Patents

Literature

317results about How to "The test data is accurate and reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

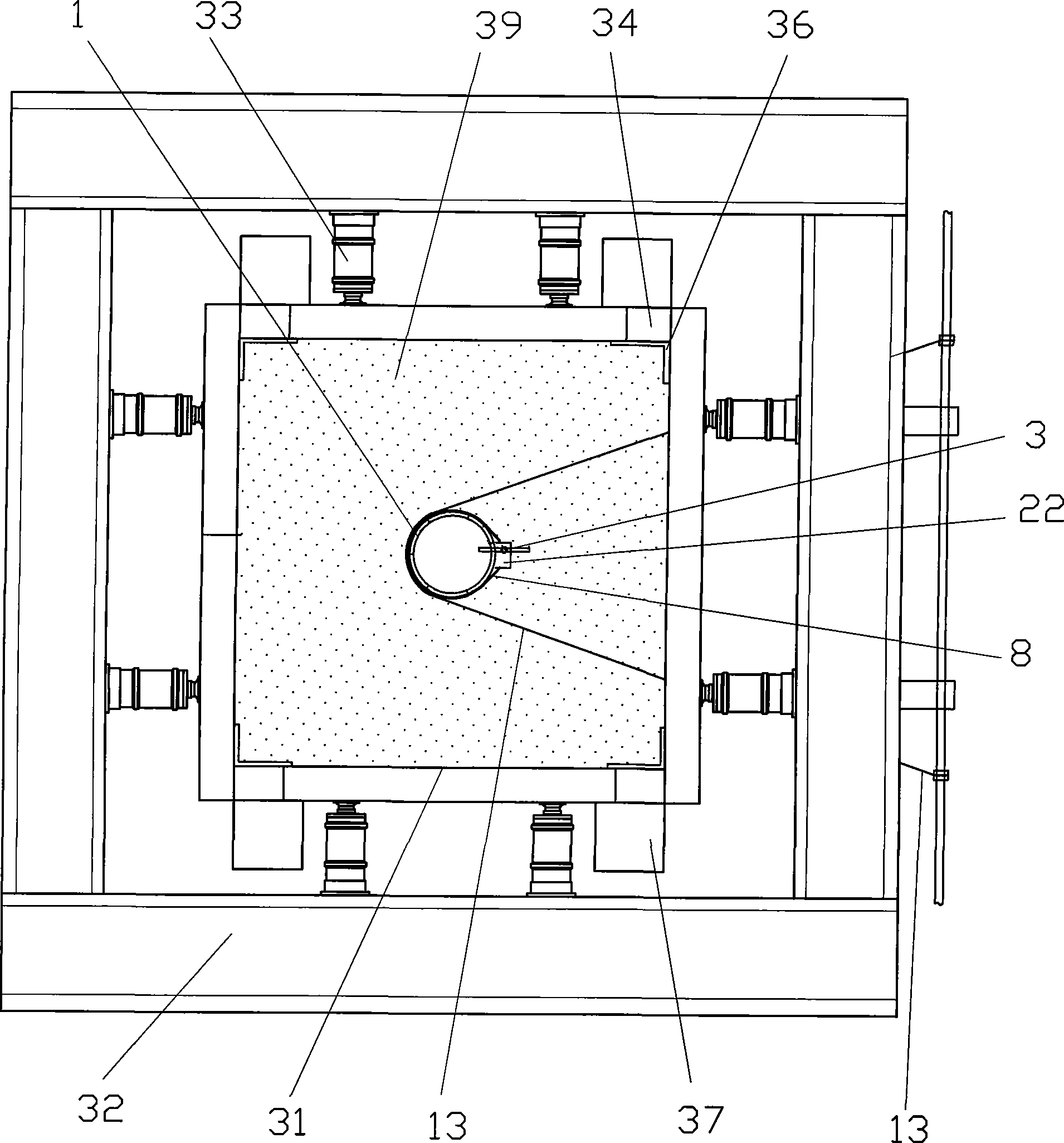

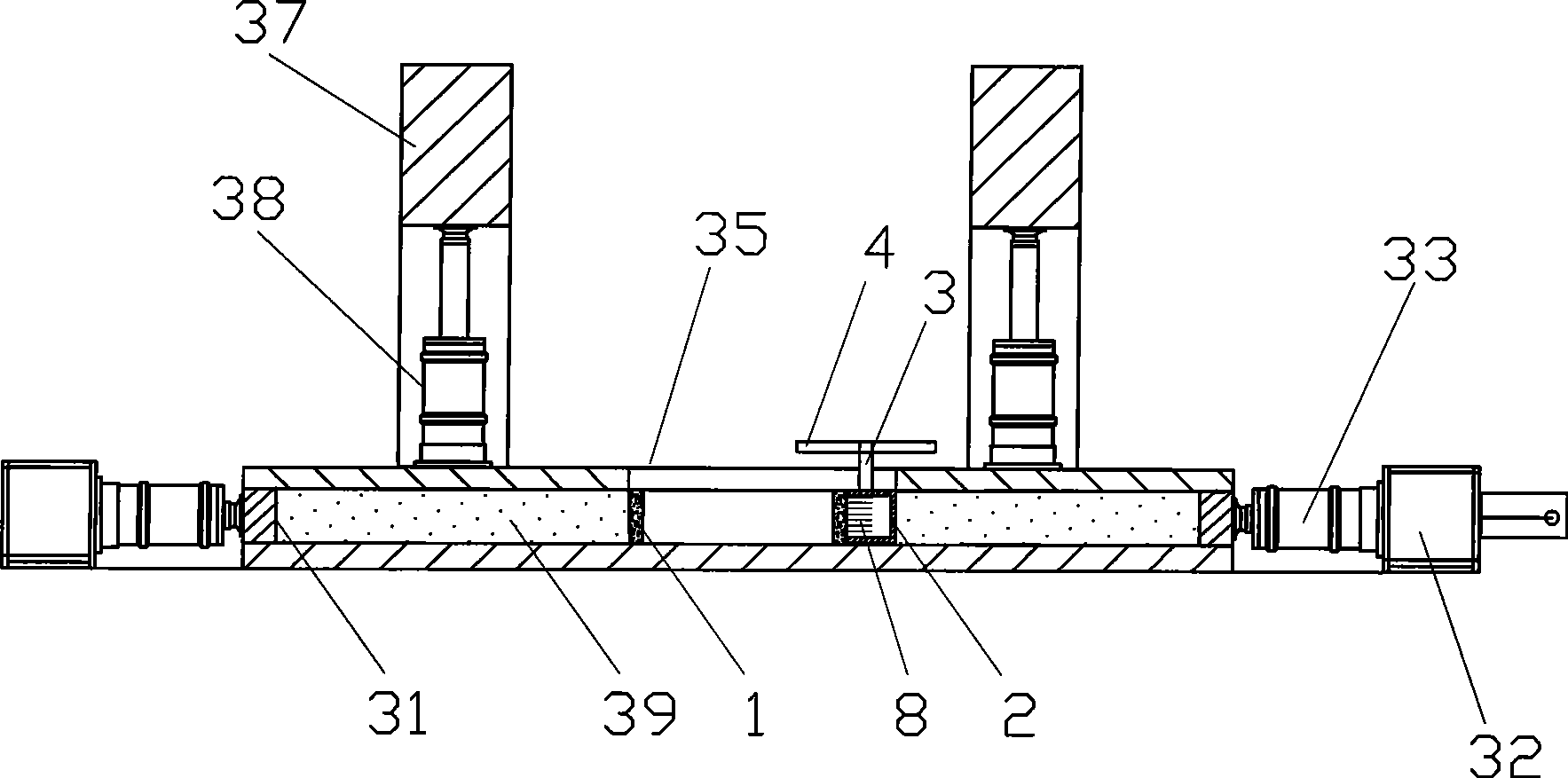

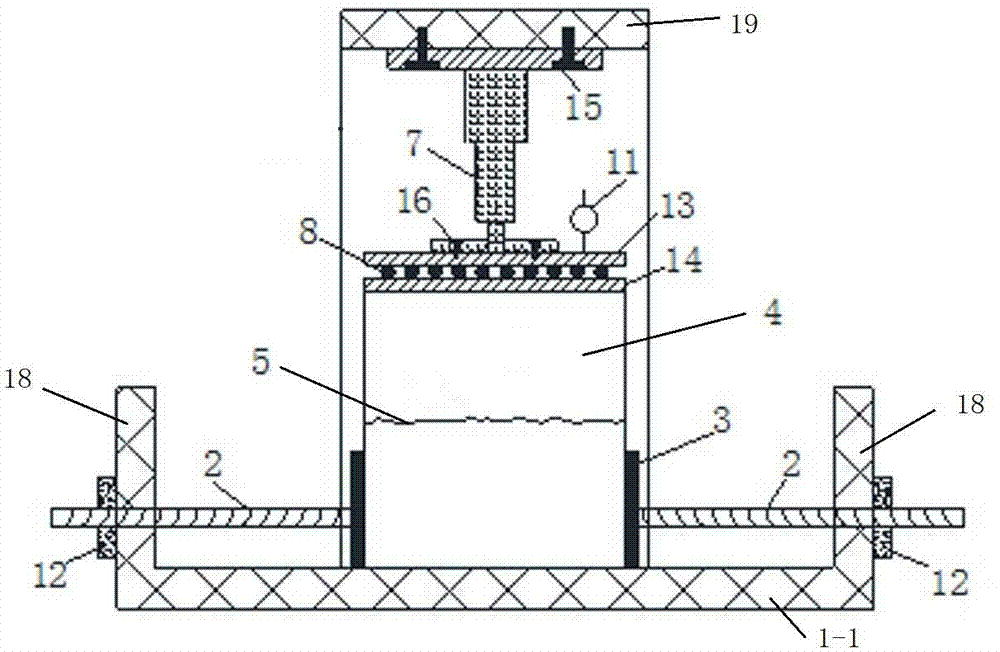

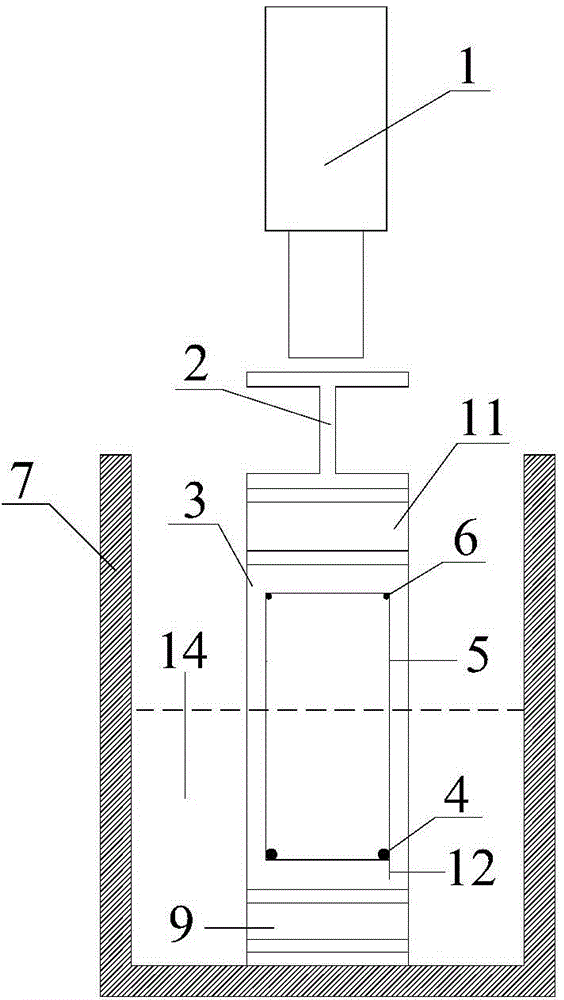

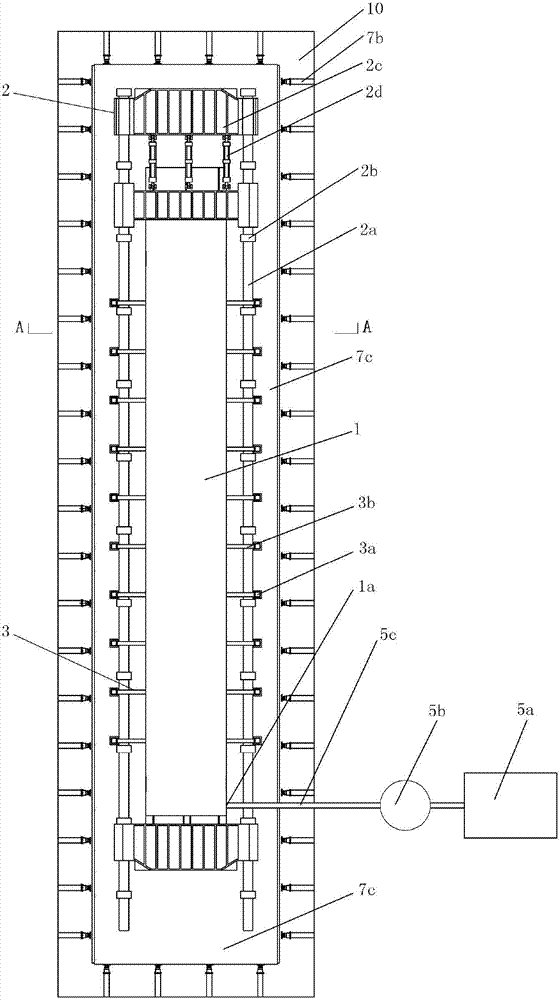

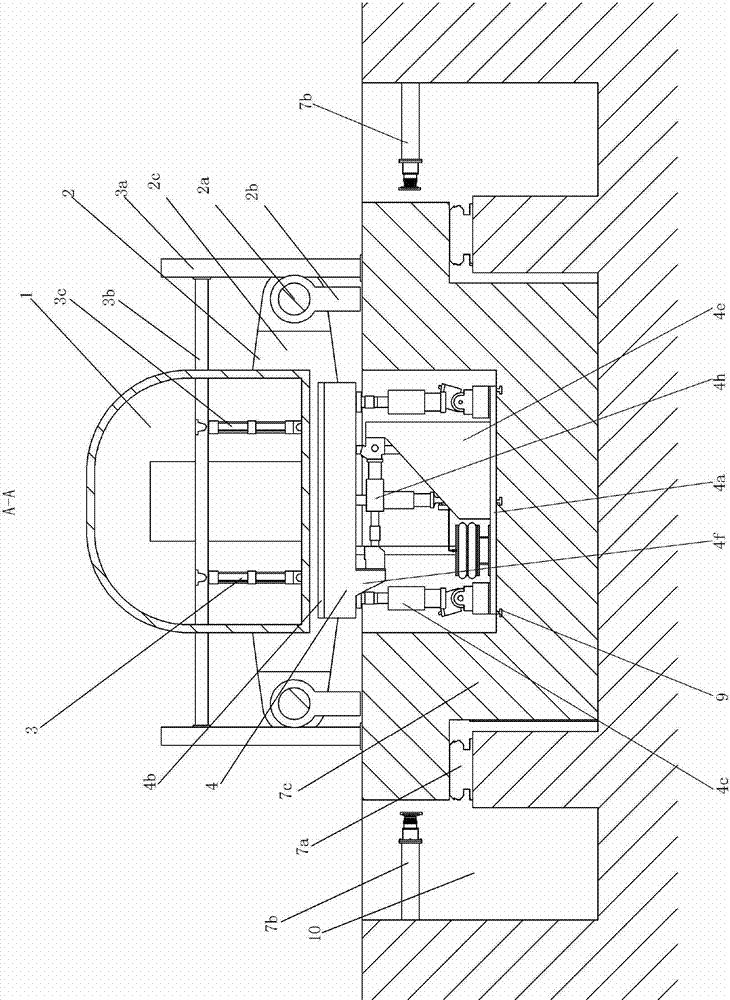

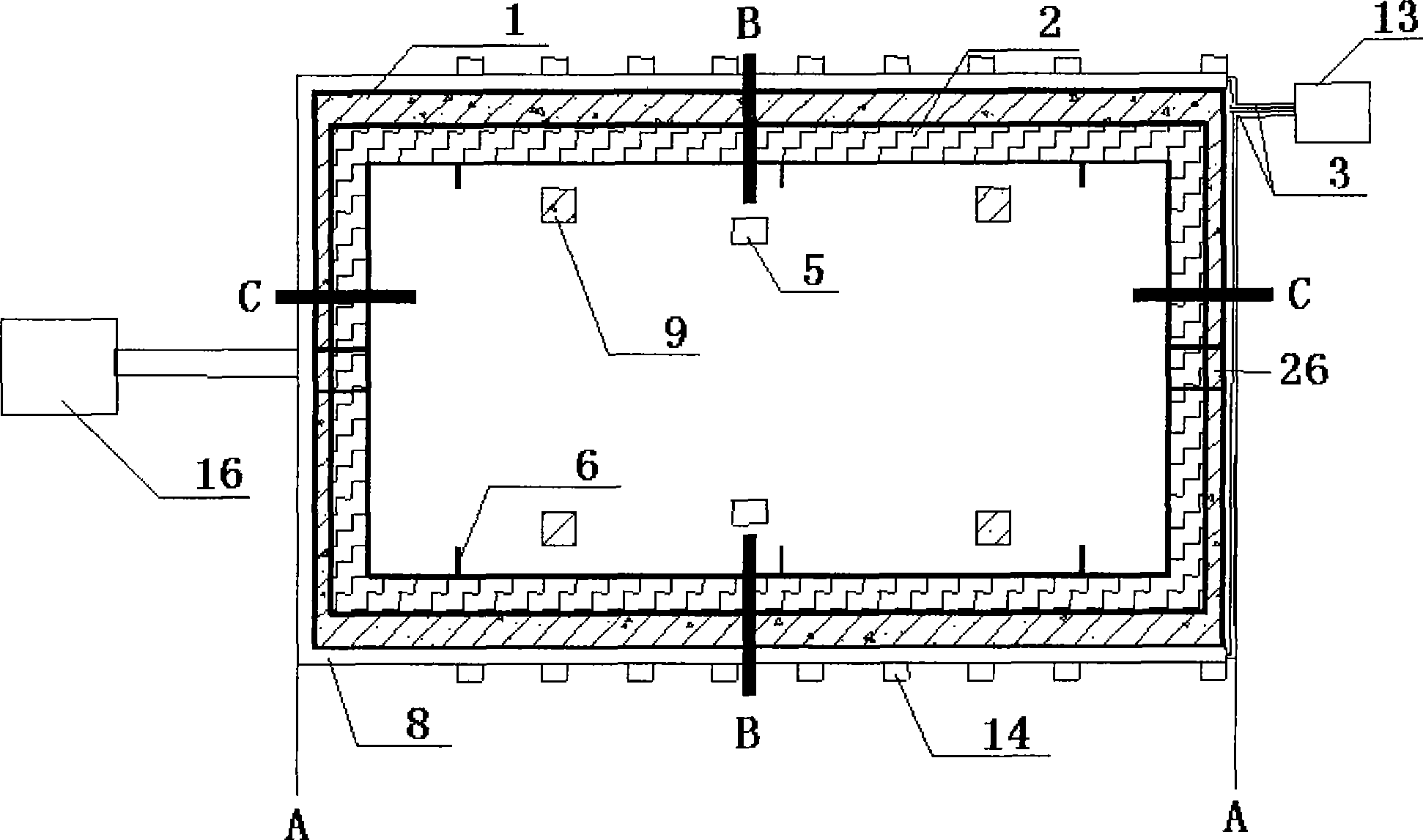

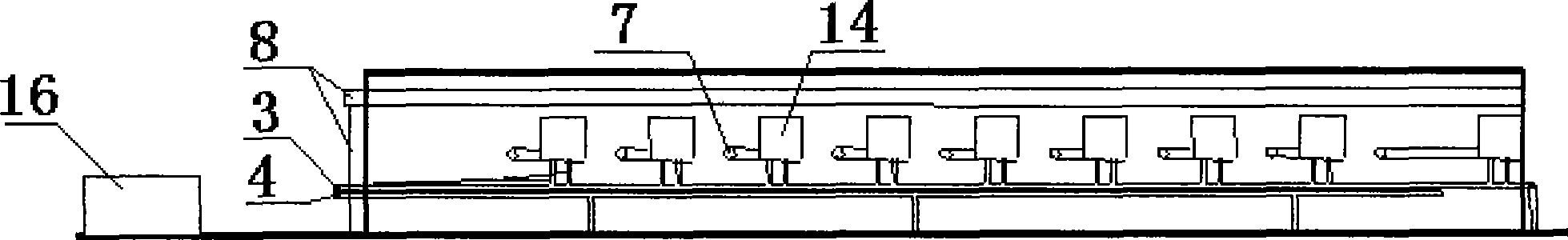

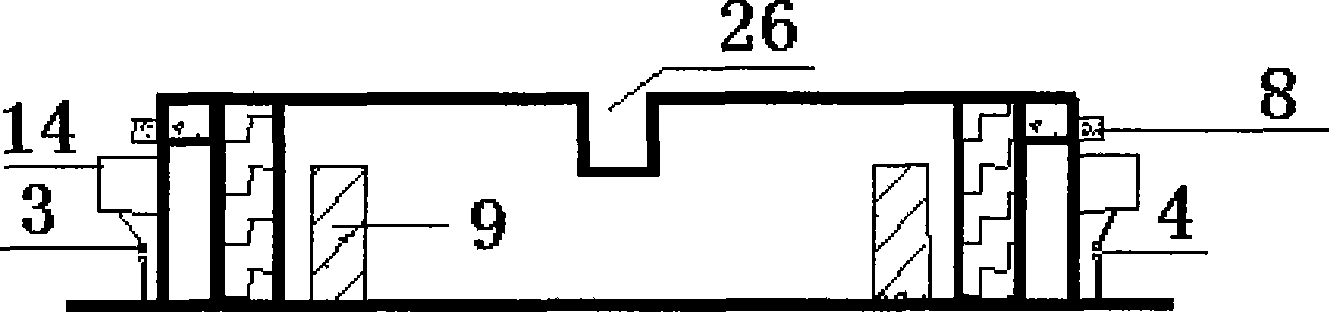

Comprehensive test system of shield tunnel construction model

InactiveCN101435746ARealistic simulation of formation pressureThe test data is accurateForce measurementStructural/machines measurementEngineeringShield tunnelling

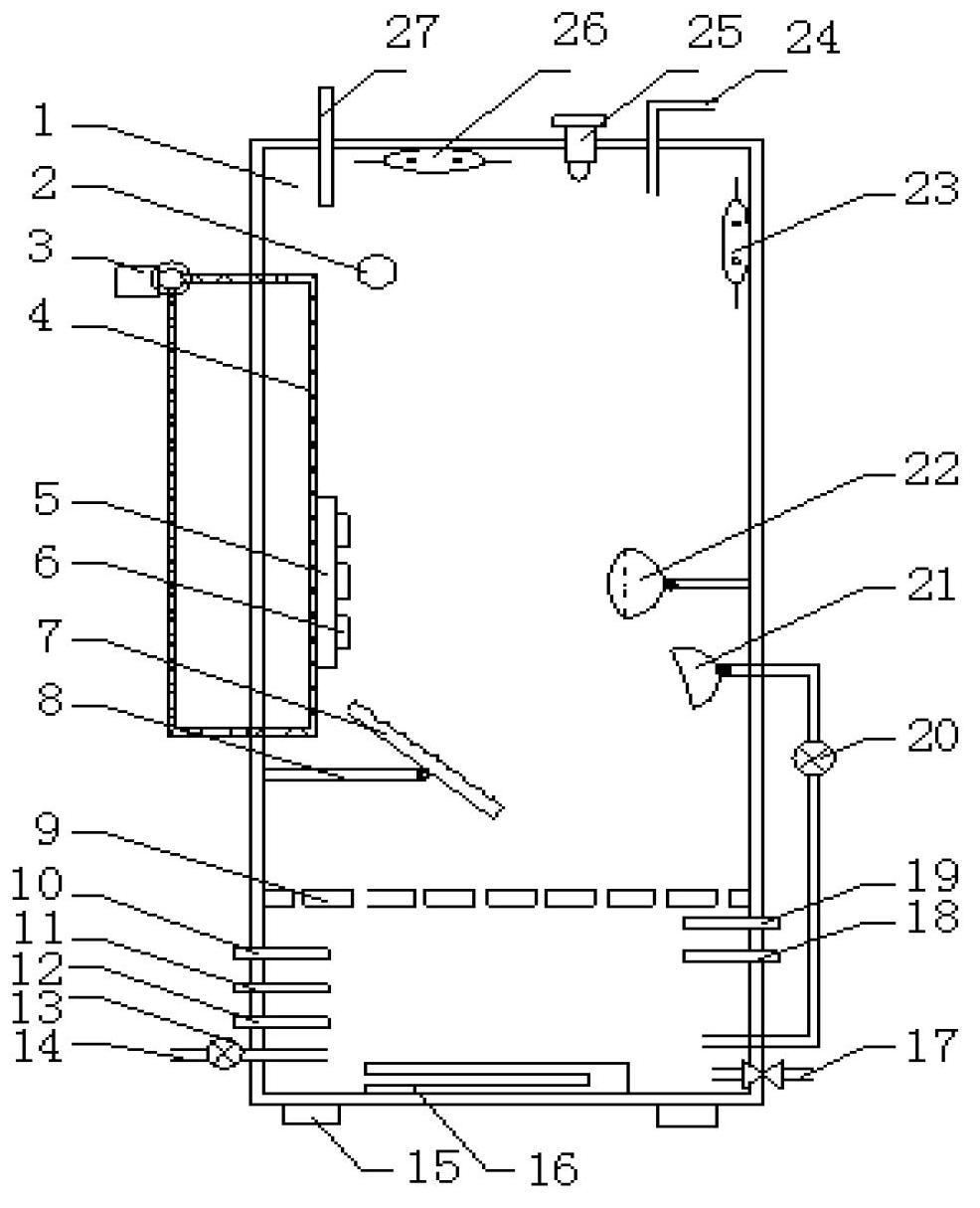

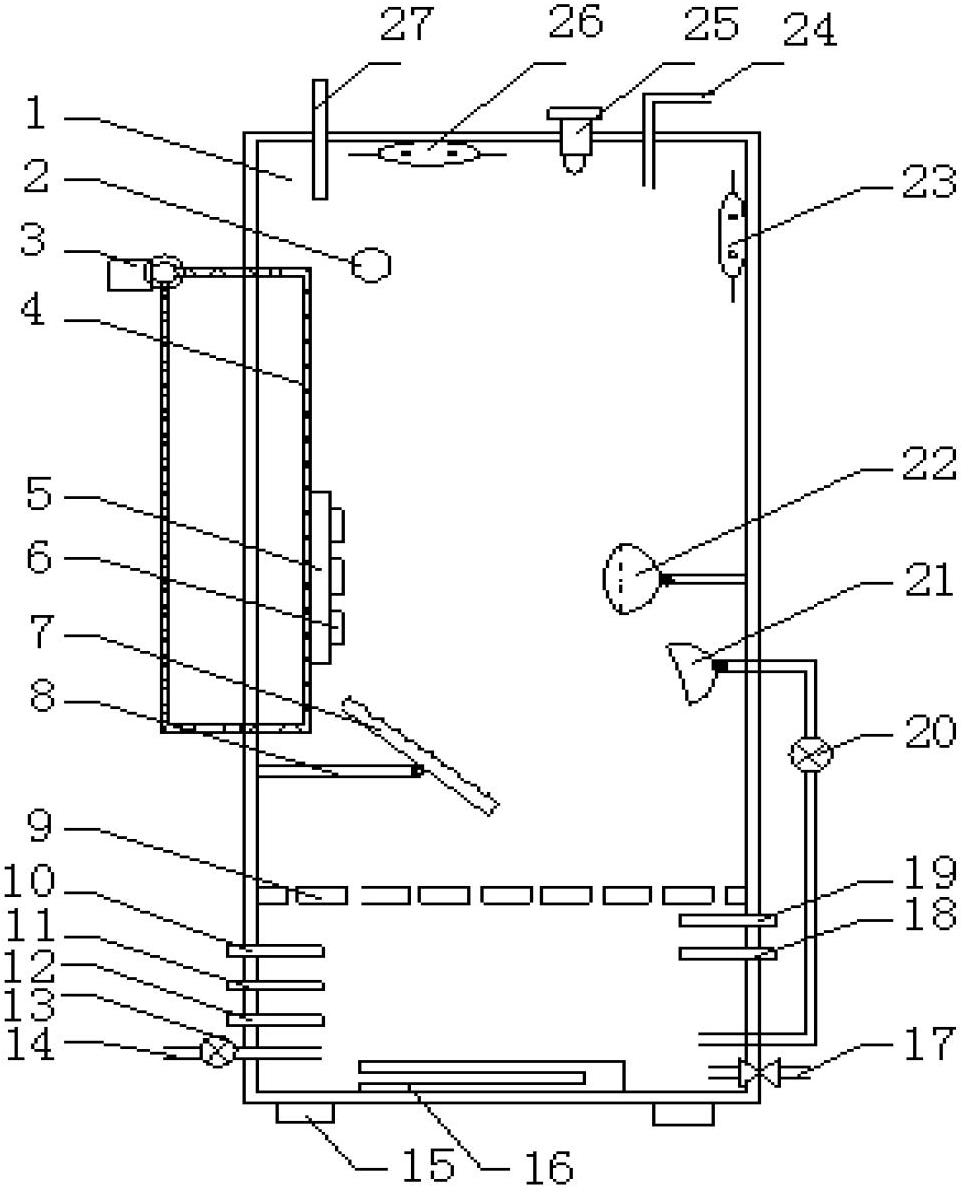

The invention provides a comprehensive testing system for a shield tunnel structural model, which comprises a soil horizon simulating and soil pressure loading device and a tunnel structural model; the soil horizon simulating and soil pressure loading device is a simulated soil body cavity enclosed by steel plates; a horizontal reaction frame is arranged outside the soil body cavity; a horizontal soil pressure jack is connected between each edge of the reaction frame and the soil body cavity; the tunnel structural model is attached with a uniform water pressure loading device and a non-uniform water pressure loading device, and is axially and vertically arranged in the center of the soil body cavity; simulation testing soil is filled between the tunnel structural model and the soil body cavity; the upper part of the soil body cavity is covered by a steel cover board; a vertical reaction portal frame is arranged above the soil body cavity; and a vertical soil pressure jack is connected between the lower part of a girder of the vertical reaction portal frame and the steel cover board. The system can simulate interactions between tunnel structures in different forms of fractures with the stratum under different stratigraphic and hydrologic conditions, and more truly simulate the environment conditions of the tunnel structures with more accurate and reliable test data, thereby providing more reliable safeguard for shield tunnel constructions.

Owner:SOUTHWEST JIAOTONG UNIV

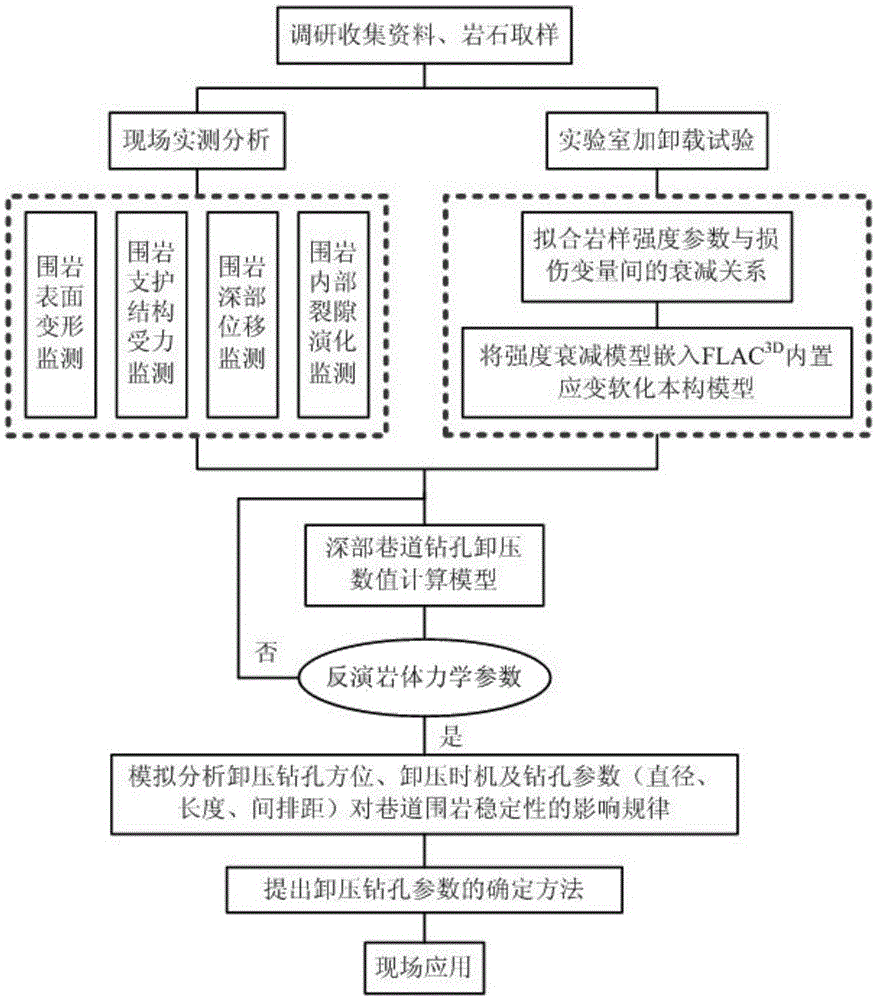

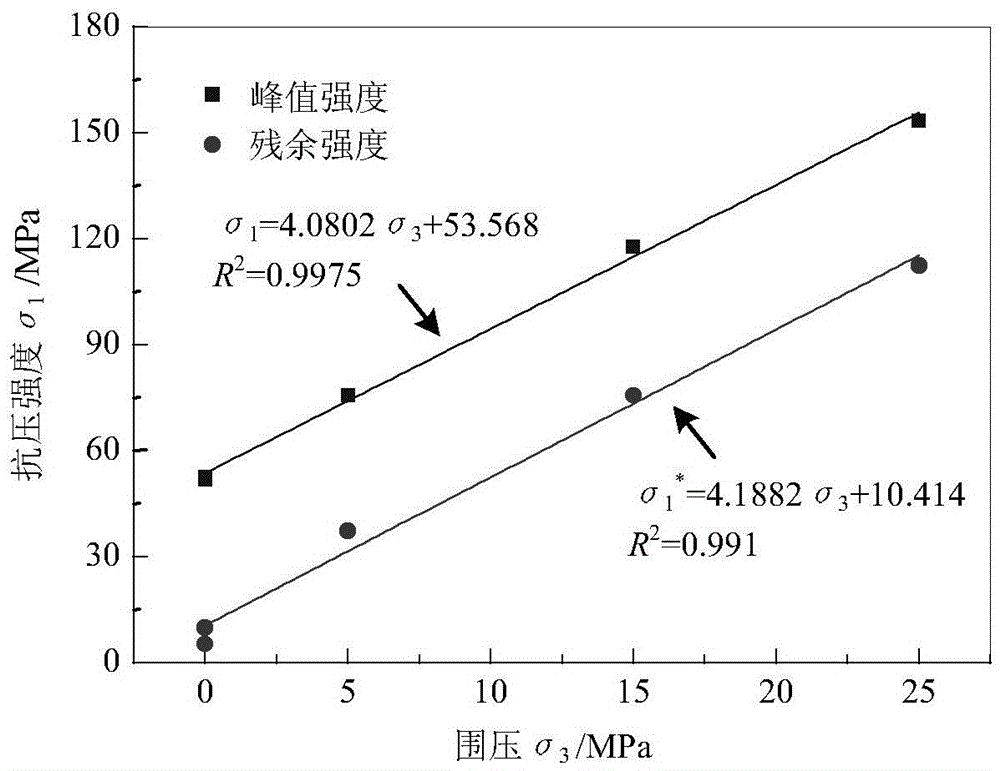

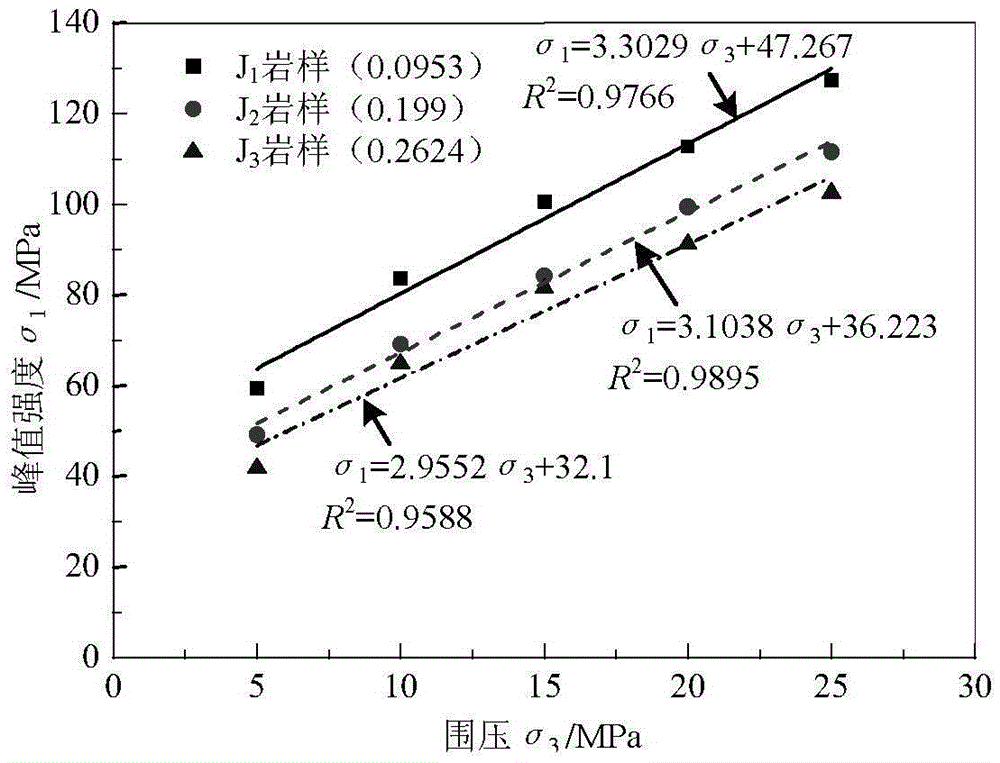

Numerical simulation determination method of deep high-stress roadway drilling pressure relief parameter

ActiveCN105631102AGood pressure relief effectStrong innovation significanceGeometric CADSpecial data processing applicationsModel parametersHigh stress

The invention discloses a numerical simulation determination method of a deep high-stress roadway drilling pressure relief parameter. Before simulation is carried out, a test roadway surrounding rock sample is firstly subjected to a loading and unloading test in a laboratory, an attenuation relationship between a rock sample strength parameter and a damage variable is obtained by fitting and is embedded into a FLAC<3D> (Fast Lagrangian Analysis of Continua) built-in strain softening constitutive model, and an actual measurement mine pressure expression law of a test roadway is taken as a known characteristic value to carry out inversion on the numerical calculation model parameter of a rock mass. A deep roadway drilling pressure relief numerical calculation model is established to simulate and analyze the influence law of a pressure relief drilling orientation, pressure relief opportunity and drilling parameters (diameter, length and inter-row spacing) on the stability of roadway surrounding rock, and a determination method of each factor which affects a pressure relief effect is put forward, and a drilling pressure relief technology system is perfected. The numerical simulation determination method considers the mutual action relationship of a pressure relief degree and the stability of the surrounding rock while pressure relief drilling parameters are determined, and the designed pressure relief drilling can perform a maximum pressure relief effect on a premise that the stability of the surrounding rock is guaranteed. The method is simple and exhibits high application value.

Owner:HENAN POLYTECHNIC UNIV

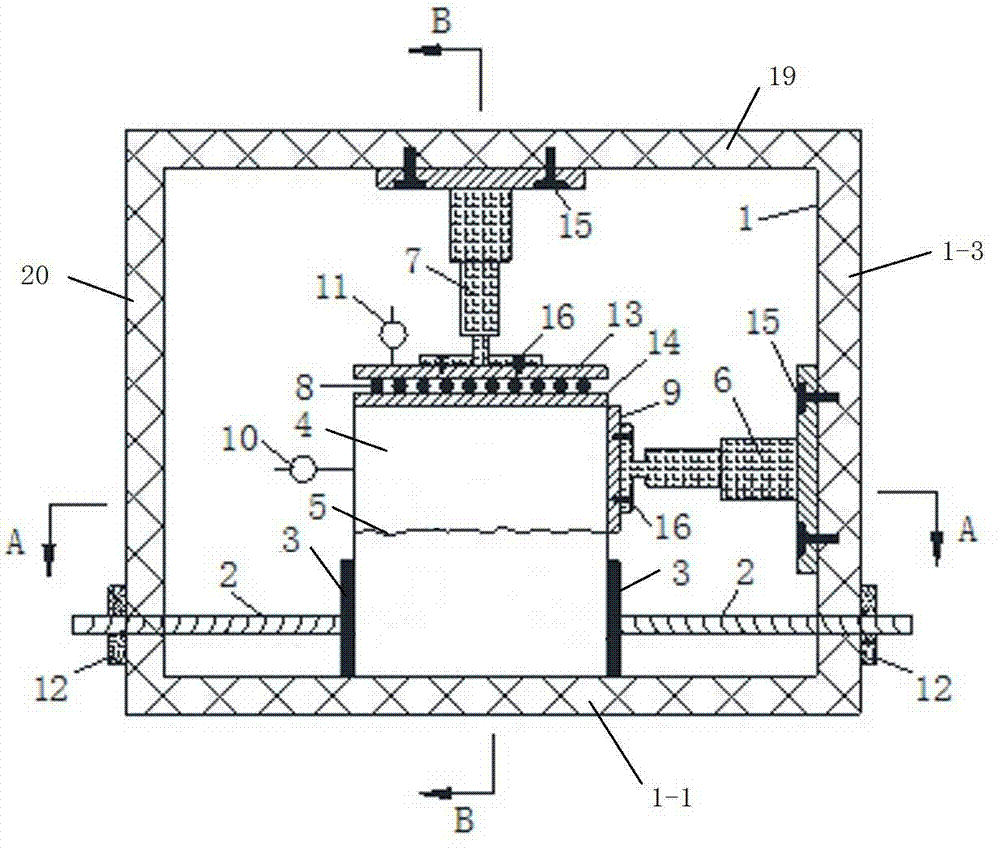

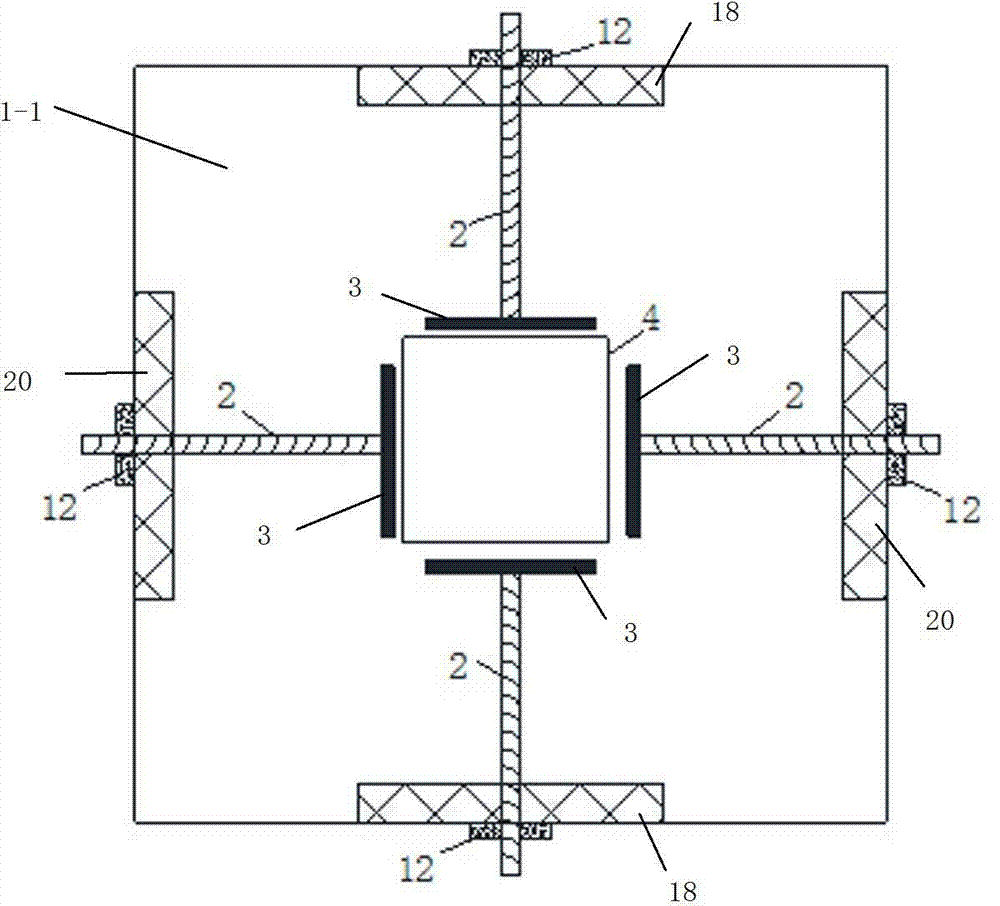

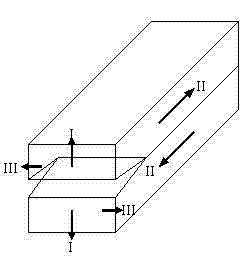

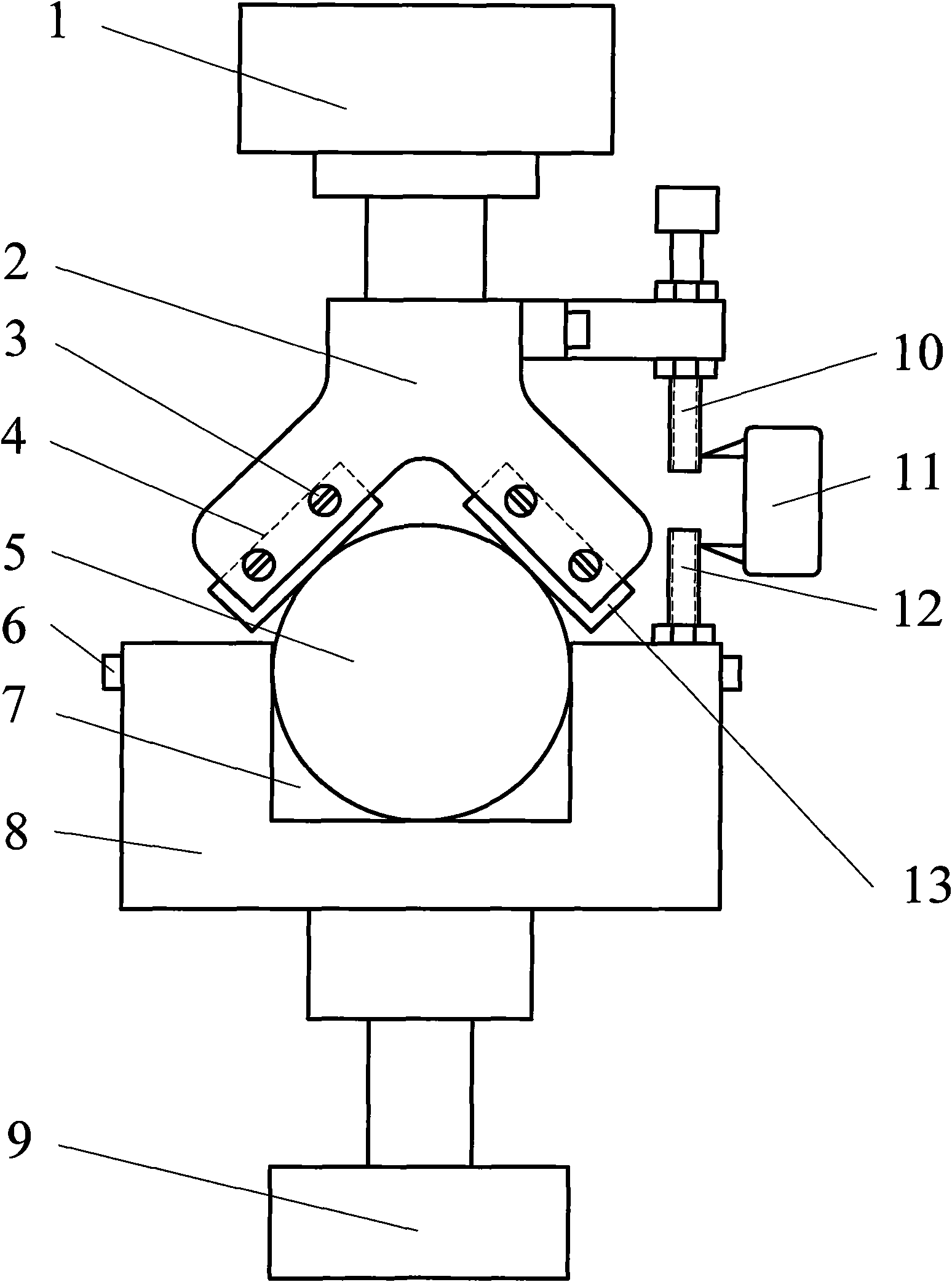

Rock mass structural surface shear test method and device

InactiveCN104749049AGuaranteed shear strengthGuaranteed StrengthMaterial strength using steady shearing forcesHorizontal axisSurface shear

The invention discloses a rock mass structural surface shear test method, which comprises the following steps of firstly, cutting a rock mass test piece into a cuboid and marking a vertical axis line and a horizontal axis line; then adjusting an adjusting rod, fixing the rock mass test piece by a movable steel baffle, enabling the vertical axis line of the rock mass test piece to coincide with the vertical axis line of a normal loading mechanism, enabling the horizontal axis line of the rock mass test piece to coincide with the horizontal axis line of a shear loading mechanism, and enabling the structural surface of the rock mass test piece to be located above the movable steel baffle; carrying out grading force application on the rock mass test piece by the normal loading mechanism from the vertical direction, and carrying out grading force application on the rock mass test piece by the shear loading mechanism from the horizontal direction; receiving the force application data of the normal loading mechanism and the shear loading mechanism and the displacement values of a normal displacement sensor and a horizontal displacement sensor by a computer, and analyzing and calculating the data. The invention also provides a rock mass structural surface shear test device. According to the invention, the stress bearing condition of a rock mass in the reality can be simulated, and test data are accurate and reliable.

Owner:WUHAN UNIV OF TECH

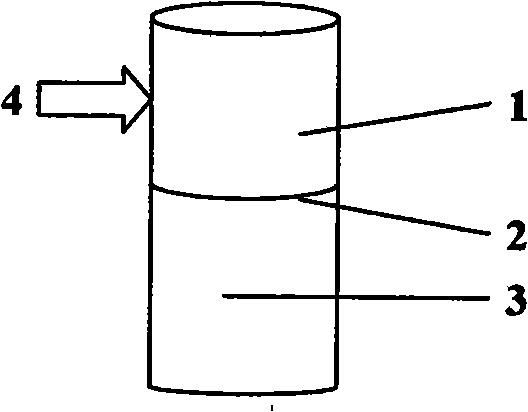

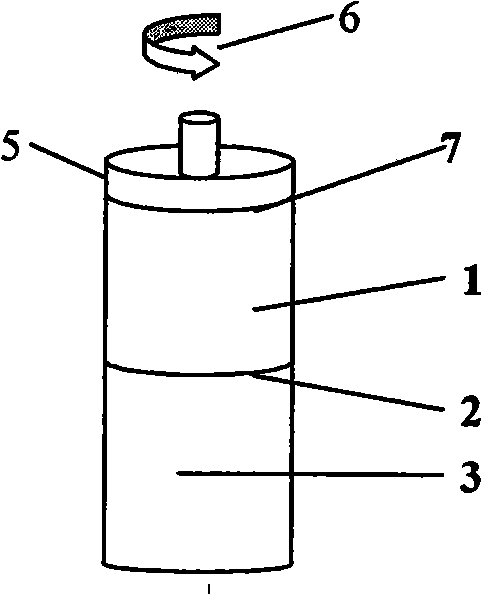

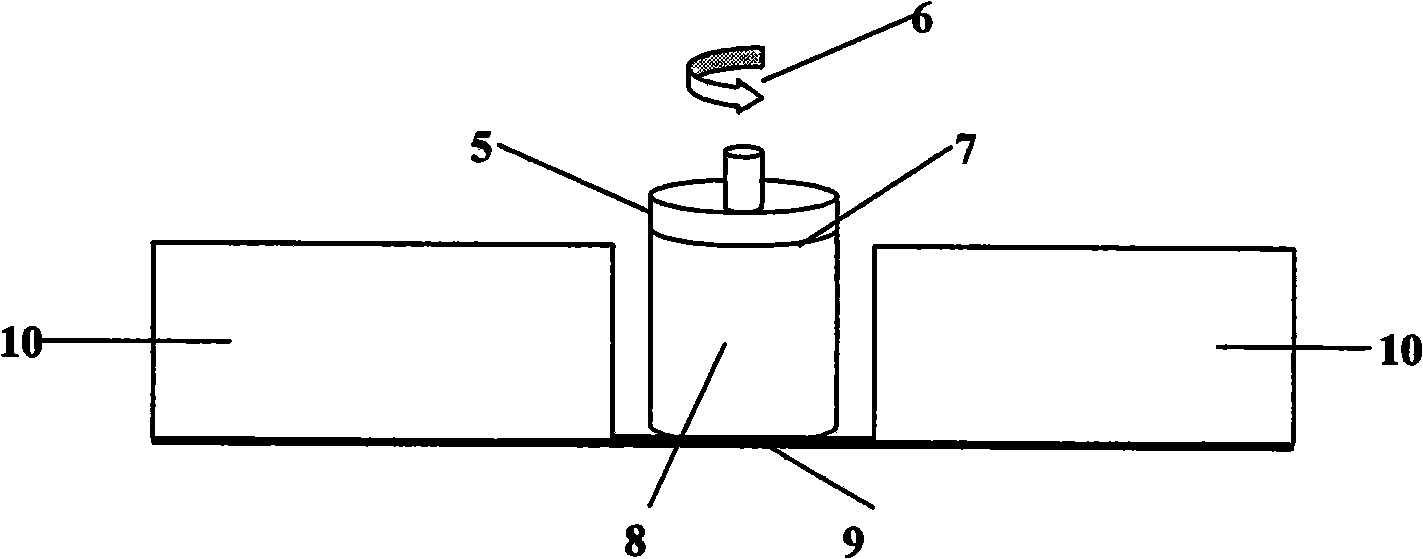

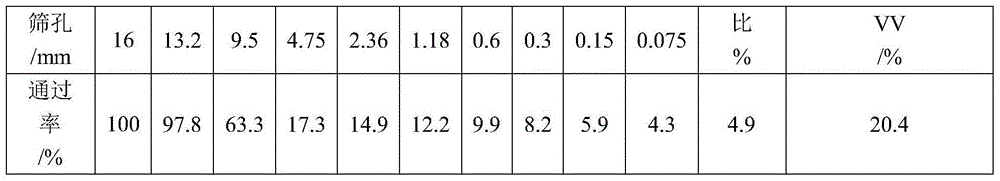

Road surface interlayer cementing shearing strength test method

InactiveCN101275903AAvoid tensile stressThe test data is accurate and reliableUsing mechanical meansMaterial strength using steady shearing forcesSurface layerRoad surface

An adhesive shearing strength between surface layers test method is a method for effective evaluation of the shearing strength of adhesive materials between surface layers, especially an easier solution whose test mode is also easier of the current problem that the shearing strength of adhesive materials between surface layers is inaccurately tested because of a unreasonable loading method. This method has the following steps: 1. indoor test: step one, preparing a sample and fixing the sample; step two: starting a motor and do a twisting and shearing test; step three, collecting and analyzing data. 2. Field test: step one: drilling a core of the surface layer, but not taking it out, and then drying the upper surface of it with hot wind; step two, bonding a shearing test fixture head and a core sample together; step three, implementing a twisting and shearing test after 30 minutes; step four, collecting and analyzing the data.

Owner:SOUTHEAST UNIV

Marine splash environment simulation test device

ActiveCN102680385AImprove the simulation effectComprehensive monitoring of water qualityWeather/light/corrosion resistanceEngineeringMarine equipment

The invention belongs to the technical field of marine equipment, and particularly relates to a marine splash environment simulation test device, wherein stringed testing cable holes are arranged in the upper part of one side surface of the box-structured test box, a frame-structured drive pull rod is arranged on the other side, a splash plate angle adjusting rod is arranged at the lower part, and a splash plate is formed at the inner end of the splash plate angle adjusting rod; sensors and water inlets are arranged on the side surface of a liquid area from top to bottom; a gas exhaust opening, a ventilating and moisture exhausting device, an infrared heating lamp and a box temperature sensor are fixedly and sequentially arranged on the top side surface of the test box body from right to left; and a ultraviolet lamp, an air blower, a nozzle, a water spray pump, a liquid level controller, a dissolved oxygen sensor and a water drain opening are arranged on the opposite side of the test box corresponding to the side surface provided with the drive pull rod. The marine splash environment simulation test device has simple structure and higher automation degree, is convenient to operate, needs no staff attendance, and can simulate marine splash environment in a laboratory, so as to analyze and evaluate the corrosion and aging of the material.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

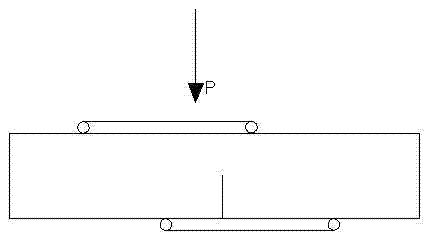

Corrosion-fatigue testing method for reinforced concrete on basis of optical-fiber sensing and device thereof

ActiveCN104483258AThe test data is accurate and reliableRealize real-time synchronous monitoringWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceReinforced concreteRebar

The invention discloses a corrosion-fatigue testing method for reinforced concrete on the basis of optical-fiber sensing and a device thereof. The corrosion-fatigue testing method comprises the following steps: (1) casting a reinforced concrete beam and arranging fiber grating sensors; (2) installing the reinforced concrete beams; (3) connecting with a power supply; (4) injecting electrolyte; and (5) acquiring test data. The device constructed according to the method comprises the reinforced concrete beam to be tested, a load distributing beam, a supporting device, a corrosion groove with an opened upper end, a hydraulic jack, a monitoring device and a direct-current voltage stabilizing power supply. The corrosion-fatigue testing method and the device disclosed by the invention have the advantages that the coupling action of a corrosion medium and alternating stress is fully considered, and the environment is closer to the use environment of the reinforced concrete structure in service, so that the test data is more effective and reliable.

Owner:ZHEJIANG UNIV

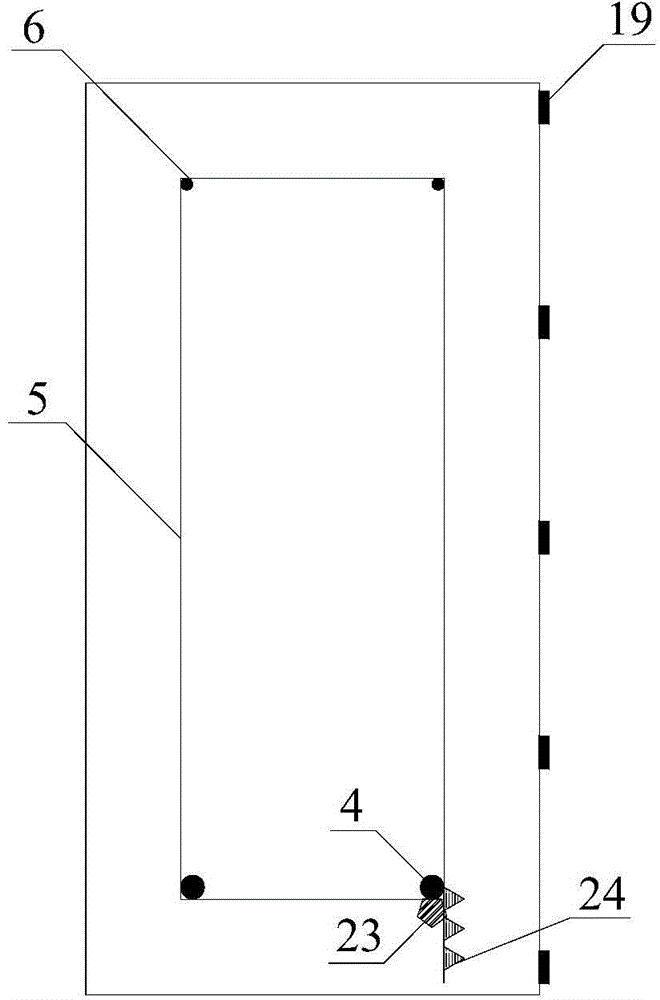

Testing device and method of soil body II-type fracture damage

ActiveCN102128742AThe test data is accurate and reliableFacilitate mechanical analysisStrength propertiesType fractureTest sample

The invention discloses a testing device of soil body II-type fracture damage. A front stop iron and a thrust providing device are respectively connected to two ends of a base, and the front stop iron or the thrust providing device is in sliding connection with the base; the power output part of the thrust providing device is connected with one end of a load sensor, and the other end of the load sensor is connected with a thrust plate; the signal output ends of the load sensor and a displacement sensor are both connected to a computer; the load sensor detects a load applied to a test sample; and the displacement sensor detects the deformation of the test sample in a test. The invention has the beneficial effects that the loading state of the test sample in the whole testing process is kept as a pure II-type, and the damage to the test sample is II-type fracture damage, thereby ensuring that the test data is accurate and credible, and facilitating the later mechanical analysis.

Owner:昌泰建设集团有限公司

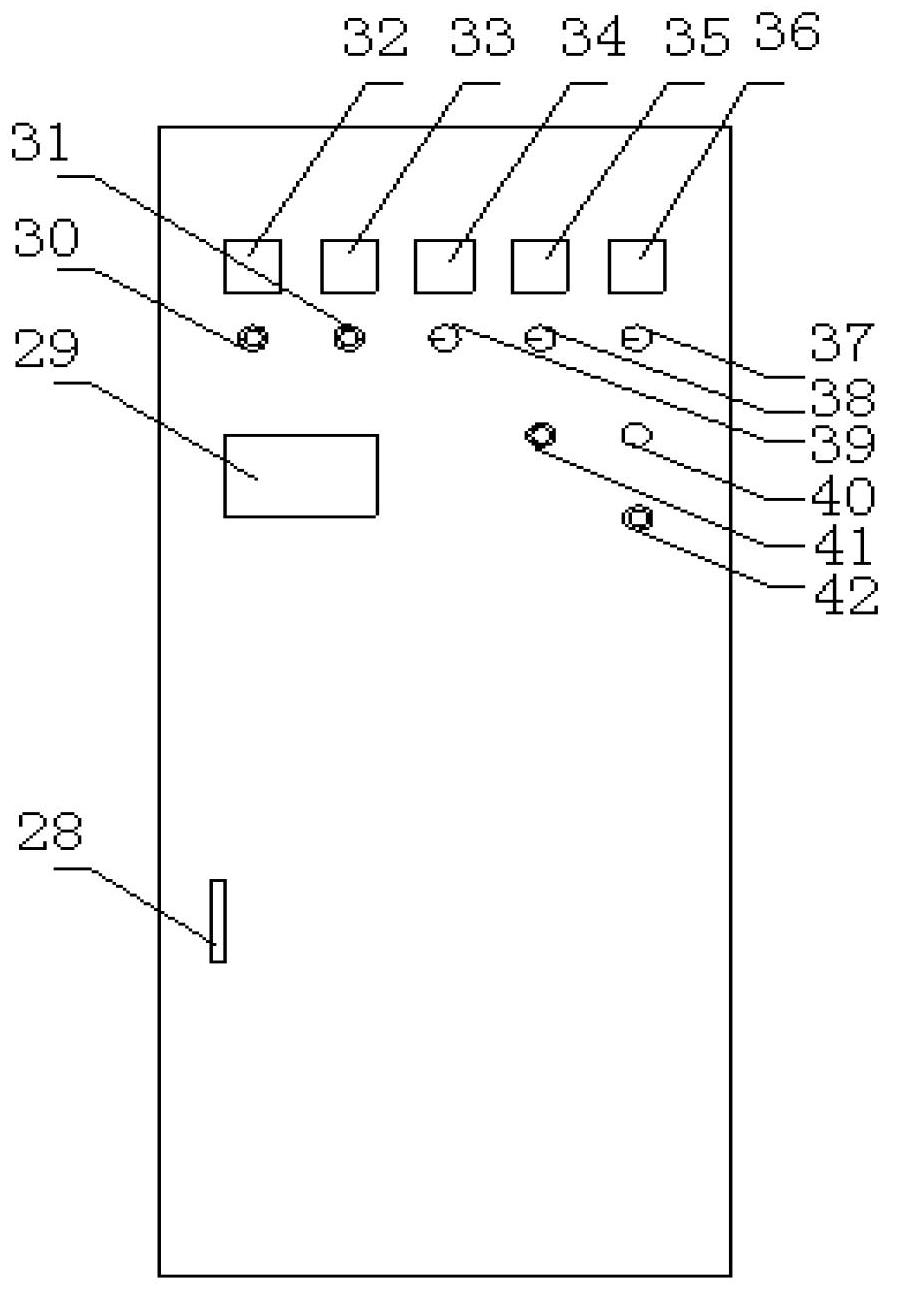

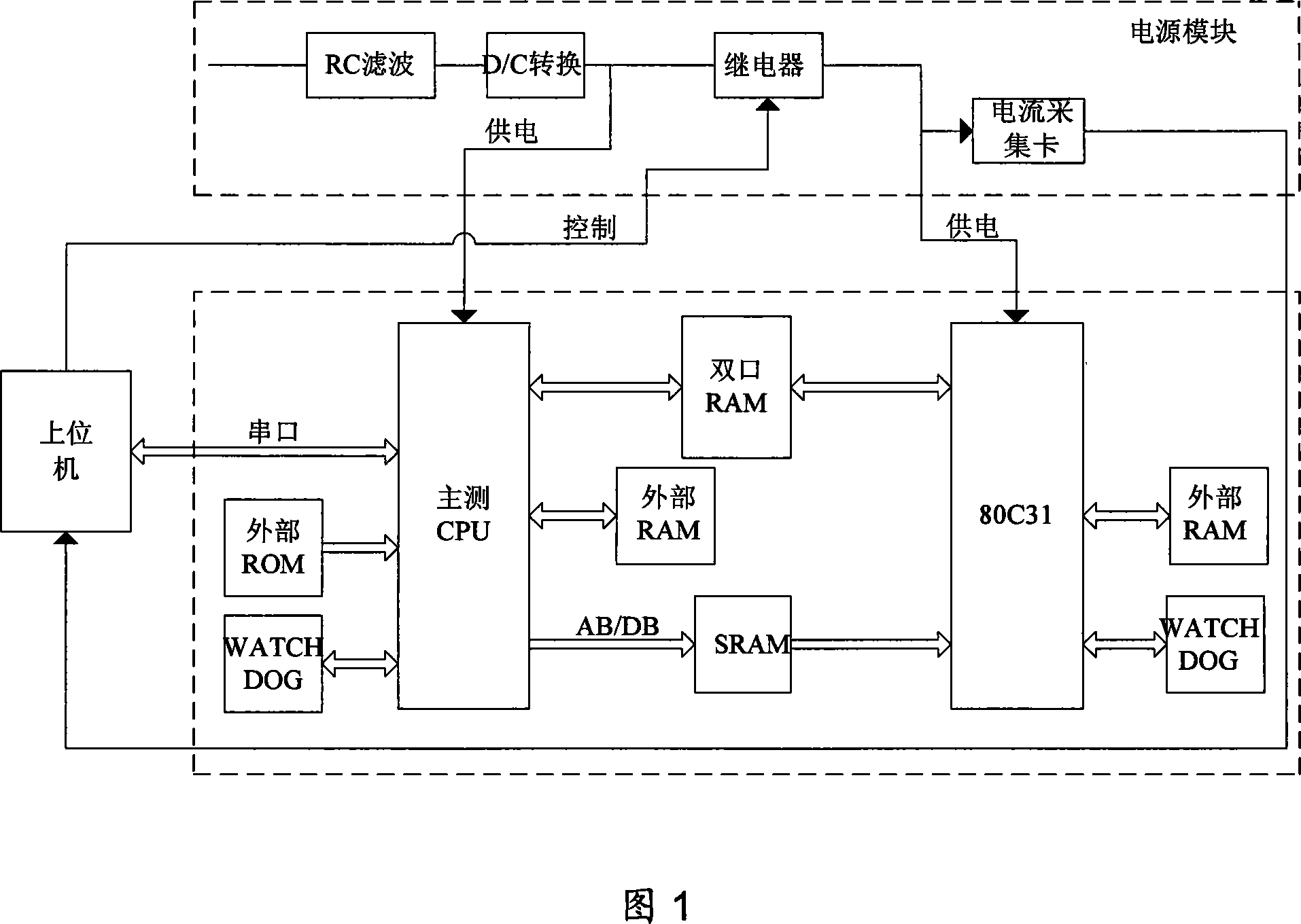

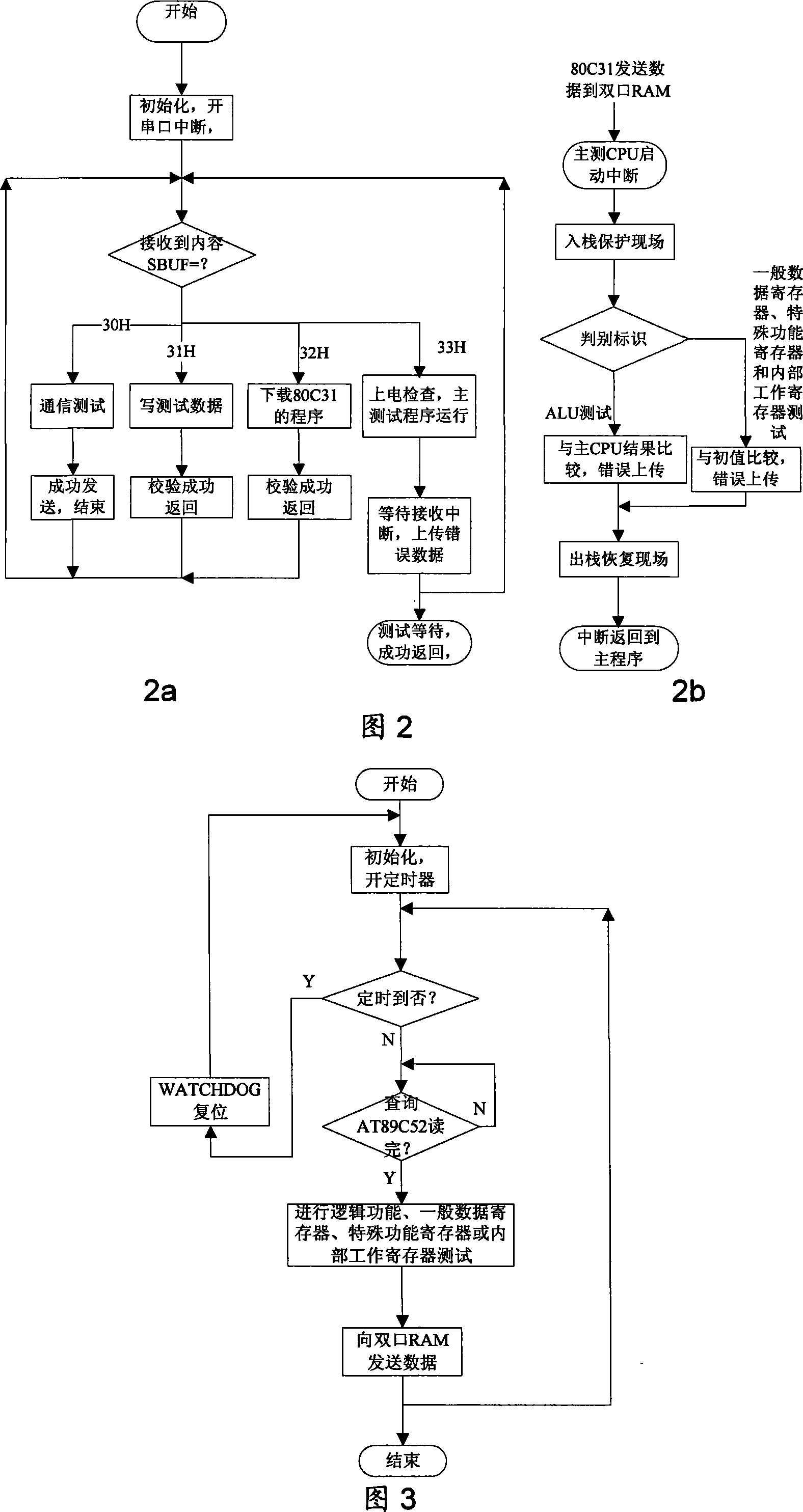

Device for detecting 80C31 single particle effect

The invention discloses a device for detecting 80C31 single event effect. A power module supplies power for a main detecting CPU and a detected 80C31; a current acquisition card acquires the current supplied for the detected 80C31 and sends the acquired current value to a host computer; when the current value exceeds the preset threshold value, latch happens; the host computer sends command to the power module and a power module 0 disconnects power of the detected 80C31; the main detecting CPU receives codes of test program from the host computer through a serial port and writes the received codes in SRAM; the detected 80C31 reads the codes from SRAM and operates the test program according to the read codes as well as stores the program operation results in a double-port RAM temporarily; the main detecting CPU extracts the operation results from the double-port RAM and sends the results of occurrence of single event upset to the host computer. The invention realizes the online downloading and revision of the test program with complete test contents and high device reliability.

Owner:BEIJING MXTRONICS CORP +1

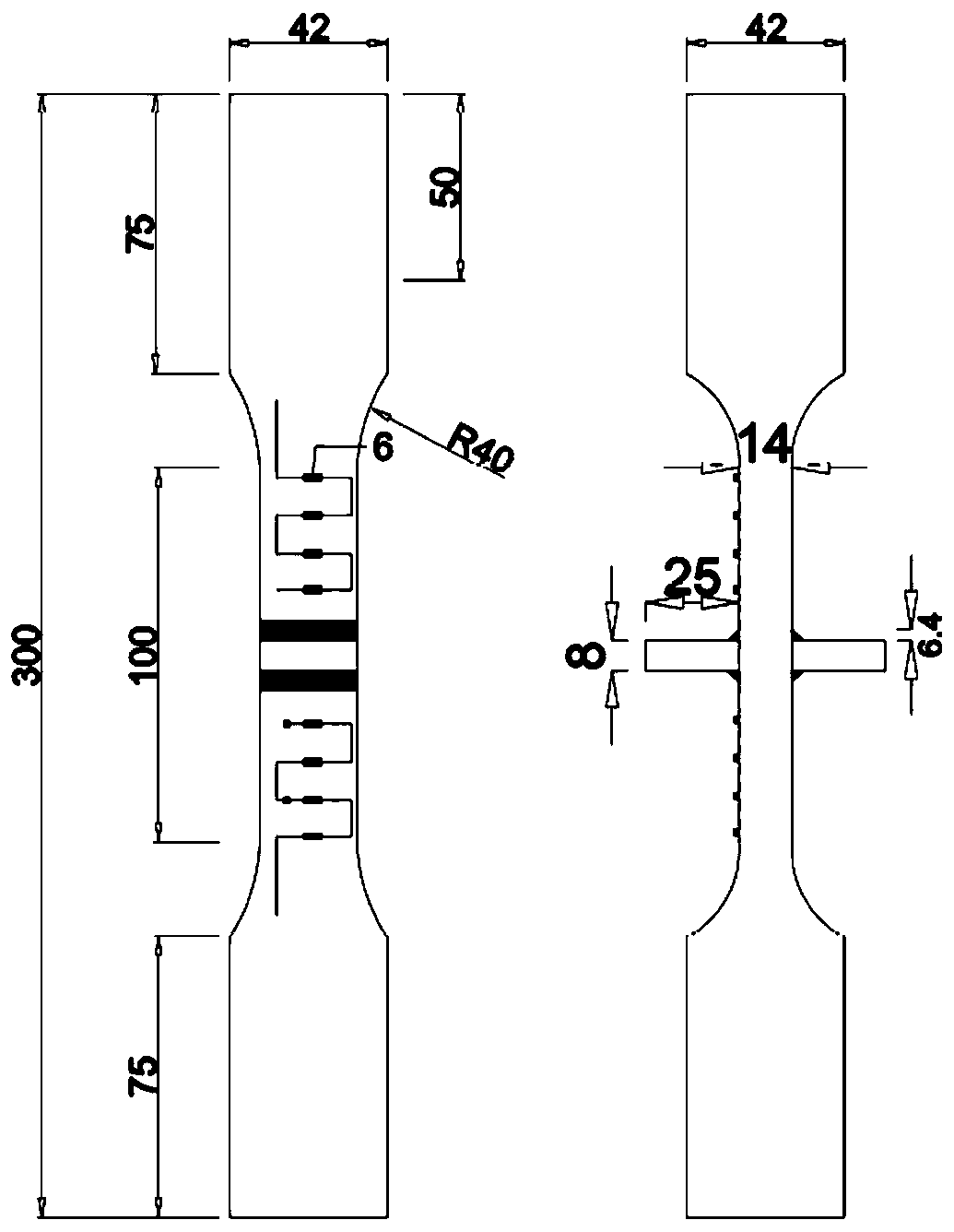

Bidirectional final motion test fixture and bidirectional final motion test method thereof

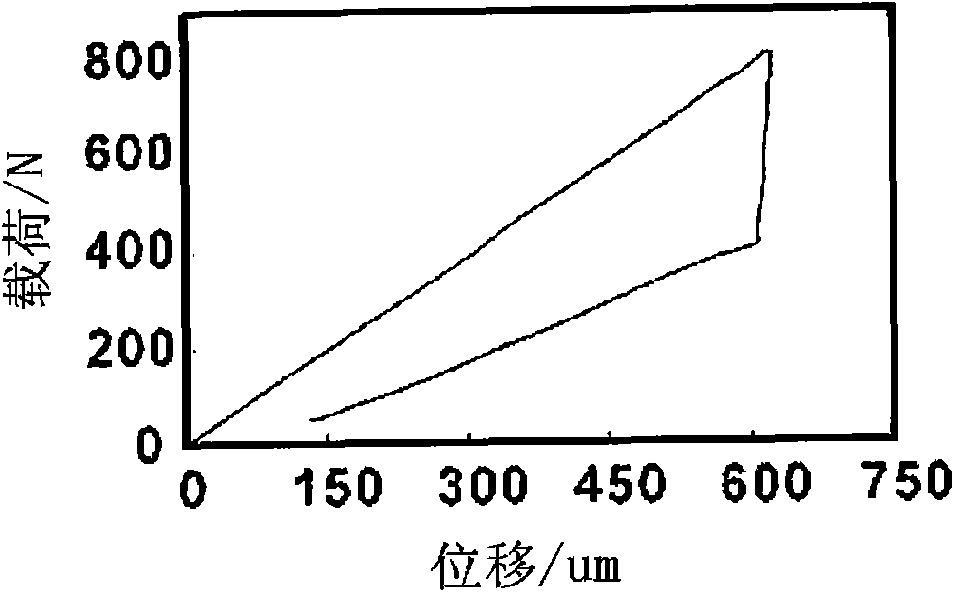

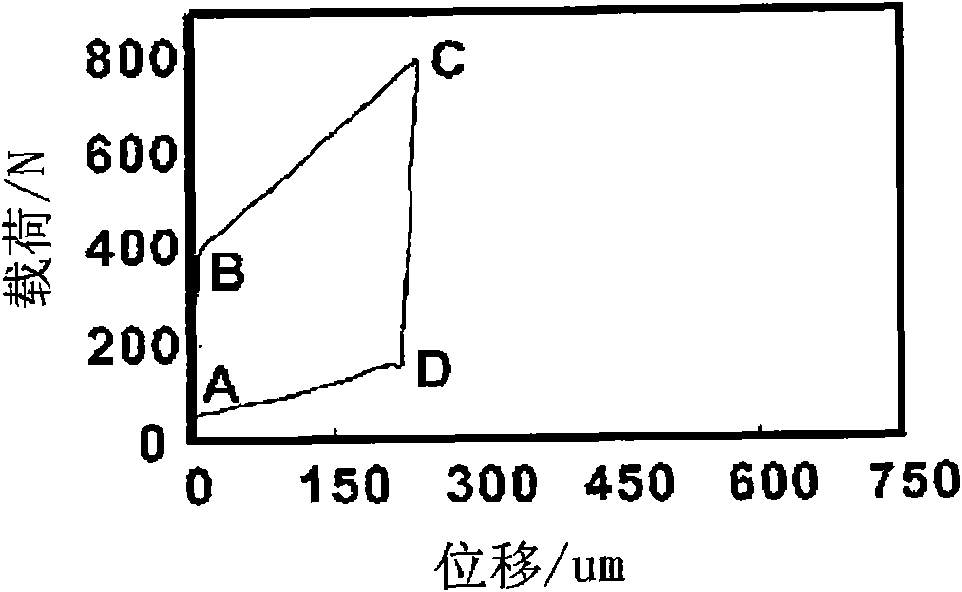

InactiveCN101608986ARealize two-way inchingShorten the lengthUsing mechanical meansMaterial strength using repeated/pulsating forcesFrettingEngineering

The invention relates to a bidirectional micro motion test fixture and a bidirectional micro motion test method thereof. The fixture is mainly in the structure that: a planar test-piece fixture (2) is in an inversed V shape, the opposite surfaces of the left and right sides of the lower part are all opened with a groove (4) fit to a planar test-piece (13), and the wall of the groove (4) is provided with a puller screw (3); a spherical test-piece fixture (8) is opened with a spherical test-piece cavity (7) fit to a spherical test-piece (5), and the wall of the spherical test-piece cavity (7) is provided with a puller screw (6); and the vertical axes of the spherical test-piece cavity (7), a piston (9) and the planar test-piece fixture (2) are coincided. One side of the upper part of the planar test-piece fixture (2) is connected with an upper vertical screw (10) while the spherical test-piece fixture (8) is connected with a lower vertical screw (12), and a displacement sensor is connected with the upper vertical screw (10) and the lower vertical screw (12). The test fixture can effectively simulate bidirectional fretting under spherical / surface contact condition, test tribology properties and estimate contact fatigue life of a coating under spherical / surface bidirectional micro motion condition on the existing hydraulic servo micro motion test platform.

Owner:SOUTHWEST JIAOTONG UNIV

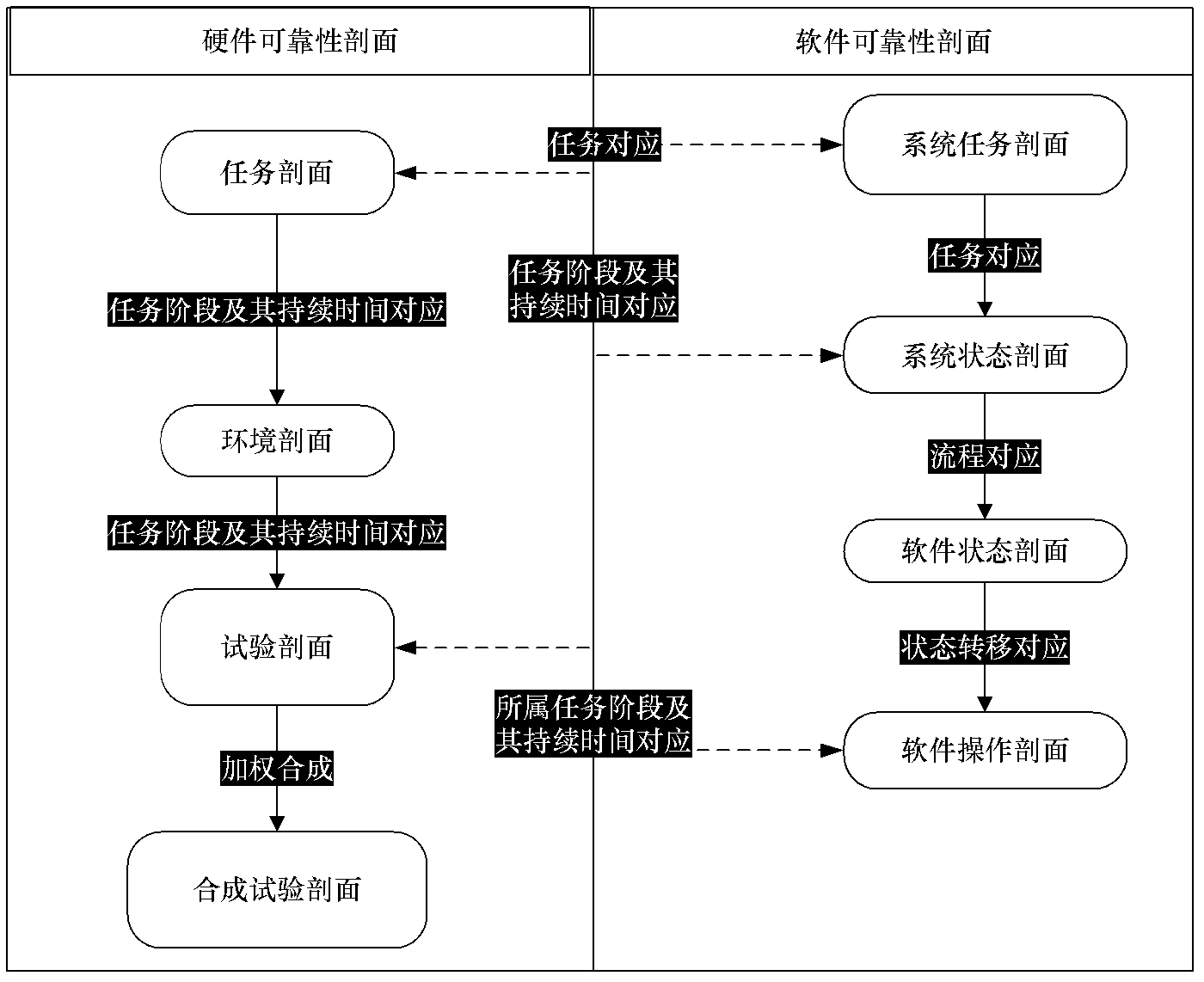

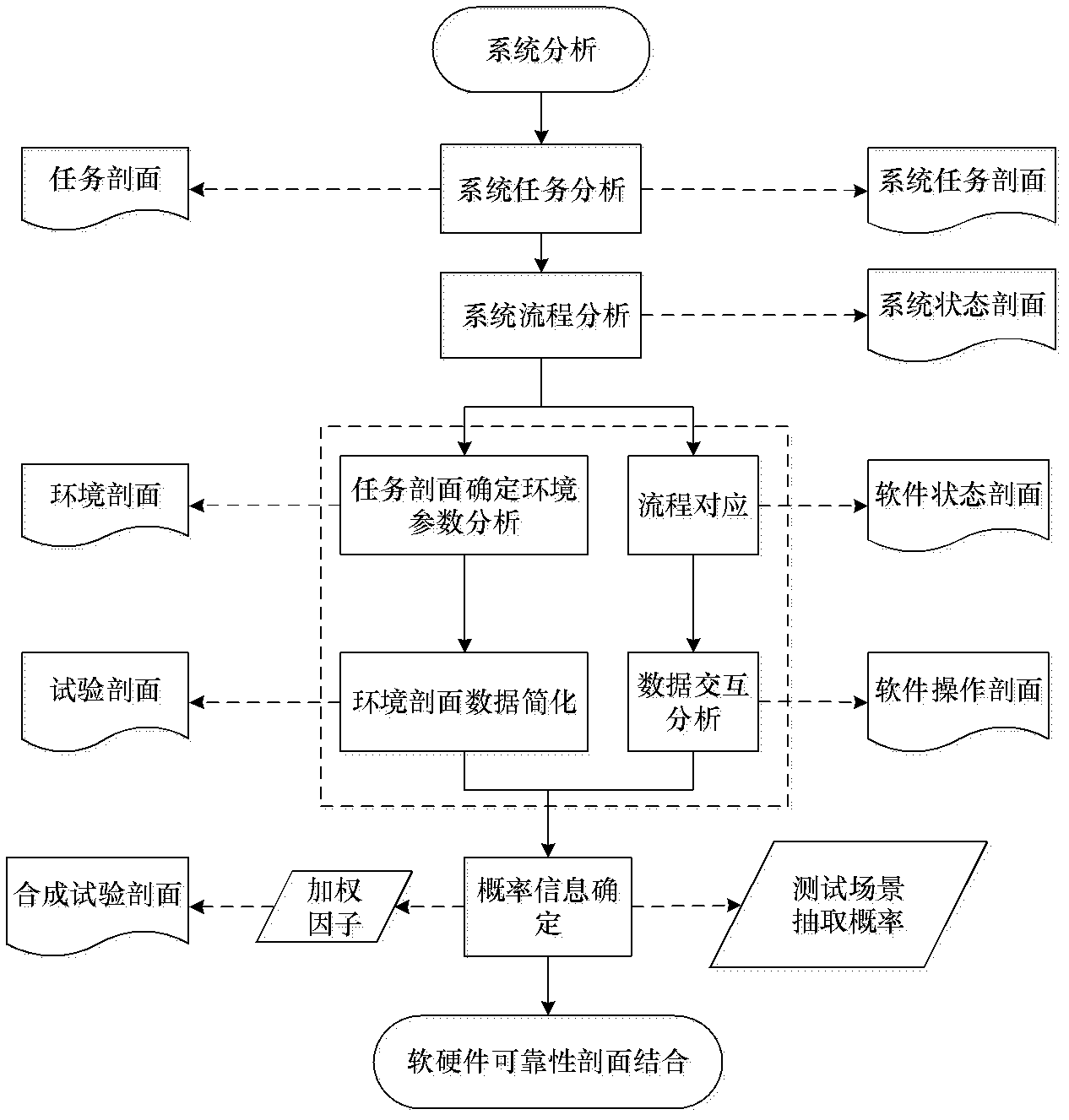

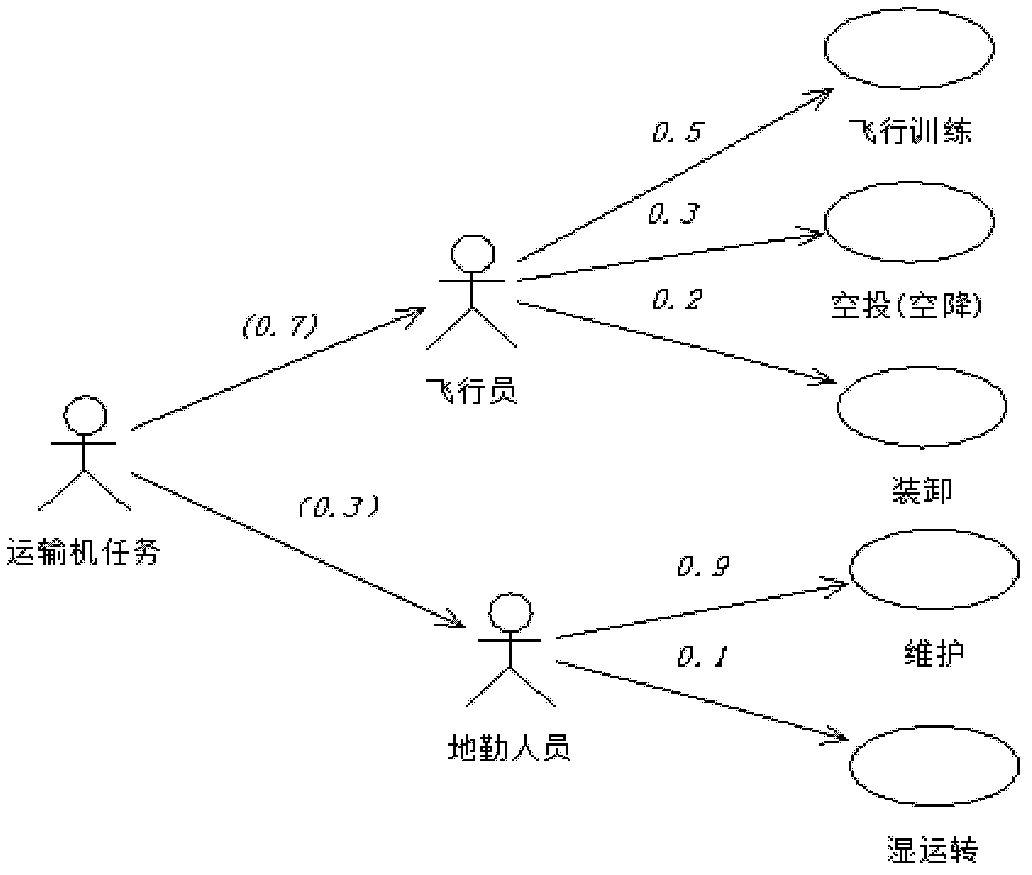

Constitution method of comprehensive reliability testing profile for both software and hardware

InactiveCN102662841AThe test data is accurate and reliableDetecting faulty computer hardwareSoftware testing/debuggingTask analysisSystems analysis

The invention provides a constitution method of comprehensive reliability testing profile for both software and hardware. The method is used for reliability testing of an embedded system and includes the steps of system analysis, system task analysis, system flow analysis, core profile constitution, probabilistic information determining and software-hardware reliability profile combining. A hardware reliability profile and a software reliability profile are constituted and are sectioned, sections are combined on the basis of a task combing point and a time combining point, and accordingly the profiles are effectively combined. By the constitution method, true service condition of the embedded system can be truly embodied, reliability test data of the tested embedded system, which is generated on the basis of the comprehensive test profiles, is more reliable and more adaptable to reliability testing of systems, and the constitution method can be used for failure analysis for the tested embedded systems.

Owner:BEIHANG UNIV

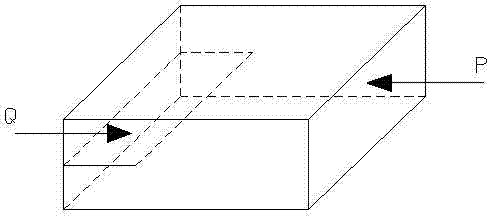

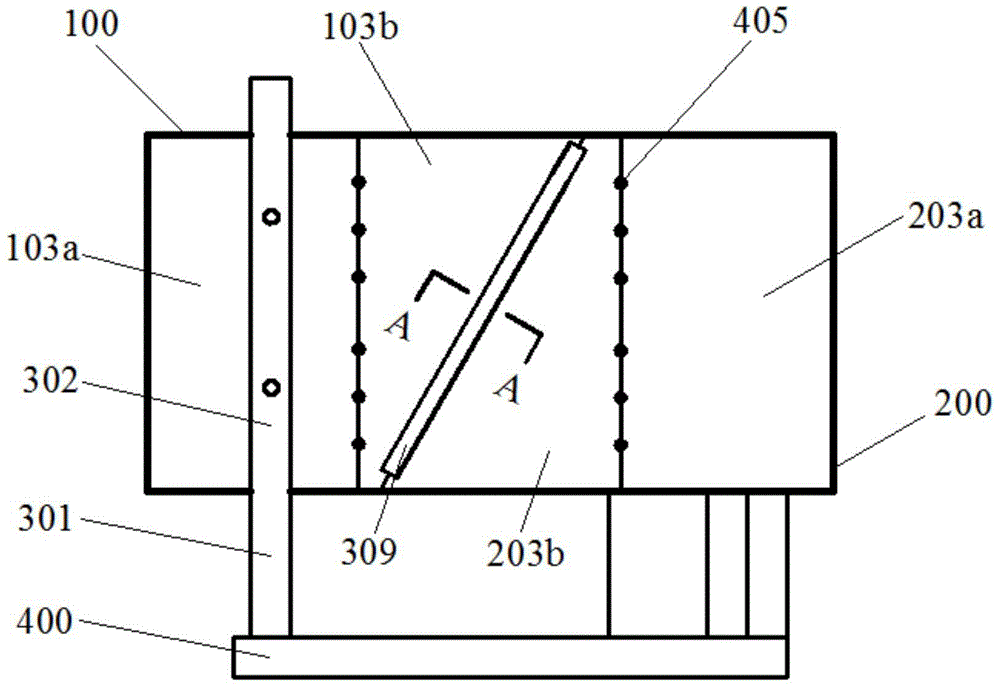

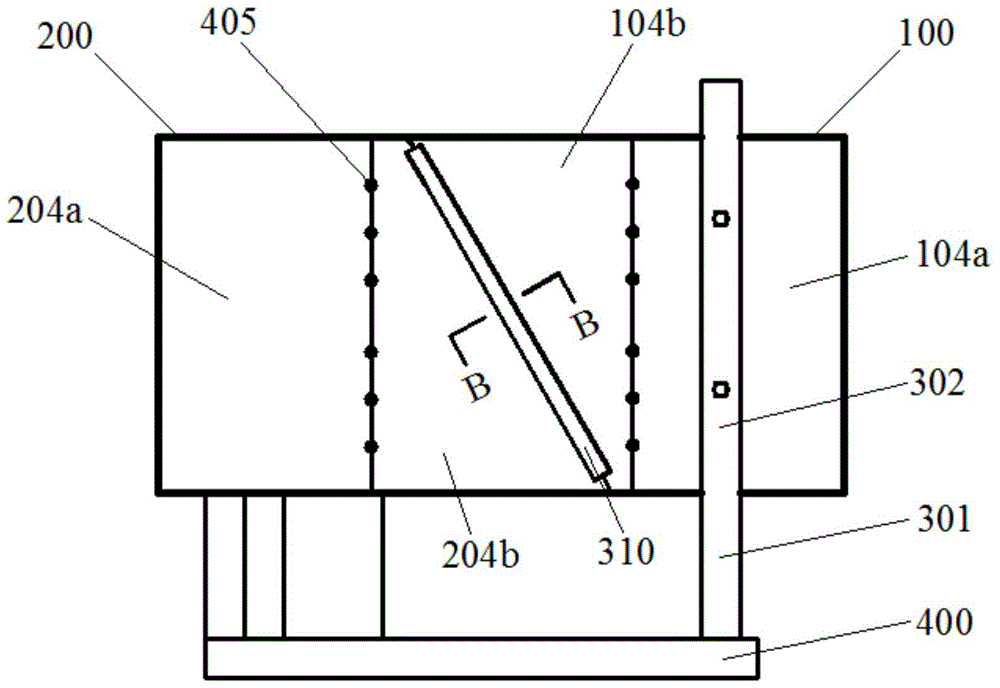

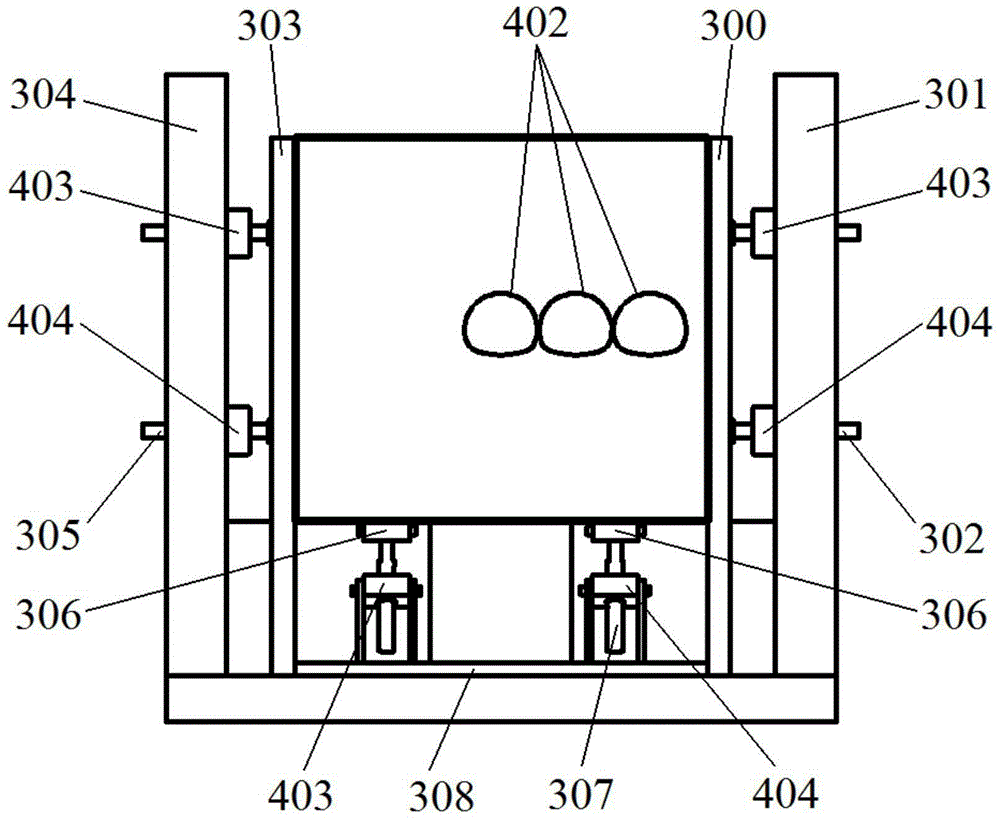

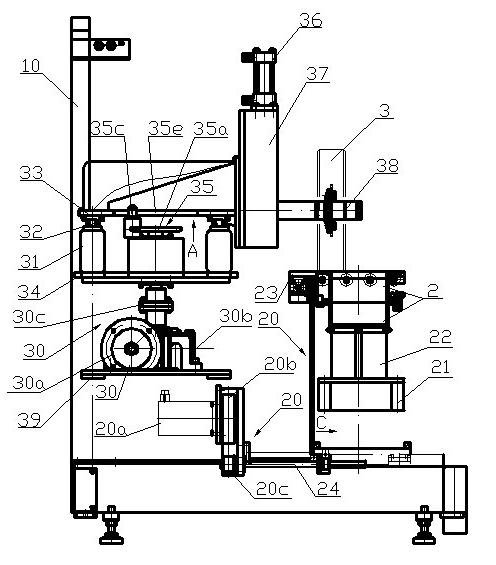

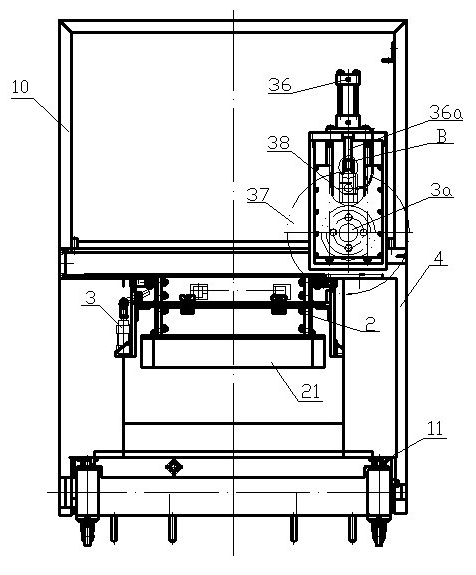

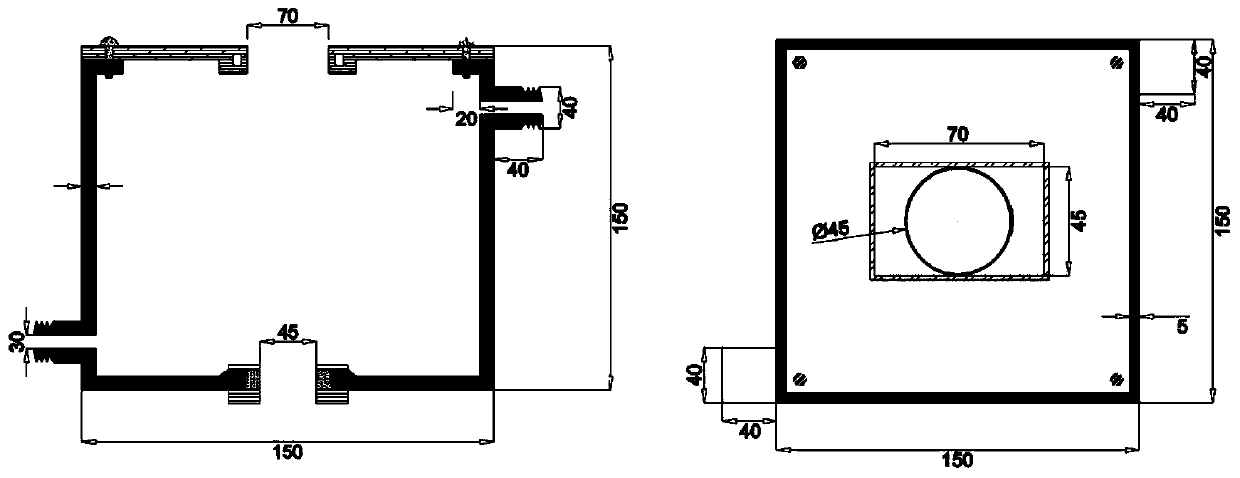

Destructive testing apparatus and method for simulating tunnel going through oblique displaced active fault

ActiveCN105785468AGuaranteed operational safetyThe test data is accurate and reliableGeological measurementsActive faultLeft half

The invention discloses a destructive testing apparatus and method for simulating tunnel going through oblique displaced active fault. The apparatus is mainly configured in that: a lidless model testing sample box is composed of a movable left half box 100 and a fixed right half box 200; the movable left half box 100 is connected to the fixed right half box 200 through a front bilateral sliding pair 309 and a rear bilateral sliding pair 310; a left bottom plate 102 of the left half box hinges an upper end of a vertically loading apparatus 307, and a lower end of the vertically loading apparatus 307 is connected to a horizontal moving platform 308 which can move forward and backward to the left side of a pedestal 400; a left front plate 103 and right front plate of the left half box cling closely and respectively to a front horizontal loading apparatus 302 and a rear horizontal loading apparatus. The apparatus can implement a tunnel structure and spatial positions of multiple dip angles and multiple crossing angles among active faults, simulates stress states and destructive methods of the tunnel structure in a more accurate manner so as to provide more reliable testing data for the design and construction of going through fault tunnel structure.

Owner:SOUTHWEST JIAOTONG UNIV

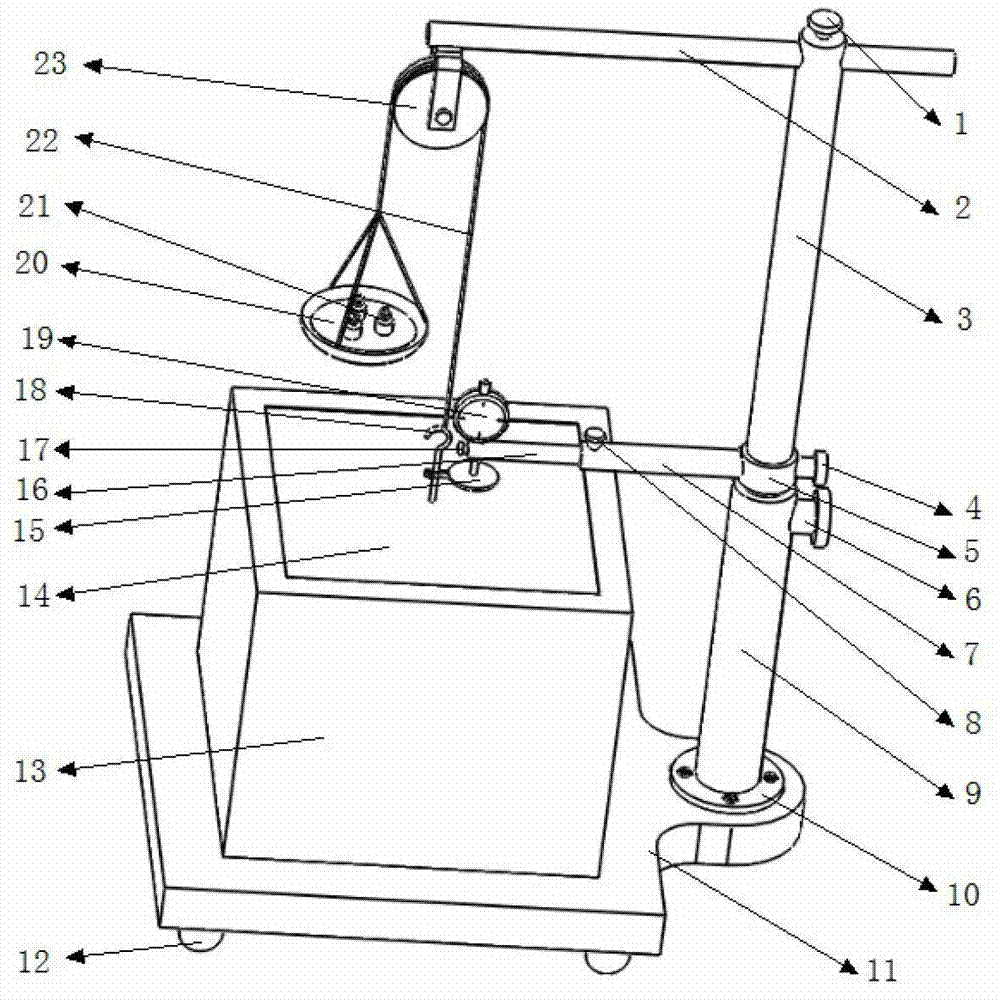

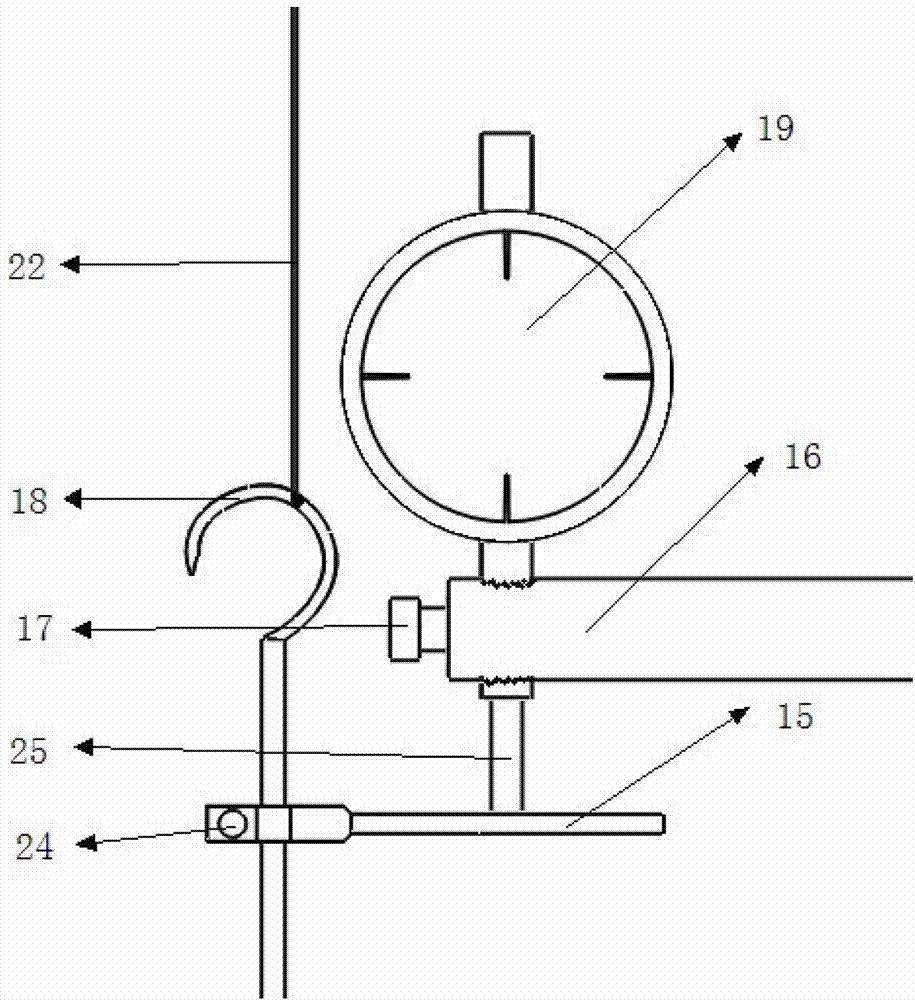

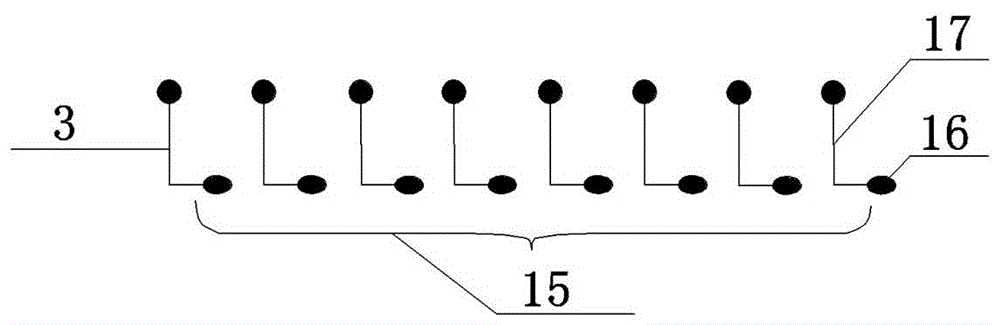

Simulation experiment apparatus used for testing drawing force of anchor pole and application method thereof

InactiveCN103323336AComplete simulationEasy to useMaterial strength using tensile/compressive forcesVertical tubeSoil material

The invention relates to a simulation experiment apparatus used for testing drawing force of an anchor pole and an application method thereof. The experiment apparatus comprises a testing box and a tester. The testing box comprises a box body (13); rock and soil materials (14) placed in the box body, wherein the rock and soil materials are used for testing; the testing anchor pole (18) which is inserted in the center of the rock and soil materials (14); and a contacting slice (15) arranged on the anchor pole (18). The tester comprises a pedestal (11), and a casing (13) arranged on the pedestal (11). One side of the pedestal (11) is provided with a vertical tube (9); a vertical stick is arranged on the vertical tube (9); a first cross bar (2) is arranged on the vertical stick (3), wherein one end of the cross bar (2) in inserted into the top of the vertical stick (3), and the other end is welded with a fixed pulley (23); a cross pipe (7) is arranged at the middle of the vertical stick (3); a second cross bar (16) is inserted in the cross pipe(7); and a dial gauge (19) is arranged on one end of the second cross bar (16). The apparatus possesses following beneficial effects comparing with existing technologies: the apparatus is capable of realizing a complete and realistic simulation of the drawing force mechanism of the anchor pole, providing more accurate and full experiment data for the design of actual anchor pole parameters, and ensuring the safety in practical applications.

Owner:TONGJI UNIV

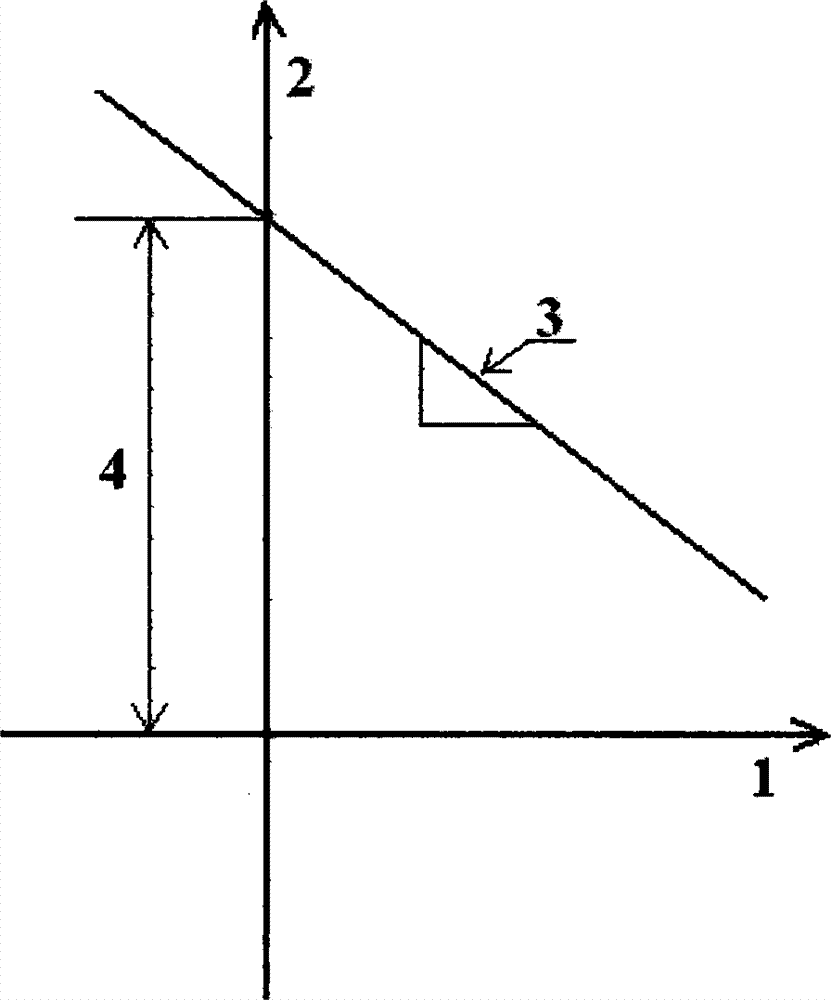

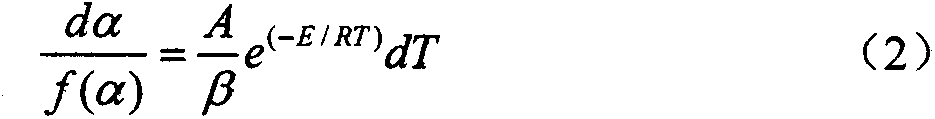

Method for evaluating flame retardant efficiency of asphalt

InactiveCN103293079AAccurate evaluationFast testWeighing by removing componentMaterial heat developmentBituminous materialsEngineering

The invention discloses a method for evaluating the flame retardant efficiency of asphalt, belonging to the technical field of an asphalt pavement and solving the problem that a method for evaluating the flame retardant efficiency of the asphalt is difficultly accurately quantified by using an existing flame retardant. According to the method, based on the combination of a thermogravimetry-differential thermal analysis synchronous test and a thermal analysis kinetics theoretical equation, the flame retardant efficiency of a flame retardant to the asphalt is quantificationally evaluated. The method comprises the steps of: respectively testing the asphalt and prepared flame-retardant asphalt by adopting a thermogravimetry-differential thermal analyzer to obtain test data such as TGs (Thermal Gravity), DTGs (differential thermogravimetry), DTAs (Differential Thermal Analysis) and char yields; secondly, drawing curves of 1n[g(alpha) / T2] to 1 / T according to the thermal analysis kinetics theoretical equation, and determining reaction mechanism functions g(alpha) in the thermolysis process of the asphalt and the prepared flame-retardant asphalt through linear fitting of a least square method; thirdly, drawing a straight line of the 1n[g(alpha) / T2] to the 1 / T, solving kinetics parameter activation energies E and frequency factors A through a slope and an intercept; finally, comparing the E and the A of the asphalt with the E and the A of the prepared flame-retardant asphalt so as to completely and accurately evaluate the flame-retardant efficiency of the flame retardants with different types and doping quantities to the asphalt.

Owner:NANJING FORESTRY UNIV

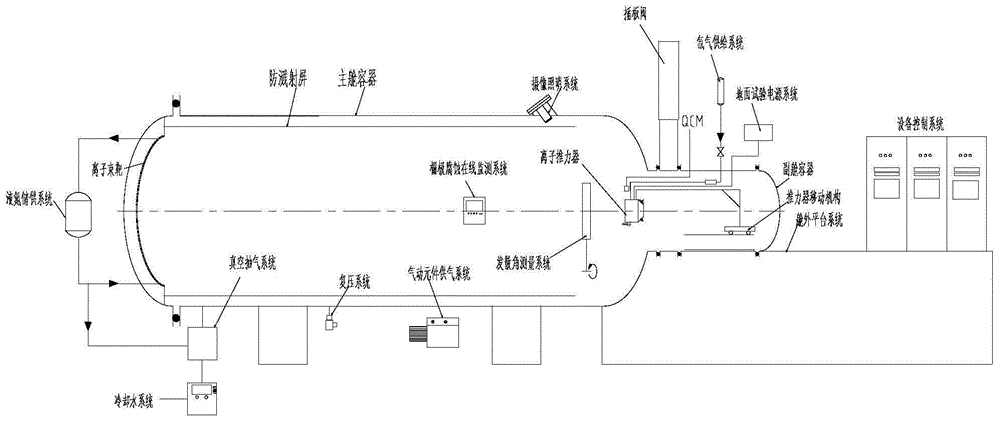

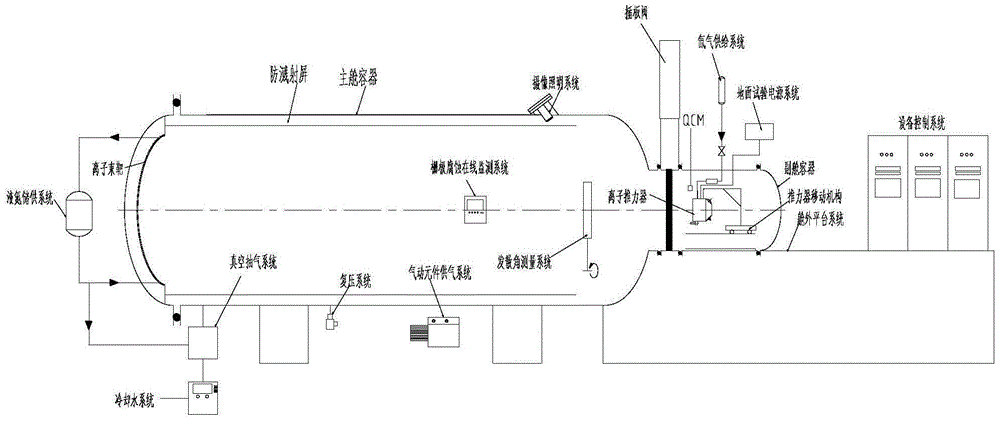

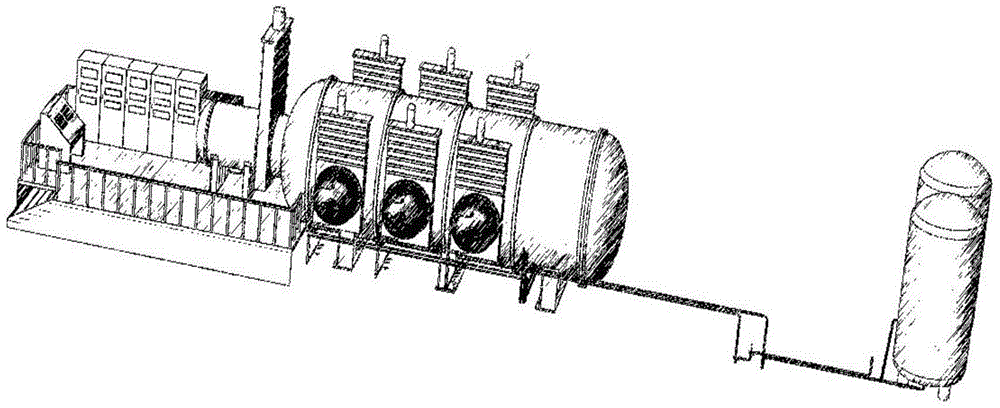

Service life ground test method for ion thruster

ActiveCN105173124AReal-time monitoring statusReduce the impactCosmonautic ground equipmentsDependabilityLife time

The invention discloses a service life ground test method for an ion thruster. By using the ground test method, a ground service life test for the iron thruster can be performed for a long time. According to the ground test method, service life ground test equipment is built first of all, the performance of the ion thruster after working for a long time is tested on the basis of the simulation space condition of the test equipment, and accordingly actual results of the service life of the ion thruster can be obtained, and real and reliable test data are provided for evaluation of the service life and the reliability of the thruster. Main performance parameters of the ion thruster in the whole service life can be obtained through substantive tests in the test process, and the change rule of the performance parameters of the thruster along with accumulative working time is further obtained; the basis for long-service-life working and application of the ion thruster is provided, and essential data can be obtained for more effective acceleration tests of the iron thruster in future. The test method is effective and reliable, and the economic cost and the time cost of the service life test are greatly lowered.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

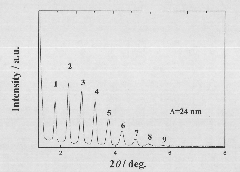

Novel super-hard TiB2/c-BN nano multi-layer film prepared by magnetron sputtering technique

InactiveCN101798678AProof of independenceThe test data is accurate and reliableLayered productsVacuum evaporation coatingSlice thicknessFrictional coefficient

The invention provides a novel super-hard TiB2 / c-BN nano multi-layer film, a method for preparing the same and application thereof, wherein the method comprises the followings steps of: depositing 40 to 70 nanometers of TiB2 serving as a transitional layer on an Al2O3(111) substrate, and alternately depositing h-BN and TiB2 to prepare a nano multi-layer film, wherein the layer thickness in each modulation period is 20 to 25 nanometers, the modulation period of the multi-layer film is 8 to 32 layers, the total layer thickness is 500 and 800 nanometers, and a modulation ratio of the h-BN to the TiB2 is 1:3 to 1:16. The novel super-hard TiB2 / c-BN nano multi-layer film has the desirable comprehensive characteristics of high hardness, low internal stress, small frictional coefficient and high film-substrate bonding strength; and the novel super-hard TiB2 / c-BN nano multi-layer film has important application prospects in surface strengthening films of knife blade tools and dies.

Owner:TIANJIN NORMAL UNIVERSITY

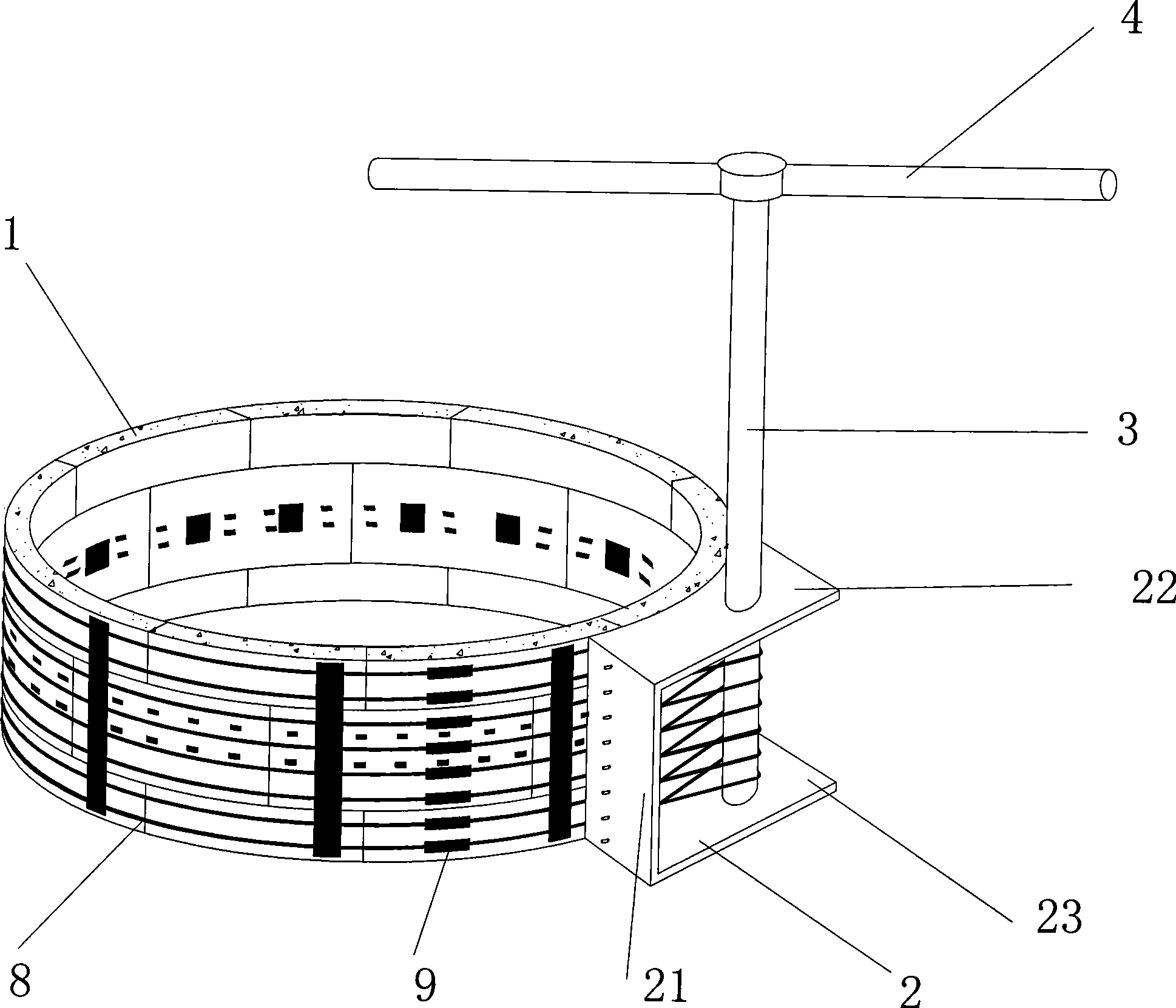

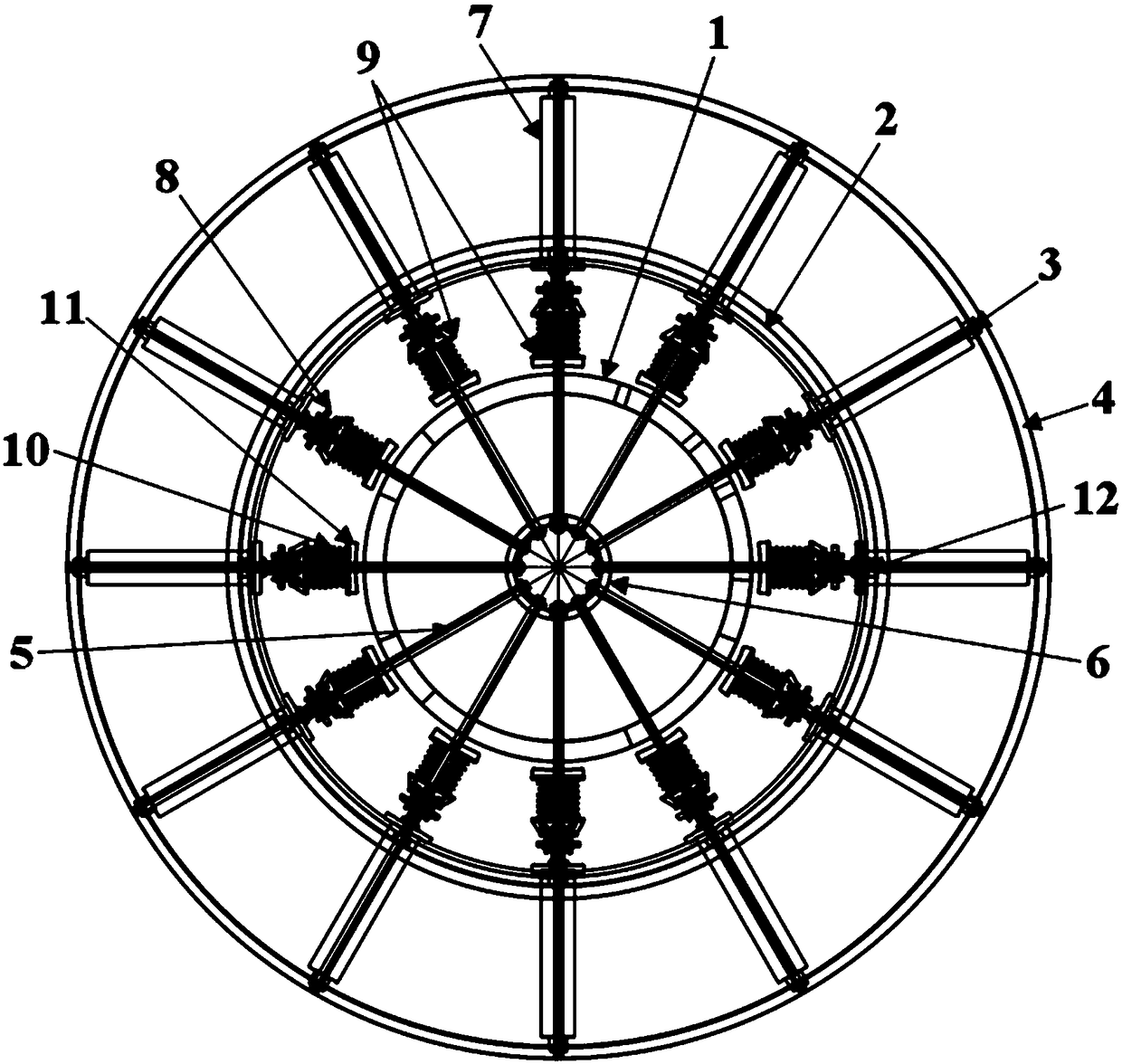

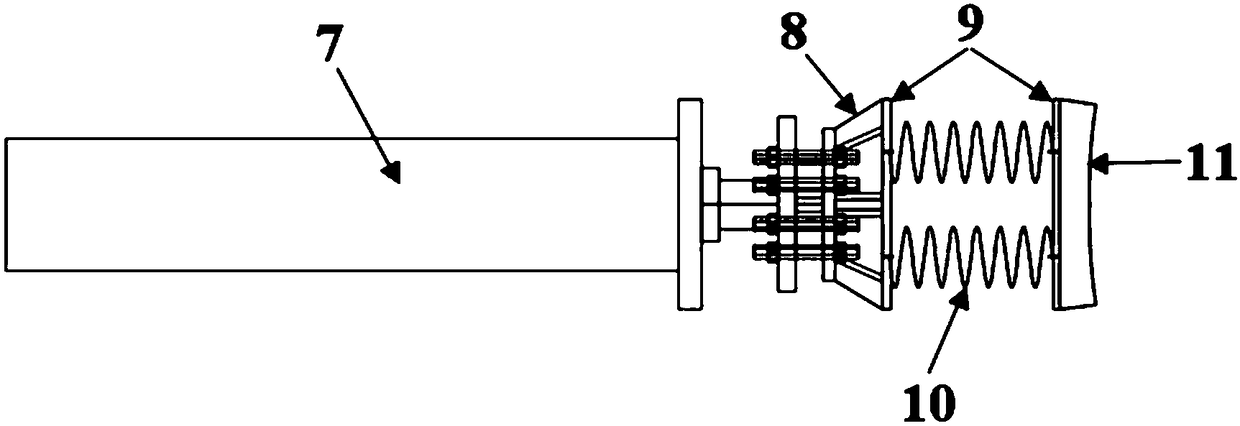

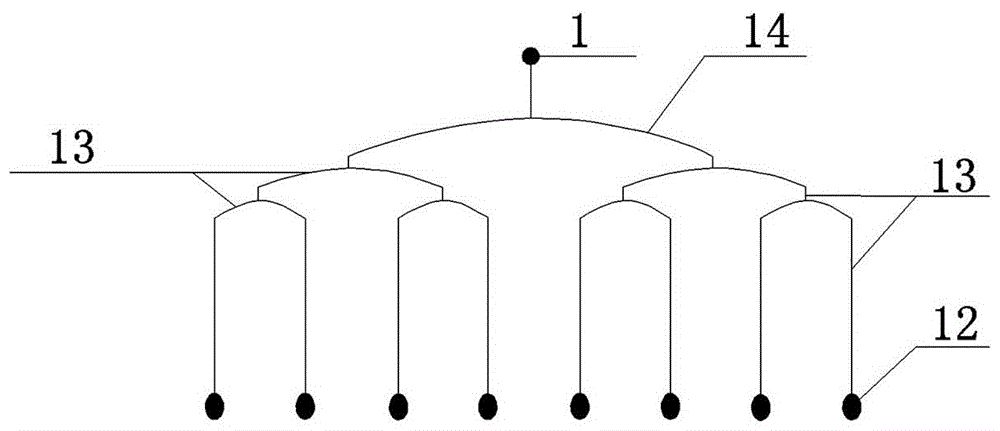

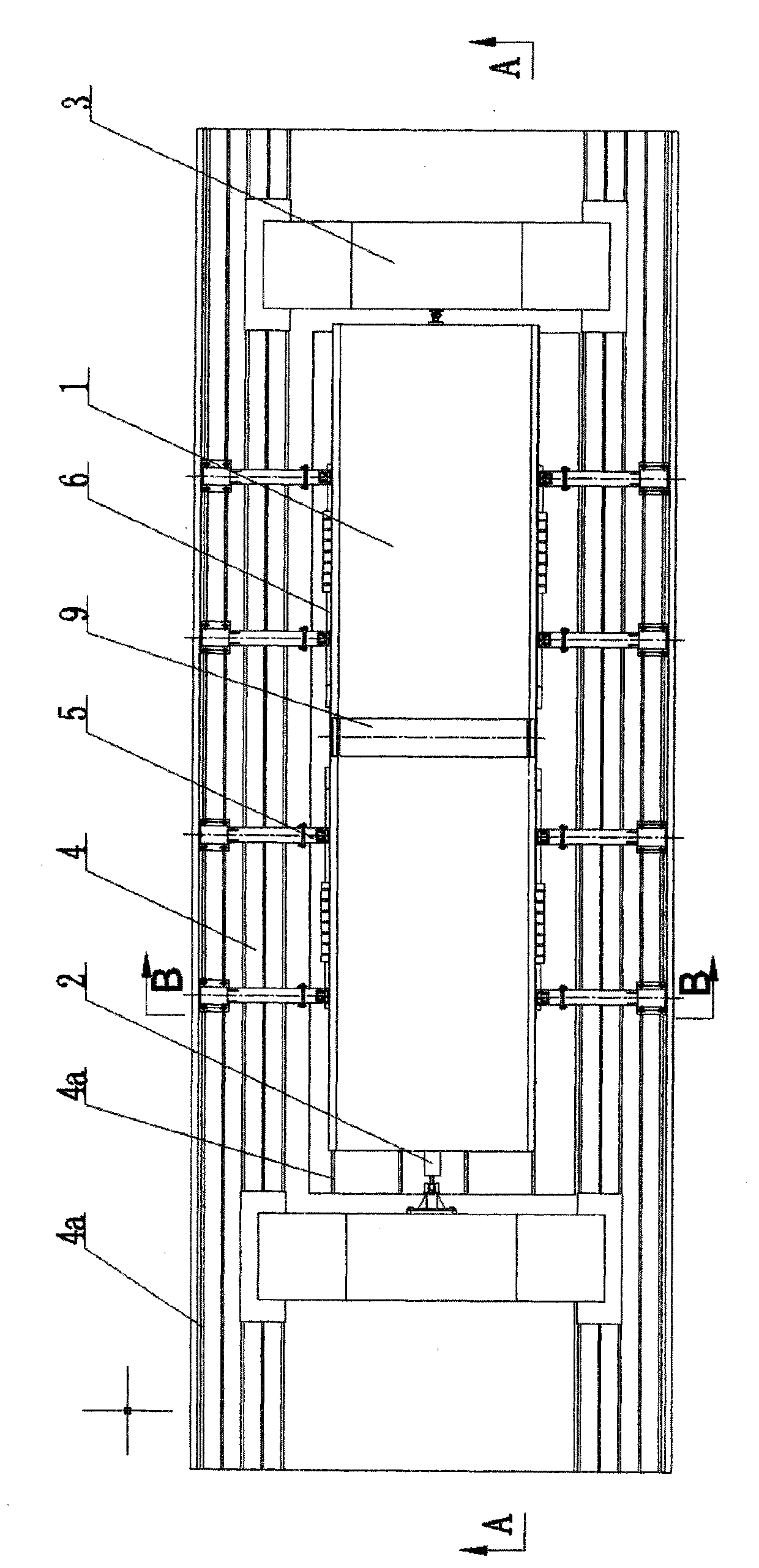

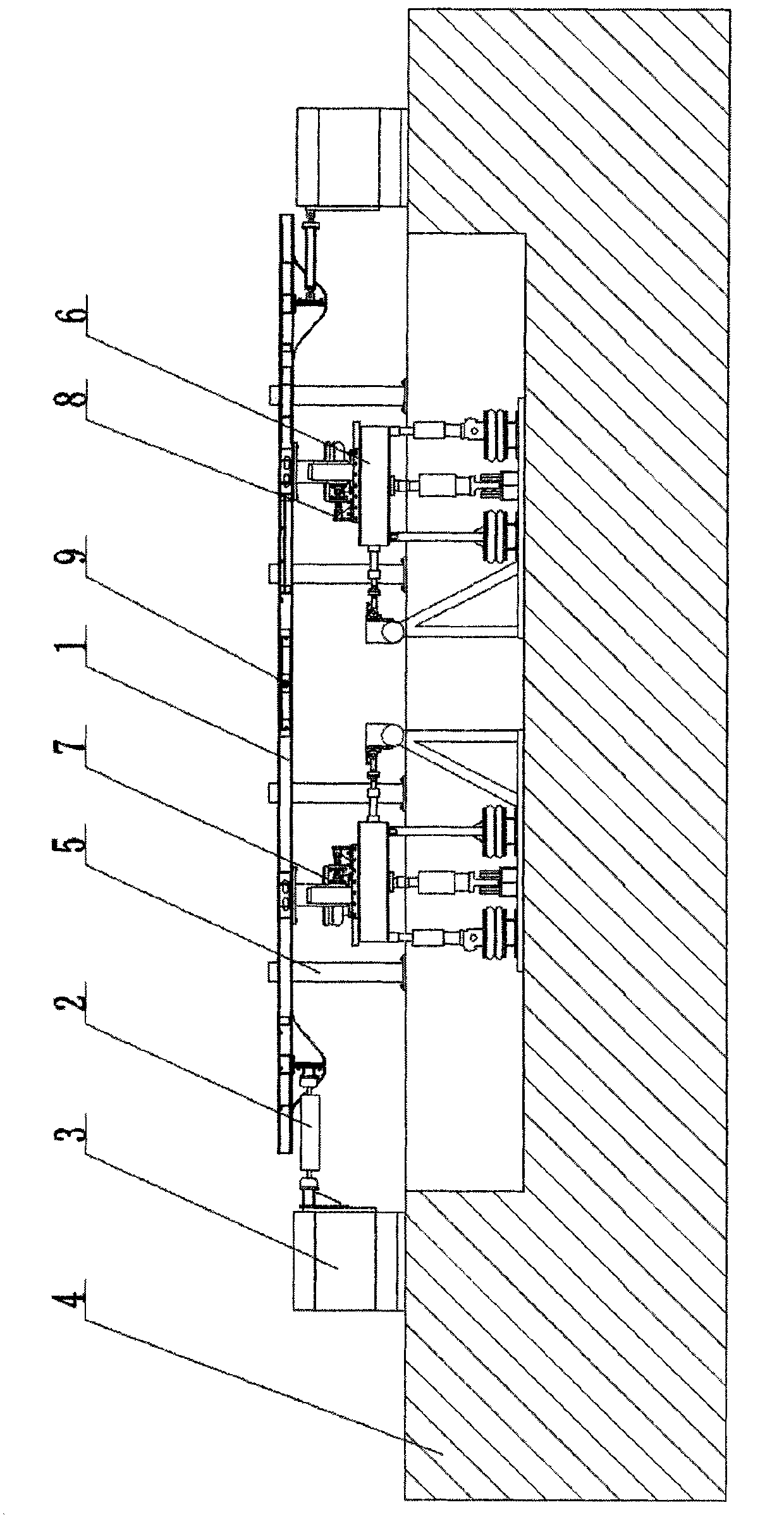

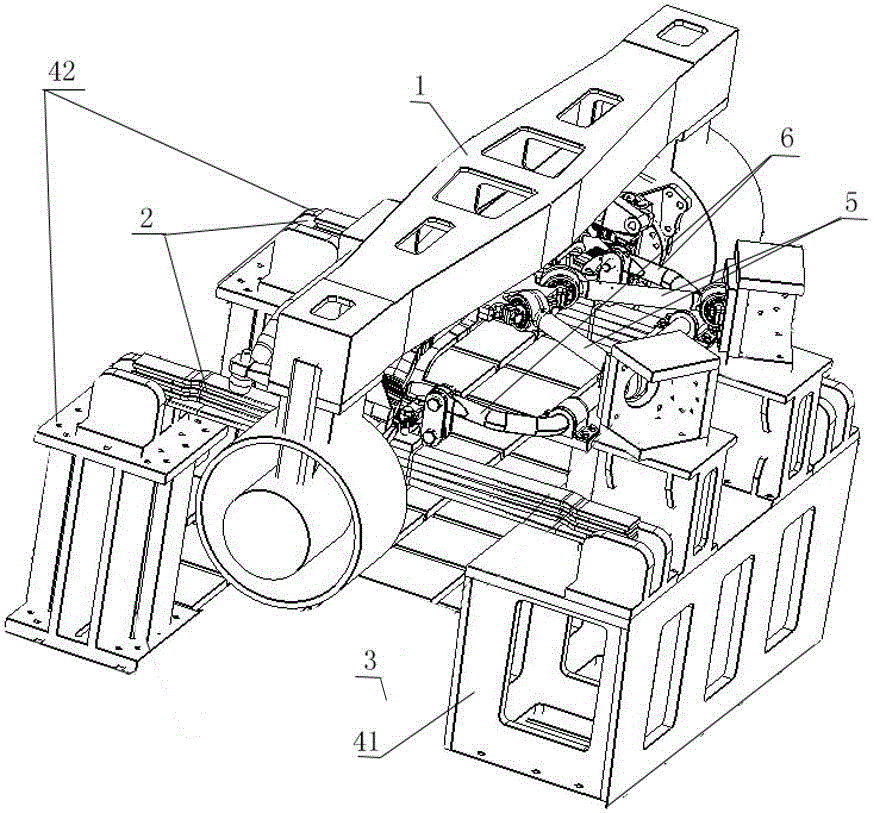

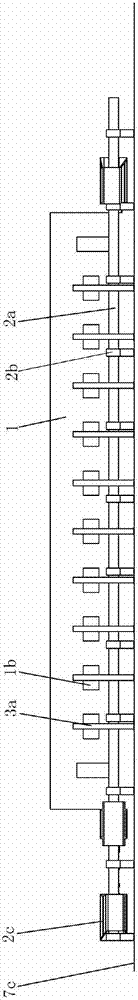

Stratum simulation and loading test device used for multi-ring shield tunnel structure

ActiveCN109269900AThe test data is accurate and reliableFully simulate the stress stateMaterial strength using tensile/compressive forcesComputer moduleEngineering

The invention relates to a stratum simulation and loading test device used for a multi-ring shield tunnel structure. The device includes a self-balancing load bearing module and stratum simulation andresistance loading modules. The self-balancing load bearing module includes a hoop beam, a circular baffle, a center ring and standing columns. The hoop beam, the circular baffle and the center ringare concentrically arranged to form an outer-medium-inner three-layer load bearing framework. The standing columns are multiple, and are uniformly fixed onto the hoop beam. The standing columns, the circular baffle and the center ring are fixedly connected through pulling rods. The stratum simulation and resistance loading modules are multiple, and are arranged in matching with the standing columns. Each stratum simulation and resistance loading module includes a jack, a rigid thruster and a load distribution unit. One end of the jack is connected with a standing column, and the other end is connected with the circular baffle, the rigid thruster and the load distribution unit in turn. Compared with the prior art, the device has advantages such as the advantages that jack thrust can be converted into uniformly distributed loads, and stress performance and reinforcement effect tests of various-structure shield tunnels can be simulated.

Owner:TONGJI UNIV

Multifunctional micro-fluidic chip used for simultaneous screening of multiple drugs and cells

ActiveCN106497771AHigh research valueImprove economyBioreactor/fermenter combinationsCompound screeningCell cavityControl channel

The invention provides a multifunctional micro-fluidic chip used for simultaneous screening of a plurality of drugs and cells, belonging to the technical field of micro-fluidic chips. The multifunctional micro-fluidic chip used for simultaneous screening of a plurality of drugs and cells is composed of an upper PDMS micro-valve-controlled channel layer, a middle PDMS fluid channel layer and a lower glass substrate layer exerting supporting and cell attaching effect, wherein the PDMS micro-valve-controlled channel layer comprises a first micro-valve group and a second micro-valve group; the PDMS fluid channel layer comprises an array cell culture zone; and the PDMS fluid channel layer undergoes thermal bonding and is then integrated with the glass substrate layer through plasma bonding. The array cell culture zone is composed of a plurality of culture units and multiple stages of branch fluid sample introduction channels; the first micro-valve group is composed of linked micro-valves; and the second micro-valve group is composed of a plurality of independent micro-valves used for controlling connection and disconnection of a sample introduction port in a cell cavity with an S-shaped bent channel.

Owner:浙江弘瑞医疗科技有限公司

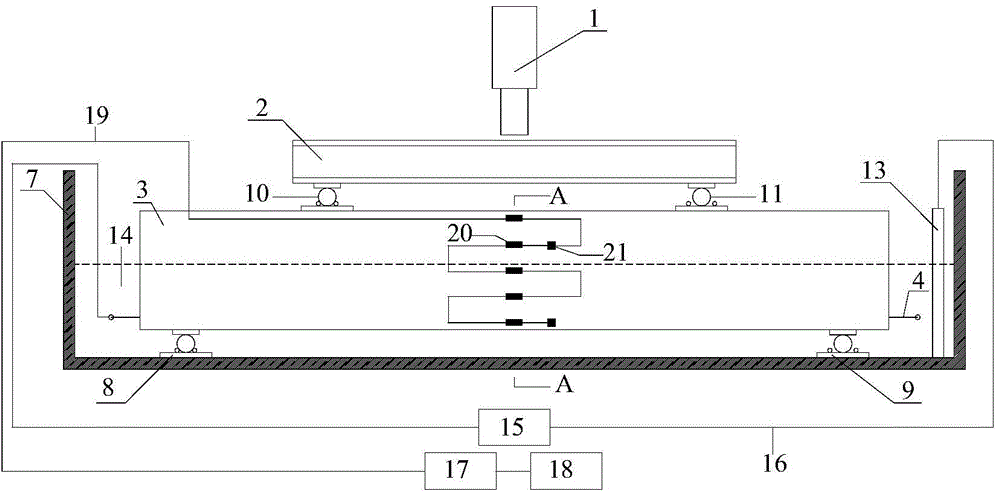

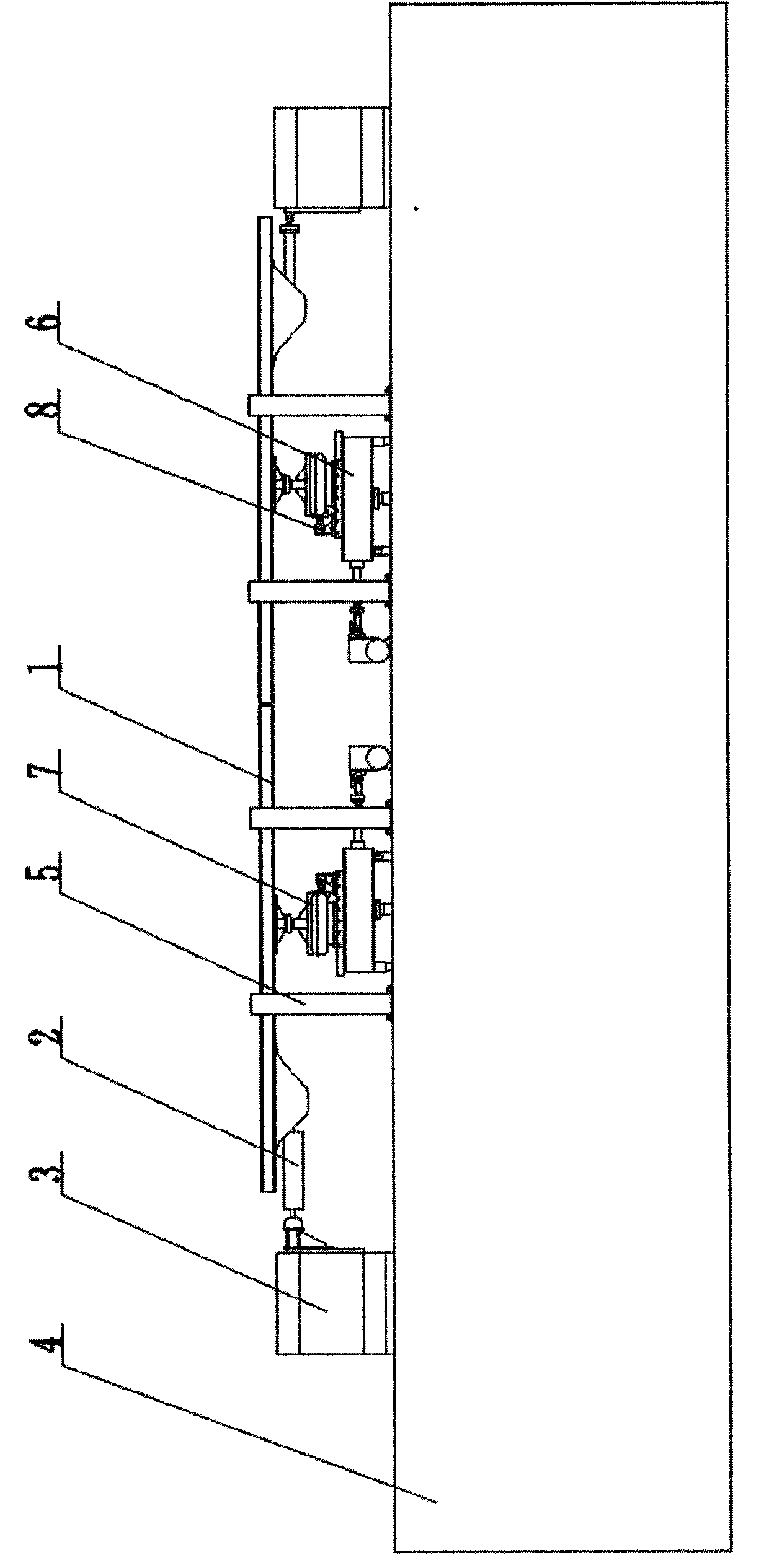

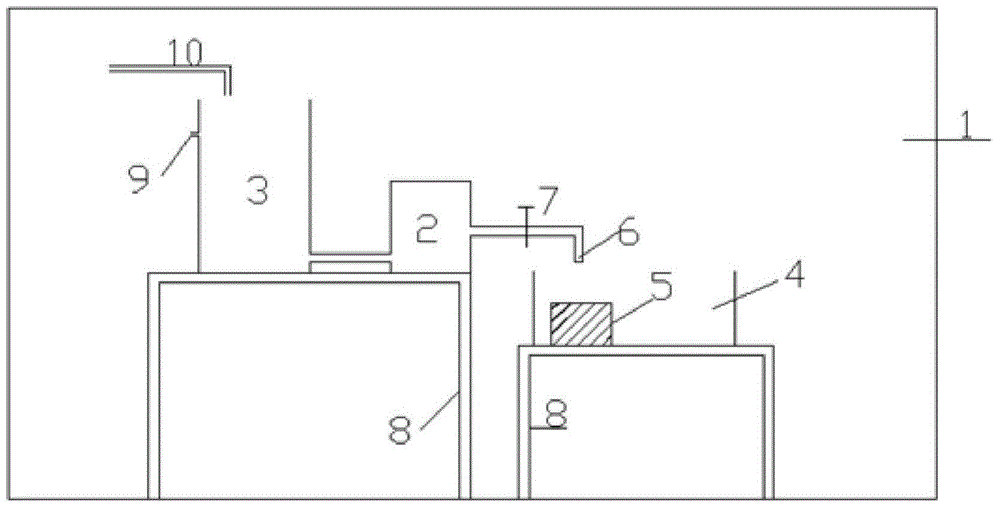

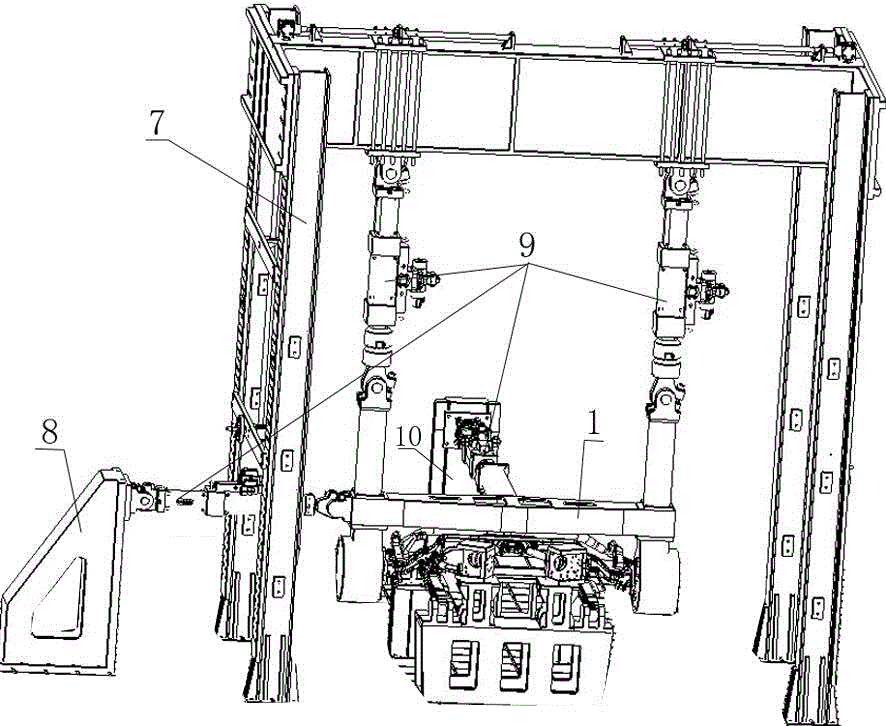

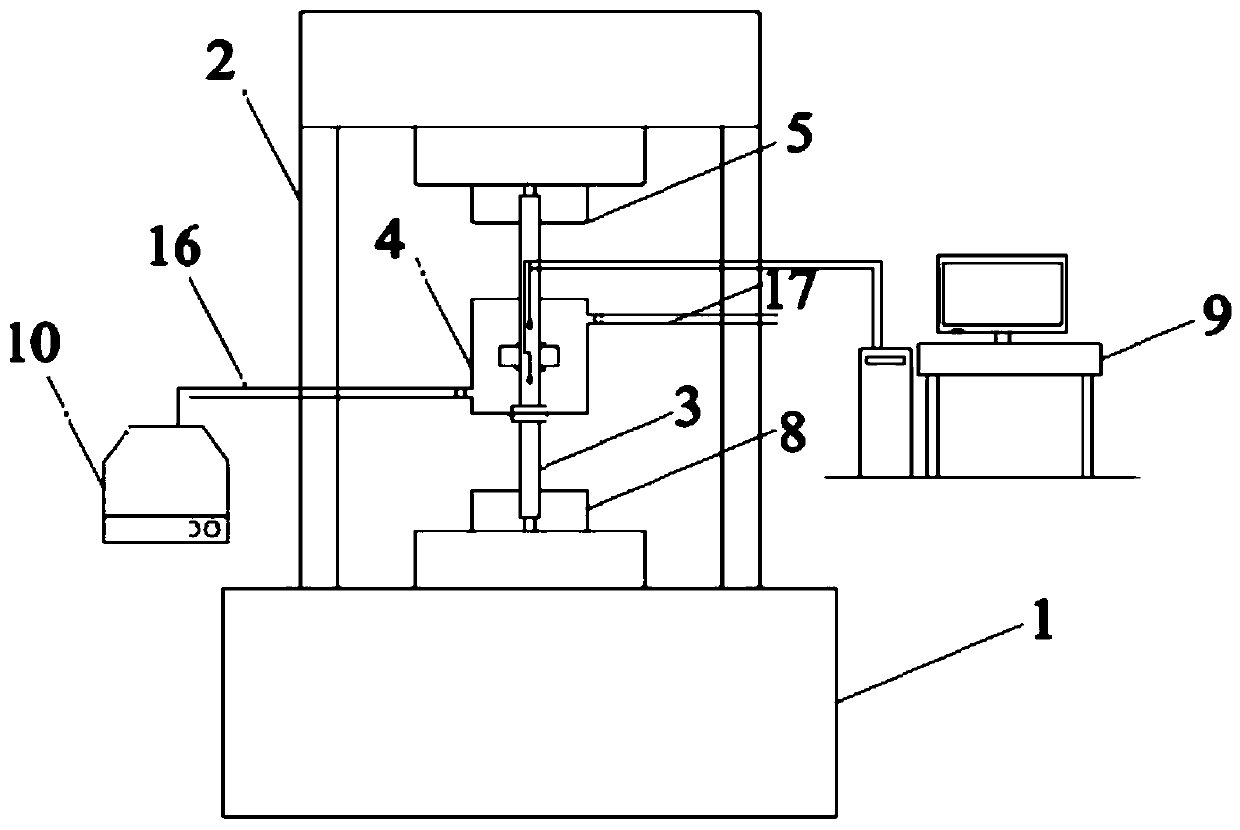

Train body chassis fatigue strength test bed and testing method

ActiveCN104215466AStrong targetingReduce testing costsRailway vehicle testingTest efficiencyEngineering

The invention discloses a train body chassis fatigue strength test bed and a testing method. The test bed comprises a train body chassis (1) for the testing and an actuator (2) used for fixing the two ends of the chassis (1), wherein the other end of the actuator (2) is fixed on a counter-force base (3); the counter-force base (3) is fixed on the end part of a basin-shaped foundation (4); the chassis (1) is placed on a support device (5); the support device (5) is fixed on the two sides of the basin-shaped foundation (4); a six-freedom vibration excitation device (6) is arranged inside the basin-shaped foundation (4); a vertical loading device (7) and a dragging device (8) are fixed on the upper part of the six-freedom vibration excitation device (6); the other ends of both the vertical loading device (7) and the dragging device (8) are respectively connected with the chassis (1). The test bed can finish the fatigue strength test of one train body chassis or the fatigue strength test of two train body chassis, and is low in test cost, high in test efficiency, and more real and more reliable in test result.

Owner:CHINA RAILWAYS CORPORATION +1

Scouring freeze-thaw splitting test method for porous asphalt mixtures

ActiveCN104406868AEasy to useReasonable designMaterial strength using repeated/pulsating forcesPorous asphaltMaterials science

The invention discloses a scouring freeze-thaw splitting test method for porous asphalt mixtures. The method comprises the following steps: firstly, performing grading and asphalt-aggregate ratio design on the porous asphalt mixtures, blending the porous asphalt mixtures indoors and forming test pieces; secondly, randomly equally dividing the test pieces into two groups, directly performing a splitting test on the first group of test pieces, scouring the surfaces of the second group of test pieces under the corresponding pressure intensity for the corresponding time according to the actual vehicle speed and pavement design traffic volume, performing a freeze-thaw test, and after the scouring freeze-thaw circulation is finished twice, performing the splitting test; finally, comparing the average splitting strength of the second group of test pieces with that of the first group of test pieces. According to the method, whether the design of the porous asphalt mixtures is reasonable or not can be judged and the water stability of different porous asphalt mixtures can be compared; also, an actual pavement sample can be analyzed, the performance of pavement materials in different service stages can be judged, the basis can be provided for developing pre-maintenance measures of pavement performance, and the long-term service performance of the pavement can be guaranteed.

Owner:SOUTHEAST UNIV

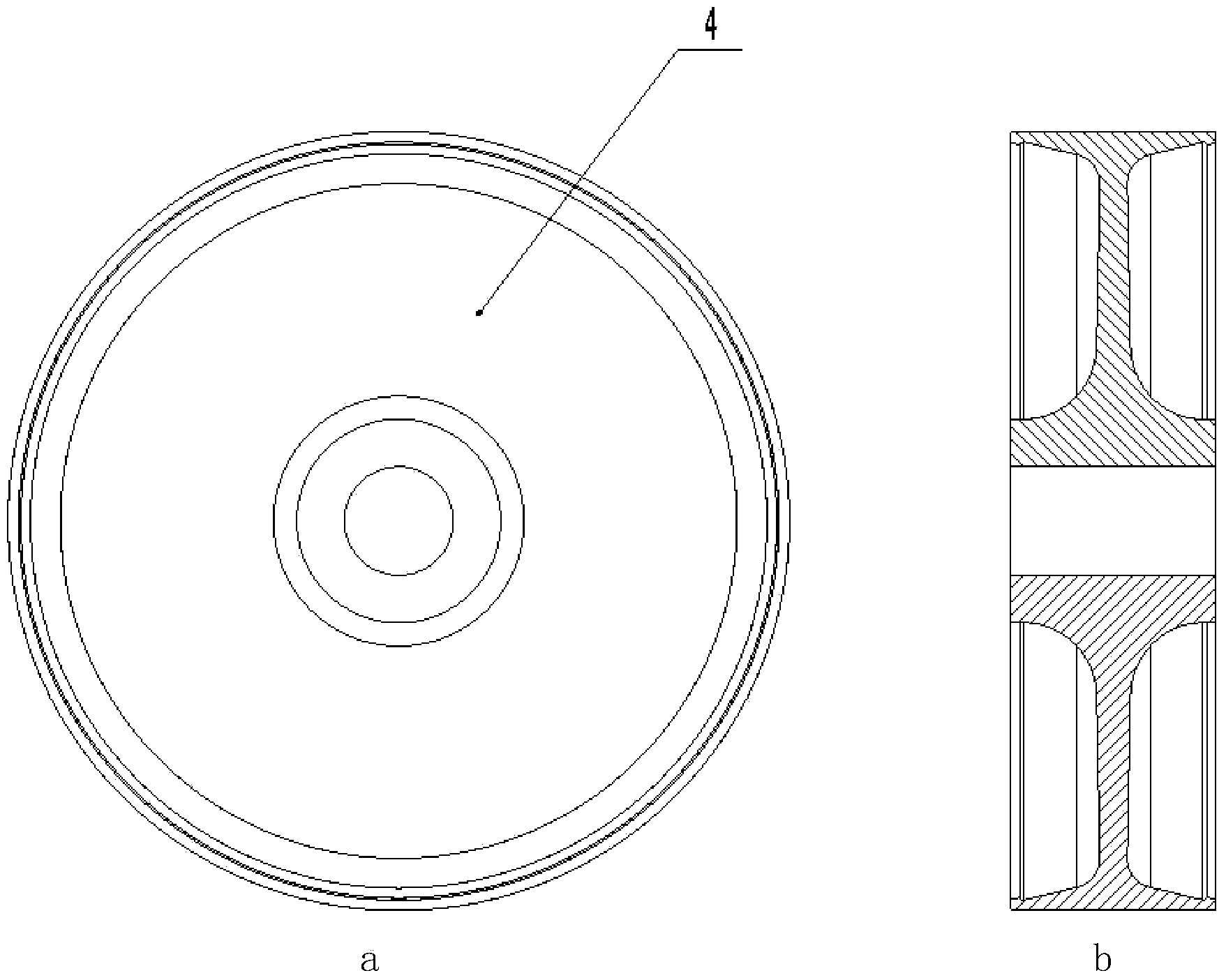

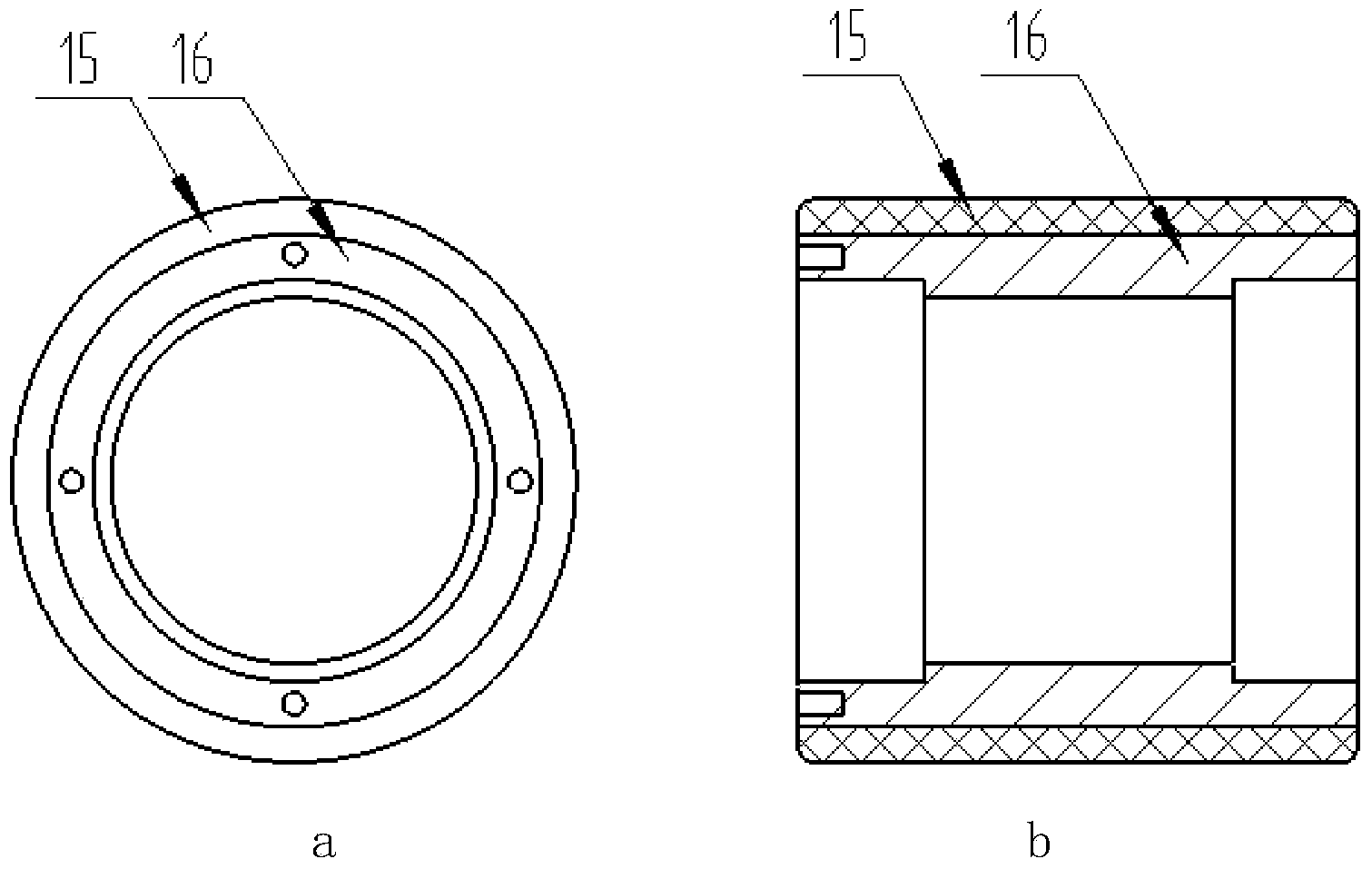

Drive unit for rotating outer ring and fixing inner ring of airplane wheel bearing

The invention relates to a drive unit for rotating an outer ring and fixing an inner ring of an airplane wheel bearing. The drive unit is composed of a motor, a clutch, bearing seats, a drum wheel, a wheel axle and a coupler. The wheel axle is installed at the two bearing seats; and one end of the wheel axle is connected with a flange arranged at one end of the clutch by the coupler. The drum wheel is installed at the wheel axle by a key and is between the two bearing seats; and the external circumferential surface of the drum wheel rubs against the circumferential surface of a rubber wheel installed at a loading device in a cooperative mode. The rubber wheel is sleeved at the outer ring of the tested bearing. A brake plate is fixed at one end surface of the rubber wheel by a flange; and the braking disc of the brake plate is arranged at a braking clamping plate of a brake. The upper end of the brake is fixed at the lower surface of a loading substrate of the loading device. According to the invention, the working situation of the wheel bearing of the airplane in a sliding state can be simulated; and the bearing load is large and the rotating speed is fast. Therefore, the provided drive unit can be applied to various bearing testing machines.

Owner:XIAN AVIATION BRAKE TECH

Test tool for steel plate spring suspension system and test method thereof

ActiveCN105865813AGuarantee factory qualityEnsure user safetyVehicle suspension/damping testingSteel platesEngineering

Owner:东风汽车底盘系统有限公司

Car body intensity fatigue and airtight fatigue test stand

ActiveCN103091117AReduce testing costsEasy to testRailway vehicle testingFluid-tightness measurement using fluid/vacuumAir springEngineering

Disclosed are car body intensity fatigue and an airtight fatigue test stand. The car body intensity fatigue and the airtight fatigue test stand comprise a car body tested for a train, a longitudinal loading device, a vertical loading device and a plurality of shock excitation devices installed below the car body. The shock excitation devices are six degree of freedom shock excitation devices. The six degree of freedom shock excitation devices, the longitudinal loading device and the vertical loading device are installed in a pit through a vibration isolation device. Air vents of the car body are connected with an airtight device. The vibration isolation device specifically comprises a rectangular basin shaped base inner bottom is connected with base plates of the six degree of freedom shock excitation devices through a T-typed guiding rail. The longitudinal loading device and the vertical loading device are fixed on the upper surface of a side edge of the base. The side edge of the base is connected with a wall of the pit through a buffering rubber-metal pad. The lower surface of the base is connected with a step of the pit through an air spring. Intensity fatigue test can be carried out. Full-scale car body airtight fatigue test can be completed. The car body intensity fatigue and the airtight fatigue test stand are low in testing cost, high in testing efficiency, authentic and reliable in testing results. Influences towards the surrounding environment are small when the car body intensity fatigue and the airtight fatigue test stand are tested.

Owner:CHINA RAILWAYS CORPORATION +1

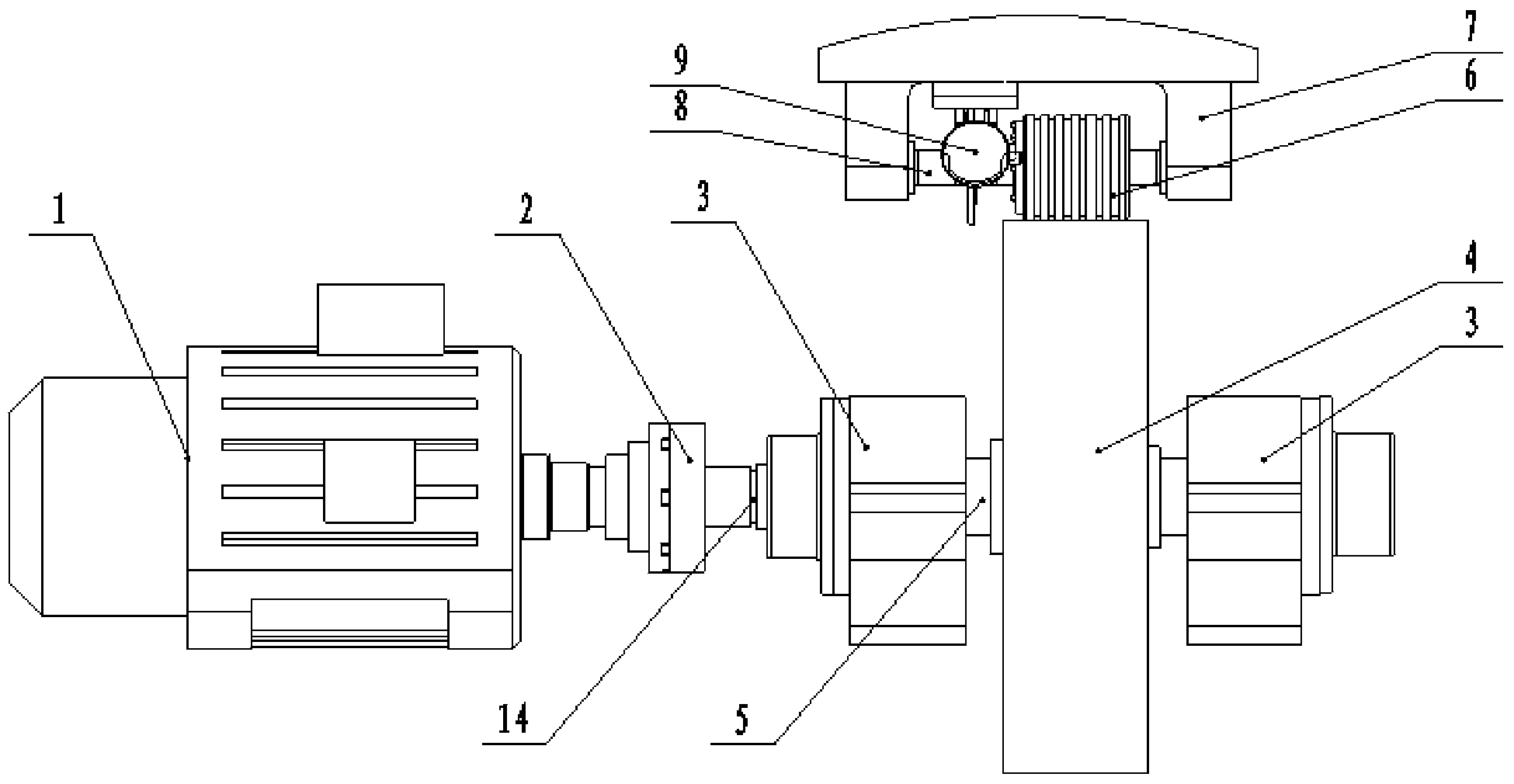

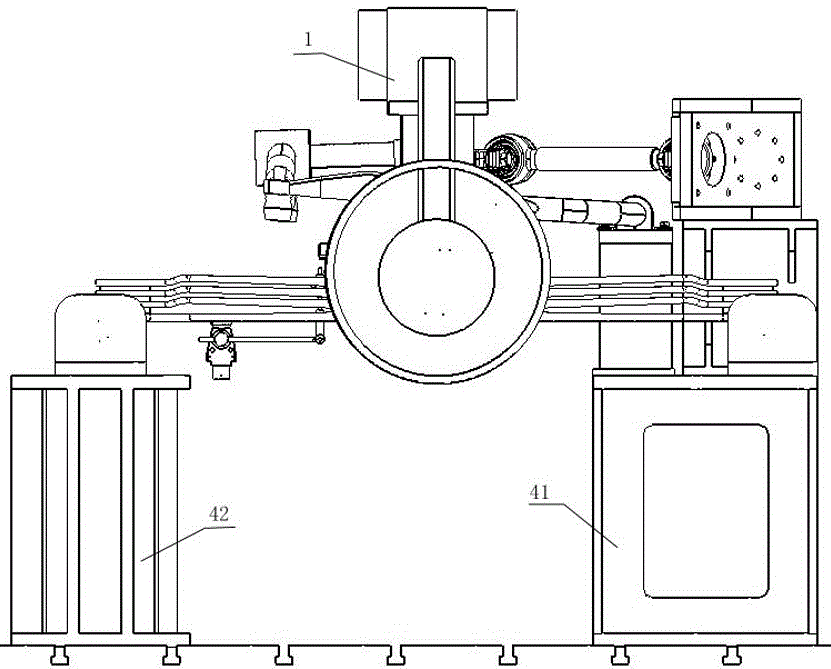

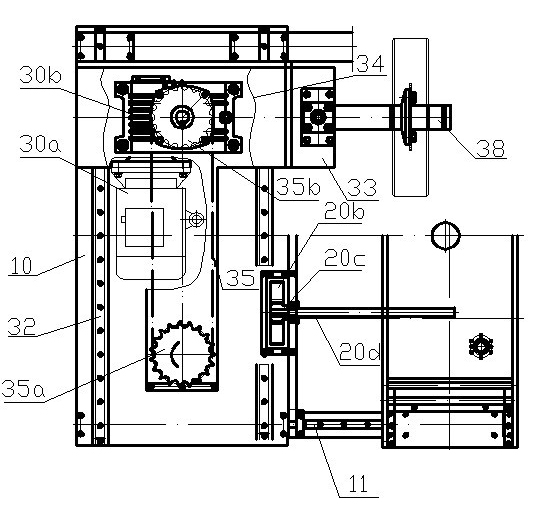

Indoor grinding and forming instrument of bituminous mixture test specimen and forming control method thereof

InactiveCN102042923ASmooth rollingUniform densityPreparing sample for investigationHydraulic ramGrinding wheel

The invention relates to an indoor grinding and forming instrument of a bituminous mixture test specimen and a forming control method thereof. The forming instrument comprises a rack, a grinding wheel, a mould and a mould drive device, and also comprises a grinding wheel drive device; the device mainly comprises a first reducing gear, a grinding wheel support, a hydraulic ram, a first guide rail and a driving chain; the mould drive device mainly comprises a mould driving support, a second guide rail, a second reducing gear, a speed reducing elevator mechanism, an elevating platform and a horizontal screw; the grinding wheel is arranged on the grinding wheel support, the grinding wheel support is connected with the first reducing gear, the mould drive support is connected with the second reducing gear through the horizontal screw, and the speed reducing elevator mechanism is fixed on the mould driving support and connected with the elevating platform. The method comprises the steps of:setting parameters, judging whether a starting position is reached or not, applying a grinding force, comparing a pressure value with a set value, grinding with the grinding wheel, judging whether one round of grinding is ended or not, and the like. The grinding and forming instrument has the advantages of high simulation degree, high automation degree and wide application range.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD +1

Column support full-size steel reinforced concrete two-way slab fire-resistant tester and its implementing method

InactiveCN101477109AVersatilityReal-time temperature monitoringMaterial testing goodsReinforced concreteFire test

The invention provides a testing device for testing the fire resistance of a column support full-scale reinforced concrete two-way slab and an implementation method thereof. The testing device mainly comprises a furnace body, a support column, a counterforce loading device and a data acquisition system, wherein the furnace body is arranged under a reinforced concrete two-way slab; the counterforce loading device is arranged above the reinforced concrete two-way slab; the reinforced concrete two-way slab is arranged on the support column; and the data acquisition system is arranged on the reinforced concrete two-way slab and the furnace body. The testing device can carry out better fire test of the column support full-scale reinforced concrete two-way slab to simulate actual fire to carry out fire-tolerant test, test the fireproof limit of the column support full-scale reinforced concrete two-way slab and carry out research on the working mechanism of the slab in fire; therefore, the testing device provides a basis for structural design based on fire safety.

Owner:HARBIN INST OF TECH

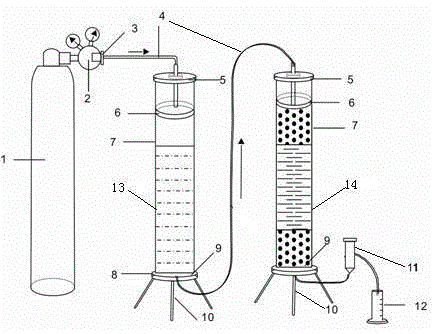

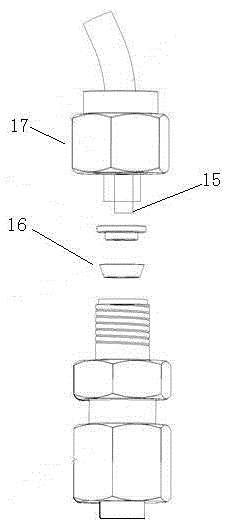

Underground water contaminant movement simulation device on transfluence condition and using method

The invention discloses an underground water contaminant movement simulation device on the transfluence condition and a using method, and belongs to the technical field of underground water contamination simulation instrument equipment. The underground water contaminant movement simulation device comprises a pressure supply unit, a water supply unit, an earth pillar unit and a sample receiving unit. The pressure supply unit comprises a pressure air cylinder, and a pressure reducing valve is arranged at an outlet of the pressure air cylinder. The water supply unit comprises a closed organic glass pillar I capable of bearing pressure. The earth pillar unit comprises an organic glass pillar II capable of bearing pressure. A simulated earth pillar is arranged inside the organic glass pillar II. The top and the bottom of the simulated earth pillar are water-bearing layer settlings, and the middle of the simulated earth pillar is weak water permeable layer settling media. The sample receiving unit comprises a water stabilizing tank and a sampler with scale marks. The pressure reducing valve, the organic glass pillar I and the organic glass pillar II are sequentially connected through guiding pipes. The organic glass pillar II, the water stabilizing tank and the sampler are sequentially communicated through guiding pipes. The high water head difference supplied by underground water transfluence and the reducing environment of the weak water permeable layer are provided, the transfluence water head difference is 0-15 cm, operation is easy, adjustment is convenient, and test data is more accurate and reliable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

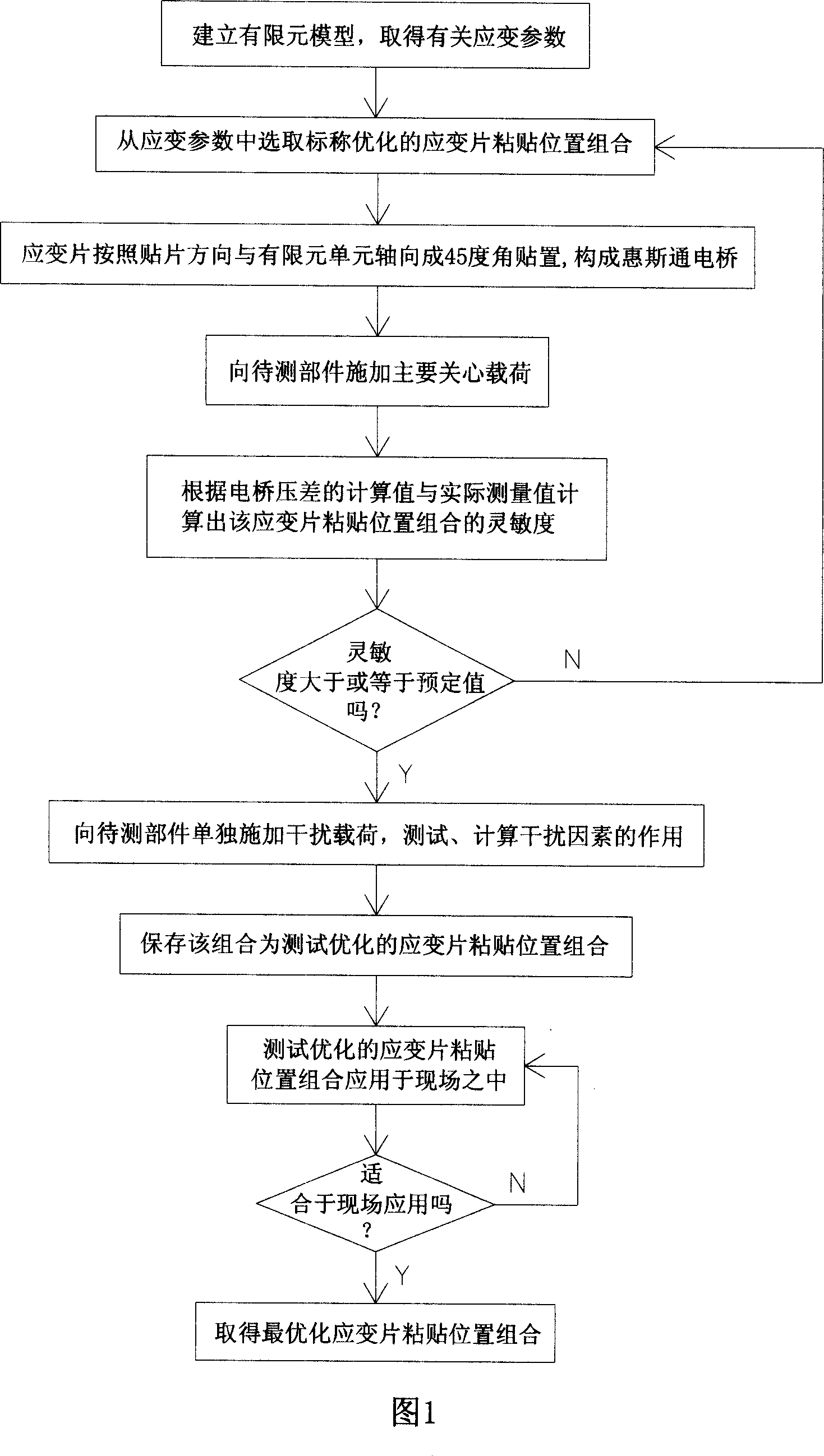

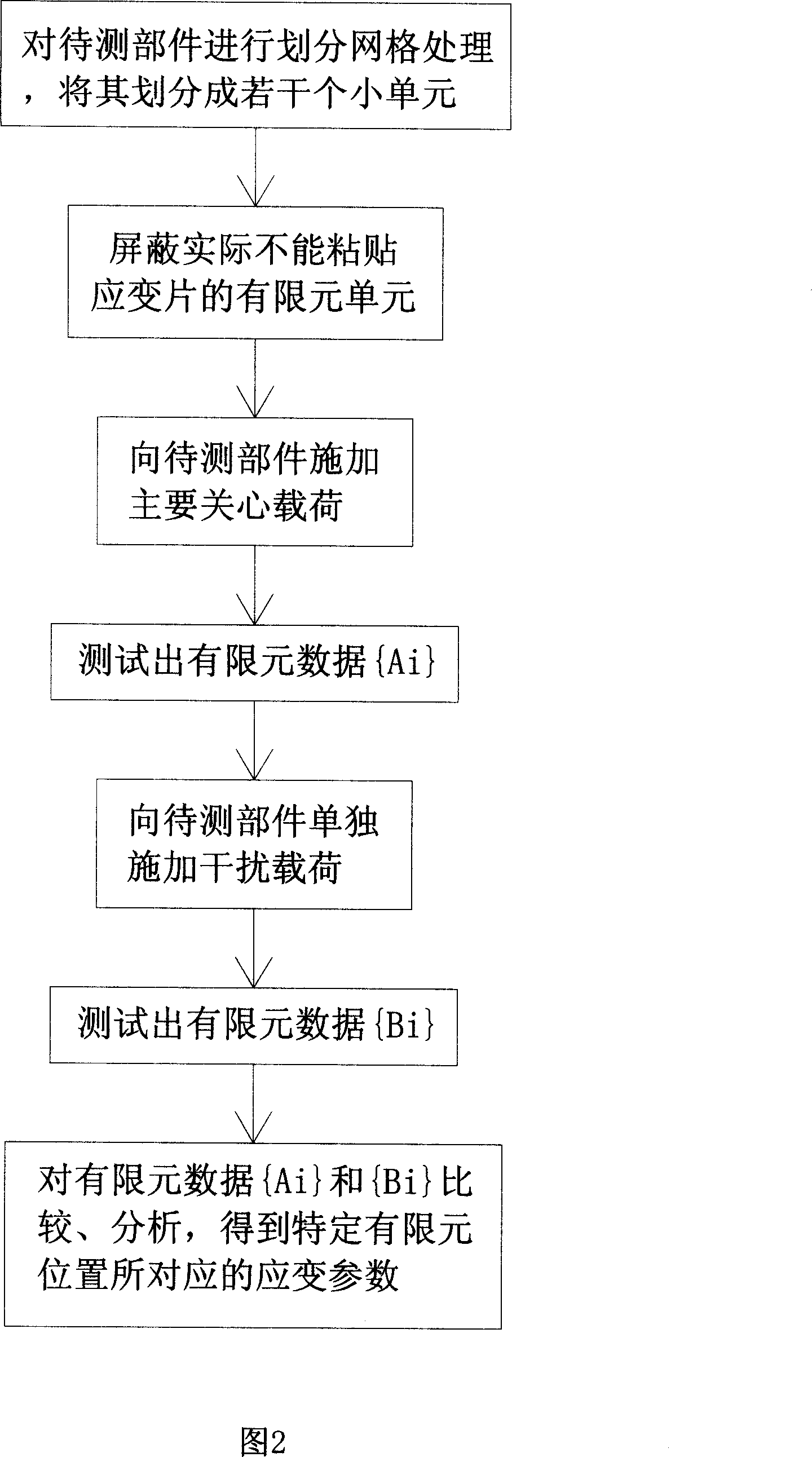

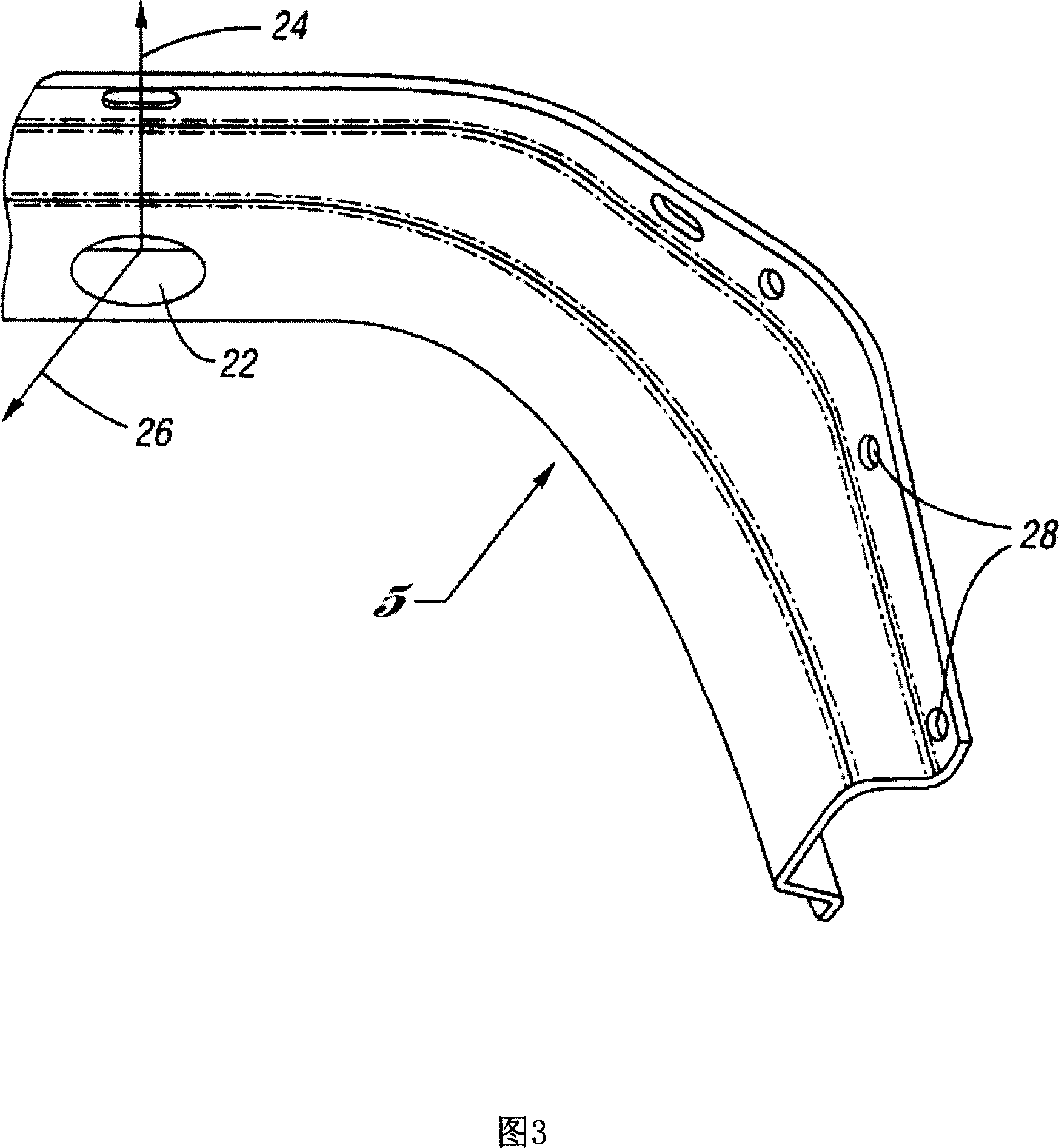

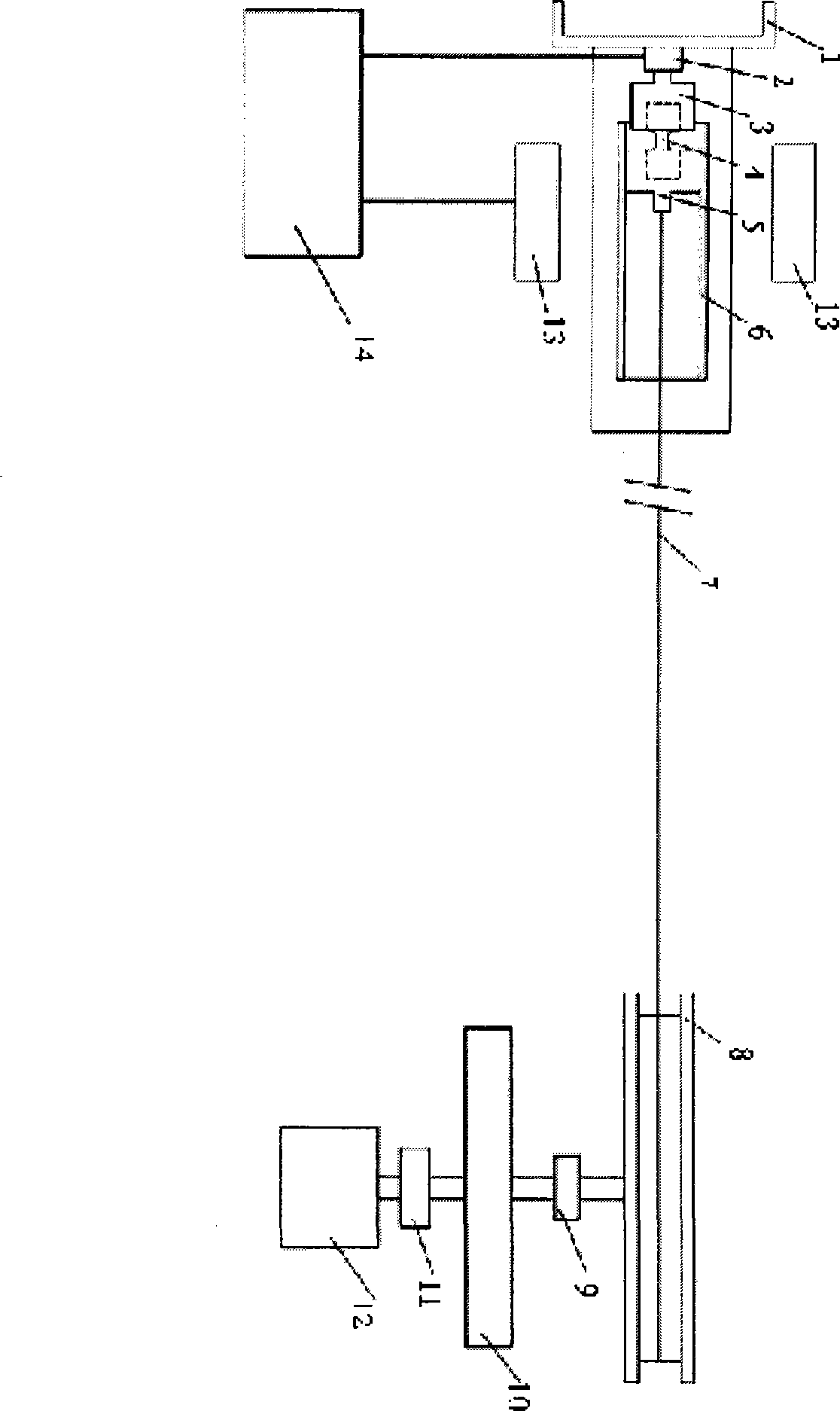

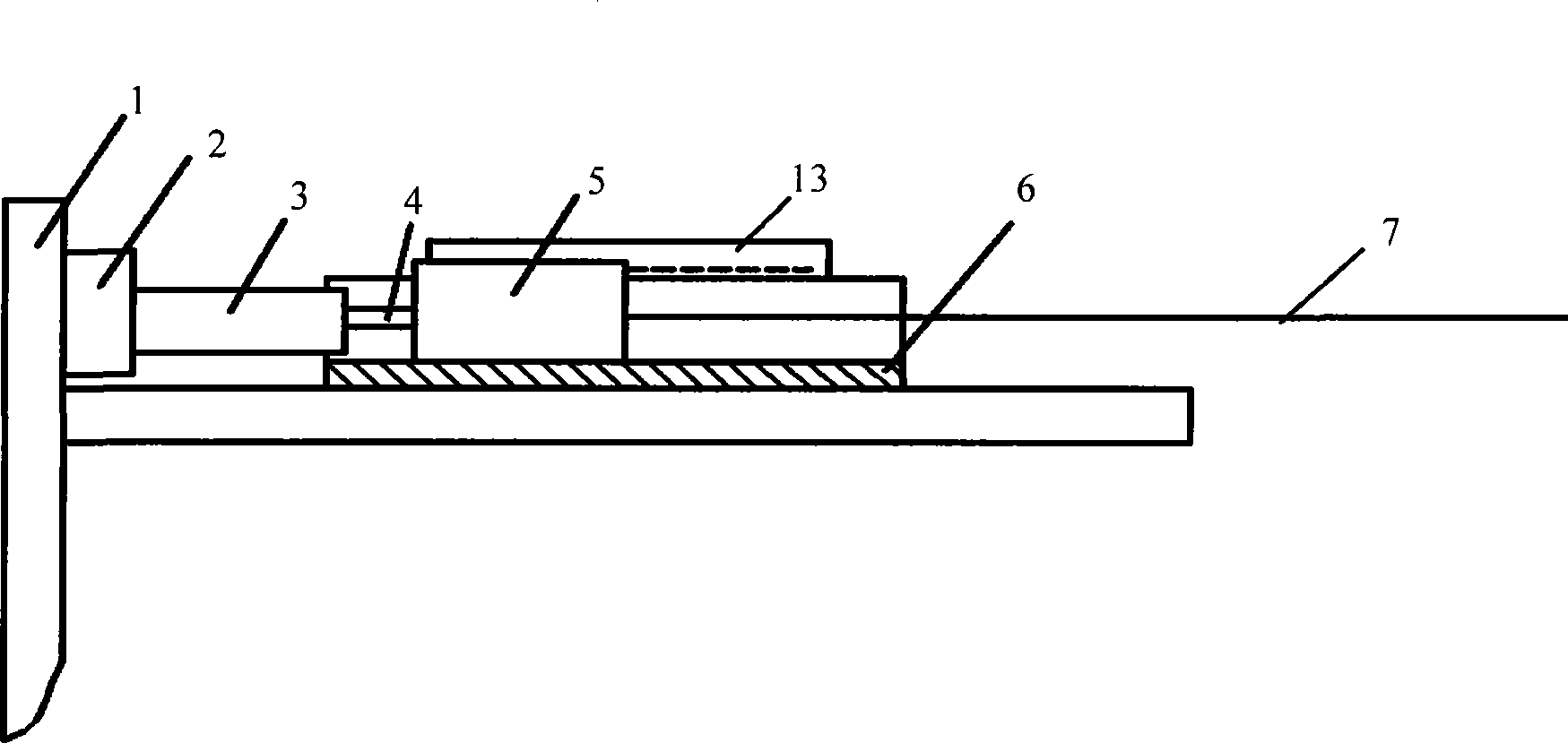

Force-measuring sensing method

InactiveCN1940514AAccurate correctionEliminate additional errorsWeighing apparatus using elastically-deformable membersForce measurementEngineeringStrain gauge

A method for testing force-sensing includes analyzing finite element of component to be tested to obtain strain parameter of finite element, selecting out nominal optimized sticking-position combination of strain foil gauge from said strain parameters, sticking strain foil gauges on positions listed in said sticking-position combination as per specific angle to form Wheatstone bridge, lading electric charge on component to be tested and comparing calculated bridge voltage difference with actually measured bridge voltage difference and testing optimized sticking-position combination of strain foil gauge according to comparison result, applying said combination at on-site for selecting out most optimum one.

Owner:BYD CO LTD

Hyper-elastic material high-speed stretching tester and experiment method

InactiveCN101504348AThe principle is simpleSolved the problem of not being able to apply a large amount of stretch to the specimenMaterial strength using single impulsive forceExperimental methodsCoupling

The invention relates to a high-speed stretching tester for a hyperelastic material and an experimental method. A speed regulation motor (12) is connected with a mass disc (10) through a coupler (11); the mass disc is connected with a turnplate (8) through a clutch (9); and two ends of a haulage rope (7) are fixedly connected with the turnplate (8) and a front stretching clamp (5) respectively. A test sample (4) is arranged between the front stretching clamp (5) and a rear stretching clamp (3). The centerlines of the haulage rope (7), the front stretching clamp (5), the test sample (4), the rear stretching clamp (3) and a load sensor (2) are in the same plane. When the speed regulation motor (12) rotates at high rotational speed, the outer edge of the turnplate (8) coaxially connected with the speed regulation motor (12) has high linear velocity and drives the haulage rope (7) to be wound on the turnplate (8) at a high speed and simultaneously drives the test sample (4) to move along the direction of the haulage rope (7) to allow the test sample (4) to have deformation; and the high-speed stretching tester solves the problem that a Hopkinson pull rod and other loading devices are adopted and cannot apply large elongation on the test sample and has the characteristics of simple operation and reliable testing data.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

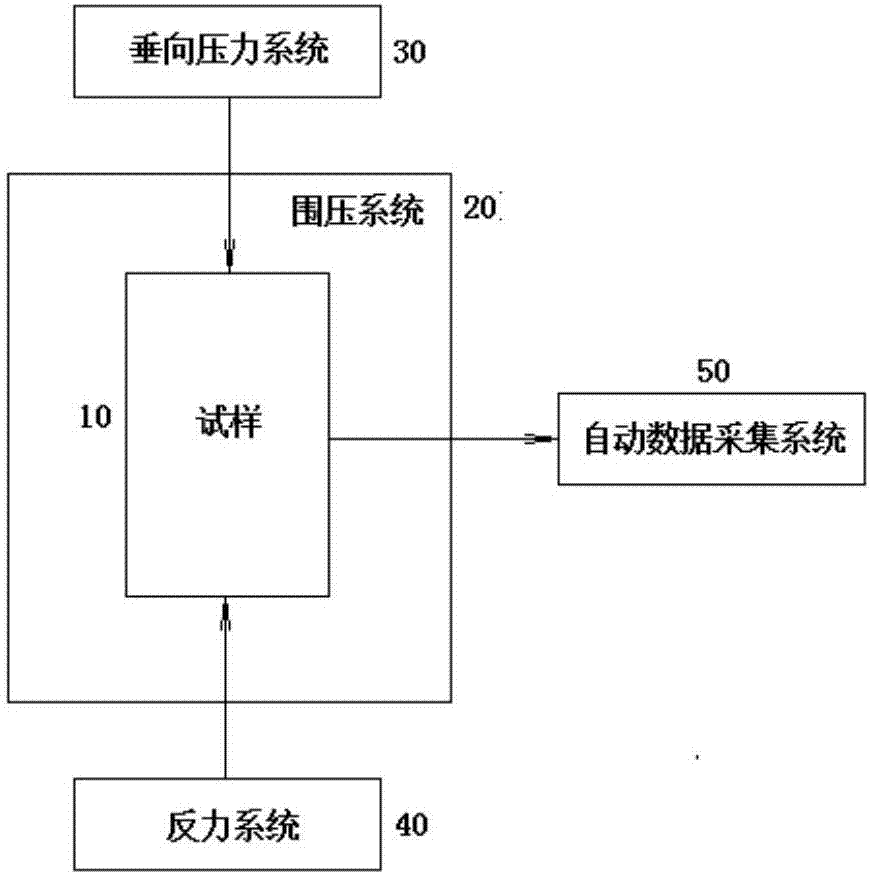

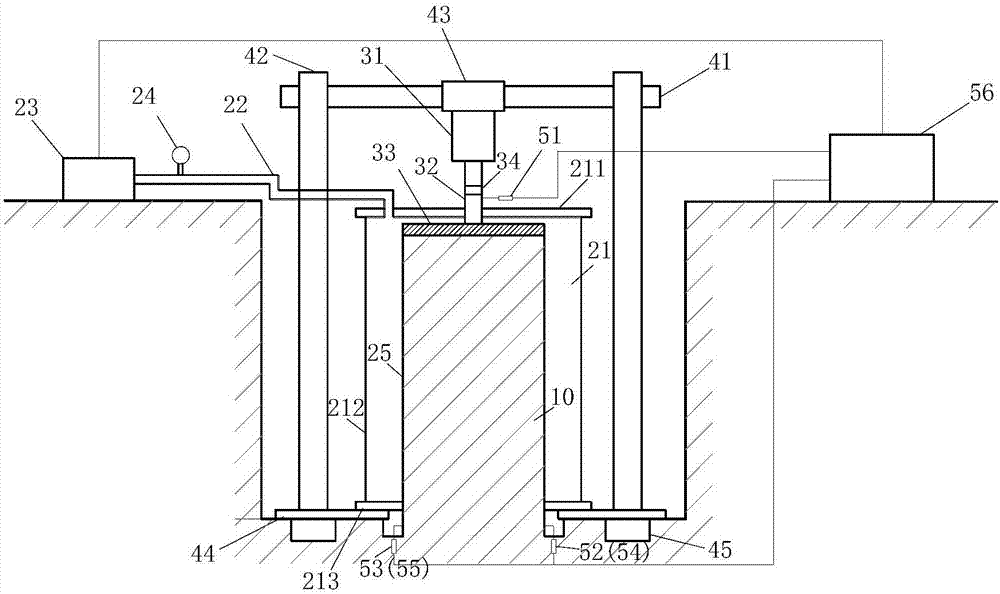

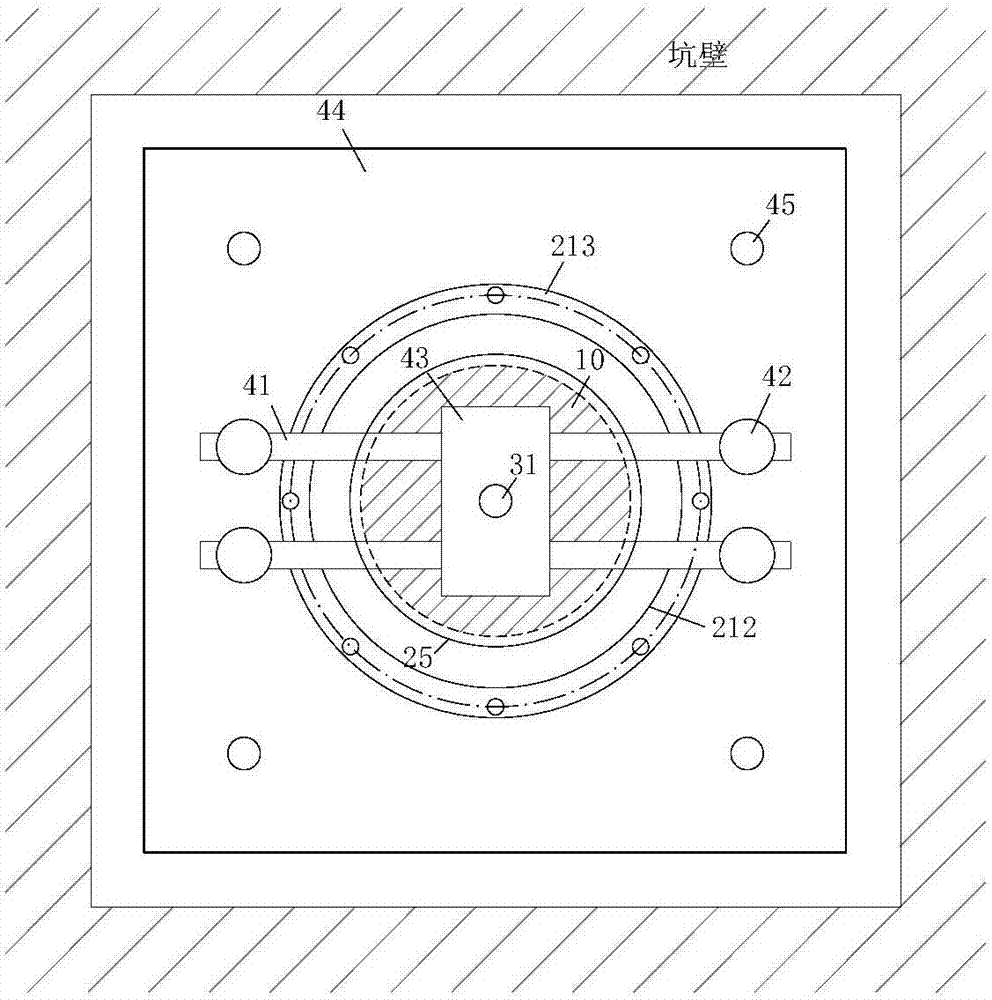

Large-scale in-situ triaxial shear test device and method thereof

PendingCN107449678AThe test data is reliableLarge sample sizeMaterial strength using steady shearing forcesStress systemTriaxial shear test

The invention discloses a large-scale in-situ triaxial shear test device and a method thereof, and belongs to the technology of mechanical property test of soil in the field of geotechnical engineering. The device comprises a sample (10), a confining pressure system (20), a vertical pressure system (30), a counterforce system (40) and an automatic data acquisition system (50); the sample (10) is arranged in the confining pressure system (20); the vertical pressure system (30) and the counterforce system (40) are respectively arranged above and below the confining pressure system (20); and a vertical displacement meter of the automatic data acquisition system (50) is arranged in the sample (10). Compared with the prior art, an original structure of the sample can be maintained; confining pressure can be applied to the sample; an in-situ stress field of a measured soil body can be reproduced; the soil body can be damaged along the weakest surface thereof; and the size of the sample is large, so that the size effect influence is reduced. The large-scale in-situ triaxial shear test device and the method thereof have the characteristics of being real and comprehensive on the issue of researching the shear strength of the soil body; and test data are reliable, and powerful guarantee is provided for design and construction in the field of geotechnical engineering.

Owner:INST OF GEOMECHANICS

Asphalt mixture aging test method

InactiveCN102735824AAccurately judge aging performanceAccurately judge its anti-aging abilityMaterial testing goodsStructural engineeringHighway engineering

The invention discloses an asphalt mixture aging test method. The method comprises the steps that: a short-term aging hot-mixed asphalt mixture sample is obtained with a hot-mixed asphalt mixture accelerated-aging method specified by highway engineering asphalt and asphalt mixture testing procedures; the short-term aging hot-mixed asphalt mixture sample is obtained, and a testing method and testing equipments same as those of a pressure-aging-vessel-accelerated asphalt aging test specified by the highway engineering asphalt and asphalt mixture testing procedures are adopted, and an asphalt mixture long-term aging test is carried out; the performances of the long-term aging hot-mixed asphalt mixture obtained by the test is compared with the performances of an original non-aged asphalt mixture, such that the aging degree of the hot-mixed asphalt mixture can be accurately determined. With the testing method provided by the invention, the performance aging condition of the asphalt mixture after long term use in an actual environment can be simulated, such that the aging performance or the anti-aging ability of the asphalt mixture can be accurately determined.

Owner:JIANGSU SHANSHUI ENVIRONMENT CONSTR GRP

Method and device for testing corrosion fatigue of welding nodes of orthotropic steel bridge deck

ActiveCN110333155AThe test data is accurate and reliableWide measurement rangeWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesData acquisitionBridge deck

The invention discloses a method and a device for testing corrosion fatigue of welding nodes of an orthotropic steel bridge deck. The method comprises: 1) assembling a corrosion environment box, manufacturing a long cross welding test piece and arranging a fiber grating sensor; 2) performing a fatigue test on the long cross welding test piece; 3) carrying out a long cross welding test piece corrosion test; 4) establishing a time matching relation of a corrosion-fatigue coupling action process; 5) installing a corrosion environment box and a water mist releaser; 6) long cross welding test piececorrosion-fatigue coupling test data acquisition. The device constructed according to the method comprises the long cross welding test piece, the corrosion environment box, the water mist releaser, afatigue testing machine, a monitoring device and corrosion paste. A device used for executing the method provided by the invention is also provided. According to the method, coupling effect of corrosive media and alternating stress is fully considered, the method is closer to the service environment of the steel bridge welding node in service, and the test data is more effective and reliable; meanwhile, the device is simple and easy to operate, convenient to operate, low in cost and easy to popularize.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com