Train body chassis fatigue strength test bed and testing method

A technology of fatigue strength and test bench, which is applied in the direction of railway vehicle testing, etc., can solve problems such as the influence of hardware facilities, no test bench, no vibration loading, etc., and achieve the effects of strong pertinence, cost saving of test, and real test data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

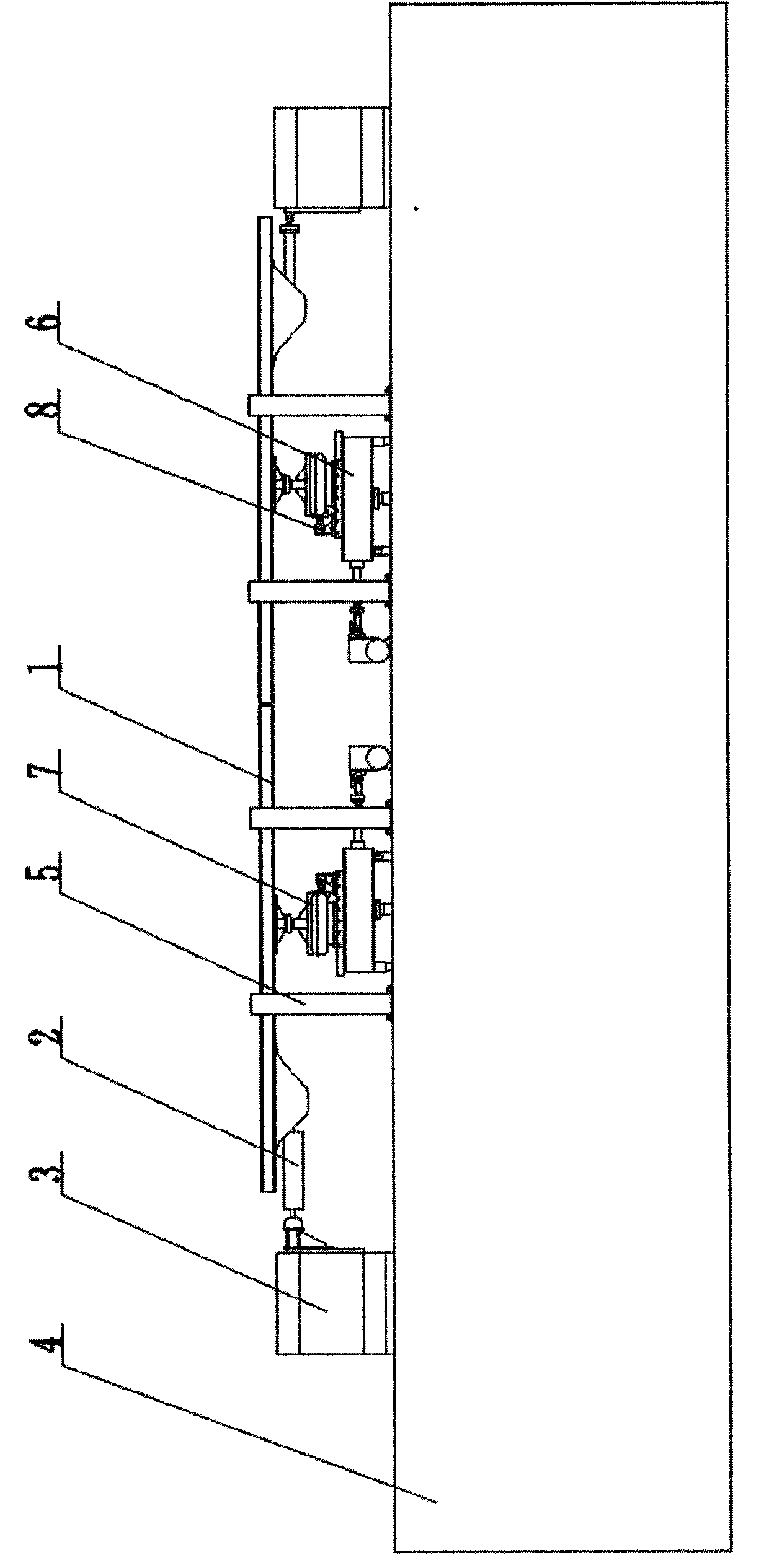

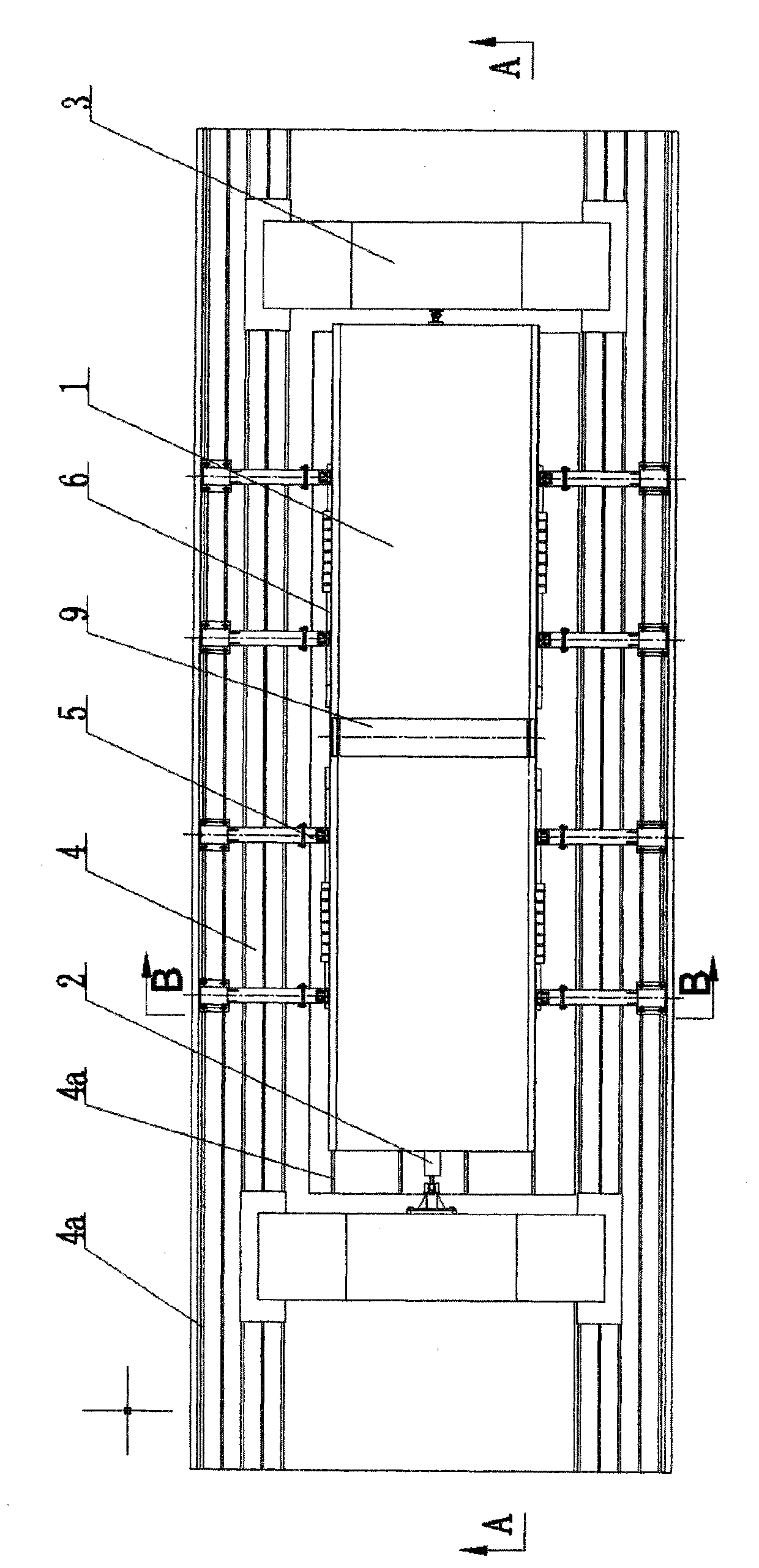

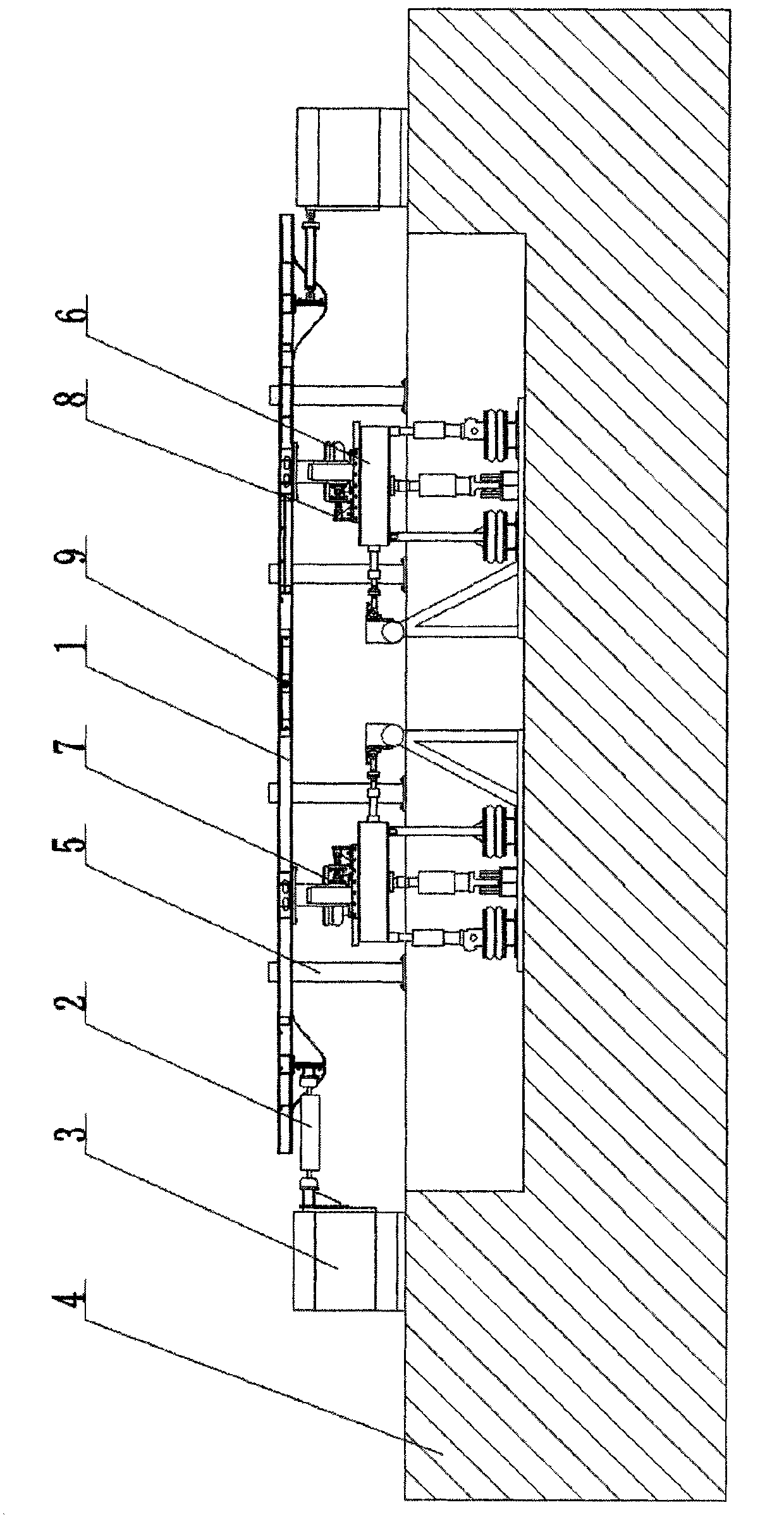

[0035] Figure 1~4 Shown: a kind of specific embodiment of this invention is: a kind of train car body underframe fatigue strength test bench, comprises the train car body underframe 1 used for test, the actuator 2 used for fixing the two ends of underframe 1, The other end of the actuator 2 is fixed on the reaction force seat 3, the reaction force seat 3 is fixed on the end of the basin-shaped foundation 4, the bottom frame 1 is placed on the supporting device 5, and the supporting device 5 is fixed on both sides of the basin-shaped foundation 4, A six-degree-of-freedom vibration device 6 is provided inside the basin-shaped foundation 4, and a vertical loading device 7 and a traction device 8 are fixed on the upper part of the six-degree-of-freedom vibration device 6. The other ends of the vertical loading device 7 and the traction device 8 are respectively connected to the bottom. Rack 1 is connected.

[0036] image 3 and figure 1 , 2 shows: the specific composition of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com