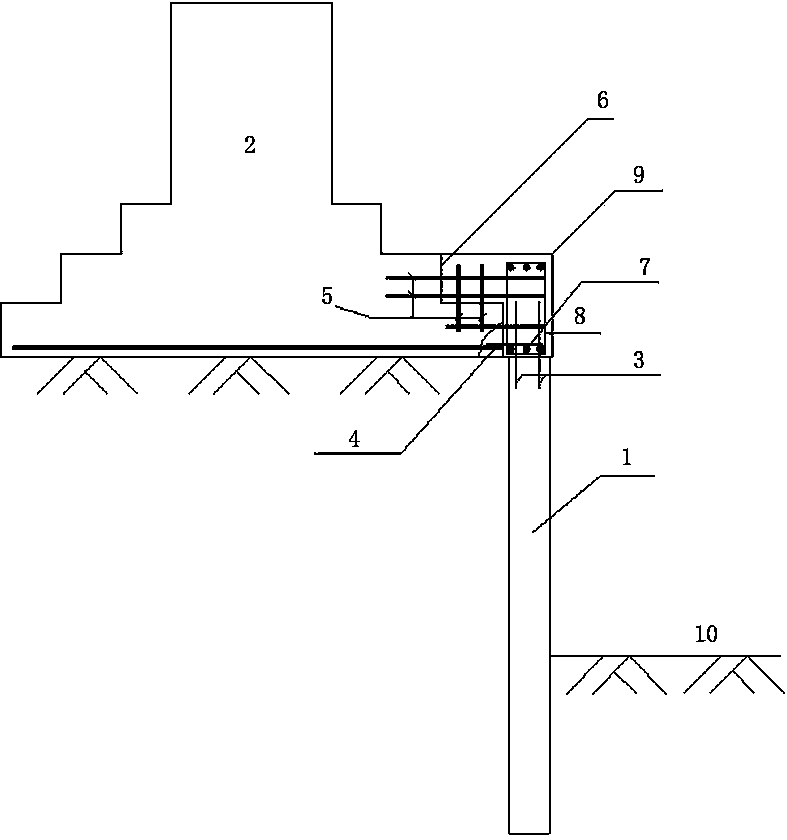

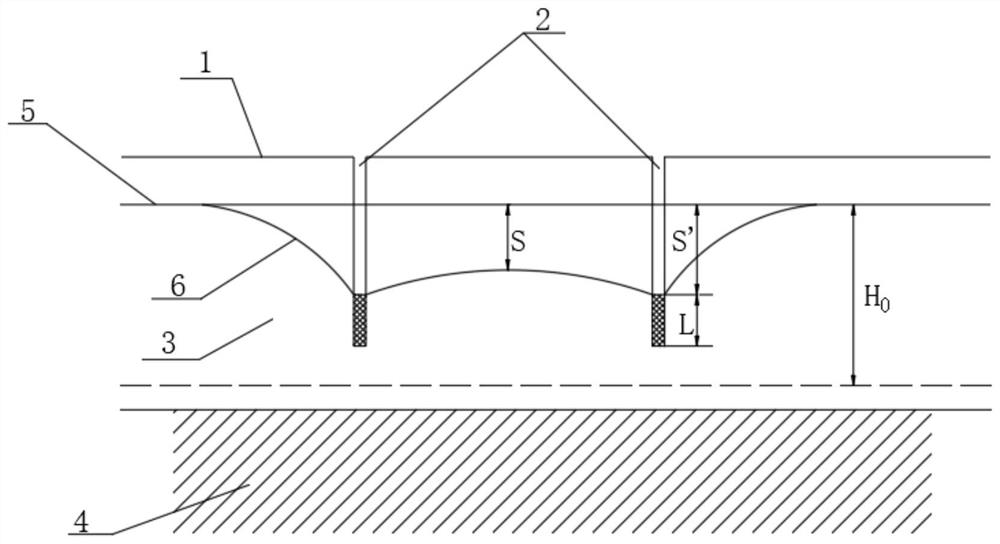

Pile foundation underpinning method for building foundation adjacent to deep foundation pit

ActiveCN104179204AMeet bending resistanceMeet punching resistanceFoundation repairArchitectural engineeringShear resistance

The invention relates to the technical field of civil engineering foundation reinforcing of industrial and civil construction projects, in particular to a pile foundation underpinning method for a building foundation adjacent to a deep foundation pit. The method includes the steps of firstly, investigating and designing, to be more specific, investigating the existing building, selecting foundation underpinning pile types according to building foundation size, buried depth, distance between the building foundation and the deep foundation pit and the depth of the deep foundation pit, calculating to determine the required length and number of foundation underpinning piles according to bearing capacity, allowing the foundation underpinning piles to exceed the depth of the bottom of the deep foundation pit, and completing ring beam design; secondly, pressing the piles at the edges of the building foundation; thirdly, performing pile foundation underpinning on the building foundation. The method has the advantages that the building foundation satisfies the requirements of bending resistance, punching resistance and shearing resistance by the aid of pile foundation underpinning, natural foundation bearing of the building foundation is changed into pile foundation bearing, additional load of the building foundation to the deep foundation pit is lowered greatly, sedimentation and horizontal displacement of the building foundation adjacent to the deep foundation pit are solved, and factory building safety is guaranteed.

Owner:山西钢铁建设(集团)有限公司

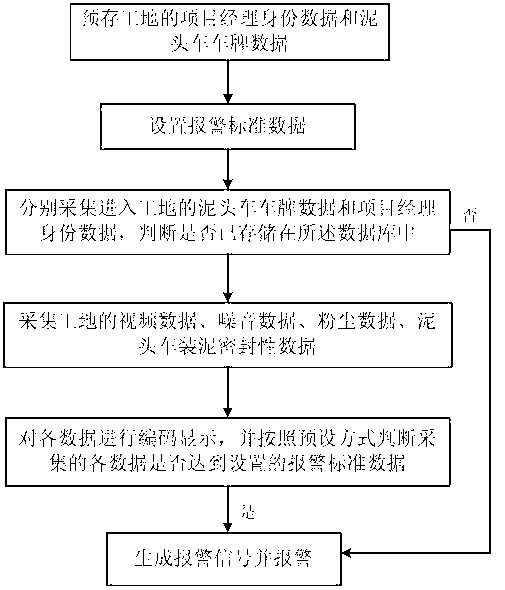

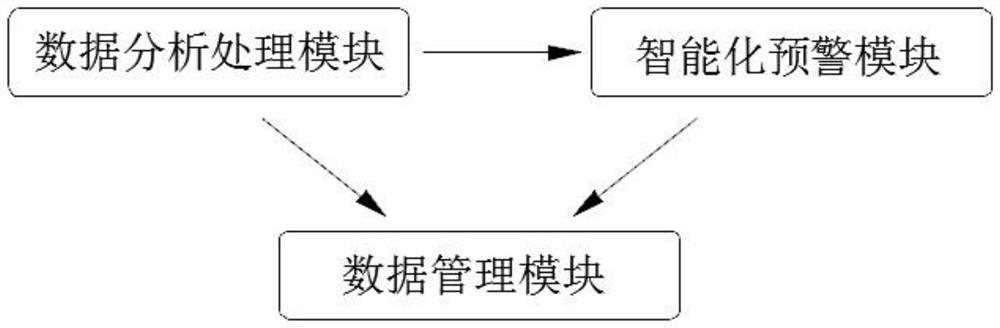

Intelligent construction site monitoring and management method

InactiveCN103313041ARealize intelligent monitoringSafe and smooth constructionClosed circuit television systemsAlarmsSite monitoringProject manager

The invention discloses an intelligent construction site monitoring and management method. The method includes: setting alarm standard data by pre-storing construction site project manager identity data and plate number data of dump trucks, collecting the plate number data of dump trucks entering a construction site and the identity data of a project manager entering the construction site, collecting video data, noise data, dust data and dump truck mud carrying airtightness data of the construction site, and using preset manners to give out alarm. By the method, construction videos and construction dust and noise can be monitored intelligently, the project manage in charge of construction guidance and the dump trucks for carrying mud can be managed in a centralized manner, abnormality can be discovered and alarmed timely, construction at the construction site can be performed safely and smoothly, and monitoring and management are centralized, intelligent and convenient.

Owner:GUANGDONG NEW VISION INFO TECH

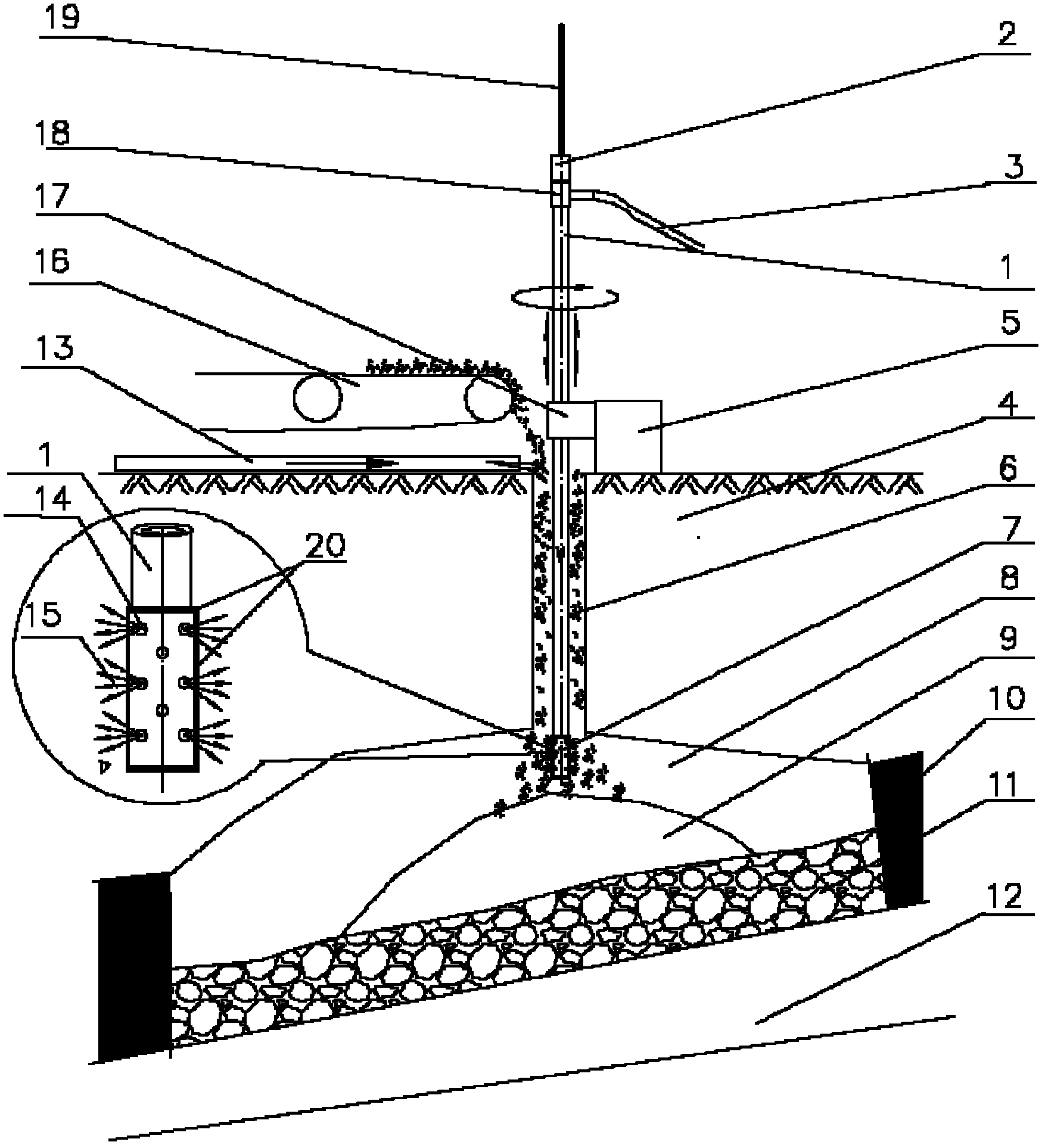

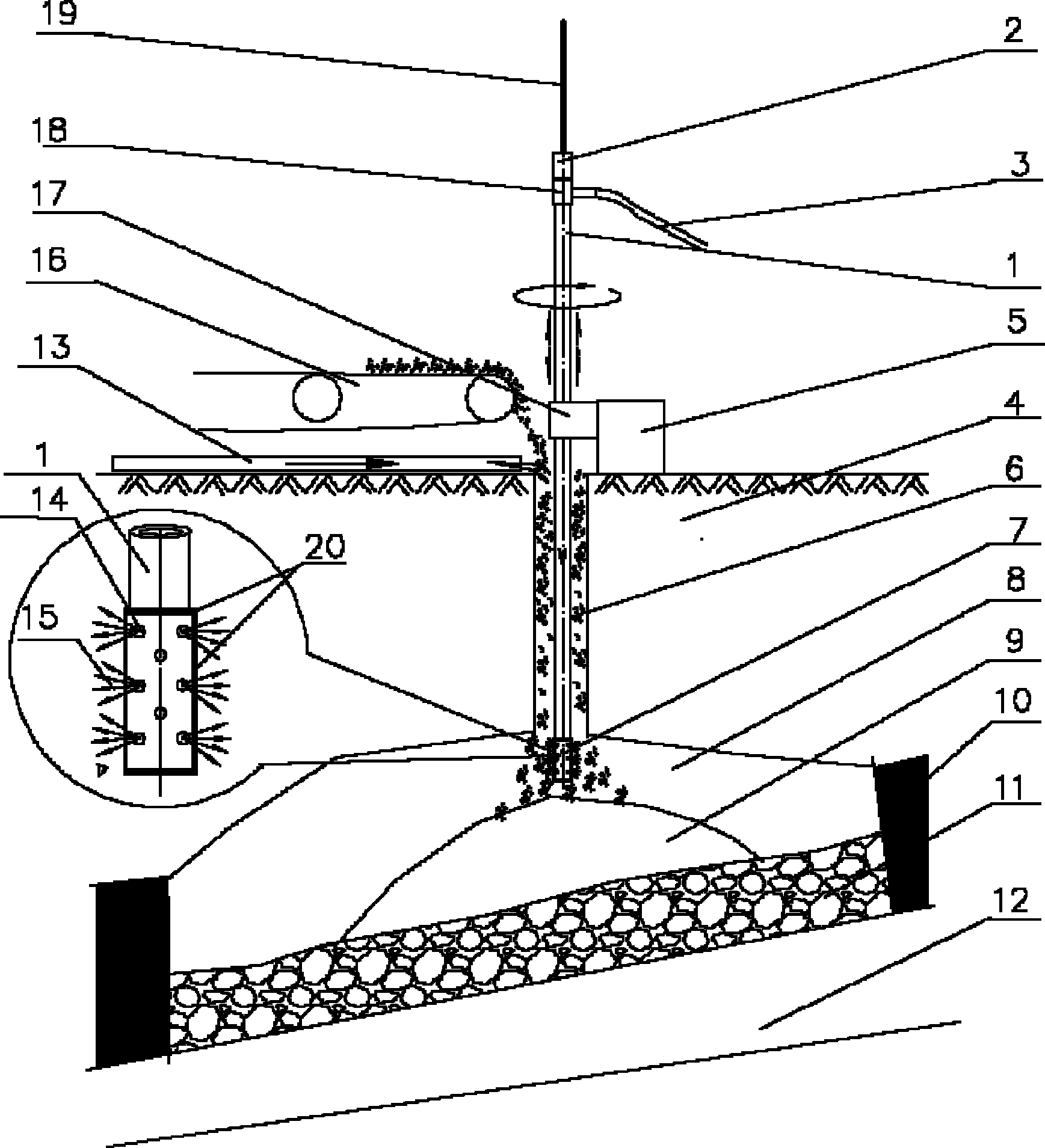

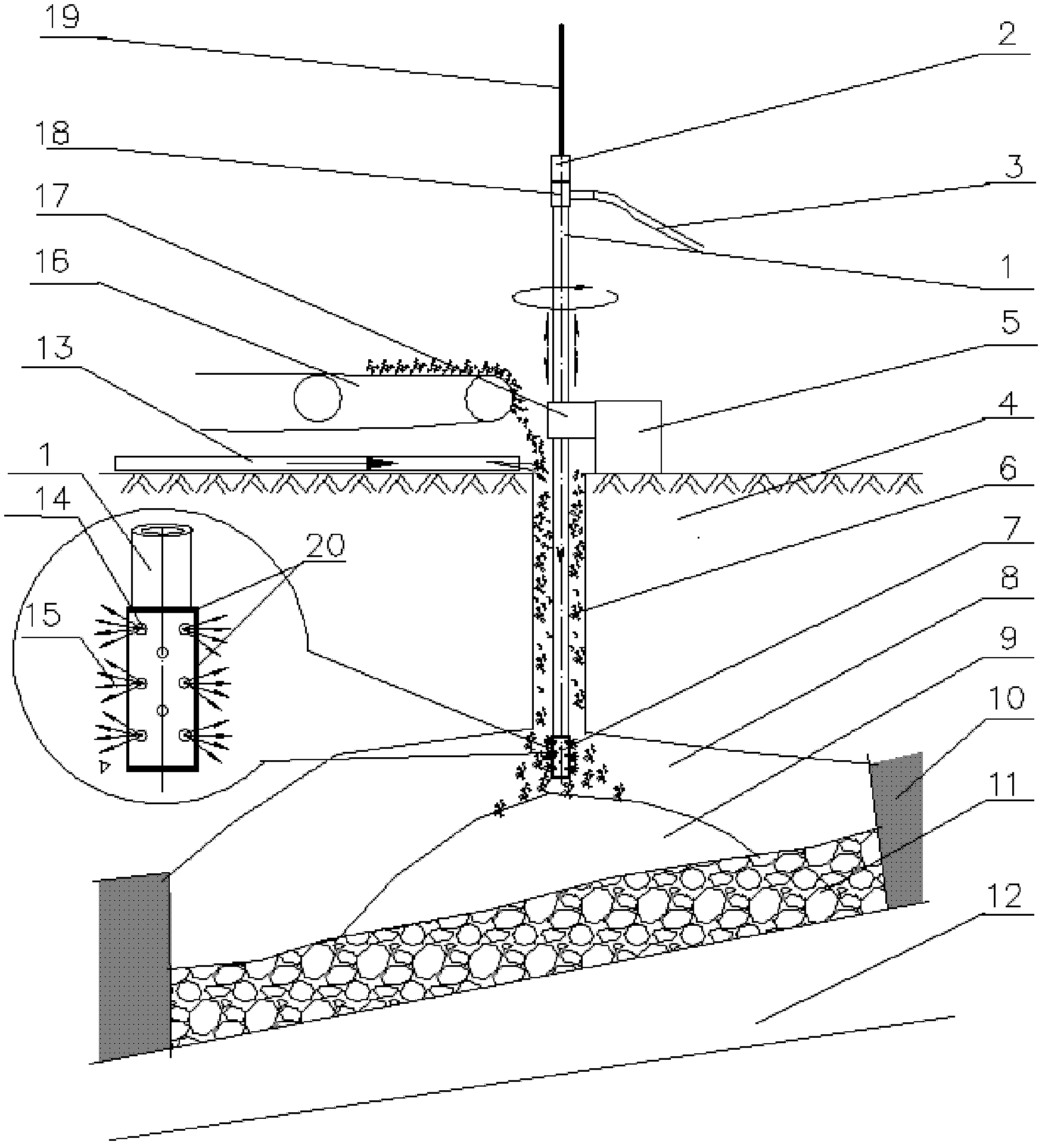

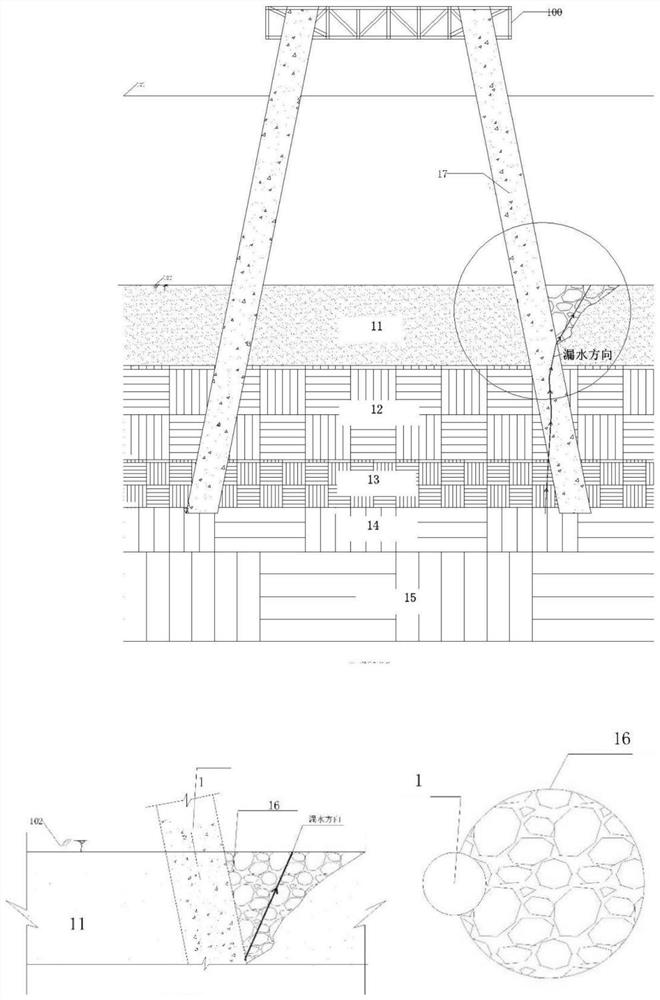

Device and process for filling aggregate into stratum cavities through surface drilling

ActiveCN102536317AEnsure safe and smooth constructionSafe and smooth constructionMaterial fill-upDrill holeWater pipe

The invention relates to a device and a process for filling aggregate into stratum cavities through surface drilling. The device comprises a hollow drill column extending into a drilled hole; a spraying head is arranged at the lower end of the drill column; a water joint is arranged at the upper end of the drill column, and is connected with an injection pump through a high-pressure rubber tube; an aggregate belt conveyor, a gyrator and a water pipe are arranged in the opening of the drilled hole; the drill column is inserted into the gyrator; the gyrator is connected with a drilling machine; the water pipe is connected with a water pump, so as to supply water to the drilled hole; and the aggregate belt conveyor conveys aggregate to the drilled hole. The invention has the advantages that various accidents generated when surface drilling is conducted on the stratum cavities are eliminated; and when aggregate is added during surface drilling, the drill column swings and shuttles, and aggregate entering into the drilled hole is washed out by water to a mined out space, so as to ensure that aggregate enter into the cavities smoothly and the drilling construction is safe and smooth.

Owner:SHANDONG UNIV

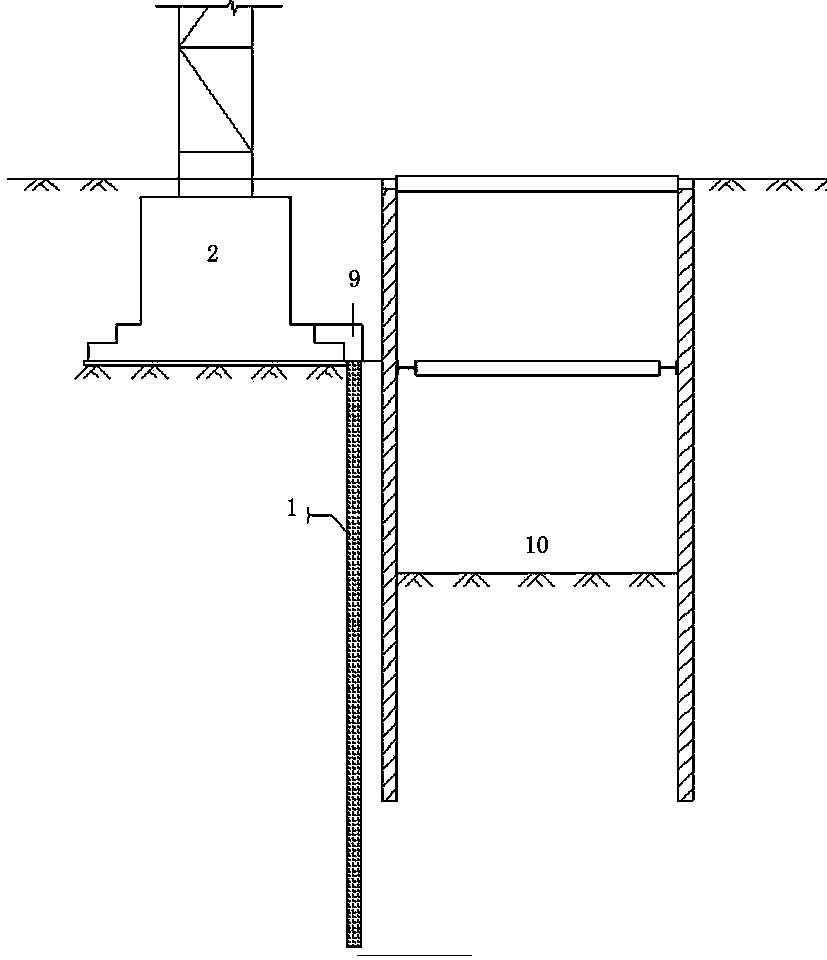

Deep basement supporting construction method

InactiveCN105887891AMeet the requirements of construction safety and stabilityControl Horizontal ShiftArtificial islandsExcavationsSteel columnsBasement floor

The invention discloses a deep basement supporting construction method. The deep basement supporting construction method is characterized by comprising the following construction steps of: (1) constructing a layer of steel column foundation piles, two layers of steel column foundation piles, a layer of steel columns and two layers of steel columns; (2) constructing basement supporting row piles; (3) constructing basement waterproof curtains, and using cement mixing piles as the basement waterproof curtains; (4) constructing a layer of basement inner ring ring-beams and a layer of basement outer ring ring-beams; (5) constructing a layer of diagonal braces and angle braces; (6) carrying out pit earth excavation till reaching the construction elevation of the bottoms of two layers of basement inner ring ring-beams; (7) constructing two layers of basement inner ring ring-beams and two layers of basement outer ring ring-beams; (8) constructing two layers of diagonal braces; (9) carrying out pit earth excavation till reaching the construction elevation of the bottoms of three layers of basement bottom plates; (10) constructing the basement bottom plates; (11) constructing the outer concrete wall of the basement; (12) dismantling the two layers of basement inner ring ring-beams, the two layers of basement outer ring ring-beams and two layers of diagonal braces; (13) constructing two layers of basement floors; (14) dismantling a layer of basement inner ring ring-beams and a layer of basement outer ring ring-beams; and (15) constructing a layer of basement floors.

Owner:朱奎

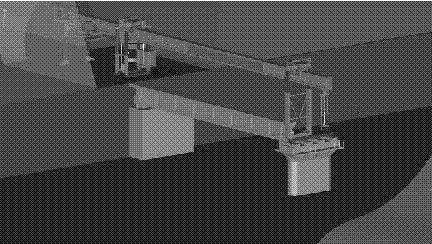

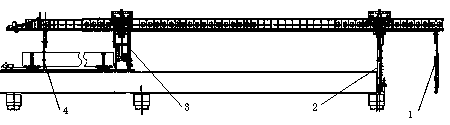

Tunnel portal beam erection simulated construction method through DJ180 bridge erection machine by using BIM (Building Information Modeling) technology

ActiveCN106930193AMeet needsSafe and smooth constructionGeometric CADDesign optimisation/simulationArchitectural engineeringTunnel construction

The invention discloses a tunnel portal beam erection simulated construction method through a DJ180 bridge erection machine by using a BIM (Building Information Modeling) technology and relates to the technical field of tunnel construction. The method comprises the following steps: () modeling in BIM; (2) simulating the construction process; (3) determining an optimal construction scheme; and (4) producing a construction video. According to the simulated construction scheme, the overall construction scheme is optimized, the tunnel portal beam erection requirement is met, and safe and smooth beam erection construction is guaranteed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Water-rich round-gravel stratum shield muck improvement method and muck improvement agent

ActiveCN109749748AEasy to prepareReduce the cost of improvementOther chemical processesBuilding constructionsSodium BentonitePermeability coefficient

The invention discloses a muck improvement agent which comprises liquid A and liquid B. The liquid A comprises, by weight, 0.25-0.33 parts of sodium bentonite, 0.01-0.015 part of carboxymethylcellulose and 1 part of water. The liquid B comprises, by weight, 0.001-0.003 part of polyacrylamide and 1 part of water. The invention further discloses a method for improving water-rich round-gravel stratumshield muck by the muck improvement agent. According to the muck improvement agent, the liquid A with the volume injection ratio of 30%, the liquid B with the volume injection ratio of 7.5% and soilsamples from an on-site water-rich round-gravel stratum are stirred and mixed, the collapsing degree can be controlled within 20cm, a permeability coefficient K of improvement soil reaches 1*10<-7>m / sunder water pressure of 2.5bar (25m water head), continuous time reaches 4 hours or more, the permeability coefficient is smaller than 1*10<-5>m / s serving as a flowing critical value, and improvementeffects are good.

Owner:CHINA RAILWAY DEV INVESTMENT CO LTD +2

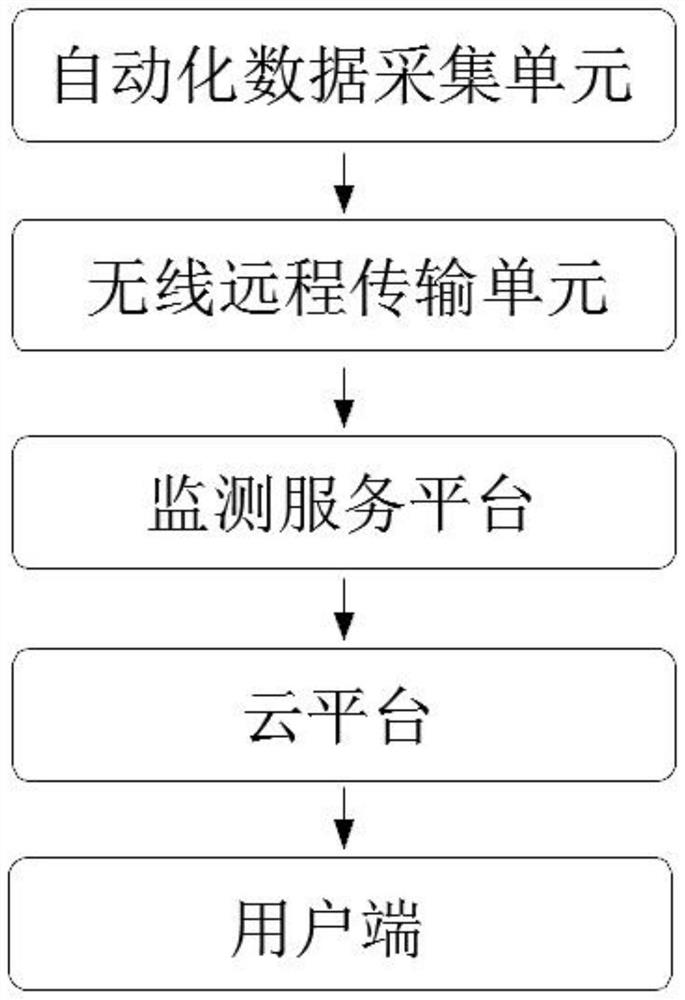

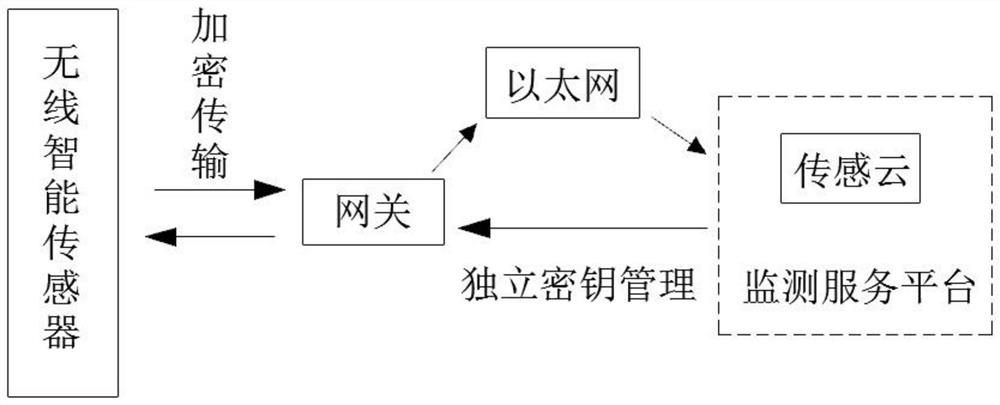

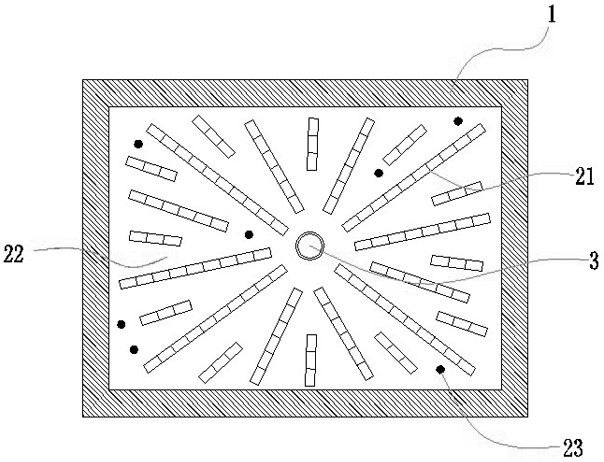

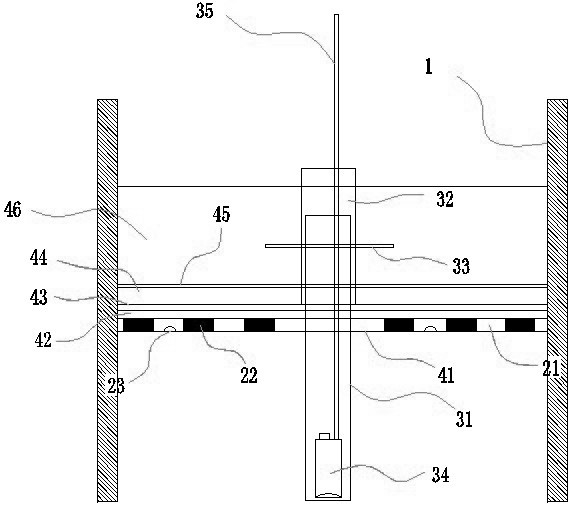

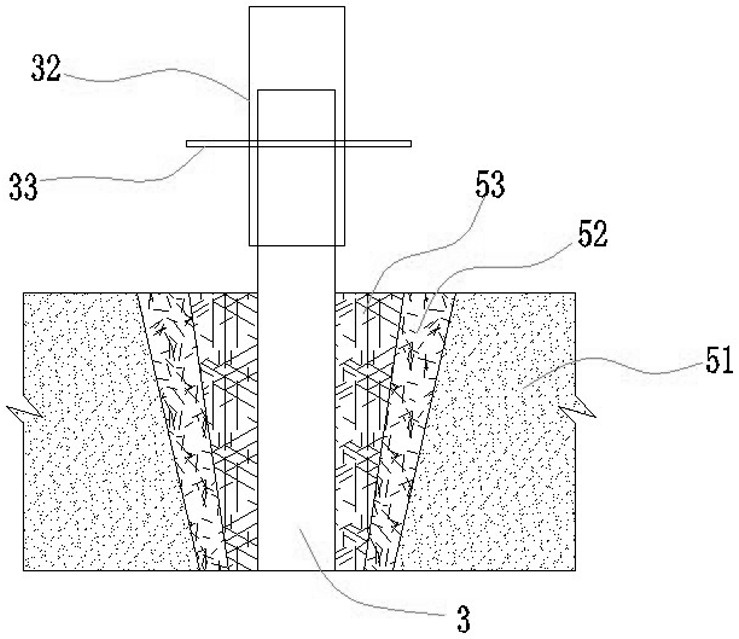

Deep and large foundation pit wireless intelligent monitoring system

PendingCN113945238ASafe and smooth constructionReduce usageMeasurement devicesThe InternetData acquisition

The invention relates to the technical field of foundation and foundation engineering, and discloses a deep and large foundation pit wireless intelligent monitoring system which comprises an automatic data acquisition unit used for acquiring foundation pit monitoring data and a wireless remote transmission unit used for wirelessly transmitting the acquired data, and a monitoring service platform which analyzes the foundation pit monitoring data. The deep and large foundation pit monitoring system integrating automatic data acquisition, wireless data transmission, sensor free networking and remote intelligent control is developed by using the Internet of Things technology, real-time, accurate and continuous data are provided for monitoring of the deep and large foundation pit, the deformation trend of the foundation pit is predicted, a scientific early warning mechanism is established, and the safety state of the foundation pit is judged so that safe and smooth construction of the foundation pit is guaranteed, the defects that a conventional manual monitoring means needs more personnel investment, time consumption is long, errors are large and data processing is lagged are overcome, meanwhile, data collection is continuous, the dynamic change conditions under various working conditions can be reflected, and real-time monitoring and early warning are achieved.

Owner:SHENZHEN HONGYEJI GEOTECHNICAL TECH CO LTD

Substrate water gushing and sand gushing treatment method

InactiveCN112281882AEffectively closedInhibition of harmful effectsFoundation engineeringBrickReinforced concrete

The invention belongs to the technical field of building construction, and particularly relates to a substrate water gushing and sand gushing treatment method. The treatment method comprises the following steps that S1, surveying and setting out are carried out, and the position of a secondary excavation foundation pit is determined; S2, supporting piles and a waterproof curtain are constructed; S3, a foundation pit is excavated; S4, the soil surface is excavated to a preset elevation and flattened, and a submersible pump is placed to pump and drain accumulated water; S5, water and sand gushing points on the soil surface of the substrate are found out, and a water flowing pipeline is built by using bricks, so that water flowing out of the water gushing points is collected to a middle dewatering well to be discharged; S6, a formwork and plastic cloth are laid on the top faces of the bricks; S7, a water stop steel shaft is installed in the dewatering well, and a cushion layer is poured;S8 a waterproof layer is laid, and concrete is poured; and S9, the dewatering well is plugged. According to the substrate water gushing and sand gushing treatment method, the bottom surface of the foundation pit can be rapidly and effectively sealed, the harmful effect of water gushing and sand gushing of the substrate on the foundation pit is restrained to a large extent, and safe and smooth construction of a main body reinforced concrete structure is guaranteed; and the construction method is simple, low in cost and remarkable in effect.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

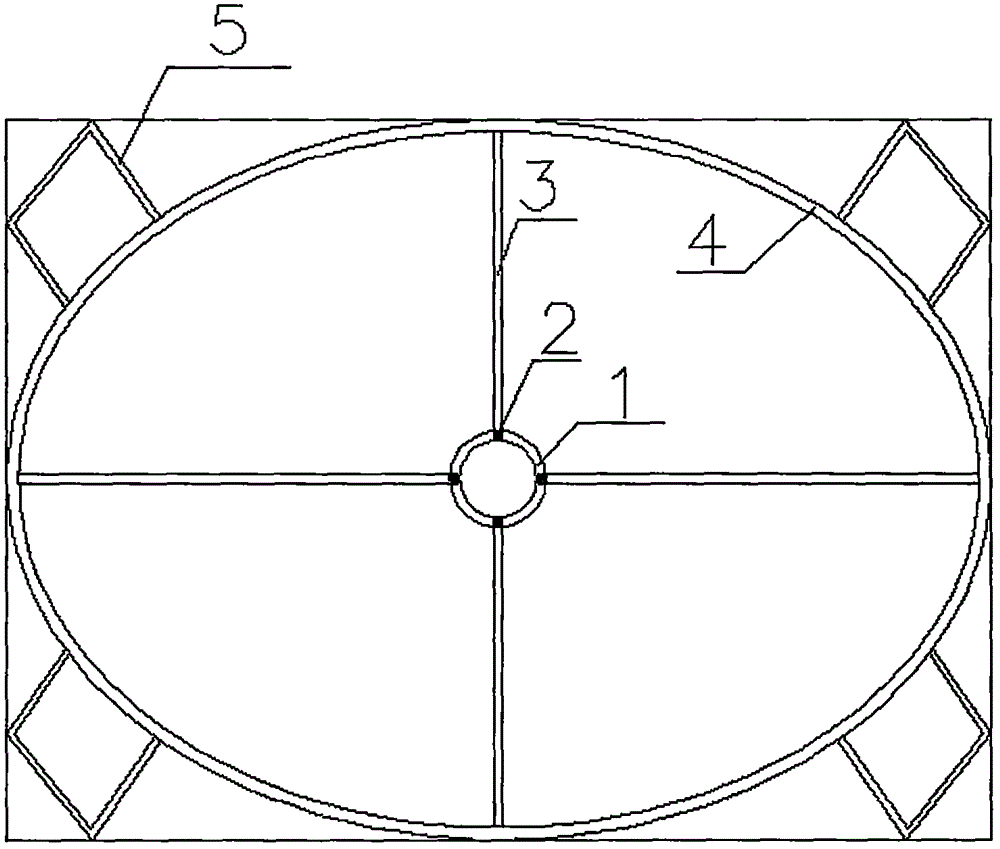

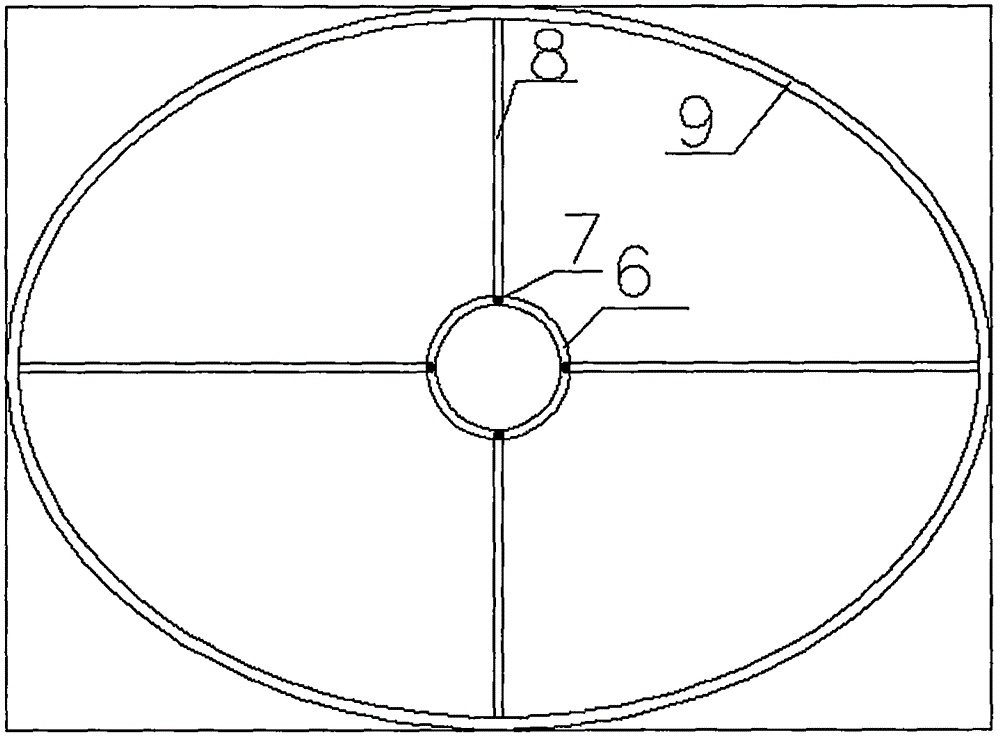

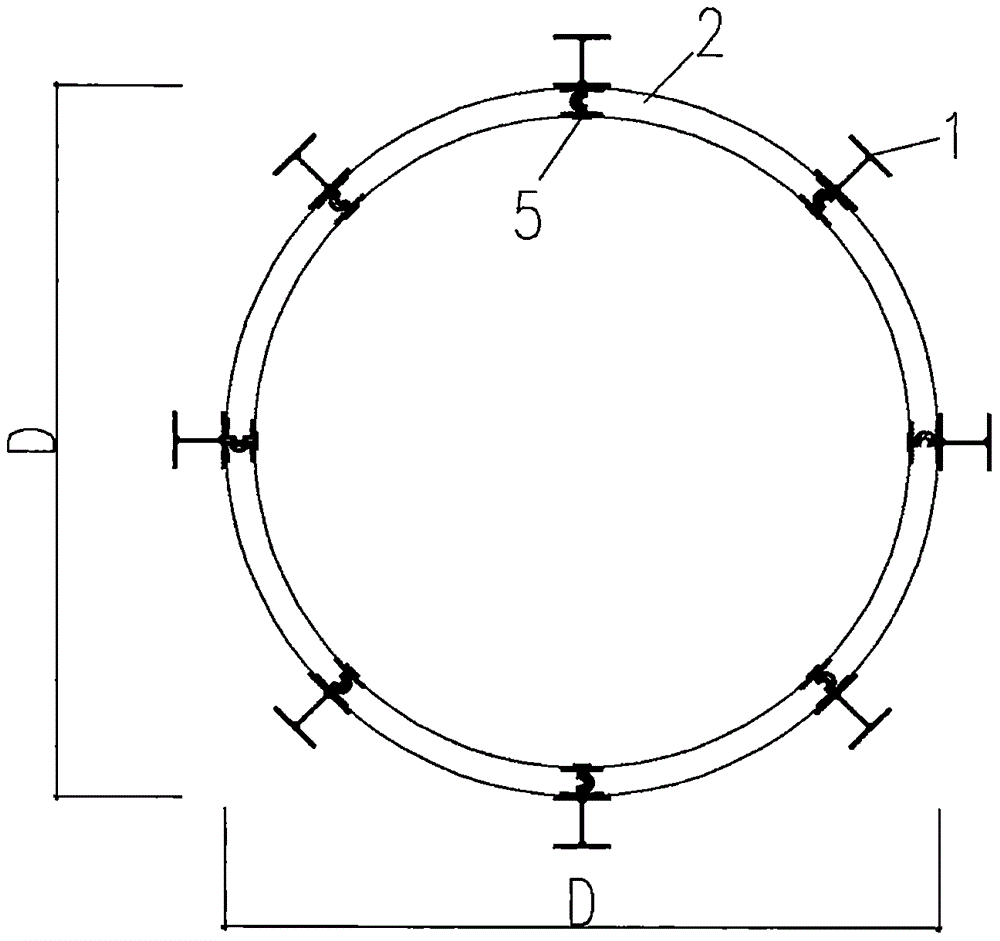

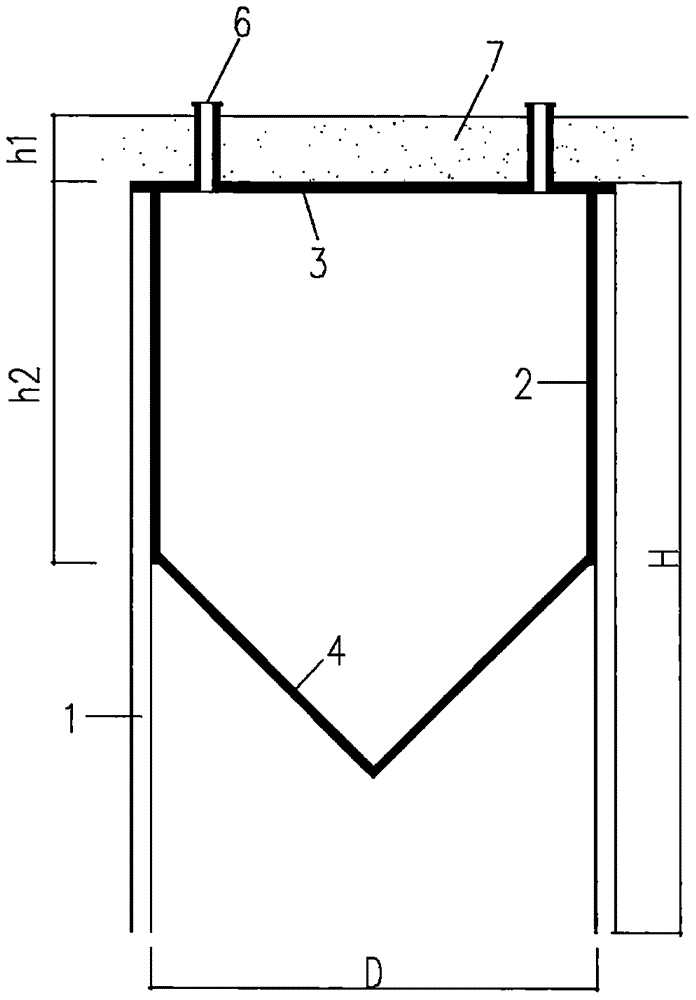

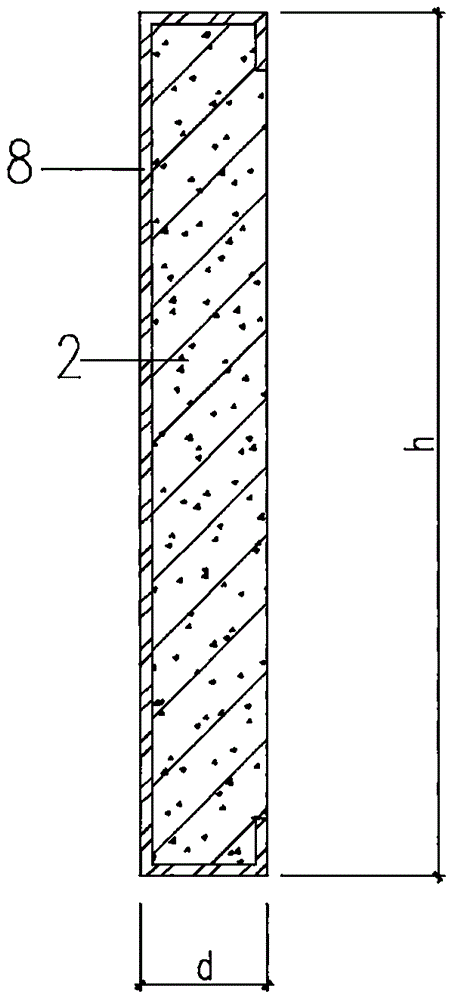

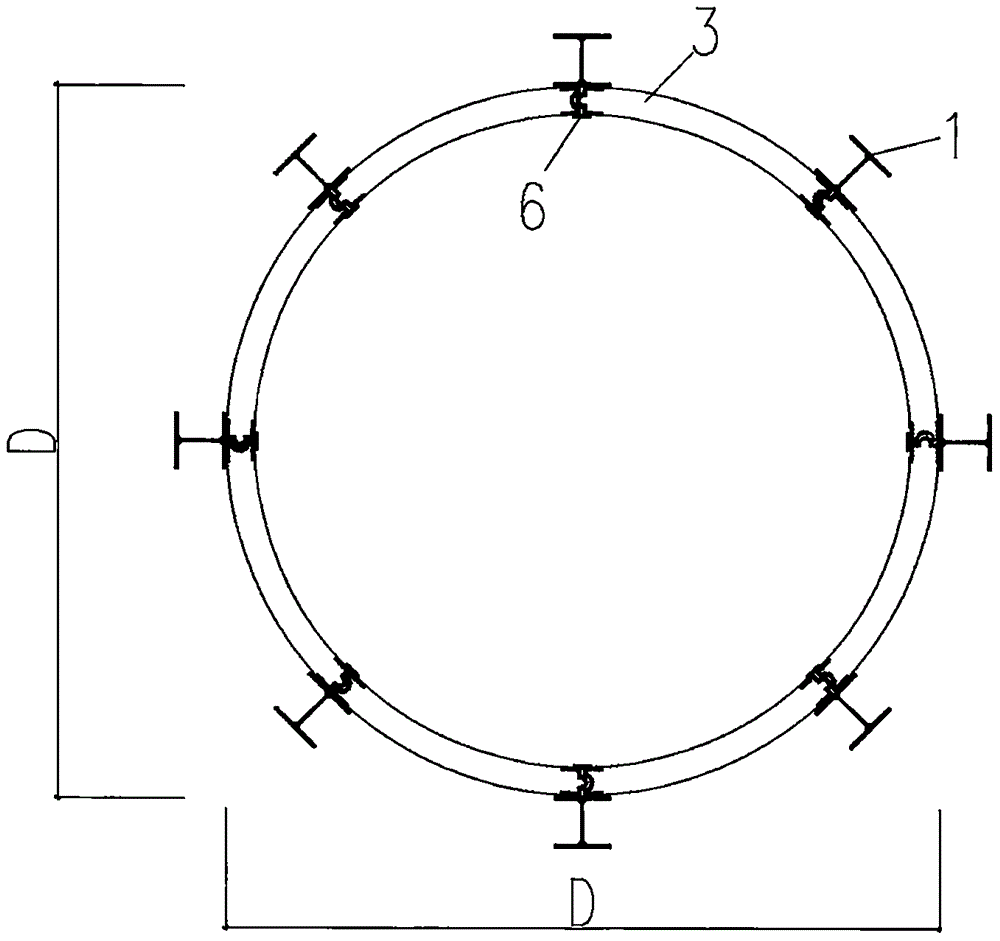

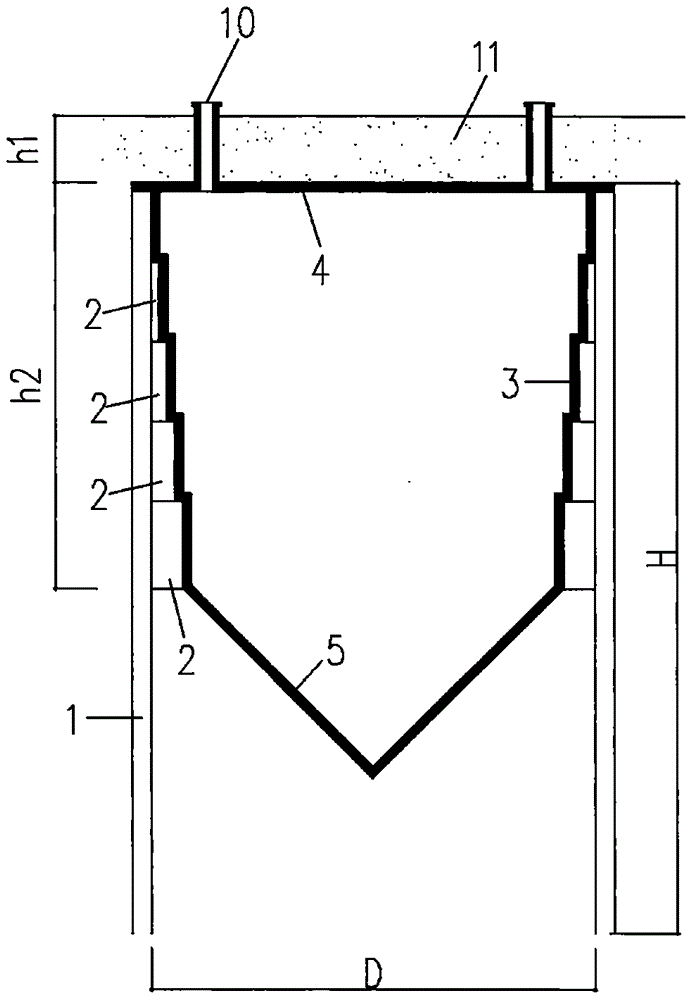

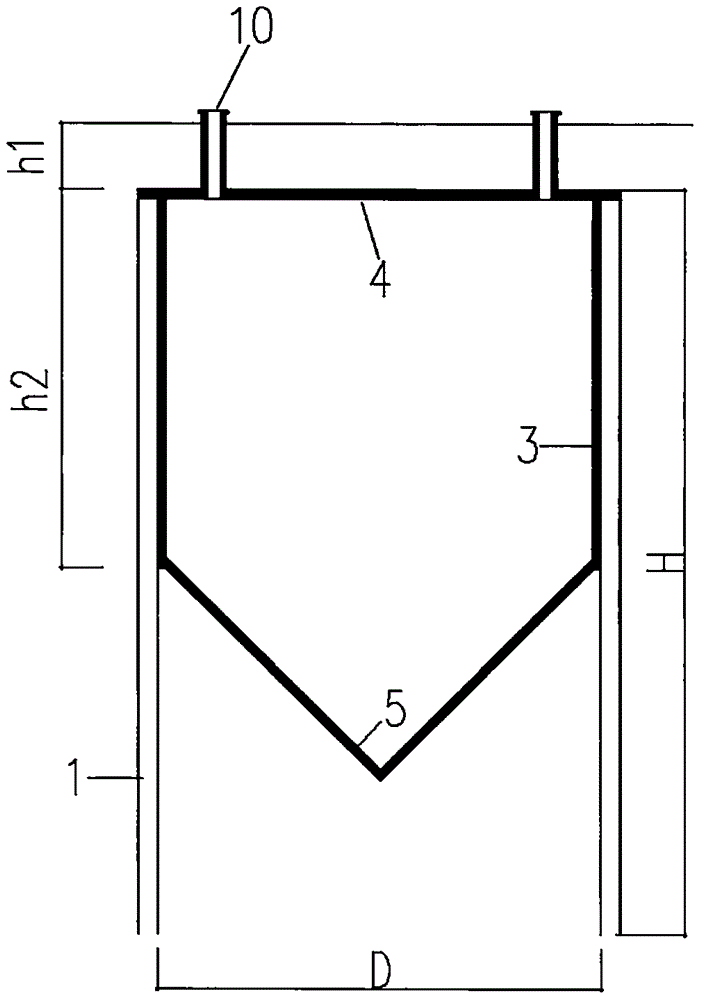

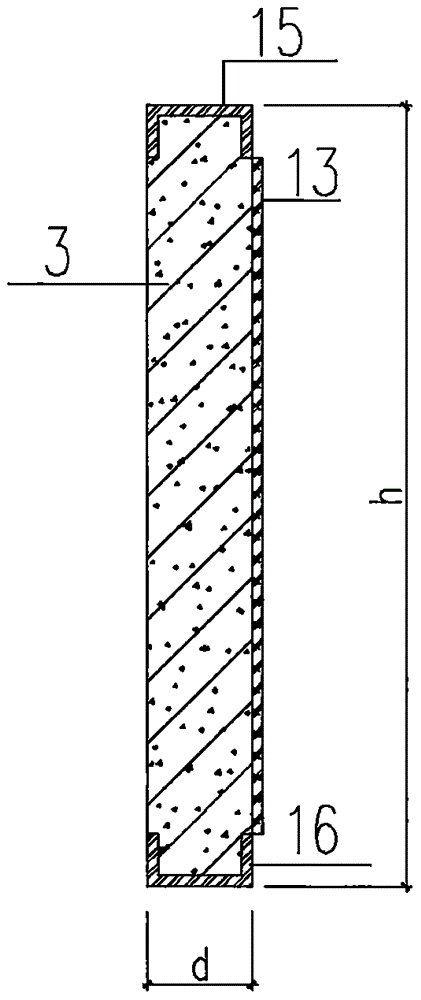

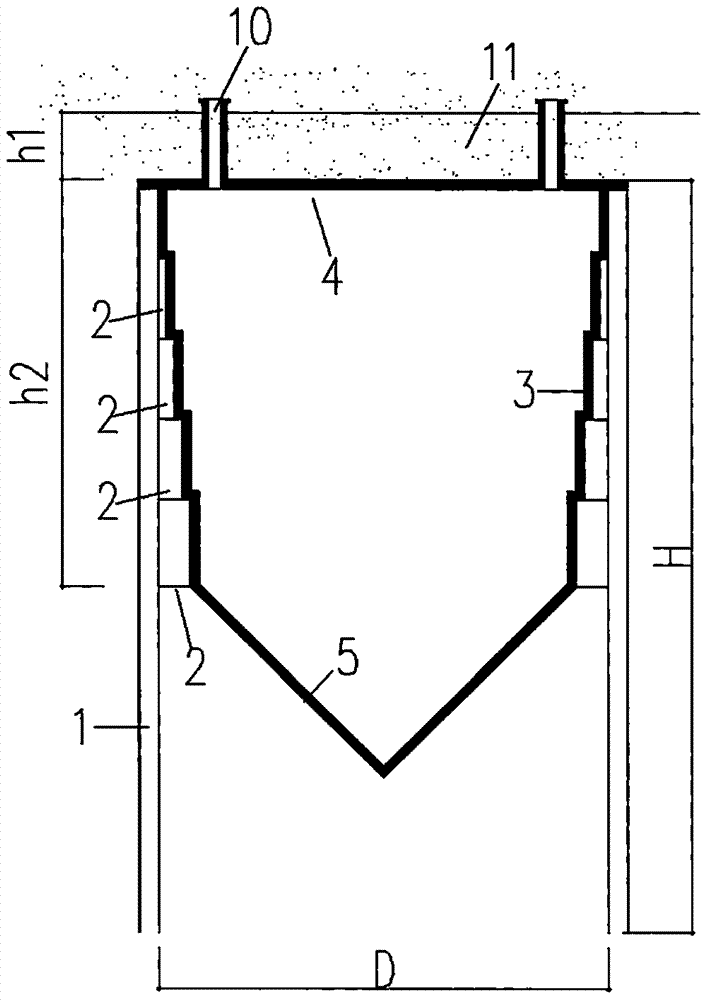

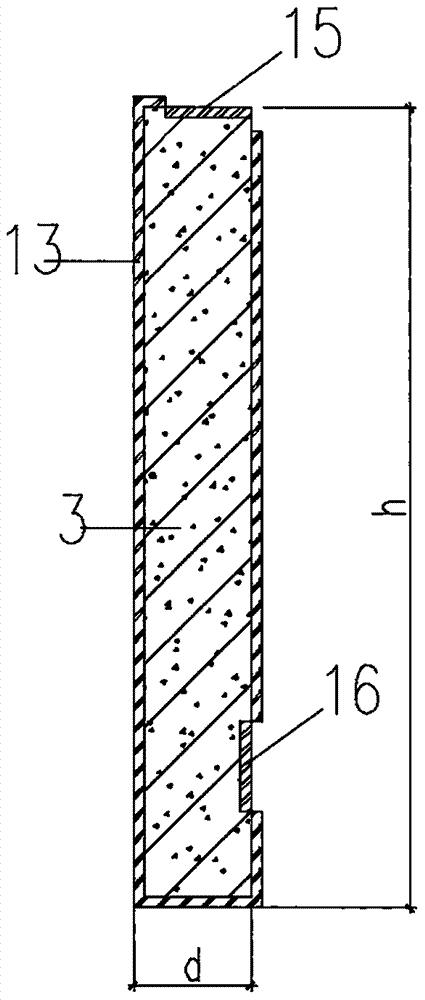

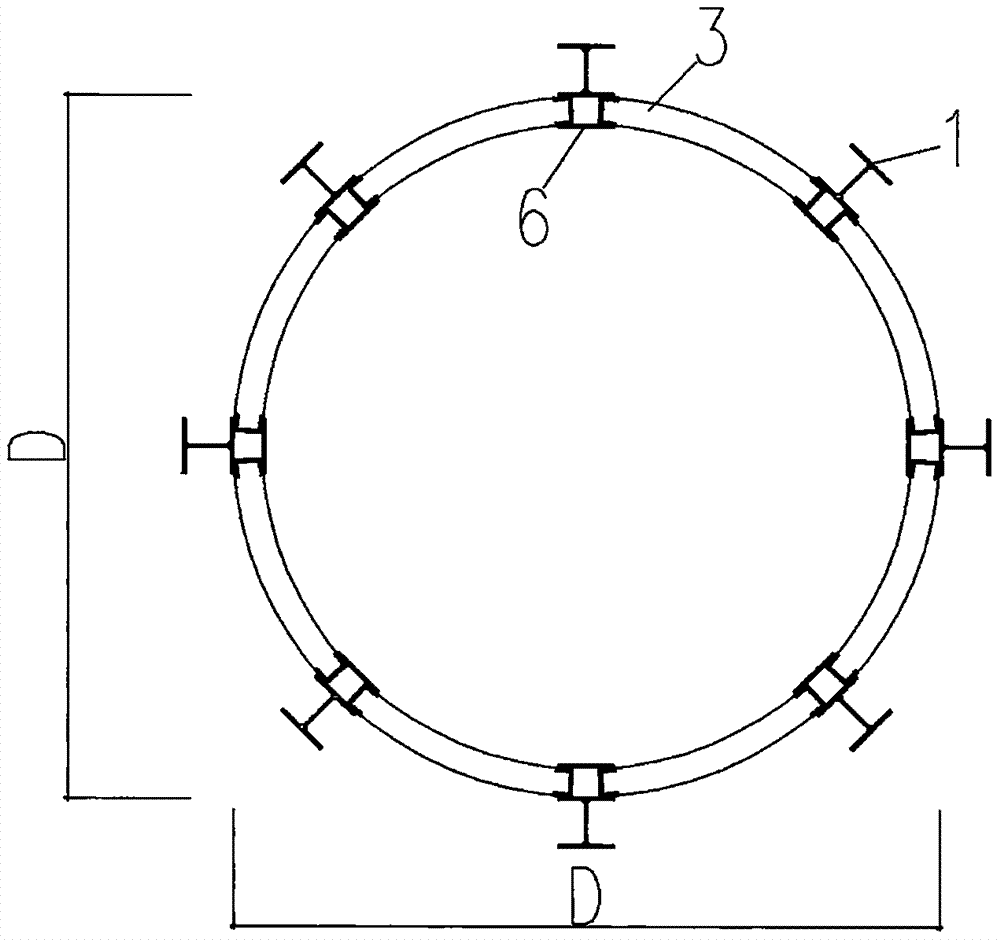

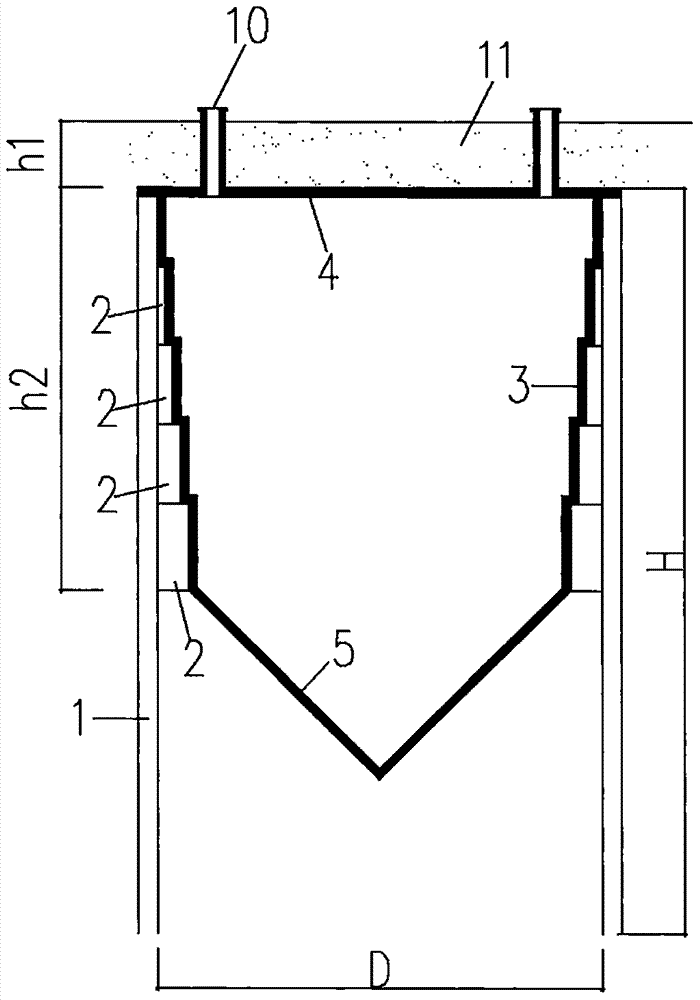

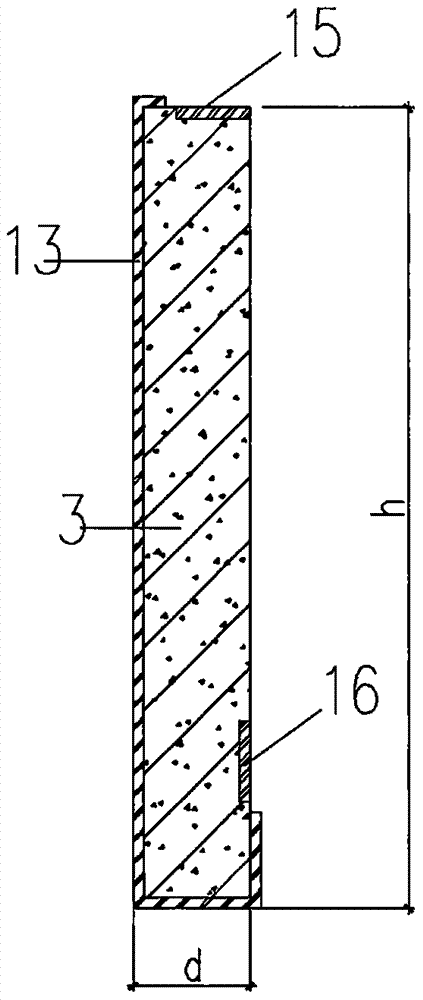

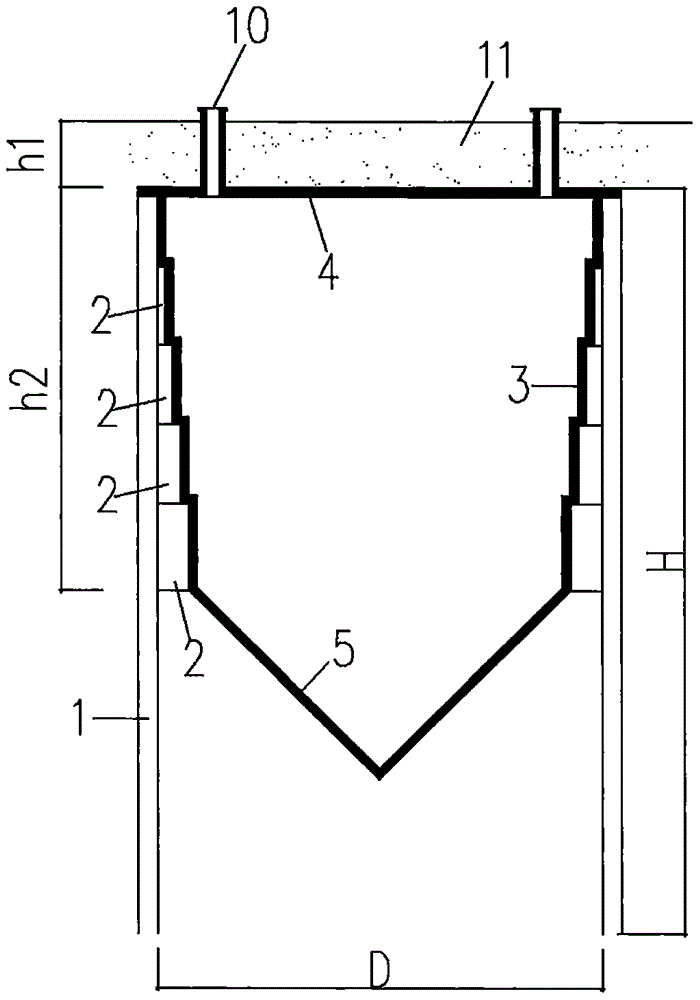

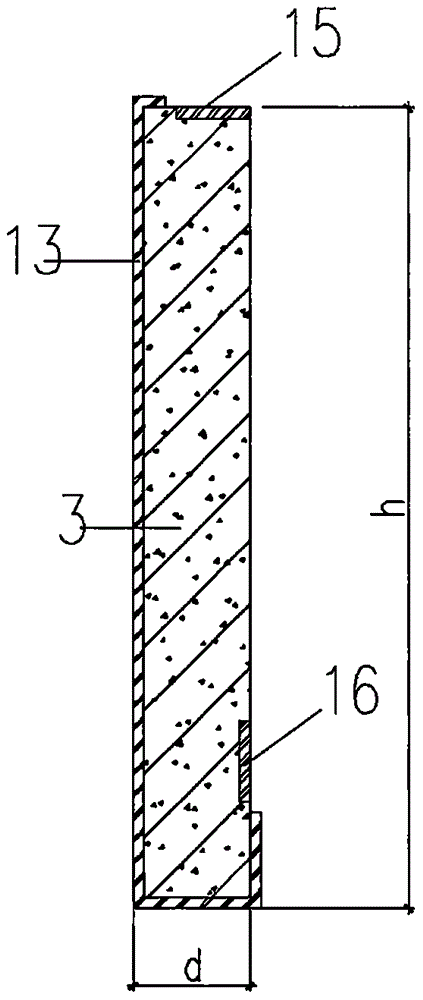

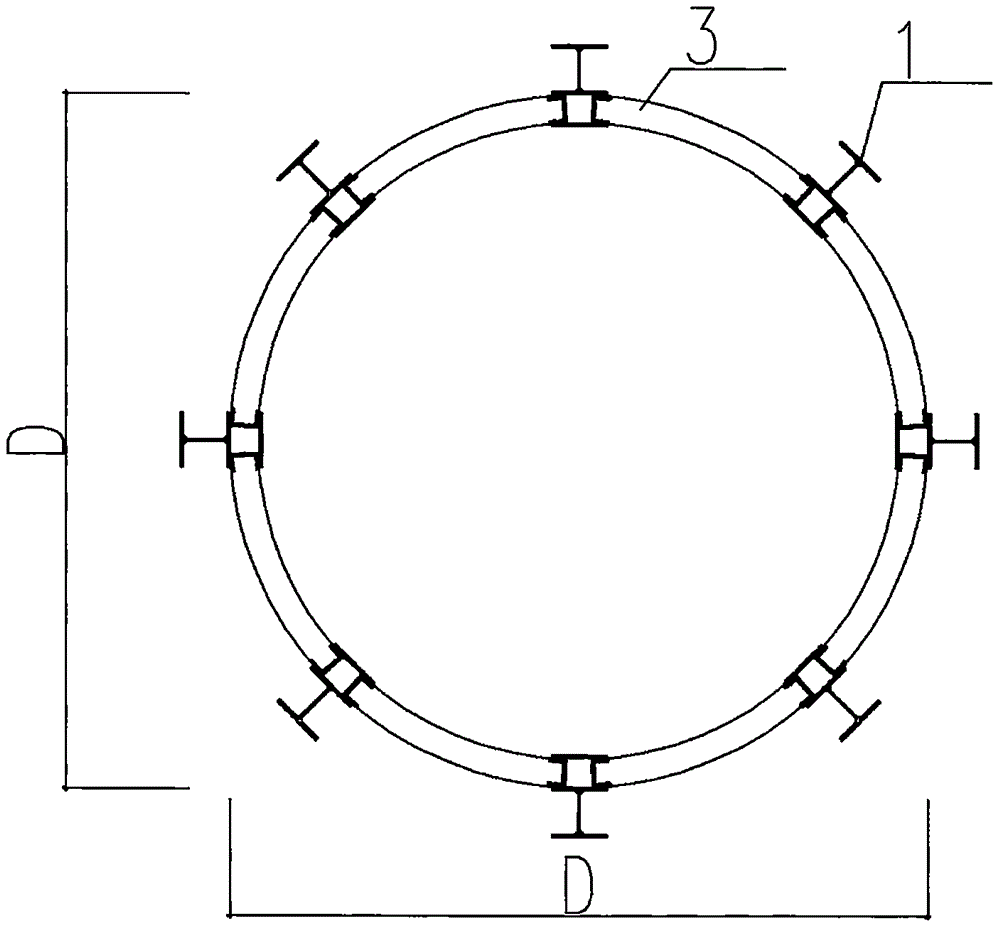

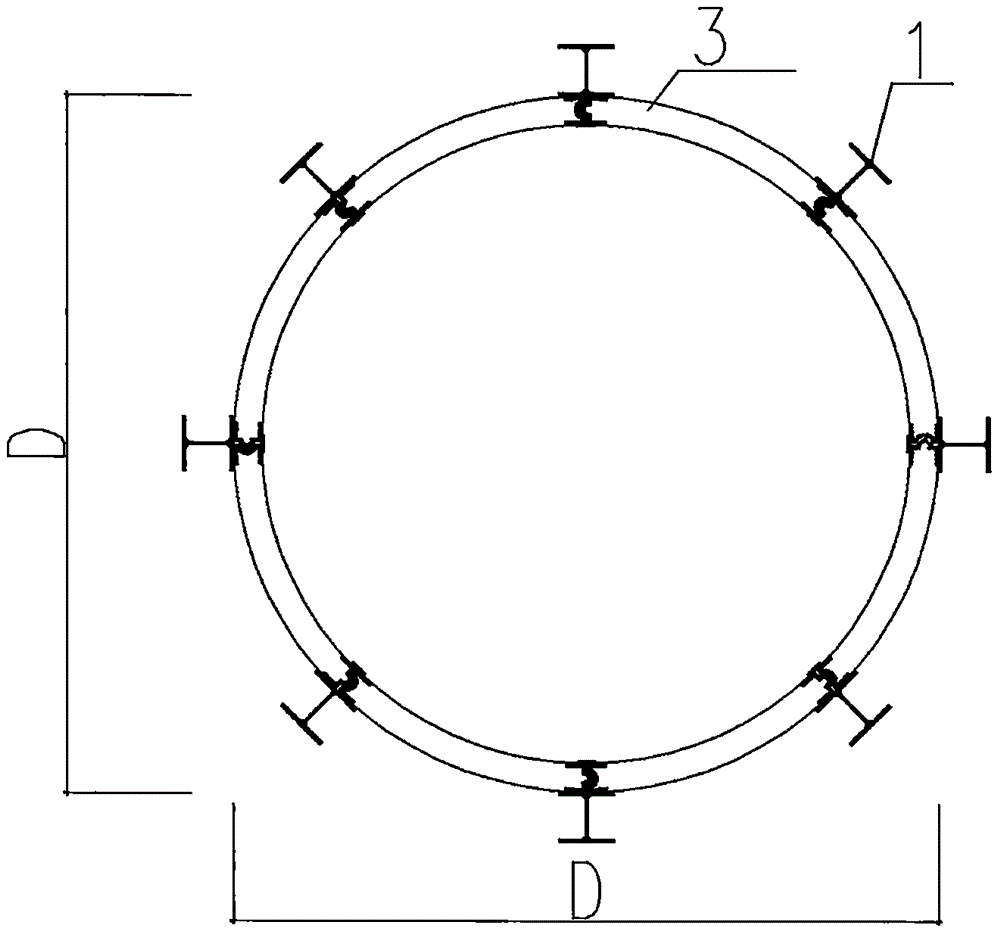

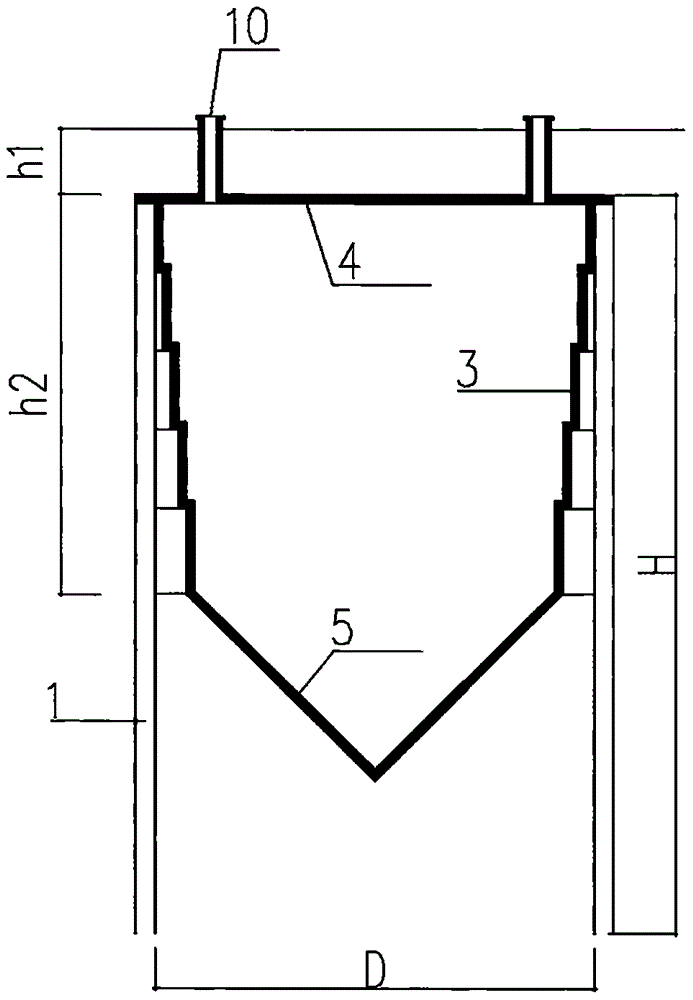

Slot-type prefabricated assembly-type round underground granary clad with steel plates externally

ActiveCN106088762AReduce construction difficultyIncrease stiffnessClimate change adaptationExcavationsSheet steelEngineering

The invention discloses a prefabricated assembly-type underground granary, which comprises a granary bottom, prefabricated granary wall plates, a granary top and multifunctional columns, wherein the granary wall plates are arc-shaped prefabricated plate blocks; connecting devices are arranged on the peripheries of the granary wall plates; the granary wall plates can be connected with the adjacent granary wall plates and the multifunctional columns through the connecting devices; the multifunctional columns are used for locating a granary wall; the depths that the multifunctional columns are anchored into earth are more than the depth of the granary bottom; the multifunctional columns are main stress components for bearing the pressure of the earth and the lateral pressure of grains and resisting buoyant force. The prefabricated assembly-type underground granary is characterized in that the outer sides, the left ends and the right ends of the prefabricated granary wall plates are all clad with steel plates; further, the left ends of the prefabricated granary wall plates are provided with convex-type trapezoidal or semi-elliptical plugs; the right ends of the prefabricated granary wall plates are provided with concave-type trapezoidal or semi-elliptical slots; the multifunctional columns are divided into several sections from tops to bottoms; the inner sides of first sections of the uppermost layer are provided with a first layer of the granary wall plates; the inner sides of second sections are provided with a second layer of the granary wall plates; the granary wall plates are arranged until the bottommost layer of the granary wall plates by using a similar arrangement way, so as to form a round assembly-type underground granary structure.

Owner:HENAN UNIVERSITY OF TECHNOLOGY +1

Hydraulic movable dam with high impact resistance

ActiveCN112030895AExtended service lifePrevent damage,Barrages/weirsVibration suppression adjustmentsHydraulic cylinderElectro hydraulic

The invention discloses a hydraulic movable dam with high impact resistance, and relates to the technical field of hydraulic movable dams. A first-stage energy dissipation mechanism and a second-stageenergy dissipation mechanism are arranged in an impact force energy dissipation unit, the first-stage energy dissipation mechanism performs primary offsetting on impact force which is generated during wave impacting and acts on a pressure-resistant plate through a simple spring and a telescopic rod structure, the second-stage energy dissipation mechanism is integrally and technically characterized in that remaining impact force, namely kinetic energy, is converted into potential energy, due to the fact that multiple whole impact force energy dissipation units are arranged and evenly distributed on an existing movable dam body structure, impact force generated during wave impacting acts on the pressure-resistant plate in a large area instead of a dam body, so that on one hand, the whole dam body structure can be protected, on the other hand, a whole electric hydraulic cylinder is protected, the problem that the dam body and an electric hydraulic rod are damaged due to long-term impactand the dam body cannot be normally opened and closed is solved, and the service life of the hydraulic movable dam is prolonged.

Owner:ANHUI MINGCHUAN ACTIVITIES DAM TECH CO LTD

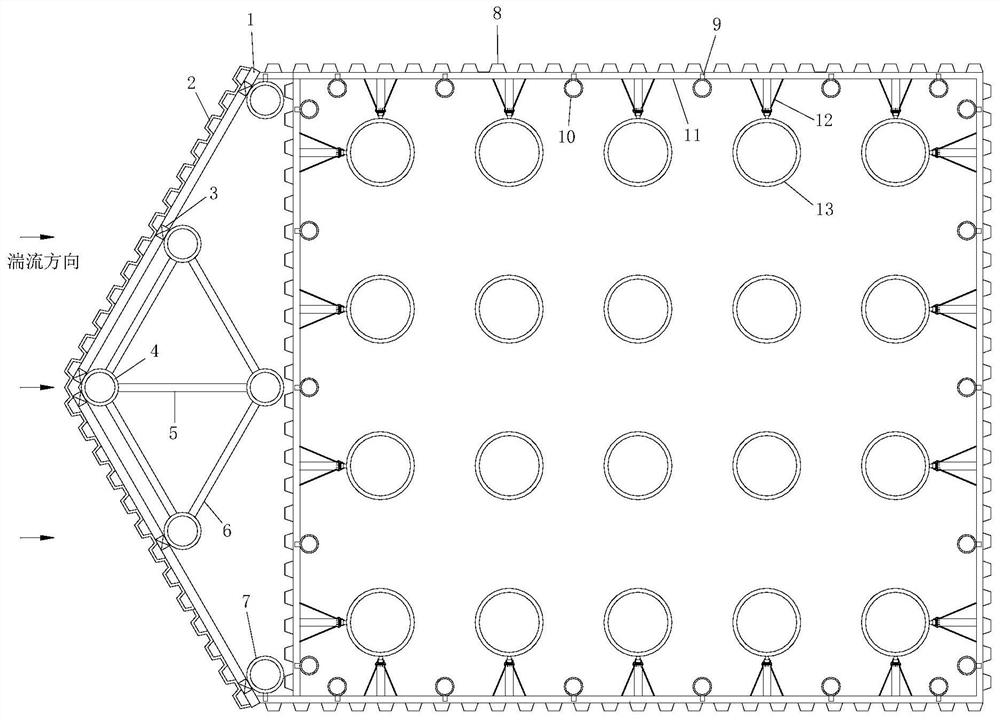

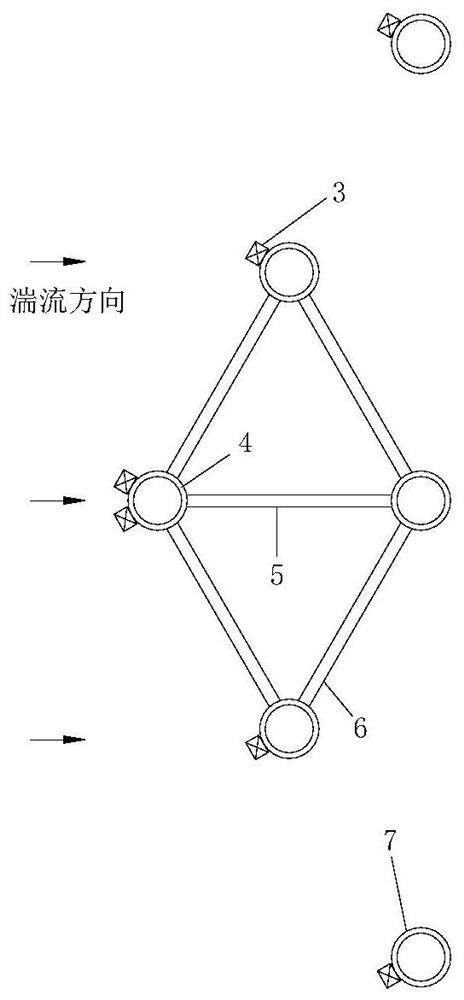

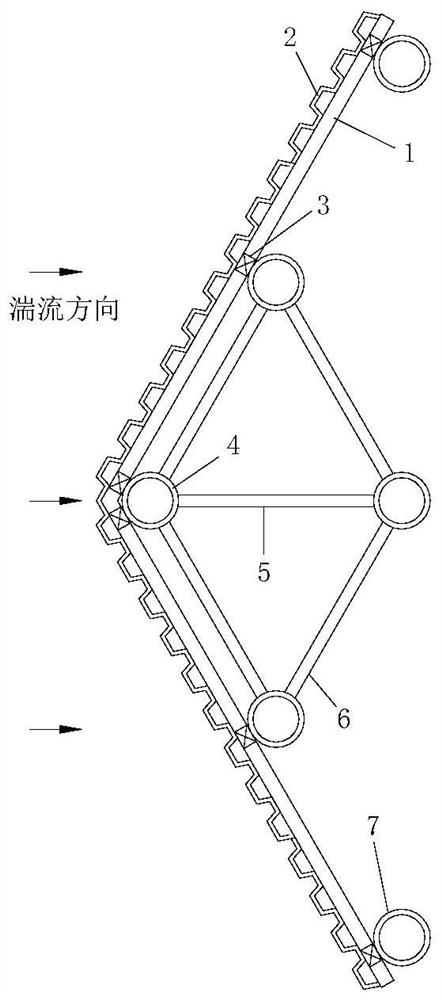

Construction method for steel cofferdams in complex torrential water area

The invention relates to a construction method for steel cofferdams in a complex torrential water area. The method comprises the following steps that, firstly, a rhombic fixed pile group and two corner fixed steel pipe piles are constructed; then an underwater cofferdam support is hoisted on a turbulent flow facing surface, and a double-layer steel cofferdam is constructed; then, guide piles, guide beams and a single-layer steel cofferdam on two sides are synchronously constructed, and guide piles, guide beams and a single-layer steel cofferdam on the inner side are constructed; next, steel casings are driven in the steel cofferdams, and overwater support frames are constructed on the steel casings close to the steel cofferdams for later water pumping to resist the pressure of outer water; next, guide piles, guide beams and a single-layer steel cofferdam on the outer side are constructed; and finally, desilting is conducted in the steel cofferdams, underwater concrete is poured for bottom sealing, and water in the steel cofferdams is pumped. The construction method has the beneficial effects that a supporting frame with the sliding rail system is arranged between the peripheral steel pile casings and the guide beams, so that the steel pile casings can be used for supporting the steel cofferdams, and the influence of continuous driving of steel pile casings can be avoided.

Owner:ZHEJIANG UNIV CITY COLLEGE

Method for treating boulders in reinforced zone of starting end

InactiveCN111058862ASafe and smooth constructionUnderground chambersTunnel liningStructural engineeringMechanical engineering

The invention discloses a method for treating boulders in a reinforced zone of a starting end. According to the condition of the boulders in the reinforced zone of the starting end, three boulder treatment manners of boulder detonation, rotary excavating and drilling mechanical treatment and in-hole perforated smashing are compared and analyzed, it is confirmed that the construction method of in-hole perforated smashing is mainly adopted for treating the boulders in the reinforced zone of the starting end, and safe and smooth conduction of shield construction is achieved.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

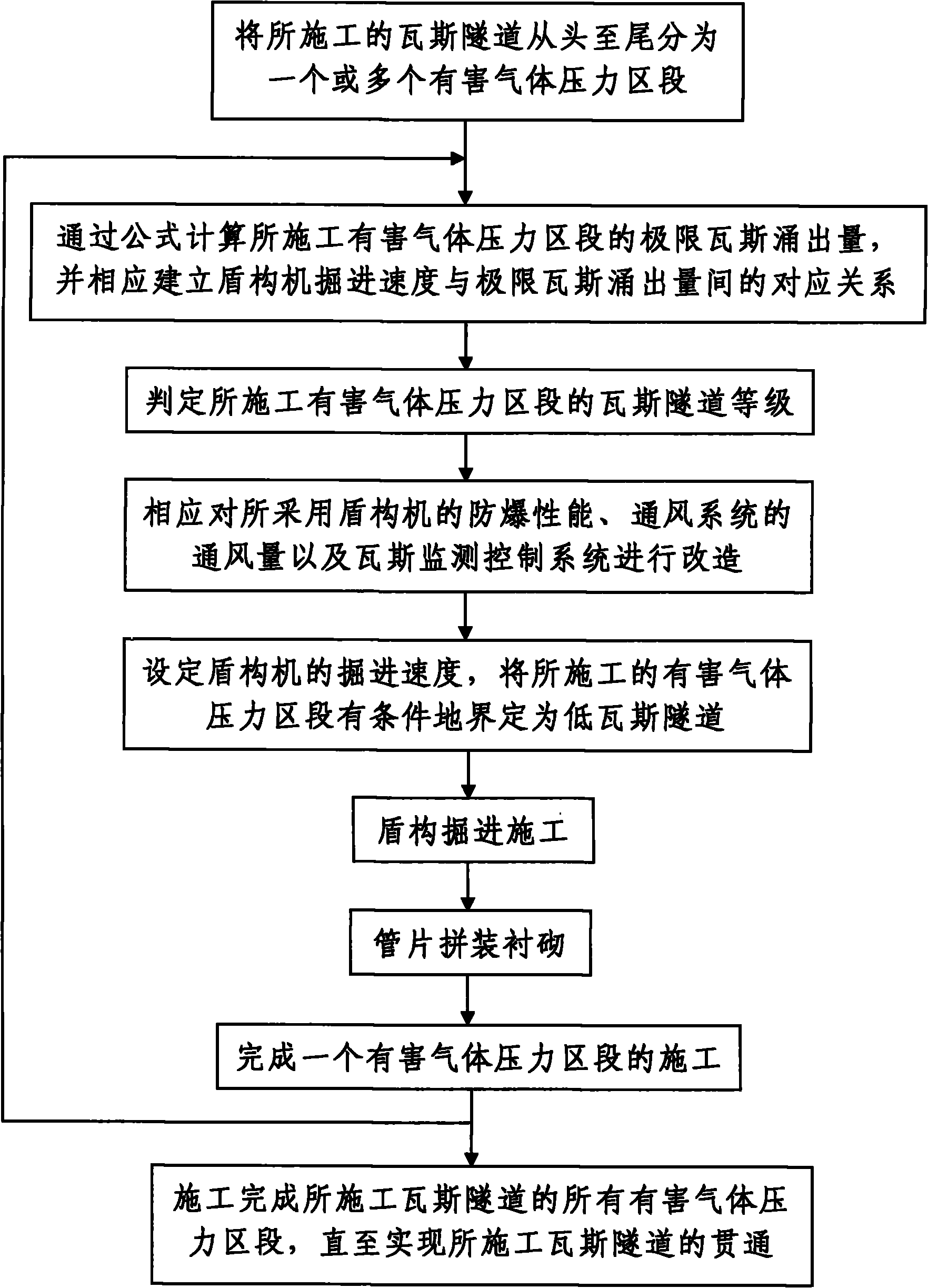

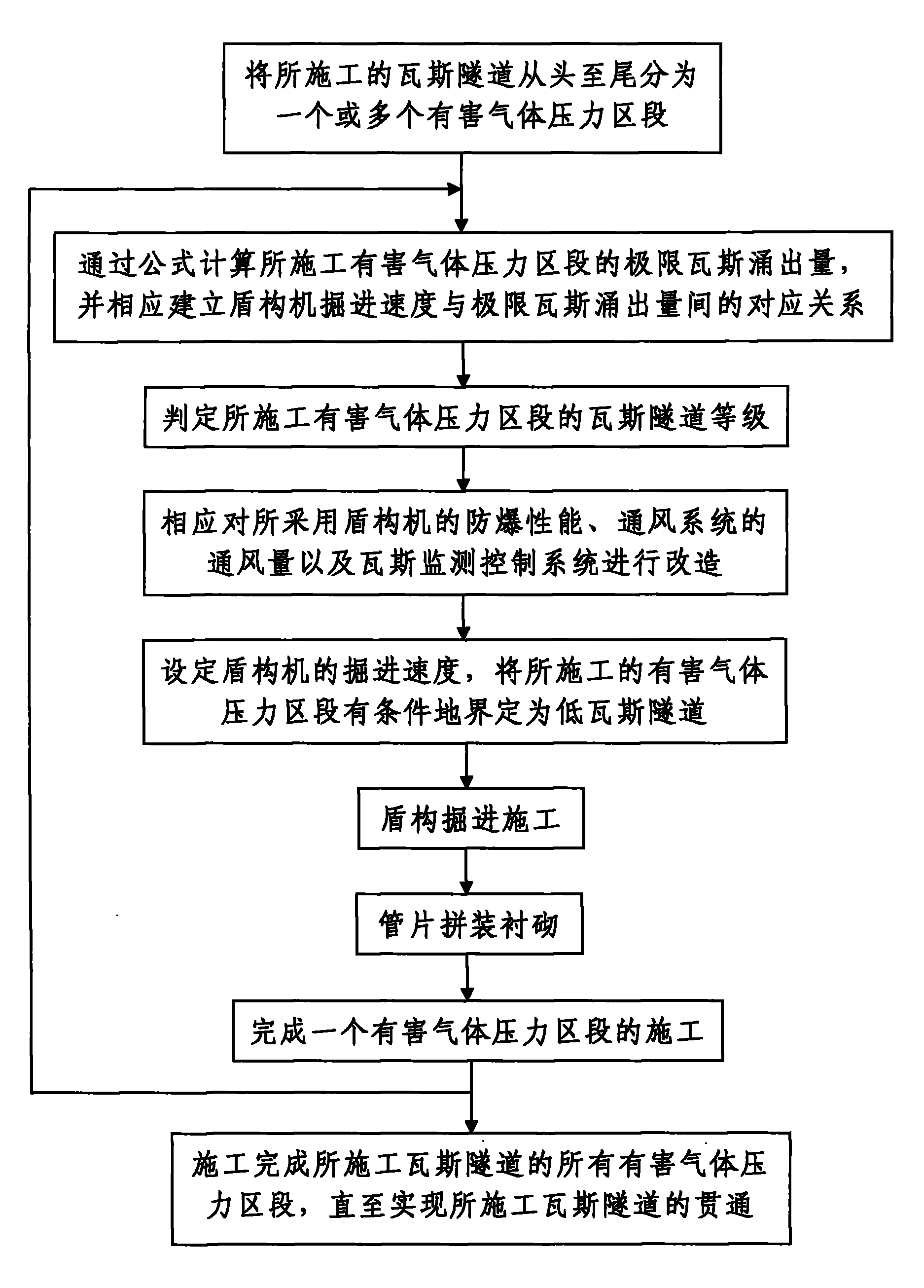

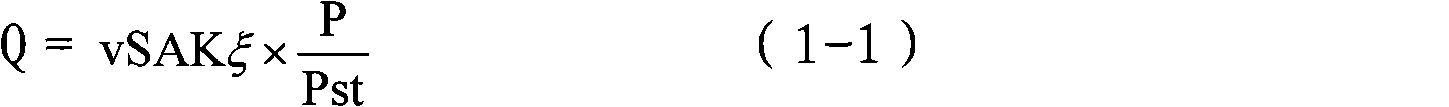

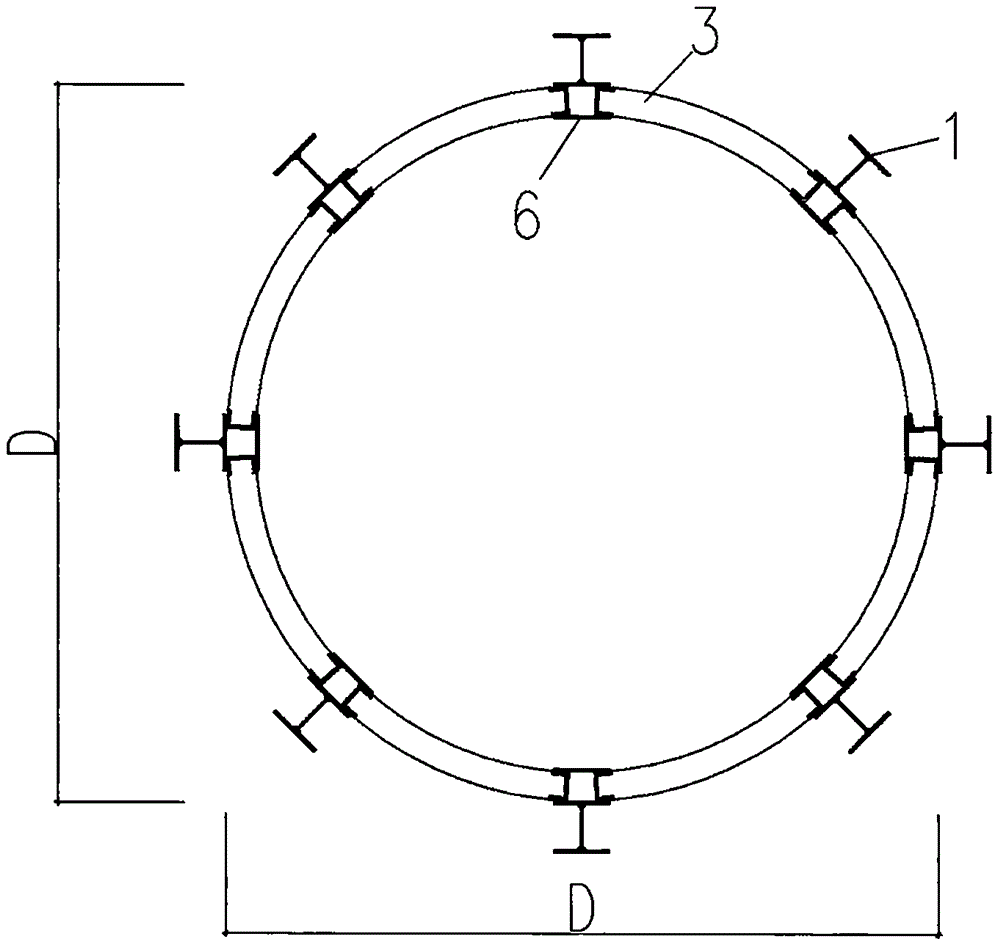

Subway shield gas tunnel construction method

ActiveCN101571044BIngenious designReasonable designMining devicesUnderground chambersControl systemExplosion protection

The invention discloses a subway shield gas tunnel construction method, which comprises the following steps: 1, dividing a gas tunnel to be constructed into one or more harmful gas pressure sections from end to end; 2, respectively constructing the harmful gas pressure sections in turn according to the construction work stages of the gas tunnel to be constructed, wherein construction processes ofone harmful gas pressure section are as follows: calculating limit gas emission and correspondingly judging the level of the gas tunnel, and modifying the explosion protection performance of a shieldmachine, the ventilation quantity of a ventilation system and a gas monitoring control system; setting the driving speed of the shield machine; performing shield driving construction; and performing duct piece assembly and lining construction; and 3, completing constructing all the harmful gas pressure sections of the gas tunnel to be constructed until realizing the run-through of the gas tunnel to be constructed. The method has the advantages of skillful and reasonable design, convenient implementation, small construction difficulty and good construction effect, and can effectively solve theproblem of safe construction for running through a shield tunnel of a gas reservoir, namely a subway shield gas tunnel.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Step-like prefabrication assembly type round underground granary with steel plates wrapped internally and externally

ActiveCN106088759AReduce construction difficultyIncrease stiffnessBulk storage containerEngineeringPrefabrication

A prefabrication assembly type round underground granary comprises a granary bottom, a plurality of prefabricated granary wall plates, a granary top beam plate, multifunctional pillars and a plurality of layers of enhancing pillars, wherein the granary wall plates are arc prefabricated plates, and can be connected with the adjacent granary wall plates, the multifunctional pillars and the plurality of layers of enhancing pillars by means of connection devices; each multifunctional pillar is used for positioning a granary wall, and the depth of each multifunctional pillar anchored into soil is greater than the depth of a granary bottom plate; each multifunctional pillar is divided into a plurality of sections from top to bottom, the inner side of each first section on the uppermost layer is provided with a first-layer granary wall plate, one enhancing pillar is firstly arranged on the inner side of the corresponding second section, the inner side face of each enhancing pillar is enabled to be flush with the inner side face of the first-layer granary wall plate, then a second-layer granary wall plate is arranged on the inner side face of the corresponding enhancing pillar, and each first-layer granary wall plate and the corresponding second-layer granary wall plate are partially overlapped; by using an arrangement mode similar to that above, the second-layer granary wall plates and third-layer granary wall plates are partially overlapped, and overlapping is performed until the bottommost-layer granary wall plate is overlapped; the inner-side and outer-side steel plates and concrete therebetween are connected by adopting rivets.

Owner:郑州地天粮油仓厂科技有限公司

Device and process for filling aggregate into stratum cavities through surface drilling

The invention relates to a device and a process for filling aggregate into stratum cavities through surface drilling. The device comprises a hollow drill column extending into a drilled hole; a spraying head is arranged at the lower end of the drill column; a water joint is arranged at the upper end of the drill column, and is connected with an injection pump through a high-pressure rubber tube; an aggregate belt conveyor, a gyrator and a water pipe are arranged in the opening of the drilled hole; the drill column is inserted into the gyrator; the gyrator is connected with a drilling machine; the water pipe is connected with a water pump, so as to supply water to the drilled hole; and the aggregate belt conveyor conveys aggregate to the drilled hole. The invention has the advantages that various accidents generated when surface drilling is conducted on the stratum cavities are eliminated; and when aggregate is added during surface drilling, the drill column swings and shuttles, and aggregate entering into the drilled hole is washed out by water to a mined out space, so as to ensure that aggregate enter into the cavities smoothly and the drilling construction is safe and smooth.

Owner:SHANDONG UNIV

Insertion groove type underground barn with internally covered plastics and prefabricated barn wall

ActiveCN106049948AReasonable forceSafe and smooth constructionArtificial islandsClimate change adaptationMechanical engineeringWall plate

The invention relates to a prefabricated and assembled underground barn, which comprises a barn bottom, a plurality of prefabricated barn wall plates, a barn roof and multifunctional columns, wherein each barn wall plate is of an integral structure formed by combining a plastic plate arranged at the inner side and a concrete plate arranged at the outer side; connecting devices are arranged on the periphery; through the connecting devices, the barn wall plates can be connected with the adjacent barn wall plates and the multifunctional columns; the multifunctional columns can be used for positioning the barn wall plates; the soil entering depth of the multifunctional columns is greater than the depth of the barn bottom; the multifunctional columns are major stress components for bearing soil pressure and grain lateral pressure and resisting the buoyancy force. The prefabricated and assembled underground barn is characterized in that the multifunctional columns are separated into a plurality of sections from top to bottom; a first layer of barn wall plate is arranged at the inner side of the first section at the uppermost layer; and a second layer of barn wall plate is arranged at the inner side of the second section; the similar setting mode is used till the lowermost layer of barn wall plate is reached; an assembled underground barn structure is formed; steel plates are covered on the left end part and the right end part of the prefabricated barn plates; the left end of the prefabricated barn plates is provided with a convex trapezoidal or semicircular plug; and the right end of the prefabricated barn plates is provided with a concave trapezoidal or semicircular insertion groove.

Owner:郑州地天粮油仓厂科技有限公司

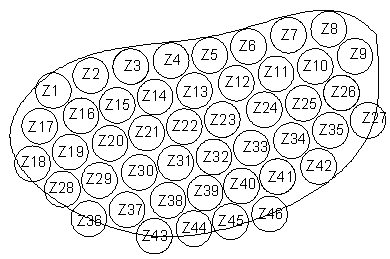

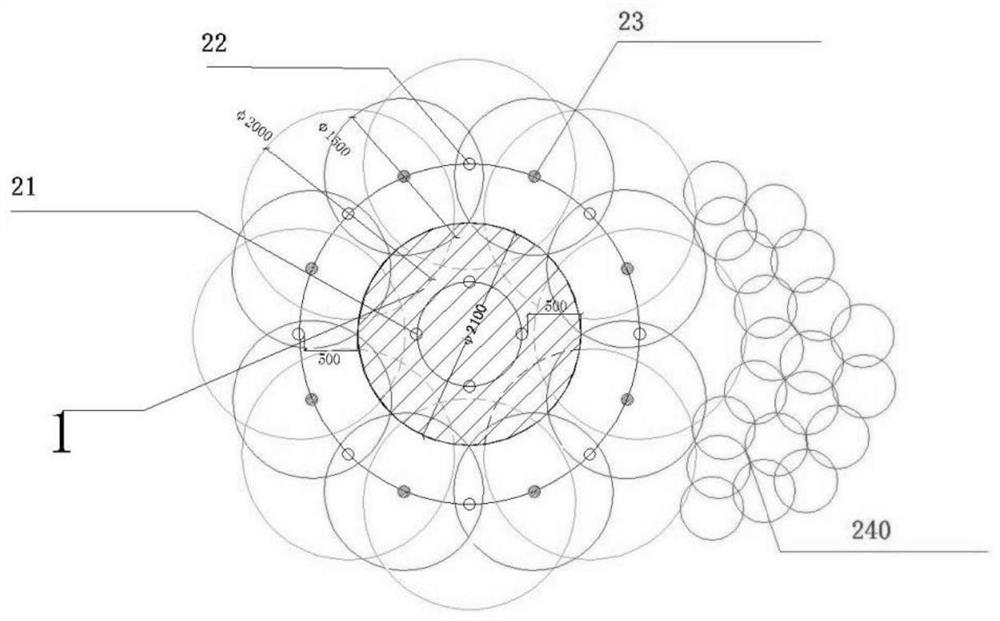

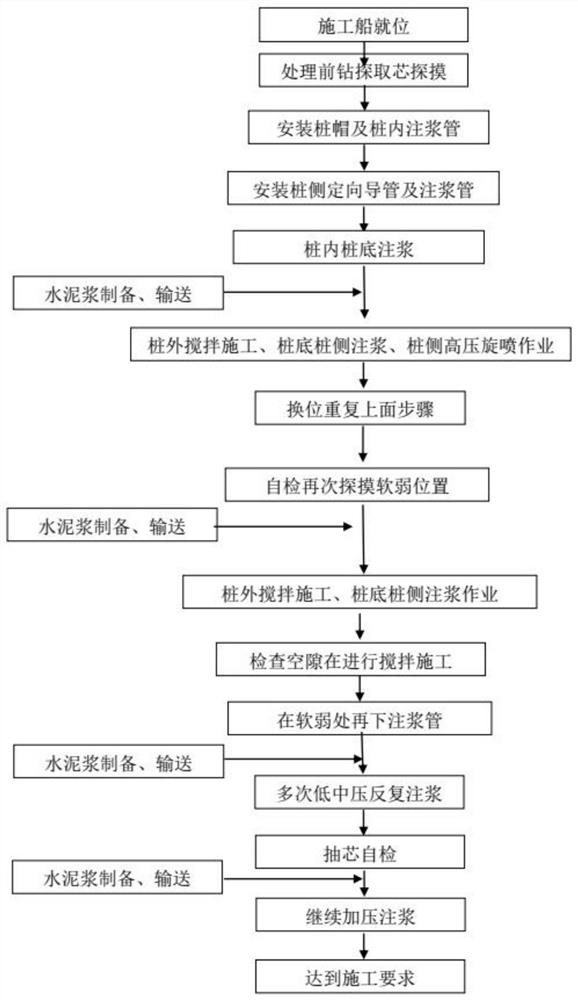

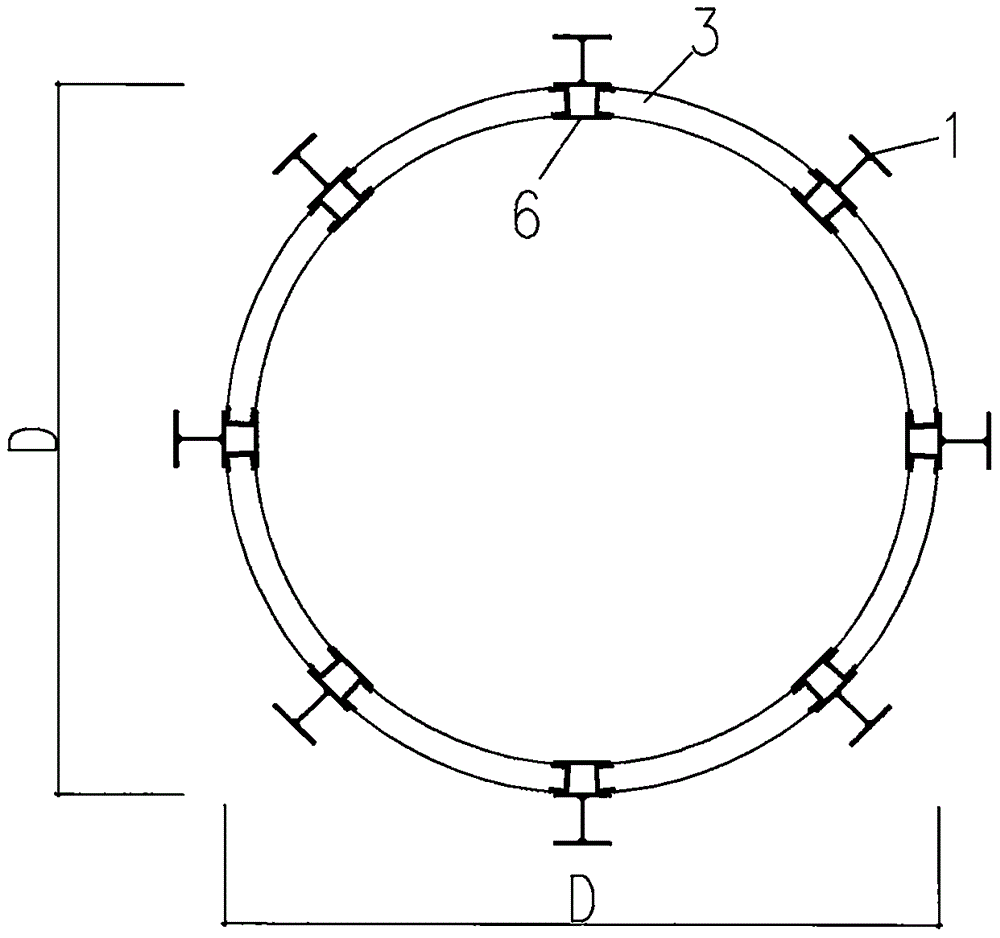

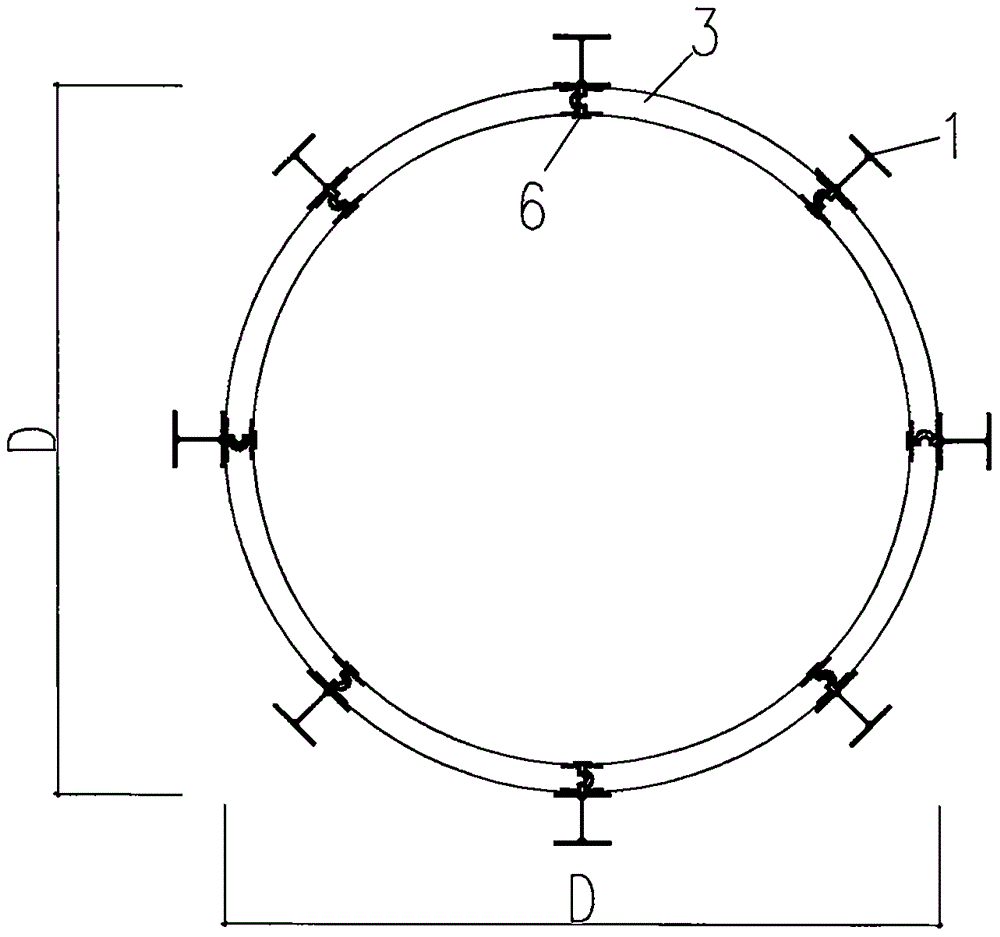

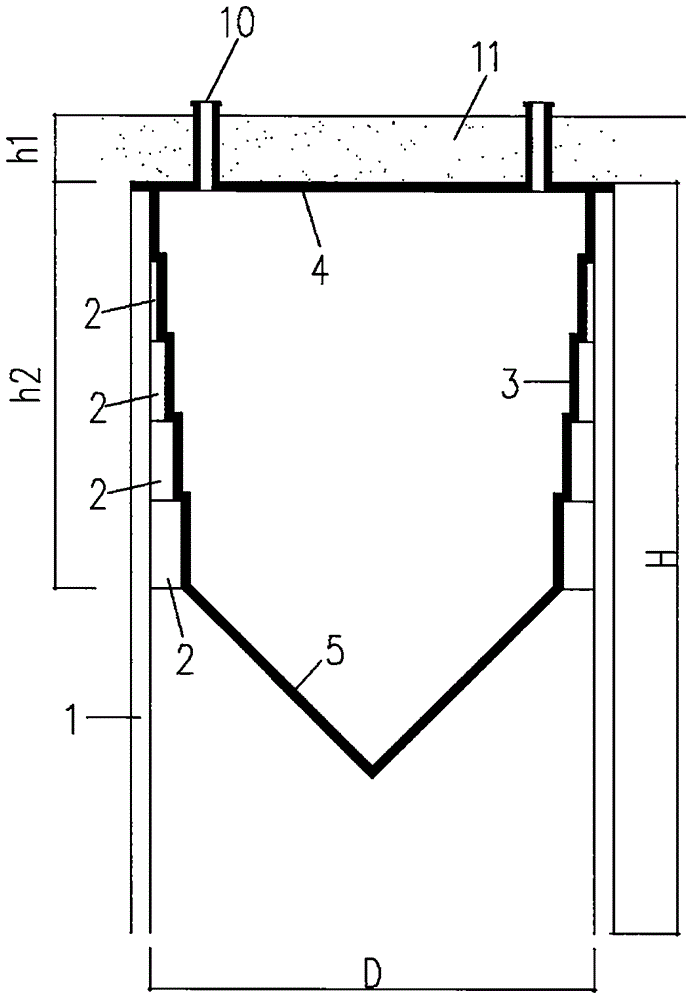

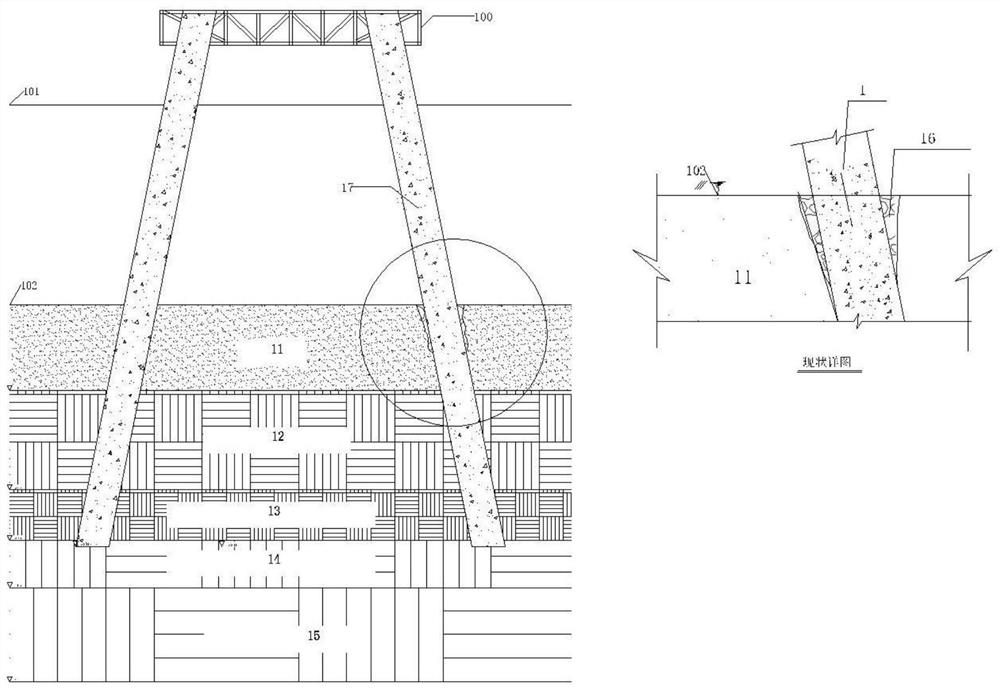

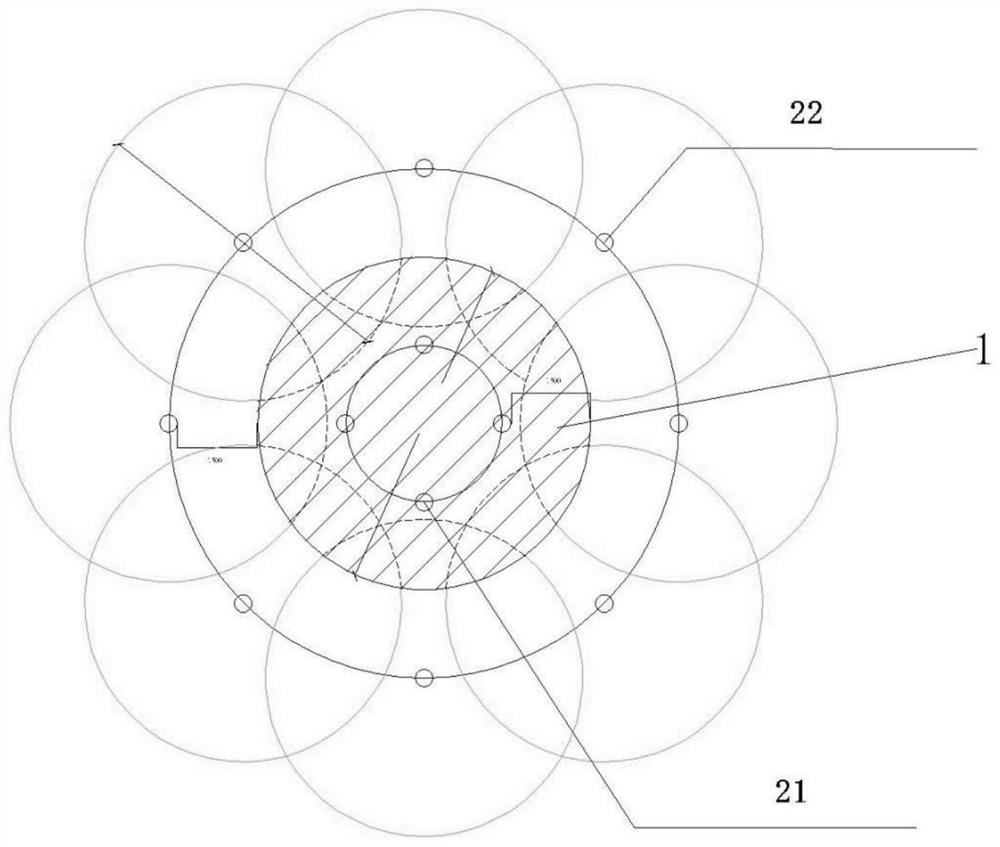

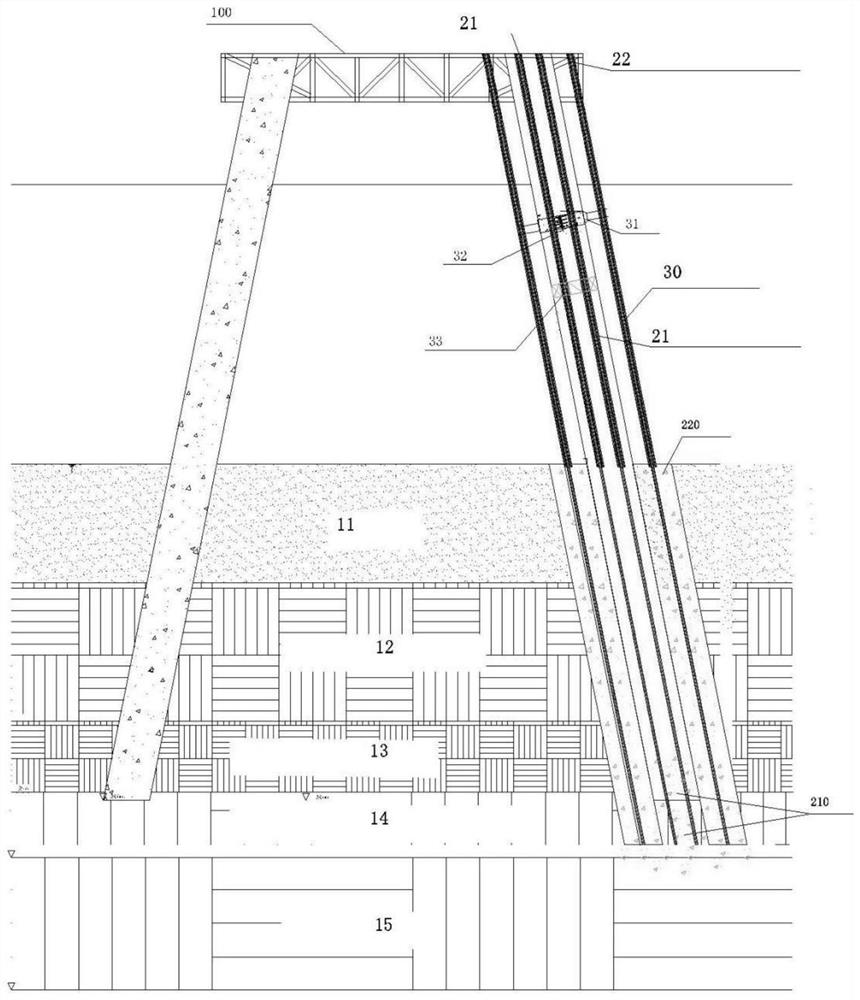

Comprehensive treatment and reinforcement method for collapse of stratum around offshore deepwater inclined pile

ActiveCN113174992AImprove bearing capacityImprove stabilityFoundation repairBulkheads/pilesBearing capacityCivil engineering

The invention discloses a comprehensive treatment and reinforcement method for collapse of a stratum around an offshore deepwater inclined pile. According to the comprehensive treatment and reinforcement method for collapse of the stratum around the offshore deepwater inclined pile, multiple means such as inclined hole grouting, inclined hole jet grouting and pile mixing are adopted, an integrated new composite foundation is formed to reinforce soil around the pile, the treatment effect and quality of the collapse of the stratum around the offshore deepwater inclined pile are remarkable, the follow-up pile foundation construction is effectively ensured to be safely and smoothly carried out, the construction period is greatly shortened, the economic loss is greatly reduced, the bearing capacity and stability of the offshore deepwater inclined pile foundation are effectively guaranteed, and potential safety hazards are completely eradicated.

Owner:FUJIAN YONGQIANG SOIL

Step-like prefabricated assembling type round underground barn externally clad with steel plates

ActiveCN106088764AReduce construction costsReduce construction difficultyArtificial islandsClimate change adaptationSteel platesSheet steel

The invention provides a prefabricated assembling type underground barn. The plane shape of the underground barn is round; the underground barn comprises a barn bottom, a plurality of prefabricated barn wall plates, a barn top, a multifunctional column and a reinforcing column; the barn wall plates are arc-shaped prefabricated plate blocks and a connecting device is arranged at the periphery; the barn wall plates can be connected with the adjacent barn wall plate, the multifunctional column or the reinforcing column through the connecting device; the multifunctional column is used for positioning a barn wall; the depth of anchoring the multifunctional column into soil is greater than the depth of the barn bottom and the multifunctional column is a main stress component for bearing the soil pressure and the grain pressure and resisting buoyancy; the prefabricated assembling type round underground barn is characterized in that the multifunctional column is divided into a plurality of sections from top to bottom; a first-layer barn wall plate is arranged at the inner side of the first section of the uppermost layer; the reinforcing column is firstly arranged at the inner side of the second section so that the inner side face of the reinforcing column is leveled with the inner side face of the first-layer barn wall plate; a second-layer barn wall plate is arranged on the inner side face of the reinforcing column, so that the first-layer barn wall plate and the second-layer barn wall plate are partially overlapped; a similar setting manner is adopted so that the second-layer barn wall plate and a third-layer barn wall plate are partially overlapped until the barn wall plate on the bottommost layer is overlapped to form the step-like assembling type round underground barn.

Owner:郑州地天粮油仓厂科技有限公司

Grouting reinforcement method for collapse of stratum around marine deepwater inclined pile

ActiveCN113174991AImprove bearing capacityImprove stabilityFoundation repairBulkheads/pilesBearing capacityCivil engineering

The invention discloses a grouting reinforcement method for collapse of a stratum around a marine deepwater inclined pile. Reinforcement means of intra-pile inclined hole grouting and extra-pile inclined hole grouting are adopted, an integrated new composite foundation is formed to reinforce a soil body around the pile, the treatment effect and quality of the collapse of the stratum around the marine deepwater inclined pile are remarkable, the follow-up pile foundation construction is effectively ensured to be safely and smoothly carried out, the construction period and the economic loss are greatly reduced, the bearing capacity and the stability of the marine deepwater inclined pile foundation are effectively guaranteed, and potential safety hazards are eradicated.

Owner:FUJIAN YONGQIANG SOIL

A stepped prefabricated underground granary covered with plastic both inside and outside

ActiveCN106013908BReasonable forceConstruction safetyClimate change adaptationExcavationsEngineeringMultiple layer

Owner:郑州地天粮油仓厂科技有限公司

Method for quickly treating soft construction surface of pile foundation in sandy soil area

PendingCN113605428AImprove carrying capacityEasy to handleExcavationsSewer pipelinesGroundwater rechargeEarth surface

The invention discloses a method for quickly treating a soft construction surface of a pile foundation in a sandy soil area. The working surface is in a foundation pit excavated in the sandy soil area. The method comprises the following steps that drainage ditches and guardrails are arranged on the periphery of the exterior of the foundation pit, a plurality of light well point dewatering wells used for blocking or reducing supply of underground water on the outer side of a site are drilled in the exterior of the foundation pit, and a plurality of light well point dewatering wells which are arranged in a longitudinal and transverse mode are drilled in the interior of the foundation pit; the multiple dewatering well pipes are lowered into the light well point dewatering wells outside the foundation pit and the light well point dewatering wells inside the foundation pit correspondingly, and the tops of the dewatering well pipes communicate with and are connected into a vacuum pump; and a simple observation well is arranged in the middle of a dewatering area, and after the water level is lowered to 1 meter, the foundation pit is rolled by an excavator until the ground surface of the foundation pit is free of water seepage and a soil layer is compacted. According to the method, the adverse effects of the underground high water level and the high stratum permeability of the construction site on the construction surface can be quickly solved at low cost, safe and smooth construction is guaranteed, and the positive effects on improving the construction efficiency and improving the engineering benefits are achieved.

Owner:中煤长江基础建设有限公司

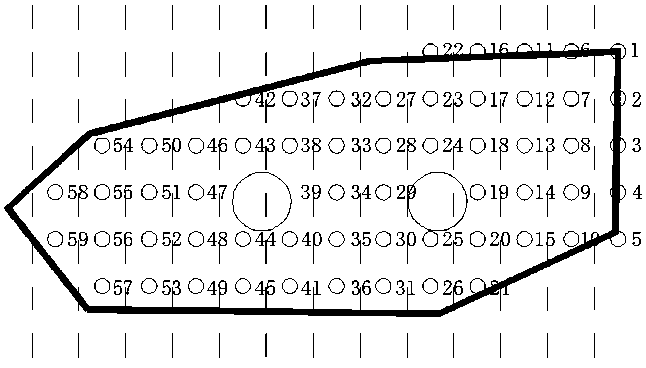

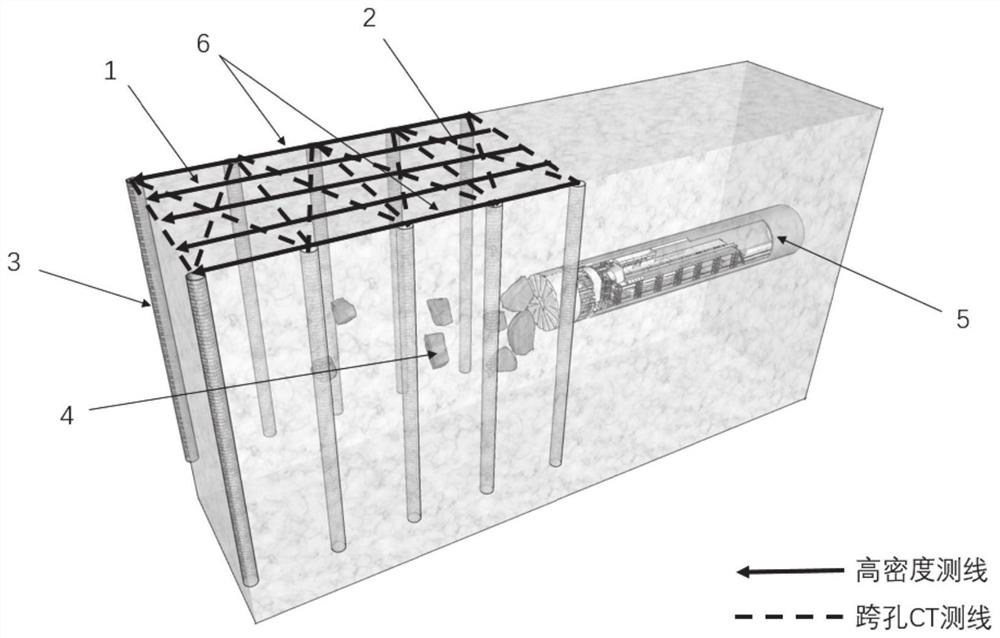

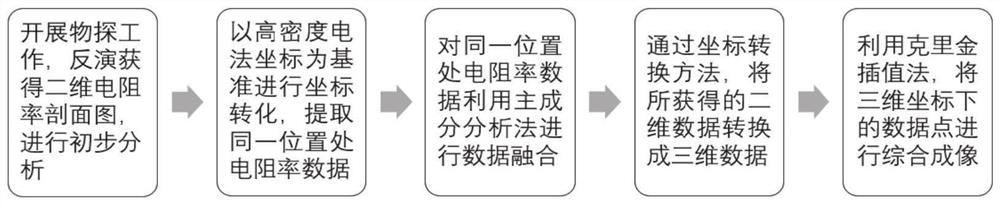

Three-dimensional imaging method of resistivity data fusion for boulder detection in subway shield section

ActiveCN111812731BSafe and smooth constructionProvide guarantee for safe construction and smooth developmentElectric/magnetic detectionAcoustic wave reradiationHigh densityThree-dimensional space

The invention discloses a three-dimensional imaging method for merging the resistivity data of boulder detection in the subway shield section to obtain the original data of cross-hole CT and high-density electrical geophysical exploration in the subway shield section, and after inverting the two original data, the span Hole CT and high-density electrical method two-dimensional resistivity profile; extract cross-hole CT and high-density electrical method data at the same position, and then use principal component analysis method to fuse the two data; perform two-dimensional imaging of resistivity data to obtain multiple A two-dimensional cross-sectional view of the resistivity data, and convert the two-dimensional coordinates into three-dimensional coordinates to form a three-dimensional model diagram. This disclosure better describes the distribution of boulder groups in three-dimensional space, and the correlation between each boulder is more obvious, which provides guarantee for the safe construction and smooth development of shield tunneling.

Owner:SHANDONG UNIV

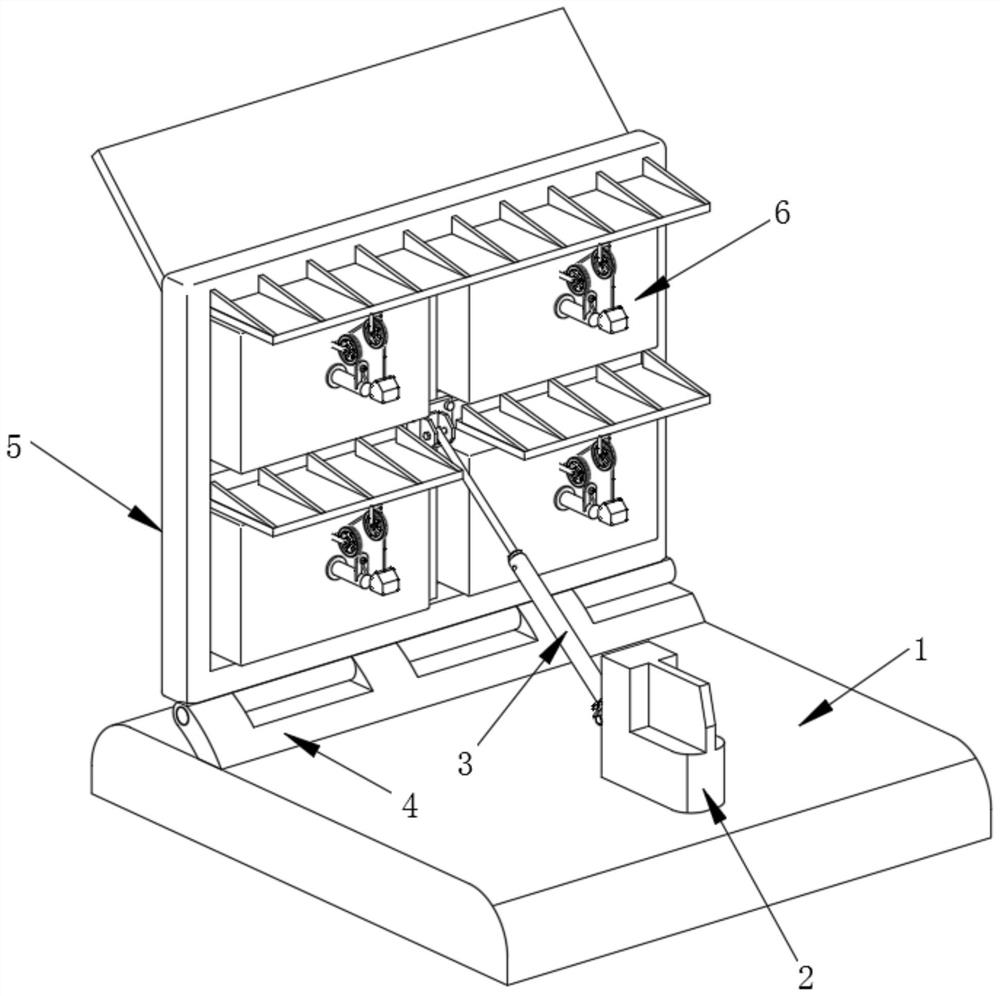

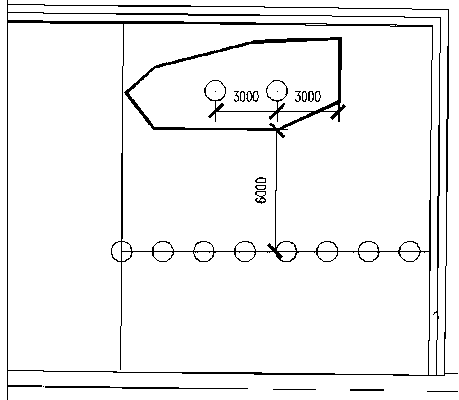

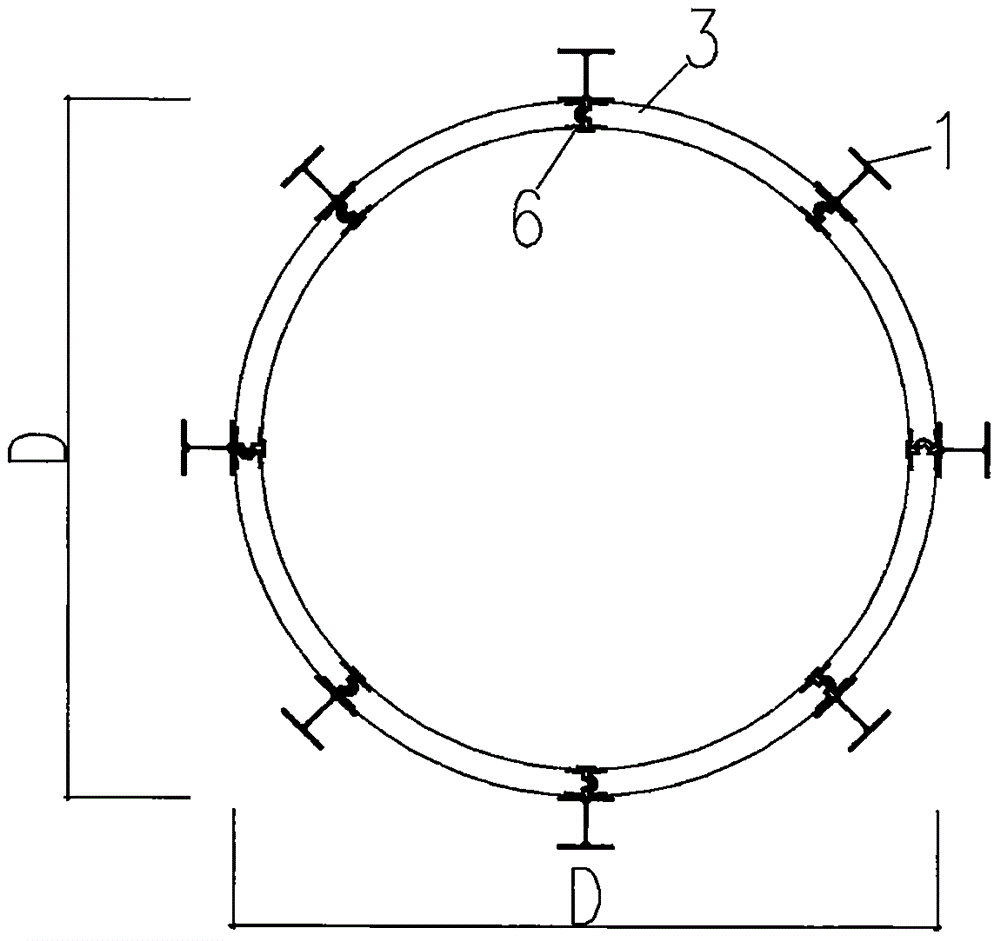

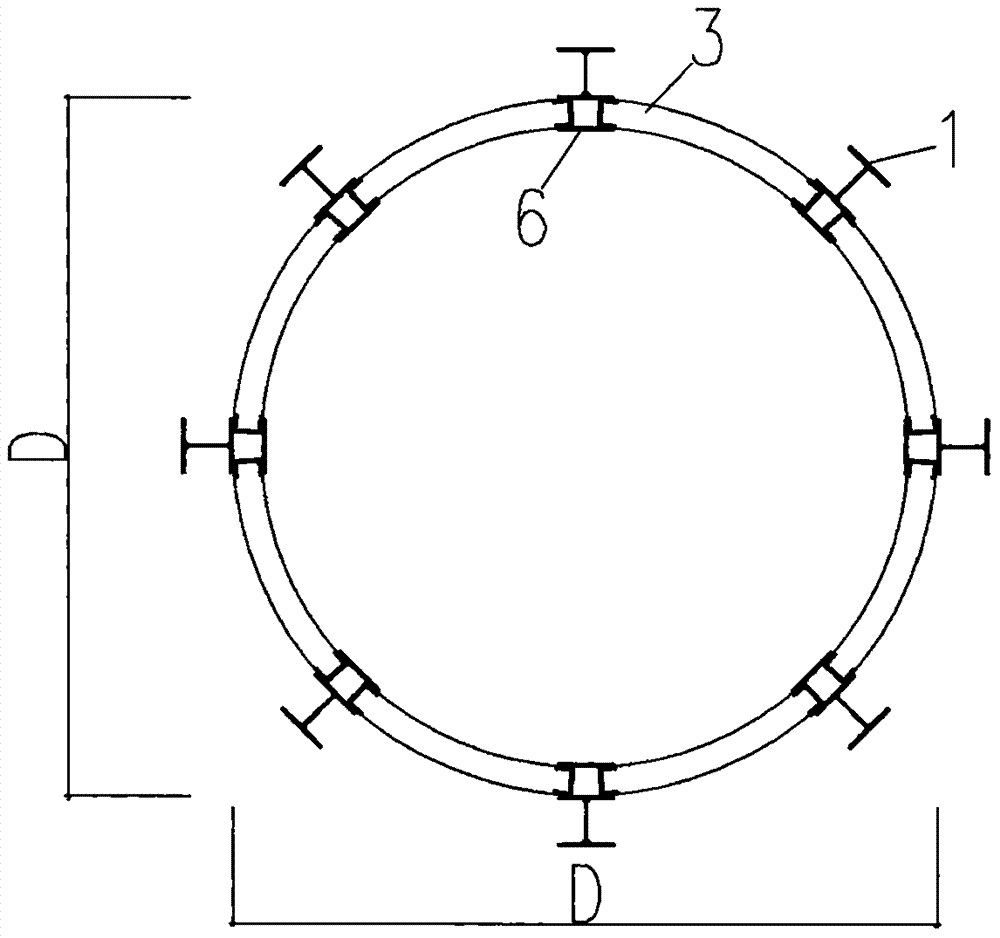

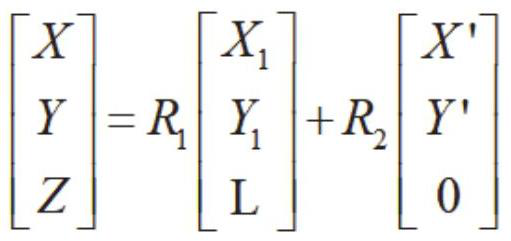

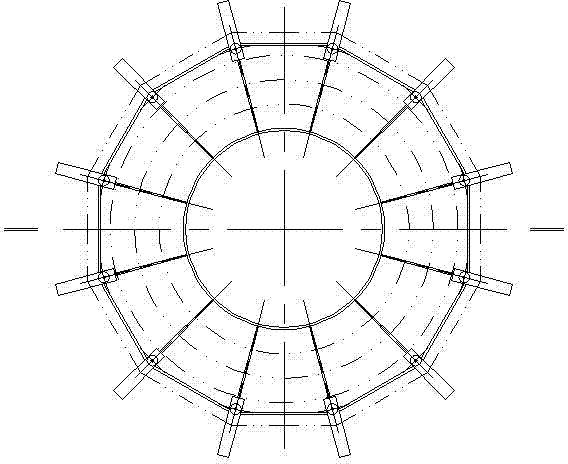

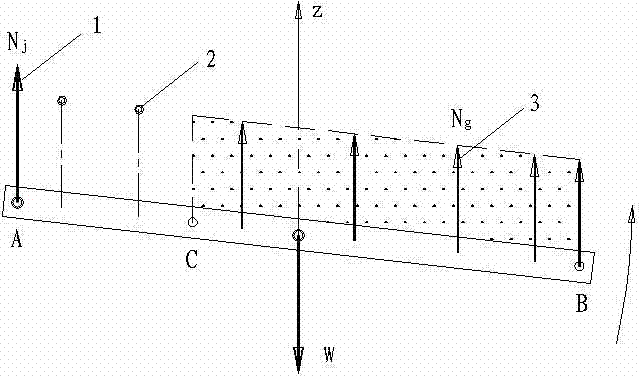

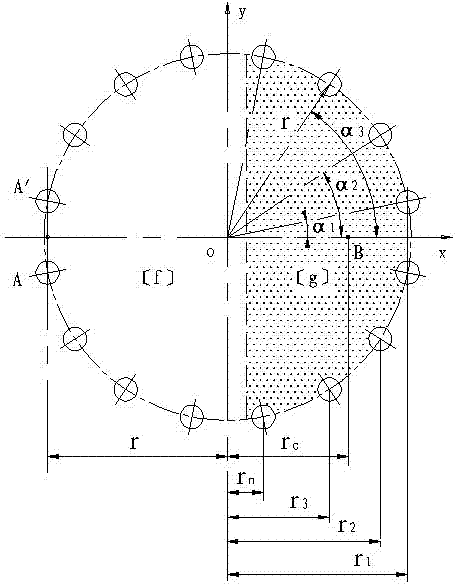

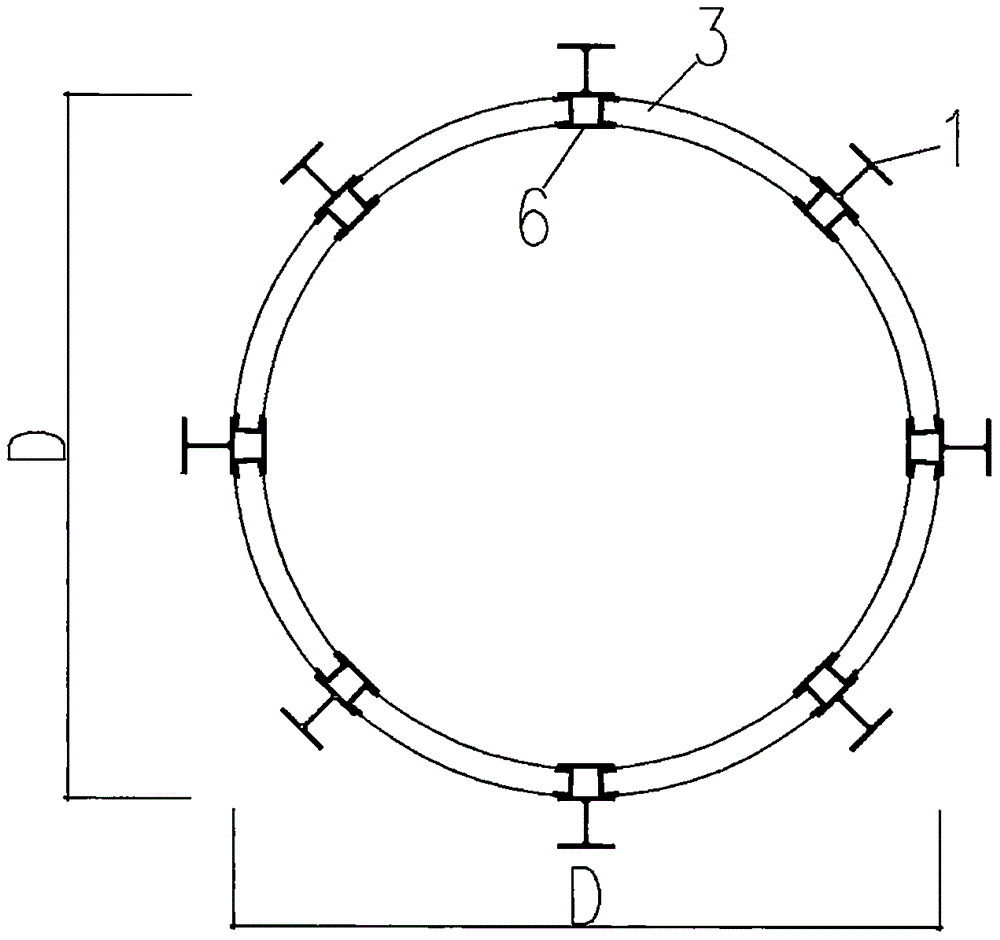

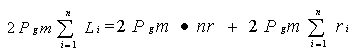

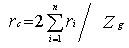

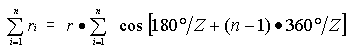

Selecting method of stress suspender used for hydraulic lifting and leveling of circular structure

ActiveCN103130147BAccurate force sizeSafe and smooth constructionLifting devicesEngineeringSelf weight

The invention discloses a selecting method of a stress suspender used for hydraulic lifting and leveling of a circular structure. The selecting method comprises the following steps of (a) assuming that the total number of suspenders is Z, the number of suspenders in a work area is Zg, the number of suspenders in a non-work area is Zf, and Zf = Z-Zg; (b), assuming that m jacks are arranged on each suspender in series, lifting force of each jack is Pg, and stress of each work suspender is Ng, and Ng = m*Pg; (c), determining the distance between the total resultant force Nc and a center line of the circular structure; (d), determining a function relation between the PG, the m, the Zg, the Z and the self weight W of the circular structure; (e), determining work stress Nj of a static load suspender; and (f), selecting a proper suspender specification. By the adoption of the method, the stress of a lifting and leveling suspender of the circular structure can be calculated accurately, thus a basis can be provided for selection of a proper suspender, and safe proceeding of construction can be ensured.

Owner:CHINA MCC5 GROUP CORP

A stepped prefabricated underground granary covered with plastic

ActiveCN106013914BReasonable forceFirmly connectedClimate change adaptationExcavationsEngineeringMultiple layer

A prefabrication assembly type underground granary comprises a granary bottom, multiple prefabricated granary wall plates, a granary top, multifunctional pillars and multiple layers of enhancing pillars, wherein each granary wall plate is of an integral structure formed by combining a plastic plate on the outer side and a concrete slab on the inner side, each granary wall plate is provided with connection devices on the periphery, and the granary wall plates can be connected with adjacent granary wallboards, the multifunctional pillars and the multiple layers of enhancing pillars by means of the connection devices; the multifunctional pillars and the enhancing pillars are wrapped by plastic plates, can be used for positioning the granary wall plates, and are main stress components for bearing soil pressure and grain pressure and resisting buoyance, and the depth of each multifunctional pillar and each enhancing pillar anchored into soil is greater than the depth of the granary bottom; the underground granary is characterized in that each multifunctional pillar is divided into a plurality of sections from top to bottom, the inner side of each first section on an uppermost layer is provided with a first-layer granary wall plate, the corresponding enhancing pillars are firstly arranged on the inner side of the corresponding second section, the inner side faces of the enhancing pillars are enabled to be flush with the inner side face of the first-layer granary wall plate, then a second-layer granary wall plate is arranged on the inner side face of the corresponding enhancing pillar, and the first-layer granary wall plate and the second-layer granary wall plate are partially overlapped; by using an arrangement mode similar to that above, the second-layer granary wall plate and a third-layer granary wall plate are partially overlapped, and overlapping is performed until a bottommost-layer granary wall plate is overlapped, thus forming the ladder-like assembly type underground granary.

Owner:郑州地天粮油仓厂科技有限公司

DJ180 Bridge Erecting Machine Tunnel Girder Simulation Construction Method Using BIM Technology

ActiveCN106930193BMeet needsSafe and smooth constructionGeometric CADDesign optimisation/simulationEngineeringTunnel construction

The invention discloses a tunnel portal beam erection simulated construction method through a DJ180 bridge erection machine by using a BIM (Building Information Modeling) technology and relates to the technical field of tunnel construction. The method comprises the following steps: () modeling in BIM; (2) simulating the construction process; (3) determining an optimal construction scheme; and (4) producing a construction video. According to the simulated construction scheme, the overall construction scheme is optimized, the tunnel portal beam erection requirement is met, and safe and smooth beam erection construction is guaranteed.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

Plastic-wrapped ladder-like prefabrication assembly type rectangular underground granary

ActiveCN106013914AReduce construction difficultyIncrease stiffnessClimate change adaptationExcavationsEngineeringBuoyancy

A prefabrication assembly type underground granary comprises a granary bottom, multiple prefabricated granary wall plates, a granary top, multifunctional pillars and multiple layers of enhancing pillars, wherein each granary wall plate is of an integral structure formed by combining a plastic plate on the outer side and a concrete slab on the inner side, each granary wall plate is provided with connection devices on the periphery, and the granary wall plates can be connected with adjacent granary wallboards, the multifunctional pillars and the multiple layers of enhancing pillars by means of the connection devices; the multifunctional pillars and the enhancing pillars are wrapped by plastic plates, can be used for positioning the granary wall plates, and are main stress components for bearing soil pressure and grain pressure and resisting buoyance, and the depth of each multifunctional pillar and each enhancing pillar anchored into soil is greater than the depth of the granary bottom; the underground granary is characterized in that each multifunctional pillar is divided into a plurality of sections from top to bottom, the inner side of each first section on an uppermost layer is provided with a first-layer granary wall plate, the corresponding enhancing pillars are firstly arranged on the inner side of the corresponding second section, the inner side faces of the enhancing pillars are enabled to be flush with the inner side face of the first-layer granary wall plate, then a second-layer granary wall plate is arranged on the inner side face of the corresponding enhancing pillar, and the first-layer granary wall plate and the second-layer granary wall plate are partially overlapped; by using an arrangement mode similar to that above, the second-layer granary wall plate and a third-layer granary wall plate are partially overlapped, and overlapping is performed until a bottommost-layer granary wall plate is overlapped, thus forming the ladder-like assembly type underground granary.

Owner:刘丽华 +1

Plastic-lined step-like prefabrication assembly type underground granary

ActiveCN106088761AReasonable forceSafe and smooth constructionClimate change adaptationExcavationsBuoyancyPrefabrication

A prefabrication assembly type underground granary comprises a granary bottom, a plurality of prefabricated granary wall plates, a granary top, multifunctional pillars and a plurality of layers of enhancing pillars, wherein each granary wall plate is of an integral structure formed by combining a plastic plate on the inner side and a concrete slab on the outer side, the granary wall plates are provided with connection devices on the peripheries, and can be connected with the adjacent granary wall plates, the multifunctional pillars and the plurality of layers of enhancing pillars by means of the connection devices; the multifunctional pillars can be used for positioning the granary wall plates, and are main stress components for bearing soil pressure and grain side pressure and resisting buoyance, and the depth of each multifunctional pillar anchored into soil is deeper than the depth of the granary bottom; the underground granary is characterized in that each multifunctional pillar is divided into a plurality of sections from top to bottom, the inner side of each first section on the uppermost layer is provided with a first-layer granary wall plate, the corresponding enhancing pillars are firstly arranged on the inner side of the corresponding second section, the inner side faces of the enhancing pillars are enabled to be flush with the inner side face of the first-layer granary wall plate, then a second-layer granary wall plate is arranged on the inner side face of the corresponding enhancing pillar, and the first-layer granary wall plate and the second-layer granary wall plate are partially overlapped; by using an arrangement mode similar to that above, each second-layer granary wall plate and a third-layer granary wall plate are partially overlapped, and overlapping is performed until the bottommost-layer granary wall plate is overlapped, thus forming the step-like assembly type underground granary.

Owner:郑州地天粮油仓厂科技有限公司

Selecting method of stress suspender used for hydraulic lifting and leveling of circular structure

ActiveCN103130147AAccurate force sizeSafe and smooth constructionLifting devicesEngineeringHydraulic pressure

The invention discloses a selecting method of a stress suspender used for hydraulic lifting and leveling of a circular structure. The selecting method comprises the following steps of (a) assuming that the total number of suspenders is Z, the number of suspenders in a work area is Zg, the number of suspenders in a non-work area is Zf, and Zf = Z-Zg; (b), assuming that m jacks are arranged on each suspender in series, lifting force of each jack is Pg, and stress of each work suspender is Ng, and Ng = m*Pg; (c), determining the distance between the total resultant force Nc and a center line of the circular structure; (d), determining a function relation between the PG, the m, the Zg, the Z and the self weight W of the circular structure; (e), determining work stress Nj of a static load suspender; and (f), selecting a proper suspender specification. By the adoption of the method, the stress of a lifting and leveling suspender of the circular structure can be calculated accurately, thus a basis can be provided for selection of a proper suspender, and safe proceeding of construction can be ensured.

Owner:CHINA MCC5 GROUP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com